Page 1

Instruction book

Atlas Copco Stationary Air Compressors

Instruction book

SF1 - SF2 - SF4 Skid -Tank-mounted

SF6 - SF8 Twin

SF6 - SF8 - SF11 - SF15 Multi

Copyright 2003, Atlas Copco Airpower n.v, Antwerp, Belgium.

Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in

particular to trademarks, model denominations, part numbers and drawings.

This instruction book meets the requirements for instructions specified by the machinery directive

98/37/EC and is valid for CE as well as non-CE labelled machines.

Note: The PED instructions for this machine are included at the end of the book.

No. 2920 1521 00

Registration code: APC SF / 38 / 980

2003-10 www.atlascopco.com

2920 1521 00 1

Page 2

Instruction book

This instruction book describes how to handle the machines to ensure safe operation, optimum

efficiency and long service life.

Read this book before putting the machine into operation to ensure correct handling, operation

and proper maintenance from the beginning. The maintenance schedule comprises measures for

keeping the machine in good condition.

Keep the book available for the operator and make sure that the machine is operated and that

maintenance is carried out according to the instructions. Record all operating data, maintenance

performed, etc. in an operator's logbook available from Atlas Copco. Follow all relevant safety

precautions, including those mentioned on the cover of this book.

Repairs must be carried out by trained personnel from Atlas Copco who can be contacted for any

further information.

In all correspondence mention the type and the serial number, shown on the data plate.

For all data not mentioned in the text, see sections "Preventive maintenance schedule" and "Principal

data".

The company reserves the right to make changes without prior notice.

2920 1521 00 2

Page 3

Instruction book

1 LEADING PARTICULARS................................................................................................................... 5

1.1 General description........................................................................................................................ 5

1.2 Air flow ........................................................................................................................................... 9

1.3 Cooling and condensate drain systems (Fig. 1.9) ......................................................................... 9

1.4 Regulating system on SF Skid - Tank-mounted - Twin ............................................................... 10

1.5 Regulating system on SF Multi .................................................................................................... 11

1.6 Electric cabinet on SF Multi ......................................................................................................... 15

1.7 Air dryer on SF Full-Feature (Fig. 1.15)....................................................................................... 16

2 INSTALLATION ................................................................................................................................. 17

2.1 Dimension drawings (Figs. 2.1 up to 2.5) ....................................................................................17

2.2 Installation proposal (Fig. 2.6) ..................................................................................................... 22

2.3 Electrical connections .................................................................................................................. 24

2.4 Pictographs .................................................................................................................................. 27

3 OPERATING INSTRUCTIONS .......................................................................................................... 28

3.1 Initial start-up ............................................................................................................................... 28

3.2 Starting......................................................................................................................................... 28

3.3 During operation .......................................................................................................................... 29

3.4 Stopping....................................................................................................................................... 29

3.5 Taking out of operation at end of compressor service life........................................................... 29

4 MAINTENANCE ................................................................................................................................. 30

4.1 Compressor drive motors ............................................................................................................ 30

4.2 Preventive maintenance schedule for the compressor................................................................ 30

5 ADJUSTMENTS AND SERVICING PROCEDURES ........................................................................ 32

5.1 Air filter (1-Figs. 1.7/1.8) .............................................................................................................. 32

5.2 Belt exchange/tensioning (Fig. 5.1) ............................................................................................. 32

5.3 Coolers......................................................................................................................................... 32

5.4 Safety valve ................................................................................................................................. 33

6 PROBLEM SOLVING ........................................................................................................................ 34

7 PRINCIPAL DATA ............................................................................................................................. 35

7.1 Electric cable size for SF1-8 ........................................................................................................ 35

7.2 Electric cable size for SF 6-15 Multi ............................................................................................ 35

7.3 Overload relays for SF1-8............................................................................................................ 36

7.4 Overload relays for SF6-15 Multi ................................................................................................. 36

7.5 Main fuses for SF1-8.................................................................................................................... 37

7.6 Main fuses for SF6-15 Multi......................................................................................................... 37

7.7 Reference conditions/limitations .................................................................................................. 37

7.8 SF1-4 8bar 50 Hz 1) ................................................................................................................... 38

7.9 SF2-4 10 bar 50 Hz 1) ................................................................................................................ 38

7.10 SF1-4 100 psi 60 Hz 1)............................................................................................................. 38

7.11 SF2-4 145 psi 60 Hz 1)............................................................................................................. 38

7.12 SF6-15 Multi 8 bar 50 Hz 1)...................................................................................................... 39

7.13 SF6-15 Multi 10 bar 50 Hz 1).................................................................................................... 39

7.14 SF6-15 Multi 100 psi 60 Hz 1) .................................................................................................. 39

7.15 SF6-15 Multi 125 psi 60 Hz 1) .................................................................................................. 40

1.1.1 Compressor variants ............................................................................................................... 5

1.1.2 Compressor elements (Fig. 1.1).............................................................................................. 5

1.5.1 Controlling the compressor ................................................................................................... 11

1.5.2 Protecting the compressor .................................................................................................... 11

1.5.3 Monitoring components subject to service............................................................................ 11

1.5.4 Automatic restart after voltage failure ...................................................................................11

1.5.5 Control panel (Fig. 1.11) ....................................................................................................... 12

1.5.6 Display – keys ....................................................................................................................... 13

1.5.7 Function keys (5-Fig. 1.11) ................................................................................................... 13

3.2.1 Multi....................................................................................................................................... 28

3.2.2 Skid - Tank-mounted - Twin .................................................................................................. 28

3.3.1 Multi....................................................................................................................................... 29

3.3.2 Skid - Tank-mounted - Twin .................................................................................................. 29

3.4.1 Multi....................................................................................................................................... 29

3.4.2 Skid - Tank-mounted - Twin .................................................................................................. 29

2920 1521 00 3

Page 4

Instruction book

7.16 SF6-15 Multi 145 psi 60 Hz 1) .................................................................................................. 40

8 REGULATOR FUNCTIONS FOR SF MULTI .................................................................................... 41

8.1 Menu-driven control programs..................................................................................................... 41

8.2 Quick look at actual compressor status ....................................................................................... 44

8.3 Status data menu......................................................................................................................... 45

8.4 Measured data menu................................................................................................................... 47

8.5 Counters menu ............................................................................................................................ 48

8.6 Test menu .................................................................................................................................... 48

8.7 Modify parameters menu ............................................................................................................. 49

8.8 Modifying parameters .................................................................................................................. 49

8.9 Modifying protection settings ....................................................................................................... 51

8.10 Modifying service plans ............................................................................................................. 52

8.11 Programming Clock function...................................................................................................... 54

8.12 Configuration menu.................................................................................................................... 59

8.13 Service menu ............................................................................................................................. 60

8.14 Saved data menu....................................................................................................................... 63

8.15 Programmable settings.............................................................................................................. 64

9 CONVERSION LIST OF SI UNITS INTO US/BRITISH UNITS ......................................................... 65

8.1.1 Function of control programs ................................................................................................ 42

8.1.2 Main screen........................................................................................................................... 42

8.1.3 Calling up other menus ......................................................................................................... 44

8.3.1 No message exists ................................................................................................................ 45

8.3.2 A shut-down message exists ................................................................................................45

8.3.3 A warning message exists .................................................................................................... 46

8.3.4 A service warning message exists ........................................................................................ 47

8.8.1 Modifying the pressure bands ............................................................................................... 50

8.9.1 Checking protections for compressor modules..................................................................... 51

8.9.2 Modifying protections for Dryer LAT on Full-Feature machines ........................................... 52

8.11.1 Programming start/stop/pressure band commands............................................................ 54

8.11.2 To activate/deactivate the timer .......................................................................................... 56

8.11.3 To modify a command......................................................................................................... 56

8.11.4 To add a command ............................................................................................................. 57

8.11.5 To delete commands........................................................................................................... 58

8.12.1 Programming compressor control modes ........................................................................... 60

8.15.1 Regulation settings.............................................................................................................. 64

8.15.2 Service settings ................................................................................................................... 65

2920 1521 00 4

Page 5

Instruction book

1 LEADING PARTICULARS

1.1 General description

SF1 up to SF15 are stationary, oil-free compressors driven by an electric motor.

1.1.1 Compressor variants

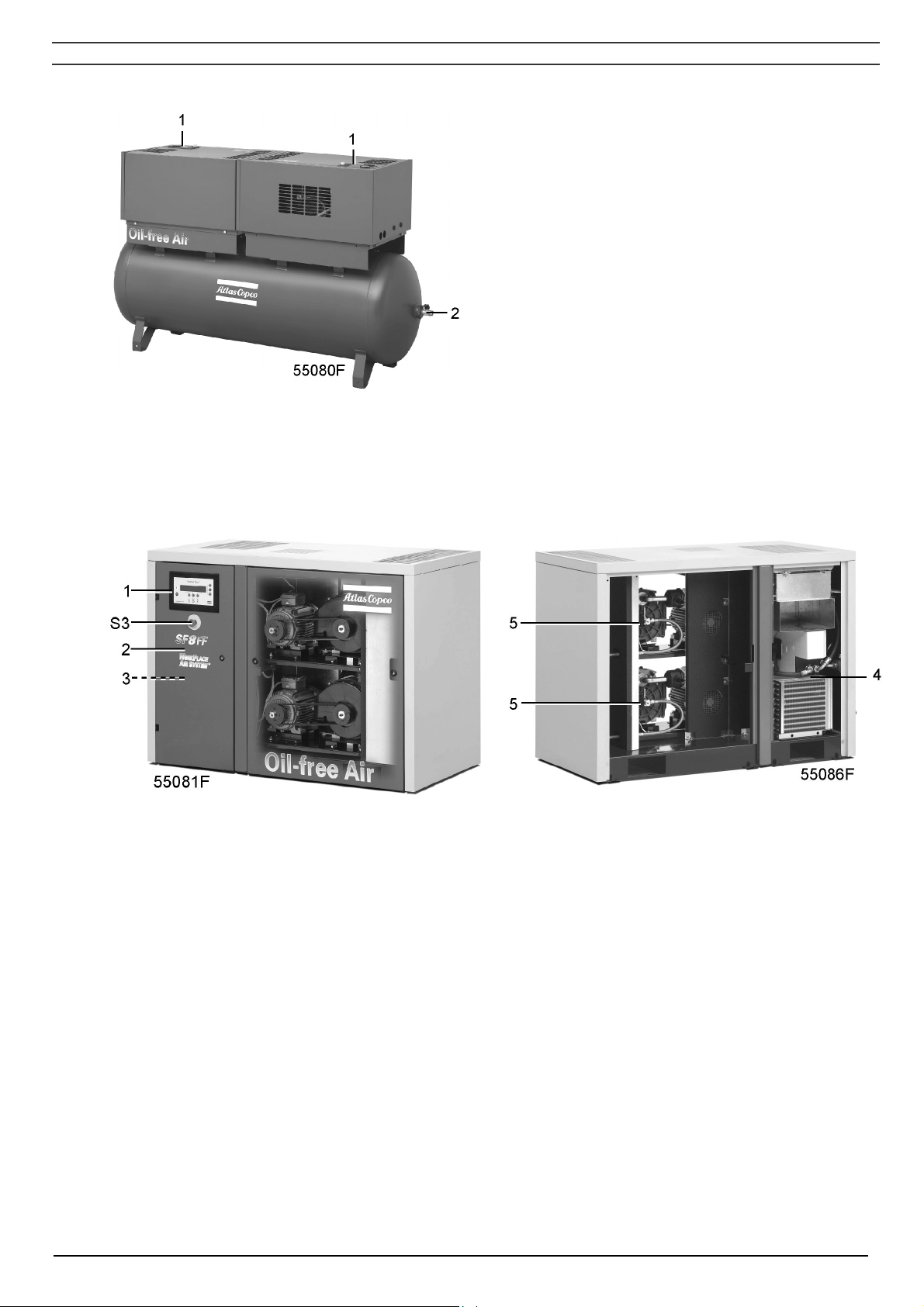

SF Skid (Fig. 1.2)

The components of the compressor are housed in a bodywork with removable front/top panel. The

compressor is mounted on a frame designed to allow easy installation at the required spot.

SF Tank-mounted (Fig. 1.3)

The components of the compressor are housed in a bodywork with removable front/top panel. The

compressor is mounted on an air receiver.

SF Twin (Fig. 1.4)

Two compressor modules are mounted on an air receiver. Each module is provided with its own control

panel.

SF Multi Pack

The compressors have two up to four compressor modules enclosed in a sound-insulated bodywork.

The front door comprises an Elektronikon regulator including the start and stop buttons. An

emergency stop button is also provided. An electric cabinet comprising the motor starter is installed

behind the front door.

SF Multi Full-Feature (Figs. 1.5 and 1.6)

Full-Feature compressors are Pack compressors additionally provided with an air dryer integrated in

the bodywork. The dryer removes moisture from compressed air by cooling the air to near freezing

point and automatically draining the condensate. See section 1.7.

1.1.2 Compressor elements (Fig. 1.1)

Each compressor element consists of a fixed scroll-shaped housing and a scroll-shaped rotor. Air

enters the compressor element through inlet opening (1). Once the air is drawn in, the orbiting scroll

(4) seals the inlet opening and forces the air into a continuously decreasing space. As scroll (4) keeps

orbiting, this process of compression is constantly repeated, resulting in discharging of oil-free

compressed air through outlet opening (3).

