Page 1

Zone Temperature

Controller

for Runnerless Molding

Applications

Manual

IMP PIM SAM

Page 2

ATHENA...

TEMPERATURE/PROCESS AND POWER

CONTROLS YOU CAN DEPEND ON.

Since 1965, Athena Controls, Inc. has been at

the forefront of control technology, and was

one of the first companies to offer a fully

microprocessor-based, 1/4 DIN digital temperature controller. Our product line has

expanded to include a complete range of

panel, rack-mounted, and open-card process

controllers, highly efficient SCR power controllers and solid-state motor contactors, and

specialized temperature control products and

systems for the plastics industry.

Athena’s products are sold and serviced

worldwide through a network of authorized

sales representatives and distributors.

•General Purpose Microprocessor and Analog

Controllers

• SPI-Compatible 1/32, 1/16, 1/8, and 1/4 DIN

Auto-Tune Process Controllers

• Ramp-Soak and Multi-Input Process Controllers

• Low-Cost, Non-Indicating Temperature

• Phase Angle and Zero Switched SCR Power Controls

• Phase Angle and Zero Switched Solid-State Contactors

• Staging Controllers for Large KW Loads

• Single and Multi-Zone Hot Runner Control Modules

• Portable Controller and Mainframe Systems

• Cables, Mounting Boxes, and Accessories

2

Controllers

Page 3

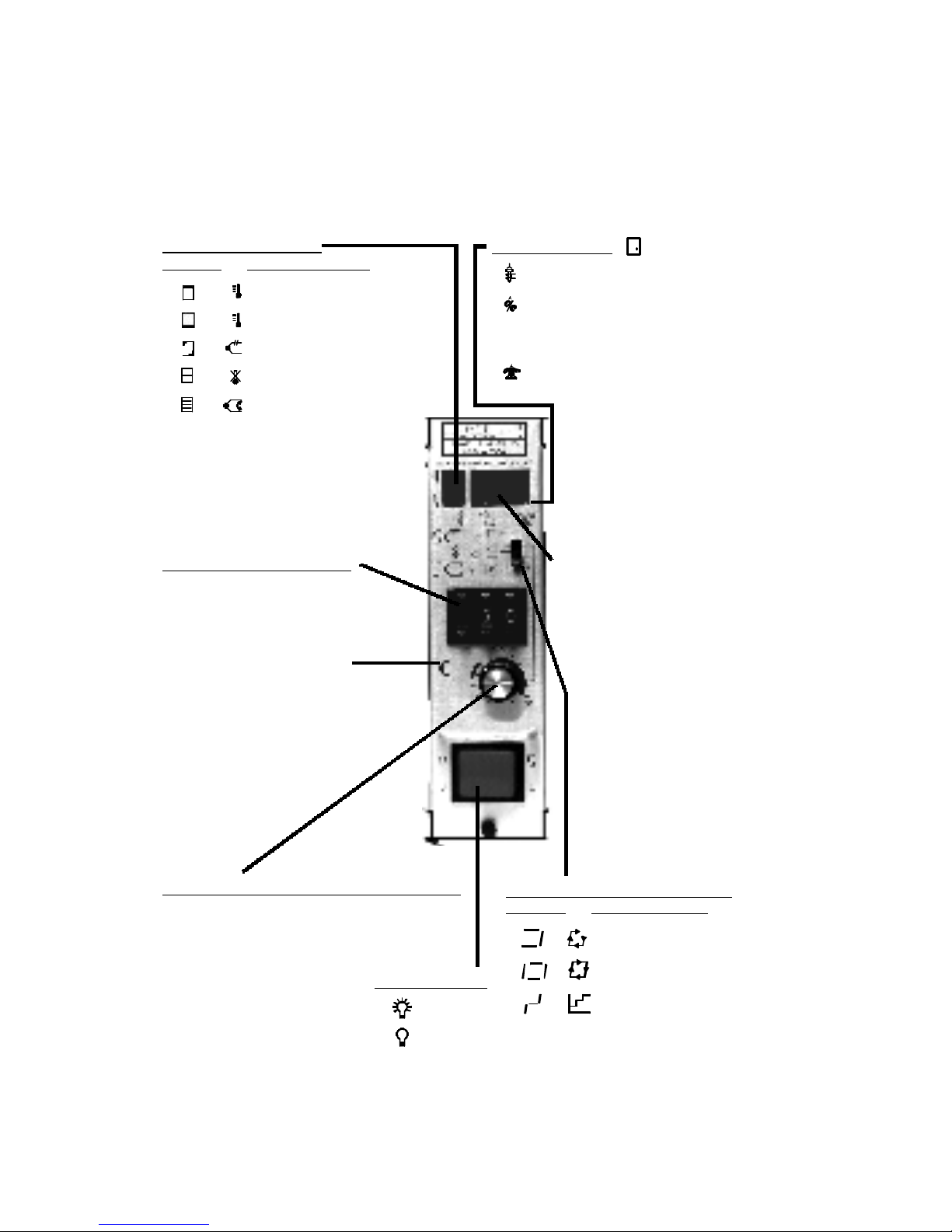

OPERATING INSTRUCTIONS

ALARM/MODE DISPLAY

DISPLAY ALARM SYMBOLS

OVER TEMPERATURE

UNDER TEMPERATURE

THERMOCOUPLE OPEN

NO HEAT

THERMOCOUPLE REVERSED

DIGITAL SETPOINT SWITCH

ACCURATELY SETS A

SETPOINT TEMPERATURE

STANDBY (WARM) REGION

DOT INDICATORS

POWER BEING DELIVERED TO LOAD

MANUAL MODE ON

(DISPLAY INDICATES PERCENTAGE

OF POWER)

REMOTE AND STANDBY OPERATION

TEMPERATURE AND PERCENTAGE

POWER DISPLAY

PERCENTAGE POWER ADJUSTMENT KNOB

CONTROLS PERCENTAGE OF POWER

SUPPLIED TO LOAD IN MANUAL

POWER SWITCH

ON

OFF

MODE SELECT TOGGLE SWITCH

DISPLAY MODE SYMBOLS

OPEN LOOP (MANUAL MODE)

CLOSED LOOP (AUTO MODE)

