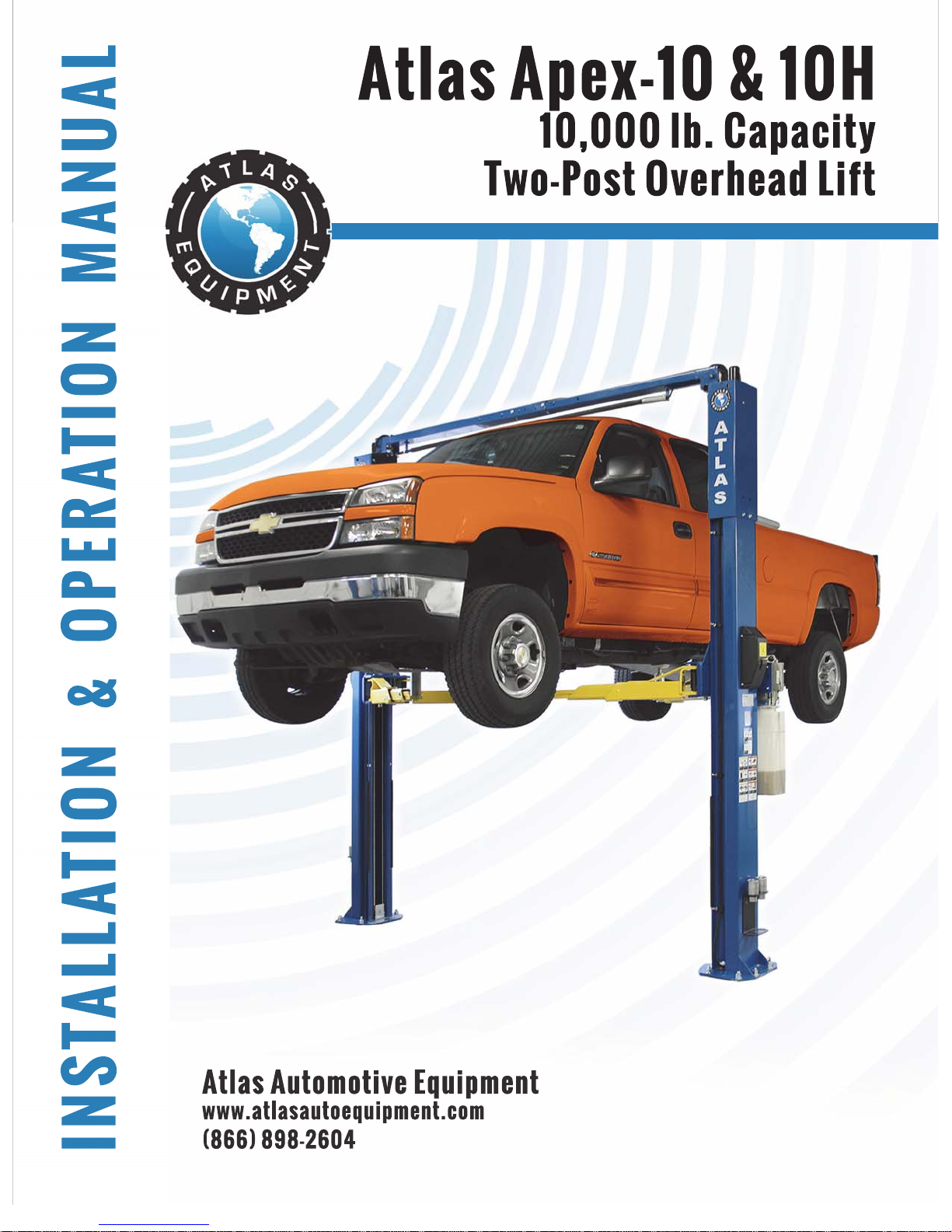

Page 1

Page 2

Read this entire manual before operation begins.

Record below the following information which is located on the serial number

data plate.

Serial No.

Model No.

Date of Installation

Page 3

Contents

Important Safety Instructions . . . . . 6

General Information. . . . . . . . . . 9

Product Identifi cation . . . . . . . . .12

Packing, Transport, Storage . . . . . .14

Lift Description . . . . . . . . . . . .16

Technical Specifi cation. . . . . . . . .17

Safety . . . . . . . . . . . . . . . .24

Installation . . . . . . . . . . . . . .28

Operation And Use . . . . . . . . . .45

Maintenance . . . . . . . . . . . . .48

Troubleshooting. . . . . . . . . . . .50

Additional Information. . . . . . . . .51

Parts Catalogue. . . . . . . . . . . .61

Warranty . . . . . . . . . . . . . . .75

Page 4

Operations and Maintenance Manual: 2-Post Lifts

Please read this manual in its entirety before installing or operating

your lift. By proceeding, you agree that you fully understand the

contents of this manual and the installation, operation, and maintenance

instructions contained within. Please deliver this manual to the lift

owner and/or operator along with all other documentation provided

with the lift. Failure to operate this equipment as intended may cause

injury or death.

Check for any freight damages. The shipment should be thoroughly inspected

as soon as it is received. The signed bill of lading is acknowledgement by the

carrier of receipt in good condition of shipment covered by your invoice. If any of

the goods called for on your bill of lading are shorted or damaged, do not accept

to unload until the carrier makes a notation on the freight bill of the missing

or damaged goods. Do this for your own protection. Check the contents of the

accessory and hardware boxes to make sure no parts are missing.

Important notice and operating conditions

• This lift is not intended for outdoor use. It is intended for indoor installation

only, with an operating temperature range of 41 – 104 °F (5 – 40 °C);

• Concrete fl ooring must be 4 ¼” minimum thicknesses with 3,000 psi. Do

not install on asphalt or other similar unstable surface type;

• Check ceiling height and electrical requirements as described in this

manual;

• Reference ANSI/ALI ALIS, Safety Requirements for Installation and Service

of Automotive Lifts;

• Consult a qualifi ed expert to address all seismic load concerns and other

local or state requirements;

• Atlas Automotive Equipment and its distributors will assume no liability for

loss or damage of any kind, express or implied, resulting from improper

installation, operation or maintenance of this lift.

4

Apex-10 / Apex-10H

Page 5

Owner, Operator, & Employer Responsibilities:

• Shall ensure that lift operators are qualifi ed and that they are trained in

the safe use and operation of the lift using the manufacturer’s operating

instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90

ALI Safety Tips card; ANSI/ALI ALOIM-2008, American National Standard

for Automotive Lifts - Safety Requirements for Operation, Inspection and

Maintenance; ALI/WL Series, ALI Uniform Warning Label Decals/Placards;

and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting

Points/Quick Reference Guide for Frame Engaging Lifts;

• Shall establish procedures to periodically inspect the lift in accordance

with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008,

American National Standard for Automotive Lifts - Safety Requirements

for Operation, Inspection and Maintenance; and the Employer shall ensure

that the lift inspectors are qualifi ed and that they are adequately trained in

the inspection of the lift;

• Shall establish procedures to periodically maintain the lift in accordance

with the lift manufacturer’s instructions or ANSI/ALI ALOIM-2008,

American National Standard for Automotive Lifts - Safety Requirements

for Operation, Inspection and Maintenance; and the Employer shall

ensure that the lift maintenance personnel are qualifi ed and that they are

adequately trained in the maintenance of the lift;

• Shall maintain the periodic inspection and maintenance records

recommended by the lift manufacturer’s instructions or ANSI/ALI

ALOIM-2008, American National Standard for Automotive Lifts - Safety

Requirements for Operation, Inspection and Maintenance;

• Shall display the lift manufacturer’s operating instructions; ALI/SM 931, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card;

ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts

- Safety Requirements for Operation, Inspection and Maintenance; ALI/

WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of

frame engaging lifts, ALI/LP- GUIDE, Vehicle Lifting Points/Quick Reference

Guide for Frame Engaging Lifts in a conspicuous location in the lift area

convenient to the operator;

• Shall provide necessary lockout/tagout means for energy sources per ANSI

Z244.1-1982 (R1993), Safety Requirements for the Lockout/Tagout of

Energy Sources, before beginning any lift repairs and maintenance;

• Shall not modify the lift without the prior written consent of the

manufacturer.

5

Apex-10 / Apex-10H

Page 6

Important Safety Instructions

Please read carefully

• Read all instructions and warnings thoroughly before servicing, or

maintaining the lift;

• Inspect the lift daily. Never operate if there are broken or damaged parts

or if the lift is malfunctioning;

• Do not operate if there are damaged cords or if any piece of the equipment

has been dropped or damaged until it has been examined by a qualifi ed

professional;

• Do not touch hot parts as burns can occur;

• Keep area well lit at all times and do not use in damp or wet locations;

• Do not let any cords come in contact with hot manifolds or moving blades;

• A cord with a current rating equal to or more than that of the equipment

should be used if an extension cord is necessary. Cords rated for less

current than the equipment may overhead. Be careful to avoid putting in

an area where it could be tripped over or interfered with;

• Always unplug equipment when not in use. Do not attempt to grab the

cord, grasp plug to disconnect;

• Allow equipment to cool completely before storing away. Loop cord loosely

around the equipment when storing;

• To reduce the risk of fi re, never operate near open containers of fl ammable

liquids (for example, gasoline);

• Adequate ventilation should be provided when working on or operating

internal combustion engines;

• Always keep loose clothing, hair, fi ngers, and all parts of the body away

from any moving parts;

• To reduce the risk of electric shock, never use on wet surfaces or expose to

rain;

• Always wear safety glasses. Everyday glasses are not safety glasses and do

not provide adequate protection;

• Use only as described in this manual – use only Atlas Automotive

Equipment optional accessories and attachments;

• Never attempt to overload the lift. The rated capacity is shown on the

identifi cation label;

Important Safety Instructions 6

Apex-10 / Apex-10H

Page 7

• Never modify the lift or attempt to override the operating controls;

• Do not attempt to raise a vehicle until installation is completed per

instructions in this manual;

• Only trained and qualifi ed personnel are to operate, maintain, service or

repair the lift;

• Keep hands and feet clear of any moving parts and avoid pinch points;

• Always use all four arms to raise and support the vehicle;

• Never work under or near the lift unless the mechanical safety locks are

securely engaged;

• Always keep the work area free of spills and debris;

• Never permit anyone in a vehicle or on the lift when it is either being raised

or lowered;

• Always check for obstructions before lowering the lift;

• Never remove hydraulic fi ttings while the lift is under pressure;

• Clear the work area immediately if a vehicle is in danger of falling;

• Do not hit or drive over arms or adapters. Always provide an unobstructed

entrance between columns prior to loading vehicle onto the lift;

• Always ensure that the lift is grounded while in use to protect the operator

from electric shock;

• Disconnect power unit before performing any electrical repairs;

• Avoid rocking a vehicle while it is on the lift;

• Always use safety and/or support stands when removing or installing heavy

vehicle components;

• Never remove or tamper with safety components;

• Use common sense and always stay alert;

• SAVE THESE INSTRUCTIONS

Record the following information which can be located on the serial

number data plate: Serial No, Model No, and Date of Installation.

