Page 1

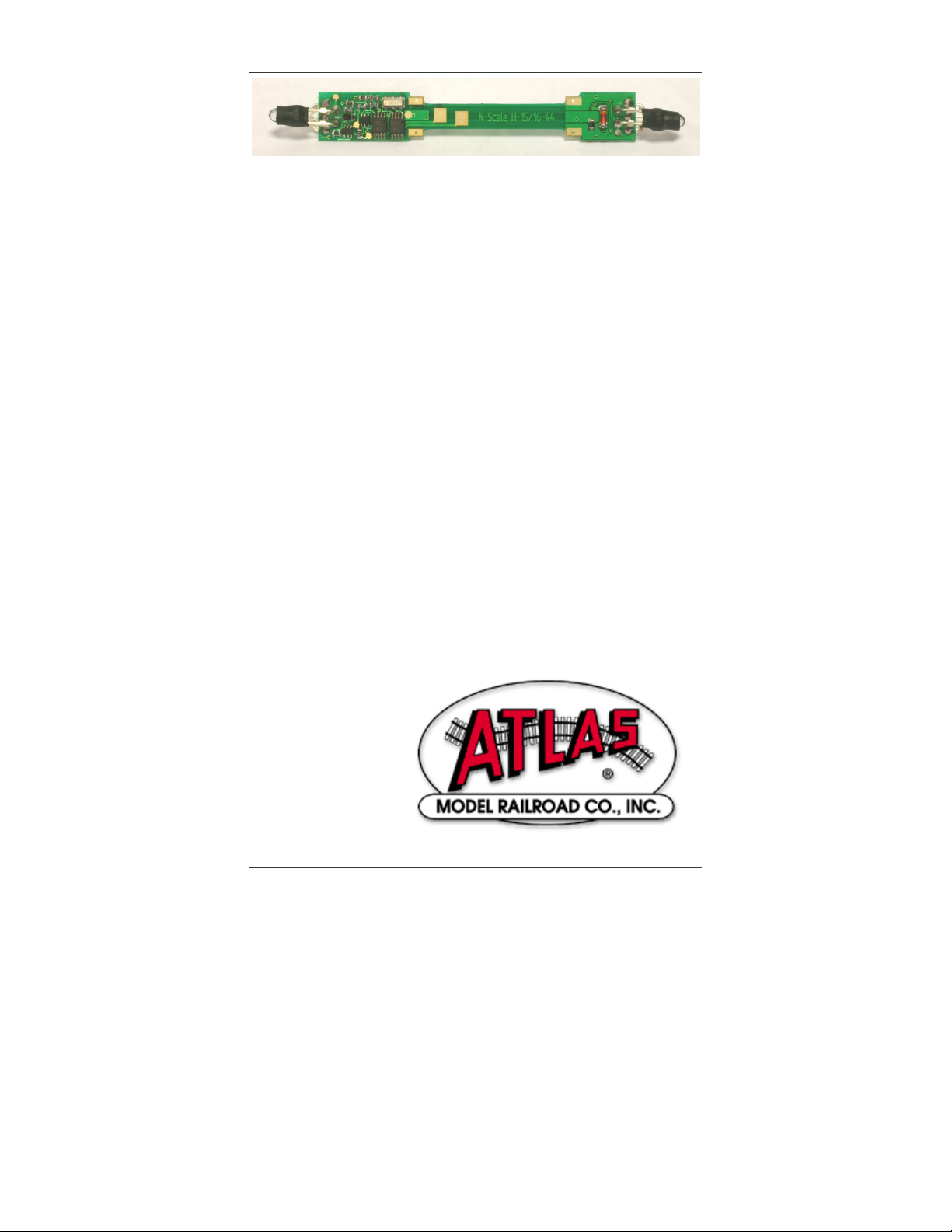

Decoder for Atlas N Scale H15/16-44 Locomotives

1

The #520099 DCC decoder is designed for Atlas N scale H15/1644 locomotives. The characteristics of this decoder are:

∗ Provides 0.5A continuous motor current.

∗ Has two function outputs with built-in white LED headlights that can be

configured for special effects including directional, independent, dimming,

Mars light, Gyro light, single Strobe, and double Strobe.

∗ Provides two additional function outputs with built-in bi-color LEDs that

provide directional green or red marker lights at front and rear and can be

configured for on/off control by a specified DCC function.

∗ Supports both short (2-digit) and long (4-digit) addressing.

∗ Supports advanced consist control (lashing up locomotives that have

different DCC addresses)

∗ Operates on conventional DC layouts; this feature may be disabled by

setting a CV.

∗ Provides full support for all forms of programming that are described in

NMRA RP-9.2.3.

∗ Supports both short form instructions and long form instructions in

operations mode programming (programming on the main line)

∗ Can be set for operation with 14/27 speed-steps, 28/55 speed-steps, or 128

speed-steps with direct drive.

∗ Can choose either Precision Glide Control or Silent Drive for motor control

DCC Decoder for Atlas N

Scale H15/16-44

Locomotives

Item # 520099

Revised 09/14/2004

Atlas Model Railroad Co., Inc.

Page 2

Decoder for Atlas N Scale H15/16-44 Locomotives 2

N Scale H15/16-44 DCC Decoder

The N-scale H15/16-44 DCC decoder can be used with all popular

NMRA-compliant DCC systems. This decoder is in full conformance with

all NMRA Standards and Recommended Practices and has been

augmented to work well with all major DCC systems on the market.

The N scale H15/16-44 decoder is packed with all the features that you

expect in a high-end decoder:

• Special lighting effects for front and rear headlights including

directional, independent, dimming, Mars light, Gyro light, single

Strobe, and double Strobe.

• Directional bi-color (green and red) front and rear marker lights.

• Supports both short (2-digit) and long (4-digit) addressing.

• Advanced consist control (operating and controlling several

locomotives as if they were a single entity by sending speed and

direction commands to a common consist address that is stored in

the decoder of every locomotive in the consist).

• Operations mode programming (programming on the main line).

