Page 1

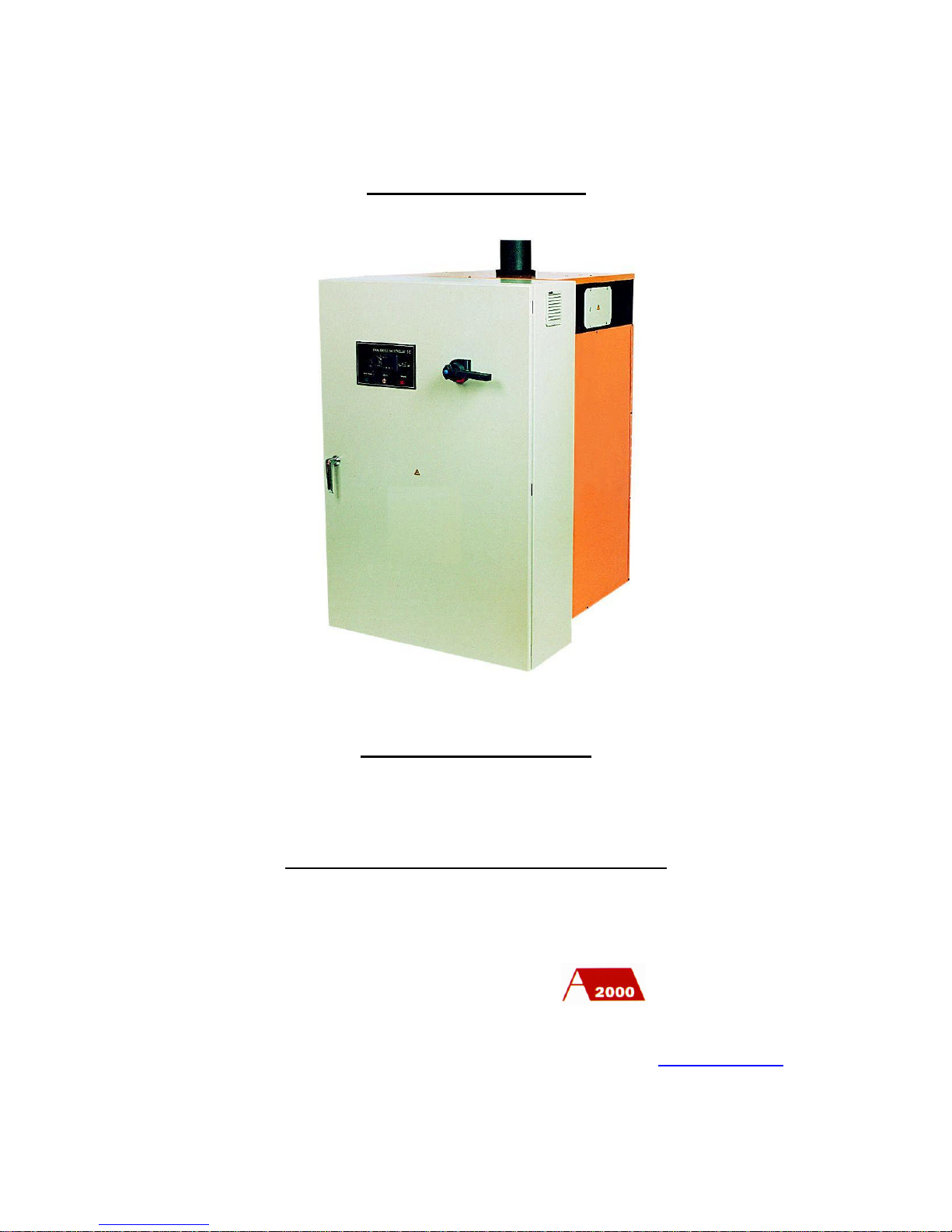

MULTI ELEC

Electric Boilers

TECHNICAL MANUAL

POBox11AshtonUnderLyneOL67TR

+44.(0) 1616215960 Fax+44.(0)1616215966

info@atlantic2000.co.uk

www.atlanticboilers.com

Page 2

2

Page 3

3

CONTENTS

DESCRIPTION………….………………………………...……………………………………1

PERFORMANCE………………………………………………………………………………

SCHEMATIC………………………………………………………………………………….…

CONTROL PANEL DIAGRAM

COMMAND ELECTRIC DIAGRAM…………………..……………….……………………5

POWER ELECTRIC DIAGRAM…………………….……………………………….………

FUSES…………………………………………………………………………………………..

