Page 1

MAINTENANCE AND USER MANUAL - WARRANTY

ODYSSEO 2

HEAT PUMP WATER HEATER USING NON-HEATED AIR

EN

GUIDE

TO BE KEPT

BY THE USER

Page 2

WIRING DIAGRAM

STARTING YOUR

HEAT PUMP

WATER HEATER

In order to protect the tank against corrosion,

the water heater must remain switched on at all times.

The wires in the electric cable are crimped. If you need to cut them, remember to crimp

them again before connecting to the electric power supply.

Electric

panel

Active – brown

Neutral –blue

FOR TIME CLOCK CONTROL - TIME OF USE TARIFF:

240 volt supply with 2 amp protection connected to the black auxiliary wire and the time clock programmed

in accordance with the time of use tariff hours. Set HCHP parameter to ON, see page 15 setting the regulation.

FOR ACI PROTECTION:

The HPWH must remain connected to the permanent power supply at all times so that the operation of the

(ACI) anti-corrosion protection of the water heater is ensured.

For more information

Please refer to the «Electric connections» and «Getting started» chapters in this manual.

Page 3

Contents

Important recommendations.......................................................................................................2

Transportation & Storage...................................................................................................................... 2

Safety instructions................................................................................................................................. 2

Presentation of the product ........................................................................................................ 3

How it works ........................................................................................................................................... 3

Technical characteristics ...................................................................................................................... 4

Dimensions / components .................................................................................................................... 5

Installation.................................................................................................................................... 6

Selecting the location............................................................................................................................ 6

Installing the product............................................................................................................................. 9

Hydraulic connection............................................................................................................................. 9

Air connections.................................................................................................................................... 11

Electric connections............................................................................................................................ 12

Getting started...................................................................................................................................... 14

Use............................................................................................................................................... 16

Control panel........................................................................................................................................ 16

Description of the pictograms:........................................................................................................... 16

Description of the modes.................................................................................................................... 17

Adapting the mode of your appliance to your needs....................................................................... 19

Recommendations – Maintenance & Repairs ......................................................................... 20

Advice for users................................................................................................................................... 20

Domestic maintenance........................................................................................................................ 20

Maintenance by a qualified professional........................................................................................... 21

Troubleshooting .................................................................................................................................. 22

Fault diagnosis for professionals....................................................................................................... 23

After-sales............................................................................................................................................. 25

Warranty Conditions............................................................................................................................ 26

Warranty Exclusions............................................................................................................................ 26

Good, compliant installation Guidelines : Atlantics Europe :......................................................... 27

- 1 -

Document reference : 112 30 618 C

Controlled : Mars 2012

Page 4

Important recommendations

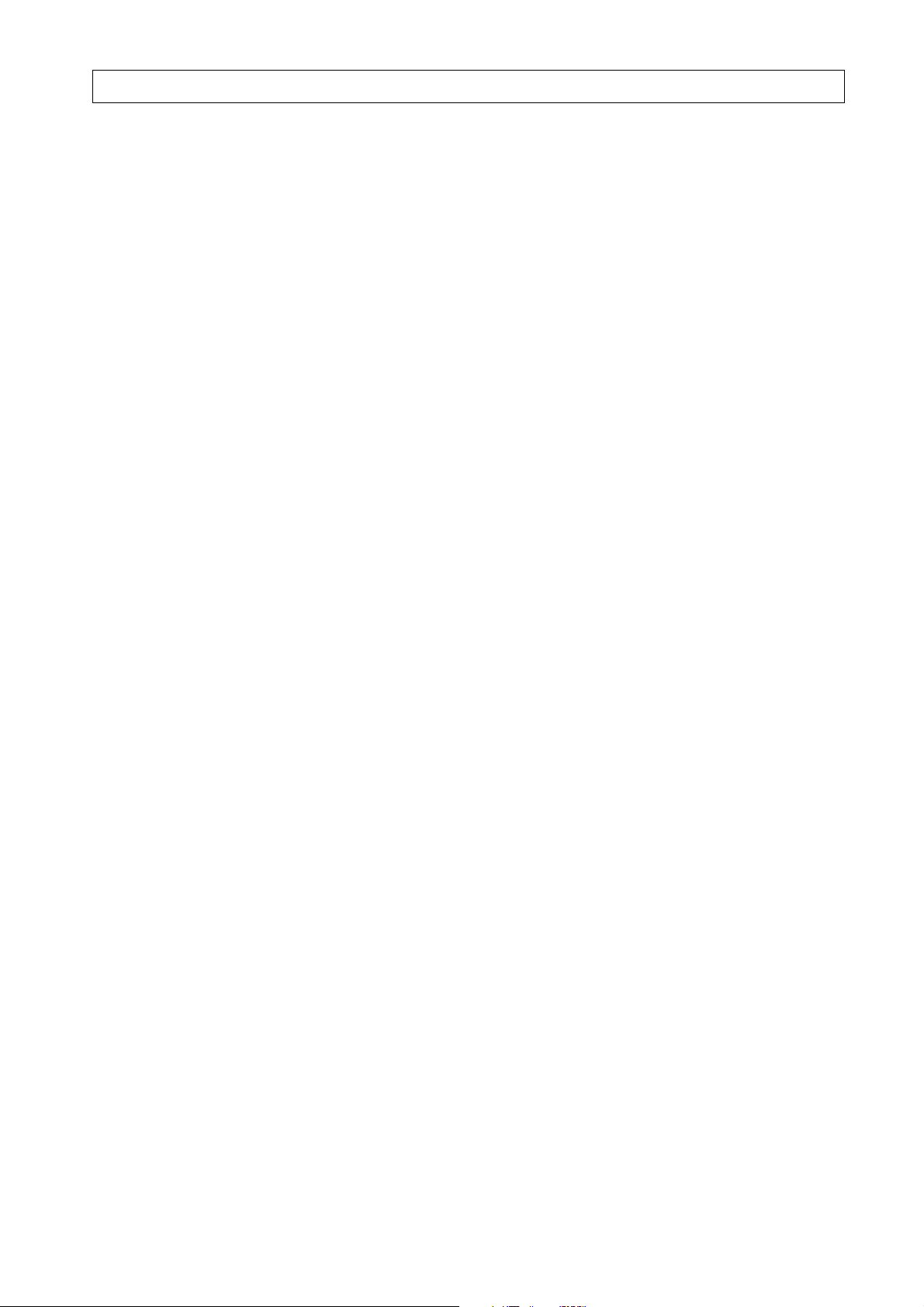

Transportation & Storage

The product can be inclined at 90° on one side. This side is clearly shown by a sign on

the packaging. It is forbidden to incline the product on the other sides. An indicator

shows whether the product has been transported and handled according to our

recommendations. You are advised to make sure that these recommendations are

followed. If the inclination indicator is red, our warranty is null and void. We cannot

be held liable for any faults in the product resulting from transporting or handling the

product in a manner that does not comply with our recommendations.

It is strictly forbidden to stack this product.

Acceptable positions Forbidden positions

Safety instructions

Installing and starting up heat pump water heaters may be hazardous due to high pressure and live parts.

The heat pump water heater must be installed, started up and maintained by trained and qualified

personnel only.

This device is not intended for use by persons (including children) with physical, sensory or mental

disability, or by persons lacking experience or knowledge, unless they have received from a person in

charge of their safety adequate supervision or preliminary instructions on how to use the device. Care must

be taken at all times to keep children from playing with the device.

- 2 -

Page 5

Presentation of the product

How it works

The heat pump water heater uses unheated air to prepare domestic hot water.

Heat energy extracted from the ambient air is absorbed by the refrigerant through heat transfer at the

Evaporator. This energy is concentrated by the Compressor and then transferred by the Condenser into

the hot water tank. This cycle is repeated after the refrigerant has cooled. A low energy fan ensures

ambient air movement across the Evaporator.

The air is propelled through the appliance

by a fan, which ventilates the various parts,

including the evaporator.

As it passes through the evaporator, the

coolant evaporates and absorbs calories

from the incoming air.

The compressor compresses the coolant,

thereby increasing its temperature.

This heat is transferred to the domestic

water in the tank by the condenser.

The coolant expands in the thermostatic

expansion valve and cools down. It is then

ready to absorb heat again in the

evaporator.

The colder the air, the more difficult it is to extract the calories. Similarly, the higher the hot water setting,

the more difficult it is for the heat pump to transfer the extracted calories.

