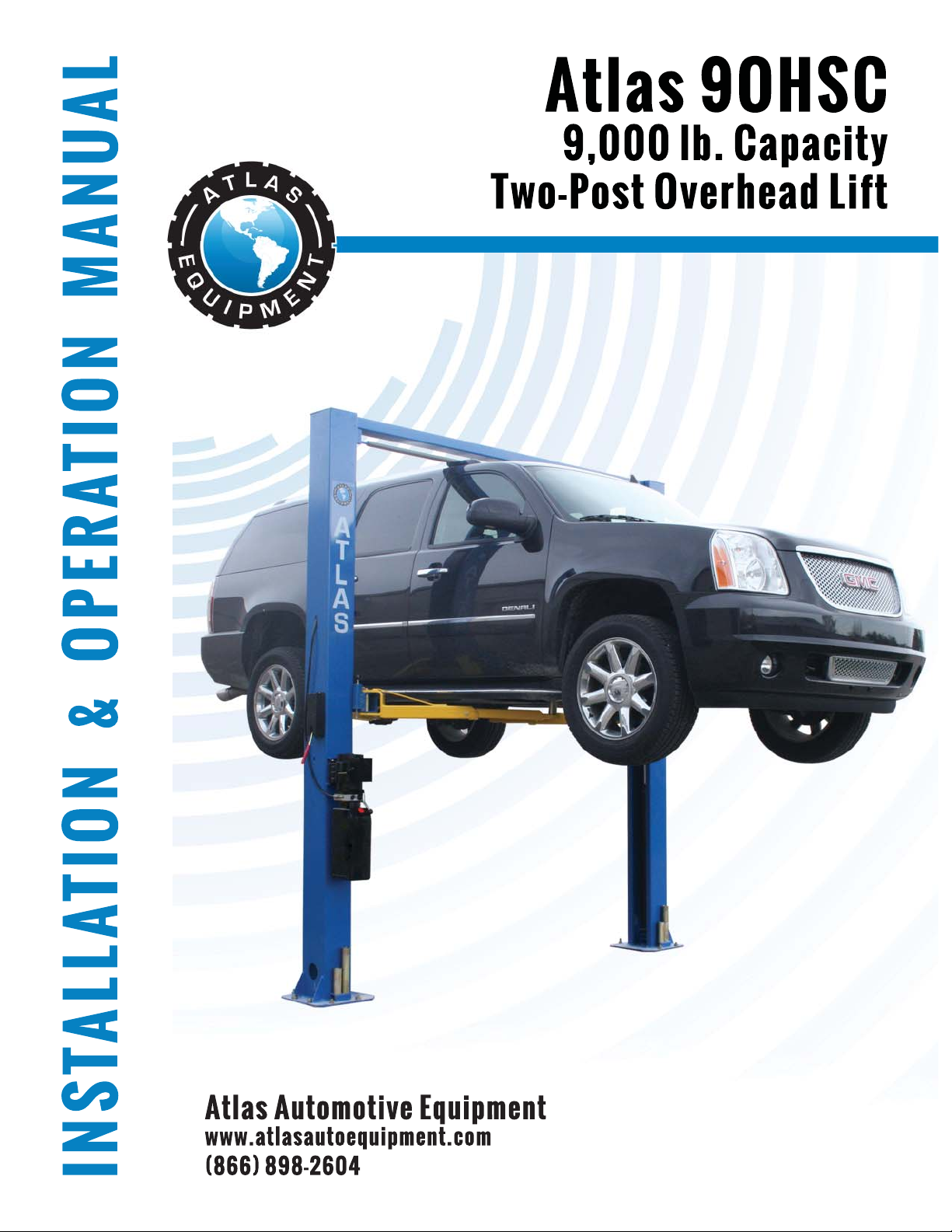

Atlas 90HSC Installation & Operation Manual

Read this entire manual before operation begins.

Record below the following information which is located on the serial number

data plate.

Serial No.

Model No.

