Page 1

Page 2

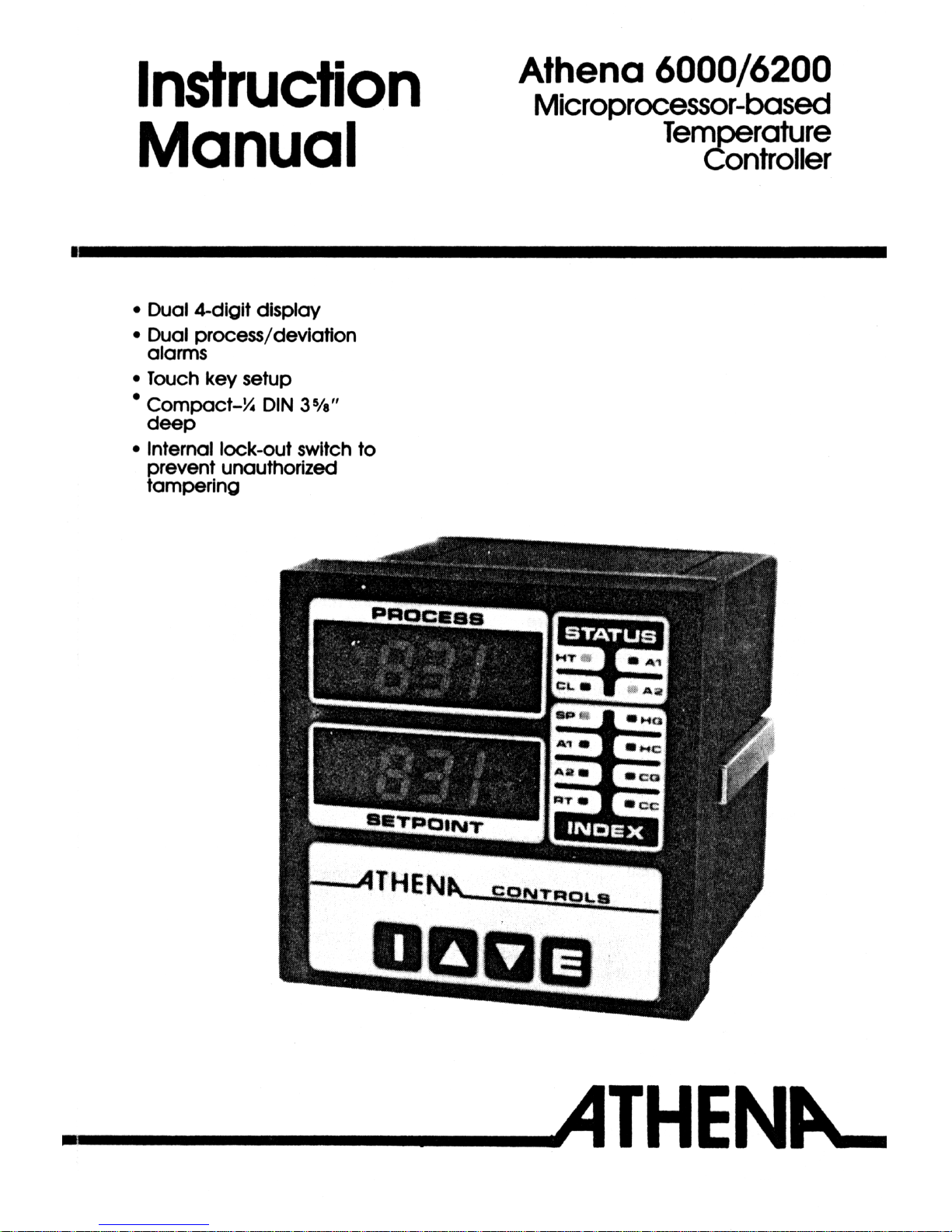

Athena

6000/6200

Microprocessor-based Temperature Controller

Designed for the user

Athena’s

unique

new

6000

microprocessor-based controller

was developed to satisfy the needs

of actual end users, designers, and

specifiers. Data was gathered on

the temperature controller features,

functions, and performance capabilities that they desired. Then

Athena designed a controller to

satisfy them.