COMPUSTEP START-UP

ON DURING FIVE MINUTE

COMPUSTEP TIME PERIOD

Page 4

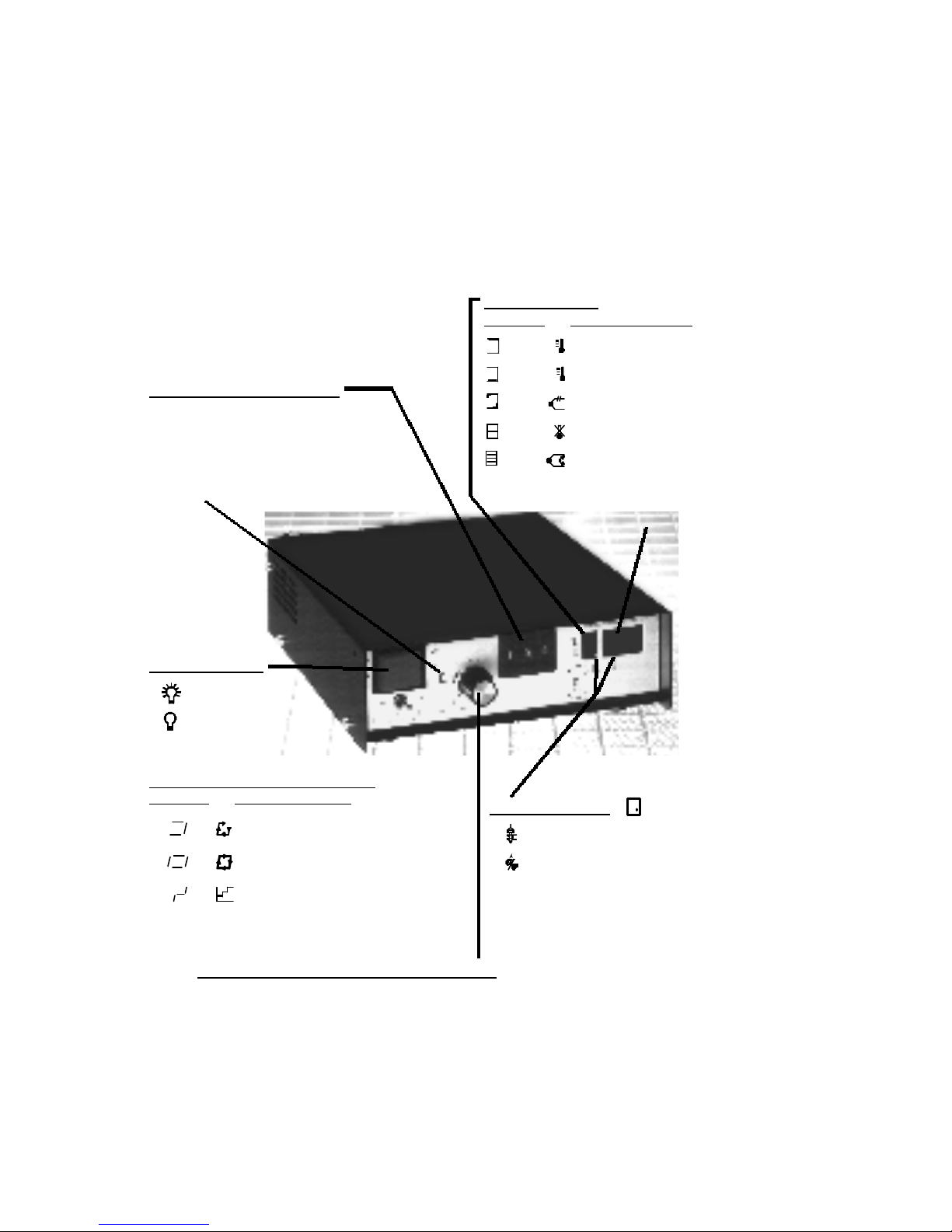

PIM SERIES

PORTABLE SINGLE ZONE

HORIZONTAL CONTROLLER

ALARM/DISPLAY

DISPLAY ALARM SYMBOLS

OVER TEMPERATURE

DIGITAL SETPOINT SWITCH

ACCURATELY SETS A

SETPOINT TEMPERATURE

STANDBY (WARM) REGION

POWER SWITCH

ON

OFF

MODE SELECT TOGGLE SWITCH

DISPLAY MODE SYMBOLS

OPEN LOOP (MANUAL MODE)

CLOSED LOOP (AUTO MODE)

COMPUSTEP START-UP

ON DURING FIVE MINUTE

COMPUSTEMP TIME PERIOD

UNDER TEMPERATURE

THERMOCOUPLE OPEN

NO HEAT

THERMOCOUPLE REVERSED

TEMPERATURE AND PERCENTAGE

POWER DISPLAY

DOT INDICATORS

POWER BEING DELIVERED TO LOAD

MANUAL MODE ON

(DISPLAY INDICATES PERCENTAGE OF POWER)

PERCENTAGE POWER ADJUSTMENT KNOB

CONTROLS PERCENTAGE OF POWER

SUPPLIED TO LOAD IN MANUAL

4

Page 5

OPERATING INSTRUCTIONS

IMPSeries 15 and 30 Amp Temperature Controllers

PIMSeries 10 and 15 Amp Temperature Controllers

Section I. General Description

The IMP and PIM Series are microprocessor based PID controllers

specifically designed to perform most operator functions

automatically. The IMP Series are plug-in units, while the PIM

Series are portable, stand-alone instruments. Both are

self-adjusting and capable of maintaining a very high degree of

temperature accuracy over a wide range of operating conditions.

A digital display eliminates parallax error caused by conventional

analog methods of display. This enhances the accuracy of the

controller while making information easier to see.

Simplified controls and the use of status symbols allow the

operator to make adjustments easily. The status display also

provides visual indication of normal or abnormal operating

conditions in both controller and load.

All that is required of the operator is to set the temperature

desired. From that point on, the controller will automatically

perform all the operations required to achieve and maintain the

selected temperature.

Included in the design is a built-in safety feature which when

operating in closed-loop mode will automatically cut off the

controller output power when any TC fault is detected. In openloop operation, the display shows percentage of power as set by

the power control potentiometer (0-100%).