The following are included with your lift:

• ALI/SM Lifting it Right • ALI/ST Safety Tips

• ALI/ALOIM • ALI/LPG Lifting Point Guide

• Attachment/accessory Notice labels

Important Safety Instructions 7

Apex-10 / Apex-10H

Page 8

Printing Characters And Symbols

Throughout this manual, the following symbols and

printing characters are used to facilitate reading:

Indicates the operations which

need proper care

Indicates prohibited

Indicates a possibility of danger to

the operators

BOLD

TYPE

Important information

WARNING: before operating the lift and

carrying out any adjustments, read carefully

chapter 7 “Installation” where all operations

for a properly functioning lift are shown.

Important Safety Instructions 8

Apex-10 / Apex-10H

Page 9

General Information

This chapter contains warning instructions to operate the lift properly and

prevent injury to operators or objects. This manual has been written to be used

by shop technicians in charge of the lift (operator) and routine maintenance

technician (maintenance operator). The operating instructions are considered to

be an integral part of the machine and must remain with it for its whole useful

life. Read every section of this manual carefully before operating the lift and

unpacking. It provides helpful information about:

• Safety Of People

• Safety Of The Lift

• Safety Of Lifted Vehicles

The company is not liable for possible problems, damage, accidents, installation,

etc. resulting from failure to follow the instructions contained in this manual.

Only skilled technicians of AUTHORIZED DEALERS or SERVICE CENTERS

AUTHORIZED by the manufacturer shall be allowed to carry out lifting, transport,

assembling, installation, adjustment, calibration, settings, extraordinary

maintenance, repairs, overhauling and dismantling of the lift.

The manufacturer is not responsible for possible damage to people,

vehicles or objects if said operations are carried out by unauthorized

personnel or the lift is improperly used.

Any use of the lift by operators who are not familiar with the instructions and

procedures contained herein is unauthorized.

1.1 Manual Keeping

This manual is an integral part of the lift. It shall be given to the new owner if

and when the lift is resold. For the proper use of this manual, the following is

recommended:

• Keep the manual near the lift, in an easily accessible place;

• Keep the manual in an area protected from the moisture;

• Use this manual properly without damaging it;

• Any use of the lift made by operators who are not familiar with the

instructions and procedures contained herein is unauthorized.

General Information 9

Apex-10 / Apex-10H

Page 10

1.2 Obligation In Case Of Malfunction

In case of a lift malfunction, follow the instructions contained

in the following chapters. Call Atlas @ 1-866-898-2604

1.3 Cautions For Operator Safety

Operators must not be under the infl uence of sedatives, drugs or alcohol when

operating the lift.

Before operating the lift, operators must be familiar with the

position and function of all controls, as well as the machine

features shown in the chapter “Operation and use”

1.4 Warnings

Unauthorized changes and/or modifi cations to the lift relieve

the manufacturer of liability for possible damages to objects

or people. Do not remove or make inoperative the safety

devices, this would cause a violation of safety at work laws

and regulations.

Any unauthorized use which differs from that provided for by

the manufacturer of the machine is strictly prohibited.

The use of non genuine parts may cause damage to people or

objects

General Information 10

Apex-10 / Apex-10H

Page 11

1.5 Scrapping

When the lift’s working life is over and it can no longer be used, it must be

made inoperative by removing any connection to power sources. These units are

considered as special waste material, and should be broken down into uniform

parts and disposed of in compliance with current laws and regulations. If the

packing are not biodegradable, deliver them to appropriate handling station.

Declaration Of Warranty And Limitation Of Liability

The manufacturer has paid proper attention to the preparation of this manual.

However, nothing contained herein modifi es or alters, in any way, the terms

and conditions of manufacturer agreement by which this lift was acquired, nor

increase, in any way, manufacturer’s liability to the customer.

To The Reader

Every effort has been made to ensure that the information contained in this

manual is correct, complete and up-to date. The manufacturer is not liable for

any mistakes made when drawing up this manual and reserves the right to make

any changes due to the development of the product at any time.

General Information 11

Apex-10 / Apex-10H

Page 12

Product Identifi cation

The identifi cation data of the lift is shown in the serial plate placed on the power

side column.

LOGO

Type:

Model:

Serial Number:

Year of manufacturing:

Capacity:

Voltage:

Power:

Use the above data both to order spare parts and when

getting in touch with the manufacturer (inquiry). The

removal of this label is strictly prohibited.

Machines may be updated or slightly modifi ed from an aesthetic point of view

and, as a consequence, they may present different features from these shown,

without contradicting what has been described herein.

2.1 Warranty Certifi cate

The warranty is valid for a period of 2 years on structural components, 2 years

on hydraulic components and 90 days on wear parts starting from the date

of purchase. This warranty does not include labor or shipping. The warranty

consists of parts only.

Product Identification 12

Apex-10 / Apex-10H

Page 13

The warranty will come immediately to an end when unauthorized modifi cations,

faulty assembly and improper use to the lift or parts of it are carried out.

The presence of defects in workmanship must be verifi ed by the Manufacturer’s

personnel in charge.

2.2 Technical servicing

For all servicing and maintenance operations not specifi ed or shown in these

instructions, contact your dealer where the lift has been purchased or the

Manufacturer’s Commercial Department.

Product Identification 13

Apex-10 / Apex-10H

Page 14

Packing, Transport, Storage

Only skilled personnel who are familiar with the lift and this manual shall

be allowed to carry out packing, lifting, handling, transport and unpacking

operations.

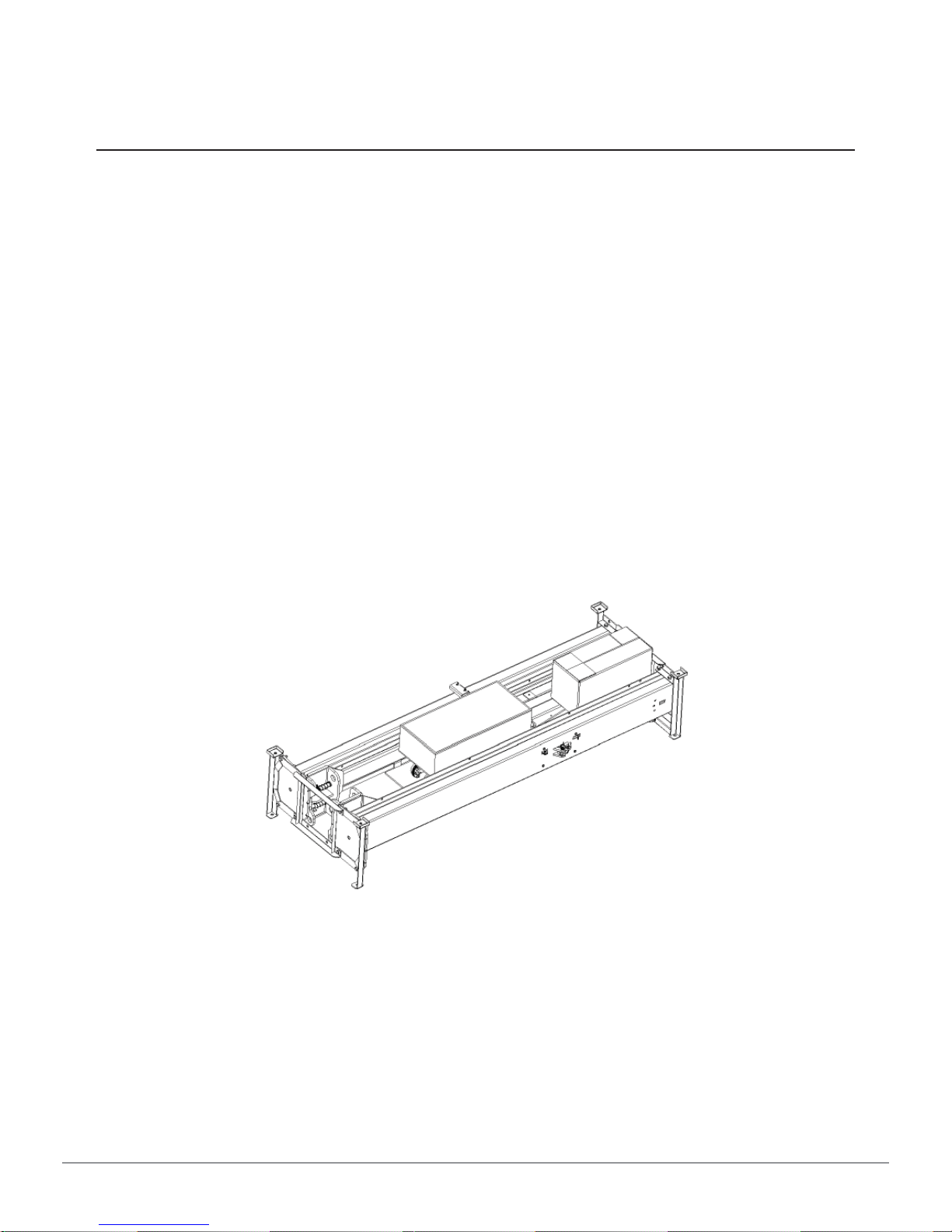

3.1 Packing

The packing of the lift is shown in the fi gure 1: N. 1 base unit packed in a steel

frame, wrapped up in non-scratch material, including the accessory box, and the

power unit.

The package weight is about 1750 lbs.

If requested, optional accessories are available to satisfy each customer’s

requirements.

3.2 Lifting and handling

When loading/unloading or transporting the lift to the site, be sure to use suitable

loading (e.g. cranes, trucks) and hoisting methods. Be sure to hoist and transport

the components securely so that they do not drop, taking into consideration the

package’s size, weight and center of gr a vity and it’s fragile parts.

Packing, Transport, Storage 14

Figure 1

Apex-10 / Apex-10H

Page 15

3.3 Storage and stacking of packages

Packages must be stored in a covered place, out of direct sunlight and in low

humidity, at a temperature between +14°F and +104°F.

3.4 Delivery and check of packages

When the lift is delivered, check for possible damages due to transport and

storage; verify that what is specifi ed in the manufacturer’s confi rmation of order

is included. In case of damage in transit, the customer must immediately inform

the carrier of the problem.

Packages must be opened paying attention not to cause damage to people (keep

a safe distance when opening straps) and parts of the lift (be careful the objects

do not drop from the package when opening).

Packing, Transport, Storage 15

Apex-10 / Apex-10H

Page 16

Lift Description

The lift is suitable for lifting motor vehicles having maximum weight as described

in the nameplate on the power side column of the lift. Providing that the

vehicle’s weight is EVENLY distributed.

All mechanical parts such as columns, carriages and lift arms have been built of

steel plate to make the frame stiff and strong while keeping a low weight.

The electro hydraulic operation is described in detail in chapter 8.

This chapter describes the lift’s principal elements, allowing the user to be

familiar with the lift.