Dual

lndication

Now you can compare process

temperature and setpoint

at a

glance - hands free. This dual

digital

display concept has formerly

only been available in high priced

multifunction process controls.

Microprocessors reduce size,

add extras

By using microprocessor

hardware and a highly sophisticated

software package, Athena designers

and engineers have included more

features than have ever been

available before in a controller this

size. Incorporating two digital

displays, touch-key

operation,

software

linearized

and

stabilized

thermocouple input with 3-mode PID

action heat/cooling control and dual

alarms,

ºF to ºC

conversion,

alarms

that can be energized for temp

rise/fall

and selectable as process

or deviation type, and a program

restart circuit that eliminates

program lock-up due to transient

voltage

spikes

or line voltage

“brown out.” Program automatically

restarts within 2

milliseconds

after

condition passes.

PID

Control

Three mode (Proportional,

lntegral, and Derivative) action

eliminates offset (droop) as cooling

and heating requirements change in

the process, and provides fast

output response to rate of change

and reduces temperature overshoot

and undershoot.

Thermocouple linearization

The 6000 has a program to

linearize signal input from the

thermocouple. Without it, temperature controllers have accurate

temperature indication over only

certain

portions of the scale.

Contents

General:

Introduction

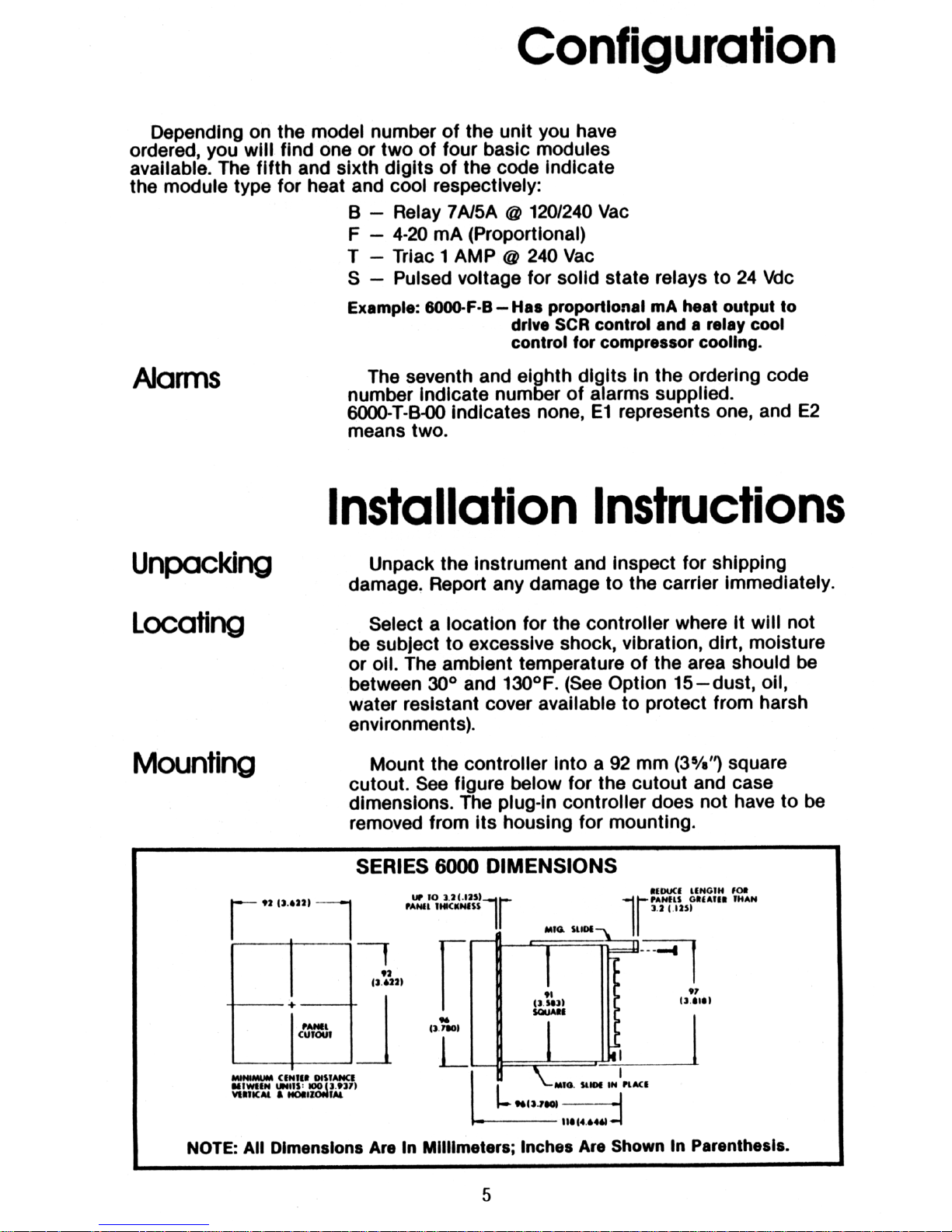

Configuration:

Output Forms

Alarm Types

ºC/°F

Installation

lnstructlons:

Unpacking

Locating

Mounting

Terminal Designations

Output Modules

Wiring Examples

Internal

Switches

Thermocouple lnstallation

PAGE

2

4-5

4-5

4-5

5

5

5

6

6-7

6-9

10

11

Operating Instructions:

Control Panel Description

Start-up

Parameter Entry

Heat Galn Setting

Rate

Setting

Examples

Cool Gain

Setting

Trouble Shootlng

Repairs and Warranty

PAGE

13

13

13-14

15

15

15

15

16

16

2

Page 3

Specifications

Inputs:

Line

Voltage

Sensor

Power

consumption:

Ranges

available:

Accuracy:

Temperature

stability:

Cold end

tracking:

Operating ambient

for

rated accuracy:

Maximum lead

resistance for rated

accuracy:

Series

mode noise

rejection:

Common mode

noise

rejection:

T/C break

protection:

Dual display:

Display update rate

and filtering

ºF/ºC:

Alarm 1 & 2:

Outputs:

- B

Relay (time

proportioning)

-F Current

proportional

-S Pulsed

voltage

-T

Triac

(time

proportional

-

E1 & E2

Auxiliary

alarm relays

(on/off)

Filtered

LED

display:

T/C linearization:

Connections:

Dimensions:

Mounting:

Weight:

Recorder output:

(RTD

only)

120/240

Vac

50,60

Hz

T, J or K thermocouple or Platinum 100Ω at 0°C

Less than 6 VA (Instrument)

J couple 0-1400°F (0-760%)

K couple 0-2000°F (0-1093ºC)

±1 digit of full scale

5 µV/ºC Max 3 µV/ºC typ.

0.05ºC/°C ambient

0 to 55%

Thermocouple: 100Ω

RTD: 10Ω/lead

60 dB

120 dB

upscale standard

Process temp displayed continuously; setpoint or other

parameters updated on lower display

Greater than 5 times per second.

Analog and digital filtering techniques increase stability of

process & display.

Internal switch selection-process, setpoint and alarms

affected.

Adjustable over full range of control. LED displays alarm

status. 3 amp relay at 120 Vac normally open contact.

Reverse acting relay by switch selecting or low alarms.

Process/deviation mode selectable (internal switch).

Available heating only or heat/cool

SPST relay 7 amps resistive at 120 Vac, 5 amp resistive

at 240 Vac, 50 VA inductive

4-20 mAdc into 500 ohm max.