1 Air inlet

2 Fixed scroll

3 Compressed air outlet

4 Orbiting scroll

Fig. 1.1 Compressor element

2920 1521 00 5

Page 6

Instruction book

1 Control panel

2 Air outlet valve

Fig. 1.2 SF4 Skid

1 Control panel

2 Air outlet valve

1.3 SF4 Tank-mounted

2920 1521 00 6

Page 7

Instruction book

1 Control panels

2 Air outlet valve

Fig. 1.4 SF Twin

1 Elektronikon regulator

2 Electric cabinet

3 Air outlet valve

4 Dryer (on Full-Feature)

5 Compressor modules

S3 Emergency stop button

Fig. 1.5 SF8FF Multi

2920 1521 00 7

Page 8

Instruction book

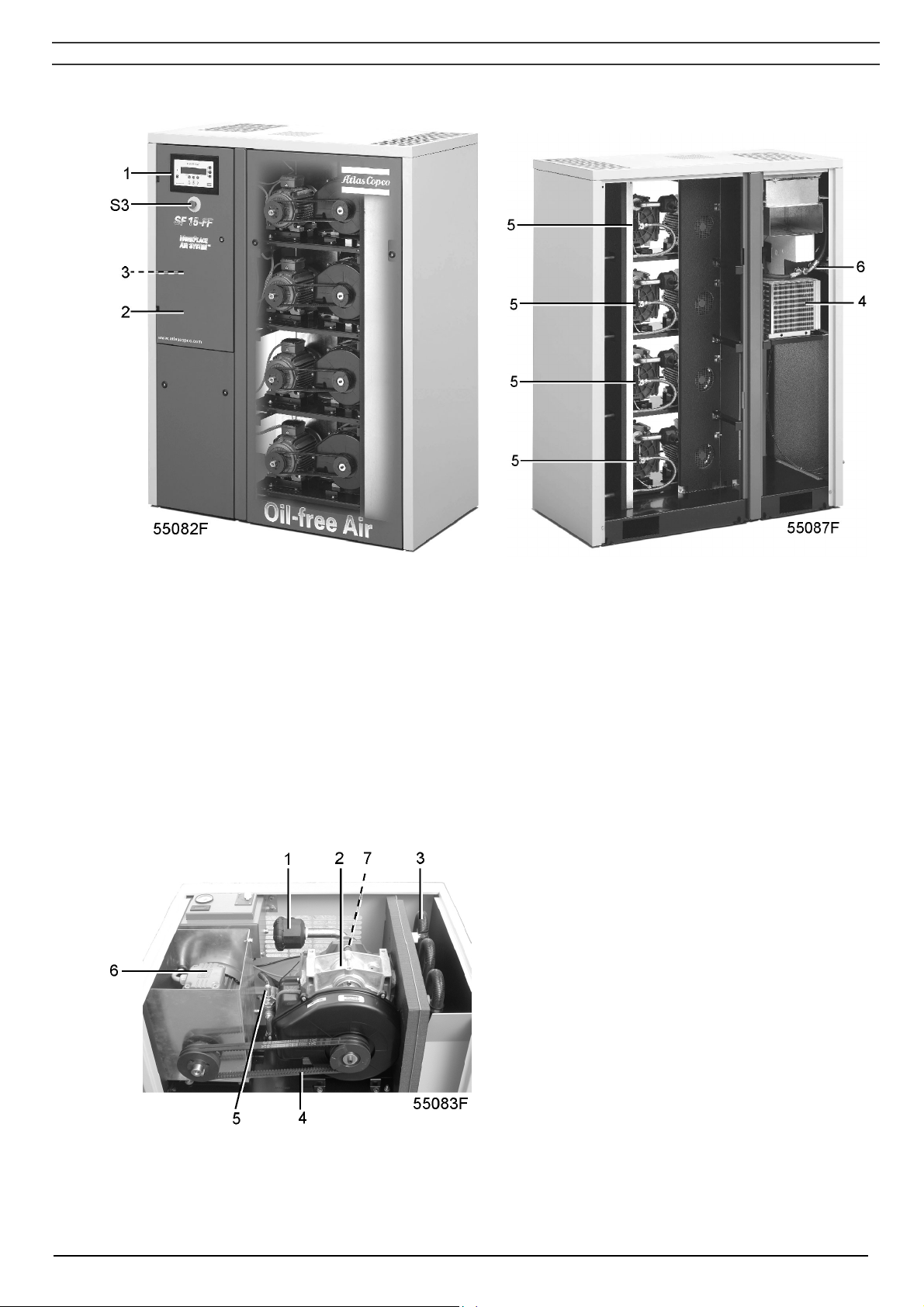

1 Elektronikon regulator

2 Electric cabinet

3 Air outlet valve

4 Dryer (on Full-Feature)

5 Compressor modules

6 Safety valve (ASME)

S3 Emergency stop button

Fig. 1.6 SF15FF Multi

1 Air filter

2 Compressor element

3 Air cooler

4 Belts

5 Safety valve

6 Drive motor

7 Safety valve

Fig. 1.7 Details of a compressor module on SF Tank-mounted

2920 1521 00 8

Page 9

Instruction book

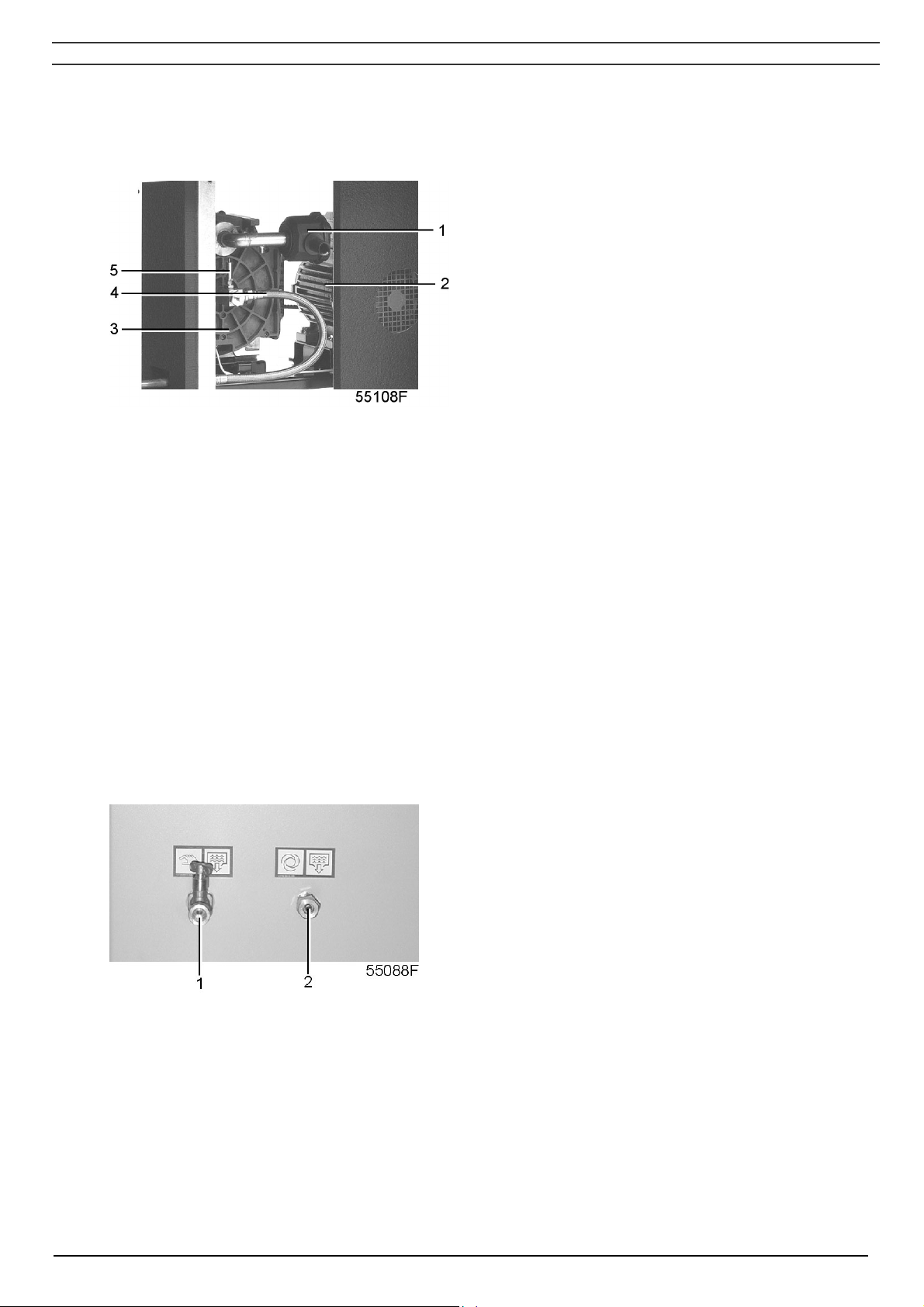

1 Air filter

2 Drive motor

3 Compressor element

4 Compressed air outlet

5 Safety valve (CE)

Fig. 1.8 Details of a compressor module on SF Multi

1.2 Air flow

Air is drawn through the air filter into the compressor modules and is compressed. Compressed air is

discharged through the check valve and air cooler towards the air net.

1.3 Cooling and condensate drain systems (Fig. 1.9)

Each compressor element is cooled by a fan. The fan is mounted on the drive shaft of the compressor

element. The cooling air is blown over the compressor element and air cooler via a duct.

For SF Multi two fans, driven by electric motors, expel warm air from the bodywork.

SF Multi have a condensate trap, with an automatic condensate outlet (2) and a manual drain valve

(1).

Fig. 1.9 Condensate drains on SF Multi

2920 1521 00 9

1 Manual condensate drain valve

2 Automatic condensate outlet

Page 10

Instruction book

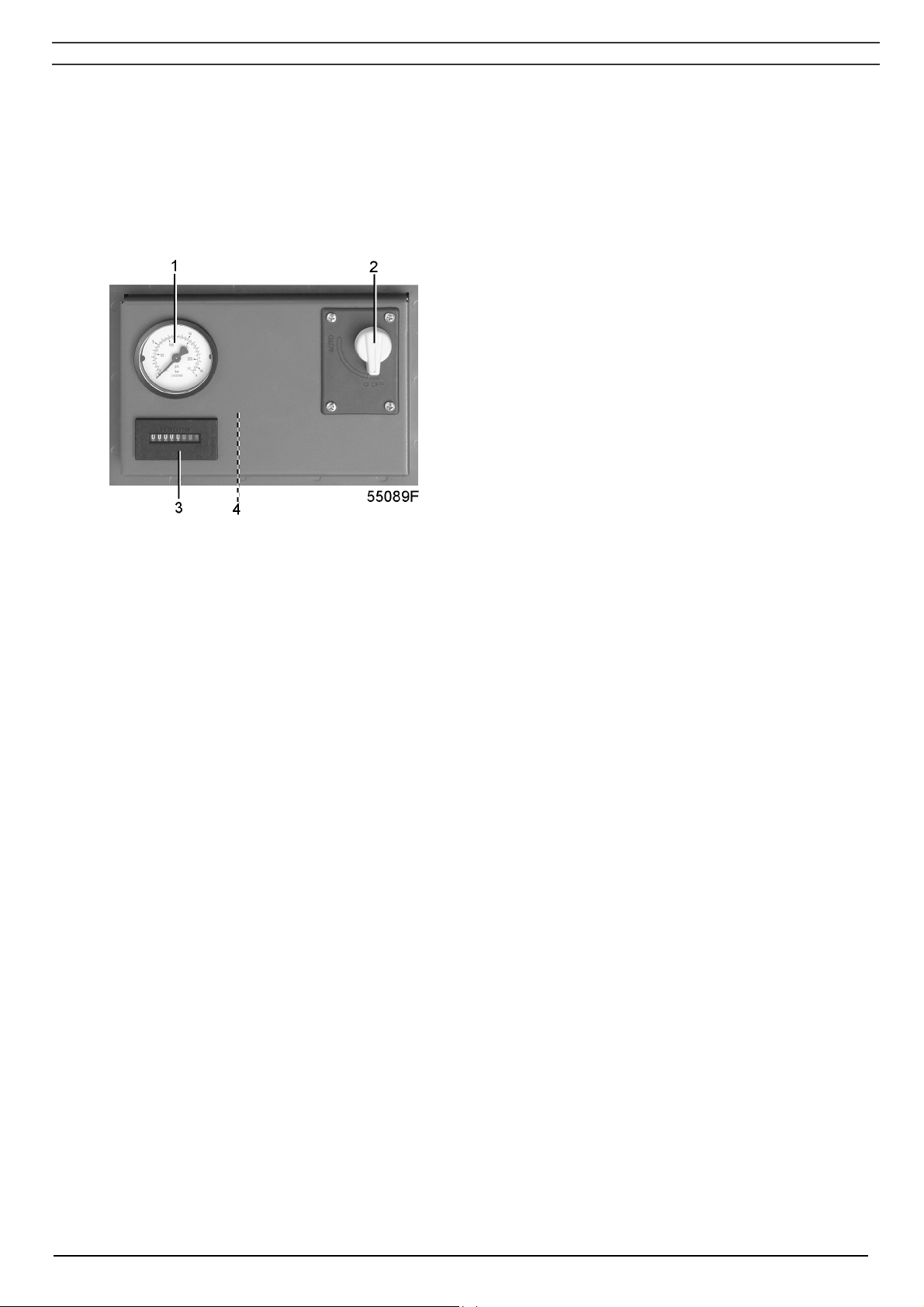

1.4 Regulating system on SF Skid - Tank-mounted - Twin

The air net pressure is kept within limits by a pressure switch mounted in the cabinet below the control

panel (Fig. 1.10). The switch is connected to the air outlet and electrically connected in the circuit of

the drive motor. The switch opens and closes its contacts at pre-set pressures.

1 Pressure gauge

2 On/off switch

3 Hourmeter

4 Air pressure switch/circuit breaker

Fig. 1.10 Control panel SF Skid - Tank-mounted - Twin

When the contacts are closed, the circuit to the drive motor is made: the compressor is operating. The

air output is maximum.

When the pressure reaches the pre-set maximum, the circuit to the drive motor is broken, causing the

compressor to stop. The air output is stopped.

Protecting the compressor

The compressor will be shut down in case temperature switch (TSHH11-Fig. 2.7) trips.

Warning

Before carrying out any inspection or repair, stop the compressor, switch off the voltage, open the

isolating switch and depressurize the compressor.

