Page 1

WH/WIH/WIHL

Service and Installation Manual

Please read this manual completely before attempting to install or operate this equipment!

Notify carrier of damage! Inspect all components immediately. See page 1.

Drop-in Hot Pans

Specifications subject to change without notice.

Effective Date: 2017

IMPORTANT INFORMATION

READ BEFORE USE

Page 2

CONTENTS

RECEIVING & INSPECTING EQUIPMENT....................................................................................................................................................................................1

SERIAL AND MODEL NUMBER

WH SPECIFICATIONS, FEATURES AND ACCESSORIES.....................................................................................................................................................2-3

WIH SPECIFICATIONS, FEATURES AND ACCESSORIES.....................................................................................................................................................4-5

WIHL SPECIFICATIONS, FEATURES AND ACCESSORIES...................................................................................................................................................6-7

INSTALLATION, OPERATION AND S/S MAINTENANCE........................................................................................................................................................8

ELECTRICAL CHARACTERISTICS AND CUT-OUT REQUIREMEMENTS..............................................................................................................................8

REMOTE CONTROL INSTALLATION............................................................................................................................................................................................9

PARTS LIST........................................................................................................................................................................................................................................10

AUTOMATIC WATER FILL INSTALLATION, OPERATION & PARTS DIAGRAM..............................................................................................................11

TROUBLE SHOOTING GUIDE.......................................................................................................................................................................................................12

ELECTRICAL SCHEMATICS............................................................................................................................................................................................................13

LIMITED WARRANTY......................................................................................................................................................................................................................14

WARRANTY INFORMATION.........................................................................................................................................................................................................15

LOCATION...............................................................................................................................................................................1

RECEIVING AND INSPECTING THE EQUIPMENT

1. VISUALLY INSPECT THE SHIPPING CRATE. DAMAGE SHOULD BE NOTED AND REPORTED TO THE DELIVERING CARRIER.

2. IF DAMAGED, OPEN AND INSPECT CONTENTS WITH CARRIER.

3. IF CRATE IS NOT DAMAGED AND THERE IS CONCEALED DAMAGE TO THE EQUIPMENT, NOTIFY THE CARRIER. NOTIFICATION MUST BE

MADE VERBALLY AND IN WRITING.

4. REQUEST AN INSPECTION BY THE SHIPPING COMPANY FOR THE DAMAGED EQUIPMENT WITHIN 10 DAYS FROM RECEIPT OF THE

EQUIPMENT

5. FREIGHT CARRIERS CAN SUPPLY THE NECESSARY FORMS ON REQUEST.

6. SAVE ALL CRATING MATERIALS UNTIL INSPECTION HAS BEEN MADE OR WAIVED.

SERIAL NUMBER LOCATION

THE SERIAL AND MODEL# CAN BE FOUND ON THE OPERATORS CONTROL PANEL. WHEN CALLING ATLAS FOR PARTS AND SERVICE

ALWAYS HAVE THIS INFORMATION AVAILABLE.

