Atlantic TA1800, TA3600 Product Manual

Product Manual | Manuel du Produit | Manual del Producto

1.330.274.8317

www.ATLANTICWATERGARDENS.com

M

TA1800 / TA3600

Introduction

Thank you for purchasing Atlantic’s Typhoon TA1800/TA3600 Air Pump. Before using this air

pump please take a moment to review this manual.

This pump is designed to pump air. The oil-free, double damping air pump system

produces a large volume of air with little noise. The aluminum casing and outer housing

cover dissipate heat quickly and shield the compressor from the elements in an outdoor

application.

Atlantic’s Typhoon Air Pump may be used in a variety of water-related applications

including oxygenation of ponds and aquariums and de-icing of outdoor ponds.

To avoid an accident, do not use the pump in any way other than as described in this

manual. Please note the manufacturer cannot be responsible for accidents arising because

the product was not used as prescribed. After reading this manual keep it as a reference in

case questions arise during use.

2

Prior to Operation and Installation

When the pump is delivered, first perform the following checks:

• Check for any damage to pump and power cable that may have occurred during shipping.

• Check the model number to make sure it is the product that was ordered and verify the

voltage and frequency are correct.

Caution

• DO NOT operate this product under any condition other than those for which it is specified.

Failure to observe this precaution can lead to electrical shock, electrical leakage, fire, water

leakage or other problems.

• Please only use with a power supply voltage within 110-120 volt 60 Hz.

• Always turn o power or unplug the pump prior to performing any maintenance or placing

your hands into the water.

• CAUTION:

THIS AIR PUMP IS TO BE USED IN A CIRCUIT PROTECTED BY A GROUND FAULT

CIRCUIT INTERRUPTER.

• WARNING:

RISK OF ELECTRIC SHOCK - THIS PUMP IS SUPPLIED WITH A GROUNDING CONDUCTOR AND

GROUNDING-TYPE ATTACHMENT PLUG. TO REDUCE THE RISK OF ELECTRIC SHOCK, BE CERTAIN

THAT IT IS CONNECTED ONLY TO A PROPERLY GROUNDED, GROUNDING TYPE RECEPTACLE.

