Athena C10, Platinum C10, Platinum M10, Platinum M300, Platinum M400 Communications Manual

...Page 1

COMMUNICATION MANUAL

Universal Digital Controller

C10

M10 – M300 – M400 – M5000

X100 – X400 – X5000 – X7000

ATHENA CONTROLS, INC.

5145, Campus Drive

Plymouth Meeting

Pennsylvania 19462-1129 U.S.A

Page 2

Copyright 1996 Athena Controls

All rights reserved

No part of this document may be stored in a retrieval system, or

transmitted in any form, electronic or mechanical, without prior written

permission of Athena Controls.

Athena Controls has used the best care and efforts in preparing this book

and believes the information in this publication are accurate. The Athena

Controls Products are subjected to continuous improvement, in the

pursuit the technological leadership, these improvements could require

changes to the information of this book. ATHENA CONTROLS reserves

the right to change such information without notice.

ATHENA CONTROLS makes no warranty of any kind, expressed or

implied, with regard to the documentation contained in this book.

ATHENA CONTROLS shall not be liable in any event - technical and

publishing error or omissions - for any incidental and consequential

damages, in connection with, or arising out of the use of this book.

TATION, AC PROGRAPH e AC EDIT, are trademarks of ATHENA

AC S

CONTROLS.

All the other tradenames or product name are trademark or registered

trademarks.

2

Page 3

C O N T E N T S

MODBUS PROTOCOL.................................................................................................................................... 6

1.

2. MESSAGE FORMAT.......................................................................................................................................6

2.1 CHARACTERS FORMAT .................................................................................................................................7

2.2 THE ADDRESS...............................................................................................................................................7

2.3 THE FUNCTION CODE ...................................................................................................................................7

2.4 THE CRC 16 ALGORITHM ............................................................................................................................7

2.4.1 CRC 16 Flow Chart.............................................................................................................................9

2.4.2 Visual Basic Calculate CRC16 example............................................................................................10

2.5 MESSAGE SYNCHRONISATION ....................................................................................................................10

3. THE MODBUS FUNCTIONS........................................................................................................................10

3.1 READ OUTPUT STATUS (01) .......................................................................................................................10

3.2 READ INPUT STATUS (02)...........................................................................................................................11

3.3 READ OUTPUT REGISTERS (03) ..................................................................................................................11

3.4 READ INPUT REGISTERS (04)......................................................................................................................11

3.5 FORCE SINGLE COIL (05)............................................................................................................................12

3.6 PRESET SINGLE REGISTER (06)...................................................................................................................12

3.7 READ STATUS (07) .....................................................................................................................................13

3.8 FORCE MULTIPLE COILS (15) .....................................................................................................................13

3.9 PRESET MULTIPLE REGISTERS (16) ............................................................................................................14

4. ERROR MANAGEMENT..............................................................................................................................14

4.1 ERROR CODES ............................................................................................................................................15

5. MODBUS ON ATHENA CONTROLS PLATINUM® INSTRUMENTS .................................................15

5.1 SERIAL COMMUNICATIONS PARAMETERS....................................................................................................15

5.2 COMMUNICATIONS TIME.............................................................................................................................15

5.3 DATA BASE ................................................................................................................................................16

5.4 BIT ZONE....................................................................................................................................................16

5.5 WORD ZONE ...............................................................................................................................................16

5.6 ASSIGNMENT OF THE PARAMETERS AND E2PROM .....................................................................................17

6. ELECTRICAL CONNECTIONS ..................................................................................................................17

6.1 GENERAL DESCRIPTION..............................................................................................................................17

6.2 COMMUNICATION CABLE LAYING RECOMMENDATIONS ............................................................................18

6.3 INSTRUMENTS WITH AN RS-485 INTERFACE (2 WIRE) ................................................................................18

6.3.1 References..........................................................................................................................................19

7. C10 / M10 CONTROLLERS.......................................................................................................................... 19

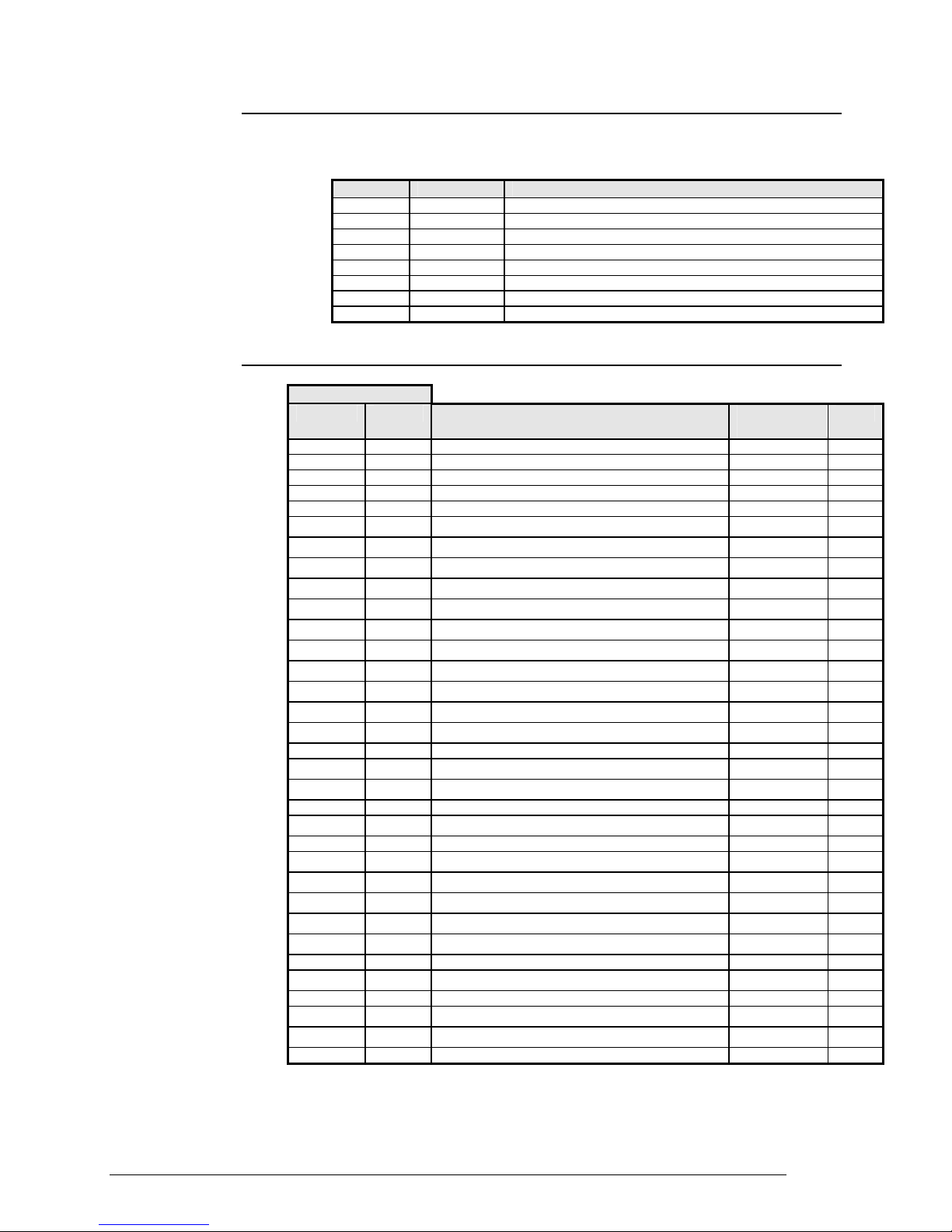

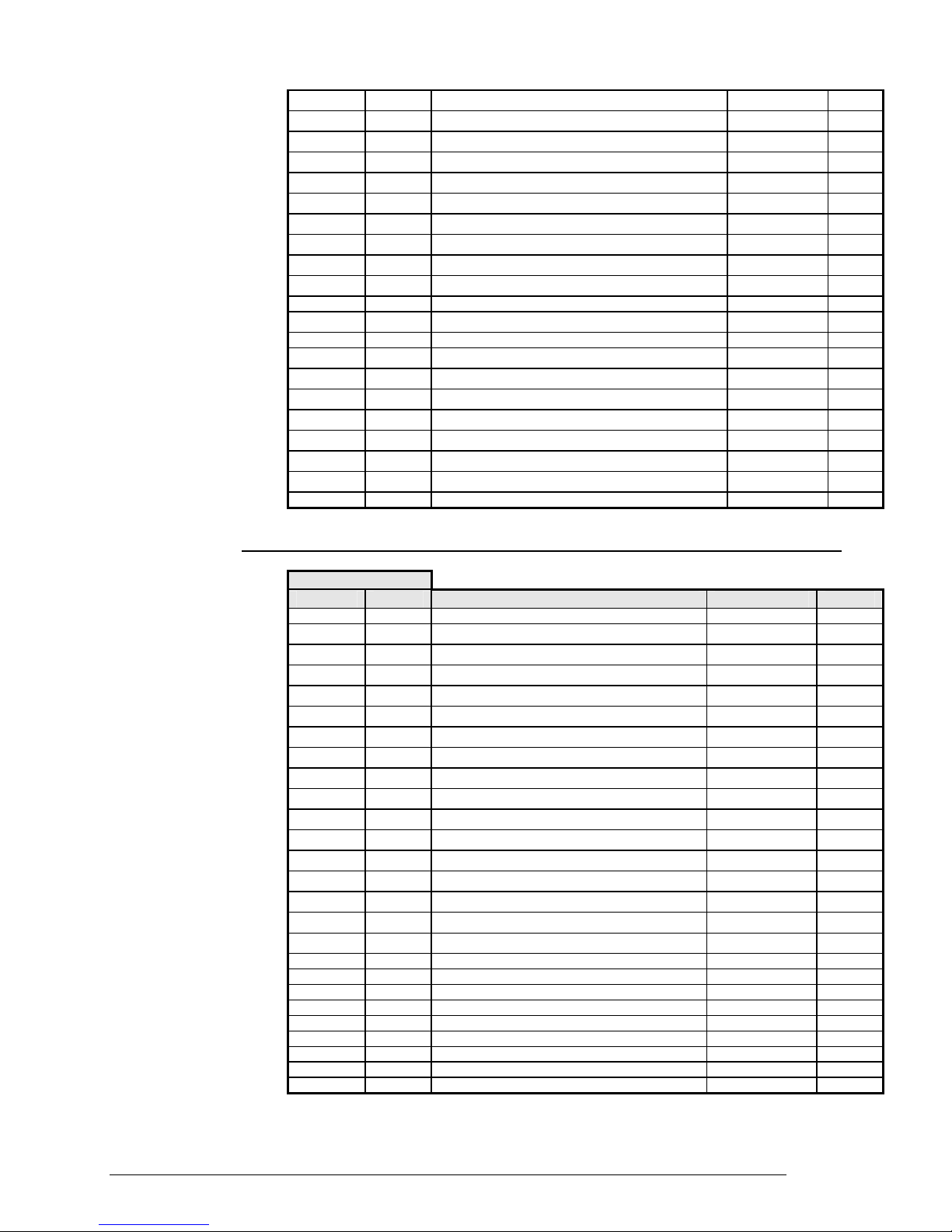

7.1 BIT ZONE....................................................................................................................................................19

7.2 READ STATUS.............................................................................................................................................20

7.3 WORD ZONE - PAGE 1 PARAMETERS ..........................................................................................................20

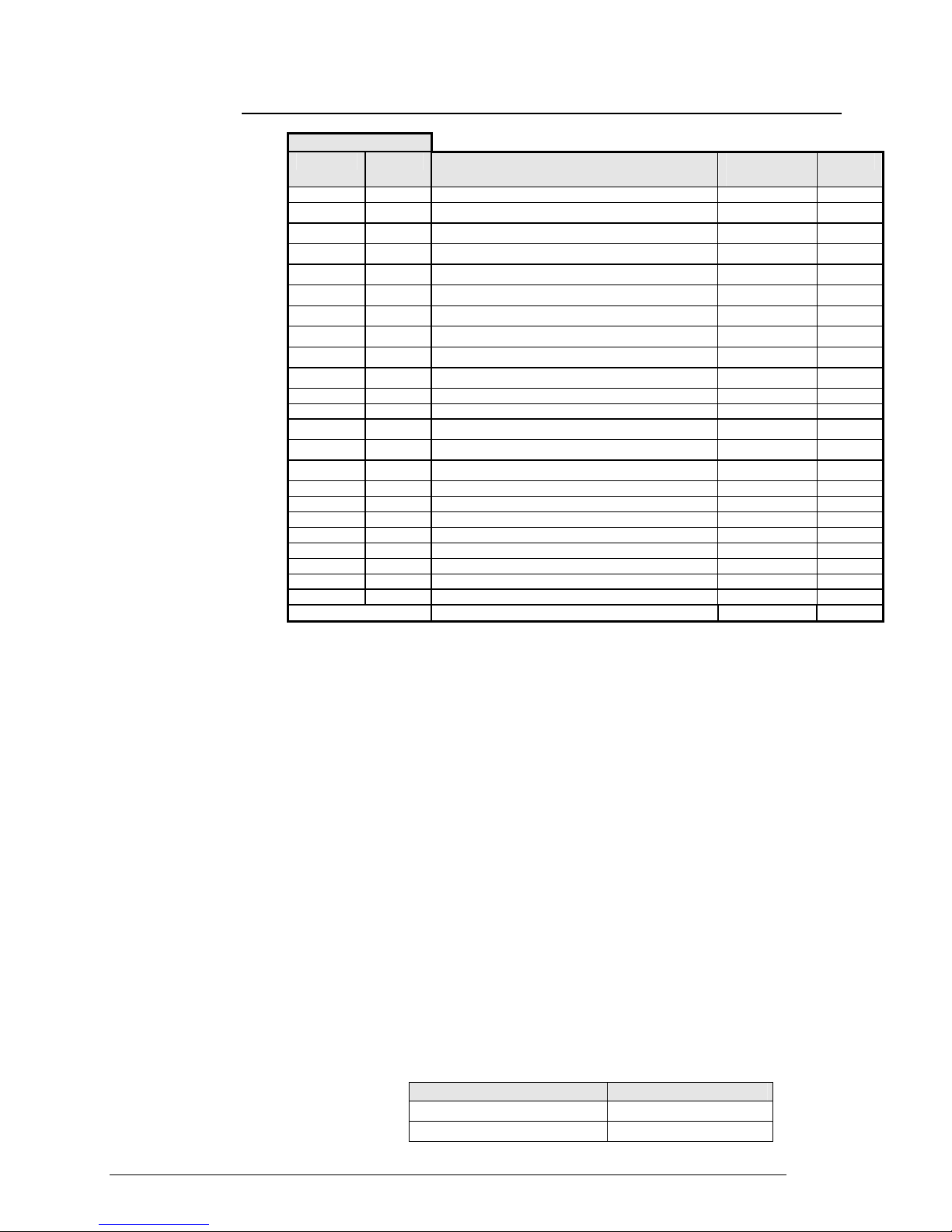

7.4 WORD ZONE - PAGE 2 CONFIGURATION.....................................................................................................21

7.5 TERMINATION AND POLARISATION.............................................................................................................22