2920 1521 00 10

Page 11

Instruction book

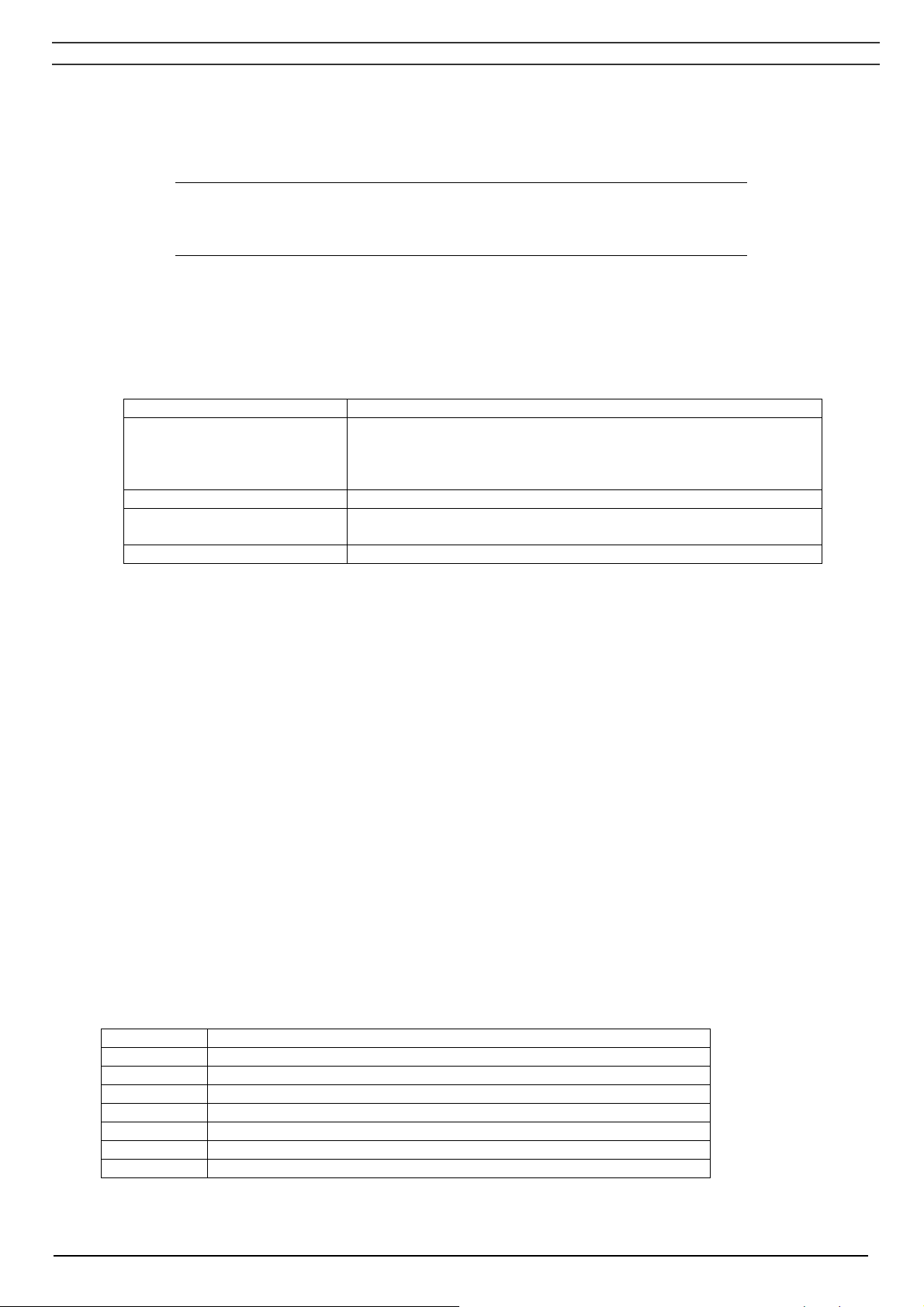

1.5 Regulating system on SF Multi

SF Multi are provided with an Elektronikon® regulator (Fig. 1.11) to control the compressor.

The following is a short description of the main functions of the regulator. Consult section 8 for a

detailed description of all functions.

1.5.1 Controlling the compressor

The Elektronikon regulator keeps the net pressure within programmable limits by starting and stopping

the compressor modules, depending on the air consumption. The regulator distributes the running

time among the compressor modules, taking into account the availability and number of running hours

of each compressor module.

When the compressor has stopped automatically and the net pressure decreases, the regulator will

start a compressor module before the net pressure has dropped to the starting pressure to prevent the

net pressure from falling under the programmed minimum level.

1.5.2 Protecting the compressor

If one or more compressor modules are shut down due to a protection function a warning message will

be shown on the display.

The compressor will be shut down in case temperature switch (TSHH20-Fig. 2.8) trips. See also

section 8.3.2.

Warning

Before carrying out any inspection or repair, stop the compressor, switch off the voltage, open the

isolating switch and depressurize the compressor.

After remedying, switch on the voltage and press the key “Reset” (F3).

1.5.3 Monitoring components subject to service

A number of service operations are grouped in plans (called Service plans I, A, B and D). Each

Service plan has a programmed time interval. If a time interval is exceeded, a message will appear on

the display to warn the operator to carry out the service actions belonging to that plan.

1.5.4 Automatic restart after voltage failure

The regulator has a built-in function to automatically restart the compressor if the voltage is restored

after voltage failure. For compressors leaving the factory, this function is made inactive. If desired,

the function can be activated. Consult Atlas Copco.

2920 1521 00 11

Page 12

Instruction book

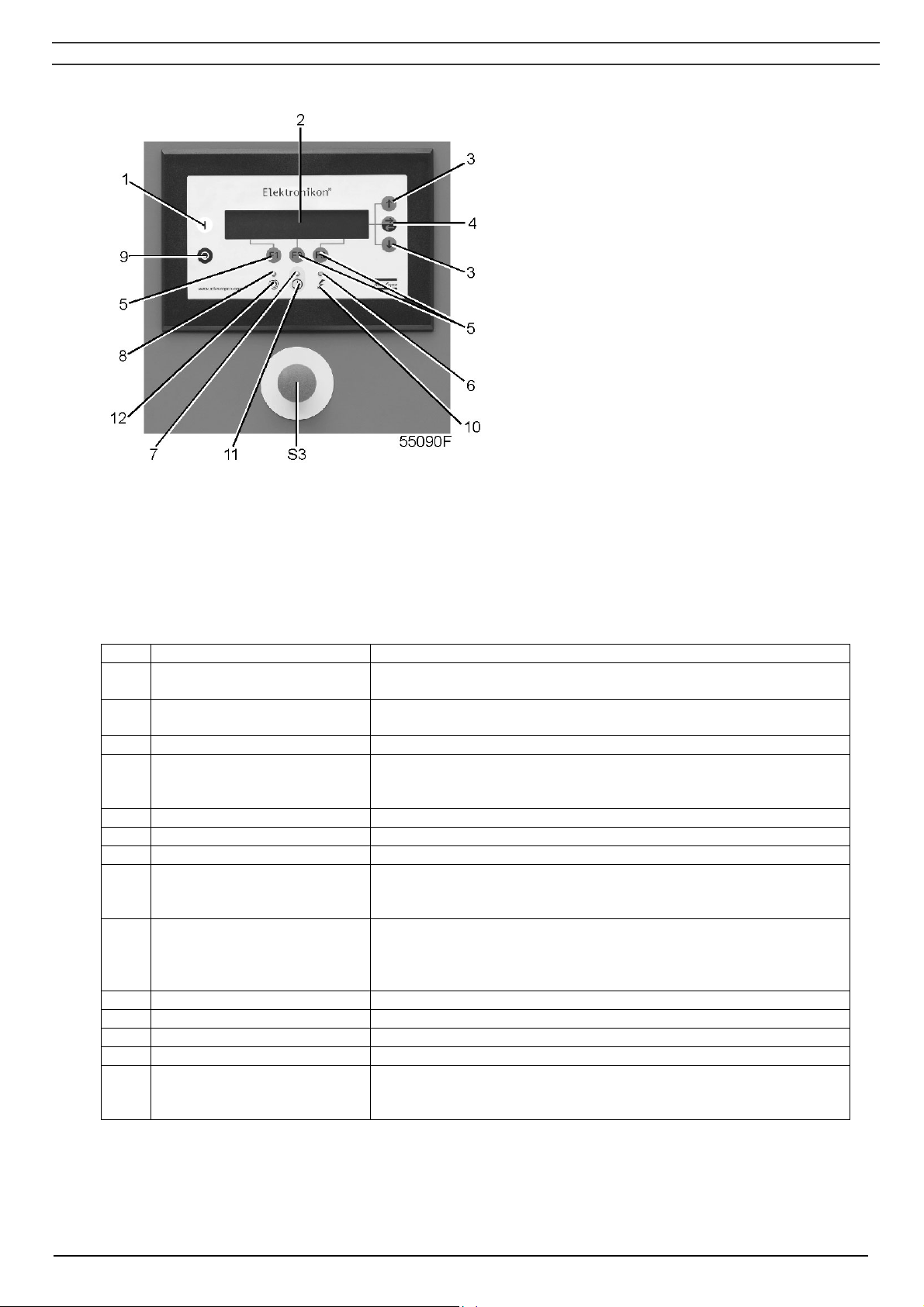

Fig. 1.11 Elektronikon regulator on SF Multi

1.5.5 Control panel (Fig. 1.11)

To control the compressor and to read and modify programmable parameters, the regulator is provided with a

control panel including:

Ref Designation Function

1 Start button

2 Display

Push button to start the compressor. LED (8) lights up indicating

that the regulator is operative (in automatic operation).

Indicates messages concerning the compressor operating

condition, a service need or a fault.

3 Scroll keys Keys to scroll through the display.

Key to select the parameter indicated by a horizontal arrow.

4 Tabulator key

Only the parameters followed by an arrow pointing to the right

are accessible for modifying.

5 Function keys Keys to control and program the compressor.

6 Voltage on LED Indicates that the voltage is switched on.

7 General alarm LED Is alight in case of a warning condition, see section 8.3.

Blinks in case of shut-down condition, if a sensor with shut7 General alarm LED

down function is out of order or after an emergency stop. See

section 8.3.

Indicates that the regulator is automatically controlling the

8 Automatic operation LED

compressor: the compressor is stopped and restarted

depending on the air consumption and the limitations

programmed in the regulator.

9 Stop button Push button to stop the compressor. LED (8) goes out.

10 Pictograph Voltage on.

11 Pictograph Alarm condition.

12 Pictograph Automatic operation.

Push button to stop the compressor immediately in case of

S3 Emergency stop button

emergency. After remedying the trouble, unlock the button by

pulling it out.

2920 1521 00 12

Page 13

Instruction book

1.5.6 Display – keys

Fig. 1.12 Typical example of a display

Operating condition of a compressor module

The symbols shown above key F3 indicate the operating condition of each control module, see also section

8.1.2:

Symbol Indicates

-

▄ that the compressor module is running

- (blinking)

* (blinking) that the compressor module is shut-down

Scroll keys (3-Fig. 1.11)

These keys, labelled with vertical arrows, allow to scroll through the display.

As long as a downwards pointing arrow is shown at the utmost right position of the display, the key (3) with

the same symbol can be used to see the next item.

As long as an upwards pointing arrow is shown at the utmost right position of the display, the key (3) with the

same symbol can be used to see the previous item.

Tabulator key (4-Fig. 1.11)

This key, labelled with two horizontal arrows, allows the operator to go to the next field of the display, e.g.

during modifying of programmable parameters.

Compressor Outlet 7.0 bar

Compressor Running

↓

Menu - - - F1 F2 F3

that the compressor module is available (ready to run), each

symbol stands for a compressor module (the left symbol stands for

the lowest mounted module, the right symbol stands for the

highest module)

that the compressor module is not available (due to minimum stop

time or too many starts)

1.5.7 Function keys (5-Fig. 1.11)

The keys are used:

- To call up or program settings

- To reset an active shut-down or service message, or an emergency stop

- To have access to all data collected by the regulator

The function keys allow to make the required selection from a menu of possibilities. The functions of the keys

vary depending on the displayed menu. The actual function is abbreviated and indicated on the bottom line of

the display just above the relevant key. Only the active and relevant functions at a moment are shown:

Designation Function

Back To return to a previously shown option or menu

Cancel To cancel a programmed setting when programming parameters

Delete To delete compressor start/stop commands

Extra To find the module configuration of the regulator

Help To find the Atlas Copco internet address

Limits To show limits for a programmable setting

Mainscreen To return from a menu to the main screen

2920 1521 00 13

Page 14

Instruction book

Designation Function

Menu Starting from the main screen, to have access to submenus

Menu Starting from a submenu, to return to a previous menu

Modify To modify programmable settings

Program To program modified settings

Reset To reset a timer or message

Return To return to a previously shown option or menu

Selecting a menu

To facilitate controlling the compressor, menu-driven programs are implemented in the electronic module.

Use the function keys (5) to select the menus in order to program and monitor the compressor. See also

section 8.