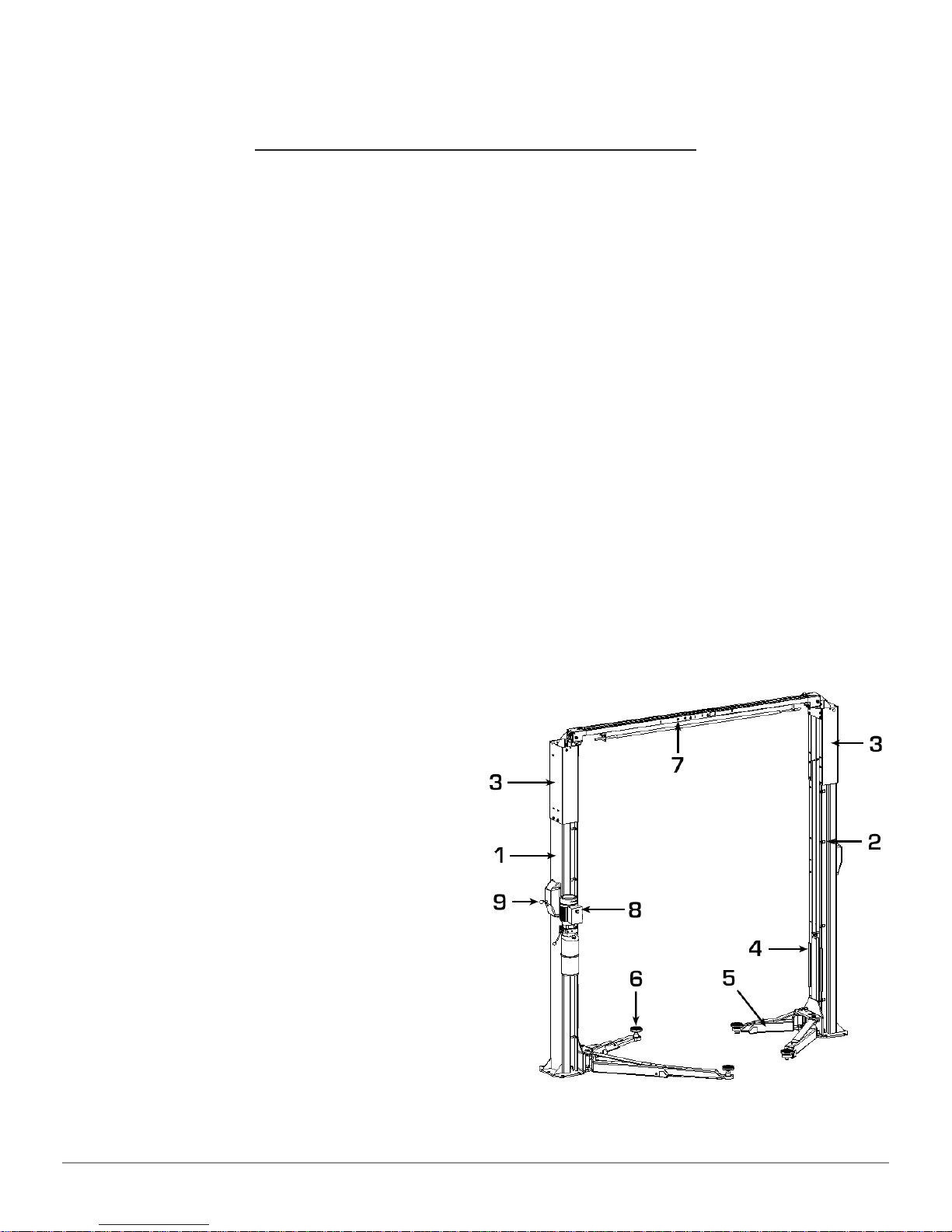

As shown in fi gure 2, the lift is composed of two columns: power-side column

(1) and off-side column (2) with the extension (3) on each, each equipped with

a carriage (4) and a pair of lifting arms (5) with the adaptor (6) anchored to the

ground by means of the base plates.

The overhead beam (7) is equipped with the anti-crush safety bar and an

overhead cut-off switch for protection of the vehicle roof.

Raising motion is carried out by pushing the lifting button on the power unit (8),

which delivers the hydraulic fl uid to cylinders inside the columns.

The mechanical safety release is

carried out by pushing the safety

release lever (9) on the power-side

column.

Lowering motion is controlled by

pushing the lowering lever on the

power unit and carried out under the

weight of the load lifted.

The synchronization is controlled by

the equalizer cables.

The arm safety is engaged

automatically when the lift is raised.

Lift Description 16

Figure 2

Apex-10 / Apex-10H

Page 17

Technical Specifi cation

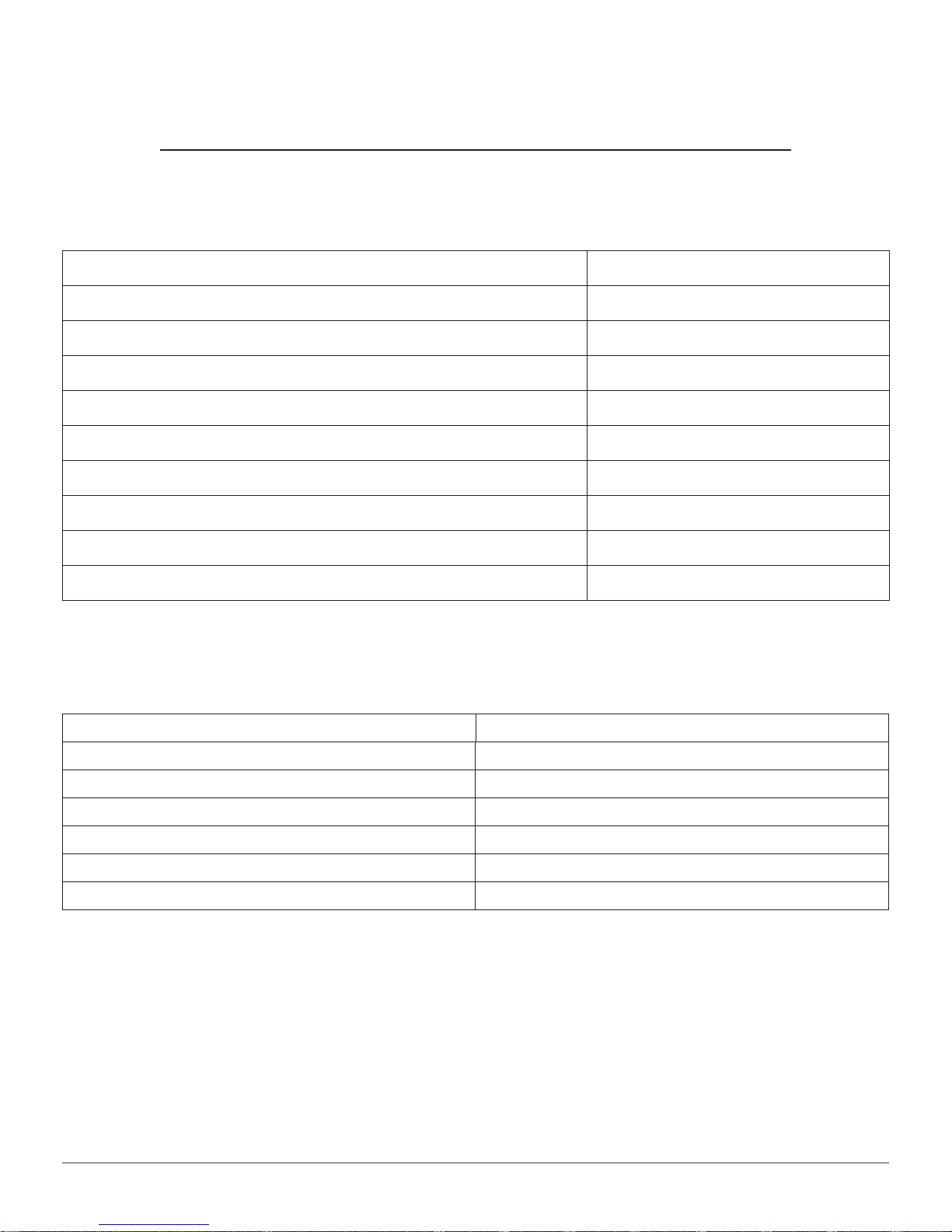

5.1 Size And Main Features

CAPACITY 10,000lbs (4600kg)

Max. stroke 70 5/8in

Max. lifting height (with no pad extension) 76 in

Min. height 3 1/2in

Overall height (with max. stroke of cylinder) 142 1/2in

Overall width 137 7/8in

Lifting time 52-58 S

Noise level 75 dB(A)/1m

Working temperature 14 °F - 104 °F

Average weight of package 1750lbs

5.2 Electric motor

Type ML90L2

Voltage 220V/60Hz/1Ph

Power 1.5 KW

N° Poles 2

Speed 1700 rpm

Motor enclosure type B14

Insulation class IP 54

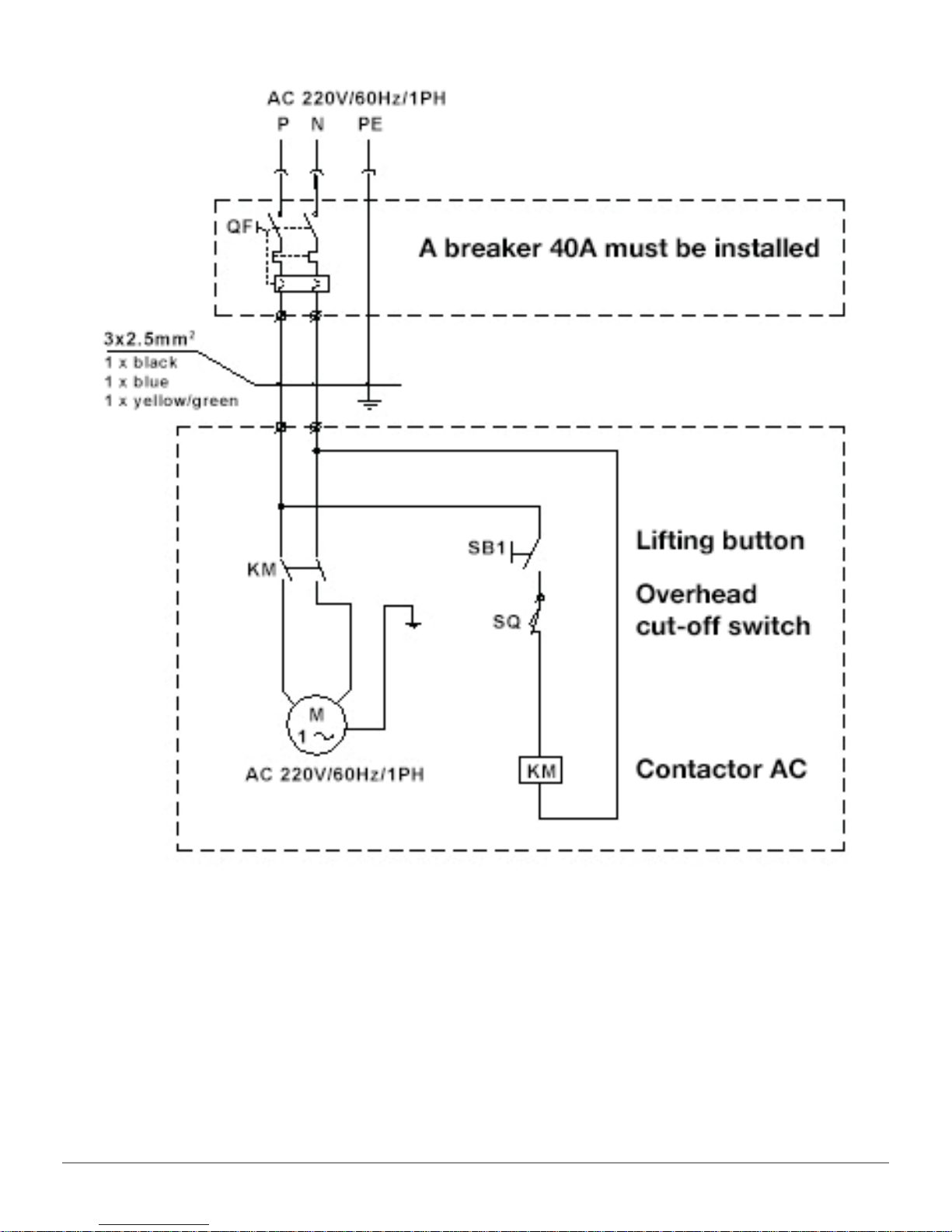

Motor connection must be carried out referring to the attached wiring diagrams

(fi gure 6). The motor direction of rotation is shown on the label attached to

the motor. Before using the lift, verify if the motor specifi cation shown in the

nameplate of the motor conforms to the local electric supply. If there is over

10% fl uctuation on the electrical power supply, it is suggested to use the voltage

stabilizer to protect the electrical components and system from overloading.