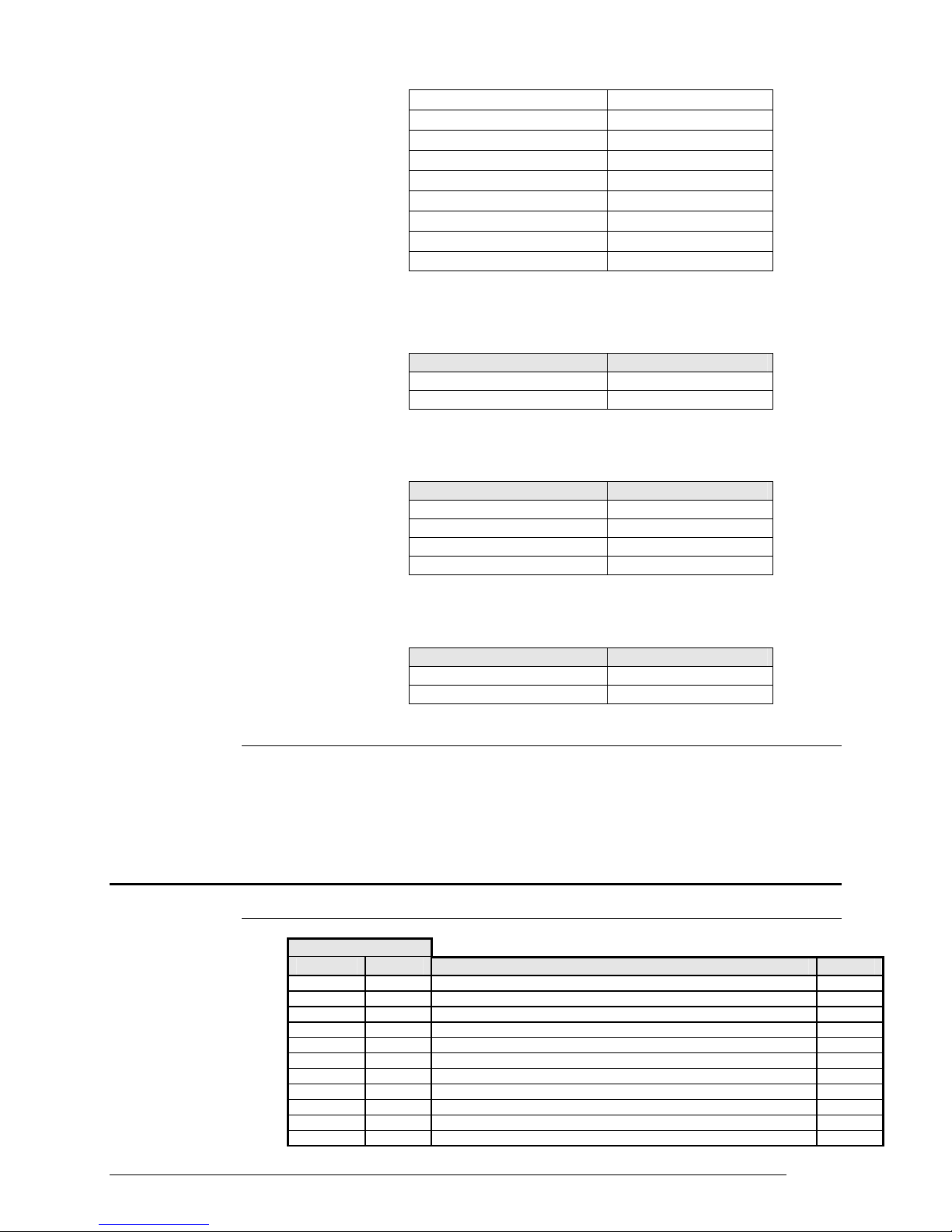

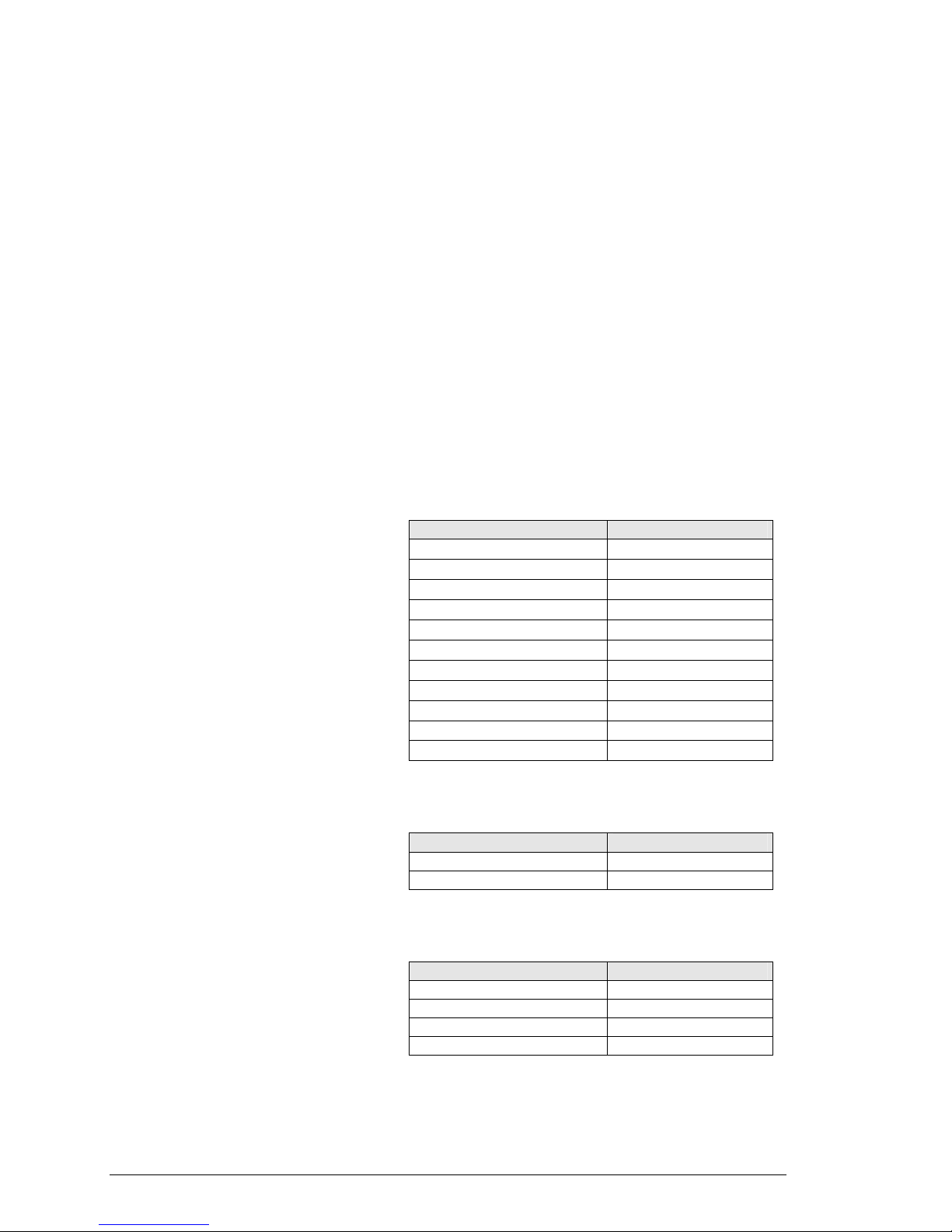

8. M300 CONTROLLER ....................................................................................................................................22

8.1 BIT ZONE ....................................................................................................................................................22

8.2 READ STATUS.............................................................................................................................................23

8.3 WORD ZONE - PAGE 1 PARAMETERS ..........................................................................................................23

8.4 WORD ZONE - PAGE 2 CONFIGURATION.....................................................................................................24

8.5 TERMINATION AND POLARISATION.............................................................................................................26

3

Page 4

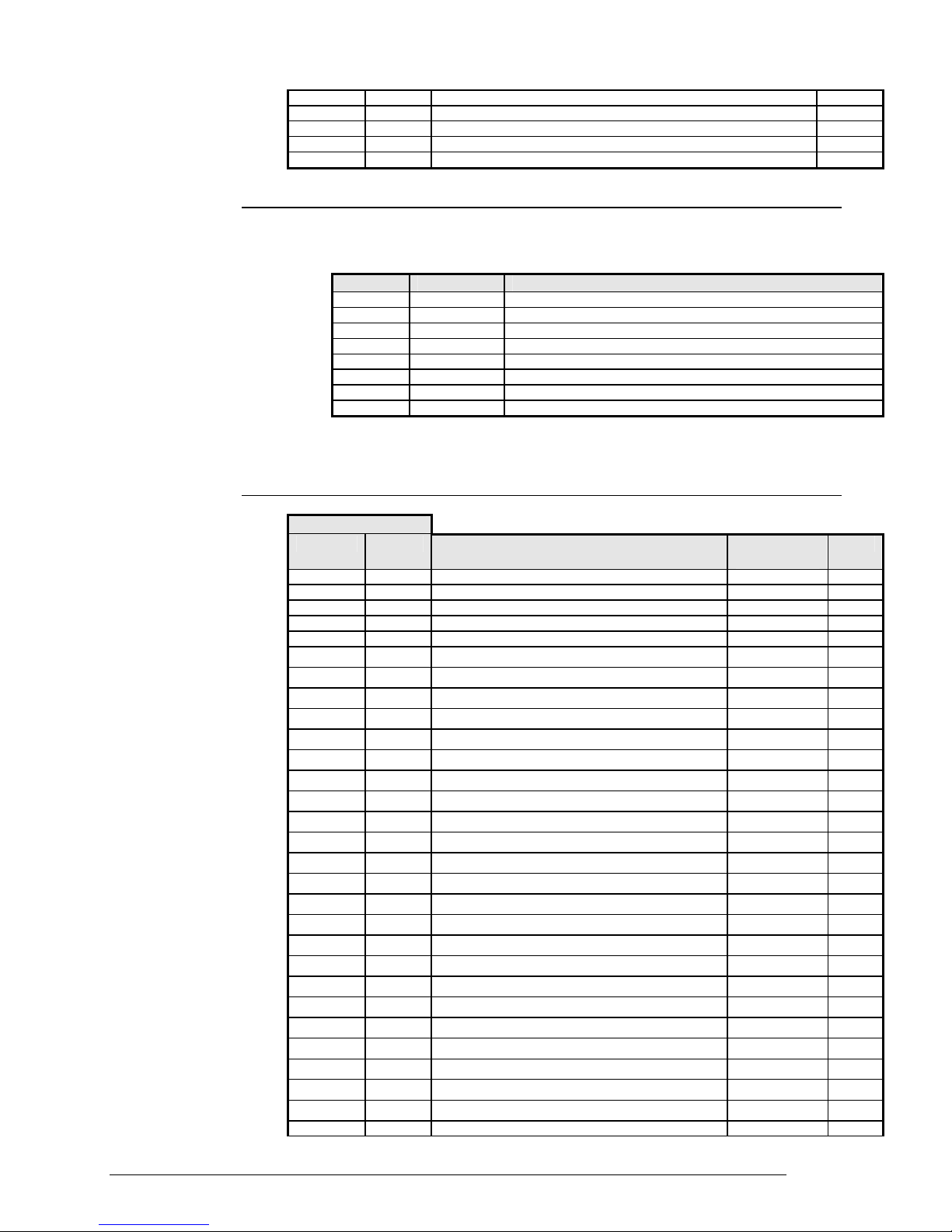

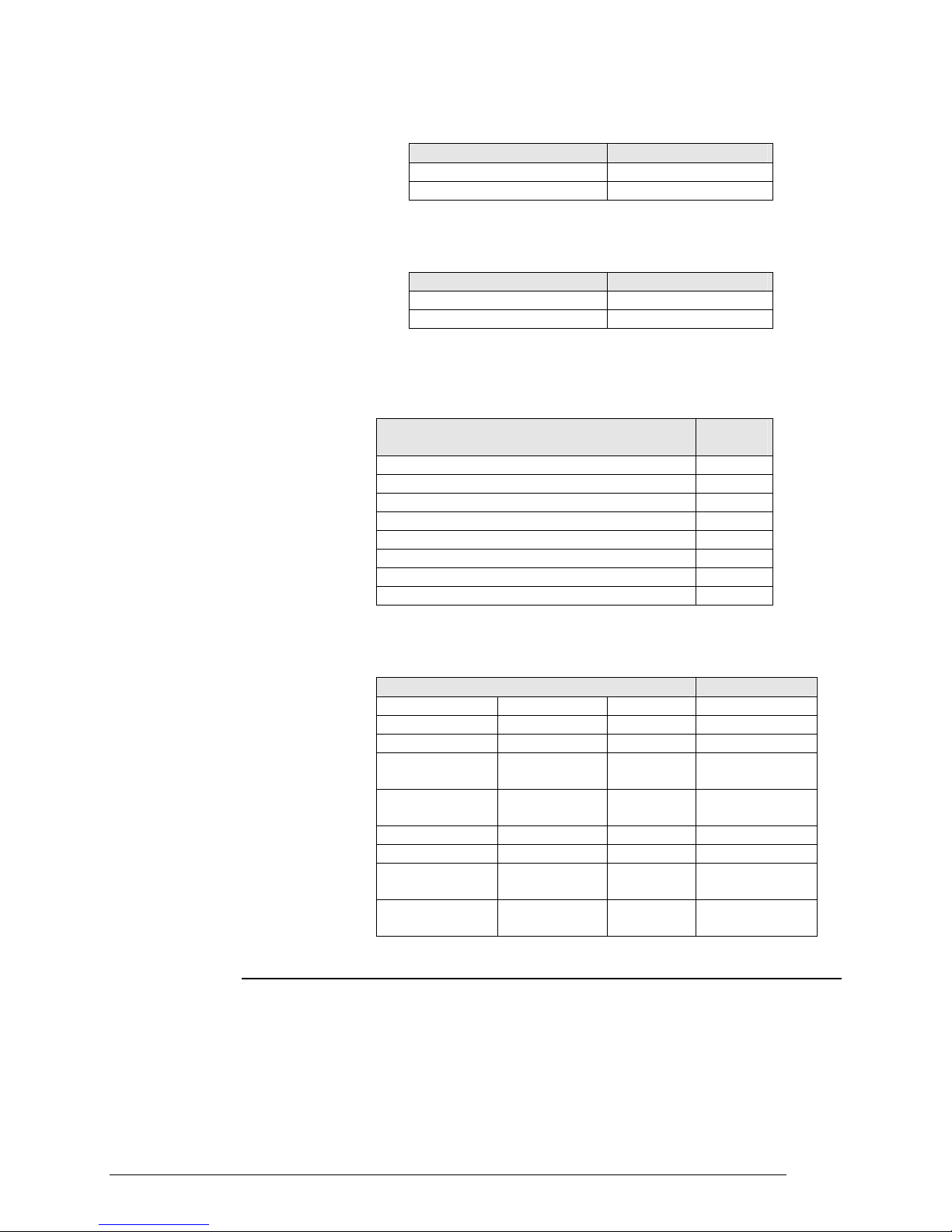

M400 CONTROLLER ....................................................................................................................................27

9.