Date of Installation

Contents

Specifi cations. . . . . . . . . . . . . 4

Installation Requirement . . . . . . . 6

Steps Of Installation . . . . . . . . . 8

Exploded View . . . . . . . . . . . .25

Test Run . . . . . . . . . . . . . . .29

Operation Instructions. . . . . . . . .31

Maintenance Schedule. . . . . . . . .32

Trouble Shooting . . . . . . . . . . .33

9-OHSC Parts List. . . . . . . . . . .34

Warranty . . . . . . . . . . . . . . .39

Specifi cations

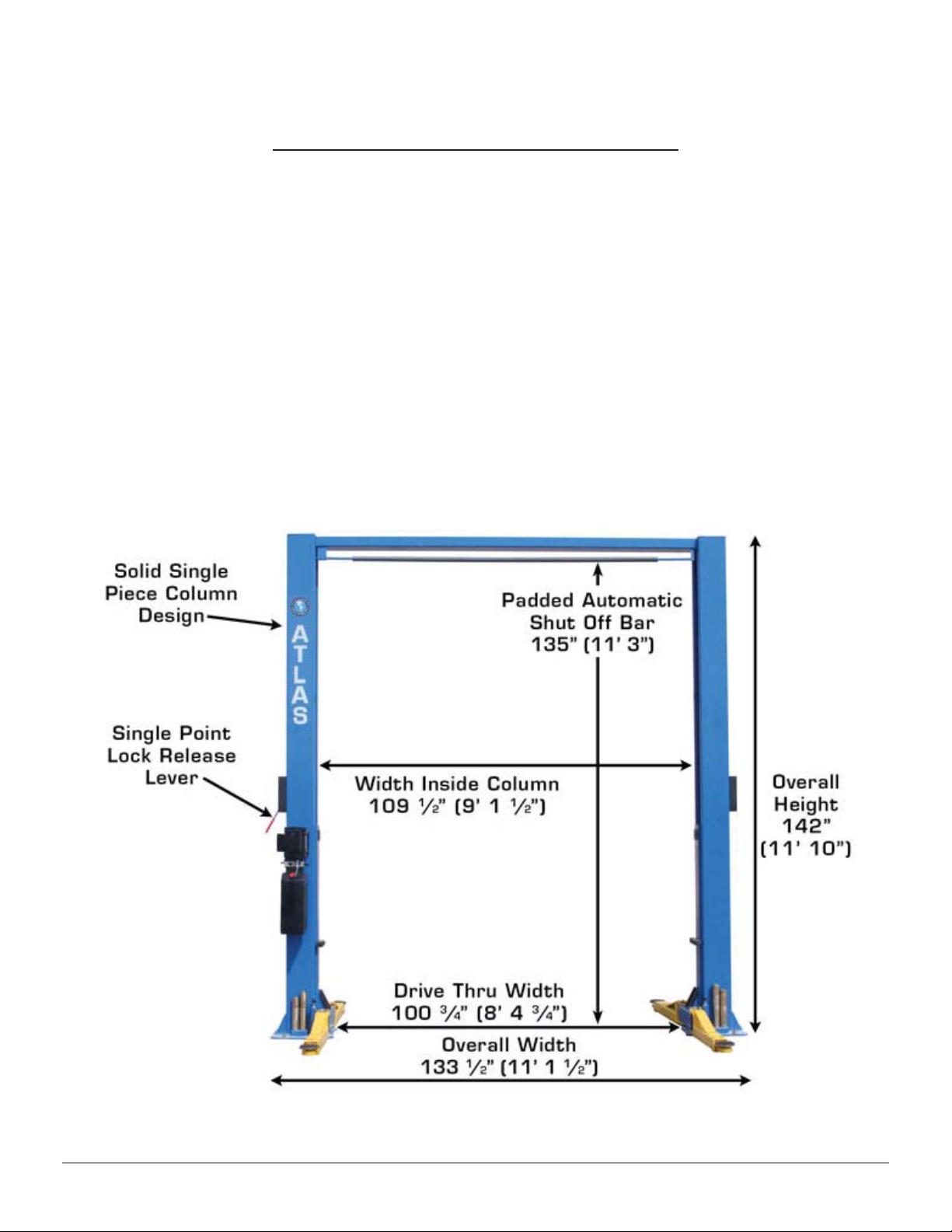

9-OHSC Clear Floor, Chain-Drive Features (See Fig. 1)

• Dual hydraulic cylinders designed and made to ANSI standard, utilizing

NOK oil seal in cylinder.

• Self-lubricating UHMW Polyethylene sliders and bronze bush.

• Single-point safety release, and dual safety design.

• Clear fl oor design, provide unobstructed fl oor space.

• Overhead safety shutoff device.

• Super symmetric arm design with 3-stage front arms and 2-stage rear arms.