Fig. 1.13 Menu flow, SF Multi

2920 1521 00 14

Page 15

Instruction book

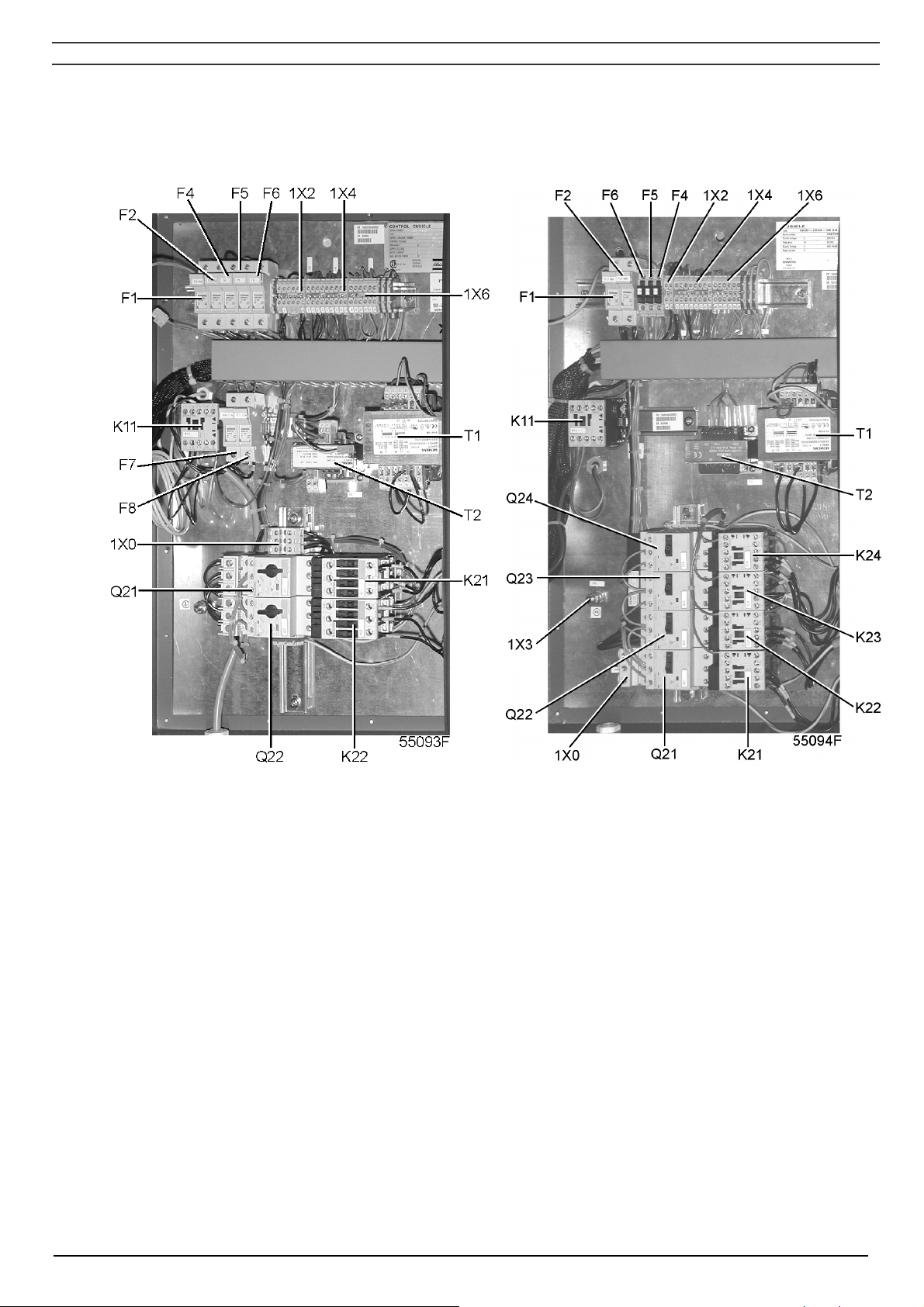

1.6 Electric cabinet on SF Multi

F1/8 Fuses

K11 Auxiliary contactor, dryer

K21/24 Contactors

Q21/24 Circuit breakers

T1/2 Transformers

1X0 Terminal strip, mains supply

1X2 Terminal strip, dryer

1X3/6 Terminal strips

Fig. 1.14 Electric cabinets, SF Multi

2920 1521 00 15

Page 16

Instruction book

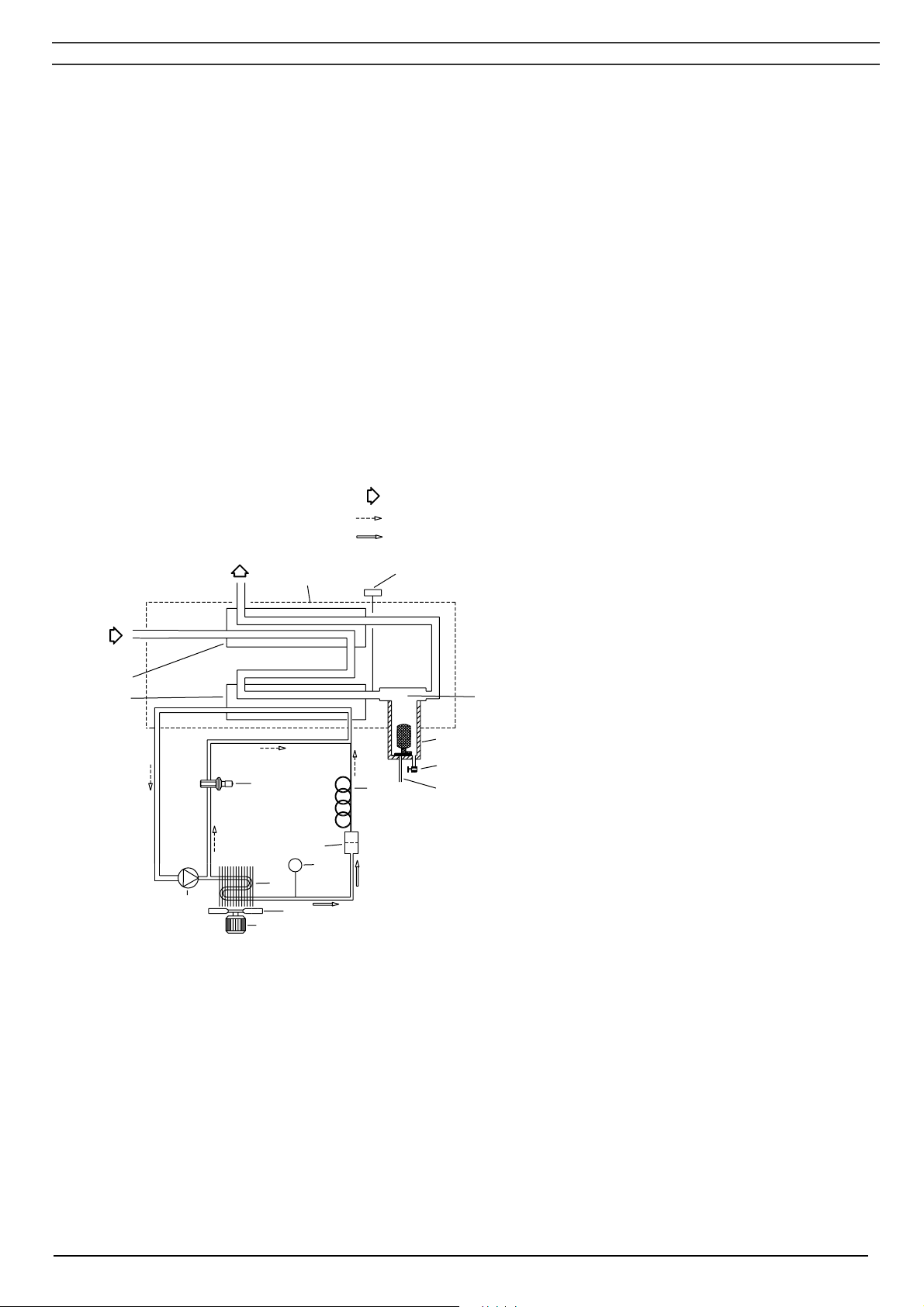

1.7 Air dryer on SF Full-Feature (Fig. 1.15)

Compressed air circuit

Wet compressed air enters heat exchanger (13) and is cooled by the outgoing, cold, dried air. Water in the

incoming air starts to condense. The air then flows through heat exchanger (11) where the refrigerant

evaporates and withdraws heat from the air. More water in the air condenses. The cold air then flows

through condensate separator (3) where the condensate is separated from the air. The condensate is

automatically drained through outlet (5). The cold, dried air then flows through heat exchanger (13), where it

is warmed up by the incoming air.

Refrigerant circuit

Compressor (M1) delivers hot, high-pressure refrigerant gas which flows through condenser (9) where most

of the refrigerant condenses.

The liquid flows through liquid refrigerant dryer/filter (12) to capillary tube (7). The refrigerant leaves the

capillary tube at evaporating pressure.

The refrigerant enters evaporator (11) where it withdraws heat from the compressed air by further evaporation

at constant pressure. The heated refrigerant leaves the evaporator and is sucked in by the compressor.

AIR (1)

REFRIGERANT GAS (2)

REFRIGERANT LIQUID (3)