9.1 BIT ZONE ....................................................................................................................................................27

9.2 READ STATUS.............................................................................................................................................27

9.3 WORD ZONE - PAGE 1 PARAMETERS ..........................................................................................................27

9.4 WORD ZONE - PAGE 2 CONFIGURATION .....................................................................................................28

9.5 TERMINATION AND POLARIZATION.............................................................................................................31

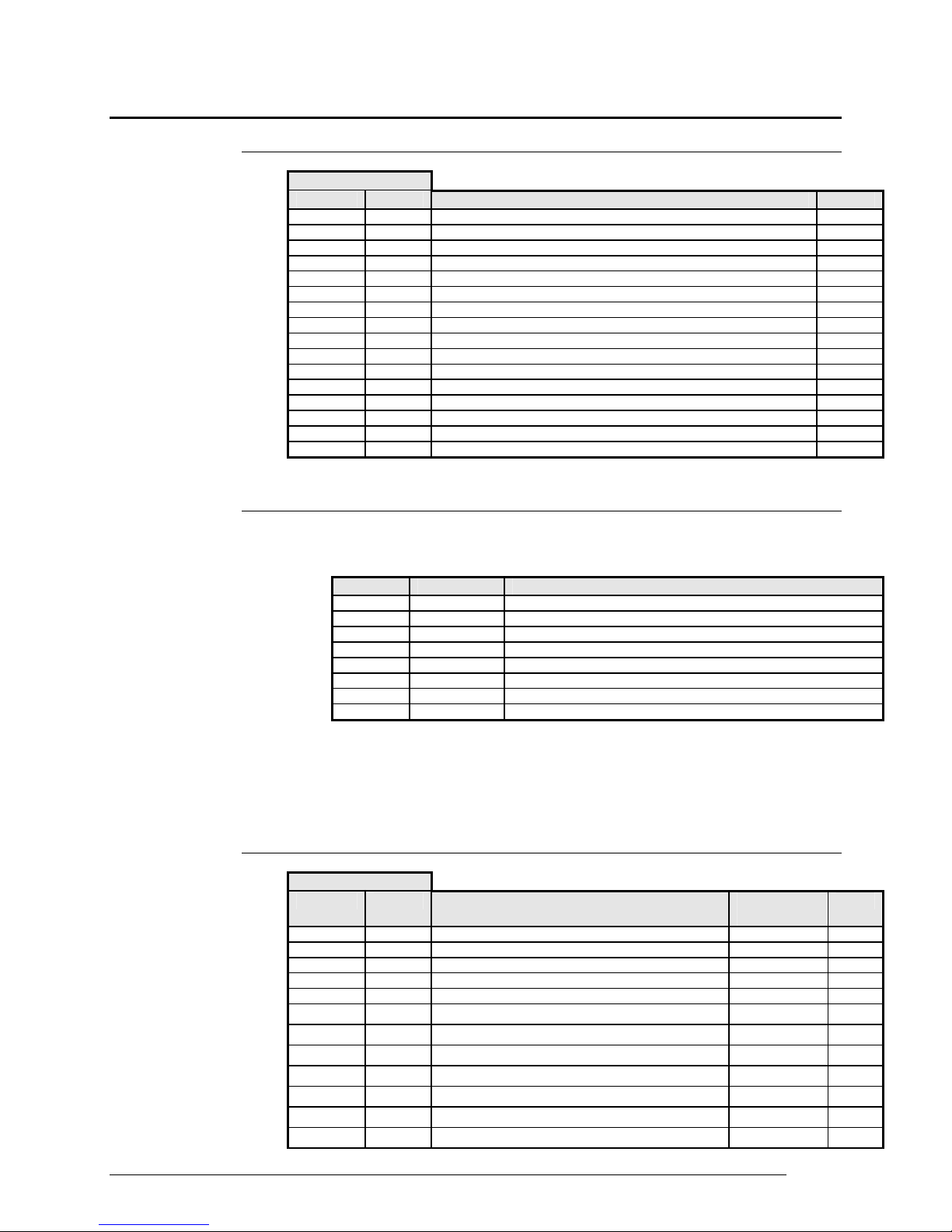

10. M5000 CONTROLLER ..............................................................................................................................31

10.1 BIT ZONE ....................................................................................................................................................31

10.2 READ STATUS.............................................................................................................................................32

10.3 WORD ZONE - PAGE 1 PARAMETERS ..........................................................................................................32

10.4 WORD ZONE - PAGE 2 CONFIGURATION .....................................................................................................33

10.5 WORD ZONE - PAGE 3 PROGRAMMER.........................................................................................................34

10.6 RS-485 CONFIGURATION DIP SWITCH .......................................................................................................39

11. X100 / X400 CONTROLLER .....................................................................................................................39

11.1 BIT ZONE....................................................................................................................................................39

11.2 READ STATUS.............................................................................................................................................40

11.3 WORD ZONE - PAGE 1 PARAMETERS..........................................................................................................40

11.4 WORD ZONE - PAGE 2 PARAMETERS..........................................................................................................41

11.5 WORD ZONE - PAGE 3 PROGRAM ...............................................................................................................42

11.6 WORD ZONE - PAGE 4 CONFIGURATION.....................................................................................................42

11.7 RS-485 CONFIGURATION DIP SWITCH .......................................................................................................46

12. X5000 CONTROLLER ...............................................................................................................................47

12.1 BIT ZONE ....................................................................................................................................................47

12.2 READ STATUS.............................................................................................................................................47

12.3 WORD ZONE - PAGE 1 PARAMETERS ..........................................................................................................48

12.4 WORD ZONE - PAGE 2 CONFIGURATION .....................................................................................................49

12.5 WORD ZONE - PAGE 3 PROGRAMMER.........................................................................................................50

12.6 RS-485 CONFIGURATION DIP SWITCH .......................................................................................................61

13. CONFIGURATION SOFTWARE FOR PLATINUM CONTROLLERS .............................................61

13.1 USE OF INSTRUMENTS WITH THE RS 485 COMMUNICATIONS OPTION .........................................................62

13.2 TO LOAD THE SOFTWARE ............................................................................................................................63

13.3 TO ENTER THE CONFIGURATION SOFTWARE ...............................................................................................64

13.4 CONFIGURATION SOFTWARE SETTINGS .......................................................................................................65

13.5 TO STORE THE SCREEN SETTINGS INTO THE INSTRUMENT............................................................................66

13.6 TO LOAD A CUSTOM SENSOR CONFIGURATION ............................................................................................66

13.7 TO CLONE SEVERAL INSTRUMENTS .............................................................................................................68

13.8 TO STORE THE SCREEN SETTINGS AS A FILE.................................................................................................68

13.9 TO RECALL A PREVIOUSLY STORED FILE .....................................................................................................69

13.10 PRINTING OF THE CONFIGURATION .........................................................................................................70

13.11 TREND MENU .........................................................................................................................................70

13.12 PROGRAMMED SETPOINT (ONLY IF THE PROGRAM OPTION IS PRESENT) .....................................................71

13.12.1 M5000 Controller ..........................................................................................................................71

13.12.2 X400 Controller.............................................................................................................................77

13.12.3 X5000 Controller...........................................................................................................................82

13.13 CONFIGURATION OF THE MASTER COMMUNICATIONS (ONLY X5000) ....................................................88

13.14 CONFIGURATION OF THE MATHEMATICAL / LOGICS OPERATIONS............................................................90

13.15 CONFIGURATION OF THE NUMERICAL CONSTANTS..................................................................................92

13.15.1 To modify the value of a constant ..................................................................................................93

13.15.2 To eliminate a constant..................................................................................................................94

13.15.3 Reading/writing of the configuration of the mathematical packet in the device............................94

13.15.4 Save the configuration of the mathematical packet on files ..........................................................94

13.16 DEFINITION OF THE PROFIBUS PARAMETERS (X5000 CONTROLLER ONLY) ...............................................94

13.16.1 How to insert the parameters in the configuration (X5000 controller only)...............................95

4

Page 5

13.16.2

13.16.3 How to save the configuration (X5000 controller only) ..............................................................103

13.16.4 How to send the configuration of the Profibus parameters (X5000 controller only)...............................103

13.16.5 How to receive the configuration of the Profibus parameters (X5000 controller only) ...............................104

14. RECOMMENDED RS-232 TO RS-485 CONVERTER ........................................................................106

14.1 ATHENA PART# 223A001401 RS-232 TO RS-485 OPTICALLY ISOLATED COMMUNICATIONS CONVERTER106

14.2 GENERAL INFORMATION..............................................................................................................................107

Parameters of the Data Base (X5000 controller only) ..................................................................97

5

Page 6

1. MODBUS Protocol

The Modbus protocol defines the format and method of communications

between a “master” which controls the system and one or more “slaves”

which respond to commands sent by the master. The Modbus defines

how the transmitter and reciever are identified, how messages are

exchanged and how errors are detected.

There may be one master and up to 247 slaves on a common line; this is

the protocol’s logical limit, the physical interface may limit the number of

devices further, for example, the standard RS485 interface handles a

maximum of 31 slaves connected on the line. Substituting the last device

on the line with a proper “repeater” or “bridge”, another 31 instruments

can be added to the line and so on up to the above mentioned limit (247).

All transactions are started by the master. A transaction may be a direct

question/reply to a single slave or broadcast in which the message is

sent to all the devices on the line and no answer is given. A transaction

consists of a single question/replay frame or a single broadcast

message/no answer frame.

Some of the characteristics of the protocol are not defined. These are:

standard interface, baud rate parity, number of bits.

The protocol also enables the user to choose between two

communications modes, ASCII and RTU (binary). Only the RTU mode is

implemented on ATHENA CONTROLS instruments as it is more efficient.

The Jbus protocol is functionally identical to Modbus and differs from it in

how the addresses are numbered: with Modbus the addresses are

numbered starting from zero) 0000= 1

start from one (0001=1

throughout all addresses. From here on, unless explicitly specified, even

though reference is made to Modbus, the description is valid for both.

st

address). This difference is maintained

st

address, while with Jbus they

2. Message Format

For communication to take place between the two devices, the message

must be put in a "packet". The packet leaves the transmitter through a

"port" and is "carried" along the line to a similar "port" on the receiver.

MODBUS establishes the format of this packet which includes, for both

the master and the slave:

• The address of the device with which the master has established the

connection (address 0 corresponds to a broadcast message sent to

all slave devices).

• The code of the function that is to be or has been performed.

• The data that is to be exchanged.

• The error check based on the CRC16 algorithm.

If a device detects an error in the message received (in the format, parity

or CRC16) the message is considered invalid and rejected, a slave that

detects an error in the message will therefore not take any action or

answer the question, such as when the address does not correspond to a

device on the line.

6

Page 7

2.1 Characters Format

The above mentioned packets referred to the transmitted character from

the PC or Supervisor.In this case this character cannot be modified

because they are set by Athena Controls. The default value is 8 , N, 1. It

means 8 data bits without parity check and with 1 stop bit.

2.2 The Address

As mentioned above, MODBUS transactions always involve the master,

which handles the line, and one slave at a time (except in the case of

broadcast messages). To identify the user to whom the message is sent,

the first character sent is a byte containing the numeric address of the

selected slave device. Each of the slaves will therefore be assigned a

different address that identifies it uniquely. The valid addresses range

from 1 to 247, while address 0, which cannot be assigned to a slave, set

at the start of the message sent by the master indicates that the message

is to be "broadcast", that is, sent to all the slaves at the same time.

Broadcast messages are exclusively those that do not require an answer

to carry out their function, i.e. assignments only.

2.3 The Function Code

The second character in the message identifies the function that is to be

performed in the message sent by the master, to which the slave

answers by sending back the same code to indicate that the function has

been performed. On ATHENA CONTROLS instruments, a subset of the

MODBUS functions has been implemented as follows:

• 01 Read Coil Status

• 02 Read Input Status

• 03 Read Holding Registers

• 04 Read Input registers

• 05 Force Single Coil

• 06 Preset Single register

• 07 Read Status

• 15 Force Multiple Coils

• 16 Preset Multiple Registers

In the implementation for ATHENA CONTROLS instruments, functions 01

and 02 are functionally identical and interchangeable, as are functions 03

and 04. For a full and detailed description of the functions, see chapter 3.

2.4 The CRC 16 Algorithm

The last two characters in the message contain the Cyclic Redundancy

Check based on the CRC16 algorithm. To calculate these two

characters, the message (address, function code and data without the

start, stop and parity bits) is considered as a single continuous binary

number whose most significant bit (MSB) is sent first. The message is

first multiplied by x16 (shifted to the left by 16 bits) and then divided by

16+215+22

2

integer part of the quotient is then rejected and the 16 bit remainder

(initialised at FFFFh at the start to avoid messages consisting exclusively

of zeros) is added on to the end of the message sent. The resulting

message, when divided by the same polynomial (2

receiving device must give zero as a remainder if no errors occurred (the

receiving device recalculates the CRC).

+1 expressed as a binary number (1100000000000101). The

16+215+22

+1) by the

7

Page 8

In reality, as the device that converts the data to be sent into serial form

(UART) sends the least significant bit (LSB) first instead of the MSB as it

should do for the CRC calculation, the CRC is carried out by inverting the

polynomial. In addition, as the MSB of the polynomial only affects the

quotient and not the remainder, the remainder is eliminated, thus giving

1010000000000001.

The step by step procedure for the CRC16 calculation is as follows:

1) Load a 16-bit register with FFFFh (all bits set to 1).

2) Execute the exclusive OR of the first character with the high order

byte in the register and place the result in the register.

3) Shift the register to the right by one bit.

4) If the bit that left the register on the right (flag) is a 1, execute the

exclusive OR of the polynomial 1010000000000001 with the

register.

5) Repeat steps 3 and 4 eight times.

6) Execute the exclusive OR of the next character with the high order

byte in the register and place the result in the register.

7) Repeat steps 3 to 6 for all the characters in the message.

8) The contents of the 16 bit register are the CRC code that is to be

added to the message.

8

Page 9

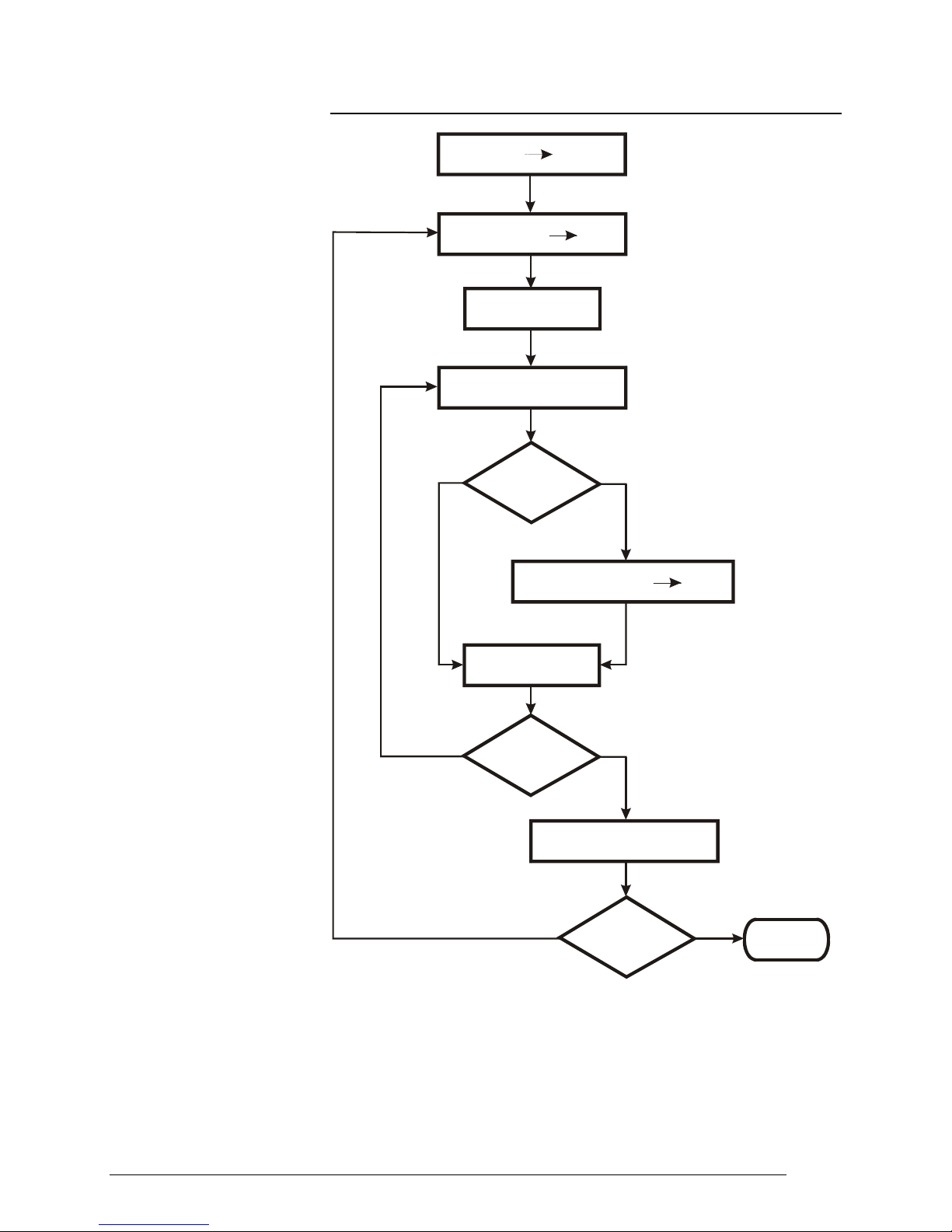

2.4.1 CRC 16 Flow Chart

CRC 16 XOR byte

NO

Hex FFFF

n = 0

Shift to right CRC 16

Carry

CRC 16 XOR Hex A001

CRC 16

CRC 16

YES

CRC 16

n = n + 1

NO

N > 7

NO

YES

Next Byte

End

message

YES

END

9

Page 10

2.4.2 Visual Basic Calculate CRC16 example

Function CRC16(String As String) As String

Dim N As Integer, i As Integer, NByte As Integer

Dim CRC As Long, a As Byte

Dim Buffer As String

NByte = Len(String)

CRC = 65535

For i = 1 To NByte

a = Asc(Mid$(String, i, 1)) 'C(I)

CRC = (CRC Xor a) And &HFFFF

For N = 0 To 7

If CRC And 1 Then

CRC = (CRC \ 2)

CRC = (CRC Xor 40961)

Else

CRC = CRC \ 2

End If

Next

Next

Buffer = Right$("0000" + Hex$(CRC And &HFFFF), 4)

CRC16 = Chr$("&H" + Right$(Buffer, 2)) + Chr$("&H" + Left$(Buffer, 2))

End Function

2.5 Message Synchronisation

Message synchronisation between the transmitter and the receiver is

obtained by inserting a pause of at least 3.5 times the time of one

character between the messages. If the receiving device does not

receive for the time required for 3 characters, it considers the previous

message completed and concludes that the next byte received will be the

first of a new message and, consequently, an address.