AIR PUMP OUTPUT

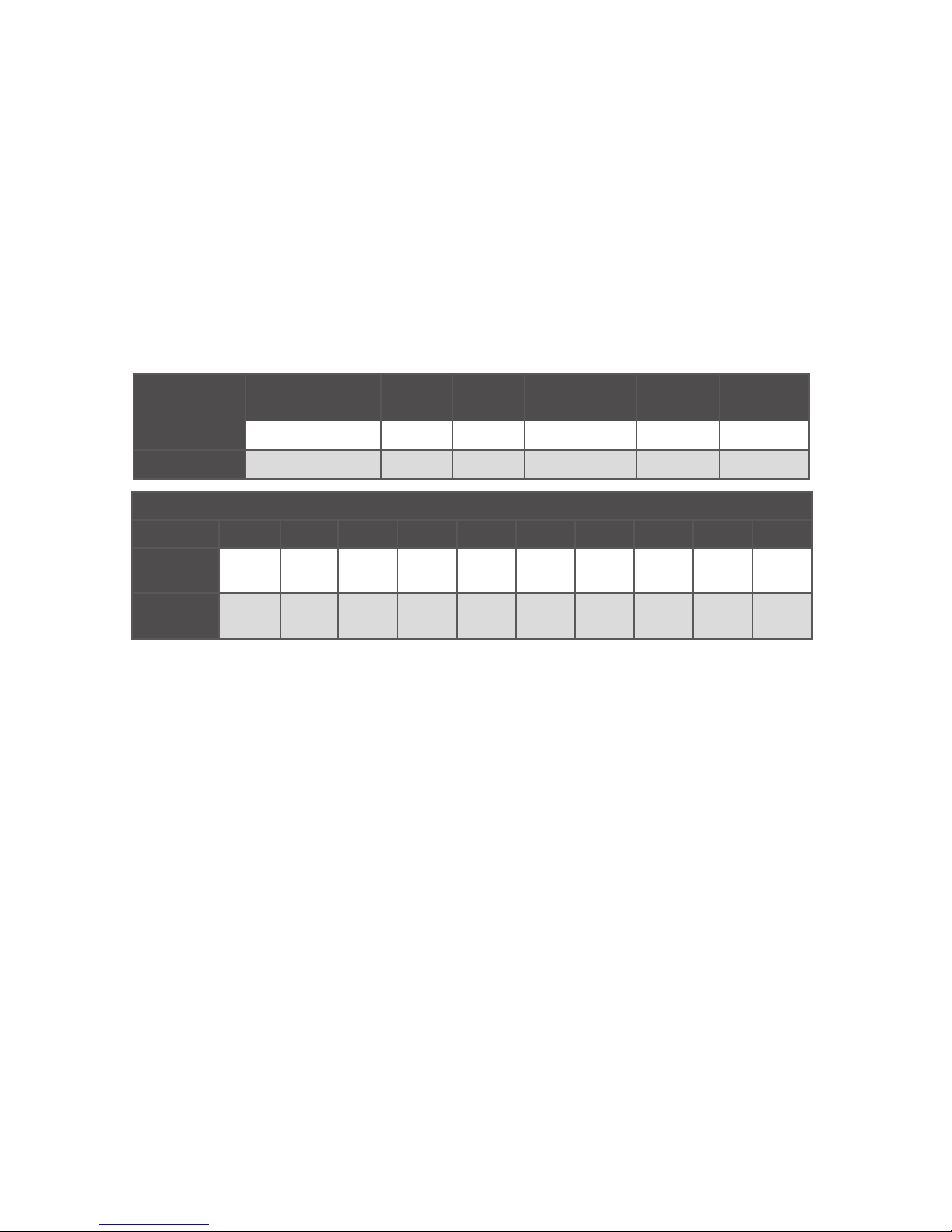

MODEL MAX @ 1' @ 2' @ 3' @ 4' @ 5' @6' @8' @10'

TA1800

LPM /

CFM

30 /

1.06

25 /

0.88

21 /

0.74

17 /

0.60

13 /

0.46

9 /

0.32

4 /

0.14

--- ---

TA3600

LPM /

CFM

60 /

2.12

54 /

1.91

47 /

1.66

40 /

1.41

34 /

1.2

28 /

0.99

23 /

0.81

12 /

0.42

2 /

0.07

MODEL OUTLET VOLTS WATTS

MAX

PRESSURE

MAX

DEPTH

CORD

LENGTH

TA1800

⅜" insert, ½" slip 115 25 3 psi 7’ 6'

TA3600

⅜" insert, ⅝" slip 115 35 5 psi 11’ 6'

3

Electrical Safety

• Electrical wiring should be installed by a qualified electrician in accordance with all

applicable safety regulations. Incorrect wiring can lead to pump malfunction, electrical

shock or fire.

• Air Pumps must be protected by a ground fault circuit interrupter (GFCI).

• Air Pumps must be plugged into a standard, properly grounded, three pronged outlet.

Safety Instructions

• If the pump falls into the water, do not reach for it. First unplug the air pump or disconnect

the power supply and then retrieve the pump. Let a qualified technician inspect the pump if

immersion occurs.

• Do not lift, lower or handle the pump by pulling on the electrical cord. Make sure the

electrical cable does not become excessively bent or twisted and does not rub against a

structure in a way that might damage it.

• The submersible pump should not be used if the electrical supply cable is damaged in

any way. If a cable with damaged insulation is submerged in water, there is danger of

ATTENTION

Typhoon air pumps are NOT submersible, and must be

placed in a secure area away from the water’s edge.

water seeping into the pump motor and causing a short. Altering the electrical cable in any

way will void the warranty.