•

Full support for all the various motor speed-step modes, including

the 128 speed-step mode

•

Choice of either Precision Glide Control or Silent Drive for motor

control.

Many characteristics of the H15/16-44 decoder can be programmed to

customize the decoder to its locomotive. Please read The Configuration

Variables and their Definitions section for details on the configuration

variables supported by the H15/16-44 decoder. The H15/16-44 decoder

supports all forms of programming described in NMRA Recommended

Practice 9.2.3, including the user friendly direct CV (Configuration

Variable) programming mode and operations mode programming. For

example, you can operate the decoder with the factory-default speed

curve, or you may specify your own customized speed curve. You can

also set which end of the locomotive is to be the forward end. You can

even decide whether or not you want to be able to operate the

locomotive on conventional DC layouts. If your DCC system supports

operations mode programming, you can change the values of all CVs

(except for the locomotive’s 2-digit, 4-digit, and consist addresses

in CV1, (CV17 and CV18), and CV19; respectively) while the

locomotive is on the main line.

.

Atlas Model Railroad Co., Inc.

Page 3

Decoder for Atlas N Scale H15/16-44 Locomotives

3

Lighting Options for the H15/16-44 Decoder

The H15/16-44 decoder has four function outputs: A, B, C, and D.

Decoder outputs A and B are designed to control the white LEDs used

for the front and rear headlights, respectively, in these locomotives. The

front and rear headlights can be configured by Bit 0 in CV51 to be either

directional or independently controlled. It is also possible to dim, using a

DCC function, either directional headlights or independently controlled

headlights.

If the headlights are configured for independent control, the front

headlight may be configured with the appropriate bits in CV51 to operate

as a Gyro light, a Mars light, a single pulse Strobe light, or a dual pulse

Strobe light. Similarly, when the headlights are configured for

independent control, the rear headlight may be configured with the

appropriate bits in CV57 to operate as a Gyro light, a Mars light, a single

pulse Strobe light, or a dual pulse Strobe light.

Decoder outputs C and D are designed to control the bi-color LEDs

used for the front and rear marker lights in these locomotives. Decoder

outputs C and D are auto-reversing so that the bi-color LEDs show

green in the direction that the locomotive is traveling and red in the

opposite direction. The only control over these marker lights is on or off.

By default, function F2 is used to turn these lights on or off. If desired,

this default setting can be changed simply by modifying CV54; by writing

the proper value into CV54, the marker lights can be switched on or off

by any function F1 through F8. If you are using a DCC system where

function F2 is momentary (e.g., Digitrax), it is recommended that you

remap F2 to another function with on/off control.

If you are using an NCE Power Pro DCC system, you will need to

change the values of two parameters in your command station to get

proper operation of the H15/16-44 directional marker lights. The Number

of Temp Packets must be changed from 5 to 8, and the Function Repeat

Rate must be changed from 0 to 250. Refer to the NCE System

Reference Manual for instructions on how to change the values of these

parameters.

The H15/16-44 decoder comes with two white LED

headlights and two bicolor marker light LEDs already

installed. The light outputs of this decoder are designed

only to drive these four LEDs. The Atlas warranty is void if

any of these LEDs are removed from the H15/16-44 circuit

board.

Atlas Model Railroad Co., Inc.

Page 4

Decoder for Atlas N Scale H15/16-44 Locomotives 4

Silent Drive or Precision Glide Control

The H15/16-44 decoder provides an option to use either Silent Drive or

Precision Glide Control for motor control. Silent Drive is best for

coreless motors and for applications were you want absolutely silent

operation. Precision Glide Control provides much more precise slow

speed operation because it pulses the motor to ensure the friction of the

motor and drive train does not interfere with the operation. The default is

Precision Drive Control. The motor control selection is made using

CV50.

Preparing to Install the H15/16-44 Decoder

Before installing the H15/16-44 decoder in your locomotive, it is

necessary to test (and adjust, if necessary) the locomotive for proper

operation on conventional DC power. Replace any worn out parts, such

as brushes. Also clean any dirt or oxidation from the wheels and pickups

to insure that electrical contact is good. Now is also a good time to

lubricate your locomotive. A locomotive that runs well under

conventional DC will also run exceptionally well under DCC.

Precautions to Take When Installing the Decoder:

Although the H15/16-44 decoder has many internal safeguards to

prevent damage, you must not allow any metal part of the locomotive to

touch surface components of the decoder other than the pickup pads on

the decoder that connect to the wheel-sets, the headlights, and the

motor. Any contact to other parts of the decoder can cause a direct

internal short circuit and destroy the DCC decoder.

The H15/16-44 decoder is not completely protected against static

electricity and has sensitive electronic parts. When installing this

decoder in your N scale locomotive, it is recommended that you wear a

grounded anti-static wrist strap. Also be careful in handling the decoder,

especially in the area around the top rear part of the decoder (the area

where the microprocessor is located).

Atlas Model Railroad Co., Inc.