3. The MODBUS Functions

3.1 Read Output Status (01)

This section provides a detailed description of the MODBUS functions

implemented on ATHENA CONTROLS instruments.

This function is used for requesting the ON or OFF status of binary

logical variables. Broadcast mode is not allowed.

Question

In addition to the address of the slave and the function code (01), the

message contains the starting address expressed in two bytes and the

number of bits to be read, also occupying two bytes. Address numbering

starts from zero (bit1 = 0) for MODBUS, or one (bit1 = 1) for JBUS.

10

Page 11

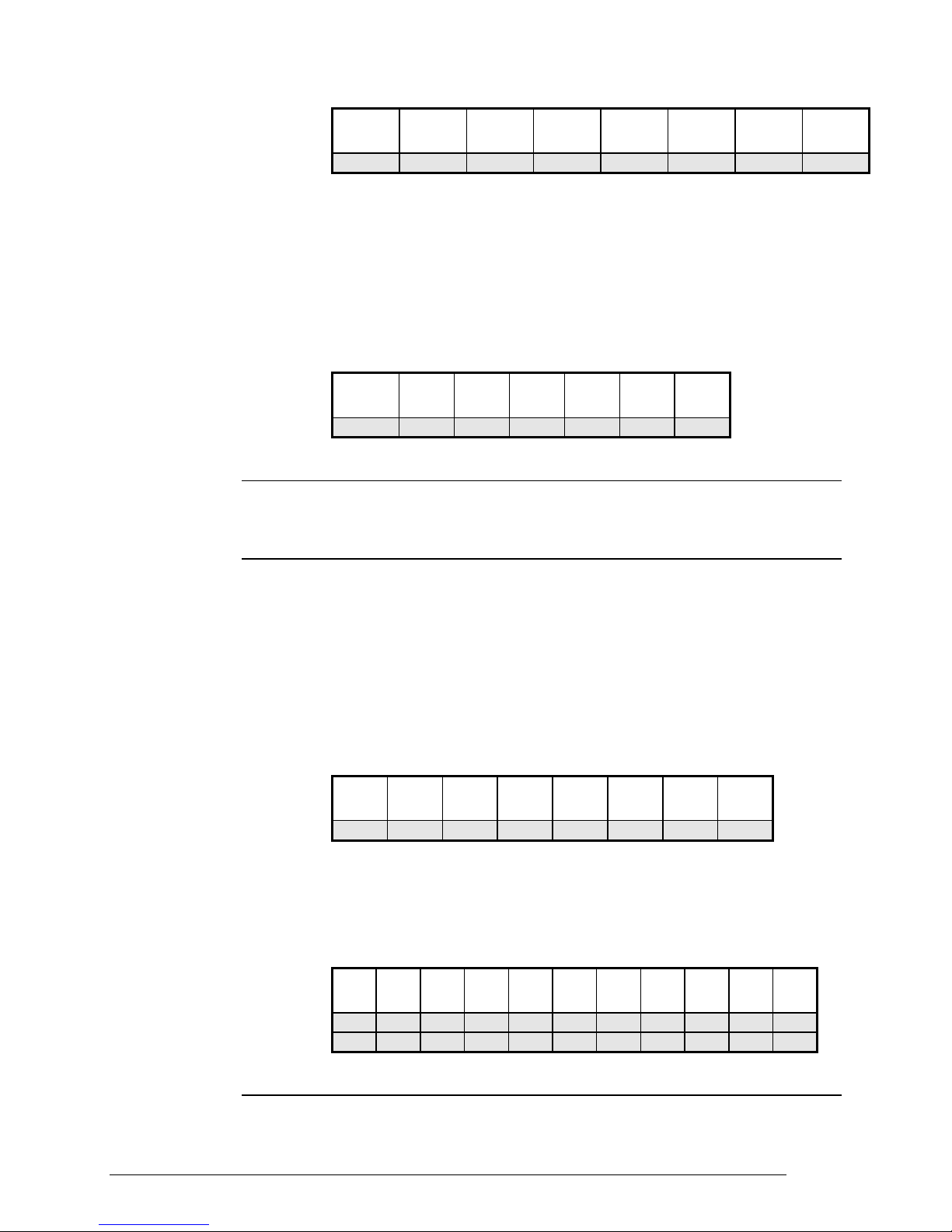

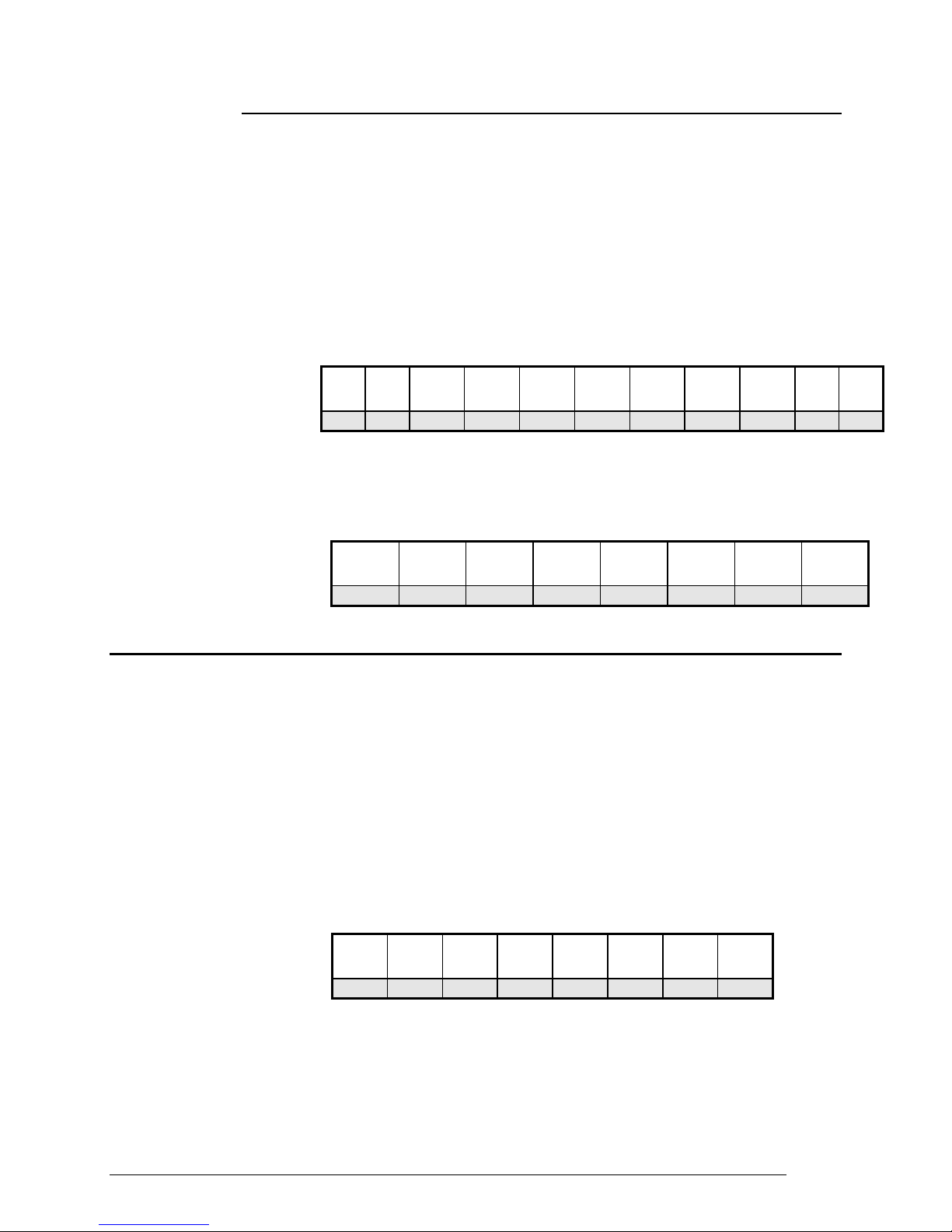

Example: Request for slave 17 to read bits 0004 to 0015.

ADDR FUNC

DATA

start

Addr HI

DATA

start

Addr LO

DATA

bit #

HI

DATA

bit #

LO

CRC

HI

CRC

LO

11 01 00 03 00 0C CE 9F

Answer

In addition to the address of the slave and the function code (01), the

message comprises a character containing the number of data bytes and

the characters containing data. The data are compacted, so one byte

contains the status of 8 bits, the least significant bit of the first byte must

contain the bit corresponding to the starting address and so on. If the

number of bits to be read is not a multiple of 8, the last character must be

completed with zeros in the most significant bits.

Example: Answer to the request indicated above.

ADDR FUNC

DATA

Byte

Count

DATA

bit

04..11

DATA

bit

12..15

CRC

HI

CRC

LO

11 01 02 CD 0B 6D 68

3.2 Read Input Status (02)

This function works in exactly the same way as the previous one.

3.3 Read Output Registers (03)

This function is used for requesting the value of 16-bit (word) registers

containing numeric variables. Broadcast mode is not allowed.

Question

In addition to the address of the slave and the function code (03), the

message contains the starting address expressed in two bytes and the

number of words to be read, also occupying two bytes. The maximum

number of words that may be read is 125. Address numbering starts from

zero (word1 = 0) for MODBUS, or one (word1 = 1) for JBUS.

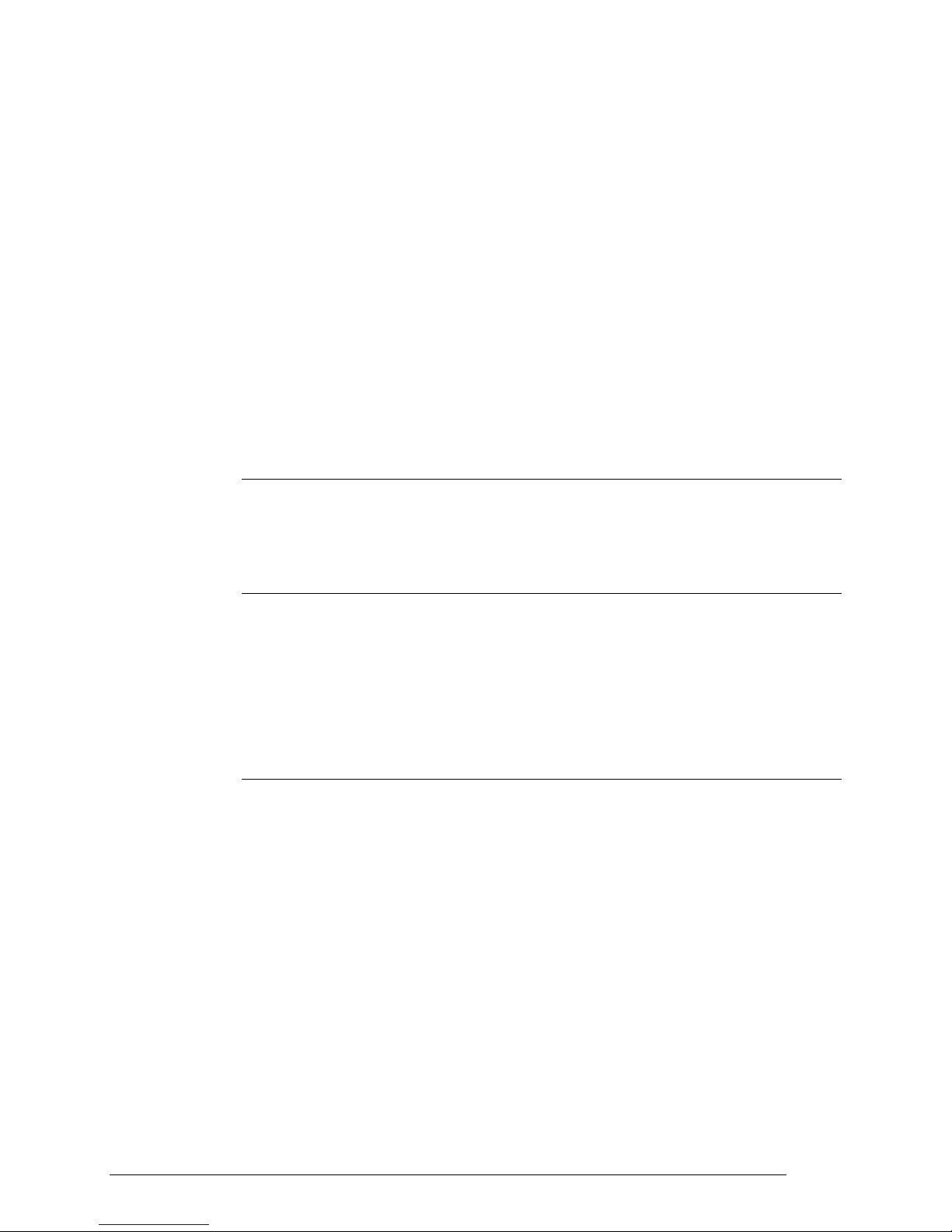

Example: Request for slave 25 to read registers 069 to 0071.

ADDR FUNC

DATA

start

Addr HI

DATA

start

Addr LO

DATA

word #

HI

DATA

word #

LO

CRC

HI

CRC

LO

19 03 00 44 00 03 46 06

Answer

In addition to the address of the slave and the function code (03), the

message comprises a character containing the number of data bytes and

the characters containing data. The registers require two bytes each, the

first of which contains the most significant byte.

Example: Answer to the request indicated above.

ADDR FUNC

DATA

Byte

Count

DATA

word

69 HI

DATA

word

69 LO

DATA

word

70 HI

DATA

word

70 LO

DATA

word

71 HI

DATA

word

71 LO

CRC

HI

CRC

LO

19 03 06 02 2B 00 00 00 64 AF 7A

3.4 Read Input Registers (04)

This function works in exactly the same way as the previous one.