1

Text on Fig. 1.15

3

13

11

AO

AI

2

(1) Air

4

(2) Refrigerant gas

(3) Refrigerant liquid

6

M1

10

12

S3

9

8

M2

50972D

7

5

AI Wet air inlet 5 Automatic condensate drain

AO Dry air outlet 6 Manual condensate drain valve

M1 Refrigerant compressor 7 Capillary tube

M2 Condenser fan motor 8 Condenser cooling fan

S3 Fan control switch 9 Refrigerant condenser

1 Pressure dewpoint sensor 10 Hot gas by-pass valve

2 Insulating block 11 Air/refrigerant heat exchanger/evaporator

3 Condensate separator 12 Liquid refrigerant dryer/filter

4 Condensate trap 13 Air/air heat exchanger

Fig. 1.15 Dryer on SF Full-Feature

2920 1521 00 16

Page 17

Instruction book

2 INSTALLATION

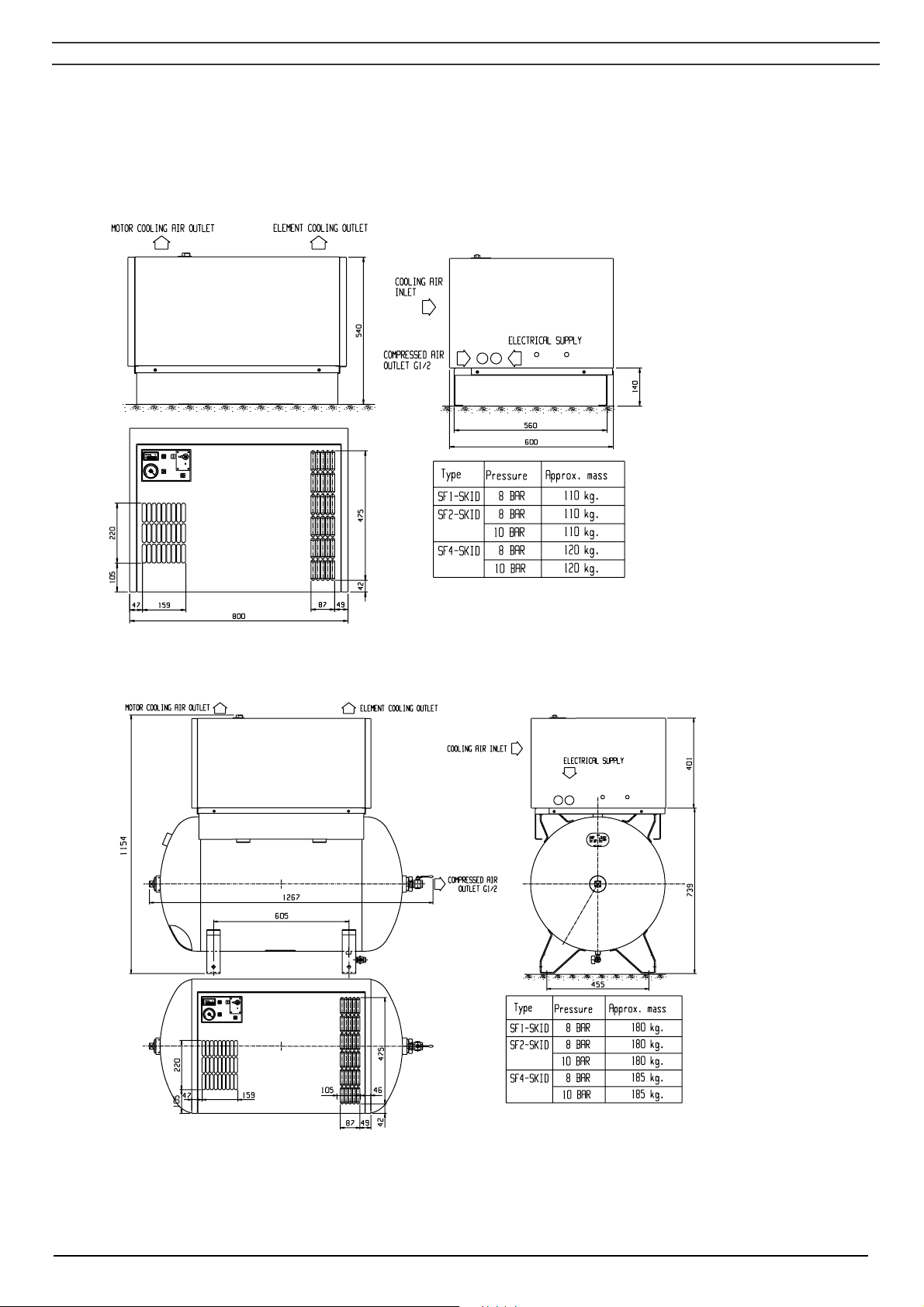

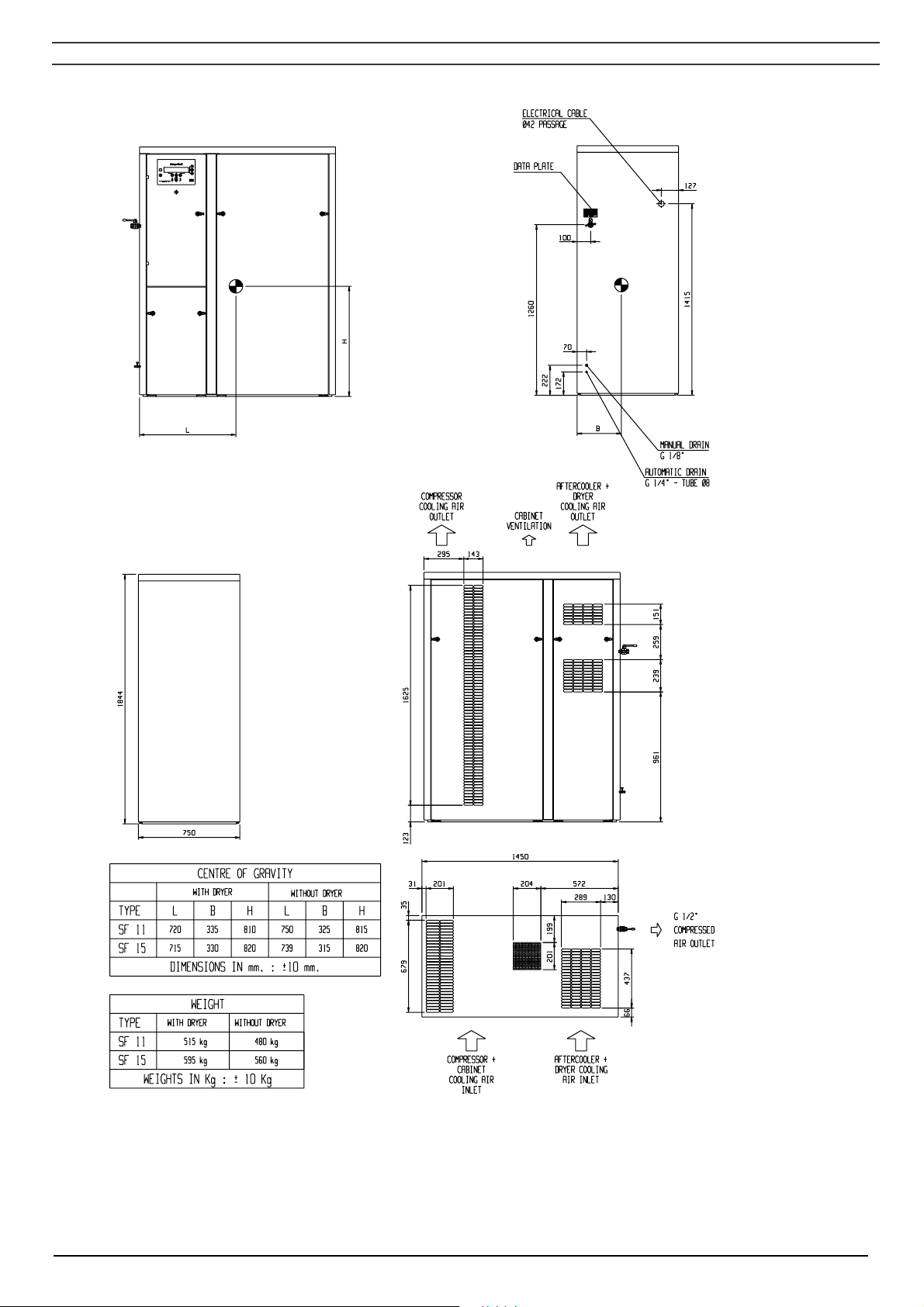

2.1 Dimension drawings (Figs. 2.1 up to 2.5)

(1)

(2)

Fig. 2.1 Dimension drawing, SF 1-4 Skid

(1)

(3)

(5)

(4)

(6)

(2)

(7)

9820 4052 00/1

55100D

(8)

Fig. 2.2 Dimension drawing, SF 1-4 Tank-mounted

(3)

(5)

(4)

(6)

(7)

9820 4053 00/1

55101D

(8)

2920 1521 00 17

Page 18

Instruction book

(1)

(2)

(2)

(1)

(3)

(4)

(5)

(6)

(7) (8)

9820 4054 00/1

55102D

Fig. 2.3 Dimension drawing, SF 6-8 Twin

Text on Figs.2.1/2.3

1 Motor cooling air outlet 5 Electrical supply

2 Element cooling outlet 6 Type

3 Cooling air inlet 7 Pressure

4 Compressed air outlet 8 Mass, approx.

2920 1521 00 18

Page 19

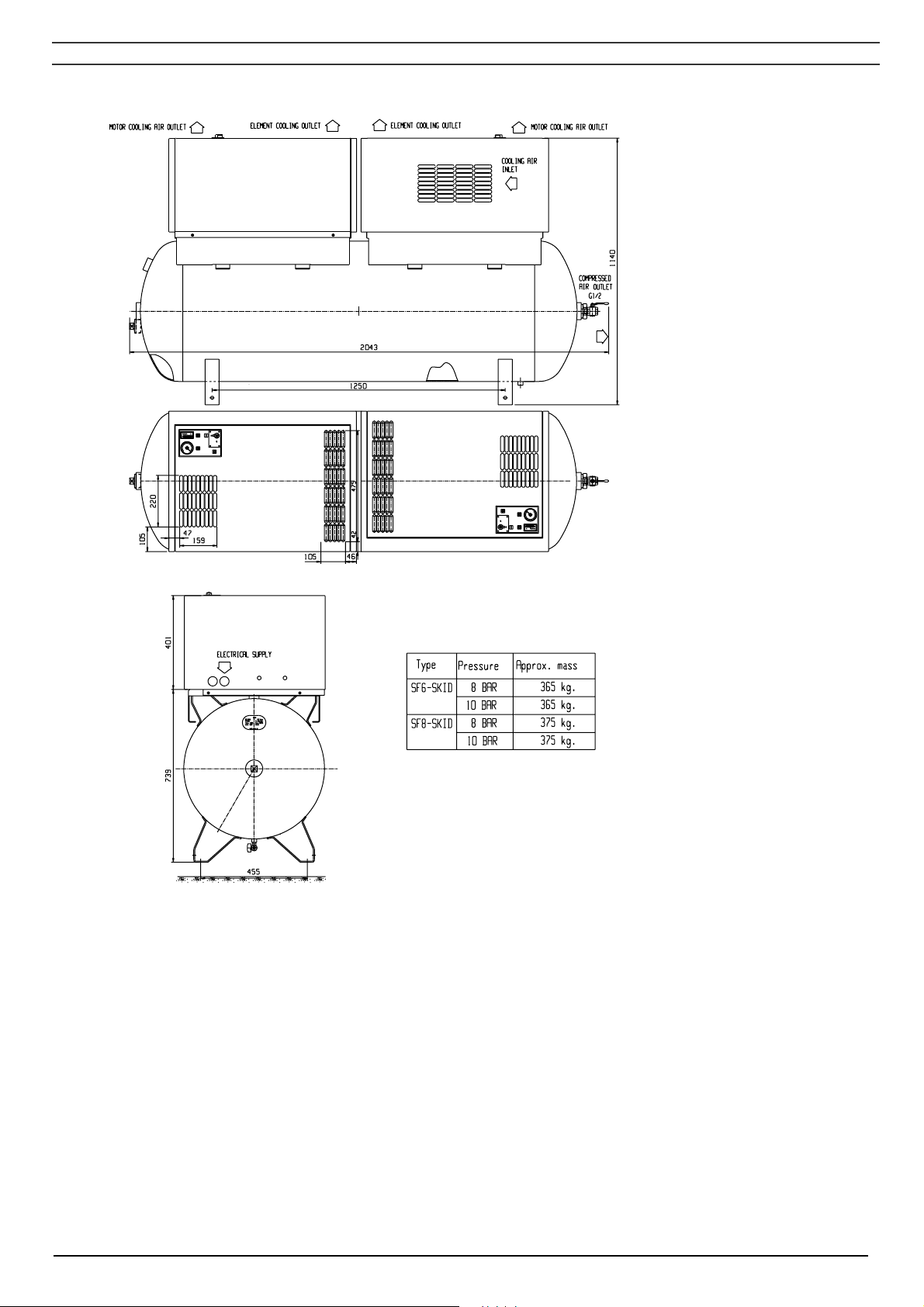

Instruction book

(1)

(2)

(3)

(10)

(4)

(5)

(7)

(8)

(9)

(6)

(15)

(11)

(8)

(12)

(9)

Fig. 2.4 Dimension drawing, SF 6-8 Multi

2920 1521 00 19

(13)

(14)

9820 4027 00

55098D

Page 20

Instruction book

(1)

(16)

(2)

(4)

(5)

(6)

(3)

(7)

(12)

(10)

(11)

(8)

(8)

(9)

(9)

Fig. 2.5 Dimension drawing, SF 11-15 Multi

2920 1521 00 20

(13)

(14)

9820 4026 00

55099D

(15)

Page 21

Instruction book

Text on Figs. 2.4/2.5

(1) Electric cable

(2) Manual drain

(3) Automatic drain

(4) Compressor cooling air outlet

(5) Bodywork ventilation

(6) Aftercooler and dryer cooling air outlet

(7) Centre of gravity

(8) With dryer

(9) Without dryer

(10) Dimensions +/- 10 mm

(11) Weight

(12) Weight +/- 10 kg

(13) Compressor and bodywork cooling air inlet

(14) Aftercooler and dryer cooling air inlet

(15) Compressed air outlet

(16) Data plate

2920 1521 00 21

Page 22

Instruction book

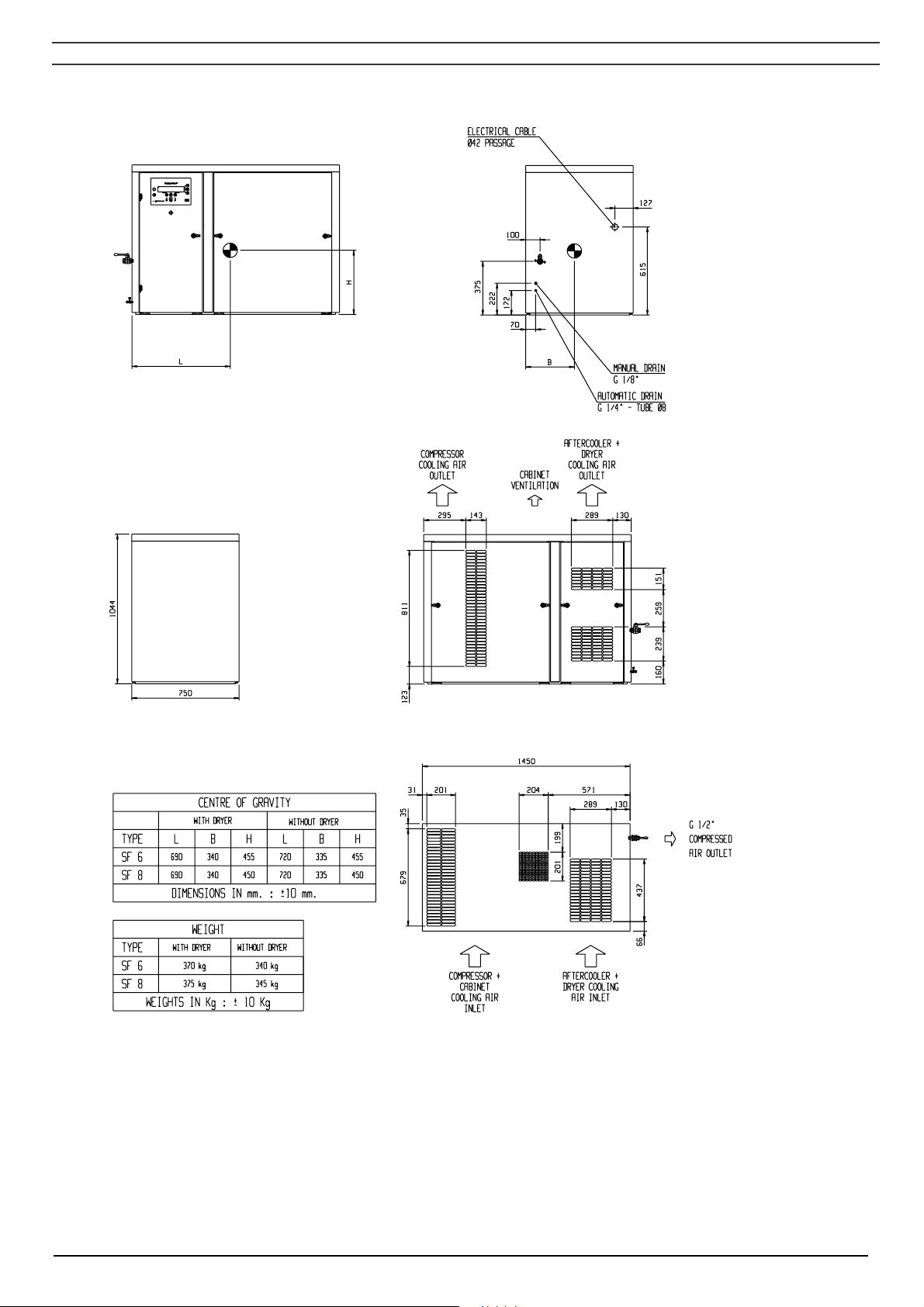

2.2 Installation proposal (Fig. 2.6)

(1)

(2)

Fig. 2.6 Installation proposal, SF Multi

Text on Figs. 2.6

(1) Minimum free area

(2) Compressor

(3) Ventilation proposals

(3)

9820 3960 00

55097D

2920 1521 00 22

Page 23

Instruction book

1 Install the compressor on a level floor, in a cool but frost-free room which is well-ventilated.

2 Position of compressed air outlet valve.

3 The maximum total pipe length can be calculated as follows:

L = (dP x d

L = pipe length in m

dP = maximum allowable pressure drop (recommended 0.1 bar)

d = inner diameter of pipe in mm

P = compressor outlet pressure in bar absolute

Qc = free air delivery of compressor in l/s

4/13 Ventilation: the inlet grids and fan for compressor room ventilation should be installed in

5 Position of control cubicle with monitoring panel.

6 Position of main cable entry. See section 7.1 for the recommended electric cables. See

7 Optional filters can be installed in the pressure line downstream of the air outlet valve, e.g.:

8 Safety valve.

9 Position of the drain flexibles. The flexibles towards the drain collector must not dip into the

10 Cooling air outlet, compressor elements.

11 Bodywork ventilation outlet.

12 Cooling air outlet, air cooler and dryer.

14 Data plate

The air should be clean.