5

Page 6

The IMP plug-in controller is capable of receiving a standby

command from the SAM auxiliary module. When a standby or low

heat command is acknowledged from the SAM during closedloop operation, the controller will operate with a fixed setpoint.

When receiving a standby command during open-loop operation,

the output power of the controller will be reduced to 1/4 of the

front panel power control setting.

The IMP controller also sends alarm status conditions to

the SAM auxiliary module for annunciation and remote

control functions.

Section II. Installation (IMP Series Only)

All IMP Series controllers are ready to use as shipped from the

factory. Prior to installation into a mainframe, make sure the

voltage, Hz and degree options are as ordered and correspond to

the Product ID label.

Never insert or remove a controller from a mainframe

with the AC power on. Hazardous potentials exist on

components inside the mainframe and controller.

Always disconnect AC power to the mainframe when

servicing.

CAUTION

6

Page 7

To install a plug-in controller into a mainframe, release the

locking device on the lower edge of the unit by pulling the plunger

gently away from the panel. Align the upper and lower edges of

the printed circuit board on the controller with the mainframe

card guide slot and slide in until the rear connector is completely

engaged. Lock the controller into the frame by depressing the

plunger on the locking device.

Section III. Operation

Note: Any flashing display indicates that a fault has been detected

by the controller. Refer to section on

A.Automatic Closed-loop Operation

1- Position Mode select switch to closed-loop (“o”).

2- Set temperature on Setpoint switch.

3- Turn on AC power.

4- After a short reset delay, the measured temperature will

be displayed. If the temperature is 30 degrees F (17°C) or

more below setpoint, the undertemperature alarm

display (lower segment of the leftmost digit) will flash. If

the temperature is 30 degrees F (17°C) or more above

setpoint, the overtemperature alarm display (upper

segment of the leftmost digit) will flash. During alarm

conditions, temperature display will also flash. If the

temperature is within alarm limits, the display will stop

flashing, and the leftmost digit will display closed-loop

mode (“o”).

5- Power to load indicator (the decimal point of the

leftmost digit) will be on if any power is being

applied to the load.

Faults.

7

Page 8

6- When any of the thermocouple (TC) faults are detected,

output power will be cut-off automatically and the

temperature display will be blanked out. The leftmost

digit will show “ ” for (TC open), “ ” for (TC reverse)

or “ ”for No Heat and flash twice per second.

B.Automatic Operation with CompuStep®system

When starting from cold, it is recommended that the

CompuStep system be used, as this will serve to lengthen

heater life considerably.

1- Position the mode select switch to CompuStep mode

(“ ”).

2- Set the desired temperature on the setpoint switch.

3- Turn on the AC power.

4- After reset delay, the measured temperature will be

displayed. If temperature is less than 200 degrees F

(93°C) the controller will enter the CompuStep mode.

This is indicated by the step symbol “ ” on the leftmost

digit. During this mode, the controller gradually

increases power to load in small steps and limits the

load temperature to 256 degrees F (124°C). After 5

minutes, the controller will exit from CompuStep mode

and automatically go to setpoint. Any thermocouple

faults detected during the 5 minute interval will cause

the CompuStep mode to end prematurely. A standby

command from a SAM module will also terminate

CompuStep mode. When CompuStep ends, the

controller will operate as described in the Automatic

Closed-Loop Operation section. If temperature is above

200 degrees F (93°C), controller will bypass CompuStep

and go directly to setpoint.

8

Page 9

C. Manual Open-Loop Operation

1- Position the mode select switch to open-loop (“ ”).

2- Turn the AC power on.

3- After reset delay, the controller will display the percent-

age of output power as adjusted by the power control

knob. The percentage power indicator will be on. Thus

0.00 corresponds to 0% (no power) and 1.00

corresponds to 100% (full power). The leftmost digit will

display open-loop mode ( “ ” ). 75% power is shown

as 0.75.

D. Manual Control Pre-Set

The following procedure can be used to pre-set the Manual power

control knob position in the event of a thermocouple break in

closed-loop operation.

A good thermocouple is required to start with, as this procedure

compares the temperature attained using automatic (closed-loop)

control with that obtained using manual (open-loop) control.