SERIAL #: _______________________________________________________

MODEL #:_______________________________________________________

INSTALLATION DATE: _____________________________________________

Page 3

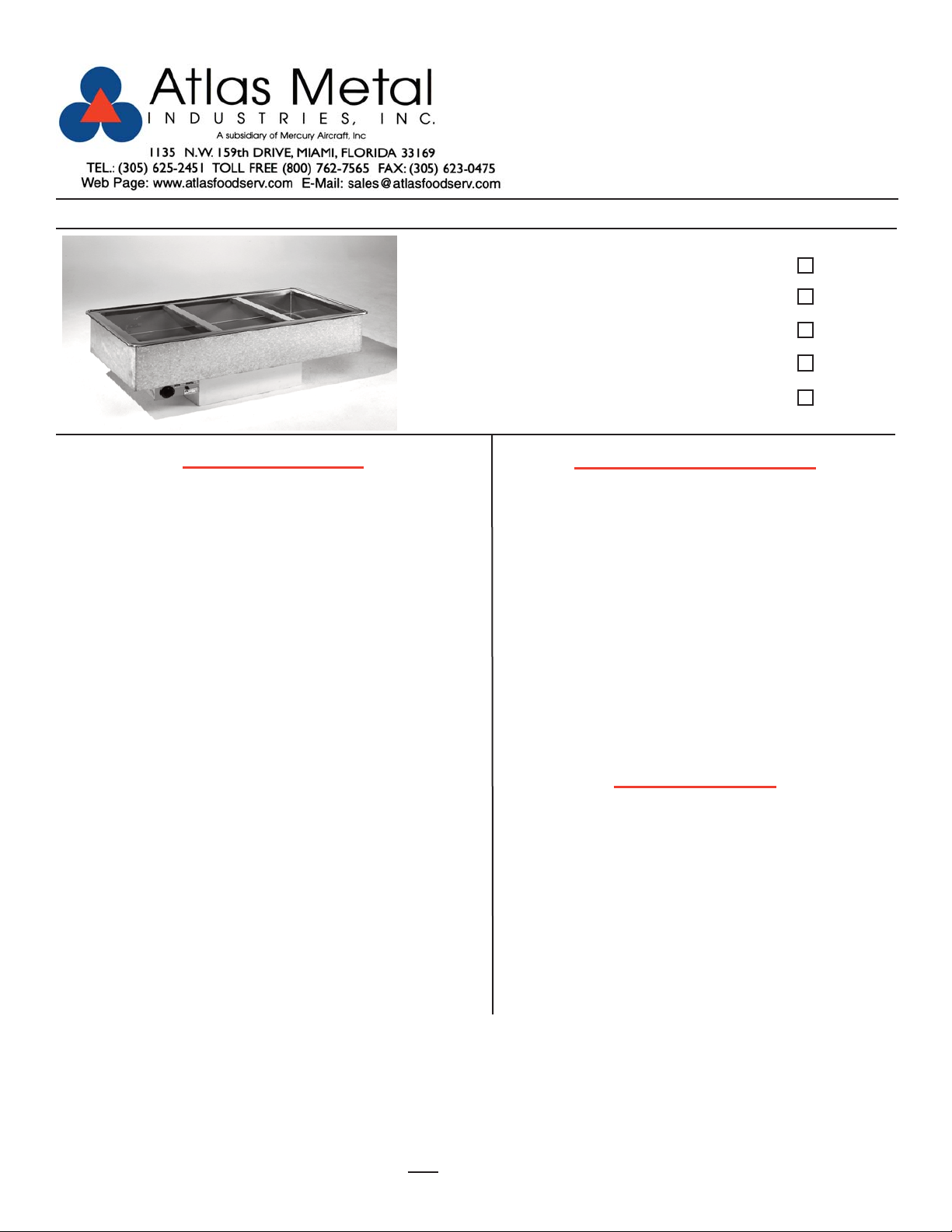

Project: ___________

Item No.: ___________

Quantity: ___________

DROP-IN SERVING EQUIPMENT

WH-2

HOT PAN

Electrically Heated

Single Control

WH-3

SPECIFICATIONS

TOP: Constructed of 18 gauge, type 304 stainless steel, die

stamped flange with a raised perimeter bead. There shall be

a solid vinyl gasket under the beaded edge to form a seal to

the counter top, thus preventing seepage or marring of the

counter top. Embossed mounting lugs are provided along the

inner surface of the top to hold the removable separator

channels in place.

LINER: The inner liner shall be 18 gauge, type 304 stainless

steel, one piece construction, all welded ground and polished

to a uniform finish. All corners are coved with a minimum 1/4"

radius. A 3/4" dia. drain, with strainer, brass nipple, and valve

is provided.

INSULATION: The pan is fully insulated with high density

fiberglass insulation, 1" thick on all sides, 2" thick on the bottom and enclosed by a 22 gauge galvanized steel outer case.

ELECTRICAL: The unit is provided with individual 850 watt

heating elements, pre-wired to a single thermostat control

with a pilot light. A 6’ long, 3-wire cord and plug is provided,

extending from the control box located under the unit, on

operator's left. Bottom of outer case can be removed for access to electrical components. Available for single phase

power only.

Specifications subject to change without notice.

WH-3

WH-4

WH-5

WH-6

STANDARD FEATURES

Fully insulated to retain heat - protects fixtures and

saves energy

Open Bain Marie construction

Thermostatically controlled

Factory applied gasket - makes installation a snap and

seals units to the counter top, thus eliminating seepage

Accommodates standard 12” X 20” pans with the use

of separator channel(s), or fractional size pans with

the use of optional adapter bars

Wet operation only

1-Year Parts & Labor Warranty

UL Listed, ETL Listed

ACCESSORIES

Stainless steel adapter bars (pgs. DI-51-52)

Stainless steel adapter plates (pgs. DI-51-52)

CP - Cover Plate with handles, S/S

RDVE - Rear Drain Valve Extension (1) required

RT-1 - Remote Thermostat for counter installation, 24”

long

RTL-1 - Remote Thermostat for counter installation,

50” long

MS - Master on/off switch

AF - Automatic water fill

*Please see Operation & Installation Manual for ALL

operation and maintenance details.