CONTROL PANEL + REGULATION………………………………………………………..

INSTALLATION……………………………………………………………………………….10

STARTING THE BOILER…………………………………………………..……………………….…….

.

SERVICING…………………………………………………………………………………….11

THE COMMISSIONING OF THE MULTI-ELEC……………………………………………27

THE GUARANTEE ON THE MULTI-ELEC……………………………………………….32

4

5

6

8

9

10

11

12

14

15

16

17

18

Page 4

BOI

LER

CONTROL PANEL

- 1 waterproof control panel mounted on the boiler including:

- 1 main switch

- 3 industrial cylinder cartridge fuse per stage

- 3 contactors ( 1 per stage )

- 1 protected transformator 415 / 240 V

- 1 light « operation »

- 1 light « lock out »

( circulation and safetythermostat )

- 1 digital régulation

- Terminals for external connections

- Output from 36 to 630 kW

- Boiler body in welded steel E 24

- Working pressure 4 bars

- Test pressure 6 bars

- Working temperature below 110°C

- 50mm thick mineral fibre insulation, polyester film

aluminized glass cloth

- Safety thermostat with manual reset 110°C

- Internal expansion vessel

INCOLOY IMMERSION HEATERS

For boiler output between 36 and 288 kW

- Screwed elements diam.40

- Power of each unit: 12 kW

- 240/415Volts 3 phase + earth

- Removal of the immersion heaters: minimum

height of 2 m.

.

For boiler output between 315 and 630 kW

- Screwed elements diam.80

- Power of each unit : 35 kW

- R=1MΩ

- 415 Volts 3 phase + earth

- Removal of the immersion heaters: m

inimum height

of 2.5 m.

- Résistance d’isolement à froid à 1 mégohm

DESCRIPTION

The “Multi Elec” electric boilers have been designed for any heating system (maximum

working pressure 4 Bars)