Page 5

Decoder for Atlas N Scale H15/16-44 Locomotives

Step by Step Installation

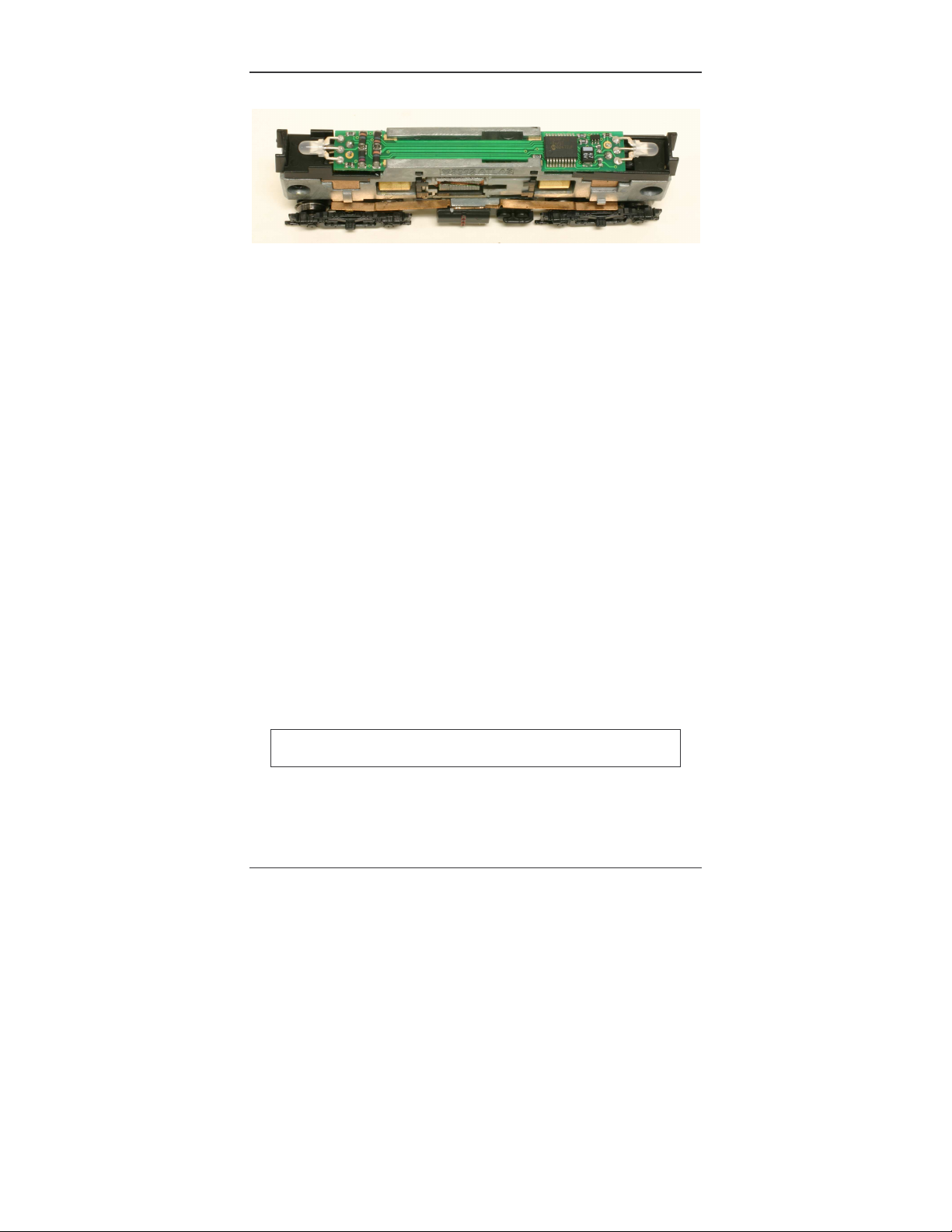

Figure 1: Installing the H15/16-44 decoder

In the following steps, please refer to the instructions provided with your

Atlas locomotive.

1) Remove the locomotive's body shell and fuel tank. Use care so as

not to damage any of the fragile parts.

2) Loosen the two screws that hold the frame together; these screws

are located at the front and rear of the frame.

3) Carefully remove the lighting control circuit board, which is located

at the top of the frame.

4) Place the decoder between the two halves of the frame so that the

two motor contact pads are at the bottom of the decoder and will

press firmly against the two copper contact strips from the motor

when the decoder installation has been completed. In the

photograph of the bottom of the H15/16-44 decoder on the first

page, these motor contact pads are the two rectangles in the

narrow center portion of the circuit board.

5) Carefully press the two frame halves together, with the sides of the

decoder inserted into the notches in the two halves of the frame.

Some pressure is needed to press the two frame halves together.

This pressure fit insures good electrical contact between the frame

and the decoder.

6) Tighten the two screws that hold the locomotive frame together.

7) Carefully check to make sure that the motor contact strips are not

touching either half of the frame. It is necessary to look down from

the top through the frame cutouts to check for such unwanted

shorts.

There must be NO electrical contact between the motor

contacts and any part of the frame

Place the locomotive (without its body shell) on your DCC programming

track and read back the locomotive's address from the decoder. If the

decoder is properly installed, you will be able to read back the factory

pre-set address 03. If your DCC system does not support reading

Atlas Model Railroad Co., Inc.

5

Page 6

Decoder for Atlas N Scale H15/16-44 Locomotives 6

decoder properties, observe carefully the decoder's behavior while on

the isolated programming track. Each time you try to program the

decoder you can see the acknowledgement that is sent by the decoder

in the form of a brief and minor jerk of the locomotive. A successful

acknowledgement means that you have installed the decoder correctly.

Remove the locomotive from the programming track and, if necessary,

correct any installation errors. Once you have successfully programmed

the decoder, reinstall the body shell and retest the locomotive on the

programming track. If this test is successful, the locomotive is ready to

use.

Programming the H15/16-44 Decoder

The H15/16-44 decoder supports all forms of both service mode

(programming on an isolated programming track) and operations mode

programming (programming on the main line). Using any of these

programming methods, many features (such as the locomotive's

address, acceleration, and configuration) can be customized to the

individual locomotive in which the decoder is installed. These

customized properties will be saved in non-volatile memory locations on

the decoder so that they will retain their values even after power has

been removed. All parameter values are set electronically, which means

that the locomotive does not need to be opened again after the decoder

has been installed to read or modify the values of these so-called

Configuration Variables (CVs). The H15/16-44 decoder has a total of

128 CVs. Not all of them are used at this time because many have been

reserved for future use.

Any NMRA-compliant DCC Command Station, such as the Atlas Master

Commander, can be used to program the H15/16-44 decoder. With

several entry-level systems, only CV #1 (the locomotive address) can be

set unless you use a separate DCC programmer. More advanced DCC

systems, including the Atlas Commander, support the ability to set many

more CVs. The H15/16-44 decoder supports all programming modes

and can be programmed by all NMRA-compliant DCC systems. The

locomotive’s 2-digit and 4-digit addresses in CV1, CV17, and CV18

CANNOT be programmed in operations mode. Instructions for

reading and writing CVs are given in the user manual of your DCC

system.