DI-1

Page 4

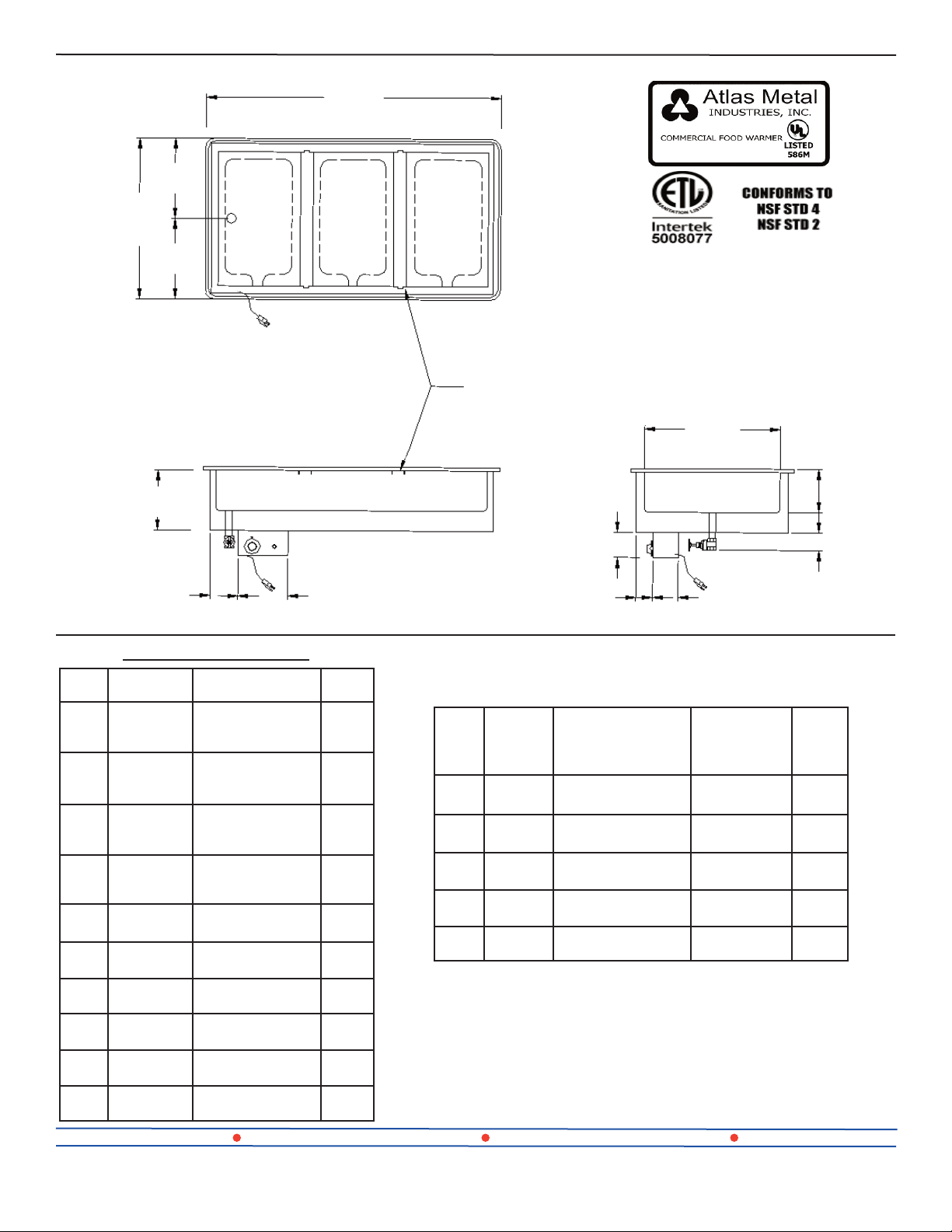

24”

A

12”

12”

PLAN VIEW REMOVABLE SEPARATOR

CHANNEL

19-7/8” ID

9”

4-1/8”

7-1/4”

Electrical Characteristics

MODEL WATTAGE VOLTAGE/KW/AMPS

WH-2

WH-3 850WATT

WH-4

WH-5

WH-6

850WATT

1000WATT

1000WATT

850WATT

1000WATT

850WATT

1000WATT

850WATT

1000WATT

120V - 1.7KW - 14.2

208V - 1.7KW - 8.2

240V - 1.7KW - 7.1

120V - 2.0KW 16.7

208V - 2.0KW - 9.6

240V - 2.0KW - 8.3

120V - 2.55KW - 21.3

208V - 2.55KW - 12.3

240V - 2.55KW - 10.6

120V - 3.0KW - 25.0

208V - 3.0KW - 14.4

240V - 3.0KW - 12.5

208V - 3.4KW - 16.4

240V - 3.4KW - 14.2

208V - 4.0KW - 19.2

240V - 4.0KW - 16.7

208V - 4.25KW - 20.4

240V - 4.25KW - 17.7

208V - 5.0KW - 24.0

240V - 5.0KW - 20.8

208V - 5.1KW - 24.5

240V - 5.1KW - 21.3

208V - 6.0KW - 28.8

240V - 6.0KW - 25.0

NEMA

# PLUG

5-20P

6-15P

6-15P

5-30P

6-15P

6-15P

5-30P

L6-20P

6-15P

5-50P

L6-20P

L6-20P

L6-30P

L6-20P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

6-50P

L6-30P

6-50P

6-50P

ELEVATION

MODEL “A” PAN SIZE

3-3/4”