They are Class 1 boilers that required earth connections IP21 / IK 08

Page 5

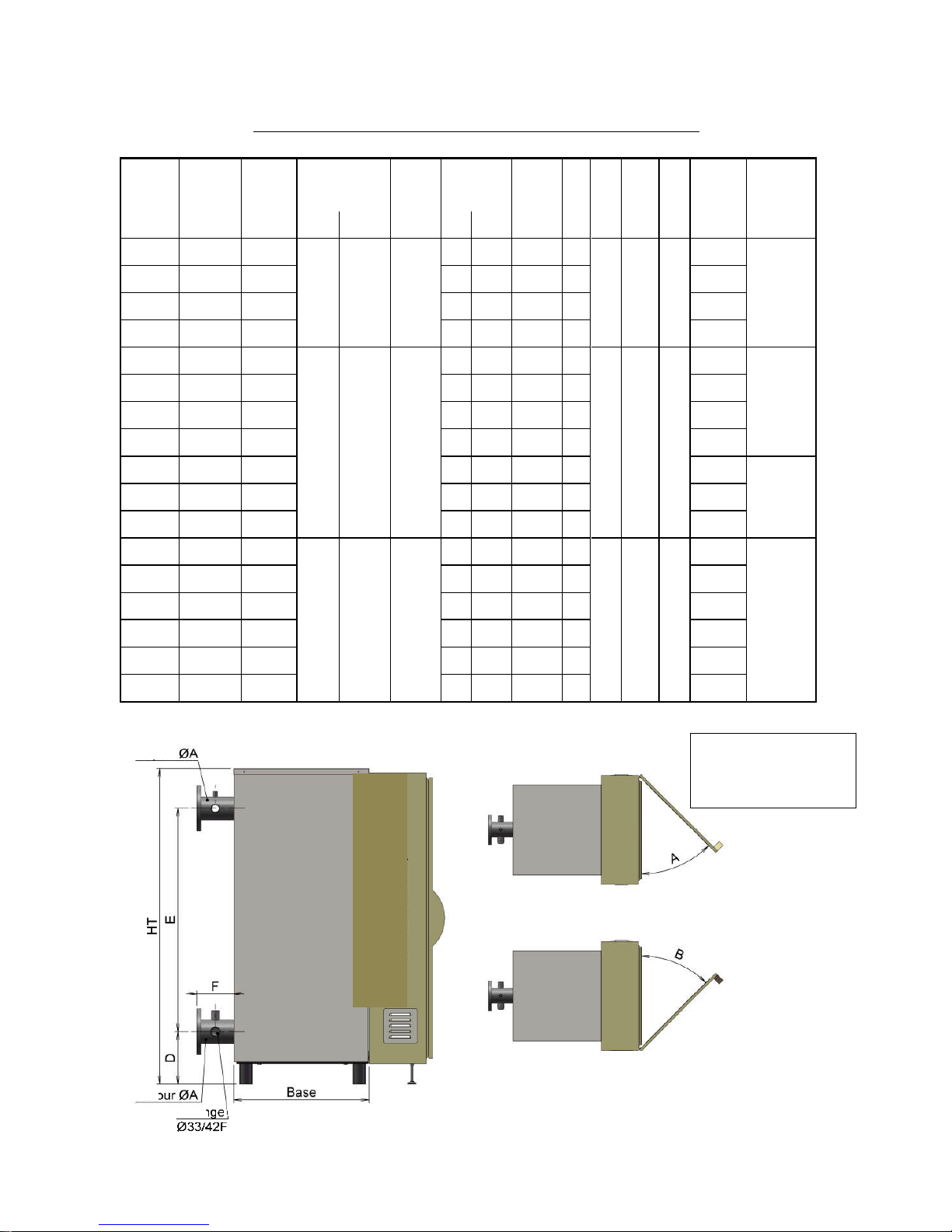

PERFORMANCE, DIMENSIONS & CONNECTIONS

OUTPUT

No.of

elements

kW per

element

Boiler

dimensions Volume Flow rate l/s

Pressure

drop

max flow

rate kPA

ØAD E F

Boiler

dry

weight

kg

Overall

dimensions

kW Foot

print

Height Litres Min Maxi H x L x P

90

3 30

520 1330 128

0.6 5.0 0.8

DN

80

235 920 180

117

1200x600x3

00

120

4 30 0.9 5.0 0.8

DN

80

121

150

5 30 0.9 9.7 2.8

DN

80

125

180

6 30 1.1 9.7 2.8

DN

80

129

210

6 35

670 1520 283

1.7 12.0 1.6

DN

100

255 1075 180

233

1400x800x3

00

245

7 35 1.7 12.0 1.6

DN

100

238

280

8 35 1.7 12.0 1.6

DN

100

243

315

9 35 1.7 12.0 1.6

DN

100

248

350

10 35 2.2 12.0 1.6

DN

100

253

1600x1000x

400

385

11 35 2.2 12.0 1.6

DN

100

258

420

12 35 2.2 12.0 1.6

DN

100

263

455

13 35

770 1520 395

2.8 26.0 1.6

DN

150

280 1020 180

340

1800x1000x

400

490

14 35 2.8 26.0 1.6

DN

150

345

525

15 35 2.8 26.0 1.6

DN

150

350

560

16 35 2.8 26.0 1.6

DN

150

355

595

17 35 3.6 26.0 1.6

DN

150

360

630