IR

Tank

Compressor

Evaporator Condenser

Expansion valve

- 3 -

Page 6

Technical characteristics

Dimensions mm H 1897 x l 591 x D 674

Empty weight kg 90

Capacity of the tank L 270

Hot water / cold water connection 3/4 ’ ’ M

Corrosion-proof protection Impressed current anode

Minimum conductivity of the water μS/cm 40

Rated pressure

Permissive excessive operating pressure

Electric connection (voltage / frequency) 240 V single phase 50 Hz

Maximum total power input of the appliance W 2635

Average power input of the heat pump W 425

Maximum power input of the heat pump W 755

Power output of the heat pump (under nominal conditions +15°C) W 1660

Power input of the electric backup W 1880

Water temperature setting range of the heat pump °C

Operating temperature range of the heat pump (air temperature) °C -5 to 35

kPa

Mpa

560

1

45 to 62 (factory setting =

55°C)

Vacuum air flow (without duct) (230V)

3

m

Speed 1

Speed 2

Admissible head loss in the air circuit without impacting

performance

/h 230

3

m

/h 390

Pa 25

Noise level** dB(A) 54

Acoustic pressure at 2m in the open dB(A) 37

Coolant fluid

Nota : R134a GWP (Global Warming Potential) is 1350

-/kg R134a / 1.35

Certified performances at an air temperature of 7°C (CDC LCIE 103-15A) and 25Pa** ducting

Coefficient of performance (COP) (230V) 3,1

QPr (over 24h) (230V) kWh 0,77

Heating time* (230V) 8h19min

Performance measured at an air temperature of 15°C (CDC LCIE 103-15A) without ducts**

Coefficient of performance (COP) (230V) 3,8

QPr (over 24h) (230V) kWh 0,74

Heating time* (230V) 7h30min

Other performances

Max. quantity of water mixed at 40°C (setting at 62°C) L 455L

* Tested in a reverberation chamber in accordance with the measurement standard NF EN ISO 3741,

water heaters without accessories, average measurement when heating from a water temperature of 21 to

57°C at an ambient air temperature of 20°C.

** Performances measured when heating water from 15°C to 51°C according to the protocol in the

specifications of the NF Electricity performance brand N° LCIE 103-15A for standalone accumulator tank

thermodynamic water heaters (based on the standard EN 255-3).

This appliance complies with Directives 2004/108/EEC on electromagnetic compatibility and 2006/95/EEC

on low voltage.

- 4 -

Page 7

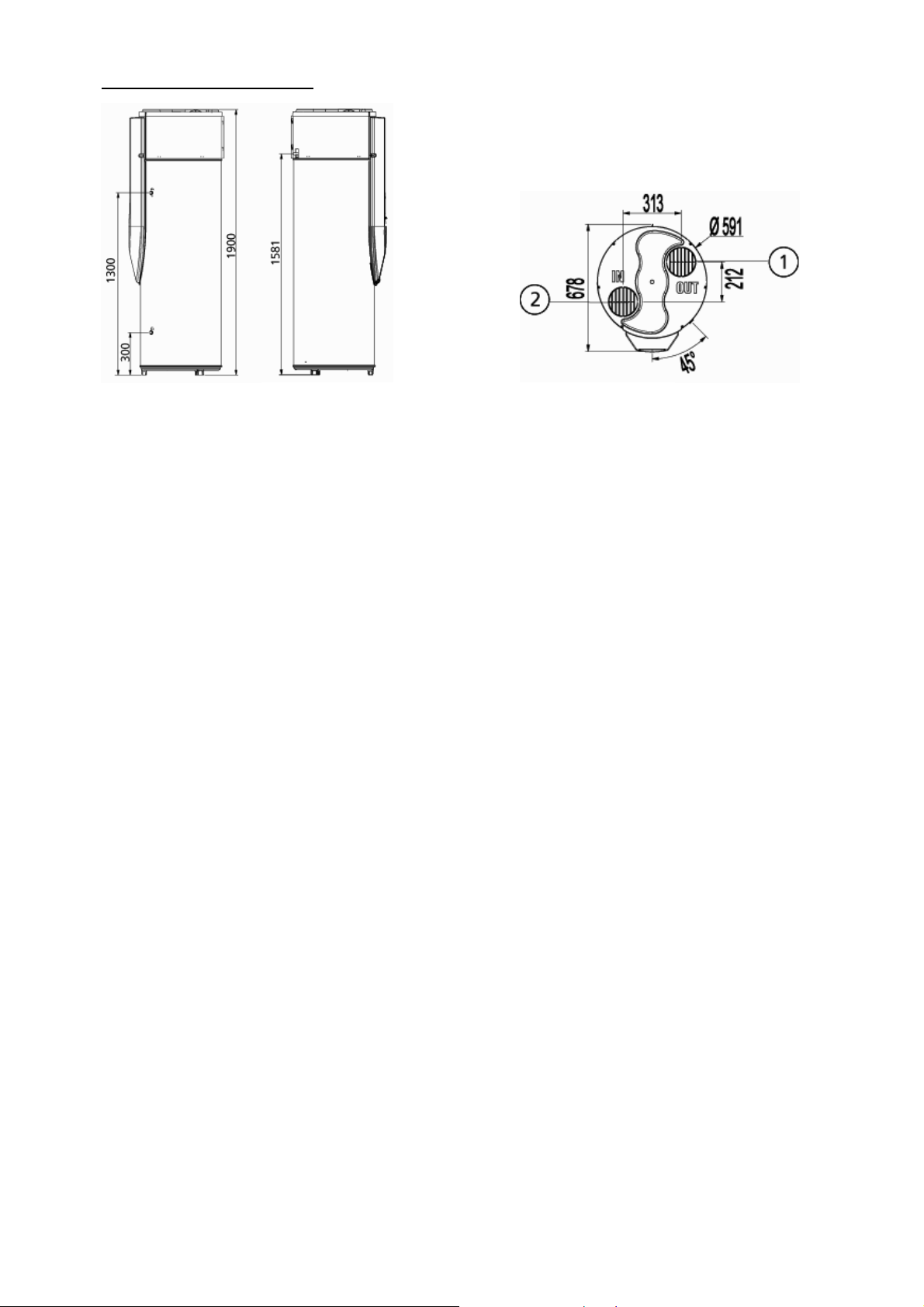

Dimensions / components

1

Air outlet

2

Air inlet

3

Fixed unit attachment

4

Fixed feet

5

Cold water inlet

6

Pocket

7

Sheath

8

Electric heating element (ceramic element) and

10

11

12

13

14

15

16

17

mechanical safety device

9

Regulation

18

Not shown:

-

Manual

-

Condensate evacuation tube

- 5 -

Hot water inlet

Compressor

Evacuation of condensate

Compressor permanent condenser

Evaporator

Fan wiring

Fan

Expansion valve

Cover

-

Dielectric coupling

Page 8

Installation

Selecting the location

in compliance with IEC 60 529 Standard, AS60529:2004

Resistance of the floor

The place where the appliance is installed must comply with protection index IP X1B

according IEC 60 529 Standard and AS60529:2004 standard and in compliance with electrical wiring