11

Page 12

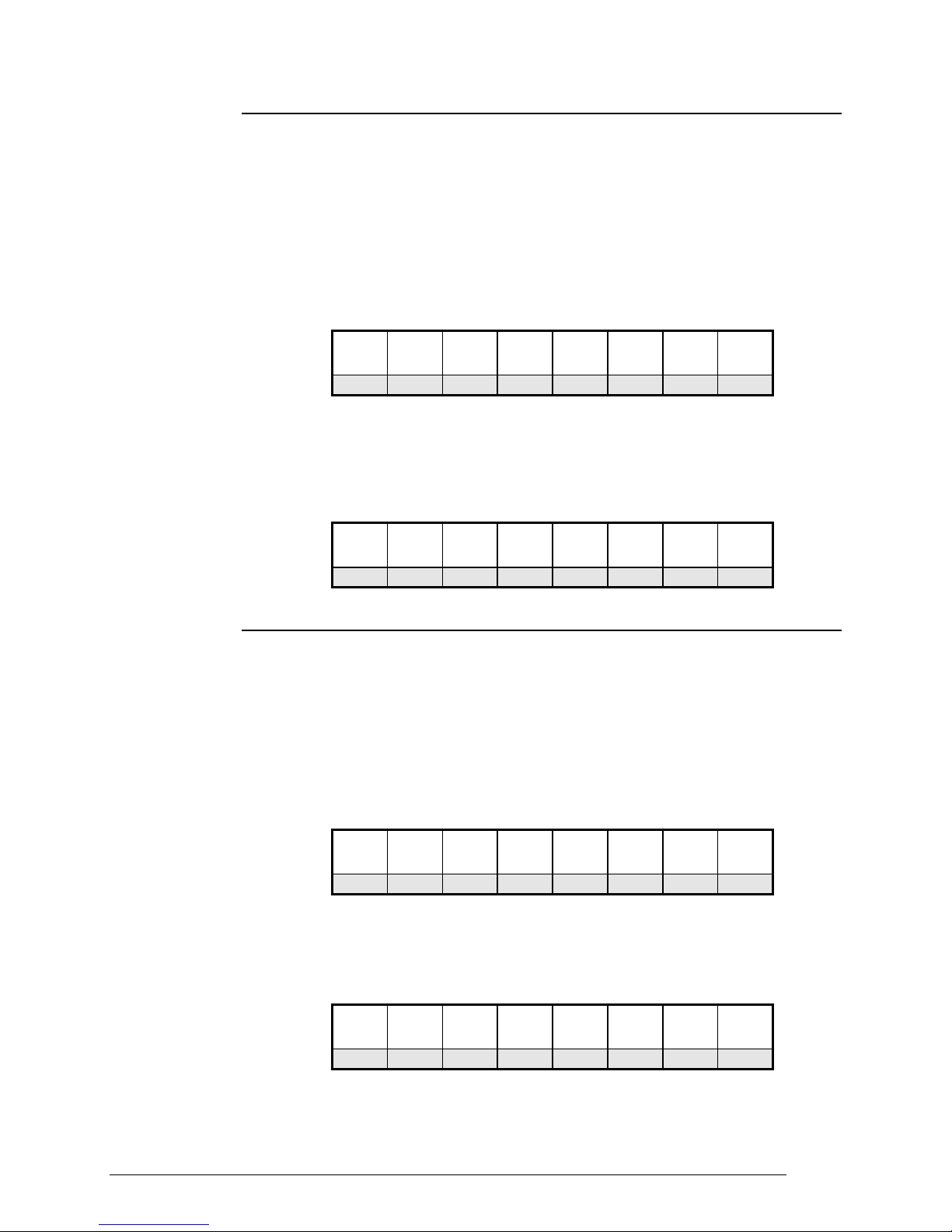

3.5 Force Single Coil (05)

This function is used for forcing the status of a single binary variable ON

or OFF. Broadcast mode is allowed.

Question

In addition to the address of the slave and the function code (05), the

message contains the address of the variable to be forced in two bytes

and two characters of which the first is set to FFh (255) to force it ON and

00h to force it OFF, while the second is always set to zero. Address

numbering starts from zero (bit1 = 0) for MODBUS, from one (bit1 = 1) for

JBUS.

Example: Request to force bit 4 on slave 47 ON.

ADDR FUNC

DATA

bit #

HI

DATA

bit #

LO

DATA

ON/OFF

DATA

(zero)

CRC

HI

CRC

LO

2F 05 00 03 FF 00 7A 74

Answer

The answer consists in retransmitting the message received once the

variable has been changed.

Example: Answer to request mentioned above.

ADDR FUNC

DATA

bit #

HI

DATA

bit #

LO

DATA

ON/OFF

DATA

(zero)

CRC

HI

CRC

LO

2F 05 00 03 FF 00 7A 74

3.6 Preset Single Register (06)

This function is used for setting the value of a single 16-bit register.

Broadcast mode is allowed.

Question

In addition to the slave and the function code (06), the message contains

the address of the variable expressed in two bytes and the value to be

assigned. Address numbering starts from zero (word1 = 0) for MODBUS,

from one (word1 = 1) for JBUS.

Example: Request to force address 26 of slave 38 to 926.

ADDR FUNC

26 06 00 19 03 9E DF 82

Answer

The answer consists in retransmitting the message received once the

variable has been changed.

Example: Answer to request indicated above.

ADDR FUNC

26 06 00 19 03 9E DF 82

DATA

bit #

HI

DATA

bit #

HI

DATA

bit #

LO

DATA

bit #

LO

DATA

WORD

HI

DATA

WORD

HI

DATA

WORD

LO

DATA

WORD

LO

CRC

HI

CRC

HI

CRC

LO

CRC

LO

12

Page 13

3.7 Read Status (07)

This function is used for reading the status of eight predetermined bits

with a compacted message. Broadcast mode is not allowed.

Question

The message consists only of the slave address and the function code

(07).

Example: Request of the status of slave 25.

ADDR FUNC CRC

HI

CRC

LO

19 07 4B E2

Answer

In addition to the address of the slave and the function code (07), the

message comprises a character containing the status bits.

Example: Answer to the request indicated above.

ADDR FUNC

DATA

status

byte

CRC

HI

CRC

LO

19 07 6D 63 DA

3.8 Force Multiple Coils (15)

This function is used for forcing the status of each binary variable in a

consecutive block. Broadcast mode is allowed.

Question

In addition to the address of the slave and the function code (15), the

message contains the starting address expressed in two bytes, the

number of bits to be written, the number of bytes containing the data and

the data characters. The data are compacted, so one byte contains the

status of 8 bits, the least significant bit of the first byte must contain the

bit corresponding to the starting address and so on. If the number of bits

to be written is not a multiple of 8, the last character must be completed

with zeros in the most significant bits. Address numbering starts from

zero (bit1 = 0) for MODBUS, from one (bit1 = 1) for JBUS.

Example: Request to force 4 bits starting from address 1 on slave 12. Bits

1 and 4 forced to "1" and the others to "0".

ADDR FUNC

0C 0F 00 00 00 04 01 09 3F 09

Answer

In addition to the address of the slave and the function code (15), the

message contains the starting address and the number of bits written.

Example: Answer to request indicated above.

ADDR FUNC

0C 0F 00 00 00 04 55 15

DATA

start

Addr HI

DATA

Addr HI

start

DATA

start

Addr LO

DATA

Addr LO

start

DATA

bit #

HI

DATA

bit #

HI

DATA

bit #

LO

DATA

bit #

LO

DATA

Byte

Count

CRC

HI

DATA

bit

1..4

CRC

LO

CRC

HI

CRC

LO

13

Page 14

3.9 Preset Multiple Registers (16)

This function is used for setting the value of a consecutive block of 16-bit

registers. Broadcast mode is allowed. Question.

In addition to the address of the slave and the function code (16), the

message contains the starting address, the number of words to be

written, the number of bytes that contain data and the data characters.

Address numbering starts from zero (word1 = 0) for MODBUS, from one

(word1 = 1) for JBUS.

NOTE: In the ATHENA CONTROLS implementation, this function is

present for compatibility but does not permit more than 8 word to be

assigned.

Example: Request to set 1 word to value 268 at address 35 on slave 17.

ADDR FUNC

11 10 00 22 00 01 02 01 0C 6C 87

Answer

In addition to the address of the slave and the function code (16), the

message contains the starting address and the number of words written.

Example: Answer to the request indicated above.

ADDR FUNC

11 10 00 22 00 01 A3 53

DATA

start

Addr HI

DATA

start

Addr LO

DATA

start

Addr HI

DATA

word #

HI

DATA

start

Addr LO

DATA

word #

LO

DATA

Count

DATA

word #

HI

Byte

DATA

word

35 HI

DATA

word #

LO

DATA

word

35 LO

CRC

HI

CRC

HI

CRC

LO

CRC

LO

4. Error Management

In MODBUS there are two types of errors, handled in different ways:

transmission errors and operating errors. Transmission errors are errors

that change the format of the message, the parity (if used) or the CRC16.

A device that detects errors of this type in the message treats it as invalid

and gives no answer. When the format of the message is correct but the

function requested cannot be executed for some reason, an operating

error has occurred. When it detects this kind of error, the slave device

answers by sending an error message. This message consists of the

address, the code of the function requested, an error code and the CRC.

To indicate that the answer is an error message, the function code is

returned with the most significant bit set to "1".

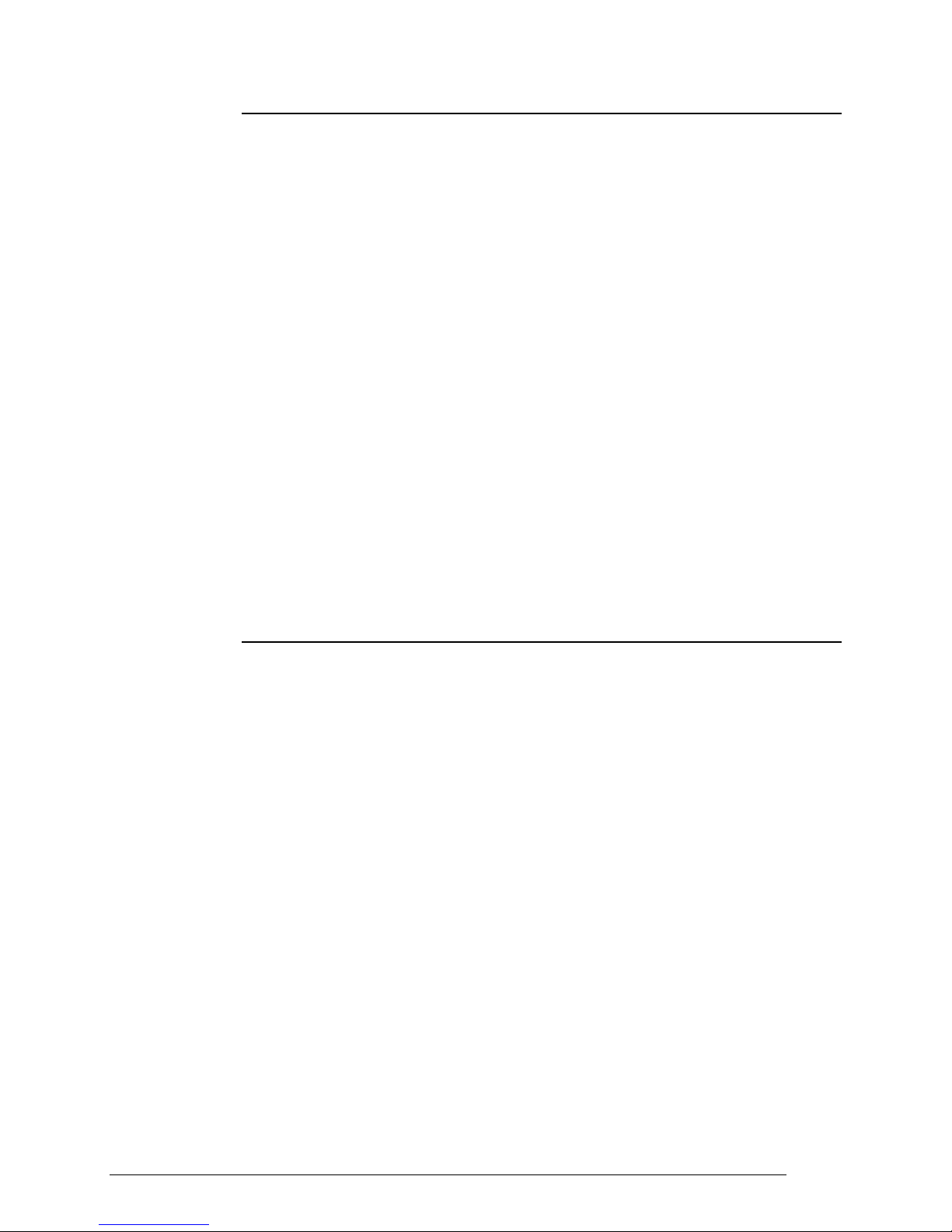

Example: Request for slave 10 to read bit 1185.

ADDR FUNC

DATA

start

Addr HI

DATA

start

Addr LO

DATA

bit #

HI

DATA

bit #

LO

CRC

HI

CRC

LO

0A 01 04 A1 00 01 AC 63

Answer

The request is for the contents of bit 1185, which is not present on the

slave. The slave answers by sending error code "02" (ILLEGAL DATA

ADDRESS) and returns the function code 81h (129).

14

Page 15

Example: Error code in response to the request indicated above.

ADDR FUNC

DATA

Except.

Code

CRC

HI

CRC

LO

0A 81 02 B0 53

4.1 Error Codes

Although the MODBUS standard uses 8 error codes, the ATHENA

CONTROLS implementation of the protocol uses only four:

Code Name Meaning

01

02

ILLEGAL FUNCTION

ILLEGAL DATA

ADDRESS

03

07

ILLEGAL DATA VALUE

NAK - NEGATIVE

ACKNOWLEDGMENT

The function code received does not correspond

to a function allowed on the addressed slave.

The address to which the data field refers is not

an address allowed on the addressed slave.

The value to be assigned, specified in the data

field, is not allowed for this address.

The function cannot be performed under the

current operating conditions or an attempt has

been made to write in a read-only address.

5. MODBUS ON ATHENA CONTROLS PLATINUM® INSTRUMENTS

5.1 Serial communications parameters

The parameters are shown in the below table:

Parameter Parameter

code

Communications protocol

Serial address

Baud rate

Prot MbuS / JbuS

Addr 1 ... 247

baudr 1200, 2400, 4800, 9600, 19200

The protocol is chosen by means the M.buS o JbuS selection.

The address can be set among 1..247 and must be unique for each

instrument connected on the same line.

The Baud rate parameter enable a clear and simple communications

speed setting.

No Parity and stop bit must be set. They have already been set by the

manufacturer as follows:

Parity = none

Stop bit = 1

5.2 Communications time

The messages, as described in Chapter 2.4, must be exchanged with an

internal pause that is less than 3 times the time required for a character

to be exchanged, otherwise it would be interpreted as the end of the

message. The ATHENA CONTROLS instruments with the MODBUS

protocol are able to receive and transmit characters without an interval.

Between a master message and the following reply on the part of the

instrument there is a latent time lapse necessary for the completion of the

function. This is connected to the fact that, once a command has been

received, the instrument responds only after having completed the

Set up range

15

Page 16

requested function. To evaluate the lapse in time for different functions

≅

+

≅++

reference can be made to the following expressions:

Request:

where:

T

= Elapsed time.

L

T

= Time of a character.

C

T

= Variable time from 0 to 10mS which is dependent on the internal

S

processes.

Assignment:

where:

T

= Elapsed time.

L

T

= Time of a character.

C

T

= Variable time from 0 to 10mS which is dependent on the internal

S

processes.

T

= Multiple time of 25mS which is dependent on the number of bytes

W

to be written. For assignment of words, this time can be 0, 25 or 50 ms

depending on whether both one or none of the two bytes is equal to

the preceding value; for the assignment of bit T

0 to 100mS.

5.3 Data Base

The ATHENA CONTROLS instrument variables available for serial

communication through the MODBUS protocol are contained in two

distinct sections: the bit zone and the word zone.

5.4 Bit Zone

The bit zone is made up of 16 addressable bits that contain information

on the functioning status of the instruments. With some instruments,

certain bits are not used; the status request for these bits with the 01 and

02 functions is permitted but returns a fixed value of 0; these bits are

indicated in the tables by the presence of a hyphen "-". The assignment

of the bit status with the 05 and 15 functions is only allowed on

addresses in which this is possible, which condition is indicated by "R/W".