18 35 3.6 26.0 1.6

DN

150

365

Standard door opening A - to right

Optional door opening -

B-to left

Return

Drain

Control panel housing

Drain

Page 6

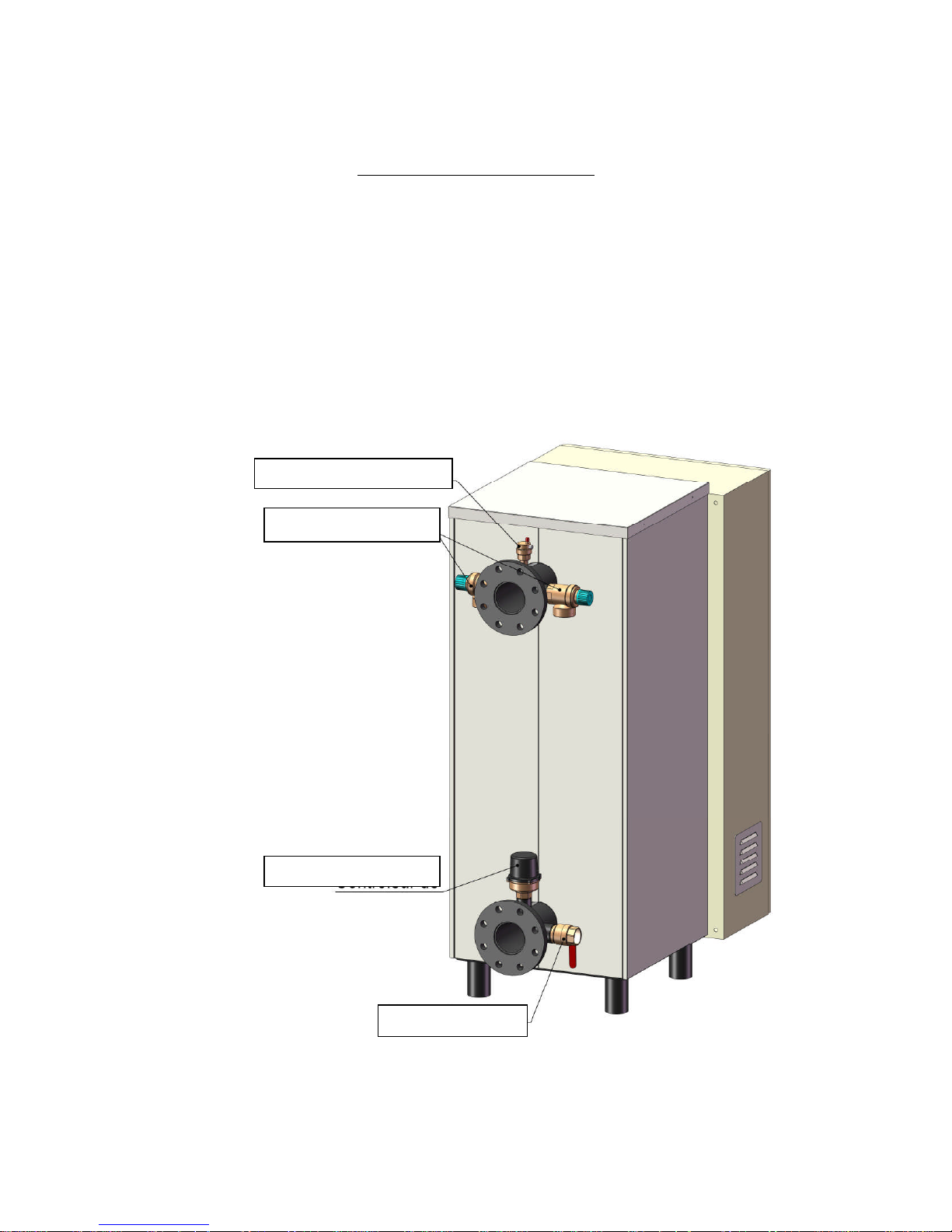

OPTIONAL ACCESSORIES

SHUNT PUMP with contact relay and run/lock-out lamps

MOUNTING PACK with automatic air release, water flow switch, drain

ball valve, safety relief valve and temperature & pressure relief valve

Automatic air release

Two relief valves

Water flow switches

Drain ball valve

Page 7

7

SCHEMATIC

1) Conventional Pipework

2) Weather compensated Pipework

3) Weather compensated pipework

Radiators or

under

-

floor heating

Page 8

8

4) Heating and hot water pipework

NB: Boiler pump flow should be 5% superior to the sum of heating and DHW primary

pump

expansion

vessel

pressure &

temperature relief

3 port valve

auto air

vent

pump

non return

valve

Fill loop

pressure relief

valve

isolating ball valve

Radiators

Page 9

MAINS POWER

400V, THREE PHASES +

EARTH (NO NEUTRAL

)

EARTH

MAIN SWITCH

TS

Fuses

COPPER PLATE

TERMINAL

TRANSFO

415/240V

Ka1

Terminal

FLEXIBLE

ISOLATED

COPPER LINKS

FAN

(from 216 kW)