END VIEW

2-1/2”

WH-2 29-3/4”

(75.5cm)

WH-3 43-1/2”

(110.4cm)

WH-4 57-1/4”

(145.4cm)

WH-5 71”

(180.3cm)

WH-6 84-3/4”

(215.2cm)

Note: Numeral following the model letters denotes the 12X20 pan capacity

19-7/8” X 25-1/2” X 6”

(50.4 X 64.7 X 15.2cm)

19-7/8” X 39-1/4” X 6”

(50.4 X 99.6 X 15.2cm)

19-7/8” X 53” X 6”

(50.4 X 134.6 X 15.2cm)

19-7/8” X 66-3/4” X 6”

(50.4 X 169.5 X 15.2cm)

19-7/8” X 80-1/2” X 6”

(50.4 X 204.4 X 15.2cm)

3-3/4”

COUNTER

CUT-OUT

(REQUIRED)

W X L

22-1/4” X 28”

(56.5 X 71.1cm)

22-1/4” X 41-3/4”

(56.5 X 106cm)

22-1/4” X 55-1/2”

(56.5 X 140cm)

22-1/4” X 69-1/4”

(56.5 X 175.8cm)

22-1/4” X 83”

(56.5 X 210.8cm)

6” ID

2-5/8”

SHIP WT.

(LBS.)

116

(52.6kg)

148

(67.1kg)

174

(78.9kg)

210

(95.3kg)

227

(102.9kg)

Atlas Metal Industries 1135 NW 159th Dr. Miami, FL 33169 (800) 762-7565 Fax: (305) 623-0475 atlasfoodserv.com

DI-2

3/17-sc

Page 5

Project: ___________

Item No.: ___________

Quantity: ___________

DROP-IN SERVING EQUIPMENT

WIH-1

HOT PAN

Electrically Heated

Individual Controls

WIH-3

SPECIFICATIONS

TOP: Constructed of 18 gauge, type 304 stainless steel, die

stamped with a raised perimeter bead. There shall be a solid

vinyl gasket under the beaded edge to form a seal to the

counter top, thus preventing seepage or marring of the

counter top.

HOT FOOD WELLS: Individual hot food wells shall be 18

gauge, type 304 stainless steel, one piece construction, all

welded, ground and polished to a uniform finish. All corners

are coved with a minimum 1/4" radius. Each well is provided

with an 850 watt heating element (1000 watt on the WIH-1).

INSULATION: The pan is fully insulated with high density

fiberglass, 1" thick on all sides, 2" thick on the bottom and enclosed with a 22 gauge galvanized steel outer case.

ELECTRICAL: The unit is provided with an individual

thermostat control with a pilot light for each well. All heating

elements and controls are pre-wired, and a 6' long, 3-wire

cord and plug is provided, extending from the control box

located under the unit, on operator's left. Bottom of outer

case can be removed for access to electrical components.

Specifications subject to change without notice.

WIH-2

WIH-3

WIH-4

WIH-5

WIH-6

STANDARD FEATURES

Fully insulated to retain heat - protects fixtures and

saves energy

Individual thermostat controls - the operator can

control the temperature of each well separately

Factory applied gasket - makes installation a snap

and seals units to the counter, thus eliminating

seepage

Accommodates standard 12”x20” pans, or fractional

size pans with the use of optional adapter bars

Wet operation only

1-Year Parts & Labor Warranty

UL Listed, ETL Listed

ACCESSORIES

Stainless steel adapter bars (pg DI-51-52)

Stainless steel adapter plates (pg DI-51-52)

CP - Cover Plate with handles, S/S

D - Individual Drain and Valve for each well (3/4” dia.

drain)

DM - Individual Drain for each well with manifold to

single valve

DMV - Individual Drain with valve for each well with

manifold to single valve

DME - Individual drain for each well with manifold to

single valve w/ rear extension

RDVE - Rear Extension for D, DM, & DMV (1)

required

RT - Remote Thermostats for counter installation, 24”

long

RTL - Remote Thermostats for counter installation, 50”

long

MS - Master on/off switch

AF - Automatic water fill (NOTE: DM required for water

fill)

*Please see Operation & Installation Manual for ALL

operation and maintenance details.