When the temperature is the same using either automatic or

manual control, then the position of the Manual power control

knob is correct.

9

Page 10

Procedure for Manual Control Pre-Set

1- Adjust controller for closed-loop operation and obtain

good molded parts. This will adjust the controller to the

proper temperature.

2- Position the module select switch to open-loop and set

the manual control knob to roughly 25%. Wait for 10

seconds, than momentarily switch to closed-loop mode

to examine the temperature. If it is above the setpoint,

the manual power is too high to maintain proper

temperature. If it is below setpoint, the manual power

is too low. Adjust the power control knob accordingly,

wait for 10 seconds, then re-examine the temperature

by switching momentarily to closed-loop mode. Repeat

this procedure until the temperature is the same in

either automatic or manual control.

E.Standby Heat (SAM module only)

Standby heat is a low heat level used to keep heaters and

associated equipment warm. Its purpose is to prevent moisture

build-up in heaters and equipment during idle periods and to

provide fast start-up when returning to normal operations.

When using a Standby Alarm Module (SAM), activate the standby

switch. The SAM will send a standby command to all controllers.

A controller, upon receiving the command, will respond accordingly to its present mode of operation:

a- If the controller is in closed-loop mode, the set-

point becomes 200 degrees F (93°C) regardless of

the setpoint switch setting. The Remote Standby

Indicator (the decimal of the last digit) will be

10

Page 11

on, indicating that the remote standby function

is active.

b- If the controller is in open-loop mode, the power

output is reduced to 1/4 of the value adjusted by

the power control knob. Notice that the % power

display will show the reduced value. The remote

standby indicator will be on.

F. Faults

1- Overtemperature alarm:

A constant overtemperature alarm is most likely caused

by a shorted triac in the controller or incorrect or

shorted mold wiring. Switch module power off as

quickly as possible and replace controller or correct

wiring error. Check for thermocouple or heater cross

wiring.

2- Undertemperature alarm:

Undertemperature alarm is normal during system

start- up before the setpoint is reached. If under

temperature persists, a No Heat fault will occur.

11

Page 12

3- Thermocouple open or reversed:

If any TC fault is detected during closed-loop operation,

the output power will be cut off. If it is necessary to

apply power to the load during a TC fault condition,

the controller can be switched to manualmode. The

output power will be a function of the manual control

knob setting. Since the controller is now operating in

open-loop mode, extreme care must be taken when

adjusting to prevent excess output power which would

overheat the load.

4- No heatfault:

The IMP series controller has included in its

microprocessor a program which detects that the

temperature is not rising as it should in response to full

power output. “No Heat” is defined as the condition

under which the temperature does not increase more

than 2 degrees F during a 60-second interval during

start-up. It takes 60 seconds to detect “No Heat” when

power is first turned on in closed-loop mode, and longer

if CompuStep is active.

In the beginning of the CompuStep mode, only a small

amount of power is applied to the load and the rate of

temperature rise could be less than 2 degrees F (1°C) in

60 seconds. In order to compensate for this, the test is

not performed until one minute after power is turned

on. By that time, enough power is being applied to the

load to sustain the rate of 2 degrees F (1°C) in 60 sec-

onds. It takes 1 minute, 60 seconds to detect “No

Heat” in CompuStep mode when power is first turned

on. When “No Heat” alarm is detected, output power is

cut off.

12

Page 13

What to do:

A. Try resetting the controller by turning its AC power OFF and

then ON.

B. If “No Heat” persists, then the problem could be one of the

following.

a- Open heater or load.

b- Thermocouple shorted. Switch to manual mode to

override this condition.

c- Load circuit open. This can be caused by an open power

cable, an open connector or a failed triac in the

controller. Exchange the module with a known good

module to eliminate suspect triac or module.

d- Slow heater. Use higher power heater or operate in

manual mode until setpoint is achieved.

e- Thermocouple too far away from heat source which

causes less than 2 degrees F (1°C) rise in 60 seconds due

to thermal lag. Move thermocouple as close to heater as

possible or use heater with built in thermocouple.

f- To defeat “No Heat” circuit, if not used or required,

remove jumper J4 and that circuit will no longer be

active.