• Rubber lift pads with 1.5” and 2.5” stackable extension adaptors.

Fig. 1

Specifications 4

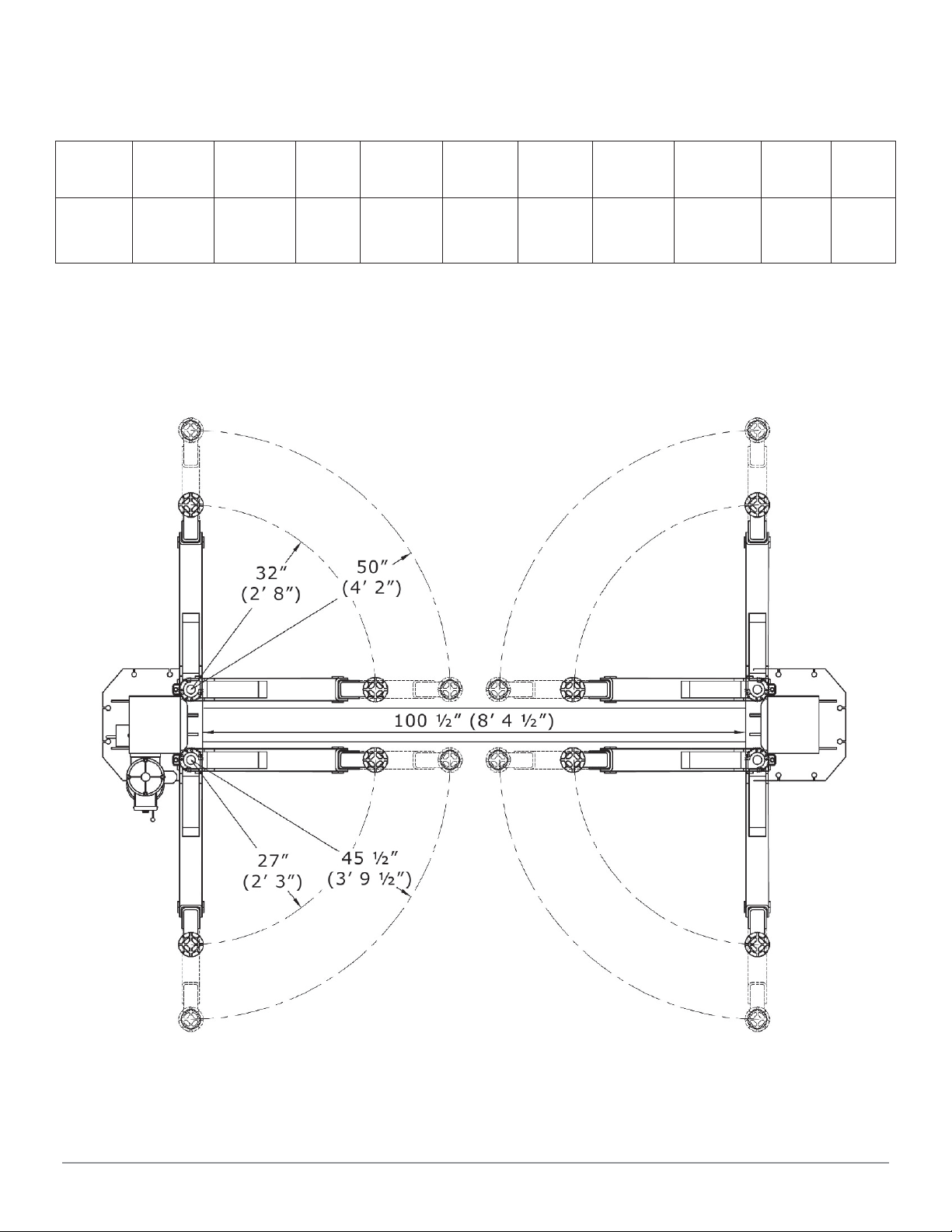

9OHSC (SS)

9-OHSC Specifi cations

Model Style

Clearfl oor

9-OHSC

Chain-

driven

Lifting

Capacity

4.5 T

9,000 lbs

Lifting

Time

45S

Lifting

Height

71 1/2”–

75 1/2”

Overall

Height

141 3/4” 133 1/2” 109 1/2” 3 1/2” 1384lbs

Overall

Width

Arm Swing View

Width

Between

Columns

Minimum

Pad

Height

Gross

Weight

Motor

2.0/3.0

HP

Fig. 2

Specifications 5

9OHSC (SS)