Technical Specification 17

Apex-10 / Apex-10H

Page 18

5.3 Pump

Continuous working pressure 2250psi

Peak pressure 2700psi

Type Gear

Flow rate 42.ml/r

Technical Specification 18

Apex-10 / Apex-10H

Page 19

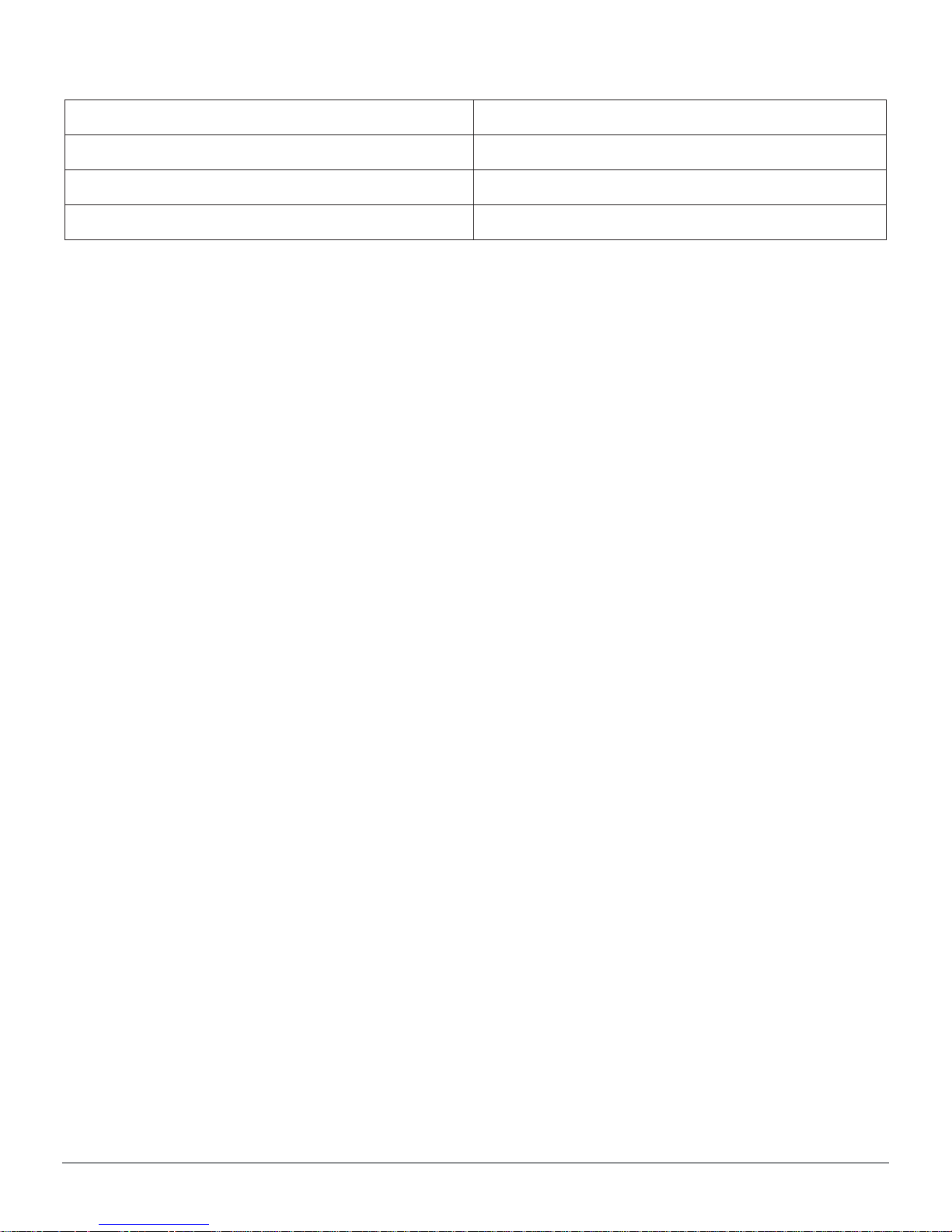

Figure 3a – Standard Version

Technical Specification 19

Apex-10 / Apex-10H

Page 20

Figure 3b – Taller Version

Technical Specification 20

Apex-10 / Apex-10H

Page 21

5.4 Hydraulic Power Unit

Lifting

button

Lowering

Lever

Filler

breather

cap

Motor

Pressure

relief valve

Oil tank

Figure 4

5.5 Oil

Use wear proof oil for hydraulic drive, in conformity with ISO 6743/4 rules (HM

class). The oil with features similar to those shown in the table is recommended.

Test standards Features Value

ASTM D 1298 Density 20°C 0.8 kg/l

ASTM D 445 Viscosity 40°C 32 cSt

ASTM D 445 Viscosity 100°C 5.43 cSt

ASTM D 2270 Viscosity index 104 N°

ASTM D 97 Pour point ~ 30 °C

ASTM D 92 Flash point 215 °C

ASTM D 644 Neutralization number 0.5 mg KOH/g

Change Hydraulic Oil At 1 Year Intervals

Technical Specification 21

Apex-10 / Apex-10H

Page 22

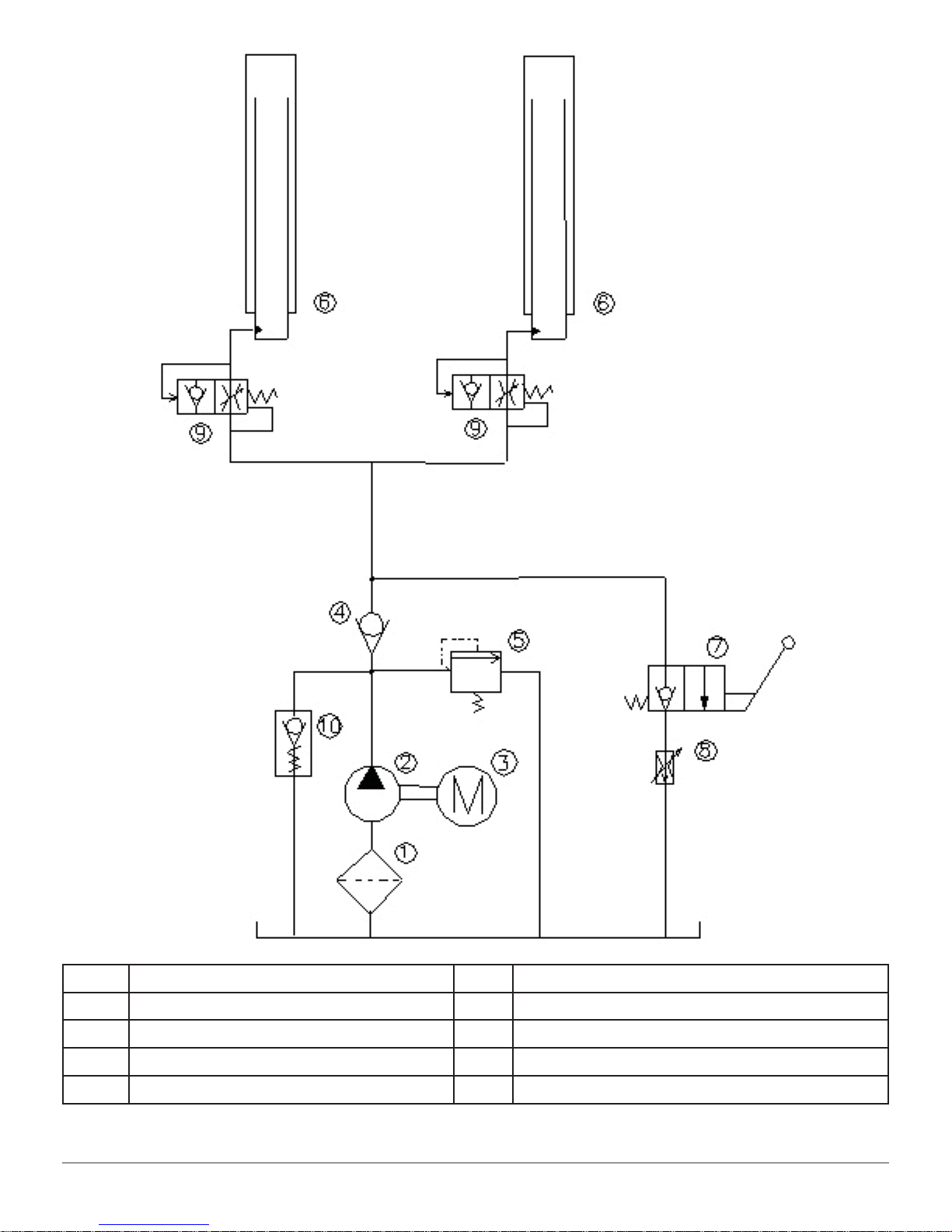

1 Oil fi lter 6 Hydraulic cylinder

2 Gear pump 7 Manual lowering valve

3 Motor 8 Flow restrictor

4 Non return valve 9 Parachute valve

5 Pressure relief valve 10 Startup valve

Figure 5 - Hydraulic Plan

Technical Specification 22

Apex-10 / Apex-10H

Page 23

Figure 6 – Electrical Diagram (220V/60Hz/1PH)

Technical Specification 23

Apex-10 / Apex-10H

Page 24

Safety

Read this chapter carefully and completely because it contains important

information for the safety of the operator and the person in charge of

maintenance.

The lift has been designed and built for lifting vehicles and

making them stand above level in a closed area. Any other use

is prohibited.

The manufacturer is not liable for possible damages to people,

vehicles or objects resulting from an improper or unauthorized

use of the lift.

For operator and personnel safety, a square space for a safety area at least 3ft

free away from the lift must be vacated during lifting and lowering. The lift must

be operated only from the operator’s control site in this safety area.

Never use the lift when safety devices are not locked. People;

the lift and the vehicles lifted can be seriously injured or

damaged if the following instructions are not followed.

Operator’s presence under the vehicle, during working, is only admitted when

the vehicle is lifted and the safety lock is engaged.

6.1 General Warnings

The operator and the person in charge of maintenance must follow OSHA

requirements.

They also must carry out the following:

Safety 24

Apex-10 / Apex-10H

Page 25

• Neither remove nor disconnect hydraulic, electric or other safety devices;

• Carefully follow the safety indications applied on the machine and included

in the manual;

• Observe the safety area during lifting;

• Be sure the motor of the vehicle is off, the gear engaged and the parking

brake put on;

• Be sure only authorized vehicles are lifted without exceeding the maximum

lifting capacity;

• Verify that no one is on the arms during lifting or standing.