DI-3

Page 6

24”

9”

A

SHOWN WITH OPTIONAL DME DRAIN AND MANIFOLD WITH

REAR EXTENSION

PLAN VIEW

19-7/8” ID

6” ID

3-3/4”

7-1/2”

ELEVATION

END VIEW

2-1/8”

Electrical Characteristics

MODEL WATTAGE VOLTAGE/KW/AMPS

WIH-1

WIH-2

WIH-3

WIH-4 850WATT

WIH-5 850WATT

WIH-6 850WATT

1000WATT

850WATT

1000WATT

850WATT

1000WATT

1000WATT

1000WATT

1000WATT

120V - 1.0KW -8.3

208V - 1.0KW - 4.8

240V - 1.0KW - 4.2

120V - 1.7KW - 14.2

208V - 1.7KW - 8.2

240V - 1.7KW - 7.1

120V - 2.0KW - 16.7

208V - 2.0KW - 9.6

240V - 2.0KW - 8.3

120V - 2.55KW - 21.3

208V - 2.55KW - 12.3

240V - 2.55KW - 10.6

120V - 3.0KW - 25.0

208V - 3.0KW - 14.4

240V - 3.0KW -12-5

208V - 3.4KW - 16.4

240V - 3.4KW - 14.2

208V - 4.0KW - 19.2

240V - 4.0KW - 16.7

208V - 4.25KW - 20.4

240V - 4.25KW - 17.7

208V - 5.0KW - 24.0

240V - 5.0KW - 20.8

208V - 5.1KW - 24.5

240V - 5.1KW - 21.3

208V - 6.0KW - 28.8

240V - 6.0KW - 25.0

Atlas Metal Industries 1135 NW 159th Dr. Miami, FL 33169 (800) 762-7565 Fax: (305) 623-0475 atlasfoodserv.com

NEMA #

PLUG

5-15P

6-15P

6-15P

5-20P

6-15P

6-15P

L5-30P

6-15P

6-15P

L5-30P

L6-20P

6-15P

5-50P

L6-20P

L6-20P

L6-30P

L6-20P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

L6-30P

6-50P

L6-30P

6-50P

6-50P

COUNTER

MODEL “A”

WIH-1 16”

(40.6cm)

WIH-2 29-3/4”

(75.5cm)

WIH-3 43-1/2”

(110.4cm)

WIH-4 57-1/4”

(145.4cm)

WIH-5 71”

(180.3cm)

WIH-6 84-3/4”

(213.3cm)

Note: Numeral following the model letters denotes the 12X20 pan capacity

CUT-OUT

(REQUIRED)

W X L

22-1/4” X 14-1/4”

(56.5 X 36.8cm)

22-1/4” X 28”

(56.5 X 71.1cm)

22-1/4” X 41-3/4”

(56.5 X 111.1cm)

22-1/4” X 55-1/2”

(56.5 X 140.9cm)

22-1/4” X 69-1/4”

(56.5 X 175.8cm)

22-1/4” X 83”

(56.5 X 210.8cm)

CONTROL

PAN EL

CUT-OUT

(IF REQUIRED)

4-1/2” X 6-1/4”

(11.4 X 15.8cm)

4-1/2” X 12-1/4”

(11.4 x 31.1cm)

4-1/2” X 26”

(11.4 X 66cm)

4-1/2’ X 39-3/4”

(11.4 X 100.9cm)

4-1/2” X 53-1/2”

(11.4 X 135.8cm)

4-1/2” X 67-1/4”

(11.4 X 170.8cm)

SHIP WT.

(LBS.)

41

(18.5kg)

112

(50.8kg)

152

(68.9kg)

188

(85.3kg)

225

(102kg)

268

(121.5kg)

5-1/4”

DI-4

3/17-sc

Page 7

Project: ___________

Item No.: ___________

Quantity: ___________

SLIM-LINE DROP-IN SERVING EQUIPMENT

SLIM-LINE

HOT PAN

Electrically Heated

Individual Controls

WIHL-2

SPECIFICATIONS

TOP: Constructed of 18 gauge, type 304 stainless steel, die

stamped with a raised perimeter bead. There shall be a solid

vinyl gasket under the beaded edge to form a seal to the

counter top, thus preventing seepage or marring of the

counter top.

HOT FOOD WELLS: Individual hot food wells shall be 18

gauge, type 304 stainless steel, one piece construction, all

welded, ground and polished to a uniform finish. All corners

are coved with a minimum 1/4" radius. Each well is provided

with an 850 watt heating element.

INSULATION: The pan is fully insulated with high density

fiberglass insulation, 1" thick on all sides, 2" thick on the

bottom, and enclosed by a 22 gauge galvanized steel outer

case.