5

x P) / (450 x Qc

1.85

)

such a way that any recirculation of cooling air to the compressor or dryer is avoided. The

air velocity to the grids must be limited to 5 m/s. The maximum allowable pressure drop

over the cooling air ducts is 50 Pa. If this pressure drop is exceeded, a fan is needed at the

outlet of the cooling air ducts. The maximum air temperature at the compressor intake

opening is 40 °C.

For alternatives 1 and 3, the required ventilation capacity to limit the compressor room

temperature can be calculated as follows:

Qv = 0.92 N/dT

Qv = required ventilation capacity in m³/s

N = shaft input of compressor in kW

dT= temperature increase in compressor room in °C

For alternatives 2 and 4, the fan capacity should match the compressor fan capacity at a

pressure head equal to the pressure drop caused by the outlet cooling air ducts.

section 2.3 for connecting the power supply.

A DD filter for general-purpose filtration. The filter traps solid particles down to 1 micron. A

PD filter for filtration down to 0.01 micron. A PD filter must be installed downstream of a DD

filter. If odours are undesirable, a filter of the QD type should be installed downstream of the

PD filter. It is recommended to install by-pass pipes to isolate the filters during servicing.

water of the drain collector.

2920 1521 00 23

Page 24

Instruction book

2.3 Electrical connections

General

The electrical installation must correspond to the local codes. The mains supply and earthing lines

must be of suitable size. See section 7.1.

The installation must be earthed and protected by fuses in each phase. An isolating switch must be

installed near the compressor. Make sure that this switch is open to isolate the compressor from

the mains before carrying out any connection.

Connections

Skid - Tank-mounted - Twin

Connect the cable to terminals 1 and 3 (single-phase) or to terminals 1, 3 and 5 (3-phase) of pressure

switch (4-Fig. 1.10). Connect the earthing conductor to the earthing terminal. SF Twin have a

pressure switch for each compressor module; provide for each pressure switch separate supply

cables.

(1)

(1)

9820 3744 61

55103D

Single-phase 3-phase

Fig. 2.7 Service diagram, SF Skid - Tank-mounted – Twin

Text on Fig. 2.7

(1) Customer’s installation

2920 1521 00 24

9820 3744 60

55104D

Page 25

Instruction book

SF Multi

Connect the supply cable to terminals L1, L2 and L3 of terminal strip (1X0-Fig. 1.14), connect the

neutral conductor to terminal (N) and the earthing conductor to the earthing bolt (1X3).

(27)

(19)

(25)

(23)

(22)

(21)

(20)

(18)

(28)

(24)

(26)

-

-

O- O-O- O- O-

(9)

(5)

(3)

(8)

(16)

(15)

(14)

(13)

(12)

(11)

(10)

9820 3748 01/2

55105D

(17)

(3)

(7)

(6)

(3)

(5)

(4)

(2)

(1)

(3)

2920 1521 00 25

Page 26

Instruction book

A1 Dryer (optional)

F1/11 Fuses

K11 Auxiliary contactor, dryer

K21/24 Contactors

M1/4 Motors

M5 Fan motor, air cooler

M6 Fan motor, bodywork

PT20 Pressure sensor, air outlet

Q21/24 Circuit breakers

S3 Emergency stop button

TSHH20 Temperature switch, air outlet protection

TT11 Temperature sensor, compressor element 1 (lowest element)

TT12 Temperature sensor, compressor element 2

TT13 Temperature sensor, compressor element 3

TT14 Temperature sensor, compressor element 4 (highest element)

TT90 Temperature sensor, dewpoint temperature

T1/2 Transformers

1X0 Terminal strip, mains supply

1X2 Terminal strip, dryer

1X3/6 Terminal strips

Fig. 2.8 Service diagram for SF Multi

Text on Fig. 2.8

(1) Customer’s installation

(2) Door

(3) Higher voltage: Y

(4) Dryer

(5) Optional

(6) Supply of dryer

(7) All other voltages

(8) Marking of connectors 2X5 to 2X12

(9) Pressure transducer: pin configuration

(10) Temperature sensor, element 1

(11) Temperature sensor, element 2

(12) Temperature sensor, element 3

(13) Temperature sensor, element 4

(14) Temperature sensor, LAT dryer

(15) Pressure transducer, delivery air

(16) Temperature switch, delivery air

(17) FF only

(18) Emergency stop

(19) Remote start/ pr. Stop

(20) Overload motor M1

(21) Overload motor M2

(22) Overload motor M3

(23) Overload motor M4

(24) Fault EWD

(25) High temperature outlet

(26) Remote pressure set point

(27) Remote emergency stop

(28) Auxiliary contacts

Lower voltage: D

Selection: Open = set 1 Closed = set 2

2920 1521 00 26

Page 27

Instruction book

2.4 Pictographs

Fig. 2.9 shows examples of pictographs which may be used on the machine.

1 Automatic condensate drain

2 Manual condensate drain

3 Switch off voltage and depressurize compressor before

maintenance or repair

4 Before connecting compressor electrically, consult Instruction

book for motor rotation direction

5 Torques for steel (Fe) or brass (CuZn) bolts

6 Warning, voltage

7 Consult Instruction book before greasing

8 Warning, hot hose

Fig. 2.9 Pictographs

2920 1521 00 27

Page 28

Instruction book

3 OPERATING INSTRUCTIONS

Safety precautions

The operator must apply all relevant safety precautions, including those mentioned in this book.

Outdoor/altitude operation

If the compressor is installed outdoors or if the air inlet temperature can be below 0 °C, precautions

must be taken. In this case, and also if operating at high altitude, consult Atlas Copco.

Before initial start-up

For SF Multi read section 8 to familiarize yourself with all regulator functions.

3.1 Initial start-up

1. Remove the red painted transport brackets:

2. For SF Multi check the settings of the overload relays (Q21, -22, -23, -24 - Fig. 1.14).

3. Connect the compressor electrically. See section 2.3.

4. Close the condensate drain valve: valve (1-Fig. 1.9 on SF Multi) or the valve underneath the air

5. Switch on the voltage. Start and stop the compressor. On 3-phase compressors, check for

- for SF Multi remove brackets (2-Fig. 5.1)

- for the other variants remove the brackets (one on each side of the frame)

receiver, if provided.

correct direction of rotation (arrows are provided on the motors). If the rotation direction is wrong,

switch off the voltage and reverse two incoming electric lines.

3.2 Starting

3.2.1 Multi

1. Open air outlet valve (3-Figs. 1.5/1.6).

2. Switch on the voltage.

3. Close condensate drain valve (1-Fig. 1.9).

4. Press start button (1-Fig. 1.11). The compressor starts running and automatic operation LED (8-

Fig. 1.11) lights up.

5. The regulator will automatically stop and start compressor modules, depending on the air

pressure.

6. On SF Full-Feature, the nominal pressure dewpoint will be reached after a few minutes.

3.2.2 Skid - Tank-mounted - Twin

1. Open air outlet valve (2-Figs. 1.2/1.4).

2. Switch on the voltage.

3. Check that the condensate drain valve underneath the air receiver (if installed) is closed.

4. Move switch (2-Fig. 1.10) to AUTO. The compressor starts running.

5. The drive motor(s) will automatically stop and start, depending on the air pressure.

Note: The maximum number of compressor starts is 30 per hour.

2920 1521 00 28

Page 29

Instruction book

3.3 During operation

3.3.1 Multi

1. If the automatic operation LED (8-Fig. 1.11) is alight, the regulator is automatically controlling the

2. Check the readings on display (2-Fig. 1.11). In case of a warning or shut-down condition, see

3. Check that condensate is discharged automatically from outlet (2-Figs. 1.9) during running.

Note: The dewpoint will deviate from nominal when the nominal conditions are exceeded. If the

3.3.2 Skid - Tank-mounted - Twin

1. Check the starting and stopping pressures (1-Fig. 1.10).

2. Regularly open the drain valve underneath the air receiver for a few seconds, close the valve after

3.4 Stopping

compressor modules (starting/stopping).

section 8.3.

dewpoint remains too high or unstable, consult section 6.

draining.

3.4.1 Multi

1. Press stop button (9-Fig. 1.11).

2. Close air outlet valve (3-Figs. 1.5/1.6).

3. Switch off the voltage.

4. Open condensate drain valve (1-Fig. 1.9).

3.4.2 Skid - Tank-mounted - Twin

1. Move switch (2-Fig. 1.10) to OFF.

2. Close air outlet valve (2-Figs. 1.2/1.4).

3. Switch off the voltage.

4. Open the condensate drain valve underneath the air receiver (if provided) for a few seconds, close

the valve after draining.

3.5 Taking out of operation at end of compressor service life

1. Stop the compressor and close the air outlet valve.

2. Switch off the voltage and disconnect the compressor from the mains.

3. Open the condensate drain valve. Depressurize the compressor

4. Shut off and depressurize the part of the air net which is connected to the outlet valve. Disconnect

the compressor from the air net.

5. Disconnect the condensate piping from the local condensate drain system.

2920 1521 00 29

Page 30

Instruction book

4 MAINTENANCE

Before carrying out any maintenance or repair:

1. Stop the compressor, switch off the voltage and open the isolating switch.

2. Close the air outlet valve (2-Figs. 1.2/1.4 or 3-Figs. 1.5/1.6) and open the manual drain valve: valve (1-

4.1 Compressor drive motors

The motor bearings are greased for life.

4.2 Preventive maintenance schedule for the compressor

The schedule comprises a summary of the maintenance instructions. Read the respective section

before taking maintenance measures. The "longer interval" checks must also include the "shorter

interval" checks.

Carry out the service operations at the period or running hours mentioned below, whichever interval

comes first.

When servicing, replace all disengaged packings, e.g. gaskets, O-rings, washers.

Important

Use only authorized parts. Any damage or malfunction by the use of unauthorized parts is not

covered by Warranty or Product Liability.

Service plans on SF Multi

A number of service operations are grouped in plans, called Service plans I, A, B or D; see the

schedule below.

Each plan has a programmed time interval at which all service actions belonging to that plan are to be

carried out.

When reaching the interval, a message will appear on the screen indicating which Service plans are to

be carried out. After servicing, the intervals are to be reset. For detailed information, consult section

8.3.

Important

Always consult Atlas Copco in case any timer setting should be changed.

Fig. 1.9) on Multi or the valve underneath the air receiver, if provided.

2920 1521 00 30

Page 31

Instruction book

Period Running

Daily

"

Monthly

3-monthly

6-monthly

"

"

"

Yearly

"

"

"

"

"

2-yearly

"

"

Notes:

1. Check more frequently if operating in a dusty atmosphere. Check for cleanness and damage.

2. Consult Atlas Copco.

hours

Service

Plan

See

section

See

notes

below

table

-- -- 3.4 -- Drain condensate

-- -- -- -- On SF Full-Feature, check dewpoint

250 -- 5.1 1 Inspect air filter

500 -- -- -- Check pressure drop over Atlas Copco filters

-- -- 5.4 -- Operate safety valve

-- -- -- -- Clean compressor

-- -- -- -- On SF Full-Feature, brush or blow off the finned

-- -- -- -- On SF Full-Feature, clean condensate trap

-- -- 5.4 -- Test safety valve

-- -- -- -- Have electrical components/shut-down switch

2500

5000

5000

5000

5000

10000

10000

I

A

A

A

B

B

B

5.2 -- Check tension/condition of V-belt(s)

5.1 -- Replace air filter

-- 2 Have ball valve mechanism of condensate trap

5.2 -- Replace V-belt(s)

-- 2 Have orbiting scroll bearing greased

-- 2 Clean compressor element fan and duct. Clean

-- 2 Have pin crank bearings greased

Replace a dirty or damaged filter by a new one.

Operation

(optional)

surface of the condenser

internally

tested

inspected

compressor element fins, have seals replaced

2920 1521 00 31

Page 32

Instruction book

5 ADJUSTMENTS AND SERVICING PROCEDURES

5.1 Air filter (1-Figs. 1.7/1.8)

1. Stop the compressor. Remove the filter cover and filter.

2. Clean the cover, if necessary. Discard damaged filters.

3. Fit a new filter and reinstall the cover.

5.2 Belt exchange/tensioning (Fig. 5.1)

In case of two belts, the belts must be replaced as a set, even if only one of them seems worn.

Use Atlas Copco belts only. The part number of the belt set is mentioned in the Parts list.

1. Loosen motor hold-down bolts (3).

2. Loosen the belt tension by screwing bolts (4) equally and take out the belts.

3. Install new belts in the grooves of the pulleys.

4. Tension the belts by screwing bolts (4) equally. The tension is correct if the deflection is between

5. Tighten bolts (3).

6. Check the belt tension after the first 500 running hours.

5 mm and 7 mm when exerting a force of 25 N on the belt midway between the pulleys. Make

sure that the pulleys remain aligned. The maximum out-of-line is:

- maximum parallel out-of-line: 0.5 mm

- maximum angular out-of-line: 0.5 degrees

1 Belts

2 Transport brackets (2x - to be removed)

3 Motor hold-down bolts (4x)

4 Tensioning bolt

Fig. 5.1 Belt tensioning / transport fixation

5.3 Coolers

Keep the coolers clean to maintain cooling efficiency.

Remove any dirt from the coolers with a fibre brush. Never use a wire brush or metal objects. Then

clean by air jet in reverse direction of normal flow. If it should be necessary to wash the coolers with a

cleansing agent, consult Atlas Copco.

2920 1521 00 32

Page 33

Instruction book

5.4 Safety valve

Operating

Operate the safety valve by unscrewing the knurled cap one or two turns. Retighten the cap.

Testing

The valve can be tested on a separate compressed air line. If the valve does not open at the pressure

marked on the valve, consult Atlas Copco.

Warning

No adjustments are allowed. Never run the compressor without safety valve.