User’s Selected Jumper Option

1- For degree Celsius operation,

install jumper on PC board marked J1

2- For 50 Hz operation

install jumper on PC board marked J2

Since the microprocessor reads the status of the jumpers during

power up, the power has to be turned off and on again in order to

activate the jumper function.

13

Page 14

3- For 120 Vac input operation,

install the 2 jumpers on the PC board as shown.

4- For 240 Vac input operation,

install the 1 jumper on the PC board as shown.

Note:

prior to installing a

14

Page 15

OPERATING INSTRUCTIONS

Model SAM Communications Module

Section I. Installation

CAUTION

Never insert or remove the module from a main frame

with the AC power on. Always switch the module

or main frame to “off.” Hazardous potentials exist on

components inside both the module and main frame.

Always disconnect the AC power to the main frame

when servicing.

SAM must be used in conjunction with a model ”MFC“

communications-type main frame, and one or more IMP type

microprocessor-based temperature controllers. It is shipped from

the factory ready to use. No special preparation is required.

Installation Procedure:

1.1 Carefully unpack module. SAM may be plugged into any

unused zone of the main frame.*

1.2 Release locking device by gently pulling push-pull fastener

away from the front panel.

1.3 Line up module printed circuit board with respective main

frame guides. Insert module firmly, making sure rear

connectors are fully engaged.

1.4 Lock module into place by depressing push-pull fastener.

*Note: SAM will work in any main frame zone. A heater connected to

a zone with a SAM inserted will not affect operation of the module.

15

Page 16

Section II. General Specifications

Standby Temperature 200 deg F (93 deg C)

AC Input Requirements 240 Vac +10% -20%, 48-63 Hz

(standard)120 Vac (Available)

Alarm Limits +/- 30 deg F (17 deg C) when used

with an IMP

Alarm Output (Audible) Over Temperature:2 KHz tone at

2 Hz interval

Under Temperature:1 KHz tone at

1Hz interval

Alarm Output (Visual) Over Temperature: 2 Hz flashing

rate

Under Temperature:1 Hz flashing

rate

Output Connector AMP MIL-style connector (4 Pin)

Communication Capacity 50 zones maximum

providing Normally Closed and

Normally Opened relay contacts.

(5 amps maximum)

16

Page 17

QUICK REFERENCE GUIDE

SPEAKER

FAST HIGHER TONE = OVER TEMPERATURE 30°F

(17°C) OR MORE ABOVE SETPOINT

SLOW LOWER TONE = UNDER TEMPERATURE

30°F (17°C) OR MORE BELOW SETPOINT

LOW TEMP ALARM MODE SWITCH

LOW TEMP ALARM MODE

INHIBIT

LOW TEMP ALARM ACTIVE

EXTERNAL OUTPUT CONNECTOR

PINS 1&2 - N.C. RELAY

CONTACTS

OVER TEMP. LED (red)

PINS 1&3 - N.O. RELAY

CONTACTS

STANDBY ON-OFF SWITCH

DAY USE OR NORMAL

NIGHT USE OR STANDBY

(YELLOW STANDBY LED

ILLUMINATES)

UNDER TEMP. LED (red)

STANDBY LED (yellow)

POWER ON LED

POWER SWITCH

ON

OFF

LOCKING DEVICE

17

Page 18

Section III. Basic Operation

3.1 Select Normal or Standby Mode.

3.2 Select Low Temperature Alarm Mode.

3.2.1. Low Temperature Alarm Inhibit : Speaker will

be off and output relay inactive in the event of

low temperature condition (useful during start-up

procedures).

3.2.2. Low Temperature Alarm Active : 30°F (17°C) or

more below IMP setpoint temperature will sound

alarm and energize output relay contacts.

3.3. Turn Power On-Off Switch to ”ON“ position.

3.4. Alarm indications are automatic.

(see detailed operation)

Section IV. Detailed Operation

4.1 Normal or Standby Operation

a. Normal : In this mode the standby feature is

defeated and temperature control is in accordance

with the IMP controller(s) settings.

b. Standby : With the toggle switch in this position,

the standby mode is engaged. This will set the temperature of all IMP controllers operating in automatic

mode to a standby temperature of 200 deg F(93 deg C).