rules of Aus/Nz

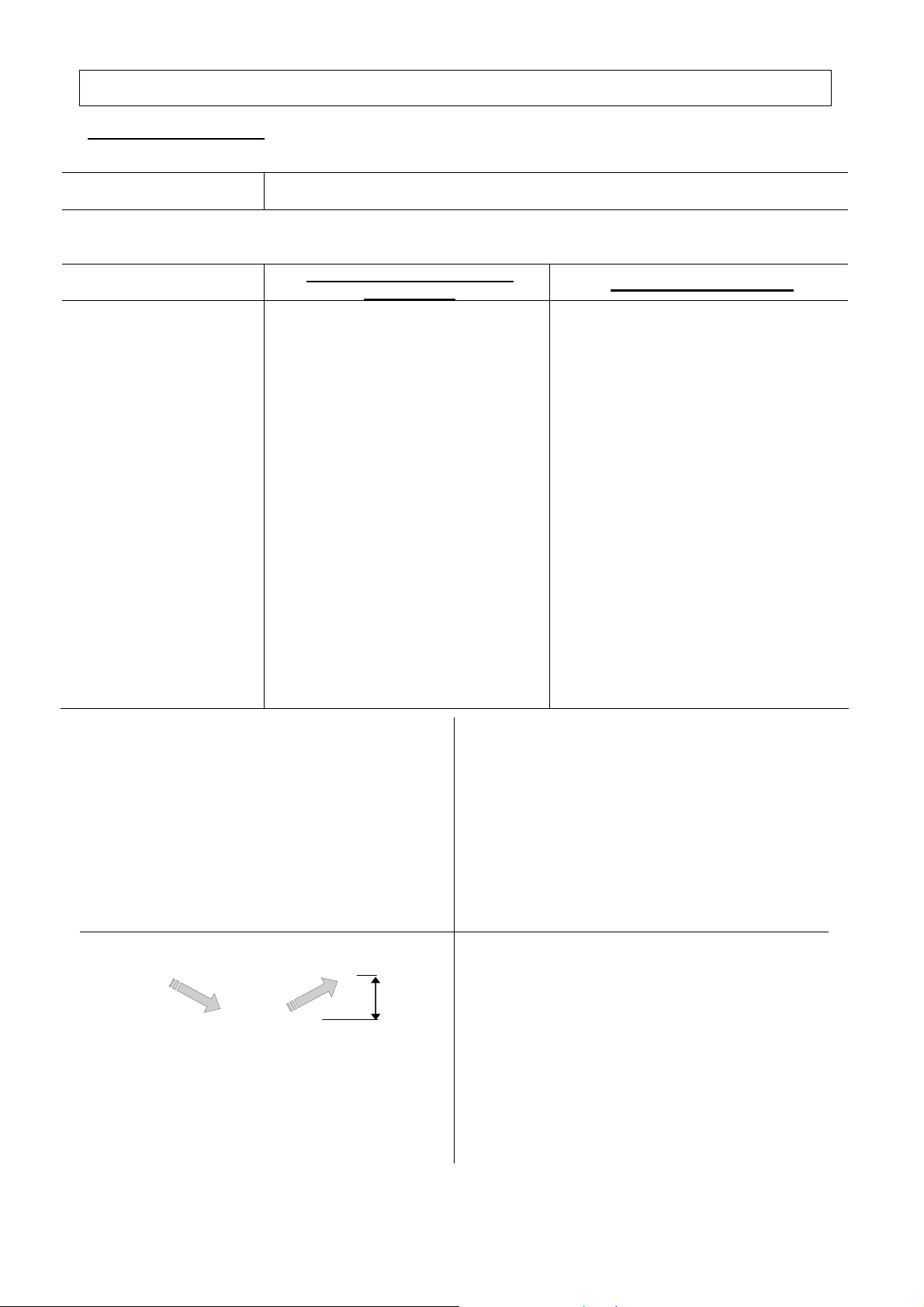

Configuration without ducts

Type of room

Examples of rooms

Volume of the room from

which the air is taken

Temperature of the room

where the water heater

is installed

Temperature of the

incoming air

Height

Required surface area

Capable of withstanding a weight of at least 400 kg (the area under the water

heater)

semi-ducted

Unheated room at a temperature

above 5° and isolated from the

heated rooms in the dwelling

Recommended room = underground

or semi-underground, a room where

the temperature is higher than 10°C

all year long, well vented location

Garage, boiler room, basement,

Room at least above freezing

Recommended room = habitable

Do not install near bedrooms to avoid

Laundry, cupboard in the hallway, etc.

Configuration with ducts

space (the heat released by the water

heater is not lost), near the exterior

walls

disturbance by the noise

laundry room, etc.

> 20m3 > 20m3

5°C to 35°C, when the water heater

1°C to 35°C

is not working

3°C to 35°C -5°C to 35°C

> 2m10 > 2m20 with bent outlet

(height of an insulated bend = approx.

300mm)

(591+400) x 700 (l x D). See

diagram below

800 x 800 (l x D). See diagram below

The surface must be level

The surface must be level

Configuration without ducts Configuration without ducts

200 mm

Configuration without ducts Configuration with ducts

CAUTION : failure to follow the recommendations for installation may result in poor system performance.

- 6 -

Page 9

Recommended configurations

1st Configuration: installation without ducts in an unheated space (Volume > 20m

FAN set to 0 (see Setting the regulation section, page 15).

3

)

Examples of unheated rooms:

- Garage: recovery of free heat released by the car engine after use or by other household

appliances.

- Laundry : dehumidification of the room and recovery of heat released by washing machines and

tumble driers.

- Semi-underground room: recovery of free heat released by the floor and walls of the basement.

2nd Configuration: installation in a heated or unheated room with ducts

FAN set to 2 (see Getting start section, page 14).

Recommendations:

Comply with the maximum duct lengths (see Air connections section, page 11).

- Use thermally insulated rigid or semi rigid ducts

- Provide air flow grills at the duct inlet and outlet to prevent entry of foreign bodies

- Ensure that grills do not impede necessary air flow by being obstructed

- 7 -

Page 10

Configuration tolerated under certain conditions

Installation in an unheated space with one duct (outlet or inlet, volume > 20m

FAN set to 1 (see Getting start section, page 14).

3

)

Possible consequences

- The negative pressure in the

room due to the expulsion of

the exterior air may result in air

entering through the doors and

windows. Provide an air inlet

(same diameter as the ducts)

from the exterior in order to

avoid sucking air from the

heated space.

- Caution: in winter, the air will

be colder than the air expelled

by the water heater, resulting

in a drop in temperature in the

garage.

* In warmer climates ducts may be reversed to provide cold air into an adjacent room for cooling. Connect

(air in) from outside and (air out) into the adjacent room. NOTE: It is not recommended to reverse ducts

(air out) into the room that the HPWH is installed. This will reduce the COP and increase the cooling of the

room.

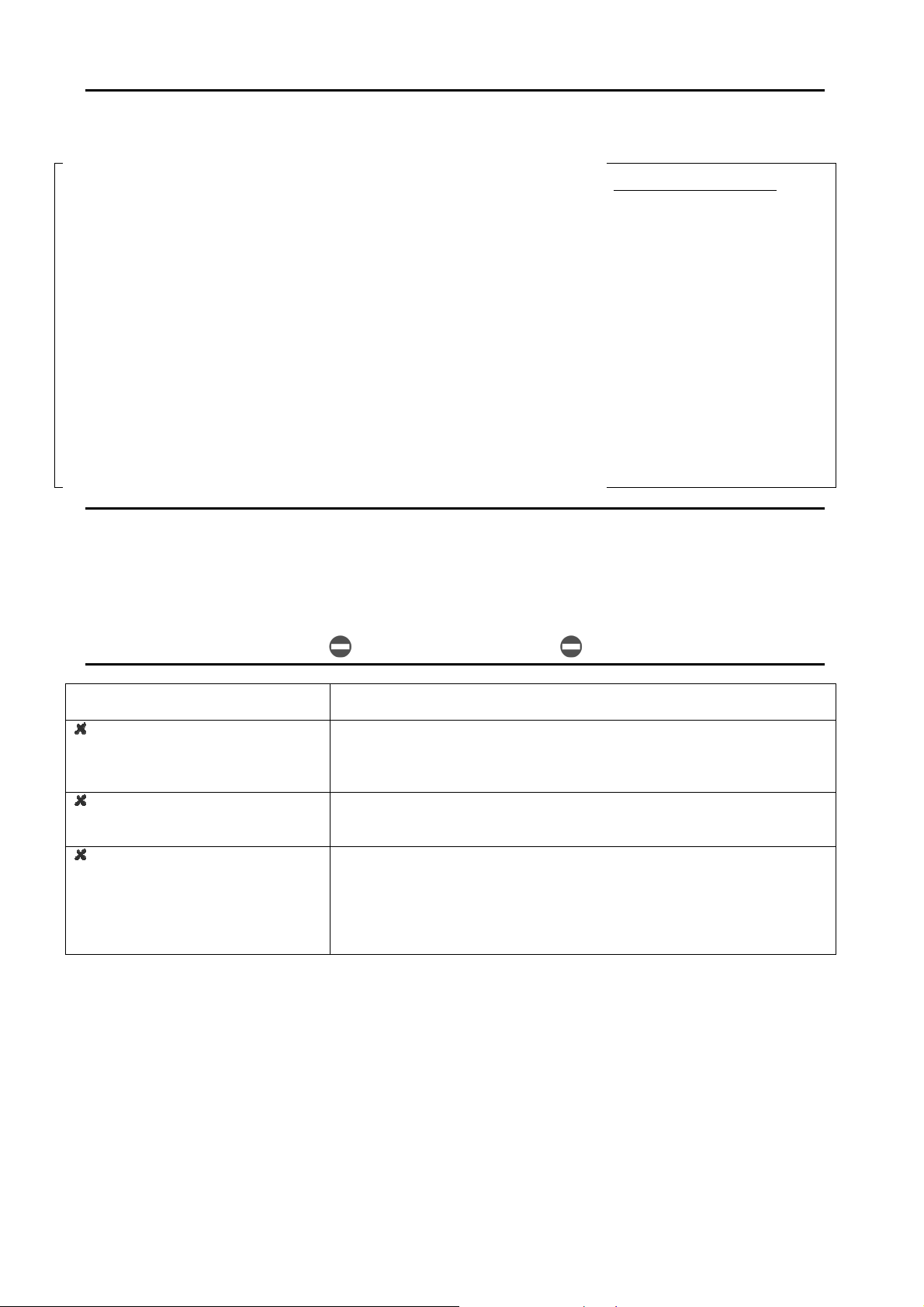

Unsuitable configurations

Prohibited Ducting installation

configurations

The water heater draws in air

from a room containing a

charged source of heat used to

heat the room.