2920 1521 00 33

Page 34

Instruction book

6 PROBLEM SOLVING

Before carrying out any maintenance or repair:

1. Stop the compressor, switch off the voltage and open the isolating switch.

2. Close the air outlet valve (2-Figs. 1.2/1.4 or 3-Figs. 1.5/1.6) and open the manual drain valve: valve

1 Compressor does not start

a Loose connection

a Have electrical connections checked

b Receiver pressure too high

b Compressor will start when the net pressure drops to the minimum pressure

2 Safety valve blows

a Safety valve opens too soon

a Replace valve

3 Compressor capacity or pressure below normal

a Air consumption exceeds capacity of compressor

a Check equipment connected

b Choked air filter

b Remove and check filter. Replace if necessary

c Safety valve leaking

c Replace valve

d Drive belt(s) slipping

d Check condition of belt(s). Correct or replace as required

4 Compressor module overheating / compressor shut down by its air temperature switch

a Insufficient compressor cooling

a Improve ventilation of compressor room.

b Cooling fan out of order

b Check and correct

5 Pressure dewpoint too high

a Shortage of refrigerant

a Have circuit repaired or recharged

b Refrigerant compressor does not run

b See 7

c Condenser pressure is too high

c See 6

6 Condenser pressure too high or too low

a Fan control switch out of order

a Have switch replaced

b Condenser fan motor out of order

b Have fan motor inspected

c Ambient temperature too high

c Improve ventilation. If necessary, draw the cooling air from a cooler room

d Condenser externally clogged

d Clean condenser

7 Motor of refrigerant compressor stops or does not start

a Thermal protection of the motor has tripped

a Compressor will restart when the motor windings have cooled down

(1-Fig. 1.9) on Multi or the valve underneath the air receiver, if provided.

On SF Full-Feature also:

2920 1521 00 34

Page 35

Instruction book

7 PRINCIPAL DATA

7.1 Electric cable size for SF1-8

Frequency Voltage SF1

IEC

50 Hz 230 V 2.5 mm² 2.5 mm² 2.5 mm² 2.5 mm² 2x 2.5

50 Hz 400 V 2.5 mm² 2.5 mm² 2x 2.5

60 Hz 380 V 2.5 mm² 2.5 mm² 2x 2.5

50 Hz 500 V 2.5 mm² 2.5 mm² 2x 2.5

CSA/UL

60 Hz 200/230 V AWG 12 AWG 12 AWG 12 AWG 10 2x AWG

60 Hz 440/460 V AWG 12 AWG 12 2x AWG

singlephase

SF2

singlephase

SF2

3-phase

SF4

3-phase

SF6

3-phase

SF8

3-phase

2x 2.5

mm²

mm²

2x 2.5

mm²

mm²

2x 2.5

mm²

mm²

2x 2.5

mm²

mm²

2x AWG

12

10

2x AWG

12

12

7.2 Electric cable size for SF 6-15 Multi

Frequency Voltage SF6

3-phase

IEC

50 Hz 230 V 6 mm² 10 mm² 16 mm² 25 mm²

50 Hz 400 V 4 mm² 6 mm² 10 mm² 10 mm²

60 Hz 380 V 4 mm² 6 mm² 10 mm² 10 mm²

50 Hz 500 V 2.5 mm² 4 mm² 6 mm² 10 mm²

CSA/UL

60 Hz 200/230 V AWG 8 AWG 6 AWG 4 AWG 3

60 Hz 440/460 V AWG 10 AWG 10 AWG 8 AWG 6

60 Hz 575 V AWG 12 AWG 10 AWG 8 AWG 6

SF8

3-phase

SF11

3-phase

SF15

3-phase

2920 1521 00 35

Page 36

Instruction book

7.3 Overload relays for SF1-8

Frequency Voltage SF1

IEC

50 Hz 230 V 12 A 14.5 A 8.3 A 14 A 8.3 and 14 A 2x 14 A

50 Hz 400 V 4.8 A 8.2 A 4.8 and 8.2 A 2x 8.2 A

60 Hz 380 V 5.1 A 8.5 A 5.1 and 8.5 A 2x 8.5 A

50 Hz 500 V 3.8 A 6.5 A 3.8 and 6.5 A 2x 6.5 A

CSA/UL

60 Hz 230 V 10.2 A 14.7 A 9.2 A 15.3 A 9.2 and 15.3 A 2x 15.3 A

60 Hz 440/460 V 4.6 A 7.7 A 4.6 and 7.7 A 2x 7.7 A

Note: SF6 Twin have compressor modules of a different size, the first value is valid for the smaller

SF2 module and the second one is valid for the bigger SF4 module

singlephase

SF2

singlephase

SF2

3-phase

SF4

3-phase

SF6

3-phase

SF8

3-phase

7.4 Overload relays for SF6-15 Multi

Frequency Voltage SF6

3-phase

IEC

50 Hz 230 V 8 and 14 A 2x 14 A 3x 14 A 4x 14 A

50 Hz 400 V 4.8 and 8 A 2x 8 A 3x 8 A 4x 8 A

60 Hz 380 V 5 and 8.5 A 2x 8.5 A 3x 8.5 A 4x 8.5 A

50 Hz 500 V 3.6 and 6.4 A 2x 6.4 A 3x 6.4 A 4x 6.4 A

CSA/UL

60 Hz 230 V 9 and 15 A 2x 15 A 3x 15 A 4x 15 A

60 Hz 440/460 V 4.5 and 7.5 A 2x 7.5 A 3x 7.5 A 4x 7.5 A

60 Hz 575 V 3.5 and 5.5 A 2x 5.5 A 3x 5.5 A 4x 5.5 A

Note: SF6 have compressor modules of a different size, the first value is valid for the smaller SF2

module (lower element) and the second one is valid for the bigger SF4 module (higher element)

SF8

3-phase

SF11

3-phase

SF15

3-phase

2920 1521 00 36

Page 37

Instruction book

7.5 Main fuses for SF1-8

Frequency Voltage SF1

IEC

50 Hz 230 V 20 A 20 A 20 A 20 A 2x 20 A 2x 20 A

50 Hz 400 V 20 A 20 A 2x 20 A 2x 20 A

60 Hz 380 V 20 A 20 A 2x 20 A 2x 20 A

50 Hz 500 V 20 A 20 A 2x 20 A 2x 20 A

CSA/UL

60 Hz 230 V 25 A 25 A 20 A 30 A 20 A 2x 30 A

60 Hz 440/460 V 15 A 15 A 15 A 2x 15 A

7.6 Main fuses for SF6-15 Multi

singlephase

SF2

singlephase

SF2

3-phase

SF4

3-phase

SF6

3-phase

SF8

3-phase

Frequency Voltage SF6

3-phase

SF8

3-phase

SF11

3-phase

SF15

3-phase

IEC

50 Hz 230 V 32 A 50 A 63 A 80 A

50 Hz 400 V 25 A 32 A 50 A 50 A

60 Hz 380 V 25 A 32 A 50 A 50 A

50 Hz 500 V 20 A 25 A 32 A 50 A

CSA/UL

60 Hz 230 V 45 A 60 A 80 A 110 A

60 Hz 440/460 V 25 A 30 A 45 A 60 A

60 Hz 575 V 20 A 25 A 35 A 45 A

7.7 Reference conditions/limitations

Reference conditions:

Air inlet pressure (absolute) 1 bar

Air inlet temperature 20 °C

Relative air humidity 0%

Nominal working pressure See values below

Limitations

Max. working pressure See values below

Max. ambient temperature 40 °C

Min. ambient temperature 0 °C

2920 1521 00 37

Page 38

Instruction book

7.8 SF1-4 8bar 50 Hz 1)

Compressor type SF1 SF2 SF4

8 bar 8 bar 8 bar

Maximum working pressure bar(e) 8 8 8

Nominal working pressure bar(e) 7 7 7

Air temperature at outlet valve (Tankmounted/Twin), approx.

Air temperature at outlet valve (Skid), approx. °C 38 45 65

Motor shaft speed r/min 2885 2885 2885

Shaft input kW 1.5 2.1 3.4

Sound pressure level dB(A) 65 67 68

7.9 SF2-4 10 bar 50 Hz 1)

Compressor type SF2 SF4

10 bar 10 bar

Maximum working pressure bar(e) 10 10

Nominal working pressure bar(e) 10 10

Air temperature at outlet valve (Tank-mounted/Twin), approx. °C 28 40

Air temperature at outlet valve (Skid), approx. °C 45 65

Motor shaft speed r/min 2885 2885

Shaft input kW 2.1 3.65

Sound pressure level dB(A) 67 68

°C 30 32 40

7.10 SF1-4 100 psi 60 Hz 1)

Compressor type SF1 SF2 SF4

100 psi 100 psi 100 psi

Maximum working pressure bar(e) 8 8 8

Nominal working pressure bar(e) 7 7 7

Air temperature at outlet valve (Tank-

°C 30 32 40

mounted/Twin), approx.

Air temperature at outlet valve (Skid), approx. °C 38 45 65

Motor shaft speed r/min 1710 3485 3485

Shaft input kW 1.5 2.1 3.4

Sound pressure level dB(A) 65 67 68

7.11 SF2-4 145 psi 60 Hz 1)

Compressor type SF2 SF4

145 psi 145 psi

Maximum working pressure bar(e) 10 10

Nominal working pressure bar(e) 10 10

Air temperature at outlet valve (Tank-mounted/Twin), approx. °C 28 40

Air temperature at outlet valve (Skid), approx. °C 45 65

Motor shaft speed r/min 3485 3485

Shaft input kW 2.1 3.65

Sound pressure level dB(A) 67 68

2920 1521 00 38

Page 39

Instruction book

7.12 SF6-15 Multi 8 bar 50 Hz 1)

Compressor type SF6 SF8 SF11 SF15

8 bar 8 bar 8 bar 8 bar

Maximum working pressure for SF Pack bar(e) 8 8 8 8

Maximum working pressure for SF Full-Feature bar(e) 7.75 7.75 7.75 7.75

Nominal working pressure bar(e) 7 7 7 7

Air temperature at outlet valve for SF Pack, approx. °C 26 28 30 32

Air temperature at outlet valve for SF Full-Feature, approx. °C 23 25 25 25

Motor shaft speed r/min 2885 2885 2885 2885

Shaft input kW 5.6 6.9 10.4 13.8

Sound pressure level dB(A) 61 62 60 63

For SF Full-Feature also:

Refrigerant type R134a R134a R134a R134a

Pressure dewpoint, approx 2) °C 3 3 3 3

7.13 SF6-15 Multi 10 bar 50 Hz 1)

Compressor type SF6 SF8 SF11 SF15

10 bar 10 bar 10 bar 10 bar

Maximum working pressure for SF Pack bar(e) 10 10 10 10

Maximum working pressure for SF Full-Feature bar(e) 9.75 9.75 9.75 9.75

Nominal working pressure for SF Pack bar(e) 10 10 10 10

Nominal working pressure for SF Full-Feature bar(e) 9.75 9.75 9.75 9.75

Air temperature at outlet valve for SF Pack, approx. °C 26 28 30 32

Air temperature at outlet valve for SF Full-Feature, approx. °C 25 25 25 25

Motor shaft speed r/min 2885 2885 2885 2885

Shaft input kW 5.9 7.5 11.3 15.0

Sound pressure level dB(A) 61 62 60 63

For SF Full-Feature also:

Refrigerant type R134a R134a R134a R134a

Pressure dewpoint, approx. 2) °C 3 3 3 3

7.14 SF6-15 Multi 100 psi 60 Hz 1)

Compressor type SF6 SF8 SF11 SF15

100 psi 100 psi 100 psi 100 psi

Maximum working pressure for SF Pack bar(e) 8 8 8 8

Maximum working pressure for SF Full-Feature bar(e) 7.75 7.75 7.75 7.75

Nominal working pressure bar(e) 7 7 7 7

Air temperature at outlet valve for SF Pack,

approx.

Air temperature at outlet valve for SF FullFeature, approx.

Motor shaft speed r/min 3495 3495 3495 3495

Shaft input SF Pack kW 5.7 7.1 10.7 14.2

Shaft input SF Full-Feature kW 5.8 7.2 10.8 14.4

Sound pressure level dB(A) 61 62 60 63

For SF Full-Feature also:

Refrigerant type R134a R134a R134a R134a

Pressure dewpoint, approx 2) °C 3 3 3 3

°C 26 28 29 30

°C 23 25 25 25

2920 1521 00 39

Page 40

Instruction book

7.15 SF6-15 Multi 125 psi 60 Hz 1)

Compressor type SF6 SF8 SF11 SF15

125 psi 125 psi 125 psi 125 psi

Maximum working pressure for SF Pack bar(e) 9.1 9.1 9.1 9.1

Maximum working pressure for SF Full-Feature bar(e) 8.85 8.85 8.85 8.85

Nominal working pressure bar(e) 8.6 8.6 8.6 8.6

Air temperature at outlet valve for SF Pack, approx. °C 26 28 30 30

Air temperature at outlet valve for SF Full-Feature,

approx.

Motor shaft speed 3505 3505 3505 3505

Shaft input for SF Pack kW 5.8 7.4 11.0 14.7

Shaft input for SF Full-Feature kW 5.9 7.4 11.1 14.8

Sound pressure level dB(A) 61 62 60 63

For SF Full-Feature also:

Refrigerant type R134a R134a R134a R134a

Pressure dewpoint, approx. 2) °C 3 3 3 3

23 25 25 25

7.16 SF6-15 Multi 145 psi 60 Hz 1)

Compressor type SF6 SF8 SF11 SF15

145 psi 145 psi 145 psi 145 psi

Maximum working pressure for SF Pack bar(e) 10 10 10 10

Maximum working pressure for SF Full-Feature bar(e) 9.75 9.75 9.75 9.75

Nominal working pressure for SF Pack bar(e) 10 10 10 10

Nominal working pressure for SF Full-Feature bar(e) 9.75 9.75 9.75 9.75

Air temperature at outlet valve for SF Pack, approx. °C 26 28 30 32

Air temperature at outlet valve for SF Full-Feature,

approx.