(1) Any IMP controller operating in manual mode will

have its output power level reduced to 1/4 of its

present level.

(2) When SAM and IMP controller(s) are in use at nor-

mal operating temperature [setpoint above 230 deg

F (119 deg C)], switching to standby mode will result

in an over temperature alarm until all zones cool

down to below 230 deg F (110 deg C).

18

Page 19

4.2 Alarm Indications: When an overtemperature or

undertemperature condition exists in any zone occupied by

an IMP controller, both audio (tones) and visual (LED)

alarms will occur in the SAM.

a. Over Temp. : Occurs when an IMP thermocouple is 30

deg F (17 deg C) or more above setpoint. The speaker will

emit a higher pitched audio tone of about 2 KHz repeating

about twice per second. At the same time, the over temperature LED will flash, and relay closure will occur.

b.Under Temp.: Occurs when an IMP-15 thermocouple is

30 deg F (17 deg C) or more below setpoint. The speaker

will emit a lower pitched audio tone of about 1 KHz repeating about once per second. At the same time, the undertemperature LED will flash, and relay closure will occur.

c. Over Temp. Alarm Priority: If an overtemperature and

undertemperature condition exist simultaneously from

more than one IMP controller, SAM will indicate only the

overtemperature condition. SAM will not recognize any

undertemperature condition, until all overtemperature

alarms have been cleared.

4.3 Front Panel Output Connector: A set of relay contacts are

available at this connector for use with external equipment if

desired. Observe the 5 amp maximum contact rating. Pins 1

and 2 have normally closed (N.C.) contacts. Pins 1 and 3 have

normally opened (N.O.) contacts.

a. During either an over-or under-temperature alarm condi-

tion, the relay will be energized.

b. Relay operation is defeated when the Low Temperature

Alarm mode switch is in the Inhibit ( ) position. (This will

be clarified in the next section.)

19

Page 20

4.4 Low Temperature Alarm Mode Switch: This switch gives the

operator the ability to defeat both the low temperature audio

alarm, and output connector relay operation. This feature is

useful to avoid sounding an alarm during startup or cooling

down procedures. The undertemperature LED is unaffected

by this switch. All overtemperature alarm indications are also

unaffected by this switch.

a. Low Temp. Alarm Active : In this position, undertem-

perature alarm indications operate normally.

b. Low Temp. Alarm Inhibit : In this position, an under-

temperature condition of 30 deg F (17 deg C) or more

below setpoint will

output connector relay will

not

sound the audio alarm. Also, the

not

be energized. The under-

temperature LED is unaffected, and will flash as usual.

4.5 Remote Standby Option: It is possible to wire the main frame

for remote standby operation as outlined in the following

procedure.

a. Locate the appropriate communications connector for the

zone to be occupied by the SAM. This is on the upper strip

of connectors on the rear of the model “MFC” main frame.

b. Carefully wire an isolated set of normally open relay

contacts, rated at 5 volts and1/2 amp, to pins 8 and 12

of the main frame connector. Note that this relay is

not included.

c. When the remote relay is energized, SAM will be placed in

the standby mode of operation.

d. A SAM must be installed for this option to work.

20

Page 21

NOTES

21

Page 22

MOLD

v

CABLE END

CKPTF1

(FEMALE)

(MALE)

CABLE END

CKPTM1

v

CABLE

MPTC10 (10 FOOT)

MPTC20 (20 FOOT)

MOLD CONNECTOR

CKPTIC1

POWER OUT

AND

THERMOCOUPLE

CKPTM1

MAINFRAME CONNECTOR

PIM1B15

NEMA IN,

5 PIN OUT

OUTPUT OUTPUT

AC INPUT AC INPUT

POWER

IN

AC2024F

FEMALE

PLUG

THERMOCOUPLE

CKPTOC1

PIM1A15

NEMA IN,

NEMA OUT

INPUT

POWER

OUT

AC1524M

MALE

PLUG

THERMO-

COUPLE

M2MJ

MALE

PLUG

22

Page 23

PIM1A10

POWER CORD IN,

5 PIN OUT

AC INPUT OUTPUT

23

Loading...

Loading...