5.5 Word Zone

The word zone is made up of 128 addressable words that contain control

variables and the instrument parameters. With some instruments certain

words are not used; the request for the values of these words with the 03

and 04 functions is permitted but returns a fixed value of 0; these words

are indicated in the table by the presence of a hyphen "-". The

assignment of the word value with the 06 and 16 functions is only allowed

on addresses in which this is possible, which condition is indicated by

"R/W". The variables and parameters are coded as integer numbers with

a plus or minus sign (two's complement) without taking into account the

decimal point in the representation (for example: the Proportional Band

displayed on the screen with a decimal digit "25.0" is transmitted as 250).

Assignment is only allowed within the values assigned to each

parameter, any attempt to assign a value outside of those permitted

within the field, will cause the instrument to respond with an error

message and a an exception code equal to 3, and the assignment will not

be carried out.

T3TT

Lcs

T3TTT

Lcsw

it can be a value from

w,

16

Page 17

5.6 Assignment of the parameters and E2PROM

All the parameters modified from keyboard or assigned through serial

communication, come written in a permanent way in the EEPROM of the

instruments. Like known good, these components have limited writing

cycles beyond to which the component could be damaged. In our case

the number of cycles of writing are about 10.000 and also if this number

could appear limited, we must be held present that the writings during the

arc of life of the instrument don't arrive to overcome the thousand of

cycles. Different thing is when we talk about the serial communication. In

fact the computer could assign any parameter and with any frequency to

the regulators.

Being well aware of this fact, Athena Controls has provided to protect the

component in matter according to different hardware formality and

resources of the instruments. One of the protection made consists of the

fact to compare the new given with the datum already resident. If the two

data correspond, no writing doesn't happen in as not necessary and the

new given comes writing only and entirely if the two data disagree

between them.

Normally the datum that has a frequency of better writing it is the value of

Setpoint. In the instruments C10, M10 and M300 in as not furnished of

NOVRAM or buffered RAM, exists two formality of assignment of the

Setpoint that is:

1) Assignment to the Jbus address 2

2) Assignment to the Jbus address 5

With the first formality, the Setpoint could be assigned endless times

because it work in the RAM of the microprocessor but attention because

at the turning off of the regulator this datum comes lost for engage the

last value that had stayed written locally from keyboard or from the serial

to the Jbus address 5.

With the second formality the datum comes written in a permanent way

directly in the EEPROM of the instrument and the writing must be limited

to a real necessity.

The instruments of the series M5000, X100, X400, X5000 and X7000

possessing a different hardware structure, furnished that is of NOVRAM

or buffered RAM, they are not subdued to the limits previously exposed

and the assignments of the Setpoint to the Jbus addresses 2 or 5 don't

involve any difference. The two addresses come maintained active only

for a problem of compatibility with the preceding series.

6. Electrical Connections

6.1 General Description

All the Platinum® controllers may be fitted with a two wire (half duplex)

RS485 serial comm.s option. It makes the wiring simpler and enables a

larger connection length (maximum 1200 m).

The Platinum ® C10, M10, M300 and M400 instruments do not have any

line termination or polarisation system. If necessary a termination

resistance (120Ω ¼ W) must be connected to the terminals of the last

instrument of the line. In any case the polarisation is not possible.

The Platinum ® M5000, X100, X400 and X5000 instruments do have any

line termination or polarisation system. Please refere to the specific

chapter on these instruments.

17

Page 18

6.2 Communication Cable Laying Recommendations

In order to minimise interference caused by the external environment to

serial communication, and thus obtain maximum efficiency between the

supervisor and the instruments, a few essential technical precautions

must be taken.

The most important and easiest to implement of all is to separate the

power or power supply lines from the communication lines and lay them

as far as possible from remote-controlled switches, electromagnets,

powerful motors, etc. The same rule applies to the control panel in that it

is pointless to cable the control panel perfectly and then haphazardly

"throw" the cables into the channel or vice versa. If the communication

cables are extended to another control panel or other equipment, leave a

space in the terminal board, isolated from all the other cables (normally

towards the sides).

The type of cable used is of fundamental importance for the functioning of

the entire system. The most important condition to be respected is the

cable's capacity per meter (pF/m). The lower the capacity of the cable is

the longer the line can be. Consequently, power cables, shielded coaxial

cables and general channel cables are to be avoided under all

circumstances in that they have an extremely high capacity per metre. In

addition, to ensure high interference rejection, the cables must be twisted

and preferably provided with a metal shield to be connected to an

efficient ground socket (on one side only).

Two examples of cables with suitable characteristics produced by Belden

are indicated below:

A) Belden code 9729 Z = 100 Ω pF/m = 41

B) Belden code 9502 Z = 150 Ω pF/m = 98

6.3 Instruments with an RS-485 interface (2 wire)

The line requires twisted cable with a characteristic impedance of about

120 Ω.

Normally this type of connection uses a standard 4-wire communication

interface. The transmission and reception signals for the computer and

the communicating device (Tx+Rx+ and Tx-Rx-) can be paralleled,

resulting in a single duplex connection RTx+ and RTx-.

The communication port cannot usually work if it is connected in this way

as every time the supervisor is transmitting a message, it is also present

on the receiving port before awaiting the reply from the other devices. To

prevent this problem occurring, the supervisor uses the RTS (Request To

Send) signal from the communication port. Before beginning a

transmission, the supervisor “raises” the status of its RTS signal to inhibit

its receiver. When the transmission has ended, the supervisor brings the

RTS signal back to “zero” to re-enable its receiver. In the same way, the

devices connected to the supervisor must be able to manage the

direction of the message that is flowing, otherwise the communication will

fail. ATHENA CONTROLS controllers include this ability in their software.

There are commercially available interfaces for handling the RTS signal

at the hardware level, so that it is completely transparent and not

required by the communications software.

It is strongly recommended that the two ends of the link between the

various devices is correctly terminated, as shown in the following drawing

to demonstrate the principle.

18

Page 19

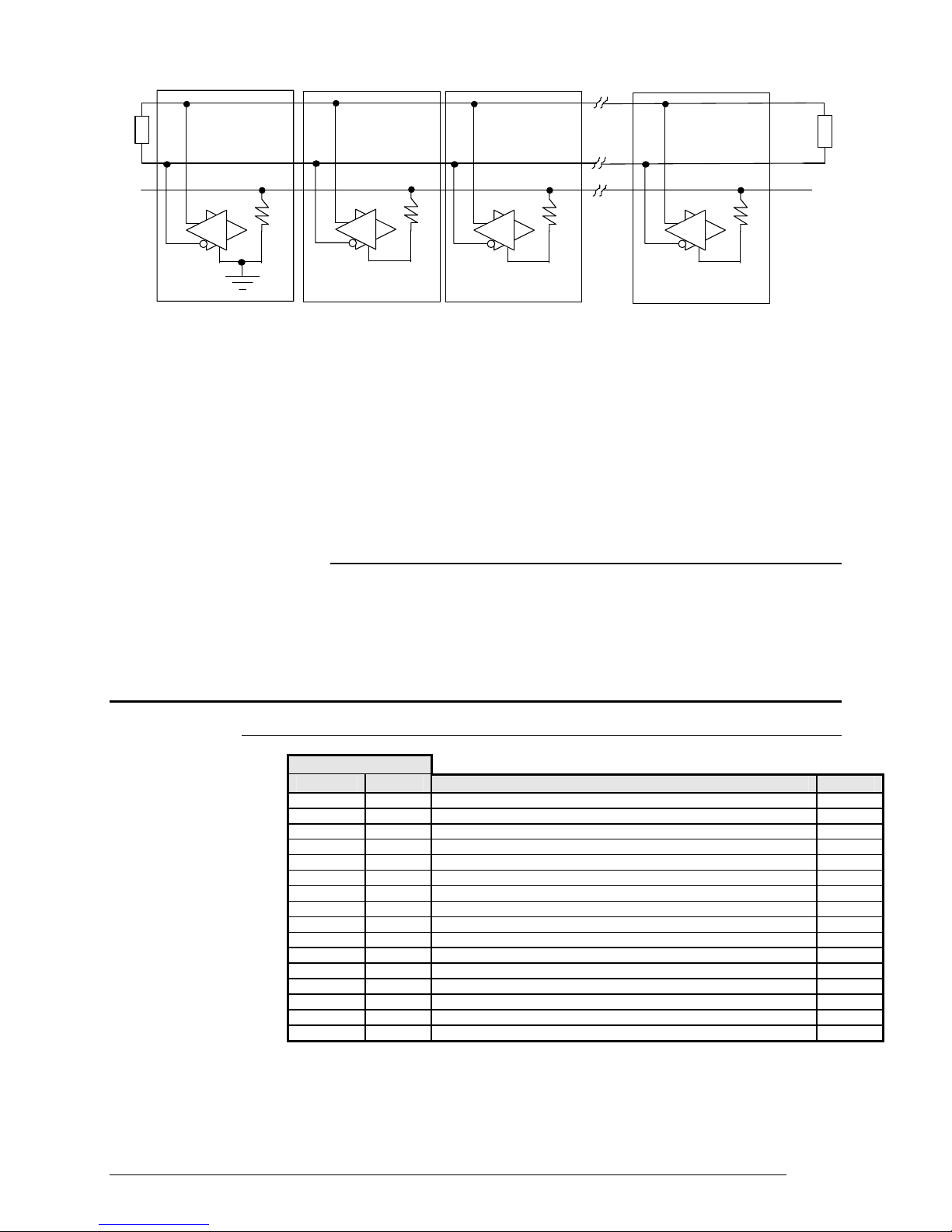

Rt

Supervisor

Rg

G/R

Device 1 Device 2 Device "n"

G/R

Rg

G/R

Rg

G/R

Rt

Co mmon

Rg

G = Transmitter

R = Receiver

G/R = Bi-directional (Receiver/Transmitter) buffer

Rt = Termination resistance: the transmitter can drives up to 32

receivers plus two 120 Ω resistors.

Rg = 100 Ω Resistor

From the above drawing it may be seen that a “star” connection is not

valid. Each branch would have to be terminated, which in turn would

reduce the overall the impedance of the line. In these conditions, the

signal level would be too low for reliable communications.

6.3.1 References

GOULD Gould Modbus Protocol Reference Guide

(PI-MBUS-300 Rev. B)

APRIL JbuS Specification

GLOBAL ENG. DOC. EIA STANDARD RS -485

7. C10 / M10 Controllers

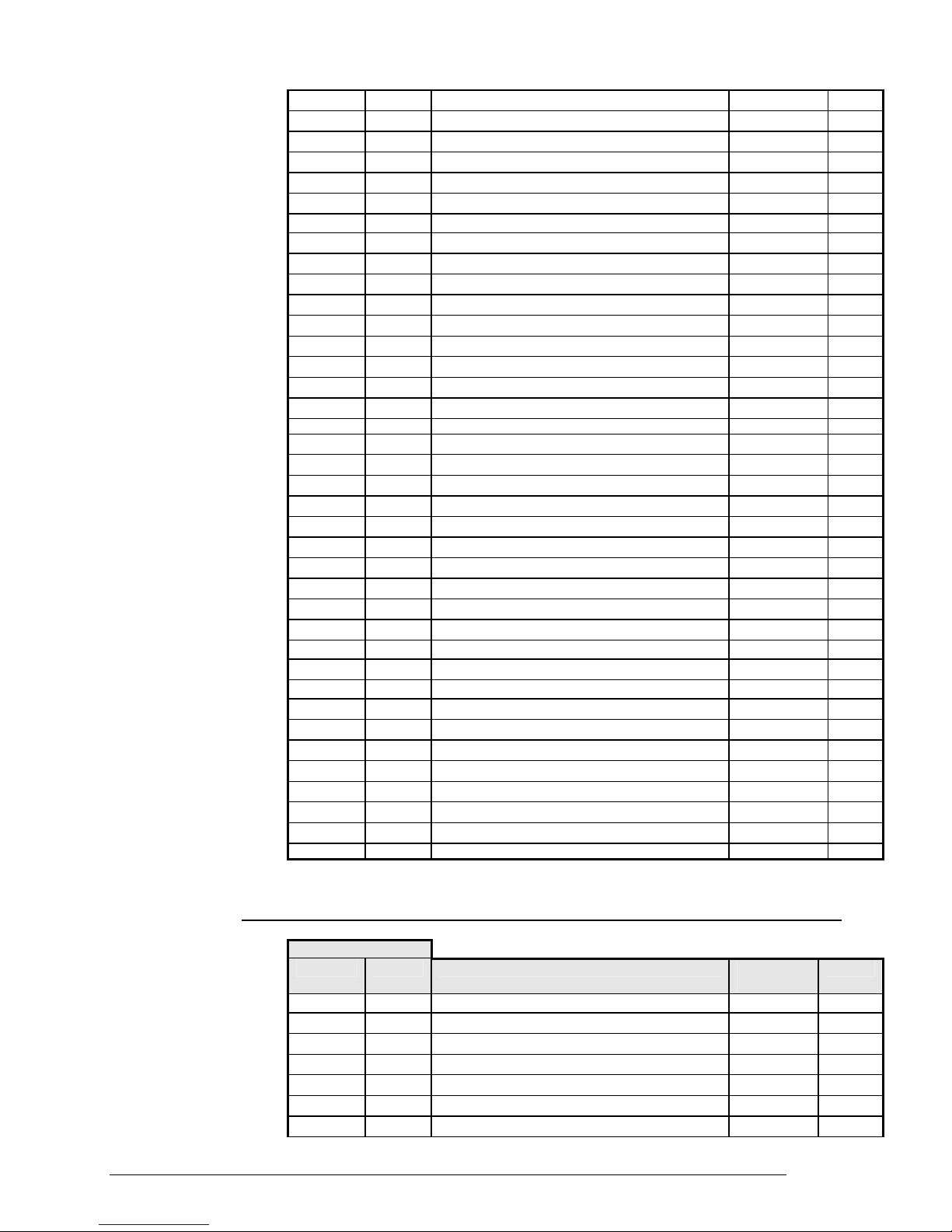

7.1 Bit Zone

Address

Modbus JbuS Variable Type

0 1 - 1 2 - 2 3 - 3 4 Main output condition (0 = OFF, 1 = ON) R

4 5 AL2 alarm status (0 = OFF, 1 = ON) R

5 6 AL3 alarm status (0 = OFF, 1 = ON) R

6 7 Out of range (0 = Normal operation, 1 = Safety) R

7 8 Auto-Tune (0 = OFF, 1 = Run) R

8 9 - -

9 10 Out of range (0 = Normal operation, 1 = Safety) R

10 11 - 11 12 - 12 13 - 13 14 - 14 15 - 15 16 - -

19

Page 20

7.2 Read Status

Function 07 (Read Status) returns an eight bit status with the following

meanings:

Bit Address Variable

1 (LSB) 1 -

2 2 3 3 4 4 Main output condition (0 = OFF, 1 = ON)

5 5 AL2 alarm status (0 = OFF, 1 = ON)

6 6 AL3 alarm status (0 = OFF, 1 = ON)

7 7 Out of range (0 = Normal operation, 1 = Safety)

8 (MSB) 8 Auto-Tune (0 = OFF, 1 = Run)

7.3 Word Zone - Page 1 Parameters

Address

Modbus JbuS Variable Parameter

Code

0 1 Process variable R

1 2 Setpoint R/W 1

2 3 Main output R

3 4 Target Setpoint R

4 5 Local Setpoint R/W 2

5 6 Proportional Band (Hysteresis ON - OFF) 3

6 7 Overshoot control

7 8 Integral time

8 9 Derivative time

9 10 Output cycling time

10 11 Low range

11 12 High range

12 13 AL2 Alarm threshold

13 14 AL3 Alarm threshold

14 15 AL2 Alarm Hysteresis

15 16 AL3 Alarm Hysteresis

16 .. 28 17 .. 29 - - -

29 30 Setpoint low limit

30 31 Setpoint high limit

31 32 - - 32 33 Main output high limit

33 34 - - 34 35 Setpoint ramp up

35 36 Setpoint ramp down

36 37 Input filter

37 38 Input shift

38 39 Auto-Tune enable

39 40 - - 40 41 Serial comm.s address

41 42 - - 42 43 Retransmission low range

43 44 Retransmission high range

44 .. 99 45 .. 100 - - -

P.b. (hy))

O.C.

t.i.

t.d.

t.c.