Km3

Km2 Km1

CONTROL PANEL DIAGRAM

Page 10

VIEW OF THE CONTROL PANEL

Page 11

11

COMMAND ELECTRIC DIAGRAM

Lockout

Power

Lockout

415 Volts

3Phases supply

415/240

Fan

Sensor

Digital

Regulation

Fan V from 216 kW

F1-F2-F3 and Transfowill vary

according to boiler output

Limit Stat

Flow switch

Pump lockout

Other lockouts

Enable

Lockout signal

Green

Red

S1: Power Switch

I 1: Controller Switch

T1: 30s delay

T2: 1min delay

T3: 2min delay

Earth

: Green/Yellow 4mm²

Wires 0 to 6 : Red 1mm²

Wire 9 : Black1mm²

Other wires : Brown 1mm²

Page 12

BOILER ELECTRICAL OUTPUT

Output per step control

Output Step 1 Step 2 Step 3

90 kW 30 30 30

120 kW 60 30 30

150 kW 60 60 30

180 kW 60 60 60

210 kW 70 70 70

245 kW 105 70 70

280 kW 105 105 70

315 kW 105 105 105

350 kW 140 105 105

385 kW 140 140 105

420 kW 140 140 140

455 kW 175 140 140

490 kW 175 175 140

525 kW 175 175 175

560 kW 210 175 175

595 kW 210 210 175

630 kW 210 210 210

Page 13

13

BOILER ELECTRICAL PROTECTION

Selection of fuses

Fuses F1, F2 & F3 - cartridge size 8.5 x 31.5

90kW to 280kW

F1 - 1A type aM F2 - 1A type gG F3 - 0.5A type gG

315kW to 630kW

F1 - 1A type aM F2 - 2A type gG F3 - 0.5A type gG

Fuses F4, F5 & F6

Cartridge size 22 x 58 - 63A type gG

Miniature circuit breakers

output - 0 - 125A type gG

output - 1 - 160A type gG

output - 2 - 250, 315 & 400A type gG

Selection of FUSES or CIRCUIT BREAKERS

Boiler

output

F4 F5 F6

Boiler

output

F4 F5 F6

90 kW 63 A 63 A 63 A 385 kW 250 A 250 A 160 A

120 kW 125 A 63 A 63 A 420 kW 250 A 250 A 250 A

150 kW 125 A 125 A 63 A 455 kW 315 A 250 A 250 A

180 kW 125 A 125 A 125 A 490 kW 315 A 315 A 250 A

210 kW 125 A 125 A 125 A 525 kW 315 A 315 A 315 A

245 kW 160 A 125 A 125 A 560 kW 400 A 315 A 315 A

280 kW 160 A 160 A 125 A 595 kW 400 A 400 A 315 A

315 kW 160 A 160 A 160 A 630 kW 400 A 400 A 400 A

350 kW 250 A 160 A 160 A

Page 14

14

CONTROL PANEL + REGULATION

CONTROL PANEL

REGULATION

FRONT

BACK

Factory Settings

(Heating Circuit)

Set Point Temperature

:

80°C

77°C

74°C

Stage 1

Stage 2

Stage 3

Maximum Temperature :

95°C

Minimum Temperature : 20°C

Delay T1 : 30 secondes

Delay T2 : 1 minute

Delay T3 : 2 minutes

Safety Thermostat : 110°C

Power On

Off

Lockout

Boiler

temperature

Set

Point

Stages

1 = Stage1

2 =Stage2

5 =Stage3

Stage3

Stage1

Stage2

240V

Sensor

Page 15

Change the set point

Increase the set point temperature: Press the key

Decrease the set point temperature: Press the key

Never press the

PGM

and

EXIT

keys

For other settings, please contact Atlantic.

Information on the control panel

1.

2.

3.

Identification number plate on the control panel

The maximum acceptable current is Icw = 23 kA.

Only authorised person should have acccess to the contrl panel

4.5.Connection to earth is compulsory. (Class 1)

After commissioning (8 days) :

A/ Check the immersions heaters tightness

B/ Check the power circuit connections tightness

For information, advised tightness of the bolts:

M6

M8

M10

1,3m.daN

2,8 m.daN

5 m.daN

Check the tightness annually.

6.

Factory test

Regulation

Isolation of the power circuit

7. The boiler and the control panel should not been installe din a corrosive atmosphere or outside.

8. Ventilation (Natural convection or fan)

Leave enough space to allow air circulation. . Do not obstruct the fan and the grid.

Page 16

INSTALLATION

The “multi-elec” electric boiler should be installed in a louvered plantroom in order to

ensure an ambient temperature below 30ºC and relative humidity between 30 and 80%.

The boiler should not be used in a corrosive atmosphere or in an external position.

Adequate access should be left around the boiler in order to carry out maintenance.

The following safety devices are obligatory:

Safety valve (4 Bars maximum)

An automatic air vent on the boiler flow

A blow down valve

Electrical wiring

The“multi-elec” electric boiler should be connected to 415V without neutral

The circuit breaker and the cables section should be chosen according to British

standards.