Connection to mechanical

ventilation

Connection to the roof space

Uses heat energy from a higher cost source.

The greasy vapour and dust that may flow through the ducts of the

mechanical ventilation system can reduce the life time of your water

heater.

If the insulation between the ceiling and the roof space is insufficient,

this installation may result in heat loss from the house. In extreme

cases, condensation may appear on the ceiling of the rooms beneath

the cooled parts of the roof space.

Risk of falling objects and aspiration of dust by the raised water heater

in this configuration, that can reduce the life time of your water heater.

Related risks

:

Other prohibitions:

There must be no Heat Pump Air Access connection between the device and a tumble dryer.

-

- Avoid dusty rooms

- Do not draw in air containing solvents or explosives

- Do not connect the appliance to hoods evacuating fatty or polluted air

- Do not install the water heater in a room that freezes

- Do not place anything on the top of the water heater

- Do not install in an attic

- 8 -

Page 11

Installing the product

1- Transport the water heater to the place where it is to be installed.

2- Cut the cardboard skirting along the dotted lines.

3- Take the water heater off the pallet and place it by the hydraulic connection.

+/- 1°

MAXIMUM!

The water heater must be installed on a smooth and horizontal

floor.

If this is not the case, it must be levelled using the supporting feet.

If this precaution is not taken, problems may occur evacuating the

condensates, resulting in frosting.

In accordance with AS/NZS

60335.2.21 the water heaters

must be fixed to the ground

using the attachment provided

and in compliance with the New

Zealand Building Code Clause

G12, Seismic restraint of

storage water heaters.

The clearance required needs to be adequate for service/re placement of cold water inlet piping devices,

PTR valve and tempering valves (where fitted), elements and thermostats. This may be facilitated by

correct orientation of the cover positions when installing. There are no operational clearance limitations to

surrounding structure. PTR valve removal requires approximately 150 mm for withdrawal.

AS/NZS 3500.4 – National plumbing & drainage. Hot Water Supply Systems – Acceptable solutions.

Combustible Material :

It is recommended to not place combustible material on or adjacent to the water heater.

Internal Installation Safe Tray :

For internal (inside home) installations, a safe tray is recommended in accordance with AS/NZS 3500.4.

Hydraulic connection

Cold water inlet

Before making the hydraulic connection, it is essential to clean the feed pipes thoroughly to avoid the risk

of metal or other particles entering the tank or the water heater.

Cold water piping should be provided with a 500 – 560 kPa Pressure Limiting Valve at the point of cold

water connection to the water heater. In addition to the Pressure Limiting Valve, it is a requirement of AS

3500.4 & NZBC G12 that both a Stop Valve and a Non Return Valve are installed upstream of the Product.

No parts (stop valve, pressure reducer, etc.) must be placed between the pressure limiting

valve and the cold water inlet of the water heater, apart from a copper pipe.

Note: since limited water discharge from pressure limiting valve is normal in the heating operation, the

discharge pipe needs be connected to external drain.

- 9 -

Page 12

Hot water outlet

(

)

Do not connect the hot water inlet directly to the copper pipes in order to avoid iron/copper galvanic

couples (risk of corrosion). The hot water inlet (item 10 on page 5) must be fitted with a dielectric coupling

(supplied with the appliance).

If corrosion occurs on a hot water inlet that is not fitted with this protective device, our warranty does not

apply.

Where a maximum hot water delivery temperature is specified by Local, State or Federal

Regulations, a Tempering Valve shall be installed at the Hot Water Outlet, as required.

The included specified Pressure & Temperature Relief Valve must be installed as shown in the

schematic. The PTR valve should be connected to a drain point to accommodate discharge as a

result of both water expansion during heating, and also pressure fluctuations.

A discharge pipe connected to the pressure relief valve is to be installed in a continuously

downward direction and in a frost- free environment.

WARNING: The Pressure Temperature Relief valve and drain line must not be sealed or blocked.

Evacuation of condensate

Air passing through the Evaporator may result in some condensation. If the humidity of the

location Warrants, it may be preferable to connect a simple polymer hose from the Condensate

Drain (Item 16), to the convenient PTR drain point.

Depending on the humidity of the air, up to 0.25l/h of condensate may form.

Installation schematic for example :

Connection tee

(Supplied)

Dielectric

fitting

(Supplied)

Untempered

hot water

(Kitchen, laundry)

Tempered

water 50°C

(Bathrooms)

Cold water

main supply

Non-return and

isolating valve

PTR Valve

700 kPa

Tempering

valve

Line

Strainer

Pressure

Limiting

Valve

(560 kPa)

Drain

line

Expansion

control

valve

Drain

line

- 10 -

Page 13

Air connections.

Your heat pump water heater can be fitted with ducting accessories that are not supplied with the water

heater.

If the volume of the room in which the thermodynamic water heater is installed is insufficient, it can be

connected to 160 diameter

during operation. Therefore, it is essential to choose insulated air ducts.

Poor ducting (crushed ducts, ducts that are too short or too many corners, etc.) may have a negative

impact on performance. Therefore, you are strongly advised to use rigid ducts.

When connected to ducts, the regulation must be adjusted accordingly (see Setting the

regulation section, page 15).

The total head loss in the ducts and accessories of the air inlet and outlet must not exceed

150 Pa. The head losses must be calculated using the measuring tools supplied by the

manufacturer and on the basis of the proposed ducting accessories.

air ducts. If the air ducts are not insulated, condensation may appear on them

Total duct length* with

Number of bends

0 bends 8 m

1 x 90° bend

2 x 90° bends

(*) semi-rigid aluminium duct

the wall-mounted air

inlet and outlet in the

catalogue

7 m

5 m

Installing the coupling accessory for duct ref. 900366

Refer to the installation instructions supplied with the kit.

If the ceiling is too low to screw the

accessory from the top, remove the

cover by undoing the 6 clips with a

screwdriver

Then return the cover and clip into

place once the accessory has been

installed. The ducts can now be

connected.

- 11 -

Page 14

Electric connections

Caution: the water heater must be filled with water first, before making the electric

connections (see Getting started section, page 14).

The HPWH must remain connected to the main power supply at all times so that the

operation of the (ACI) anti-corrosion protection of the water heater is ensured.

Electrical work must be carried out by a licensed tradesperson and in accordance with Electrical Wiring

Rules of Aus/NZ. Circuit Isolation and fixed appliance regulations of the Wiring rules shall be complied in

regard to connection to supply, circuit isolation, and protection.

The appliance must be earthed.

Never power the heating element directly.

The safety thermostat fitted to the electric backup must only be repaired in our factory. Failure to obey

this clause will cancel the warranty.

Electric connection using a timer

Electric

panel

Timer (*)

16A

(*) This assembly is not un iversal. Refer to the assembly

instructions of your timer, depending on the model.

2A

2x0.75 mm²

Active – red or brown

Neutral – white or blue

M

3x1.5 mm²

FOR TIME CLOCK – TIME OF USE TARIFF:

240 volt supply with 2 amp protection connected to the black auxiliary wire and the time clock programmed

in accordance with the time of use tariff hours. Set HCHP parameter to ON, see page 15 setting the

regulation.

- 12 -

Page 15

Electric connections

FOR RIPPLE CONTROL: NEW ZEALAND ONLY

240 volt supply with 2 amp protection connected to the black auxiliary wire. Set HCHP parameter to ON,

see page 15 setting the regulation.

The diagram shown is only the functional configuration. Wiring details (ie. switching, fusing, method of

isolation, neutrals and their locations must comply with statutory regulations and codes of practice.)