Installation

Pump Placement

The following factors must be considered when choosing a location for the air pump.

• Typhoon Air Pumps feature weather-proof aluminum housings for outdoor use. However,

installation in a dry, well-ventilated area will further prolong the service life of the air pump.

• Typhoon Air Pumps must be placed on a flat, stable surface above the water level of

the pond.

• Proper ventilation is critical for heat dissipation and operation. Never cover the air pump

unless adequate airflow to the pump is provided.

• Tubing must always be run on a downward slope away from the air pump to avoid

condensation damage.

Air Pump Connections

Typhoon Air pumps will accept multiple sizes of tubing. Please refer to the chart on page 2 for

acceptable tubing diameters for these Air Pumps. Using large diameter tubing and avoiding

sharp bends will improve performance of this air pump after installation.

• Multiple air stones can be connected to the pump outlet by adding a 2-way air splitter.

Use new and suciently large air stones with enough discharge capacity. Air stones that are

too small, old, worn out or placed too deep will reduce the output capacity. Place air stones no

deeper than 7’ (TA1800) and 11’ (TA3600) below the surface of the water. Avoid kinks and tight

turns in the tubing run and take care to never fully close o the pump outlet. Ensure that the

pump can discharge sucient air at all times, otherwise the pump will overheat leading to

diaphragm and compressor failure. Please note that an ambient temperature above 110° F can

cause the diaphragm to overheat and crack.

4

To prevent any water from flowing back into the pump when powered o, it is advisable to

install the pump above water level. Tubing must run at a downward slope away from the

compressor. The use of an inline check valve is also recommended to further prevent

moisture damage.