ELECTRICAL: The unit is provided with an individual

thermostat control and pilot light for each well. All heating

elements and controls are pre-wired, and a 6' long, 3-wire

cord and plug is provided, extending from the control box

located under the unit, on operator's left. Bottom of outer

case can be removed for access to electrical components.

Specifications subject to change without notice.

*Please see Operation & Installation Manual for ALL

operation and maintenance details.

WIHL-2

WIHL-3

WIHL-4

STANDARD FEATURES

Slim line configuration - it can install in counters only

16” wide

Fully insulated to retain heat - protects fixtures

and saves energy

Individual thermostat controls - the operator can

control the temperature of each well separately

Factory applied gasket - makes installation a snap and

seals units to the counter top, thus eliminating

seepage

Accommodates standard 12” X 20” pans, or fractional

size pans with the use of optional adapter bars.

Wet operation only

1-Year Parts & Labor Warranty

UL Listed, ETL Listed

ACCESSORIES

Stainless steel adapter bars (pg DI-51-52)

Stainless steel adapter plates (pg DI-51-52)

CPL - Cover Plate with handles, S/S

D - Individual Drain and Valve for each well (3/4” dia.

drain)

DM - Individual Drain for each well with manifold to

single valve

DMV - Individual Drain with valve for each well with

manifold to single valve

DME - Individual drain for each well with manifold to

single valve w/ rear extension

RDVE - Rear Extension for D, DM, DMV & DME (1)

required

RT - Remote Thermostats for counter installation, 24”

long

RTL - Remote Thermostats for counter installation, 50”

long

MS - Master on/off switch

AF - Automatic water fill (NOTE: DM required for water

fill)

DI-5

Page 8

A

11-7/8” ID

16”

PLAN VIEW

Electrical Characteristics

MODEL WATTAGE VOLTAGE/KW/AMPS

120V - 1.7KW - 14.2

WIHL-2 850WATT

208V - 1.7KW - 8.2

240V - 1.7 KW - 7.1

120V - 2.0KW - 16.7

1000WATT

208V - 2.0KW - 9.6

240V - 2.0KW - 8.3

120V - 2.55KW - 21.3

WIHL-3 850WATT

208V - 2.55KW - 12.3

240V - 2.55KW - 10.6

120V - 3.0KW - 25.0

1000WATT

208V - 3.0KW - 14.4

240V - 3.0KW - 12.5

WIHL-4 850WATT

1000WATT

208V - 3.4KW - 16.4

240V - 3.4KW - 14.2

208V - 4.0KW - 19.2

240V - 4.0KW - 16.7

9”

3-3/4”

NEMA

# PLUG

5-20P

6-15P

6-15P

5-30P

6-15P

6-15P

5-30P

L6-20P

6-15P

5-50P

L6-20P

L6-20P

L6-30P

L6-20P

L6-30P

L6-30P

2-1/2”

3-3/4”

10-1/4”

ELEVATION

COUNTER

MODEL “A”

CUT-OUT

(REQUIRED)

W X L

WIHL-2

46”

(116.8cm)

67-3/4”

WIHL-3

(172cm)

89-1/2”

WIHL-4

Note: Numeral following the model letters denotes the 12X20 pan capacity

(227.3cm)

14-1/4” X 44-1/4”

(36.8 X 113.6cm)

14-1/4” X 66”

(36.8 X 167.6cm)

14-1/4” X 87-3/4”

(36.8 X 222.8cm)

(IF REQUIRED)

4-1/2” X 12-1/4”

(11.4 X 31.1cm)

(11.4 X 66cm)

4-1/2” 39-3/4”

(11.4 X 100.9cm)

END VIEW

CONTROL

PANE L

CUT-OUT

4-1/2” X 26”

6”

SHIP

WT.

(LBS.)

118

(53.5kg)

176

(79.8kg)

210

(95.2kg)

Atlas Metal Industries 1135 NW 159th Dr. Miami, FL 33169 (800) 762-7565 Fax: (305) 623-0475 atlasfoodserv.com

DI-6

3/17-sc

Page 9

WH/WIH/WIHL

----------------------------------------------------------------------------------------------------------------------------------------------------------

INSTALLATION

Provide the correct counter cut-out opening and drop in. The vinyl gasket assures complete seating. A nontoxic silicone seal may be used between the gasket and counter top (not required). The unit is supplied

with a power cord and NEMA plug. Refer to the data plate on the control panel for the amperage and

voltage information. Use a licensed electrician when installing power source.

* Control box on 14 1/4" side.

---------------------------------------------------------------------------------------------------------------------------------------------------------

OPERATION

During operation the unit must be used with water and the thermostat must be set at position

#10. The thermostat dial has an off position and is numbered 1 to 10 (Number 10 is the

highest and mandatory setting for operation).