Class 1 material IP21 / IK08

If the boiler is powered without any water, it will generate the thermocouple failure (no

warrantee)

Transport and storage

The unit should be transported and stored in the original package until it reached the

installation point.

Ambiant temperature below 80ºC

Relative humidity between 30 and 80%

Page 17

STARTING THE BOILER

Remove the power fuses

Check that the boiler is filled with water

Check that the immersion heaters are sound. If isolation is below 2MΏ, please

find the reason and remdy it.

Turn the power on using the main switch and the key switch

Check that the circulation pump is running.

Check that there is a lockout if the circulations pump stops

Adjust the temperature settings

Stop the boiler using the main switch

Put the power fuse in

Switch the boiler back on

Check the immersion heaters electrically for faults. Tight all the connections up

after one week of operation

If the boiler is powered without any water, it will cause the immersion heaters or

sensors to fail (no warranty)

Page 18

SERVICING

Loss of water velocity through the boiler can lead to temperature rise

Consider a sediment vessel on the return to capture sediment deposit

Blocking immersion heaters irrigation can destroy them

NOTE : The immersion heaters can be destroyed by blockage of the water flow

It is essential that a periodical cleaning is carried out on the main heat exchanger and the

sensors. The water also needs to be clean without any antifreeze or scale remover product

Removal of sludge and sediment reduce corrosion risks

On first start:

Check the electrical operation

Check each terminal to avoid any contact resistance or temperature rise

Activate the safety valve manually

Monthly servicing

Check

The automatic air vent

The safety valve

Biannual servicing

Check each terminal to avoid any contact resistance or temperature rise

Page 19

19

THE COMMISSIONING OF THE ATLANTIC MULTI ELEC

All Atlantic boilers and water heaters are thoroughly tested for mechanical, electrical and

combustion performance at the factory

The prime object of the site commissioning of the boiler(s) is, subject to installed

conditions, to match the optimum combustion performance results reached at the factory

and to ensure the boiler(s) is/are installed according to the conditions of guarantee.

The following check list should be satisfied before the commissioning takes place. To

arrange the commissioning Atlantic should be given a minimum of ten days notice of the

date and time required.

Commissioning sheet

Page 20

THE GUARANTEE ON THE ATLANTIC MULTI ELEC

This guarantee is to the purchaser of the boiler(s) who is deemed to be the installer. If the

boiler(s) is (are) purchased by the eventual user who then arranges to install the boiler(s),

the eventual user is deemed to be the installer. The details of the guarantee are given to

assist the installer in obtaining effective action within the guarantee and they are in

addition to the installer’s legal rights under the relevant statutory enactments for the time

being in force in England, Wales, and Scotland.

Electrical equipment:

The replacement or repair of the item, including the cost of its delivery to the site of the

installation or its equal within England, Wales and Scotland, provided that the defect or

flaw occurs within 1 calendar year of the commissioning date.

Removable component of the boiler assembly (other than the electrical equipment)

The replacement or repair of the item, including the cost of its delivery to the site of the

installation or its equal within England Wales and Scotland if the defect or flaw occurs

within 1 calendar year of the commissioning date.

The main body of the boiler.

The repair of any welding defects in the main body of the water heater including any

necessary removal or replacement of that part of the water heater on site if the defect

occurs within 3 calendar years of the commissioning date.

Definitions:

The effective actions stipulated in this guarantee are subject to the purchaser complying

completely with the following:

1) The boilers are installed according to the recommendations of this technical

booklet, the recommended codes of practice of the C.I.B.S.E and the B.S.I., and

the checklist on page 13 is satisfied.

2) The commissioning of the boilers by ACM Atlantic and their regular annual

servicing and maintenance.

3) The payment in full, by the purchaser unless otherwise agreed, of the invoice for

the supply and delivery of the boiler(s) to site, any other relevant invoices

connected with the boiler positioning and fixing, and the invoices for

commissioning and any correction of installation error, all to be made within one

calendar month of the date of the invoice.

4) The presentation, at the time of a claim under the guarantee, of the boiler

registration number, the commissioning record with date, and the necessary

information for defining any replacement part.

5) When a replacement item is supplied for a defective item, the defective item must

be returned to ACM Atlantic at their registered office within 6 weeks of the date

of notification of the defect carefully labeled with registration number of the

boiler and the name and the order reference of the purchaser of the boiler. If this

is not complied with, the purchaser will be charged with the cost of the item and

its delivery.

Loading...

Loading...