Note: for newly programmed CV values to take effect after service

mode programming, the decoder must go through a power reset. If

your DCC command station does not support automatic power

reset, simply rock the locomotive off the track after programming.

Atlas Model Railroad Co., Inc.

Page 7

Decoder for Atlas N Scale H15/16-44 Locomotives

7

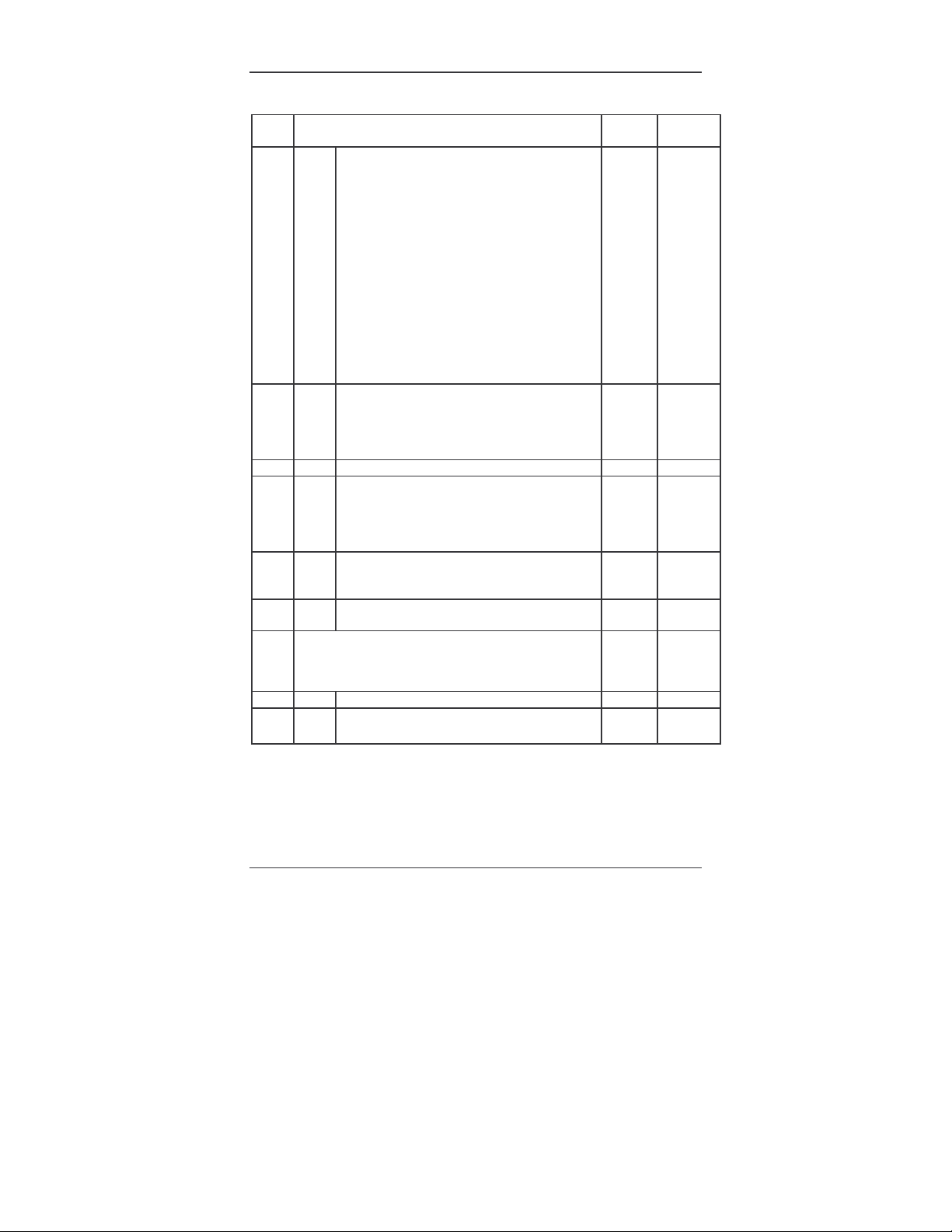

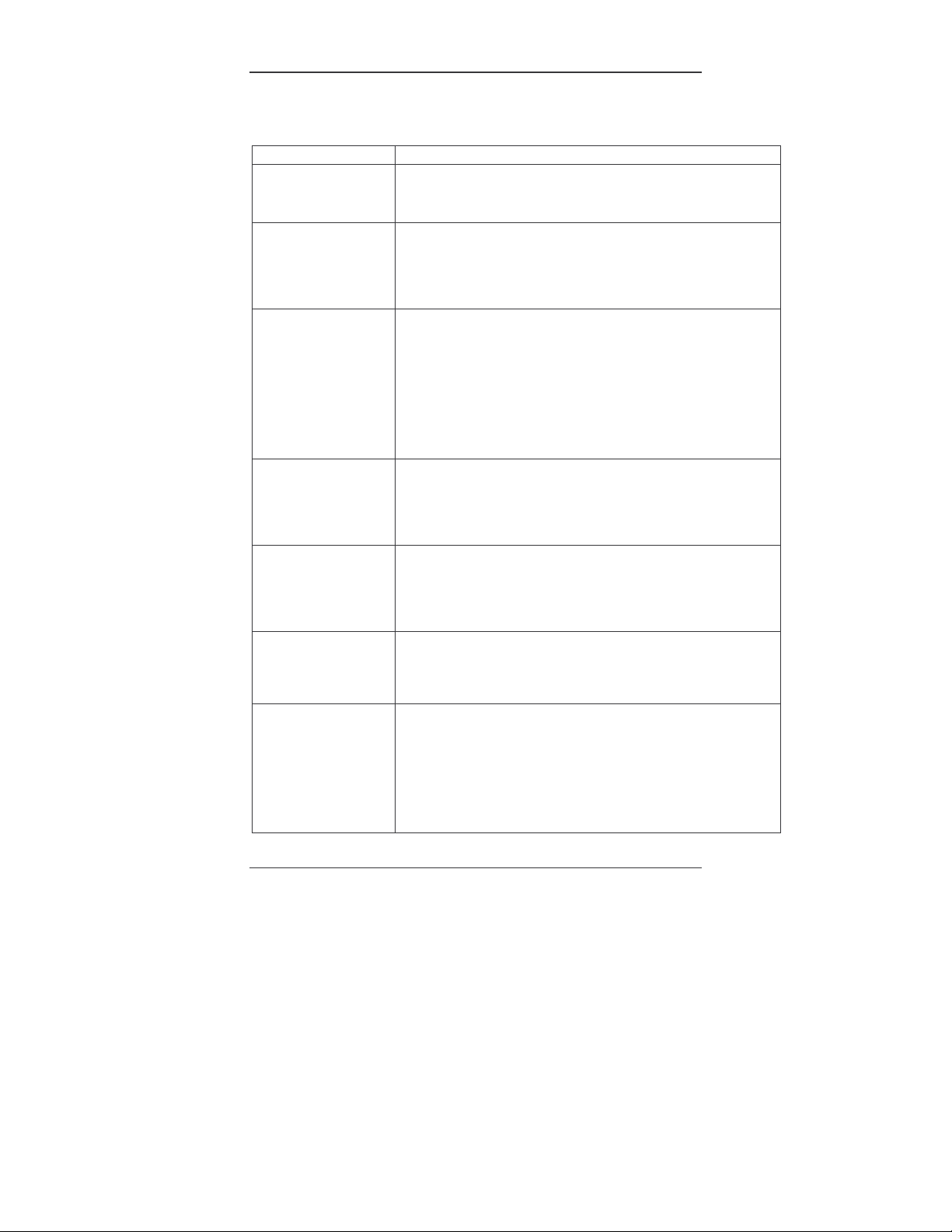

Configuration Variables and their Definitions

The H15/16-44 decoder supports a full range of features, which are

activated by setting Configuration Variables. All CVs are numbered.

These numbers are used during programming and are identical for all

decoders that conform to NMRA standards, regardless of the decoder

manufacturer. The following table lists the CVs supported in the H15/1644 decoder. Both CV numbers and Register numbers are provided for

cross-reference.

Some CVs (such as CV29) have specific meanings for each bit. To

conform to the NMRA convention for bit numbering, the CV bit

assignments shown in this table use the bit-numbering scheme of 0 to 7.

Table 1: Configuration Variables (CVs) for the

H15/16-44 Decoder

CV Reg. Description Range Default

1 1 Short address:

This is the number that you enter into your DCC

system to tell it which locomotive you wish to run

with a short (2-digit) address.

2 2 Start voltage:

This is the voltage applied to the motor in speed

step 1. Set this value so that the locomotive is

barely moving in speed step 1.

3 3 Acceleration Momentum:

Determines the rate of change of speed upon

acceleration. A higher value leads to a slower

acceleration.

4 4 Brake Momentum:

Determines the rate of change of speed upon

braking. A higher value leads to longer braking

distances.

- 5 Contains CV29 (see definition of CV29 below)

- 6 Page Register:

Normally this Register is not modified directly by

a user. For correct operation, R6 should be set to

have the value “1” after any use.

7 7 Version Number:

This location stores the version number of the

decoder. This CV is read-only.

1-99 3

0-31 8

1-255 1

1-255 1

0-55 6

0-127 1

- 46

Value**

Atlas Model Railroad Co., Inc.

Page 8

Decoder for Atlas N Scale H15/16-44 Locomotives 8

CV Reg. Description Range Default

Value**

8 8 Manufacturers Identification:

17

18

19