--------------------------------------------------------------------------------------------------------------------------------

MAINTENANCE

NEVER CLEAN PANS WITH A CHLORIDE BASED PRODUCT. CHLORIDES OR IMPROPER

CLEANING COULD SCAR, MARK AND/OR CORRODE PANS. DO NOT USE STEEL WOOL OR

ABRASIVE PRODUCTS.TO CLEAN USE SOAPY WARM WATER, RINSE THOROUGHLY TO

REMOVE ALL RESIDUES. FAILURE TO MEET THESE CONDITIONS WILL VOID

WARRANTY.

--------------------------------------------------------------------------------------------------------------------------------

Page 10

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

WH/WIH STANDARD INSTALLATION

WIH-REMOTE INSTALLATION

PANEL WITH CUT-OUT

STUDS

3

SCREW

3

5

"

4

DIAL

FRONT FACE

NUTS

3

1

"

8

1

"

8

INSTALLATION OF THE REMOTE CONTROL HOT UNITS

--------------------------------------------------------------------------------------------------------------------------------------Provide the correct Cut-Out opening for the remote control panel (see chart below).

Remove control box from the bottom of the unit.

GALVANIZED BOX

1

1

4

3

"

"

4

4

.

1) Remove black control dial from front of control panel by loosening screws.

2) Remove 6/32 fiber nuts from the back of the control box.

3) Mount the S/S front plate to the Cut-Out in apron.

4) Attach the galvanized box to the S/S front plate.

The unit is ready to be connected to the electrical receptacle. Refer to the data plate on the control panel for the

amperage and voltage information. Use a licensed electrician when installing power source.

MODEL CUT-OUT SIZE

1 4 1/2 x 6 1/4

2 4 1/2 x 12 1/4

3 4 1/2 x 26

4 4 1/2 x 39 3/4

5 4 1/2 x 53 1/2

6 4 1/2 x 67 1/4

CAUTION: HANDLE CONTROL PANEL & CONDUIT CAREFULLY,THERMOSTAT CAPILLARY TUBE IS VERY FRAGILE, IF

BROKEN, HEATING SYSTEM WILL NOT OPERATE.

FAILURE TO MEET THESE CONDITIONS WILL VOID WARRANTY.

Page 11

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

PARTS LIST ELECTRICAL HEATED UNITS

W/AUTOMATIC WATER FILL

WH/ WIHD&M/ WIHLD&M- /WIHD&M- 1-6 SERIES

2

1

32

31

33

34

36

35

45

38

44

46

3

40

ITEM

NUMBER

PART

NUMBER

42

41

39

DESCRIPTION

37

24

1 7002-0+Model # Vinyl Bead Gasket

2 86-3202 Perforated Snap in Drain

3 1097 Dial

4 1099 Pilot Light

5 3007-3 3/4" Brass Nipple 7” long

6 3016-1 Brass Gate Valve

7 1088 P-136 Terminal (#22 & 18 wire)

8 1089 P-151 Terminal (#10 & 12 wire)

9 1090 P-144 Terminal (#14 & 16 wire)

10 1098 S Screw Thermostat Mounting

11 2500 Remote Thermostat with 48" Bulb

12 2500-5 Remote Thermostat with 72" Bulb

13 1012-3 12" Nickel Wire

14 1014-4 14" Nickel Wire

15 1096 Thermostat

16 S81113-2 Element Holder

17 SC0099-238 S/S Element Holder

18 1053 120V-850W Element

19 1054 208V-850W Element

20 1055 240V-850W Element

21 1056 120V-1000W Element

22 1057 240V-1000W Element

23 1058 208V-1000W Element

1002 Power Cord 14/3

24

1004 Power Cord 12/3

1004-4 Power Cord 10/3

43

4

ITEM

NUMBER

PART

NUMBER

DESCRIPTION

25 12-228 Plug 20Amp 240V

26 1022 Plug 30Amp 240V

27 12-256 Plug 30Amp 120V

28 1014-7 #12 Green Wire (Ground)

29 1014-8 #14 Green Wire (Ground)

30 1001-1 50 Amp Cord & Plug

31 48-22 S/S 10 x 1/2 Screws

32 S84553 Reservoir Assembly

33 51-25 1/4" x 3/8" NPT Male Conn.