Installation Requirement

Tools Required

Rotary Hammer Drill (Φ19) Carpenter’s Chalk

Hammer Screw Drivers

Level Bar Tape Measure (25ft)

Crescent Wrench (12”) Pliers

Ratchet Spanner With Socket (28#) Allen Head Wrench (6#, 3#)

Wrench set

(10#, 13#, 14#, 15#, 17#, 19#, 24#, 27#)

Fig. 3

Vise Grips

Installation Requirement 6

9OHSC (SS)

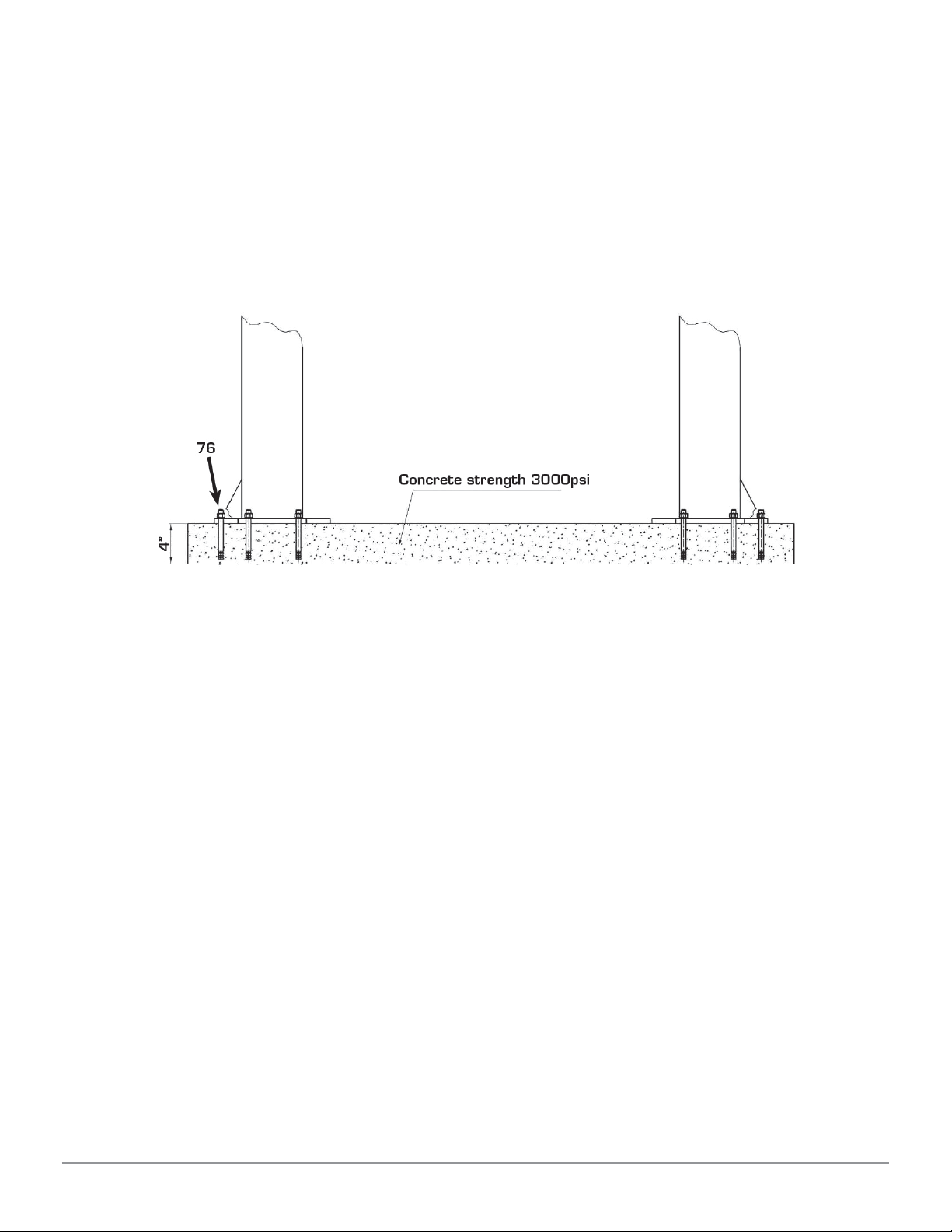

Specifi cations Of Concrete (See Fig. 4)

Concrete must adhere to the following specifi cations.