FOR CONTROLLED TARIFF: NEW ZEALAND ONLY

- 13 -

Page 16

Getting started

1. Filling the water heater.

Fill the water heater by opening all hot water taps and opening the cold water inlet to allow

the water heater to fill and air in the system to be expelled. Close each hot water tap, as the

flow becomes free of air. Check all piping for leaks.

Check that water flows freely by gently operating the lever on the Pressure Temperature

Relief valve.

Power should not be turne d on until the water h eater is completely filled with water.

2. Checking good working order

Switch on the water heater. Check the screen for errors. If an error appears, refer to the

system diagnostic section. The temperature setting appears. After 3 minutes

compressor and the fan start.

Select the "FAN" setting and configure according to the recommendations in Setting the

regulation.

the

After the compressor has been working for about 10 minutes, the temperature at the air

outlet is at least 3 to 4°C below that of the incoming air. The water drips out of the drain of

the pressure limiting valve. This drain must be connected as described in Hydraulic

connection, page 9. This is completely normal, the water is expanding due to the heat.

Check that the connections are watertight again.

If the check is OK, your appliance is ready. It is now working according to the factory

settings, in AUTO mode.

Refer to the settings section

When heating up with the electric backup and depending on the quality of water, the water

heater may make a slight kettle-like noise. This noise is normal and is not a sign of a faulty

appliance.

The relief of partial vacuum.

A vacuum would be relieved from the system whenever a tap is opened as the outlet is at

atmospheric pressure and the tank is at mains pressure.

in this manual to optimise the operation of your appliance.

NOTE

- 14 -

Page 17

3. Setting the regulation

Adjusting the temperature set point

The temperature setting of your appliance is adjusted to 55°C in the factory. It can be adjusted simply by

pressing

& directly on the default display. The lower the temperature setting of the heat pump,

the better the coefficient of performance (COP).

Possible values

: 45 to 62

Settings to be adjusted

To open or close the setting menu, press + at the same time.

In this menu, all the adjustable settings can be checked and changed, if necessary. The default values in

the factory settings guarantee optimal operation.

Once the menu is open, press to choose a setting,

The value of a setting is validated by proceeding to the next setting.

then press & to change the value of the settings.

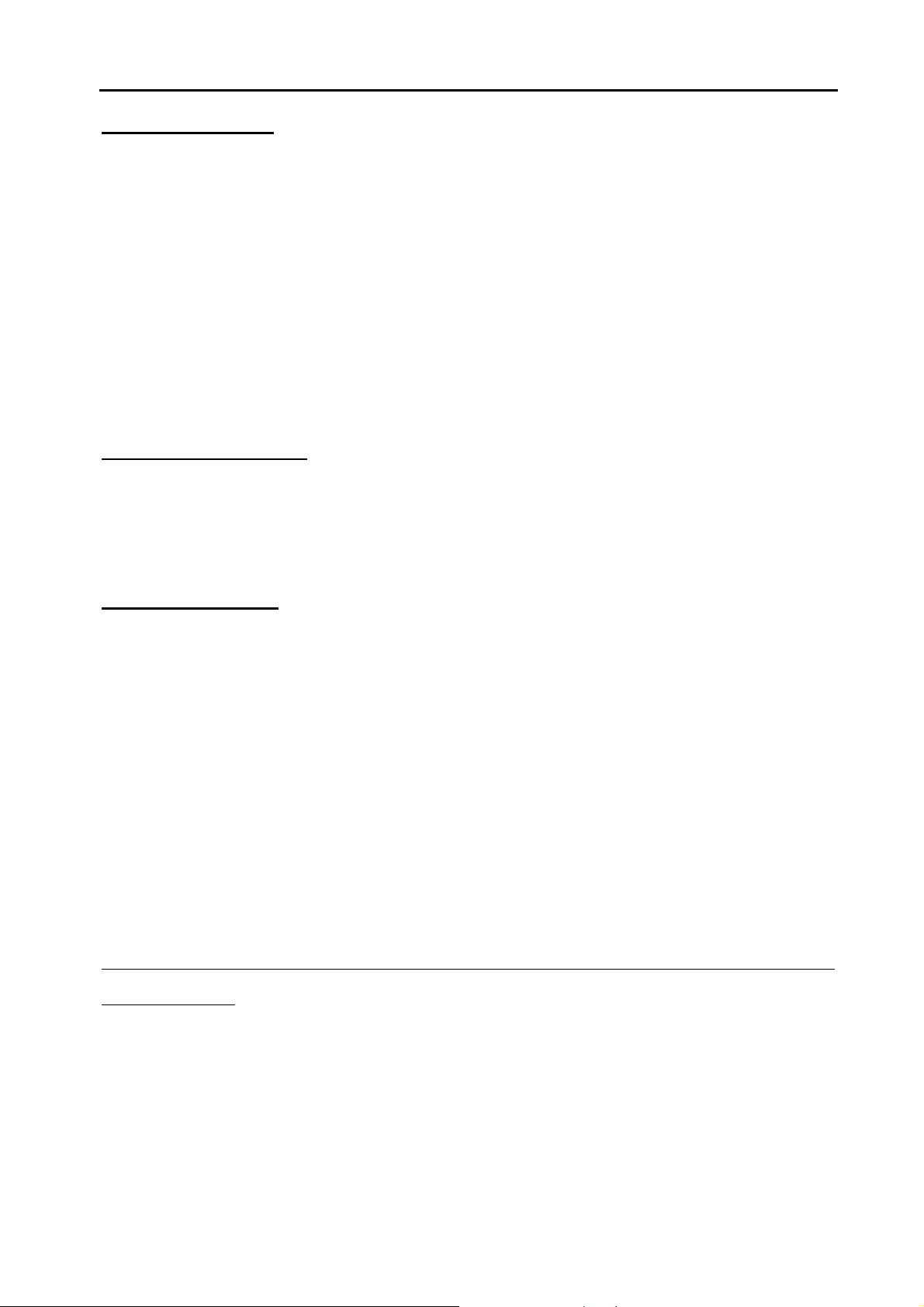

Time clock control function for time of use tariff

If the HPWH is controlled by a time clock or with a ripple relay connected to

the 2x0.75 cable then move the parameter to ON.

If 2x0.75 cable is not connected, then the parameter must be OFF.

Default value: OFF

Connecting to ducts

0 corresponds to water heaters without ducts. The regulation then adjusts

the noise level of the fan. In this configuration, the heat pump stops working

if the room freezes.

1 corresponds to semi-ducting, with a single duct installed, usually to

evacuate the cold air out of the room.

2 corresponds to ducts on both the inlet and the outlet.

In these two positions, the regulation adjusts the fan so that it can withstand

additional head losses.

Default value: 0

Possible values

: 0, 1 or 2

Avoid Legionella

This parameter is used to activate the legionnaires disease protection

mode: Once every 7 days, all domestic hot water is heated to 60C.

Default value: OFF

Electric only mode

This setting is used in the event of heat pump failure in AUTO, BOOST and

ABSENCE modes in order to guarantee a minimum hot water supply before

the technician intervenes.

Note: In this mode as only the element is heating the unit, approximately

one half of the volume of hot water is immediately available.

Default value: OFF

- 15 -

Page 18

Control panel

Use

Back-lit display

Navigation buttons in

the modes

Mode selection button

Description of the pictograms:

Symbol Name Description

Compressor

Fan

Sensor

Electric backup

Time of use hours

or

Peak hours

Risk of shortage of

hot water

Sensor associated with the temperature on display → Flashes

In TOU / peak hours mode, the symbol corresponding to the mode

In ECO mode, shows that the air temperature may result in a

Compressor working Flashes slowly

Indication of the physical position of the sensors

Electric backup working Flashes slowly

Status of the compressor:

Status of the fan:

Low speed → Flashes slowly

High speed → Flashes quickly

slowly

Status of the electric resistor:

is displayed.

shortage of hot water.

- 16 -

Minimum

MAXIMUM!

Information Indicates that you are in the information menu.

Indicates that the value on display is the minimum detected by the

Indicates that the value on display is the maximum detected by the

sensor.

sensor.

Page 19

Incoming air

temperature

Air temperature sensor in the flow of ambient air

Evaporator

temperature

Water temperature Water temperature sensor in the pocket

Heat pump time Shows the working time of the water heater heat pump in hours

Elec time Shows the working time of the water heater electric backup in hours

Temperature sensor on a cross in the evaporator

Description of the modes

Graphical icons Description Indicator

Optimised management of the heat pump and the

Forced operation with electrics + heat pump when

Long absence: water heating set to anti-freezing

Indication of the various sensor temperatures and the

operating time of the heat pump or the electric

electrics for guaranteed comfort

Heat pump only working

heating

mode and restart on the last day of absence

backup

This mode is selected

when the cursor is

positioned above the icon.