34 2050 Brass Flare Nut

35 2031 1/4" Copper Tubing

36 21-23 1/4" x 1/4" Brass Union

Dual check vacuum breaker

37 600022

#98d NPTM 1/4”

(BACK FLOW PREVENTION)

38 30-46 90º Street Elbow

39

1800-3904 Solenoid V a lve 120V

1800-3903 Solenoid V a lve 240V

40 600002 Brass In Line Strainer

41 1800-35 Ball In Valve

42 1800-39 Close Nipple

43 87-69

44 87-70

45 87-68

90º 1/2" to 1/4 Reducing

Elbow Brass

1/2 dia. Brass Pipe Threaded

Both Ends

1/8” Male to 1/4” female

reducer

46 1069-1 Switch

Page 12

AUTOMATIC WATER FILL UNITS

WIH, WH AND WCMHP/RMHP SERIES

INSTALLATION

When installing water supply to the unit, the supply lines must be purged to remove particles from

damaging the solenoid valve operation. A factory supplied in-line water strainer is installed. However, it

is recommended the customer supply a primary water filtering system for protection.

*Note-Atlas Metal Ind. Inc. is not responsible for routine maintenance of the strainer or customer

supplied water filter system.

*Atlas Metal Industries Inc. recommends that all units installed to a water source use our Autofill

or any backflow protection of your choice. Please refer to your local code.

Any attempt to change or modify the Auto Fill system will void the warranty.

OPERATION

To operate the Auto Fill system, turn the Auto-fill On/Off switch, located on the control panel, to the On

position. Allow water to complete filling the pan to the water level mark before energizing the heating

cycle.

*Note -

above the heating element cover.

DO NOT manually add water to Auto-fill units above water level mark, damage and leakage to the

Automatic sensor could result. As the water evaporates the pans will fill automatically.

recommended that the Auto Fill be in the off position when not in use.

Factory water depth settings for A/F units are 1/4" for WIH, 1/2" for WH & WCMHP/RMHP are 1/2"

It is

Page 13

Subsidiary of Mercury Aircraft, Inc.

1135 N.W. 159th DR., MIAMI, FL 33169

PHONE (305) 625-2451, (800) 762-7565, FAX (305) 623-0475, E-mail: sales@atlasfoodserv.com

Electric Hot Food Drop-In Trouble Shooting Guide

Symptom Probable Cause

Unit not plugged in.

Unit will not heat

Food products not

hot enough.

No power at receptacle.

Thermostat and or switch not in the on position.

Call factory for service at 1-800-762-7565

Thermostat’s not turned to the highest setting.

Food products not hot enough when placed in unit.

Food product not being stirred or rotated.

Heat lamp or head strip over the food product is recommended.

Call factory for service at 1-800-762-7565.

NOTE:

Before starting any warranty repair work you must first call the factory for authorization.

Failure to do so can make you responsible for repair cost.

Page 14

TWO (2) HEATED WELLS SHOWN.

QUANTITY OF HEATED WELLS

CAN BE FROM TWO (2) TO SIX (6).

Page 15

LIMITED WARRANTY

Atlas Metal Industries, Inc. warrants to the Purchaser of this product that the

same shall be free from defects in the workmanship and material for a period of

one year from the date of original installation of the equipment, but not to exceed

eighteen (18) months after date of shipment from factory. During this period of

time Atlas Metal Industries, Inc. will replace all defective parts and will pay for

authorized replacement labor. Replacement and installation of such parts and

labor shall be provided only upon prior written authority of Atlas Metal Industries,

Inc.

The Refrigeration warranty is for a twenty (20) month time period and includes

supplying the compressor at a no charge basis provided the damage to the

compressor was not caused by the customer or end user. Authorized

replacement labor will be paid for a period of one year from date of installation.

Freight costs for defective unit to and from Atlas Metal Industries, Inc. are not

included, and all defective parts must be returned to the factory freight prepaid

for evaluation. ALL WARRANTY LABOR MUST BE AUTHORIZED BY ATLAS

METAL INDUSTRIES, INC. PRIOR TO THE ACTUAL WORK BEING DONE.

This warranty does not apply to any equipment or any part thereof, which has

been subjected to shipping damage, improper voltage, alteration, abuse or

misuses, and does not cover loss of food, other products, or damage to property

due to mechanical or electrical malfunction.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE

DESCRIPTION OF THE FACE HEREOF. SELLER DISCLAIMS ANY IMPLIED

WARRANTY OF MERCHANTABILITY OF THE GOODS OR THE FITNESS OF

THE GOODS FOR ANY PURPOSE AND BUYER AGREES THAT THE GOODS

ARE SOLD “AS IS.”

Page 16

WARRANTY INFORMATION

In order to have your invoice approved for payment by the factory, please note the following:

_______________________________________________

An authorization number must be obtained from the factory prior to performing any warranty service.

_______________________________________________

Atlas Metal

will not approve excessive labor due to poor

access to the unit being serviced. If design does

not

allow reasonable access, contact the factory.

_______________________________________________

All travel time that exceeds 100 miles round trip must be authorized by the factory.

_____________________________________________________________________________________

Thank You:

Warranty service Dept.

Loading...

Loading...