29 Decoder Configuration, Byte 1:

This value is the manufacturer ID of the decoder,

(Atlas=127). Writing the decimal number “33”

to this Register will reset all CVs in the

decoder to their factory-default values

EXCEPT FOR the speed step settings in CV67

to CV94.

-

Long Address, High Byte

The long (also called extended) address, if used,

is contained in CV17 and CV18.

-

Long Address, Low Byte

-

Advanced Consist Address

The Advanced Consist address, if used, is

stored in CV19.

Several decoder properties are set with CV29. Changes

are easiest if done in binary mode, but can also be done

by adding together the decimal values (shown in

parenthesis) for all the desired features and writing the

total into CV29. (For an example, see the section

Converting Binary Values of Individual Bits within a

Configuration Variable into the Equivalent Decimal Value

of the Entire CV.)

The definitions for the individual bits of CV29 are given

below.

Bit 0

Locomotive direction:

This bit sets the direction that the locomotive will

move when told to move forward in digital (DCC)

mode.

0 = locomotive’s direction is normal

1 = locomotive’s direction is reversed

- 127

192231

0-255 0

1-99 0

0-55 6

0,1 0

0

(1)

Atlas Model Railroad Co., Inc.

Page 9

Decoder for Atlas N Scale H15/16-44 Locomotives

CV Description Range Default

Value**

29

Bit 1

Headlight mode:

0 = Operation with 14 or 27 speed-step

systems. This setting must be selected when

the locomotive decoder is used with any

DCC system that does not support the 28

speed-step mode. If the headlights turn on

and off as the speed is increased, the

command station is configured for 28 speedsteps, and the decoder is set for 14 speedsteps.

1 = Operation with 28, 55 or 128 speed

steps. If you use this setting, the Command

Station must also be configured to use either

the 28 speed-step mode or the 128 speedstep mode; otherwise, the headlights cannot

be controlled.

Bit 2

Usage on conventional DC layouts:

0 = locomotive operates only in digital (DCC)

mode

1 = locomotive can operate in either analog

(conventional DC) or digital (DCC) mode

Bit 3 Always 0 0 0

Bit 4

Speed curve:

0 = Factory-default speed curve is used

1 = User-defined speed curve is used.

Please enter the appropriate values into CVs

67 to 94 before setting this bit.