AUTO mode

This mode automatically selects the energy source for maximum savings, while guaranteeing that the

water is sufficiently hot.

The water heater always selects the heat pump first. If the air temperatures are not in the operating range,

or if a fault is detected in the heat pump, the electric backup is automatically selected to guarantee a

sufficient volume of hot water.

Examples:

Use of 3/4 of the available volume

Air temperature about 1°C

Selection by the regulation:

Heat pump plus electric backup

Severe winters

of hot water

Winter

Use of 3/4 of the available volume

of hot water

Air temperature about 7°C

Selection by the regulation:

Heat pump only, with authorisation

to continue even in case time clock

signal is off (“HP” on the screen)

Summer

Use of 2/3 of the available volume

of hot water Air temperature about

18°C

Selection by the regulation:

Heat pump only and only when

time clock signal is on

(“HC” on the screen)

- 17 -

Page 20

ECO mode

This mode uses the heat pump only to produce hot water. Under certain conditions, this mode may

result in shortages of hot water (mainly due to air temperatures outside the operating range).

BOOST mode

BOOST mode can be used to force the heat pump and the electric backup to work at the same time in the

event of high demand.

The regulation automatically returns to the previous mode at the end of the cycle.

ABSENCE mode

This mode helps to protect the tank when the user is absent. The tank is protected against corrosion and

the regulation heats the water to above 7°C. Use the arrows to select the number of days during which you

will be absent. The length of the absence can be set to between 1 and 99 days. If a number of days is not

selected, the water heater remains in ABSENCE mode permanently.

On the last day of the period of absence, the water heater performs a cycle to avoid Legionella. The

regulation automatically returns to the previous mode at the end of the ABSENCE mode.

INFO mode

In this mode, it is possible to view the temperatures measured by the various sensors, the maximum and

minimum values measured and the time for which the heat pump or the electric backup has been working.

Values can be reset by pressing

+ at the same time.

Automatic defrost

The water heater is fitted with a defrost function. In negative temperatures, the water heater is

automatically defrosted by opening a solenoid, which sends the hot gas from the compressor directly to the

evaporator, where the frost melts. In positive temperatures, only the fan is used to defrost the heat

exchanger.

The defrost mode is activated by the temperature sensor in the evaporator. This temperature sensor can

detect the formation of frost, irrespective of the air temperature or the configuration of the system.

The defrost cycle lasts a maximum of 15 minutes.

Fan controls

When FAN is set to 0 (FAN 0), the water heater draws the air in from the room. The fan permanently works

at low speed in order to reduce the noise level, while producing a sufficient volume of hot water. Do not

use ducts and the FAN 0 setting at the same time.

The FAN 1 setting is used when a single duct is installed, usually on the air outlet. This configuration

evacuates the cold and dry air from the room.

The FAN 2 setting is used when exterior ducts are installed on the air inlet and outlet.

In the positions FAN 1 or FAN2, the fan operates at high speed to compensate for the head loss caused by

the ducts.

In the positions FAN 0 or FAN 1, the lower limit for operation with the heat pump is an air temperature of

3°C, in order to prevent the water heater from freezing (-5°C in FAN 2).

- 18 -

Page 21

Adapting the mode of your appliance to your needs

1. Calculate your daily needs in terms of a number of showers (1 bath = 3 showers)

Example: daily need = 3 showers + 1 bath => 6 showers

2. Identify the mode that best meets your needs in the table below

Number of showers per

day

COMFORT

4 2

5 3

6 4

7 5

8 6

9

* Switching to AUTO mode is recommended if the temperature of the inlet air may drop below the lower

operating limit at night (see Selecting the location, page 6). AUTO mode guarantees a given volume of hot

water by using the electric backup under severe weather conditions.

Comments:

EXTRA

COMFORT

7

If your selection does not produce the quantity of hot water that you need, switch to

the mode in the next higher level.

If your needs vary, occasionally or for a lengthy period, adapt the mode to your

requirements.

AUTO ECO *

OP/P Permanent OP/P Permanent

X

X

X

X

X

X

X

X

62

51

55

X

X

X

Setting

62

51

55

3. Set the appliance to the mode you have identified (see Setting the regulation, page 15)

- 19 -

Page 22

Recommendations – Maintenance & Repairs

Advice for users

Flushing of sediment and draining :

To flush or to drain the water heater, power must be turned off and then turn off the cold water supply to

the water heater. The lever on the pressure and temperature relief valve should be opened but care

should be taken so the lever does not snap back as it could damage the valve seat. The pressure in the

water heater will be released when the lever is opened. The union at the cold water inlet to the water

heater should be undone and a hose should be attached to the water heater side of the union. The other

end of the hose should go to a drain.

Opening the pressure and temperature relief valve allows air into the water heater and for the water to

drain. Following complete draining of the water heater, the closest hot water taps may be opened fully

and the pressure and temperature relief valve closed with care. Following reconnection at the cold water

inlet, the cold water stop valve is now opened fully and the water heater may be filled with cold water

and flushed through to ensure the cylinder contains no sediment and is clean. Finally the closest hot

taps are closed and power may be turned on again to the completely filled water heater.

In the event of an anomaly - the heater does not heat or steam is released from the Pressure Temperature

Relief valve - switch off the electric power supply and contact your reseller.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety.

Domestic maintenance

Water heaters do not require much domestic maintenance by the user. Operate the Pressure Temperature

Relief valve once or twice a month to eliminate any residue of scaling and check that it is not blocked.

Regularly check the display for alarms. If an alarm appears, refer to the Troubleshooting section, page 22).

DANGER: Failure to operate the Pr essure Temper ature Re lief valve easing gear at least once every six months

may mask a problem with the water heater. Continuous leakage of water from the Pressure Temperature Relief

valve may indicate a problem with the water heater.

It is not unusual for the Pressure Temperature Relief valve to allow a small quantity of water to escape during

the heating cycle and this must be left open to the atmosphere.

- 20 -

Page 23

Maintenance by a qualified professional

To protect the performance of your appliance for many years to come, it must be checked by a

professional every 2 years.

Switch off the electric power supply (circuit breaker, fuses, etc.).

Drain the tank:

close the cold water inlet (isolating valve),

open a hot water tap,

set the safety valve to the drain position.

Remove the front cover.

Disconnect the wires from the terminals of the thermostat.

Remove the heating assembly.

Remove any scaling that is deposited in the shape of sludge or a film on the floor of the tank and

thoroughly clean the ducts of the heating elements and the thermostat. Do not scratch or strike the scaling

on the walls, or you might damage the coating. Any residue can be removed using a water and dust

vacuum cleaner.

Clean the interior of the sheath to remove any scaling.

The anti-corrosion anode is made of titanium and does not need to be inspected or replaced.

Install the heating assembly with a new seal. Tighten the nuts gradually to a reasonable torque. Alternately

tighten nuts that are opposite one another.

Fill the water heater, with a hot water tap open. When the water reaches the hot water tap, the tank is full.

Check the seal for leaks and then install the thermostat and its support and connect the electric power

supply.

On the following day, check the seal again for leaks and slightly tighten the bolts, if necessary.

Check the electric connections.

Check that the temperature sensor is properly positioned in the pocket near the electric backup. The

sensor must be fully inserted in the pocket.

Evaporator:

Check that the evaporator and the fan are clean once a year. If these parts are soiled, the performance of

the heat pump will be diminished.

To access the evaporator, remove the cover by unclipping it with a screwdriver. The left half-shell can also

be removed in cases of difficult acce ss.

If necessary, clean the evaporator and the fan with a soft brush. Brush the evaporator very carefully to avoid

damaging the vanes. If the vanes are folded, straighten them using a suitable comb.

Always switch off the appliance before opening the front cover or the top cover

Expansion valve:

Only personnel specialised in refrigerating systems can access the adjusting screw of the expansion valve.

Adjusting the expansion valve without the manufacturer's approval may result in the product warranty being

cancelled.

In general, you are advised not to touch the settings of the expansion valve without having first tried all the

other repair solutions.

Condensate evacuation tube

Check that the condensate evacuation tube (item 12 on page 5) is clean. Local pollution by dust can result

in deposits in the condensate catch tray. These deposits may block the condensate evacuation tube,

resulting in the excessive accumulation of water in the tray, which can cause malfunctions.