Failure to do so may result in the lift and/or vehicle falling.

1. Concrete must be a minimum 4” thick without reinforcing steel bars. Concrete

must be totally cured before installation.

2. Concrete must be in good condition and a minimum 3,000 psi. test strength.

3. Floors must be level with no cracks.

Fig. 4

Power Supply

220 volt single phase 30 amp breaker with minimum of 10 gauge wire

Installation Requirement 7

9OHSC (SS)

Steps Of Installation

A. Location of Installation

Check and insure the installation location (concrete, layout, space size etc.) is

suitable for lift installation.

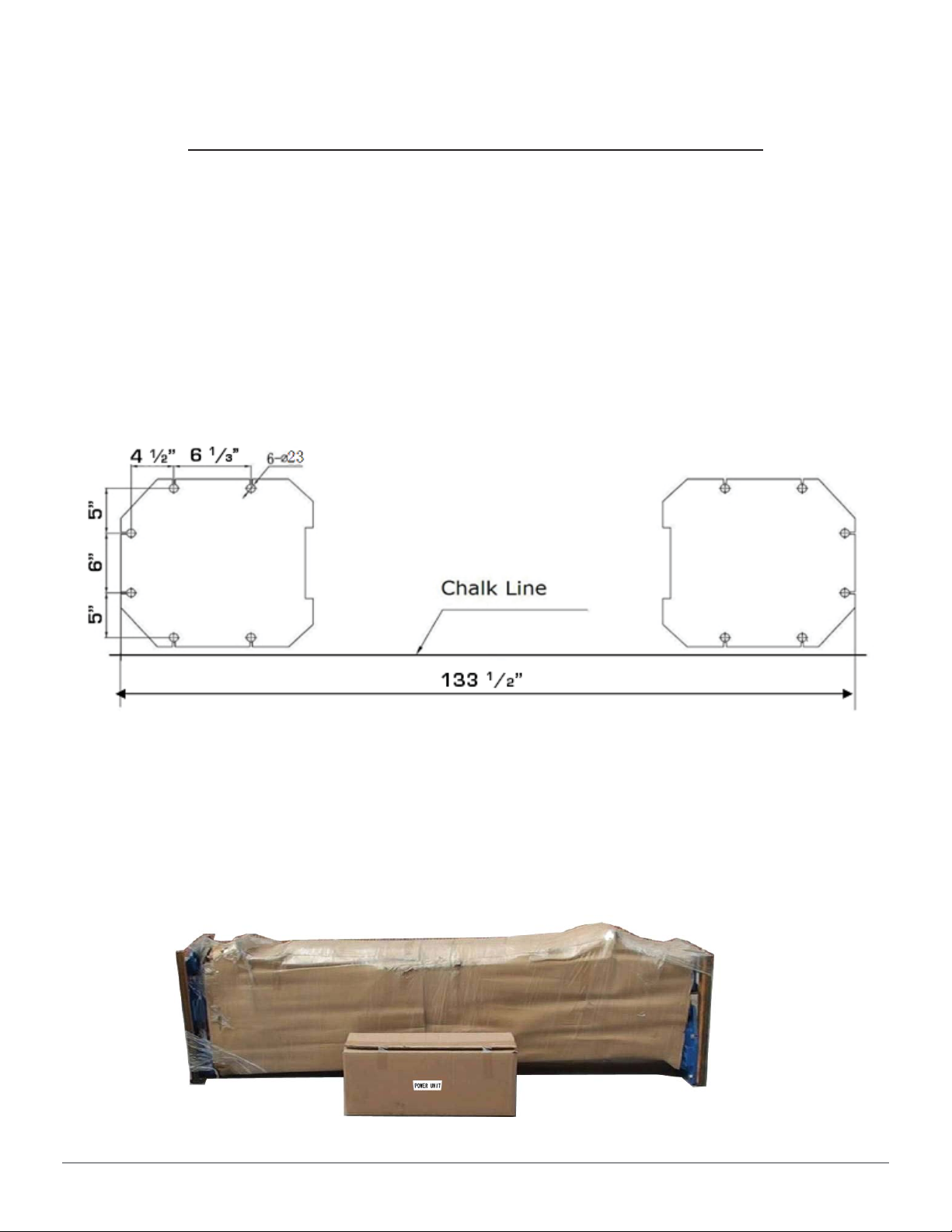

B. Use a carpenter’s chalk line to establish

installation layout of baseplate (See Fig. 5).