Service & Maintenance

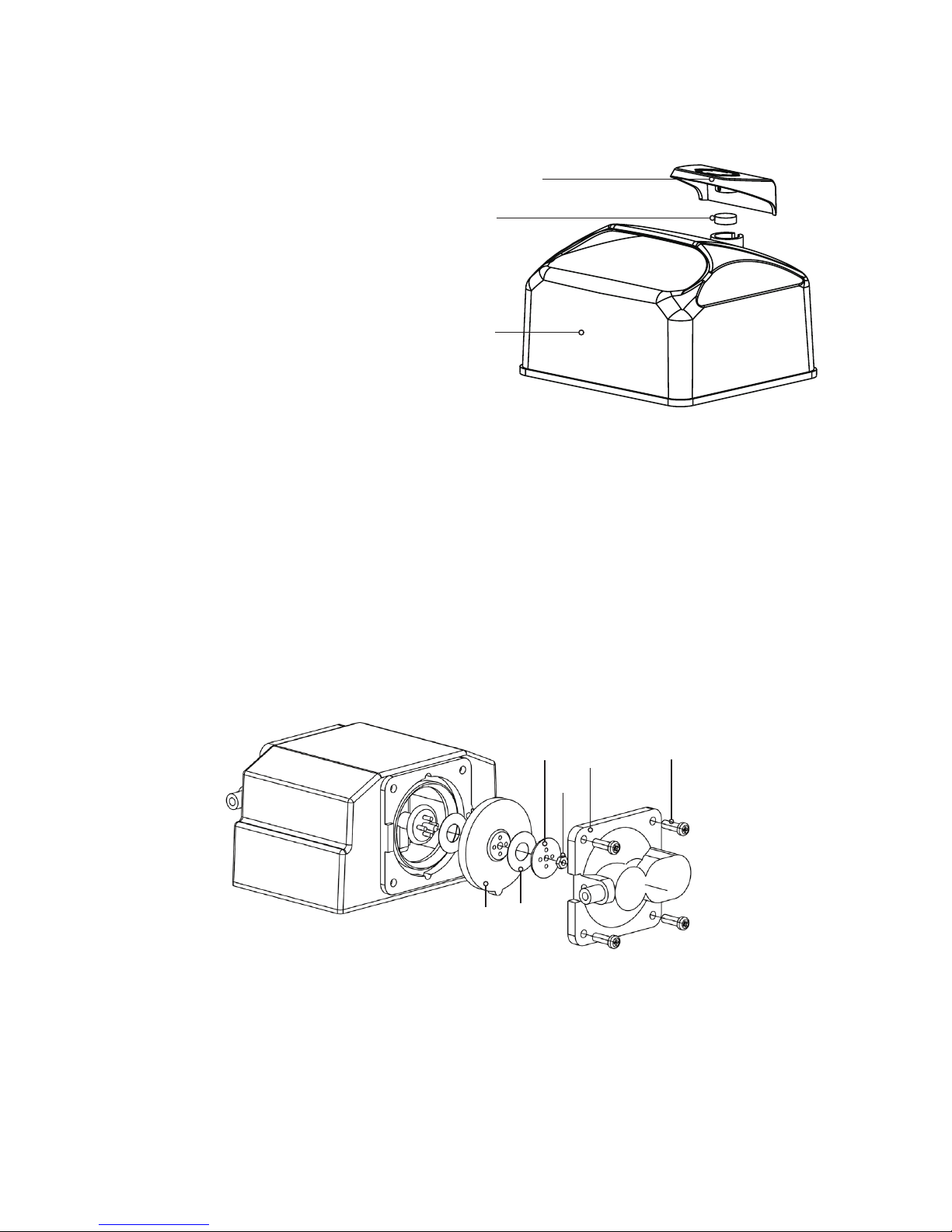

Dust and debris blocking the air intake

may cause abnormal noises or result

in a failure of the pump. Periodic

cleaning of the air intake and

sponge is recommended:

• Unplug the air pump before cleaning

or replacing the air intake sponge.

• Remove the air intake cover, intake

filter and clean with mild detergent.

• Rinse the components thoroughly and

allow to dry completely before reinstalling.

Diaphragm replacement

Rubber diaphragms are a wearable part that will need servicing over time. Moisture, heat and

dust will all shorten the life of the diaphragms. Please follow the following steps when

installing replacement diaphragms.

• Remove the top cover housing for the air pump. Loosen the air chamber screws (1) and

remove the outer air chamber (2).

• Loosen the diaphragm nut (3) and remove the diaphragm depressor (4), electrostatic

membrane (5) and the damaged diaphragm (6).

• Install the new diaphragm ensuring that the rubber tabs align properly with the notches

on the inner air chamber.

• Once the diaphragm is seated properly, assemble the components by following the

previous steps in reverse order.

Warranty

All Typhoon Air Pumps carry a three-year limited warranty. This limited warranty is extended

solely to the original purchaser commencing from the date of original purchase receipt and is

void if any of the following apply:

• The cord has been cut or altered.

• The pump has been misused or abused.

• The pump has been disassembled other than as described in this manual.

• Serial number tag has been removed.