Sc.Lo

Sc.Hi

A2S.P

A3S.P

A2hy

A3hy

S.P. L

S.P. H

OP. H

Sl. u

Sl. d

t.FiL

In.Sh

tune

Addr

rt.Lo

rt.Hi

Type

R/W

R/W

R/W

R/W

R/W

R

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

20

Page 21

7.4 Word Zone - Page 2 Configuration

Address

Modbus JbuS Variable Parameter

100 101 - - 101 102 Configuration code

102 103 AL3 alarm configuration code

103 104 Engineering units

104 105 Decimal point

105 106 Low range for engineering units

106 107 High range for engineering units

107 108 Communications protocol

108 109 Baud rate

109 110 Retransmitted range

110 111 - - 111 112 - - 112 113 Password

113 114 RTX low range calibration value (Reserved)

114 115 RTX high range calibration value (Reserved)

115..119 116..120 - - 120 121 Factory code R(W) 5

121 122 Product code (“C1”) R 6

122 123 - - R

123 124 Software release R 6

124 125 - - R

125 126 Custom code R

126 127 - - 127 128 - - -

Notes:

1. Assignment of Setpoint to the address JbuS 2 writes the Computer

Setpoint. It is different from the Local Setpoint, which can be in any case

set by keypad.

Code

ConF

Con.2

unit

Sc.d.d

Sc.Lo

Sc.Hi

Prot

baud

retr

Code

CAL.3

CAL.4

Type

R/W 4

R/W 4

R/W

R/W 4

R/W 4

R/W 4

R/W 8

R/W 9

R/W

R/W

R/W

R/W

4/7

10

2. Assignment of Setpoint to the address JbuS 5 writes the Local Setpoint

(the previous value is lost).

3. In case of ON - OFF output (address JbuS 6) the proportional band is

substituted by the output Hysteresis.

4. All the configuration parameters are accepted, if valid, but not brought

into effect. To execute the reconfiguration procedure and bring the

changes into effect, the code 55AAh must be written at the address JbuS

121.

5. Address JbuS 121 is read only, but if the code 55AAh (21930d) is written

at this address, the configuration is brought into effect.

6. The JbuS 122 + 123 and 124 + 125 addresses contain the strings (of 4

characters) for the product and release codes: each address represents

two characters, the most significant byte in the word contains the ASCII

code of the second.

7. To select the engineering unit, the value between 0 and 10 must be

assigned as per the below table:

Engineering unit Serial value

°C

°F

0

1

21

Page 22

none

nU

U

nA

A

bar

PSI

rh

Ph

2

3

4

5

6

7

8

9

10

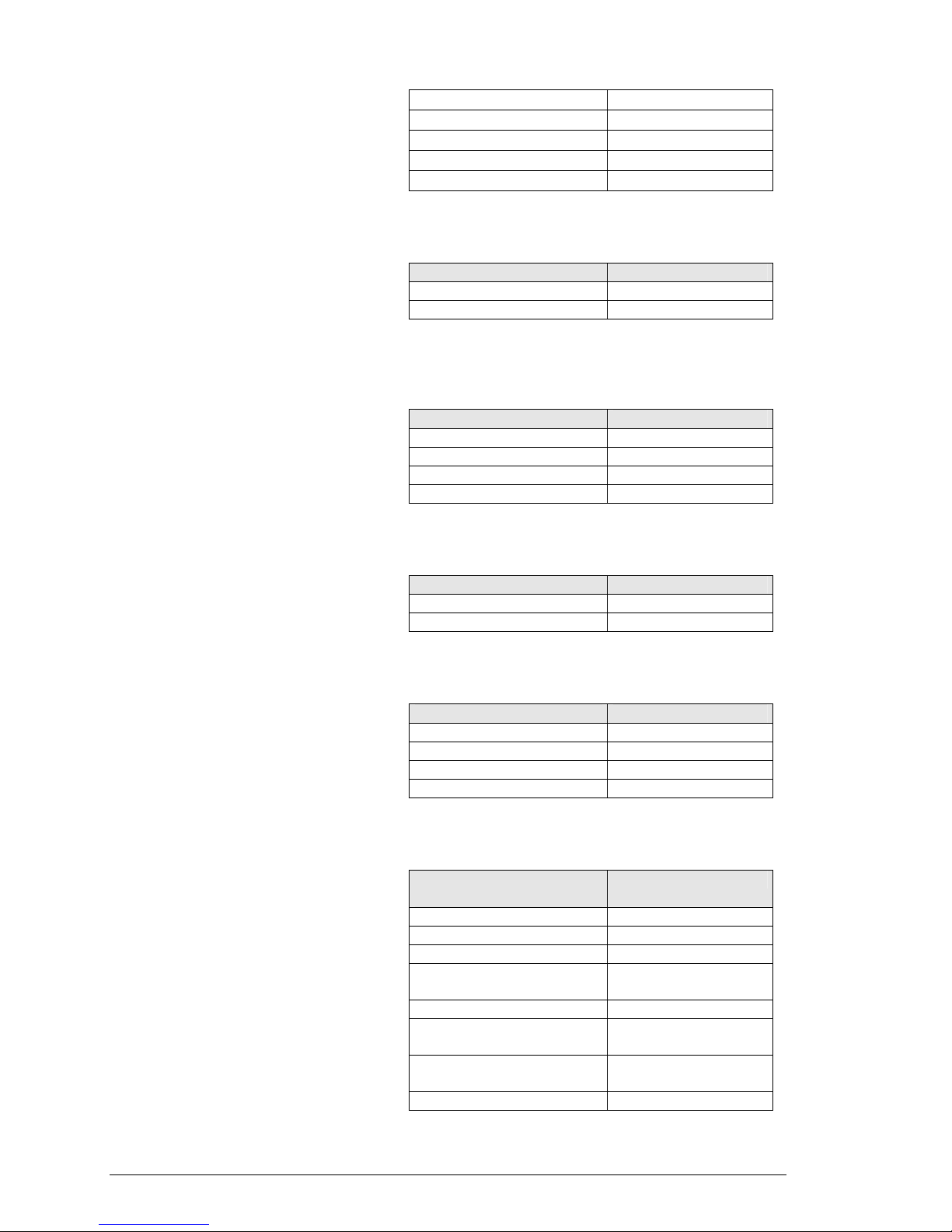

8. To select the protocol type, the value between 0 and 1 must be

assigned as per the below table:

Protocol type Serial value

Modbus 0

JbuS 1

9. To select the serial comm.s baud rate, the value between 0 and 3 must

be assigned as per the below table:

Baud Rate Serial value

1200 0

2400 1

4800 2

9600 3

10. To select the retransmission signal type, the value between 0 and 1

must be assigned as per the below table:

Retransm. signal type Serial value

0 .. 20 mA 0

4 .. 20 mA 1

7.5 Termination and Polarisation

The Platinum ® C10 and M10 instruments do not have any line

termination or polarisation system. If necessary a termination resistance

(120Ω ¼ W) must be connected to the terminals of the last instrument of

the line. In any case the polarisation is not possible.

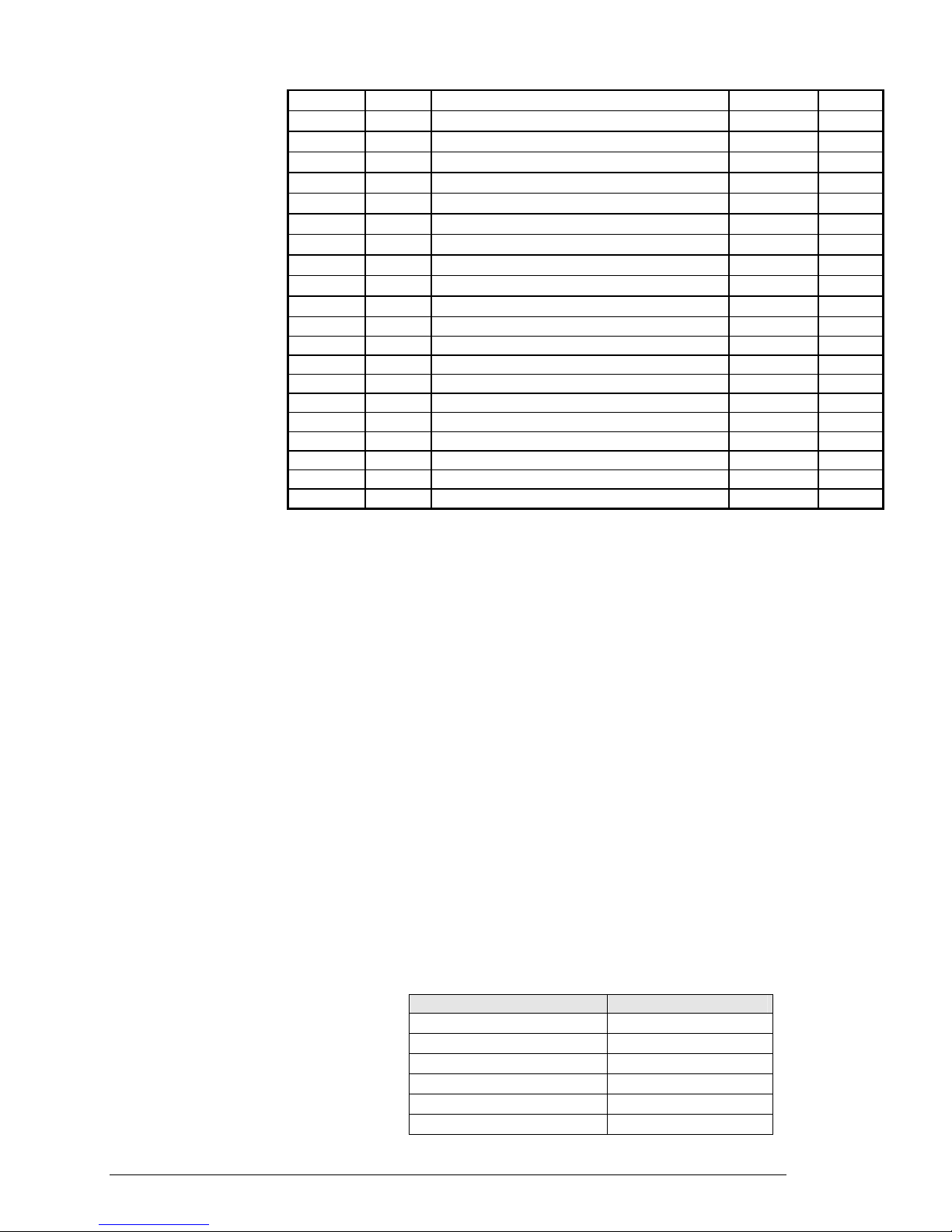

8. M300 Controller

8.1 Bit zone

Modbus JbuS Variable Type

10 11 Keypad lock (0 = locked, 1 = unlocked) R/W

Address

0 1 Timer function status (0 = OFF, 1 = Run) 1 R/W

1 2 - 2 3 - 3 4 Main output condition (0 = OFF, 1 = ON) R

4 5 Alarm condition AL2 (0 = OFF, 1 = ON) R

5 6 Alarm condition AL3 (0 = OFF, 1 = ON) R

6 7 Out of range (0 = Normal operation, 1 = Safety) R

7 8 Auto-Tune (0 = OFF, 1 = Run) R

8 9 - 9 10 Out of range (0 = Normal operation, 1 = Safety) R

22

Page 23

11 12 Outputs lock (0 = locked, 1 = unlocked) R/W

12 13 - 13 14 - 14 15 - 15 16 - -

8.2 Read Status

Function 07 (Read Status) returns an eight bit status with the following

meanings:

Bit Address Variable

1 (LSB) 1 Timer function status (0 = OFF, 1 = Run) 1

2 2 3 3 4 4 Main output condition (0 = OFF, 1 = ON)

5 5 Alarm condition AL2 (0 = OFF, 1 = ON)

6 6 Alarm condition AL3 (0 = OFF, 1 = ON)

7 7 Out of range (0 = Normal operation, 1 = Safety)

8 (MSB) 8 Auto-Tune (0 = OFF, 1 = Run)

Notes:

1. Only available with Timer option.

8.3 Word Zone - Page 1 Parameters

Address

Modbus JbuS Variable Parameter

0 1 Process variable R

1 2 Setpoint R/W 1

2 3 Main output R 2

3 4 Target Setpoint R/W 1

4 5 Local Setpoint R/W 3

5 6 Proportional Band (Hysteresis ON - OFF) 4

6 7 Overshoot control

7 8 Integral time

8 9 Derivative time

9 10 Cycle time

10 11 Low range

11 12 High range

12 13 AL2 Alarm threshold

13 14 AL3 Alarm threshold

14 15 AL2 Alarm Hysteresis

15 16 AL3 Alarm Hysteresis

16 17 Heat/cool proportional band

17 18 Heat/cool integral time

18 19 Heat/cool derivative time

19 20 Heat/cool dead band

20 21 Cool output cycling time

21 22 Cool output high limit

22 23 Motor travel time

23 24 Minimum output step

24 25 Timer setting

25 26 Stand-by Setpoint

26 27 Stand-by Setpoint of Timer

27 28 Soft-start output value

28 29 - - -

Code

P.b. (hy.)

O.C.

t.i.

t.d.

t.c.

Sc.Lo

Sc.Hi

A2S.P

A3S.P

A2hy

A2hy

P.b. C

t.i. C

t.d. C

d.bnd

t.c. C

OP.HC

MU.tM

MU.Hy

tiMe

S.P 2

tM.S.P

St.OP

Type

R/W

R/W

R/W

R/W

R/W

R

R

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

23

Page 24

29 30 Setpoint low limit

30 31 Setpoint high limit

31 32 Error dead band

32 33 Main output high limit

33 34 Output safety value

34 35 Setpoint ramp up

35 36 Setpoint ramp down

36 37 Input filter

37 38 Input shift

38 39 Auto-Tune enable

39 40 - - 40 41 Serial comm.s address

41 42 - - 42 43 Retransmission low range

43 44 Retransmission high range

44 45 start-up Setpoint

45 46 Start Up Holding time

46 47 start-up output high limit

47 48 Timer remaining time

48 49 Load current (CT option)

49 .. 99 50 .. 100 - - -

S.P. L

S.P. H

d.Err

OP. H

Sa.OP

Sl. u

Sl. d

t.FiL

In.Sh

tune

Addr

rt.Lo

rt.Hi

S.P.S.U

t.h.S.U

OP.HS

tM.r.

t.Cur

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

8.4 Word Zone - Page 2 Configuration

Address

Modbus JbuS Variable Param. Code Type

100 101 - - 101 102 Configuration code

102 103 AL3 alarm configuration code

103 104 Engineering units

104 105 Decimal point

105 106 Low range for engineering units

106 107 High range for engineering units

107 108 Communication protocol

108 109 Baud rate

109 110 Retransmission range

110 111 Retransmission signal selection

111 112 Current transformer range

112 113 Password

113 114 RTX low range calibration value (Reserved)

114 115 RTX high range calibration value (Reserved)

115 116 Timer/Start-up operating mode

116 117 Timer action

117..119 118..120 - 120 121 Factory code R(W) 6

121 122 Product code ( “M3”) R 7

122 123 - 123 124 Software release R 7

124 125 - 125 126 Custom code R

126 127 - - 127 128 - - -

ConF

Con.2

unit

Sc.d.d

Sc.Lo

Sc.Hi

Prot

baud

retr

rtH

Ht.F.S

Code

CAL.3

CAL.4

t.Mod

t.Act

R/W 5

R/W 5

R/W

R/W 5

R/W 5

R/W 5

R/W 9

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

24

5/8

10

11

12

13

14

Page 25

Notes:

1. Assignment of Setpoint to the addresses JbuS 2 and 4 writes the

Computer Setpoint. It is different from the Local Setpoint, which can

be in any case set by keypad.