- 21 -

Page 24

Troubleshooting .

Alarm codes on the control panel:

The buzzer can be stopped or reset by pressing one of the following keys:

, or

Code

Condition under

which the error

occurs

Cause

Consequences Repair

Err

03

Err

06

Err

07

Err

09

Err

21

Err

22

Err

24

Err

25

Err

28

Water temperature

sensor in the pocket

faulty

Anti-corrosion connection

shorted

Anti-corrosion connection

broken

Water temperature too

high

(> 80°C)

Measured temperature

outside the limits

Evaporator temperature

sensor faulty

Measured temperature

outside the limits

Pressure switch alarm

(high pressure fault)

Defrost malfunction

Sensor cut out or

shorted

Wiring or anti-

corrosion anode

shorted

No water in the tank or

anti-corrosion wiring

cut

Electric resistor

charged permanently

3 HS sensor

Temperature sen sor

(air inlet) cut out or

shorted

Sensor cut out or

shorted

Hot gas valve fault

Fan fault

Air temperature

outside the operating

range.

High pressure value

too high

Shortage of fluid

Hot gas valve fault

No heating

High-pressure safety device

activated (Err 25)

Anti-corrosion protection

deactivated, risk of corrosion.

No heating

Risk of triggering the mechanical

safety device

No heating

Operating ranges not respected

AUTO mode: heating with the

electric backup

ECO mode: no heating

Defrost function compromised

Risk of damage to the compressor

AUTO mode: heating with the

electric backup

ECO mode: no heating

Heat pump working outside the

range

AUTO mode: heating with the

electric backup

ECO mode: no heating

Compressor power supply failure

AUTO mode: heating with the

electric backup

ECO mode: no heating

Defrost function does not work and

the evaporator is obstructed

AUTO mode: heating with the

electric backup

ECO mode: no heating

Check the connections or replace the

sensor wiring

Check the wiring connections

Replace the wiring and/or the anti-

corrosion wiring

Put water in the tank

Replace the wiring and/or the anti-

corrosion wiring

Check the connections and the position of

sensor 3

Check that the electric backup is not

permanently working

Reset the mechanical safety device if

necessary and contact your reseller

Check the connections or replace the

sensor wiring

Check the connections or replace the

sensor wiring

Check that the fan and the hot gas valve

are in good working order

Install the water heater according to the

recommendations in the manual

Check the FAN setting (see page 15)

Check the connections and the position of

sensor 1

Check that the air temperature has not

exceeded 35°C

Press the mode key to clear this fault.

Contact your reseller.

Check the activation of the hot gas valve

in installer mode

Check that the fan is in good working

order

Press the mode key to clear this fault.

Contact your reseller.

Err

30

Heat pump works for

more than 50h without

stopping

Heat pump fault

Shortage of fluid

Compressor faul t

- 22 -

Heating time is too long

Risk of shortage of hot water

AUTO mode: heating with the

electric backup

ECO mode: no heating

Contact your reseller

Page 25

Fault diagnosis for professionals

IMPORTANT

Maintenance and repair operations must only be performed by qualified professionals.

A specific menu is available to operate the system and help you with your diagnostic.

This mode requires technical knowledge of the system. This mode is strictly for professionals only .

To open and close the TEST menu, press

To switch the actuator being tested, press:

+ at the same time

To change the status of the actuator, press:

+

PAC: ON/OFF operates the compressor in forced mode and the fan at low speed.

FAN: OFF/LO/HI starts the fan alone in forced mode.

ELEC: ON/OFF starts the electric backup in forced mode.

VGC: ON/OFF opens or closes the hot gas valve

t01, t02, t03: displays the instantaneous temperatures of the sensors

This mode does not take account of errors detected by the system (heating when dry) or the

sensor temperatures. Therefore, never allow the appliance to work in this configuration.

Forced operation of each actuator is automatically deactivated after 3 minutes to avoid

damaging the appliance.

Certain faults are diagnosed by the regulation, which informs the user using error codes. In this case, refer to the

Troubleshooting section, page 22.

FAULT POSSIBLE CAUSE DIAGNOSTIC AND REPAIR

Off-peak/peak hours mode

programmed, but the regulation

does not detect the off-peak hours

(time clock out of order, faulty

wiring, etc.)

No heating

No hot water

Water not hot enough.

- 23 -

No water heater electric power

supply: fuses, wiring, etc.

Heating element or its wiring out of

order

Circuit open: wires poorly connected

or cut.

Water heater not powered for long

enough. Day/night time clock out of

order, etc.

Temperature setting too low.

ECO mode selected and air

temperatures outside the range.

Switch to BOOST and check that the HC

logo appears on the display.

Check that the water heater power

supply wires are live

Check the power supply of the water

heater

Visual inspection of the wire

connections.

Check that the day/night time clock is in

good working order.

Increase the temperature setting. Refer

to the Settings menu on page 15.

Select AUTO mode (refer to Modes on

page 17)

Page 26

Weak flow from the hot

water tap.

Continuous loss of water

from the Pressure

Temperature Relief valve

when not heating.

The heat pump works

outside off-peak hours

The electric backup does

not work.

Heating element or its wiring partly

out of order

Cold water returns into the hot water

circuit.

Clogged pressure limiting valve

filter.

Pressure limiting valve damaged or

blocked.

Network pressure too high.

Temperature setting not reached.

The mechanical thermostat safety

device is activated.

Electric thermostat faulty. Replace the thermostat.

Resistor faulty. Replace the resistor.

Check the resistance of the plug on the

connector on the plug wiring and the

condition of the wiring.

Close the cold water supply using the

isolating valve. Then open a tap in the

hot water position. Wait for 10 minutes. If

a flow appears, identify the defective tap

and/or check that the safety valve is

correctly positioned, if there is one (see

Hydraulic

Clean the filter (see Maintenance).

Replace the Pressure Temperature

Relief valve (see Maintenance).

Check that the pressure at the water

meter outlet is no higher than 5 bar. If

this is not the case, install a pressure

reducer set to 3 bar at the start of the

general water distribution circuit.

Refer to the operation of the modes on

page 17.

Reset the thermostat safety device on

the steatite resistor (item 8 on page 5).

connection, page 9)

Condensate overflow.

Odours.

Vapour released from the

Pressure Temperature

Relief valve.

Faulty control panel or

display problem.

The heat pump does not

work for long and the

electric backup works

almost all the time.

The fan does not work.

Loud kettle-like noise.

Other malfunction.

Water heater not level. Check that the water heater is level.

Condensate discharge blocked.

No siphon. Install a siphon.

No water in the siphon. Fill the siphon.

Interference with the control panel

due to disturbance on the mains

supply network.

Temperature of the ambient air

outside the tolerated ranges.

Clogged evaporator.

Fan heavily soiled. Clean the fan.

Scaling inside the water heater Descale.

Clean (see Maintenance by a qualified

professional, page 21).

Switch off the electric power supply and

inform your resellers.

Reset the water heater by switching off

the electric power supply, then switching

it back on.

Wait for the temperatures to return to the

tolerated ranges. Make sure that the

water heater is installed in a room

measuring more than >20m3, see

Installation, page 6)

Clean the evaporator (see Maintenance

by a qualified professional, page 21).

For all other malfunctions, contact aftersales.

- 24 -

Page 27

Sensor mapping curves (Temperature vs Resistance)

Courbes de correspondance des sondes (Température vs Résistance)

120,0

100,0

80,0

60,0

Résistance [kOhms]

40,0

Resistance [kOhms]

20,0

0,0

-20 0 20 40 60 80 100 120

Température [°C]

Temperature [°C]

IMPORTANT

Never power the heating element directly.

After-sales

Only use original manufacturer's spare parts. When ordering from one of the brand's resellers, specify the

precise type of water heater and the year of manufacture. All this information can be found on the identification

plate on the rear, near to the condensate discharge coupling.

Only specialists must work on the electri c parts of the appliance

Address of the after-sales department:

See the cover of this manual.

.

- 25 -

Page 28

ATLANTIC HEAT PUMP WATER HEATER WARRANTY.

Warranty Conditions

1. The heat pump water heater (hpwh) must be installed to plumbing and electrical services that meet all

relevant statutory and local requirements of the region in which the system is installed. Relevant clauses of

AS/NZS 3500 Plumbing & Drainage Code; and NZ G12 New Zealand Building Code – must be complied with

by the Installer.

2. The hpwh requires a single phase 16 amp supply requiring a licensed electrician for connecting. A licensed

plumber must connect cold water and hot water supplies in accordance with this manual. The installers must

comply with good practice, applicable installation standards and Atlantic Australasia’s technical instructions

included in this Manual.