0-20 Vdc pulsed time proportioning signal for driving solid

state relays 500 ohms maximum input impedance

Solid state plug-in triac output. Rated 1 amp holding &

10 amps inrush

SPST relays, rated 3 amps at 120

Vac

4 digits for process, 4 digits for parameters.

Continuously calculated and updated using rom based

algorithm.

Inputs and outputs vla barrier strips with U.L. approved

Iocking sems terminals.

Front panel: 96mm x 96mm x 22mm

Case: 92mm x 92mm x 118mm

Depth behind panel: 96mm (approx. minus panel thickness)

Channel slides and screws

2 lb

1 mV/ºC for degree reading unit

0.1 mV/ºC for 1 10 degree reading unit

3

+10

-15%

Page 4

Front Panel Adjustments

Touch Key

Index:

Allows the following adjustments to be selected.

1) set

point temperature 0 to span

2) alarm one temperature setting 0 to span

3) alarm two temperature setting 0 to span

4) rate with tracking reset (1:6ratio) ** 0 to 120 sec

5) heat gain *** 1 to 400

6) heat cycle time * 1 to 120 sec

7) cool gain *** 1 to 400

6) cool cycle time * 1 to 120 sec

up/down keys: increases/decreases values of above adjustments

writes selected values to

nonvolatile

memory

Enter:

Internal switches/jumpers

A) 4 position dip switch

1) selects ºF/°C display

2) selects energized alarm two on hi/low (dev + / dev -) temperature

3) selects energized alarm one on hi/low (dev + / dev -) temperature

4) selects process or deviation alarm function

B) 2 position dip switch

1) selects reduced rate gain

2) locks out front panel parameter entry excepting set point

NOTES: *** setting to zero disables output

* setting to zero initiates 60 millisecond timebase for ultra fast cycling.

Use with external solid state relays.

**Setting to zero disables reset and rate actlon for proportional only control.

To order see price sheet C-5-82

General

Congratulations on

purchasing

an

outstanding

temperature controller Ingenious use of

microprocessor technology has given you an

economical, compact controller that:

1.

2.

3.

4.

5.

Accurately measures, linearizes and displays

temperature in

ºF

and

ºC.

Digitally

enters and displays control and alarm set

points

as well as heat and cool

gains,

cycle times,

and user simplified rate and reset action.

Can be switched

configured

for

high

and low

process alarms or deviation

alarms.

Can be field converted from relay output “B”, to

solid state relay "T" to solid state relay driver "S"

or to a 4-20 MA output SCR driver "F", with

independent outputs for heat and cool.

Will remember its “entered” settings after power

failure or shut-off and not “Go To Sleep”.

CAUTION: HIGH VOLTAGE AND HIGH TEMPERATURES CAN

CAUSE INJURY AND ARE A FIRE HAZARD. PLEASE READ

ALL INSTRUCTIONS, HAVE ONLY SKILLED PROFESSIONALS

WIRE THE

UNIT,

AND USE AN APPROVED TEMPERATURE

AND/OR PRESSURE SAFETY CONTROL. EVEN THE BEST

COMPONENTS CAN BE DAMAGED OR MAY NOT FAIL SAFE.

4

x

Page 5

Page 6

Page 7

Output Modules

Module Type F:

Module Type T:

Module Type S:

times less than ten seconds will drastically shorten

relay

life

and in no case should the cycle time be set to

zero (60

millisecond time

base). Normally open

contacts are provided for both

heating

or

cooling

use.

NOTE:

Do not use

this

output module

with mechanical

contactors

because they generate an excessive

EMI

field which

can

lnterfere with

other controllers. Instead

we recommend "T" output modules for this applicatlon.

This 4-20

mA output module can deliver full output to

loads having an input Impedance of 500 OHMS or less.

The cycle

time setting

must be ZERO for smooth

current output.

A push-on

terminal

is

utilized

as a return for ground

currents of the

milliamp

source. It is connected

Internally to the mating lug on the heatsink. To avoid

ground loops, drive floating (ungrounded) loads or use

isolated thermocouples.