6.2 Safety Device

To avoid overloading and possible breakage, the following safety devices have

been used:

• A pressure overload valve built inside the hydraulic power unit to prevent

excessive weight;

The pressure overload valve has been preset by the

manufacturer. DO NOT try to adjust it to overrun the rated

lifting capacity.

• Mechanical safeties built in each carriage with automatic engagement for

lifting safety.

It is strictly prohibited to modify any safety device. Always

check the safety device for proper operation during the use of

the lift.

6.3 Safety Signs

All safety warning signs displayed on the lift are with the purpose to draw the

operator’s attention to dangerous or unsafe situations. The labels must be kept

clean and they have to be replaced if detached or damaged. Read the meaning

of the labels carefully and memorize it.

Safety 25

Apex-10 / Apex-10H

Page 26

Safety 26

Apex-10 / Apex-10H

Page 27

Safety 27

Apex-10 / Apex-10H

Page 28

Installation

Only skilled technicians, appointed by the manufacturer, or by

authorized dealers, must be allowed to carry out installation.

Serious damage to people and to the lift can be caused if

installations are made by unskilled personnel.

Always refer to the exploded views attached during installation.

7.1 Tool Required

Rotary Hammer Drill (3/4in) Hex-Key/Allen Wrench Set

Masonry Bit (3/4in) Crow Bar For Shim Installation

Hammer Chalk Line

3ft to 4ft Level Medium Phillips Screwdriver

Open-End Wrench Set Medium Flat Screwdriver

Medium Crescent Wrench Tape Measure

7.2 Checking For Room Suitability

The lift has been designed to be used in covered and sheltered places free of

overhead obstructions.

The place of installation must not be next to washing areas, painting

workbenches, solvent or varnish deposits. The installation near to rooms, where

a dangerous situation of explosion can occur, is strictly prohibited. The relevant

standards of the local Health and Safety at Work regulations, for instance, with

respect to minimum distance to wall or other equipment, escapes and the like,

must be observed.

7.3 Lighting

Lighting must be carried out according to the effective regulations in the place of

installation. All areas next to the lift must be adequately lit.

Installation 28

Apex-10 / Apex-10H

Page 29

7.4 Floor Requirement

The lift MUST be installed on 3000 PSI concrete with the minimum thickness of

4 inches (please reference anchor bolt manufacturer website) and a concrete

extension of at least 1.5m from anchoring points. New concrete must be

adequately cured by at least 20 days minimum.

Specifi cations of concrete must be adhered to. Failure to do so

could cause lift failure resulting in personal injury or death.

A level fl oor is suggested for proper installation. Small

differences in fl oor slope may be compensated by proper

shimming. Any major slope change will affect the level lifting

performance. If a fl oor is of questionable slope, consider

pouring a new concrete slab.

7.5 Site Layout

• Now locate the lift according to the floor plan in fi gure 8, use a carpenters

chalk line to layout a grid for the column locations;

• After the column locations are properly marked, use a chalk or crayon to

make an outline of the columns on the fl oor at each location using the

column base plates as a template;

• Double check all dimensions and make sure that the bases of each column

are square and aligned with the chalk line.

Installation 29

Apex-10 / Apex-10H

Page 30

Figure 8a – Floor Plan

Installation 30

Apex-10 / Apex-10H

Page 31

7.6 Installation Of Column Extension (Ref. Fig. 9)

• Remove the column extension from

the package. Make sure to be careful

to avoid damaging the paint;

• Align the holes between the column

and the extension with carriage bolts

M10X20 and fl ange nuts M10;

• Tighten the bolts and nuts thoroughly.

7.7 Anchoring Columns

Figure 9

• Use the base plate on the column as a

guide and drill each hole in the

concrete with the rotary hammer drill 3/4in bit. Please refer to the anchor

bolt manufacture website for recommended values. To assure full holding

power, do not ream the hole or allow drill to wobble;

• After drilling, remove dust thoroughly from each hole using compressed air

and/or wire brush. Make certain that the column remains aligned with the

chalk line during this process;

• Assemble the

washers and nuts

on the anchors then

tap into each hole

with a hammer

until the washer

rests against the

base plate. Be sure

that if shimming

is required that

enough threads are

left exposed;

• If shimming is

required, insert the

shims as necessary

under the base

plate so that when

the anchor bolts

are tightened, the

columns will be

plumb;

Installation 31

Figure 10

Apex-10 / Apex-10H

Page 32

• With the shims and anchor bolts in place, tighten by securing the nut to

the base. DO NOT use an impact wrench for this procedure;

• Anchor another column as outlined in above steps;

• Make sure the columns are square and plumb as shown in the fi gure 10.

The requirements for column’s square and plumb must be

adhered to. Failure to do so could cause lift failure resulting in

personal injury or death.

7.8 Installation Of Mounting Bracket On The Overhead Beam

• Install the mounting brackets to the column extensions using the fl ange

bolts M10X20 and the fl ange nuts M10 supplied (ref. fi g. 11);

• Tighten the bolts and nuts thoroughly;

• Install the safety release wire guides using the bolts M6X25 and the hex

nuts M6 (ref. fi g. 11).

Figure 11

Bracket

Guide

7.9 Installation Of The Overhead Beam

• Assemble the left and the right overhead beams using the using the fl ange

bolts M10X20 and the fl ange nuts M10 supplied (ref. fi g. 12). Do not

tighten the bolts and nuts at this moment;

Installation 32

Apex-10 / Apex-10H

Page 33

Figure 12

Figure 13

Figure 14

• Install the left safety bar bracket on the left overhead beam using the cross

recess head screw M6X12 and the hex nuts M6 (ref. fi g. 13). Make sure to

position the bracket adjacent the power-side column;

• Install the overhead switch on the switch bracket using the bolt M8X55 and

two nuts M8;

• Install the right safety bar bracket on the right overhead beam using the

cross recess head screw M6X12 and the hex nuts M6 (ref. fi g. 14);

• Place one end of anti-crush safety bar on

the right bracket and fi x it to the right

bracket using the bolt M8X40 and the hex

nuts M8 (ref . fi g. 14), and place another

end of anti-crush bar onto the overhead

Guide

switch through the left safety bar bracket;

• Use a lifting device to raise the assembled

beam on the mounting brackets;

Figure 15

• Adjust the beam to appropriate

dimensions. Tighten the fl ange bolts

M10X20 and the fl ange nuts M10 after

adjustments (ref. fi g. 15);

• Install the safety release wire guides

using the bolts M6X25 and the hex nuts

M6 (ref. fi g. 15).

Installation 33

Apex-10 / Apex-10H

Page 34

7.10 Routing The Equalizer Cables

The equalizer cables should be checked weekly for equal

tension. Failure to do this will cause uneven lifting. The

cables should always be adjusted so that they are equal

tension when resting on the safety locks.

• Use appropriate lifting equipment to raise the

carriage to the fi rst latch position. Be sure the

carriage is engaged securely before attempting to

route the equalizer cables. Carriages must be equal

height from the fl oor before proceeding;

• With the carriages in equal height, fi t the cable

end-ups through the small holes of the carriages

(ref. fi g. 16);

• Route the equalizer cables referring to the diagram

(fi g. 17). Make sure the cables are on the pulleys.

Make sure the cables are routed properly;

Figure 16

• After the equalizer cables have been routed, adjust

the nuts M14 to make each cable in equal tension;

• Install the pulley cover (ref. fi g. 18) using a cross

recess head screw M6X10 on each column.

Figure 17

Figure 18

Cover

Installation 34

Apex-10 / Apex-10H

Page 35

7.11 Routing The Safety Release Cable

• Install the cable pulley and the retaining rings in upper slot of the

power-side column (ref. fi g. 19);

• Slip the loop end of the cable over the shoulder bolt (ref. fi g, 19);

• Feed another end of the cable through the upper slot and make sure cable is

routed under the bottom of the pulley and inside the column (ref . fi g, 19);

Pulley

Shoulder bolt

ABS plate

Installation 35

Safety release lever

Figure 19

Apex-10 / Apex-10H

Page 36

• Continue routing the cable to the off-side column referring to the diagram

(fi g. 20). Make sure the cables route on the guides mounted previously on

the columns and the column extensions and tie it using a strap if necessary

(ref. fi g. 21);

Pay attention to the position of the safety pin

Clip

Guide

Figure 20

Guide

Installation 36

Figure 21

Apex-10 / Apex-10H

Page 37

• Bring the cable down inside the off-side column and feed the end of the

cable through the lower slot (ref. fi g. 22);

• Install the cable pulley in the lower slot of the off-side column (ref. fi g. 22);

• Route the cable under the bottom side of the pulley (ref. fi g. 22);

• Insert the cable in the cable clamp along one side, loop around the

shoulder bolt and back down and insert the cable along another side of the

cable clamp (ref. fi g. 22). Slightly tighten the clamp;

• Press the safety release lever down to eliminate any clearance between the

slots and pins;

• Using the pliers, pull the cable tight and secure the clamp close to the

shoulder bolt. Tighten the clamp;

• Install the safety release lever and ABS plate using the nuts M22 (ref. fi g,

19). Install the ABS cover using the cross recess head screw M8X10 and

the washers D.10 and then install the lever ball on the lever (ref. fi g. 23).

ABS cover

Shoulder bolt

Pulley

Figure 22

Cable clamp

Lever ball

Figure 23

Installation 37

Apex-10 / Apex-10H

Page 38

7.12 Installation Of Power Unit (Ref. Fig. 24)

• Attach the power unit on the bracket on the

power side column;

• Secure it using nuts M10X20, the locking

washers D.10 and washers D. 10.

Figure 24

7.13 Connection Of Hydraulic Hoses

When routing the hydraulic hose, make sure that the hose is

clear of any moving part. Make sure to keep the hose inlets clean

from dust. Make sure not to over-tighten the hose fi ttings. This

may result in oil leakage.

• Clean the hoses and fi ttings;

• Inspect all threads for damage and make sure that all hose fi ttings are in

good condition;

• Install hose clamps and route the hoses referring to fi gure 25;

• Tighten the hose fi ttings thoroughly .

Installation 38

Apex-10 / Apex-10H

Page 39

7.14 Make The Electrical Connection

The electrical hookup work must be carried out by a qualifi ed

electrician.

Make sure that the power supply is correct.

Make sure the phase connection is correct. Improper electrical

hookup can damage the electric motor. This will automatically

void warranty.

Make sure the lift is well grounded.

The power unit must be kept dry. NOT FOR OUTDOOR USE

Do not use a 60Hz motor on a 50Hz power supply.

• Make the electric hookup to the hydraulic power unit referring to the wiring

diagram (fi g. 6) using the included electric cable;

• When routing the electric

cable for the overhead

switch, make sure to

keep it clear of any

moving parts and route

it through the hose

clamps on the power-side

column;

• Make sure to install

a circuit breaker on

the circuit: 40A for

220V/60Hz/1Ph.

Figure 26

Installation 39

Apex-10 / Apex-10H

Page 40

7.15 Oil Filling And Bleeding

DO NOT run power unit without oil. Damage to pump may occur.

If motor gets hot or sounds peculiar, stop immediately and

recheck the electric connection, amperage and incoming voltage.