Air Intake Cover

Air Intake

Filter Sponge

Top Cover

Housing

6

5

4

3

2

1

5

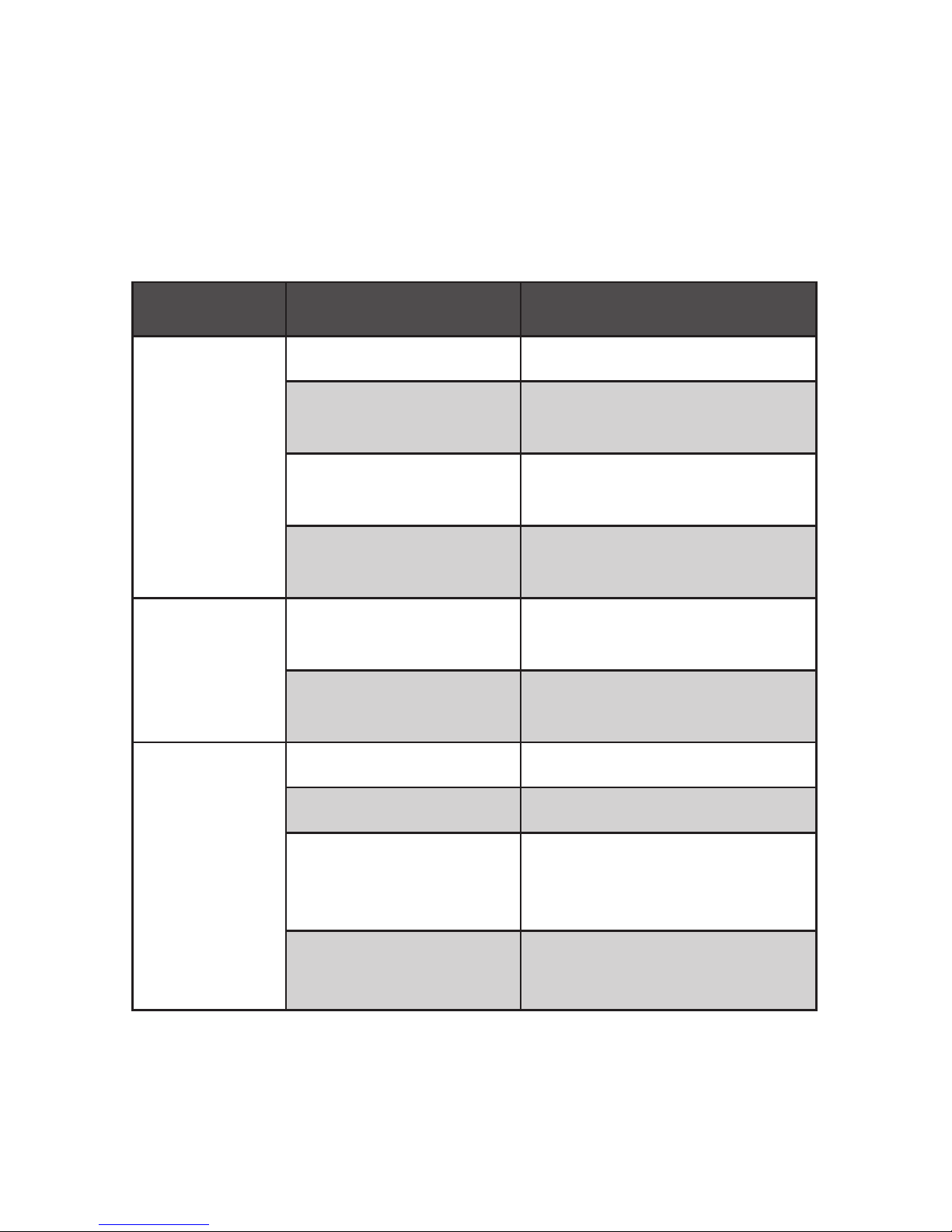

Problem Possible Cause Possible Solution

Air pump does

not run

Power is o Turn power on

Power failure

Check power supply or

contact local power company

Voltage drop/ Overload

Check/Replace the GFI (Ground

Fault Interrupter)

Power cord is not connected Connect power cord

Air pump stops

after starting

Air pump is

overheating

Allow pump to cool

Power/Current overload

Check length/size of power cable.

Check or replace GFI

Diminished

air flow rate or

no air flow

Kinked/damaged tubing Repair/replace tubing

Dirty filter media Clean filter media

Worn/damaged diaphragm

Consult your dealer. Replace

diaphragm and flappers

Air line is submerged

below operating depth

Raise air line to desired depth

Warranty Claims

In case of warranty claims, the air pump should be returned to place of purchase

accompanied by original receipt.

Troubleshooting Guide

Always turn o power before inspecting the pump. Failure to observe this precaution can

result in a serious accident.

Before ordering repairs, carefully read through this instruction booklet. If the problem persists,

contact your dealer.

Loading...

Loading...