This solid state relay is capable of 1 AMP at

120/240Vac.

It is zero voltage switched and optically

isolated from the

drive signal.

With

it,

resistive loads

up to 120 watts at 120Vac and 240 watts at 240Vac

may be controlled

directly. Using direct

control there

is no lower

limit

on the cycle time

setting

(down to

60

milliseconds).

Larger loads may be controlled

utilizing

an external

contactor. In this case, It is

advisable

to use cycle

settings of ten seconds or greater to

minimize

contactor wear. External suppresslon of the contactor

is

advisable

if

EMI

becomes a problem.

Similar

to F, but pulsed

20V/20mA

DC output for

driving

solid state relays. Up to 6 (series input

connected) solid state relays can be used.

Cycling

time

(HC)

can be set to

optimize

the load response

time

requirements

without sacrificing relay life.

7

Page 8

Page 9

Page 10

Page 11

Page 12

Installation Instructions

variable, the probe should be close to the work area.

Some experimenting with probe location is often

needed to find its optimum position.

In a bath process, the addition of a stirrer will help

to eliminate thermal lags. Since the thermocouple

is

basically a point measuring device, putting more than

one thermocouple in parallel will provide an average

temperature reading and produce better results In air

heated processes.

NOTE:

if controls

with “F”

or

"S” outputs

drive loads

with grounded or hot input terminals (not floating), an

isolated

thermocouple must be used. Otherwise, when

both input

and

output

are grounded, severe ground loop

currents will

result,

causing errors and permanent

controller damage.

Standard thermocouple limits of error are

± 4ºF

or

0.75%

(half that for special) plus drift caused by

improper protection or over temperature. This is far

greater than controller error, but can not be corrected

at the sensor except by selection and replacement. In

extreme case, total system requirements can be met by

offsetting the control to compensate for these outside

errors.

Operating Instructions

Control Panel Description

Continuous

Display Of

Process

Continuous

Display

Of

Setpoint

Or

Indexed

Parameter

Touch Key Group

Pressing

The

“I”

Button

Advances

The Cursor In The

“Index” Group

LED To

indicate

Output “Status"

Function Selected

Indicated

By LED

“Cursor”

Advanced By “I”

Button

Enters The

Selected

Value T

O

Nonvolatile

Memory

Raises

(lncreases)

Lowers

The Selected

(Decreases) The

Variable

Selected Variable

12

Variable

Page 13

Operating Instructions

Start-Up

Before line voltage is applied, double check all items

connected to controller: T

he correct type thermocouple

(see section on thermocouples, p. 11) must be on

terminals 1 and 2 (red on 2) with no AC or DC voltage

leading

or arcing to it. Proper terminals selected for

line voltage (8 & 10 for 240V). No heater shorts or

shorts to ground. No exposed bare wires or frayed

insulation.

On very fast processes heaters should be temporarily

disconnected to give operators familiarization time

without exceeding safe temperature limits of the

process.

Set point: Apply power. After allowing a few seconds

for initialization, the upper display will indicate

thermocouple temperature at the process, the lower

display

wil

show set point temperature, and the index

indicator illuminates set point (SP). The status (output)

indicator will pulse with a greater “on” time as the

difference between actual process temperature and set

point widens, and at lesser “on” time as the difference

narrows.

To establish a setpoint, first make sure the index

memory, depress the “enter” key E. Display will blink.

Alarms: Depress index key

(I)

until index indicator

lights at (Al). Now set alarm one trip point by up or

down keys as before. Enter (E). If configured as

deviation tracking alarm, the lower display shows

difference between set point and the point where alarm

is triggered. (See p. 10 to select alarm functions).

Depress index key

(I)

again and advance to alarm 2

(A2). Set as above.

Rate: Advance index to rate (RT). This is the rate

(differential or anticipating) action adjustment,

calibrated in seconds. It is software connected to

automatic reset (integral or droop correcting) action,

which automatically tracks rate.