Fig. 5

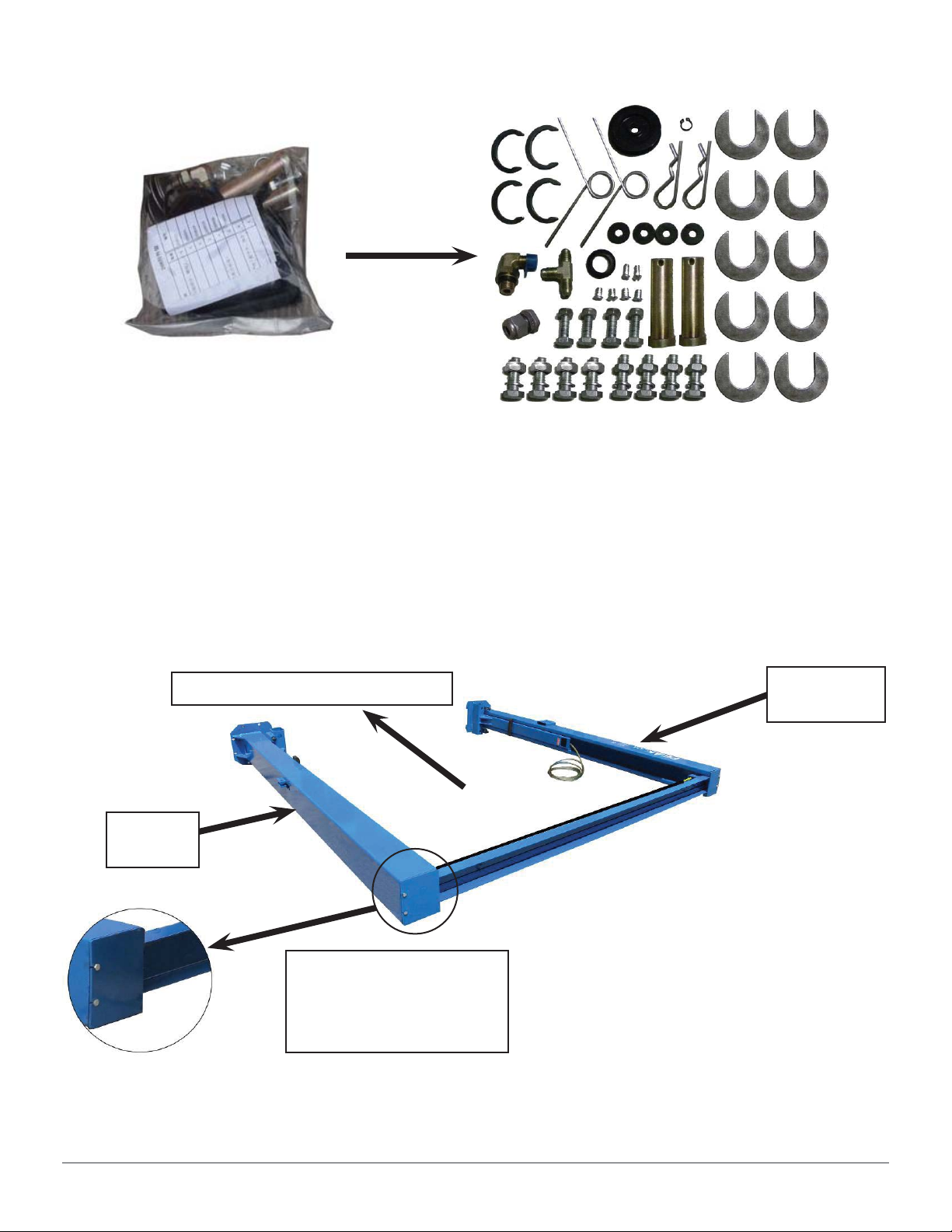

C. Check the parts before assembly

1. Packaged lift and hydraulic power unit (See Fig. 6)

Steps Of Installation 8

9OHSC (SS)

Fig. 6

2. Move aside the lift with fork lift or hoist, and open the outer packing carefully,

take off the parts from upper and inside the column, take out the parts box,

check the parts according to the shipment parts list (See Fig. 7).

Shipment Part list

Top Beam

Serial No.