• Use the hydraulic fl uid recommended in the chapter 5.5;

• Remove the oil level plug on the oil tank and pour oil in the tank about 2

3/4 gallons;

• Raise the lift about 2 feet;

• Open the bleeder of each cylinder approximate two turns (ref. fi g. 25);

• Close the bleeders when the fl uid fl ows out;

• Lower the lift completely;

• Fill with more fl uid if necessary until the tank is full.

If the oil level plug is lost or broken, order the replacement.

The oil tank must be vented well.

7.16 Installation Of The Arms

Make sure the arm safety is adjusted properly.

Make sure to check the arm safety regularly.

• Raise the carriages to a convenient height;

• Grease the holes and all pivot pins prior to installation;

• Slide the arm into the carriage yoke (ref. fi g. 27);

• Install the arm pin into the yoke hole and arm hole (ref. fi g. 27);

• After installing the arm and the pin, place the anti-rotation gear into the

arm clevis. Make sure that the beveled gear orientation is correct. To allow

the enough room to install the gear, it is advised to pull up the arm pin

during installation (ref. fi g. 28);

• Install the arm using the bolts M10X35 (ref. fi g. 29). Do not tighten the

bolts at this moment;

Installation 40

Apex-10 / Apex-10H

Page 41

Pay attention to

the pinch point!

Figure 27

• Once an arm is installed, make sure to check that each anti-rotation gear

meshes and stays aligned very well. If not, remove the anti-rotation gear

and install it in the opposite position;

• After checking that each anti-rotation gear and the toothed gear are

aligned well, tighten the bolts;

• Repeat the above procedure to install other arms.

Pay attention to the

beveled gear orientation

Figure 28

Installation 41

Figure 29

Apex-10 / Apex-10H

Page 42

7.17 Installation Of The Rubber Door Protectors (Ref. Fig. 30)

• Press the long rubber protectors on each column edge;

• Press the short rubber protectors on the top edge of the carriage.

Short

protection

Long

protection

Installation 42

Figure 30

Apex-10 / Apex-10H

Page 43

7.18 Check Before Start-Up

7.18.1 General Checks

• Make sure that the columns are plumb;

• Make sure the lift anchored to the ground and all anchor bolts tightened.

Please refer to the anchor bolt manufacture website for recommended

torque values;

• Make sure the electrical system feeding voltage is equal to that specifi ed

on the nameplate on the motor;

• Make sure the electrical system connection conforms to the electric plan

shown on the electric diagram (fi g. 6) and for proper grounding;

• Particularly, below checks must be followed:

7.18.2 Mechanical Safeties For Proper Installation

• Check to make sure that safeties will properly engage and disengage by

releasing and pushing the safety release lever slowly;

• When raising the carriages, listen to the safety pawls fall into the safety

racks. If not, loosen the cable clamp (ref. fi g. 22) and adjust tensions as

necessary.

7.18.3 Equalizer Cable For Proper Installation

• Raise the carriages to check the

equalizer cable tension by grasping the

adjacent cables between the thumb and

the forefi nger so that you can just pull

the cables together (ref. fi g. 31);

• Adjust the nuts on the carriage (ref. 16)

if necessary.

Installation 43

Figure 31

Apex-10 / Apex-10H

Page 44

7.18.4 Hydraulic System For Proper Operation

• Proper oil level in the tank, refi ll if needed;

• Raise the lift to the full height and keep the motor running for 5 seconds;

• Check all hoses connections to make sure

there is no leakage. Tighten the connections or

reseal if necessary;

• Check the lift for reaching its maximum height;

• Repeat the air bleeding of cylinders if

necessary;

• Make sure the cylinder peg rests into the hole

on the base plate.

7.18.5 Overhead Switch For Proper Operation

• Check the overhead switch. Verify that it cuts off electrical supply when the

crush proof bar is raised;

• If the overhead switch does not interrupt the electrical supply, check the

angle of the actuator or recheck wiring to the A/C contactor.

7.19 Check With Load

WARNING: please carefully follow the instructions in the

coming paragraph to avoid damages to the lift.

Carried out two or three complete cycles of lowering with the vehicle loaded:

• Repeat the checks provided for by 7.18;

• Listen for strange noises during lifting and lowering;

• Visually inspect cables, hydraulic lines and bolt connections.

Installation 44

Apex-10 / Apex-10H

Page 45

Never operate the lift with any person or equipment below.

Never exceed the rate lifting capacity.

Always ensure that the mechanical safeties are engaged

before lifting a vehicle.

Always lift a vehicle on the lifting pads.

Never leave the lift in an elevated position unless the safeties

are engaged.

If an anchor bolt becomes loose or any component of the lift

is found to be defective, DO NOT USE THE LIFT until repairs

are made.

8.1 Controls

Operation And Use

2

1

3

Figure 32

Operation And Use 45

Apex-10 / Apex-10H

Page 46

Controls for operating the lift are:

LIFTING BUTTON (1)

• When pressed, the power unit is running and the lift can be raised to a

desired height until the button is released;

SAFETY RELEASE LEVER (2)

• When pulled, the mechanical safeties will be released so that the lift can

lower to desired height;

LOWERING LEVER (3)

• If the safety release lever is not pressed, press the lower lever, the lift will

lower to engage the nearest safety lock;

• If the safety release lever is pressed (the mechanical safeties are

released), press the lower lever, the lift will lower to the desired height

under its weight and the load lifted until the lever is released.

Lift operation can be summarized into four steps:

8.2 Vehicle positioning

• Positioning the vehicle between columns;

• Adjust lift arms so that the vehicle is positioned with the centre gravity

between the pads. Make sure the arm safeties are engaged;

• Raise the lift by pressing the lifting button until the lifting adaptors contact

underside of the vehicle;

• Make sure the vehicle is secured.

Operation And Use 46

Apex-10 / Apex-10H

Page 47

8.3 Lifting

• Raise the lift by pushing the lifting button until reaching the desire height.

8.4 Standing

• Press the lowering lever to engage the nearest mechanical safety;

• Always ensure that the safety in each column is engaged before any

attempt is made to work on or near the vehicle.

8.5 Lowering

• Raise the lift a little bit by pushing the lifting button to clear off the

mechanical safeties;

• Lower the lift by pulling the safety release lever and in the meantime

pressing the lowering lever;

• Before removing vehicle from the lift area, position the lift arms to and

pads to provide an unobstructed exit;

• Never drive over the lift arms.

Operation And Use 47

Apex-10 / Apex-10H

Page 48

Maintenance

Only trained personnel, who know how the lift works, may

perform maintenance service to the lift.

To service the lift properly, the following must be carried out:

• use only genuine spare parts as well as equipment suitable for the work

required;

• follow the scheduled maintenance and check periods shown in the manual;

• diagnose the reason for possible failures such as too much noise,

overheating, oil blow-by, etc.;

• refer to documents supplied by the manufacture or dealer to carry out

maintenance.

Before carrying out any maintenance or repair on the lift,

disconnect the power supply.

9.1 Ordinary maintenance

The lift has to be properly cleaned and wiped down with mild cleaners every

week.

The use of water or fl ammable liquid is strictly prohibited

Be sure the ram on the hydraulic cylinders are always clean and not damaged

since this may result in leakage from seals and, as a consequence, in possible

malfunctions.

Maintenance 48

Apex-10 / Apex-10H

Page 49

9.2 Periodic Maintenance

Daily pre-operation

• Check hydraulic connections and hoses for leaks;

• Check safety lock audibly and visually while in operation;

• Check arm locks;

• Check bolts, nuts and screws are tight.

Every 1 month

• Check all cable connections, pins and bolts to insure proper mounting;

• Inspect all anchor bolts and retighten if necessary;

• Check columns for square and plumb;

• Check equalizer cable tension, adjust if necessary;

• Check safety cable, adjust it if necessary;

• Check all arm pivot pins. Make sure they are properly secured;

• Check all lifting pads, replace if necessary;

• Lubricant columns with grease;

• Check the hydraulic oil, fi ll or replace if necessary;

• Check hydraulic systems for proper operation.

Every 12 months

• Verify that all components and mechanisms are not damaged;

• Verify the equalizer cables are not worn up to 5%, change if necessary;

• Verify the safety cable is not worn, change if necessary;

• Check the electrical system to verify that the motor and overhead limit

switch operate properly (this work must be carried out by certifi ed

electricians);

• Empty the oil tank and change the hydraulic oil.

Maintenance 49

Apex-10 / Apex-10H

Page 50

Troubleshooting

A list of possible troubles and solutions is given below:

Trouble: Possible Cause: Solution:

There is no power Check Power on to restore if necessary

The lift does not

work

The lift does not

raise

The lifting capacity

is not suffi cient

The electrical wires are disconnected Reconnect

Check for correct voltage

The circuit breaker is tripped/ blown

Replace

The lift is overloaded Check the vehicle weight

The motor direction of rotation is not

correct.

The oil in the power unit is not suffi cient. Add some hydraulic oil

The UP button is faulty.

The pressure relief valve clogged or leaks

The lowering valve does not close.

The suction tube or pump fi lter is dirty. Check and clean if needed.

Presence of air in the hydraulic system Bleed the hydraulic system

The pump is faulty

Oil leakages in hydraulic circuit Check the circuit for any leakage

Interchange the two phases on the

main switch

Check UP button and connection for

proper operation. Replace if needed

Check and clean if dirty or replace if

faulty

Check and clean, if dirty or replace if

faulty

Check the pump and replace if

needed.

The lift does not

lower when the

lowering lever and

the safety release

lever are pressed

The lift does not

lower smoothly

The lowering valve does not work properly Check the valve and replace if needed.

The safety cable is broken Check, replace if faulty

The equalizer cables are not in the same

tension.

Presence of air in the hydraulic system Bleed the hydraulic system

Lubrication of sliders is not enough. Grease

Sliders are damaged Replace

* If the problem(s) remain unsolved, call for technical support. 1-866-898-2604

Troubleshooting 50

Readjust the equalizer cables.

Apex-10 / Apex-10H

Page 51

Additional Information

Final Check of Assembled Lift

Final dimension check after anchoring.

Base and columns properly shimmed and stable.

Anchor bolts tightened.

Runways properly attached, secured, and level.

Check for hydraulic leaks.

Ensure cables are properly routed and free from obstructions.

Check jam nuts on cables are tightened.

Check oil level and look for leaks.

Check adjustment of safety release cable to ensure both sides

are working properly.

Re-check level of towers.

Check torque of anchor bolts.

Check all fasteners, tighten if necessary.

Electric power supply confi rmed.

Check for overhead obstructions.

Check shut off at top of stroke to ensure lift shuts off.

Check proper operation of arm restraints.

Operate lift to full stroke then lower to ground while checking for

proper functionality.

Check proper operation of arm restraints.

Operation and Safety Manual at site.

Ensure all documents listed below are given to the owner.

ANSI / ALI Lift It Right Manual.

ANSI / ALI Safety Tip Card.

ANSI / ALI ALIS Safety Requirements for Installation.

ALI/LP Lifting Points Quick Reference Guide.

Train end user on operation of lift.

Additional Information 51

Apex-10 / Apex-10H

Page 52

Vehicle Lifting Points

Some vehicles may have the manufacturer’s Service Garage Lift Point locations

identifi ed by triangle shape marks on its undercarriage (reference SAE J2184).