This wide range, high resolution, single button entry

T

greatly

simplifies tuning the control to the process.

emporarily

run it down to zero (proportional only) and

enter (E).

Heat

Gain:

Heat gain

(HG),

the next index position,

sets controller gain for heat control. It is the inverse of

proportional band (P.B.) which can be calculated as

ºP. B. = Full Scale º/Gain. At HG = 0, heat is off.

Temporarily set HG = 400 or about

3.5º

prop. band on

“J”

couple units, 5º on

“K”.

Proceed to set the next

parameter.

Heat cycling (HC) is next. It should be set to the

longest possible cycling time in seconds (depending on

the mass of process) for increased life expectancy of

relays. 15 to 30 seconds for massive loads, 10 to 15 for

fast loads when relay driven. "T” output solid state

13

light is still on (SP). Then depress the UP button to

increase the value shown in the lower display, or the

DOWN button to decrease it, until the desired setpoint

is reached. To retain this parameter in the non-volatile

Page 14

Operating Instructions

Tuning

Heat Gain

Heat Gain

(HG) Setting

Rate

(RT)

Setting

(includes reset)

relays directly connected to small heaters,

0-5

sec., but

not faster than 10 sec. when driving

mechanical

contactors.

“S” solid state contactor drivers can be

used

0-10

sec.

“F” mA

output units must be set to

HC = 0, less than 1 sec.

CG Is cooling gain. If no cooling is used, set it to

100, and enter. If cooling is employed, start at CG = 400

and follow procedure to set HG.

The final index position is used to set cooling

cycling (CC) time. On all "T" output units, C = 0. Other

outputs are dictated by the type of cooling method

employed. Mechanical compressors may

require

2 minutes, liquid pumps 30 seconds,

solenoid

valves

5-15

seconds, small fans 5 seconds, large ones 30.

Decide, set and enter (E) to lock in value. Then move

index back to "SP".

Connect power to heater and observe temp. rise. Run

set polnt down to meet process. Heat output will start

proportioning within a few degrees of process

temperature, and cool will proportion once SP is below

process.

An ideal process would glve perfect results with

highest controller gain. Practically speaking however,

heaters are overpowered, have stored heat and poor

coupling, loads have multiple delays, and the sensor

reading lags behind the heating output status. A

controller must be tuneable to process characteristics

in order to compensate for the deficiencies of the rest

of the system. The Model 6000 has been designed so

that it does this and still remains easy to operate.

1.

2.

3.

4.

5.

1.

2.

3.

4.

5.

Fix set polnt (SP) at the desired process

temperature. (If overshoot can not be tolerated

durlng set-up, use

20-30%

lower temp.)

Set heat gain (HG) at 400. Record the range of

temperature oscillations around the set point. Note

their durations.

Reduce gain by half (200).

Observe and note

osclllatlon (if any).

Repeat this halving procedure until temperature

is stable.

Push (E) to enter. You have now compensated for

heater power and number of lags, but a droop

between set polnt and process exists.

Set rate (RT) to 01 seconds for fast systems, 05 for

slow, 10 seconds for massive.

Observe oscillation building up and record the range.

Double rate time. Observe oscillation.

Repeat the doubling procedure until the process

stabilizes again.

Then enter (E).

You have now optimized rate and reset times for the frequency response of

the process. If time permits, finer adjustment can be made. For faster start-up

14

Page 15

Operating Instructions

(with some overshoot) reduce rate time 10-20%. For more anticipation (giving

undershoot) increase rate slightly. Experiment with (HG) settings.

EXAMPLES OF PARAMETER SETTING ON TWO PROCESSES

Process A: Slow, 2 lag process, matched power, 200º set point.

HG RT

TEMPERATURE

REMARKS

409 00 197º-199º Process shows 2º oscillation, 2º average droop -

cut gain setting in half.

200 00 196º

200 05

200 10

200 20

200 40

194º-206º

199º-201º

200º

198º-202º

Process is stable, Gain O.K. but 4º droop-requires

addition of rate-add 05 for slow process.