Motor shaft speed 3505 3505 3505 3505

Shaft input kW 5.9 7.5 11.3 15.0

Sound pressure level dB(A) 61 62 60 63

For SF Full-Feature also:

Refrigerant type R134a R134a R134a R134a

Pressure dewpoint, approx. 2) °C 3 3 3 3

Footnotes chapter 7

1)

2)

At reference conditions

At 20 °C / 100% relative humidity

23 25 25 25

2920 1521 00 40

Page 41

Instruction book

8 REGULATOR FUNCTIONS FOR SF MULTI

8.1 Menu-driven control programs

To facilitate programming and controlling the compressor, menu-driven programs are implemented in

the electronic module.

A simplified menu flow is shown in Fig. 8.1.

Fig. 8.1 Menu flow SF15 Workplace Full-Feature

2920 1521 00 41

Page 42

Instruction book

8.1.1 Function of control programs

Program/Function Description

Main screen Shows in short the operation status of the compressor. It is the gateway

Status data Calling up the status of the compressor protection functions:

Measured data Calling up:

Counters Calling up the:

Test Allows a display test.

Modify parameters Modifying the settings for:

Service Calling up service plans and resetting the timers after carrying out the

Saved data Calling up the saved data: last shut-down data

to all functions. See Fig. 8.2.

- shut-down

- service warning

- warning

Resetting of a shut-down and service condition.

- actually measured data

- status of some inputs such as the motor overload protection per

compressor module

- running hours

- regulator (module) hours

- running hours per compressor module

- number of starts per compressor module

- number of shut-downs per compressor module

- parameters (e.g. number of starts per day)

- protections (e.g. dewpoint temperature of dryer for Full-Feature

machines)

- service plans (see section 8.10)

- clock functions (automatic compressor start/stop/pressure band

commands)

- configuration (time, date, display language, …)

service actions belonging to a plan. See section 8.13.

8.1.2 Main screen

When the voltage is switched on, the Main screen is shown automatically, showing in short the

operation status of the compressor.

Compressor Outlet 7.0 bar

Compressor Running

↓

Menu - - - F1 F2 F3

Fig. 8.2 Main screen, typical example

If the function keys or arrow keys are not used for some minutes, the display will automatically return

to the Main screen.

Whenever displayed on a submenu screen, press the key "Mainscreen" to return to the Main screen.

2920 1521 00 42

Page 43

Instruction book

Line Indicates Remarks

1

2 - -

3 Compressor status

3 Shut-down

3 Service required

3 Sensor error

3 Remote control

4

4

Note

Press key (F3) on the main screen to check which compressor module is running or stopped.

2

depending on the

Sensor which is active

and the actual reading

The unit for pressure can be bar, psi or kg/cm

programmed selection. The unit for temperature can be °C or °F.

See section 8.12.

Examples:

- Compressor Off

- Compressor Running

If the unit is shut down, the regulator will automatically show a shutdown message on the display (see section 8.3). It remains possible

to have a closer look at other parameters related to the shut-down

by means of the menus.

Indicates that the unit needs servicing. Consult section 8.13 to find

out the exact cause for this message.

Indicates that a sensor is out of order:

- Outlet pressure transducer

- On Full-Feature compressors, the dewpoint sensor

Stop the compressor. Switch off the voltage and depressurize the

compressor. Check the sensor wiring. Replace the sensor or

transducer, if necessary.

Indicates that the compressor is set in remote control. Consult Atlas

Copco.

Functions of keys

See section 1.5.7.

below display

Symbols: Indicating the status of each compressor module

- indicating that the compressor module is available (ready to run)

▄ indicating that the compressor module is running

- (blinking)

indicating that the compressor module is not available (due to

minimum stop time or too many starts)

* (blinking) indicating that the compressor module is shut down

When more than one message needs to be displayed (e.g. both warning and service), the

messages will be displayed one after the other for 3 seconds.

Element 1 Stopped

Element 2 Running

Element 3 Stopped

↓

Menu

F1 F2 F3

Fig. 8.3 Element status screen, typical example

2920 1521 00 43

Page 44

Instruction book

8.1.3 Calling up other menus

Starting from the Main screen:

- Use the ↓ key for a quick look at the actual compressor status (see section 8.2)

- Press the key "Menu" (F1), the option "Status data" will be followed by a horizontal arrow:

8.2 Quick look at actual compressor status

Procedure

1. Starting from the Main screen (see section 8.1.2), press the ↓ key: A screen similar to the one

Line 1 indicates the automatic or manual operation status of the regulator:

"Automatic operation" means that the regulator automatically adapts the operation of the

Line 2 indicates whether the regulator operates in local control, remote control or LAN control mode:

"Local control" means that the start/stop buttons on the keyboard are activated.

"Remote control" means that these functions are controlled remotely. Consult Atlas Copco.

“LAN control” means that the compressor can be controlled by an ES controller.

Line 3 indicates whether the timer, which generates time-based start and stop commands is activated

or not. See section 8.11.

See section 1.5.7 for the functions of the keys "Mainscreen", "Help" and "Extra".

2. Press the ↓ key to get other data (actual compressor conditions of the compressor) as shown in

- either press the tabulator key (5) to select this menu

- or use the ↓ key to scroll until the desired submenu is followed by a horizontal arrow and then

press the tabulator key (5) to select this menu

below appears:

Automatic Operation

Local Control

Week Timer Active

↓

Mainscreen Help Extra

F1 F2 F3

Fig. 8.4 Example of an actual compressor status display

compressor, i.e. starting and stopping the compressor modules according to the programmed

parameters.

Fig. 8.1.

2920 1521 00 44

Page 45

Instruction book

8.3 Status data menu

The status data submenu gives information regarding the status of the compressor protection

functions (shut-down, service warning and warning) and allows resetting of a shut-down and service

condition.

Procedure

Starting from the Main screen (see section 8.1.2):

- Press the key "Menu" (F1), the option "Status data" will be followed by a horizontal arrow

- Press the tabulator key (5)

8.3.1 No message exists

In this case, LED (7) is out and the message on the display indicates that all conditions are normal

(Fig. 8.5):

All Conditions are OK

Menu Help

F1 F2 F3

Fig. 8.5 Example of a status data screen

8.3.2 A shut-down message exists

In case the compressor is shut down, LED (7) will blink. A shut-down message exists after an

emergency stop or after the temperature switch (TSHH20-Fig.2.8) has tripped (indicated on the

display as Aux. Equipment Overload).

In case of a shut-down due to an emergency stop, a screen similar to the one below will appear:

Emergency Stop Open

Shutdown Open

Menu *** *** Reset

F1 F2 F3

Fig. 8.6 Example of a status data screen

1. The indicators (***) are blinking. The screen shows that the compressor is shut down due to an

emergency stop. The contacts of the emergency switch are open. The setting of the shut-down is

open.

2920 1521 00 45

Page 46

Instruction book

2. It remains possible to scroll through other menus, e.g. to check the values of other parameters.

Shut-down reset

1. Switch off the voltage, depressurize the compressor and remedy the trouble. After remedying,

2. Press the keys "Menu" and "Mainscreen" to return to the Main screen and restart the compressor

8.3.3 A warning message exists

1. If a shut-down warning exists, LED (7) is alight. The Main screen will change into a screen similar

2. The indicators (***) are blinking and the message **Warning** appears alternately with the

3. Press the key "Menu" (F1) and the tabulator key (5) to select the Status Data menu, the option

4. Scroll to this option and select it by pressing the tabulator key (5): option "Warnings" blinks. Scroll

The screen shows that the temperature at the outlet of element 1 (80 °C) is too high.

5. Stop the compressor by means of button O and wait until the compressor has stopped.

6. Switch off the voltage, inspect the compressor and remedy.

7. The warning message will disappear automatically as soon as the warning condition disappears.

When returning to the Status data menu, the option "Shutdowns" will blink. This option can be

selected by pressing the tabulator key (5) to return to the shut-down screen (Fig. 8.6).

switch on the voltage and press the key "Reset" (F3).

by means of button I.

to the one below:

Compressor Outlet 7.0 bar

** Warning

**↓

Menu *** *** * - - F1 F2 F3

Fig. 8.7 Example of a warning screen

messages indicating whether the compressor is in operation or not (Compressor Running or

Compressor Off).

"Protection" is blinking.

to this option and select it by pressing the tabulator key (5). A screen similar to the one in Fig. 8.8

appears:

Element 1 80 °C

Warning Maximum 75 °C

Menu *** ***

F1 F2 F3

Fig. 8.8 Example of a warning screen

2920 1521 00 46

Page 47

Instruction book

8.3.4 A service warning message exists

1. LED (7) is alight and the main screen will change into a screen similar to that shown in Fig. 8.9.

2. The indicators (***) are blinking and the service warning message appears alternately with the

3. Press the key "Menu" (F1) and the tabulator key (5) to select the Status data menu: the option

4. Scroll to this option and select it by pressing the tabulator key (5), two options may blink:

"Inputs": option is not applicable.

"Plan": if a service plan interval is exceeded. See section 8.15.2.

5. Stop the compressor and switch off the voltage.

6. The service message was referring to "Plan": carry out the service actions related to the indicated

Compressor Outlet 7.0 bar

** Service Required

**↓

Menu *** *** - - - F1 F2 F3

Fig. 8.9 Example of a service warning screen

messages indicating whether the compressor is in operation or not (Compressor Running or

Compressor Off).

"Service" is blinking.

plans. Reset the timers of the related plans as described in section 8.13.

8.4 Measured data menu

Function

To call up information regarding the actually measured data and the status of some inputs such as the

motor overload protection per compressor module.

Procedure

1. Starting from the Main screen (see section 8.1.2):

- press the key "Menu" (F1)

- press the ↓ key until the option "Measured data" is followed by a horizontal arrow

- press the tabulator key (5) to activate the menu

Compressor Outlet 7.0 bar ┤

Element 1 75 °C

Element 2 70 °C

Menu Extra

F1 F2 F3

Fig. 8.10 Example of a measured data screen

↓

2920 1521 00 47

Page 48

Instruction book

2. By pressing the ↓ key, a number of actually measured data can be found (see Fig. 8.1).

3. If one of the sensors is linked to a shut-down, service or warning function, both the actually

8.5 Counters menu

Function

To allow the operator to call up the:

- running hours

- regulator (module) hours (the hours the module has been under tension)

- running hours per compressor module

- starts per compressor module

- shutdowns per compressor module

Procedure

1. Starting from the Main screen (see section 8.1.2):

2. By pressing the ↓ key, the above-mentioned data can be found (see also Fig. 8.1).

measured value as well as the corresponding shut-down, warning or service level can be called up

by pressing the tabulator key (5).

- press the key "Menu" (F1)

- press the ↓ key until the option "Counters" is followed by a horizontal arrow

- press the tabulator key (5) to activate the menu

8.6 Test menu

Function

To carry out a display test, i.e. to check whether the display and LEDs are still intact.

Procedure

1. Starting from the Main screen (see section 8.1.2):

- press the key "Menu" (F1)

- press the ↓ key until the option "Test" is followed by a horizontal arrow

- press the tabulator key (5) to activate the menu

2. The option "Display test" will be followed by a horizontal arrow.

3. After pressing the tabulator key (5), the regulator will generate a series of patterns on the display

which enable the operator to check that each pixel still functions normally; at the same time the

LEDs are lit.

2920 1521 00 48

Page 49

Instruction book

8.7 Modify parameters menu

Function

The menu allows the operator to program:

- Parameters, see section 8.8.

- Protections settings, see section 8.9.

- Service plan settings, see section 8.10.

- Clock function settings, see section 8.11.

- Configuration settings, see section 8.12.

8.8 Modifying parameters

Function

To modify a number of parameters as mentioned below and in Fig. 8.1.

- Pressure Band 1 High

- Pressure Band 1 Low

- Pressure Band 2 High

- Pressure Band 2 Low

- Number Of Starts/Day (per compressor module)

- Minimum Stop Time (i.e. the time period during which the compressor, if stopped automatically,

- Power recovery time (if automatic restart after voltage failure is activated) 3)

- Restart delay (can be programmed, allowing e.g. compressors to be restarted one after the other)

- Time to next start (time between the starting of two compressor modules)

- Time to next stop (time between the stopping of two compressor modules during regulation)

Procedure

1. Starting from the Main screen (see section 8.1.2):

2. The first option ("Parameters") will be followed by a horizontal arrow.

3. Press the tabulator key (5): the first item ("Pressure Band 1 High") and its setting will appear.

4. Use the ↓ key to scroll until the parameter to be modified is followed by a horizontal arrow.

remains stopped whatever happens with the air net pressure)

- press the key "Menu" (F1)

- press the ↓ key until the option "Modify Parameters" is followed by a horizontal arrow

- press the tabulator key (5) to activate the menu

2920 1521 00 49

Page 50

Instruction book

8.8.1 Modifying the pressure bands

If desired, the operator can program two pressure bands (band 1 and band 2) with different pressure

settings. The settings for band 1 are indicated as "Pressure Band 1 High" and "Pressure Band 1

Low", the settings for band 2 are indicated as " Pressure Band 2 High " and " Pressure Band 2 Low ".

Example:

For pressure band 1:

- Pressure Band 1 Low: 6.8 bar

- Pressure Band 1 High: 7.8 bar

For pressure band 2:

- Pressure Band 2 Low: 5.5 bar

- Pressure Band 2 High: 6.5 bar

Procedure

1. Consult the section above to select the parameter Pressure Band 1 High:

2. The screen shows that the current setting of Pressure Band 1 High is 7.8 bar(e). To modify this

3. The key "Limits" (F2) can be used to find the limitations for the parameter. Use the ↓ or ↑ arrow

4. Press the key "Program" (F1) to program the new setting or the key "Cancel" (F3) to cancel the

5. The procedure to modify the Pressure Band 1 Low is similar to the description above.

6. If required, repeat the procedure for the Pressure Band 2 High and Pressure Band 2 Low

Pressure Band 1 High 7.8 bar ┤