Parts Box

Fig. 7

3. Loosen the screws of the upper package stand, take off the upper column and

remove the package stand.

4. Move aside the parts and check the parts according to the shipment parts list

(See Fig. 8, Fig. 9).

Fig. 8 - Parts in the shipment parts list | Fig. 9 - Parts in the parts box (77)

Steps Of Installation 9

9OHSC (SS)

5. Open the bag of parts and check the parts according to parts box list (See

Fig.10).

Fig. 10

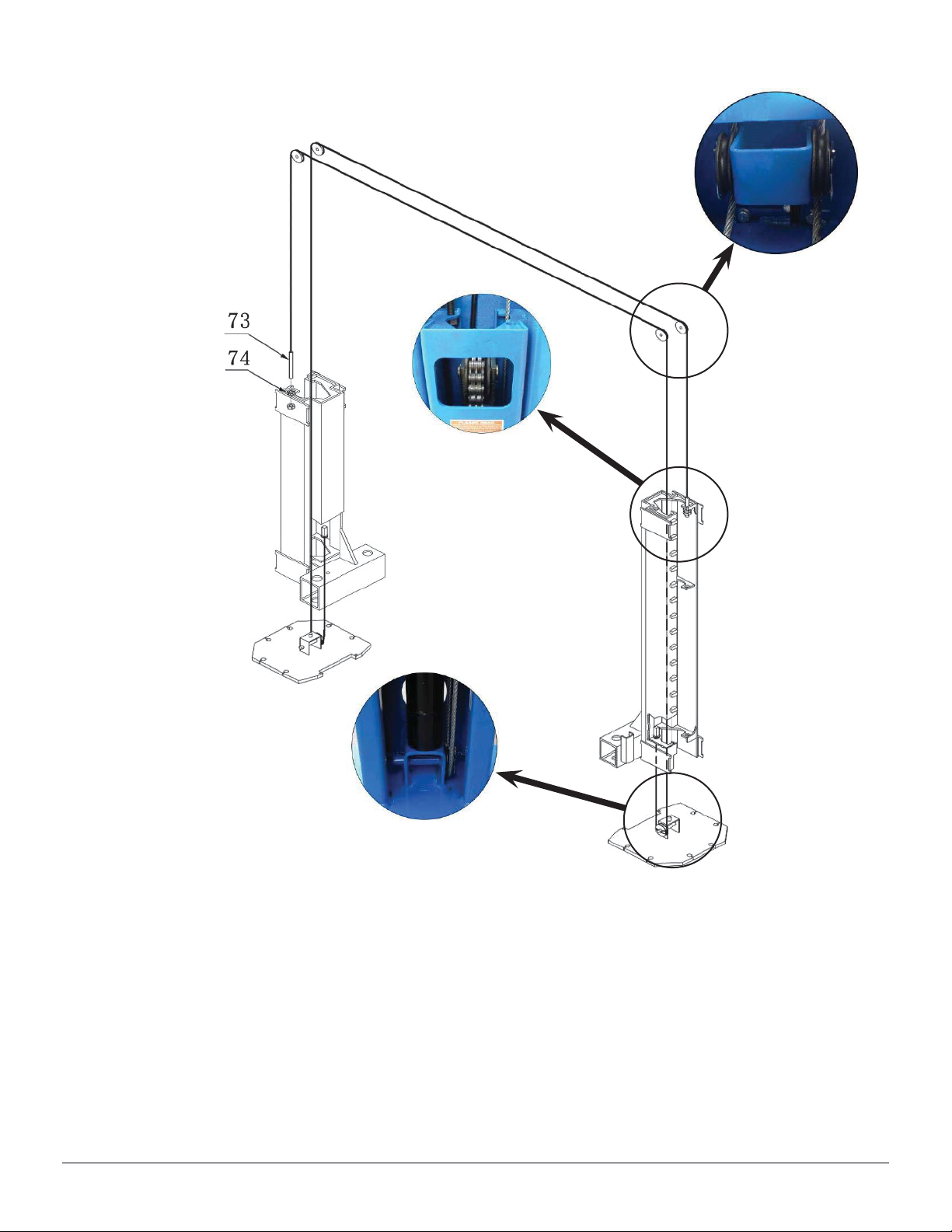

D. Position powerside column

Lay down the two columns on the installation site parallel to each other. Position

the powerside column according to the actual installation site. Usually, it is

suggested to install the powerside column on the front-right side from which

vehicles are driven to the lift. Then install the overhead top beam (See Fig. 11).