Process shows 8º slowing oscillation, reset is

hunting, double RT to 10.

Almost -double RT value again.

Good-process is stable. Double again to see if we

can improve.

Now process is showing 4º faster (rate) "hunting”.

Back up again. RT = 20.

Process B: Fast, 3 lag, overpowered process, 400° set point.

HG

RT

TEMPERATURE

REMARKS

409 00 389º-435º

25 00

375º-391

12

00

384º

12 01

371º-435º

12

02

396º-404º

12

03

400º ±

12

04

400º

Process

oscillates,

wild, skip to much less gain.

With 16º oscillation, 17º droop- galn should be cut

Gain O.K., 36º droop- now add RT = 1 for fast

process.

Need more rate tlme-double to 2.

Getting

close-add a little more.

Good-add a

little

more to see if we can

improve.

Optimum

Low gain requirement

indicates

poor thermal

coupling

or overpower.

Special

problems can be caused by very noisy

by systems havlng a pure dead time between

turbulent flow processes or

heat application and

temperature measurement. In both cases, rate is

likely to continuously

overreact. Unplug unit and set internal switch to reduced rate gain. (From

back of case, your left,

B-2,

top position).

Cool Gain

If

cooling

is to be controlled, first

optimize

the heat

(CG)

Setting

adjustments. Start heat generating mechanism

(chemical reaction,

mechanical,

subambient set

point,

etc. that will require cooling action.

Set cool

gain

to 400 (maximum). If stable, enter.

Most likely the temperature will oscillate. Record

I

1.

2.

3.

Z:

values used.

Reduce gain to 200. Compare temperature

oscillations. If oscillations are reduced, continue

lowering gain until process is stable.

If up and down temperature peaks get bigger, cool

cycling (CC) may be too long or the cooling

mechanism has too much lag or time delay. If

possible, improve dynamics of cool transfer, If not,

go to rate (RT) and double rate time.

4. Now optimize cooling gain as in step 2.

5. Since heat rate will now be too long, cut heat gain

15

in half.

Page 16

Trouble

Shooting

Unit Repairs

Front dark - no instrument power, blown fuse or burned

out transformer.

Process display shows CCCC - Open thermocouple.

Short terminals 1 and 2, should indicate temperature at

back of case. Repair or replace thermocouple.

About Half Or Twice Expected Reading- Check

position of ºC or ºF switch. Short 1 and 2 to read room

temperature. 22-30 is %, 70-85 is ºF

About 30% Error - Wrong thermocouple type.

Disconnect couple. “J” units over range above 1400°F,

“K”

above

2000°F +

.

No Heat - Heater wiring, wrong output module, blown

fuses.

Heat Stays On- Welded relay contacts or shorted

output module. Check for cause and correct the

components.

Process Display Shows 0000 Or Initially Displays Room

Temperature Then Counts Down Scale As Process

Warms - Check for reversed thermocouple.

It is recommended that units requiring service be

returned

to

an authorized service center. When a

controller is returned for service, a note stating the

problem should accompany the unit. To eliminate

service delay, consult the factory prior to returning any

A spare parts list can be supplied upon request if

complete model number, serial number and

temperature range is supplied.

Warranty

This equipment is warranted to be free from defects of material

and workmanship. It is sold subject to our mutual agreement that the

liability of Athena Controls, Inc. is to replace and/or repair at its

factory, provided the equipment is returned, transportation prepaid

within (2) years of its purchase.

The purchaser agrees that Athena Controls, Inc. shall assume no

liability for consequential damages resulting from its use or

packaging of shipments returned to the factory.

Components which wear or which are damaged by misuses are not

warranted. These include contact points, fuses and triacs. Units

which have been rewired by customer are not warranteed.

Specifications are subject to change without notice.

Athena Controls Inc., 5145 Campus Drive

Plymouth Meeting, PA 19462

(215) 828-2490

unit.

Loading...

Loading...