Bit 5

Bit 6

50 Decoder Configuration, Byte 2:

Bit 0 Not used 1

2-digit or 4-digit Addressing:

0= Short (2-digit) address used

1= Long (4-digit) address used

Not used

Bit 7

Both bits always 0

CV50 is similar to CV29, but CV50 is used to set

other properties. The definitions for the individual bits

of CV50 are given below.

Not used.

Bit 1

0,1 1

(2)

0,1 1

(4)

0,1 0

(16)

0,1 0

(32)

0

0 - 12 1

0

9

Atlas Model Railroad Co., Inc.

Page 10

Decoder for Atlas N Scale H15/16-44 Locomotives 10

CV Description Range Default

Value**

50

Bit 2

Brake momentum on DC operation.

Used to achieve prototypical braking at red

signal indications if conventional DC control

is disabled. (CV29.2 = 0*)

0 = locomotive proceeds with track-voltage-

dependent speed inside the conventional DC

section.

1 = locomotive brakes in the conventional DC

section with preset brake momentum.

Bit 3 Motor Drive Selection

Bits

51 Lighting Effects for Output A (front headlight)

Bit 0

Bit 1

Bit 2

Bit 3 Not used 0

0 = Precision Glide Control

1 = Silent Drive

Not used 0

4-7

Directional or Independent Headlights:

0 = Headlights are directional.

1 = Headlights are independent per Rule

17, with F0 controlling front headlight and F1

controlling rear headlight.

Front Headlight Dimming Control:

If CV51.2=1, the value in CV52 is used for

front headlight dimming with the dimming

controlled as follows:

CV51.1=0: Front headlight always dimmed

CV51.1=1: If CV51.0=0, function F1 dims

front headlight; if CV51.0=1, function F4 dims

front headlight.

Dimming of Front Headlight:

0 = Front headlight cannot be dimmed

1 = Front headlight can be dimmed

0,1 0

(4)

0,1 0

(8)

0-247 6

0,1 0

(1)

0,1 1

(2)

0,1 1

(4)

Bit 4 0 = No effect

1 = Front headlight functions as Gyro light

Bit 5 0 = No effect

1 = Front headlight functions as Mars light

Bit 6 0 = No effect

1 = Front headlight functions as single pulse

Strobe light

Bit 7 0 = No effect

1 = Front headlight functions as double pulse

Strobe light

0,1 0

(16)

0,1 0

(32)

0,1 0

(64)

0,1 0

(128)

Atlas Model Railroad Co., Inc.

Page 11

Decoder for Atlas N Scale H15/16-44 Locomotives

CV Description Range Default

Value**

Notes for CV51:

51

Bits 4 to 7 of CV51 are effective if and only if CV51.0=1.

Dimming is inactive if any of bits 4 to 7 are set to “1.”

If more than one of Bits 4 to 7 of CV51 is set to “1,” only the highest

numbered of these bits is effective.

52

Dimming for Output A (front headlight)

The value in CV52 is used to dim the front headlight.

Using the value “0” for this CV results in a completely

dark front headlight, when it is dimmed.

Using the value “255” keeps the front headlight at its

maximum possible brightness, even when dimmed.

54

Function Mapping for Outputs C and D (front and

rear marker lights)

Bit 0

0 = No effect

1 = Marker lights controlled by F1

Bit 1

0 = No effect

1 = Marker lights controlled by F2

Bit 2

0 = No effect

1 = Marker lights controlled by F3

Bit 3

0 = No effect

1 = Marker lights controlled by F4

Bit 4

0 = No effect

1 = Marker lights controlled by F5

Bit 5

0 = No effect

1 = Marker lights controlled by F6

Bit 6

Bit 7

57 Lighting Effects for Output B (rear headlight)

Bit 0 Not used 0

Bit 1

Bit 2

0 = No effect

1 = Marker lights controlled by F7

0 = No effect

1 = Marker lights controlled by F8

Rear Headlight Dimming Control:

If CV57.2=1, the value in CV58 is used for

front headlight dimming with the dimming

controlled as follows:

CV57.1=0: Rear headlight always dimmed

CV57.1=1: If CV51.0=0, function F1 dims

rear headlight; if CV51.0=1, function F4 dims

rear headlight.

Dimming of Rear Headlight:

0 = Rear headlight cannot be dimmed

1 = Rear headlight can be dimmed

0-255 64

0-255 2

0,1 0

(1)

0,1 1

(2)

0,1 0

(4)

0,1 0

(8)

0,1 0

(16)

0,1 0

(32)

0,1 0

(64)

0,1 0

(128)

0-246 6

0,1 1

(2)

0,1 1

(4)

Atlas Model Railroad Co., Inc.

11

Page 12

Decoder for Atlas N Scale H15/16-44 Locomotives 12

CV Description Range Default

Value**

Bit 3 Not used 0

57

Bit 4 0 = No effect

Bit 5 0 = No effect

Bit 6 0 = No effect

Bit 7 0 = No effect

58

67

to

94

128 Decoder Software Version – read only

1 = Rear headlight functions as Gyro light

1 = Rear headlight functions as Mars light

1 = Rear headlight functions as single pulse

Strobe light

1 = Rear headlight functions as double pulse

Strobe light

Notes for CV57:

Bits 4 to 7 of CV57 are effective if and only if CV51.0=1.

Dimming is inactive if any of bits 4 to 7 are set to “1.”

If more than one of Bits 4 to 7 of CV57 is set to “1,” only the highest

numbered of these bits is effective.

Dimming for Output B (rear headlight)

The value in CV58 is used to dim the rear headlight.

Using the value “0” for this CV results in a completely

dark rear headlight, when it is dimmed.

Using the value “255” keeps the rear headlight at its

maximum possible brightness, even when dimmed.

Speed Step Values for Customized Speed Curve

These CVs are used to specify the speed step

values for a customized speed curve. The factorydefault values for these CVs are specified in Table 2

in the section Creating a Customized Speed Curve.

0,1 0

0,1 0

0,1 0

0,1 0

0-255

1

(16)

(32)

(64)

(128)

Factory

Default

Speed

Step

Values

* The notation CVx.y = z means that bit y of CVx has the value ”z”. For

example, CV29.2 = 0 means that bit 2 of CV29 has the value ”0.”