Vehicle drive in Direction

Offside

Column

Fig. 11

Assemble Top Beam

using M10*35

Hex Bolt with Nut

and Washer

Powerside

column

Steps Of Installation 10

9OHSC (SS)

E. Install cables (See Fig. 12)

Fig. 12

Steps Of Installation 11

9OHSC (SS)

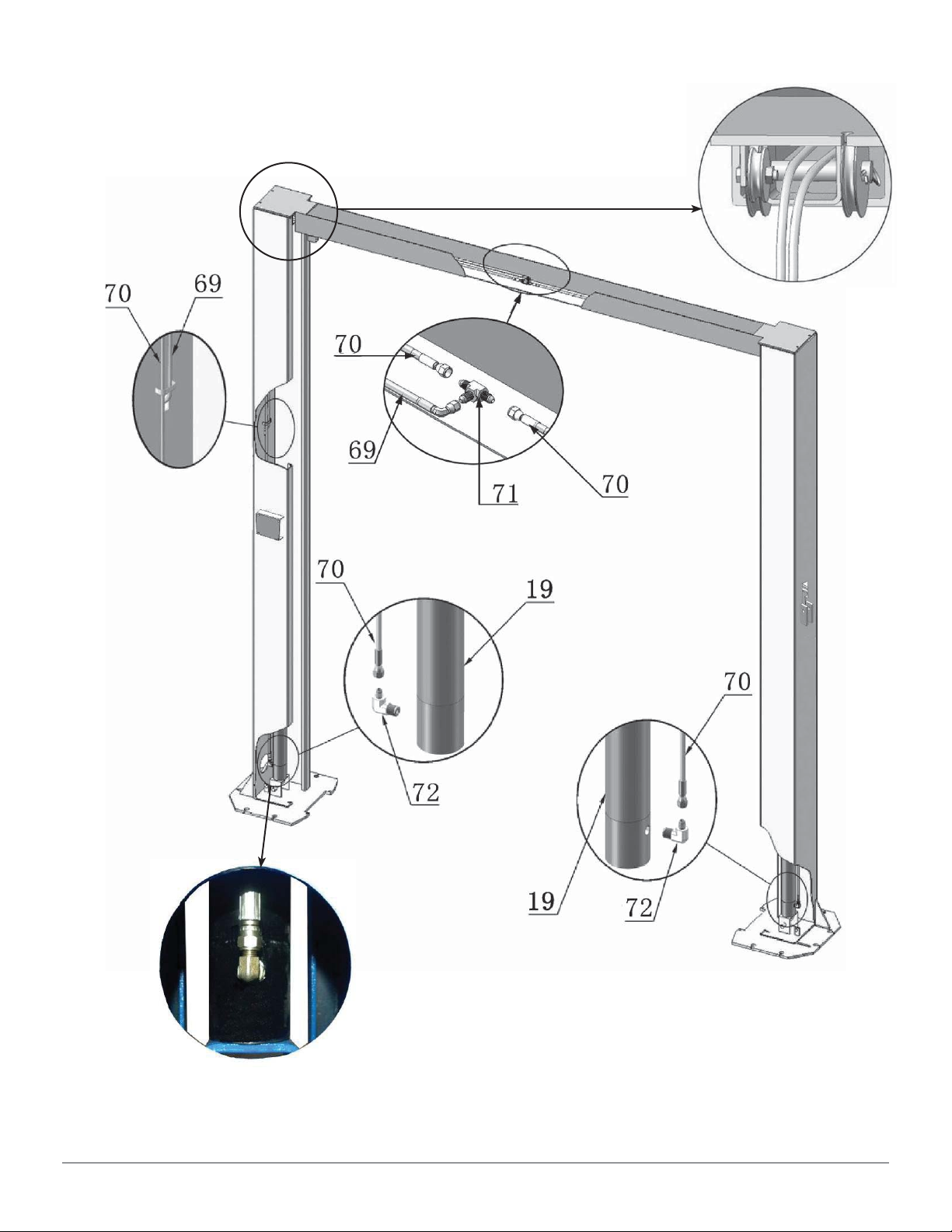

F. Oil hose assembly (See Fig. 13)

Fig. 13

Steps Of Installation 12

9OHSC (SS)

Loading...

Loading...