2. Assignment of output at the address JbuS 3 is only possible if the

Auto/Man option if fitted and when the controller is in Manual mode.

3. Assignment of Setpoint to the address JbuS 5 writes the Local

Setpoint (the previous value is lost).

4. In case of ON - OFF output (address JbuS 6) the proportional band

is substituted by the output Hysteresis.

5. All the configuration parameters are accepted, if valid, but not

brought into effect. To execute the reconfiguration procedure and

bring the changes into effect, the code 55AAh must be written at the

address JbuS 121.

6. Address JbuS 121 is read only, but if the code 55AAh (21930d) is

written at this address, the configuration is brought into effect.

7. The JbuS 122 + 123 and 124 + 125 addresses contain the strings (of

4 characters) for the product and release codes: each address

represents two characters, the most significant byte in the word

contains the ASCII code of the second.

8. To select the engineering unit, the value between 0 and 10 must be

assigned as per the below table:

Engineering unit Serial value

°C

°F

none

nU

U

nA

A

bar

PSI

rh

Ph

9. To select the protocol type, the value between 0 and 1 must be

assigned as per the below table:

Protocol type Serial value

Modbus 0

JbuS 1

10. To select the serial comm.s baud rate, the value between 0 and 3

must be assigned as per the below table:

Baud Rate Serial value

1200 0

2400 1

4800 2

9600 3

0

1

2

3

4

5

6

7

8

9

10

25

Page 26

11. To select the retransm. output range, the value between 0 and 1

must be assigned as per the below table:

Variable Serial value

0 .. 20 mA 0

4 .. 20 mA 1

12. To select the retransmitted variable (PV or SP), a value between 0

and 1 must be assigned as per the below table:

Variable Serial value

PV 0

SP 1

13. To select the Timer/Start-up operating mode, a value between 0 and

7 must be assigned as per the below table:

Timer/Start-up operating mode Serial

value

Disabled 0

Start-up 1

Counting inside band 2

Counting inside band / End mode OFF 3

Counting when launched 4

Counting when launched / End mode OFF 5

Counting disable when launched 6

Stand-by Setpoint 7

14. To select the Timer action, a value between 0 and 7 must be

assigned as per the below table:

Timer action Serial value

Launch OP3 status Time

By Keypad OFF Second 0

By Keypad ON Second 1

Key +

at power on

Key +

at power on

By Keypad OFF Minute 4

By Keypad ON Minute 5

Key +

at power on

Key +

at power on

OFF Second 2

ON Second 3

OFF Minute 6

ON Minute 7

8.5 Termination and Polarisation

The Platinum ® M300 instruments do not have any line termination or

polarisation system. If necessary a termination resistance (120Ω ¼ W)

must be connected to the terminals of the last instrument of the line.

In any case the polarisation is not possible.

26

Page 27

9. M400 Controller

9.1 Bit zone

9.2 Read Status

9.3 Word zone - Page 1 Parameters

Address

Modbus JbuS Variable Type

0 1 Timer function status (0 = OFF, 1 = Run) 1 R/W

1 2 Auto/Man (0 = Auto, 1 = Man) 2 R/W

2 3 - 3 4 Control output status (0 = OFF, 1 = ON) R

4 5 AL2 alarm status ( 0 = OFF, 1 = ON ) R

5 6 AL3 alarm status ( 0 = OFF, 1 = ON ) R

6 7 Out of range (0 = Normal operation, 1 = Safety) R

7 8 Auto Tuning ( 0=OFF 1=Run ) R

8 9 - -

9 10 Out of range (0 = Normal operation, 1 = Safety) R

10 11 Keypad lock (0 = locked, 1 = unlocked) R/W

11 12 Outputs lock (0 = locked, 1 = unlocked) R/W

12 13 Logic input #1 ( 0=Open 1=Close ) R

13 14 - 14 15 - 15 16 - -

Function 07 (Read Status) returns an eight bit status with the following

meanings:

Bit Address Variable

1 (LSB) 1 Timer function status (0 = OFF, 1 = Run) 1

2 2 Auto/Man (0 = Auto, 1 = Man) 2

3 3 4 4 Control output status (0 = OFF, 1 = ON)

5 5 Alarm 2 ( 0 = OFF, 1 = ON )

6 6 Alarm 3 ( 0 = OFF, 1 = ON )

7 7 Out of range (0 = Normal operation, 1 = Safety)

8 (MSB) 8 Auto Tune ( 0=Disabled 1=Run )

Notes:

1. Only available with Timer option.

2. Only available with Auto/Man function.

Address

Modbus JbuS Variable Parameter

Type

Code

0 1 Process variable - R

1 2 Setpoint - R/W 1

2 3 Main output - R(W) 2

3 4 Local Setpoint - R/W 1

4 5 Local Setpoint - R/W 3

5 6 Proportional Band (Hysteresis ON - OFF) 4

6 7 Overshoot Control

7 8 Integral time

8 9 Derivative time

9 10 Cycle time

10 11 Low range

11 12 High range

P.b. (hy.)

O.C.

t.i.

t.d.

t.c.

Sc.Lo

Sc.Hi

R/W

R/W

R/W

R/W

R/W

R

R

27

Page 28

12 13 AL2 alarm threshold

13 14 AL3 alarm threshold

14 15 AL2 alarm Hysteresis

15 16 AL3 alarm Hysteresis

16 17 Relative Cold Gain

17 18 Cool output Hysteresis (On-OFF only)

18 19 19 20 Heat/Cool dead band

20 21 Cool output cycling time

21 22 Cool output maximum value

22 23 Motor travel time

23 24 Minimum output step

24 25 Timer setting

25 26 Stand-by Setpoint

26 27 Soft start output high limit

27 28 Soft-start activation time

28 29 - - 29 30 Setpoint low limit

30 31 Setpoint high limit

31 32 PID Dead Band

32 33 Main output high limit

33 34 Output safety value

34 35 Setpoint ramp up

35 36 Setpoint ramp down

36 37 Input filter

37 38 Input shift

38 39 Start/Stop One shoot tuning ( 0=Stop 1=Run)

39 40 40 41 Serial comm.s address

41 42 42 43 Retransmission low range

43 44 Retransmission high range

44 45 Start-Up Setpoint

45 46 Start-Up Hold time

46 47 Output high milit during Start-up

47 48 Timer remaining time

48 49 Load current in ampere

49 - 99 50 - 100 - - -

A2S.P

A3S.P

A2hy

A2hy

r.C.Ga

Hy. C

-

d.bnd

t.c. C

OP.HC

MU.tM

MU.Hy

tiMe

tM.S.P

St.OP

St.tM

S.P. L

S.P. H

d.Err

OP. H

Sa.OP

Sl. u

Sl. d

t.FiL

In.Sh

tune

-

Addr

-

rt.Lo

rt.Hi

S.P.S.U

t.h.S.U

OP.HS

tM.r.

t.Cur

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

9.4 Word zone - Page 2 Configuration

Address

Modbus JbuS Variable Parameter

Code

100 101 101 102 Configuration code

102 103 AL3 alarm configuration code

103 104 Engineering units

104 105 Decimal point

105 106 Low range for engineering units

106 107 High range for engineering units

-

ConF

Con.2

unit

Sc.d.d

Sc.Lo

Sc.Hi

Type

R/W 5

R/W 5

R/W

R/W 5

R/W 5

R/W 5

5/8

28

Page 29

107 108 Communications protocol

108 109 Baud rate

109 110 Retransmission range

110 111 Retransmission signal selection

111 112 Current transformer range

112 113 Password

113 114 RTX low range calibration value (Reserved)

114 115 RTX high range calibration value (Reserved)

115 116 Timer operating mode

116 117 Timer action

117 118 Digital input function

118 119 119 120 120 121 Factory code

121 122 Product code (“M4”) 7

122 123 123 124 Software release (p. es. “ 00A”) 7

124 125 125 126 Custom code

126 127 127 128 -

Prot

baud

retr

rtH

Ht.F.S

Code

CAL.3

CAL.4

t.Mod

t.Act

IL.Fn

-

-

-

-

-

R/W 9

10

R/W

11

R/W

12

R/W

R/W

R/W

R/W

R/W

13

R/W

14

R/W

15

R/W

-

-

R(W) 6

R

R

R

-

R

-

-

Notes:

1. Assignment of Setpoint to the addresses JbuS 2 and 4 writes the

Computer Setpoint. It is different from the Local Setpoint, which can

be in any case set by keypad.

2. Assignment of output at the address JbuS 3 is only possible if the

the Auto/Man option if fitted and when the controller is in Manual

mode.

3. Assignment of Setpoint to the address JbuS 5 writes the Local

Setpoint (the previous value is lost).

4. In case of ON - OFF output (address JbuS 6) the proportional band

is substituted by the output hysteresis.

5. All the configuration parameters are accepted, if valid, but not

brought into effect. To execute the reconfiguration procedure and

bring the changes into effect, the code 55AAh must be written at the

address JbuS 121.

6. Address JbuS 121 is read only, but if the code 55AAh (21930d) is

written at this address, the configuration is brought into effect.

7. The JbuS 122 + 123 and 124 + 125 addresses contain the strings

(of 4 characters) for the product and release codes: each address

represents two characters, the most significant byte in the word

contains the ASCII code of the second.

8. To select the engineering unit, the value between 0 and 10 must be

assigned as per the below table:

Engineering unit Serial value

°C

°F

none

nU

U

nA

0

1

2

3

4

5

29

Page 30

A

bar

PSI

rh

Ph

9. To select the protocol type, the value between 0 and 1 must be

assigned as per the below table:

Protocol type Serial value

Modbus 0

JbuS 1

10. To select the serial comm.s baud rate, the value between 0 and 3

must be assigned as per the below table:

Baud Rate Serial value

1200 0

2400 1

4800 2

9600 3

11. To select the retransm. output range, the value between 0 and 1

must be assigned as per the below table:

Variable Serial value

0 .. 20 mA 0

4 .. 20 mA 1

12. To select the retransmitted variable, a value between 0 and 3 must

be assigned as per the below table:

Variable Serial value

PV 0

SP 1

MV ( OP Heat ) 2

MVC ( OP Cool ) 3

13. To select the Timer/Start-up operating mode, a value between 0 and 7

must be assigned as per the below table:

Timer/Start-up operating

mode

Disabled 0

Start-up 1

Counting inside band 2

Counting inside band / End

mode OFF

Counting when launched 4

Counting when launched /

End mode OFF

Counting disable when

launched

Stand-by Setpoint 7

6

7

8

9

10

Serial value

3

5

6

30

Page 31

14. To select the Timer action, a value between 0 and 7 must be

assigned as per the below table:

Timer action Serial value

Launch OP3 status Time

By Keypad OFF Second 0

By Keypad ON Second 1

Key + at power on OFF Second 2

Key + at power on ON Second 3

By Keypad OFF Minute 4

By Keypad ON Minute 5

Key + at power on OFF Minute 6

Key + at power on ON Minute 7

15. To select the digital input functions, a value between 0 and 4 must

be assigned as per the below table:

Digital input function Serial value

None 0

Keypad lock 1

Manual mode 2

Stand-by Setpoint 3

Timer launch 4

9.5 Termination and Polarization

The Platinum ® M400 instruments do not have any line termination or

polarization system. If necessary a termination resistance (120Ω ¼ W)

must be connected to the terminals of the last instrument of the line.

In any case the polarization is not possible.

10. M5000 Controller

10.1 Bit zone

Modbus JbuS Variable Type

0 1 Remote status (0=LOC, 1=REM) R/W

1 2 Auto/Man ( 0 = Auto 1 = Man ) R/W

2 3 AL3 alarm status ( 0 = OFF, 1 = ON ) R

3 4 AL4 alarm status ( 0 = OFF, 1 = ON ) R

4 5 AL1 alarm status ( 0 = OFF, 1 = ON ) R

5 6 AL2 alarm status ( 0 = OFF, 1 = ON ) R

6 7 Out of range (0 = Normal operation, 1 = Safety) R

7 8 Self Tuning ( 0=Disabled 1=Run ) R

8 9 - R

9 10 Out of range (0 = Normal operation, 1 = Safety) R

10 11 - 11 12 - 12 13 1st Stored setpoint R/W

13 14 2nd Stored setpoint R/W

14 15 - 15 16 - 16 17 IL1 Digital input status (0 = OFF, 1 = ON) R

17 18 IL2 Digital input status (0 = OFF, 1 = ON) R

18 19 - 19 20 - 20 21 Keys enable ( 0=Enabled 1=Disabled ) R/W

21 22 Slope enable ( 0=Disabled 1=Enabled ) R/W

Address

31

Page 32

22 23 Hold PV ( 0=Disabled 1=Enabled ) R/W

23 24 OP1 forced status by serial comm.s ( 0 = OFF 1 = On ) R/W 19

24 25 OP2 forced status by serial comm.s ( 0 = OFF 1 = On ) R/W 19

25 26 OP3 forced status by serial comm.s ( 0 = OFF 1 = On ) R/W 19

26 27 OP4 (logic) forced status by serial comm.s ( 0 = OFF 1 = On ) R/W 19

10.2 Read Status

Function 07 (Read Status) returns an eight bit status with the following

meanings:

Bit Address Variable

1 (LSB) 1 Local setpoint/Remote ( 0 = Local 1 = Remote )

2 2 Auto/Man ( 0 = Auto 1 = Man )

3 3 AL3 alarm status ( 0 = OFF, 1 = ON )

4 4 AL4 alarm status ( 0 = OFF, 1 = ON )

5 5 AL1 alarm status ( 0 = OFF, 1 = ON )

6 6 AL2 alarm status ( 0 = OFF, 1 = ON )

7 7 Out of range (0 = Normal operation, 1 = Safety)

8 (MSB) 8 Self Tuning ( 0=Disabled 1=Run )

10.3 Word zone - Page 1 Parameters

Address

Modbus JbuS Variable Parameter

Code

0 1 PV Process variable

1 2 SP Setpoint

2 3 MV Main output

3 4 SPT Target setpoint

4 5 SPL Local setpoint

5 6 Proportional Band (Hysteresis ON - OFF)

6 7 Overshoot Control

7 8 Integral time

8 9 Derivative time

9 10 Cycle time

10 11 Low range

11 12 High range

12 13 AL1 alarm threshold

13 14 AL2 alarm threshold

14 15 AL3 alarm threshold

15 16 AL4 alarm threshold

16 17 AL1 alarm hysteresis Up

17 18 AL1 alarm hysteresis Down

18 19 AL2 alarm hysteresis Up

19 20 AL2 alarm hysteresis Down

20 21 AL3 alarm hysteresis Up

21 22 AL3 alarm hysteresis Down

22 23 AL4 alarm hysteresis Up

23 24 AL4 alarm hysteresis Down

24 25 Heat/cool proportional band

25 26 Heat/cool integral time

26 27 Heat/cool derivative time

27 28 Cool output cycling time

28 29 Output minimum step

29 30 Setpoint low limit

-

-

-

-

-

P.b. (Hy)

O.C.

t.i.

t.d.

t.c.

Sc.1o

Sc.hi

1***

2***

3***

4***

Hy1u

Hy1d

Hy2u

Hy2d

Hy3u

Hy3d

Hy4u

Hy4d

P.b. C

t.i. C

t.d. C

tc.C

MU.tM

SPLl.

Type

R

R

R/W 1

R/W 2

R/W 2

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

32

Page 33

30 31 Setpoint high limit

31 32 Main output low limit

32 33 Main output high limit

33 34 Cool output maximum value

34 35 Setpoint ramp up

35 36 Setpoint ramp down

36 37 Input filter

37 38 Input shift

38 39 Start/Stop One shoot tuning ( 0=Stop 1=Run)

39 40 Start/Stop Adaptive ( 0=Stop 1=Run)

40 41 Serial comm.s address

41 42 Communication protocol ( 0=Modbus 1=JbuS)

42 43 Baud rate

43 44 Remote setpoint

44 45 Soft start time

45 46 Soft start output high limit

46 47 Control output maximum speed

47 48 Cool output maximum speed

48 49 CT current