** In the Default Value field, the numbers shown in parenthesis () are the

decimal values that must be written into a CV for the specified bit of that

CV to have the binary value “1”.

Atlas Model Railroad Co., Inc.

Page 13

Decoder for Atlas N Scale H15/16-44 Locomotives

13

Converting Binary Values of Individual Bits within

a Configuration Variable into the Equivalent

Decimal Value of the Entire CV

Reasons for Setting and Clearing the Individual Bits of a

Configuration Variable

To make a DCC decoder perform in the manner that you wish, you

sometimes need to set or clear individual bits of a CV. To program a

DCC decoder using a DCC system that allows only the writing of

decimal values into CVs (such as the Atlas Master Commander), it is

first necessary to convert the values of all the individual bits of that CV

that are to be set to the binary value 1 into their equivalent decimal

values. It is then necessary to add together all of these equivalent

decimal values.

Procedure for Converting Individual CV Bit Values into a

Decimal Equivalent Value for the CV

The following table illustrates how to calculate the decimal value that

must be written into a CV to set and/or clear a specified set of

individual bits within that CV.

Each bit of a CV that is to be set to the

binary value “1” can be represented by the

equivalent decimal number shown in the

second column of this table. To determine

the equivalent decimal value to be written

into the CV, first write in column 3 of this

table the decimal equivalent values of all

the bits of the CV that are to be set to a

binary 1. Write nothing in column 3 for

each bit of the CV that is to be cleared,

i.e., set to a binary 0. Then add up all the

numbers that you have written in column

3. The sum that you get is the equivalent

decimal value you need to write into the

CV.

Bit

Number

0 1

1 2

2 4

3 8

4 16

5 32

6 64

7 128

Decimal

Equivalent

SUM:

Decimal

Values for

CV

Calculation

Atlas Model Railroad Co., Inc.

Page 14

Decoder for Atlas N Scale H15/16-44 Locomotives 14

Example: Calculating the Default Value for CV29

From the definition of CV29 given in Table

1, we see that the default values of bits 1

and 2 are binary 1s; whereas, all other bits

in CV29 have a default value of binary 0.

To compute the decimal equivalent default

value of CV29, simply write in the

rightmost column of this table the number

"2" for bit 1 and the number "4" for bit 2.

Then add up all the non-zero numbers that

you have entered into this rightmost

column. Since the sum of these numbers

is 6, the decimal number to be

programmed into CV29 is 6.

Bit

Number

0 1

1 2

2 4

3 8

4 16

5 32

6 64

7 128

Decimal

Equivalent

Decimal

Values for

CV

Calculation

2

4

SUM: 6

Atlas Model Railroad Co., Inc.

Page 15

Decoder for Atlas N Scale H15/16-44 Locomotives

15

Creating a Customized Speed Curve

Common reasons for specifying a customized speed curve for a DCCequipped locomotive are to:

(1) Insure that dissimilar locomotives have the same performance

characteristics

(2) Have model locomotives perform more prototypically

In this example of creating a customized speed curve, we will assume

that the H15/16-44 decoder has been properly installed and tested. We

also assume that you are familiar with the general process of

programming CVs using your DCC system.

The first step in creating a customized (non-default) speed curve is to

assign a value to each internal speed step. This assignment is done by

specifying a value for each of the CVs from CV67 to CV94 using a table

such as that below, but substituting your desired speed step settings for

the default CV values given in the Internal Speed Step Value column of

this table.

The second step in creating a customized speed curve is to write the

value listed in the Internal Speed Step Value column into the CV

corresponding to that speed step.

The third and final step is to activate your customized speed curve by

writing the binary value “1” into bit 4 of CV29 (i.e., CV29.4 =1). Unless

this bit in CV29 has been set to a binary 1, the default speed curve that

was preset into the decoder at the factory will be used.

Atlas Model Railroad Co., Inc.