Also, there may be a label located on the right front door lock face showing

specifi c vehicle lift points. If the specifi c vehicle lift points are not identifi ed,

refer to the “Typical Lift Points” fi gure below or the ALI/LP Guide - Vehicle Lifting

Points/ Quick Reference Guide included with your lift. Consider center of gravity,

contents of vehicle and weight shifting before operating.

Make sure vehicle is neither front nor rear heavy. If the specifi c vehicle lift

points are not identifi ed, or if the vehicle has additional or uniquely positioned

payload, have a qualifi ed person calculate the vehicle center of gravity or have

the vehicle center of gravity determined at a vehicle scale. Load the vehicle with

the center of gravity midway between adapters.

Unusual vehicles, such as limousines, RV’s, and long wheelbase vehicles, may

not be suitable for lifting on this equipment. If necessary, consult with your Atlas

Automotive Equipment representative or contact the vehicle manufacturer.

Additional Information 52

Apex-10 / Apex-10H

Page 53

Operation Test with Vehicle

Prior to starting this section, please refer to the important safety instructions at

the beginning of this manual. Reference Automotive Lift-Safety Requirements for

Operation, Inspection, and Maintenance (ANSI/ALI ALOIM)

After fi nishing the above assembly instructions and adjustments, perform an

operation test of the lift using a typical vehicle.

1. Lower lift to ground.

2. Drive vehicle on to lift and position the arms as per the “Lift it Right” manual

and “Lifting Points Quick Reference” guide.

3. Raise lift to and lower onto 3-4 lock positions during full rise to ensure all

locks are working correctly.

4. Re-adjust cables if necessary while vehicle is on.

5. Check lowering speed and smooth decent rate.

6. Lower lift to ground and drive vehicle off lift.

Run the lift in the low position several times, and then run the lift to the top

completely.

If any problems occur during the fi nal checkout or operation test

of the lift with a vehicle, please contact your lift distributor, sales

representative or manufacturer immediately.

Additional Information 53

Apex-10 / Apex-10H

Page 54

Operating Instructions

Please reference enclosed ANSI/ALI ALOIM – Current Edition and ALI/LP Guide

before proceeding.

1. Ensure lift is fully lowered and service bay is clear.

2. Move swing arms to full drive thru position.

3. Center the vehicle between the lift posts and position the arms in

accordance with the supplied “Lifting it Right” and “Lifting Point” guides. Be

sure you are using the proper adapters.

4. Push the raise switch on the power unit and ensure that the arm restraint

pins for engagement.

5. Raise the vehicle until the suspension and tires clear the fl oor.

6. Stop and check the adapters for secure contact in accordance with the

vehicle manufacturer recommended lifting points and “Lifting Point” guide.

7. Moderately shake vehicle by pushing on the front or rear bumper to ensure

that vehicle is safely positioned on the lift.

8. After confi rmation that vehicle is securely positioned, continue to raise the

lift to the desired lift height.

9. Lower the lift onto the mechanical locking latches.

10. Avoid excessive rocking of the vehicle while it on the lift.

11. Always use safety support stands when removing or installing heavy vehicle

components.

12. To lower the lift, fi rst be sure that all objects and all personnel are free from

lift area. Observe pinch point and other warning decals.

13. Raise the lift off the locking latches.

14. Pull down and hold the safety release while pressing the hydraulic lowering

valve handle until the lift has fully lowered to the ground and the arm

restraints have disengaged.

15. Remove adapters and position arms in full drive thru position before

removing vehicle from the service bay.

Additional Information 54

Apex-10 / Apex-10H

Page 55

Inspection and Maintenance

Please refer to the ANSI/ALI ALOIM – Current Edition “AMERICAN NATIONAL

STANDARD for Automotive Lifts – Safety Requirements for Operation, Inspection

and Maintenance”.

Periodic inspections and maintenance shall be performed only by trained lift

service personnel. Never operate a lift that is damaged or in disrepair. Proper

inspection and maintenance is necessary for the safe operation of the lift.

Contact a local service or factory representative immediately if any issues

arise or if you are not completely familiar with automotive lift maintenance

procedures.

Daily Procedures

• Check to ensure bolts are tightened;

• Check lift components and keep clean and free of debris;

• Check for oil leakage;

• Check all electrical components and wiring;

• Check cables and sheaves;

• Check all hydraulic lines and fi ttings;

• Repair or replace all damaged, defective, worn, frayed or broken

components immediately. Only use parts approved by the original

equipment manufacturer or parts meeting original manufacturer

specifi cations.

Monthly Procedures

• Check equalizer cable tension and adjust accordingly;

• Check lubrication points and lubricate accordingly;

• Check anchor bolts for tightness and appropriate torque;

• Check fl uid levels;

• Repair or replace all damaged, defective, worn, frayed or broken

components immediately. Only use parts approved by the original

equipment manufacturer or parts meeting original manufacturer

specifi cations.

Additional Information 55

Apex-10 / Apex-10H

Page 56

Lockout and Tagout Procedures

Please refer to ANSI Z244.1

Purpose: This procedure establishes the minimum requirements for lockout of

energy sources that could cause injury to personnel by the operation of the lift.

All employees and/or operators shall comply with the procedure.

Responsibility: The responsibility for seeing that this procedure is followed is

binding upon all owners, employees and lift operators. All owners, employees

and operators shall be instructed in the safety signifi cance of the lockout

procedure by the owner, supervisor or appropriate personnel. Each new or

transferred affected employee or operator shall be instructed by appropriate

personnel in the purpose and use of the lockout procedure.

Preparation for Lockout: Employees authorized to perform lockout shall be

certain as to which switch, valve, or other energy isolating devices applies to

the lift. More than one energy source (electrical, mechanical, or others) may

be involved. Any questionable identifi cation of sources shall be cleared by

the employees, their supervisors, or appropriate personnel. Assure that job

authorization has been obtained before lockout commences.

Sequence of Lockout Procedure

• Notify all affected employees and operators that a lockout is required and

the reason therefore;

• If the lift is operating, shut it down by the normal stopping procedure (such

as assuring the disconnect switch is off);

• Operate the switch, valve, or other energy isolating devices so that

the energy source(s) (electrical, mechanical, hydraulic, and other) are

disconnected or isolated from the lift;

• If it is a lockable device, lockout with an assigned individual lock. If it is

not a lockable device, replace with a dummy device and tag accordingly.

If more than one individual is required to lock out the lift, each shall place

their own personal lock on the energy isolating device(s);

• Adequately label or tag the lift stating not to operate or tamper with the

tag or label;

Additional Information 56

Apex-10 / Apex-10H

Page 57

• Stored energy (such as that in capacitors and hydraulic systems) must also

be addressed;

• After ensuring that no personnel are exposed and as a check to ensure

the lockout is working, operate the push button or other normal operating

controls to make certain the lift will not operate. Return the lift operating

controls to neutral position after the test;

• The equipment is now locked out.

Restoring Equipment to Service

• When the job is complete and equipment is ready for testing or normal

service, check the lift area to see that no one is exposed;

• When lift is clear, remove all locks. The energy isolating devices may be

operated to restore energy to lift.

Rules for Using Lockout Procedure: The lift shall be locked out to protect

against accidental or inadvertent operation when such operation could cause

injury to personnel. Never attempt to operate any switch, valve, or other energy

isolating device bearing a lock.

Additional Information 57

Apex-10 / Apex-10H

Page 58

Wire Ropes

WARNING

• Wire ropes are critical to the safe and reliable performance of your lift.

• Cables are expendable items and should be replaced as a set.

CABLE CONDITION GUIDE

Maximum Allowable Cable Necking

Nom. Cable Diameters Max. Reduction in Diameter

Up to 5/16” 1/64”

3/8” to 1/2” 1/32”

9/16” to 3/4” 3/64”

7/8” to 1-1/8” 1/16”

1-1/4” to 1-1/2” 3/32”

Typical Good Cable Cable with Broken Wires

Cable with Severe Corrosion Cable with Necking

Additional Information 58

Apex-10 / Apex-10H

Page 59

Wire Rope Replacement Criteria

If any cable is found to be in need of replacement, the

WA RNING

The Wire Rope MUST be Replaced if One or More of the Following

Criteria Are Met:

• More than six (6) randomly distributed broken wires in one rope lay or 6xd

length;

• More than three (3) broken wires in one strand in one rope lay or 6xd

length;

• Three (3) or more broken wires at rope terminations;

• One outer wire broken at the point or contact with the core of the rope

whish has worked its way out of the rope structure and protrudes or loops

out from the rope structure;

entire cable set, pulleys and safety rollers, must be

replaced immediately. See Cable Condition Guide.

• Heavy rusting, corrosion, or pitting. A light surface corrosion on outer

wires is normal;

• Wear or scraping of one-third (1/3) of the original diameter of outside

individual wires;

• Excessive stretch. It is normal for new cable to require adjustment during

“break-in,” after which small periodic adjustments may be required.

However, if a cable that has been in service for 6 months should suddenly

require frequent adjustments or has used all the cable adjustments

available, all cables must be replaced immediately;

• Deformed strands, kinking, crushing, bird-caging, or any other damage or

distortion of wire rope structure;

• Variations in diameter (necking) or any change from normal appearance;

• Reductions from nominal diameter of more than 1/32” (for cables 3/8” to

1/2” diameter inclusive.);

• End attachments cracked, deformed or worn.

* Lay is the distance measured, parallel to the rope axis, in which a single strand makes one complete

turn around the rope axis, or the wires make a complete turn around the axis of the strand.

Please reference ANSI/ALI ALOIM standard for more information on

wire rope cable inspection.

Additional Information 59

Apex-10 / Apex-10H

Page 60

Emergency Operation If Lift Becomes

Inoperable In Raised Position

If the lift becomes inoperable in the raised position, wait until electrical power

is restored to the lift before attempting to lower the vehicle. If it is crucial for

reasons of safety that the vehicle be lowered, please DO NOT attempt to do so

on your own without fi rst contacting your local authorized service representative

or distributor, who can verbally walk you through the process or assist, in

person, where necessary.

WARNING: DO NOT LOOSEN OR REMOVE HYDRAULIC

CONNECTIONS OR FITTINGS UNDER PRESSURE.

SERIOUS INJURY OR DEATH COULD OCCUR.