3. The hpwh must be operated and maintained in accordance with instructions supplied by Atlantic Australasia

Pty Ltd. This may include draining and flush-through in areas of high suspended solids. Should this hpwh be

installed in a regional location where regular flushing is required due to sediment build-up, then a drain cock

or tee for flushing must be fitted at the time of installation. If in doubt consult your Installation Contractor.

4. The cylinder is warranted to be defect free for a period of 5 years in domestic installations, and 3 years in

commercial installations. Electric elements and component parts are warranted for a period of 2 years in

domestic installations and 1 year in commercial installations.

5. The hpwh is covered from the date of the original installation. Internet registration must be completed for

warranty protection. The customer to provide evidence of the date of installation at the time of claim.

Otherwise the installation date shall be considered to be the date of purchase.

6. This warranty takes the form of repair or determined by Atlantic Australasia Pty Ltd in the form of exchange or

supply, free of charge, excluding all labour and transport replacement charges.

7. Warranty period for exchanged or supplied parts/unit takes end at same time as applicable warranted

duration.

8. These Warranty Conditions do not exclude any of the benefits due to the purchaser that may be conferred by

Trade Practices and Consumer Law and associated articles in the country of installation.

9. For Australia: Our goods come with guarantees that cannot be excluded under the Australian Consumer Law.

You are entitled to a replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to

be of acceptable quality and failure does not amount to a major failure.

The benefits provided by this Warranty are in addition to all other rights and remedies in respect of the product

which the consumer has under the Competition and Consumer Act 2010.

PLEASE NOTE : If a Service call is requested and it is found that the defect is not a Warranted fault, the

purchaser may be charged for associated Warranty/Service call out costs even d uring the Warranty period.

Warranty Exclusions

The following warranty exclusions may cause the Atlantic Heat Pump Water Heater warranty to become void.

This may also incur a service charge and cost for parts should they be necessary.

1. Any physical damage caused by impacts or falls when the hpwh is handled after leaving the factory.

2. Where service is required to reconnect the hpwh operation due to problems related with abnormal water

supply (i.e. high water pressure above 1,000 kPa before, at system pressure relief), faulty plumbing supply

or downstream connection and/or electrical wiring or major variations in ele ctri ca l energy supply.

3. Failing to ensure the (ACI) anti-corrosion protection system to the tank.

4. Where a 560 kPa pressure limiting valve as shown in the water circuit diagrams, has not been fitted during

installation.

- 26 -

Page 29

5. Where the hpwh fails due to misuse, accidental damage, acts of God, incorrect installation including being

located in premises affected by frost or bad weather (humid, harsh or badly ventilated atmospheres) or

unlicensed service repair work attempts.

6. Any damage resulting from power surge from supply such as accidental high voltage injection or lightning

strike.

7. Damage resulting from non-detectable problems due to the inaccessible location of the device, and that

could have been avoided by immediately repairing the device if properly located.

8. Claims for damage to walls, foundations (outside), floor coverings & furnishings (inside), roofs or other

losses, directly or indirectly due to leakage from the Atlantic Heat Pump Water Heater.

9. No spacer insulation sleeves on the cold and hot water connection pipes, resulting in loss of function of

impressed current protection, that has lead to consequential corrosion.

10. Where the hpwh has been powered up before it has b een filled (heating when dry).

11. Where the hpwh has suffered external corrosion due to non-watertight piping connections.

12. If the system is either sold and/or repaired or altered by any third party without the consent of Atlantic

Australasia Pty Ltd.

13. Exclusions due to Water Composition

Please take note :

Water composition varies widely in Australia and New Zealand. In order to ensure a long and trouble free life the

Atlantic Heat Pump Water Heater incorporates an impressed current protection system, normally only found in

major installations in contact with water such as gas transmission pipelines. It is important that the composition

of water is not excessively high in salt which may result is aggressive attack, or calcium carbonate (also known

as water hardness) which will coat and isolate the effectiveness of the impressed current anode. Warranty is

therefore excluded where water composition in the hpwh exceeds the following :

Total dissolved solids 1000 mg/litre or p.p.m.

Electrical Conductivity 1400 uS/cm.

Total hardness 200 mg/litre or p.p.m.

Chloride 250 mg/litre or p.p.m.

Sulphate 250 mg/litre or p.p.m.

Magnesium 10 mg/litre or p.p.m.

Sodium 150 mg/litre or p.p.m.

pH Min 6.5 and Max 8.5

Water from springs, bores and dams is also excluded from meeting Warranty conditions because of the rapidly

variable composition of these waters due to groundwater salinity and aggressive mineralisation. Water MUST be

from a supplied, reticulated source or from rainwater to ensure Warranty compli ance.

Good, compliant installation Guidelines :

These are added to assist in the proper installation and use of your Atlantic Heat Pump Water Heater.

MECHANICAL RISKS:

1. Handling: The device must be handled and put in place with equipment adapted to its weight and size.

2. Location: The device must be located in premises protected from bad weather and frost.

3. Positioning: The device must be positioned in compliance with the manufacturer's instructions.

4. Fixing: The support and the fixing devices must be able to support at least the weight of the device filled

with water. All the fixing points allowed for by the manufacturer must be used.

- 27 -

Page 30

ELECTRICAL RISKS:

1. Connection: All connections must be made in compliance with the manufacturer's drawings. In particular,

make sure you do not neutralize the electric backup's thermostat (direct connection forbidden )

2. To avoid the power supply cable heating up, use the cable type and cross section given in the installation

manual. All regulations in force must be respected.

3. Make sure that there is an electric circuit protection upstream from the device.

4. Check all the connections are correctly tightened.

5. The device MUST be connected to good earth connection.

6. Make sure that all live parts cannot be accessed (protected by covers in their ori ginal condition).

HYDRAULIC RISKS:

1. Pressure: The devices must be used in the pressure range for which they have been designed.

2. Connection, discharge: For all pressurized devices, it is essential to install a Pressure Temperature Relief

valve that at least includes an exhaust valve. Do not obstruct the exhaust valve's discharge outlet. The

exhaust valve's discharge pipe must be connected to the waste water system.

3. Be careful not to reverse the hot and cold water connections. Ensure there are no leaks.

USE:

1. Type of product: This device is intended exclusively for heating domestic potable water and must not be

used for any other fluid.

2. Abnormal uses: Should the device not work correctly, contact a professional contractor.

3. The device must not be powered up before it has been filled. (heating when dry failure).

4. Burns, bacteria: For health reasons, the hot water must be stored at a high temperature. This temperature

may cause burns. Take all the necessary precautions (mixer taps, etc.) to avoid accidents at hot water

drawing points.

MAINTENANCE:

1. Periodically check that the Pressure Temperature Relief valve works correctly as instructed by the

manufacturer.

REPLACEMENT / SERVICING

1. It is forbidden to modify the device. All components must be replaced by a professional contractor using

original parts supplied by the manufacturer or equivalent.

- 28 -

Page 31

WIRING DIAGRAM

MAINTAINING YOUR

HEAT PUMP

WATER HEATER

1 Permanent power supply

2 Off-peak hours cable

3 Regulation

4 Incoming air sensor

5 Evaporator sensor

6 Pocket sensor

7 Anti-corrosion protection

8 1,800W steatite backup

9 Pocket

10 Mechanical safety device

11 Hot gas solenoid

12 Compressor condenser

13 Compressor

14 Low-speed condenser

15 Fan

16 Fan condenser

17 Safety pressure switch

18 Safety horn

19 Heat pump shells

Page 32

WARRANTY CERTIFICATE

TO BE KEPT BY THE USER OF THE APPLIANCE

ODYSSEO 2

HEAT PUMP WATER HEATER USING NON-HEATED AIR

Duration of the warranty*

- Water heater (cylinder): 5 years in domestic installations

- Electric elements and components parts: 2 years in domestic installations

The warranty covering service items, or replacement unit, expires at the end of the original

purchase warranty period.

* see details about warranty conditions and exclusions inside the user manual

3 years in commercial installation

1 year in commercial installations

FOR INFORMATION, REPAIRS AND SERVICE

CALL: AUSTRALIA : 1800 677 857

NEW ZEALAND : 0800 422 000

FOR WARRANTY REGISTRATION:

REGISTER AT: AUSTRALIA - www.atlantics.com.au

NEW ZEALAND - www.atlantics.co.nz

Loading...

Loading...