Page 16

Decoder for Atlas N Scale H15/16-44 Locomotives 16

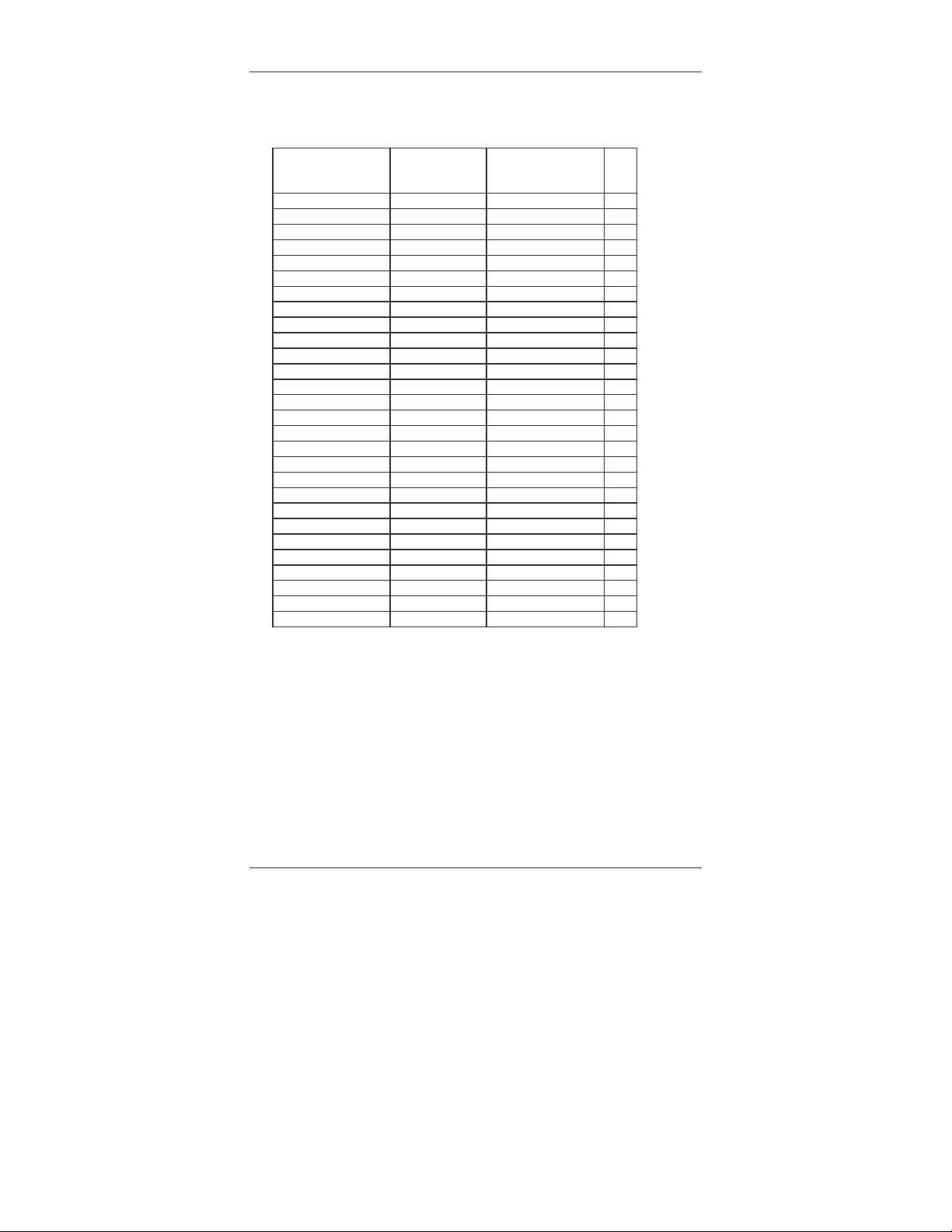

Table 2: Default Speed Step Values for Decoder in

N Scale H15/16-44 Locomotives

Speed Step

in

14/27 Step Mode

1 1 4 67

2 8 68

2 3 12 69

4 16 70

3 5 20 71

6 26 72

4 7 32 73

8 38 74

5 9 44 75

10 50 76

6 11 58 77

12 66 78

7 13 74 79

14 82 80

8 15 90 81

16 100 82

9 17 110 83

18 120 84

10 19 130 85

20 140 86

11 21 152 87

22 164 88

12 23 174 89

24 186 90

13 25 200 91

26 216 92

14 27 234 93

- 28 254 94

To calculate the correct speed-step value for the 128 speed-step mode,

the H15/16-44 decoder will internally average the values for 28 speed

steps that were specified in (CVs 67 to 94).

Speed Step

in

28 Step Mode

Internal speed

step value

(defaults shown)

CV

Atlas Model Railroad Co., Inc.

Page 17

Decoder for Atlas N Scale H15/16-44 Locomotives

17

Troubleshooting Decoder Programming Problems

Fault Cause and Solution

Locomotive does not

move when you

address it on DCC

system.

Locomotive does not

move when DCC

system is set to the

address in CV1, even

though this address can

be read from CV1.

Locomotive does not

move when DCC

system is set to the

short address in CV1.

The short address can

be read from CV1, and

DCC functions can be

activated when the

DCC system is set to

the address in CV1.

DCC functions can be

activated when DCC

system is set to the

locomotive address, but

the locomotive does not

move.

The locomotive does

not appear to be using

the customized speed

curve values that you

have entered into CVs

67 to 94.

Function 0 (lighting)

cannot be switched on

and off.

Locomotive headlights

are only illuminated

when the locomotive

speed is increased or

decreased; the

locomotive headlights

go on and off as the

locomotive speed

changes.

Check to see if you have selected the correct address for that

locomotive.

You have entered the short address (CV1), but the decoder is set to

use the long address, i.e., bit 5 of CV29 has been set.

Use the long address or else clear bit 5 of CV 29.

Check to see if an advanced consist address has been

programmed into CV19, i.e., check to see if CV19 has a value

greater than 0. If CV19 has a non-zero value, you must either use

this advanced consist address to operate the locomotive or program

the value 0 into CV19.

Decoder is set to use a customized speed curve (CV29.4 = 1), but

you entered zero values into CVs 67 to 94. Either clear bit 4 of

CV29 or enter suitable non-zero speed step values into CVs 67 to

94.

Bit 4 is not set to “1” in CV29.

Matching of speed steps is incorrect: The decoder has been set to

28/128 speed steps, but the DCC system has been set to 14/27

speed steps.

Either set the DCC system to 28/128 speed steps or change the

decoder speed step setting to 14/27 speed steps. (CV29.1 = 0).

Matching of speed steps is incorrect: The decoder has been set to

14/27 speed steps, but the DCC system has been set to 28/128

speed steps. Either set the DCC system to 14/27 speed steps or

change the decoder speed step setting to 28/128 speed steps.

(CV29.1 = 1).

Atlas Model Railroad Co., Inc.

Page 18

Decoder for Atlas N Scale H15/16-44 Locomotives 18

Atlas Limited One-Year DCC Decoder Warranty

Please fill out and mail the warranty card, within 30 days of

purchase. Atlas Model Railroad Company, Inc. warrants that this

decoder will be free from defects in material and workmanship

for a period of one year from the date of purchase. If this

decoder fails during the warranty period, uninstall and carefully

pack the item in the original carton, together with the dated sales

receipt, and return to:

Atlas Model Railroad Company, Attention HO/N Repair, 378

Florence Avenue, Hillside, NJ 07205. Defects due to misuse,

improper maintenance and/or abuse are not covered by the

warranty. This warranty gives you specific legal rights and you

may also have other rights, which vary from state to state.

For Technical Assistance

www.atlasrr.com

dcc@atlasrr.com

This equipment complies with Part 15 of FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause undesired operation.

Please save this manual for future reference.

Lenz GmbH manufactures the H15/16-44 decoder for Atlas Model Railroad Co., Inc.

© 2004 Atlas Model Railroad Co, Inc; All Rights Reserved.

Atlas Model Railroad Co., Inc.

Loading...

Loading...