Additional Information 60

Apex-10 / Apex-10H

Page 61

Parts Catalogue

Parts Catalogue 61

ED. 01/2015

Apex-10 / Apex-10H

Page 62

LIFT

ITEM PART NO. DESCRIPTION QTY

1 Z23A110000AM Power-side column assembly 1

2 Z23A120000AM Off-side column assembly 1

3a Z23A130001 Column extension L=800 (standard version) 2

3b Z23A130001-H1 Column extension L=1410 (H version) 2

4 Z23A200000 Carriage assembly 2

5 Z23A320000AM Short arm assembly 2

Parts Catalogue 62

Apex-10 / Apex-10H

Page 63

ITEM PART NO. DESCRIPTION QTY

6 Z23A310000AM Long arm assembly 2

7 Z23A400000AM Overhead beam assembly 1

8 Z23A500101 Overhead beam support 2

9 Z23A500102 Arm shaft 4

10 Z23A502201 Safety release wire guide 4

11 0201136 Screw M10X20 18

12 0204030 Flange nut M10 24

13 0201137 Round head screw M10X20 22

14 0201144 Screw M6X25 4

15 0203004 Nut M6 4

16a Z23A501100 Equalizer cable D.8 L=9170 (standard version) 2

16b Z23A501100-H1 Equalizer cable D.8 L=10390 (H version) 2

17a Z23A502100 Safety release wire D.1.5 L=8000 (standard version) 1

17b Z23A502100-H1 Safety release wire D.1.5 L=9200 (H version) 1

18 Hydraulic power unit 220V/60Hz/1PH 1.5KW 1

19 0201046 Screw M10X20 2

20 0205011 Washer D.10 2

21 0208007 Locking washer D.10 2

22 Z23A503200 Pipe U bolt 8

23 0203032 Nut M10 16

24 Z23A510101AM Long rubber protection 4

25 Z23A510102 Short rubber protection 2

26 Z23A510201 Nylon shim 1 20

27 Z23A510202 Nylon shim 2 20

28 Z23A503100 Hose clamp 8

29 Z23A313000AM Arm adaptor 4

30 0205017 Washer D.14 4

31 0204006 Self-locking nut M14 4

32 Z23AY20000 Hydraulic cylinder 2

33 XSZ-8-802-2 Square rubber protection 2

34 0202032 Screw M6X16 8

35 0205006 Washer D.6 8

36 Z23A601102 Pad extension holder 2

37 Z23A601200 Pad extension H.80 4

38 Z23A601300 Pad extension H.155 4

Parts Catalogue 63

Apex-10 / Apex-10H

Page 64

POWER-SIDE COLUMN

ITEM PART NO. DESCRIPTION QTY

1 Z23A110100AM Column 1

2 Z23A110001T Cable pulley 1

3 0211014 Seeger D.15 3

4 Z23A110002 Anti-derailment safety plate 1

5 0206031 Screw M6X10 1

6 Z23A110005 Nylon wire pulley 1

7 0211015 Seeger D.8 2

Parts Catalogue 64

Apex-10 / Apex-10H

Page 65

ITEM PART NO. DESCRIPTION QTY

8 Z23A110007 Shock absorber 1

9 Z23A110006 Safety hook 1

10 0213052 Elastic pin 6X40 1

11 Z23A110004 Hook pin 1

12 Z23A110200 Cam 1

13 0205023 Washer D.24 2

14 Z23A110009 Return spring 2 1

15 Z23A110008 Return spring 1 1

16 0201174 Shoulder bolt 8X25 1

17 Z23A110010 ABS plate 1

18 0215017 Lever knob M10X33 1

19 Z23A504101 ABS cover 1

20 0206034 Screw M8X10 4

21 0205008 Washer D.8 4

22 0203032 Nut M10 2

23 Z23A110003 Safety release lever 1

24 0204024 Flange Nut M6 1

25 0210079 Bush SF-1/1920 1

Parts Catalogue 65

Apex-10 / Apex-10H

Page 66

OFF-SIDE COLUMN

ITEM PART NO. DESCRIPTION QTY

1 Z23A110100AM Column 1

2 Z23A110001T Cable pulley 1

3 0211014 Seeger D.15 3

4 Z23A110002 Anti-derailment safety plate 1

5 0206031 Screw M6X10 1

6 Z23A110007 Shock absorber 1

7 Z23A110006 Safety hook 1

8 0213052 Elastic pin 6X40 1

9 Z23A110004 Safety pin 1

10 0204024 Flange Nut M6 1

11 Z23A110200 Cam 1

Parts Catalogue 66

Apex-10 / Apex-10H

Page 67

ITEM PART NO. DESCRIPTION QTY

12 0201174 Shoulder bolt 8X25 1

13 0205023 Washer D.24 1

14 Z23A110009 Return spring 2 1

15 Z23A110008 Return spring 1 1

16 Z23A504101 ABS cover 1

17 0206034 Screw M8X10 4

18 0205008 Washer D.8 4

19 0211015 Seeger D.8 2

20 Z23A110005 Nylon wire pulley 1

21 0210079 Bush SF-1/1920 1

Parts Catalogue 67

Apex-10 / Apex-10H

Page 68

CARRIAGE

ITEM PART NO. DESCRIPTION QTY

1 Z23A210000 Carriage 1

2 Z23A200001 Nylon slider 4

3 Z23A200002 Slider shim 4

4 Z23A200006 Safety release ring 2

5 Z23A200004 Safety release pin 2

6 Z23A200005 Spring 2

7 Z23A200003 Toothed block 2

8 0213052 Elastic pin 6X40 2

Parts Catalogue 68

Apex-10 / Apex-10H

Page 69

ARMS + ADAPTOR

ITEM PART NO. DESCRIPTION QTY

1 Z23A311000AM Long arm frame 1

2 Z23A312000AM Long arm extension 1

3 Z23A310001 Anti-rotation gear 2

4 0201050 Screw M10X35 6

5 0201060 Screw M10X16 3

6 0201022 Screw M8X12 1

7 0202020 Screw M5X8 2

8 0202032 Screw M6X16 3

9 Z23A324001 Shim 2

10 Z23A310000AM Long arm assembly 1

Parts Catalogue 69

Apex-10 / Apex-10H

Page 70

ITEM PART NO. DESCRIPTION QTY

11 Z23A324001 Shim 1

12 Z23A321000AM Short arm frame 1

13 Z23A322000 Short arm middle extension 1

14 Z23A323000AM Short arm outer extension 1

15 Z23A320000AM Short arm assembly 1

16 Z23A313000AM Arm adaptor 2

17 Z23A313100AM Pad support 2

18 Z23A313001 Inner thread bush 2

19 Z23A313002 Outer thread bush 2

20 0212034 Seeger D.42 2

21 0212035 Seeger D.32 2

22 0309091 O-ring 45X2.65 2

23 Z23A313202 Round rubber pad 2

24 0202032 Screw M6X16 2

Parts Catalogue 70

Apex-10 / Apex-10H

Page 71

OVERHEAD BEAM

ITEM PART NO. DESCRIPTION QTY

1 Z23A410000AM Left beam assembly 1

2 Z23A420000 Right beam assembly 1

3 SYJ30-17-02M1 Support 1 2

4 2L-1-07 Support 2 1

5 Z23A400001AM Crush safety bar 1

6 0206040 Screw M6X12 6

7 0203004 Nut M6 8

8 0201033 Screw M8X40 1

9 0203008 Nut M8 4

10 Z23A400002 Crush safety bar cover 1

Parts Catalogue 71

Apex-10 / Apex-10H

Page 72

ITEM PART NO. DESCRIPTION QTY

11 0201136 Screw M10X20 4

12 0204030 Flange nut M10 4

13 SP-1430-14 Mercury switch 1

14 0201020 Screw M8X55 1

15 Z23A411000AM Left beam 1

16 Z23A410001 Pulley shaft 2

17 Z23A110001T Cable pulley 4

18 0211014 Seeger D.15 4

19 0205023 Washer D.24 4

20 Z23A410002 Anti-derailment safety pin 2

21 0215041 Greaser M6X1 - GB/T1152 4

22 0210079 Bush SF-1/1920 4

Parts Catalogue 72

Apex-10 / Apex-10H

Page 73

HYDRAULIC CYLINDER

ITEM PART NO. DESCRIPTION QTY

1 Z23AY20000 Hydraulic cylinder 2

9 Z23AY22000 Cylinder liner 2

10 Z23AY21002 Cylinder shaft 2

11 Z23AY18001 Cylinder cover 2

12 0212036 Seeger D. 48 2

13 0305042 Seal support ring 44X9.5X3 2

14 0310033 Seal 48X60X11 2

15 0315043 Seal 48X9.5X2.5 4

16 0309087 O-ring 56X3.55 2

17 0305017 Bleeder 1/8 2

18 0311023 Scraper 48X56X5/6.5 2

19 Z23AY11001 Shaft head 2

20 0309088 O-ring 36.5X2.65 2

Parts Catalogue 73

Apex-10 / Apex-10H

Page 74

HYDRAULIC LINES

ITEM PART NO. DESCRIPTION QTY

1 BZ-Y1-N Power Unit 1

2 Z23AY20000 Hydraulic Cylinder 2

3 0303021 T-Fitting 1/4 (AB-04) 2

4 0303061 Straight Fitting 1/4 (1B-04-T1) 2

5 0313001 Washer 1/4 (BS/A13.7/G1/4”) 2

6 0307021 Parachute valve 1/4 (V389201A10 G1/4) 1

7a WW3800 Hydraulic hose 1/4 L=3800 (Standard version) 1

7b WW4410 Hydraulic hose 1/4 L=4410 (H version) 1

8a ZZ5090 Hydraulic hose 1/4 L=5090 (Standard version) 2

8b ZZ5700 Hydraulic hose 1/4 L=5700 (H version) 2

For Parts & Service Assistance,

Please contact Atlas Automotive Equipment

Parts Catalogue 74

Toll Free: 866-898-2604

Apex-10 / Apex-10H

Page 75

Warranty

This item is warranted for fi ve (5) years on structural

components, two (2) years on hydraulic cylinders, and one (1)

year on electric or air / hydraulic power units from invoice date.

Wear items are covered by a 90 day warranty.

This LIMITED warranty policy does not include a labor warranty.

NOTE: ALL WARRANTY CLAIMS MUST BE PRE-APPROVED BY THE MANUFACTURER TO BE

VALID.

The Manufacturer shall repair or replace at their option for this period those parts returned to

the factory freight prepaid, which prove after inspection to be defective. This warranty will not

apply unless the product is installed, used and maintained in accordance with the Manufacturers

installation, operation and maintenance instructions.

This warranty applies to the ORIGINAL purchaser only, and is non-transferable. The warranty

covers the products to be free of defects in material and workmanship but, does not cover normal

maintenance or adjustments, damage or malfunction caused by: improper handling, installation,

abuse, misuse, negligence, carelessness of operation or normal wear and tear. In addition, this

warranty does not cover equipment when repairs or alterations have been made or attempted to

the Manufacturer’s products.

THIS WARRANTY IS EXCLUSIVE AND IS LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR ANY IMPLIED WARRANTY OF

FITNESS FROM A PARTICULAR PURPOSE, AND ALL SUCH IMPLIED WARRANTIES ARE EXPRESSLY

EXCLUDED.

THE REMEDIES DESCRIBED ARE EXCLUSIVE AND IN NO EVENT SHALL THE MANUFACTURER, NOR

ANY SALES AGENT OR OTHER COMPANY AFFILIATED WITH IT OR THEM, BE LIABLE FOR SPECIAL

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OF OR DELAY IN PERFORMANCE

OF THIS WARRANTY. THIS INCLUDES, BUT IS NOT LIMITED TO, LOSS OF PROFIT, RENTAL OR

SUBSTITUTE EQUIPMENT OR OTHER COMMERCIAL LOSS.

PRICES: Prices and specifi cations are subject to change without notice. All orders will be invoiced

at prices prevailing at time of shipment. Prices do not include any local, state or federal taxes.

RETURNS: Products may not be returned without prior written approval from the Manufacturer.

DUE TO THE COMPETITIVENESS OF THE SELLING PRICE OF THESE LIFTS, THIS WARRANTY POLICY

WILL BE STRICTLY ADMINISTERED AND ADHERED TO.

Warranty 75

Apex-10 / Apex-10H

Loading...

Loading...