Page 1

SERIES

6075

TEMPERATURE CONTROLLERS

WITH AUTO-TUNING

PID AND

PLUG-IN COMPUTER INTERFACE

Page 2

Warranty Limitations

Other than those expressly stated

herein,THERE

ARE NO OTHER

WARRANTIES OF ANY KIND, EXPRESS OR

lMPLlED, AND

SPECIFI-

CALLY EXCLUDED BUT NOT BY WAY OF

LlMlTATlON, ARE THE

IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE

AND MERCHANTABILITY.

IT IS UNDERSTOOD AND AGREED THE SELLER’S LIABILITY

WHETHER IN CONTRACT, IN TORT, UNDER ANY WARRANTY, IN

NEGLIGENCE OR OTHERWISE SHALL NOT EXCEED THE RETURN

OF THE AMOUNT OF THE PURCHASE PRICE PAID BY THE PURCHASER AND UNDER NO CIRCUMSTANCES SHALL BE LIABLE

FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.THE PRICE STATED

FOR THE

EQUIPMENT IS A

CONSIDERATION IN LIMITING SELLER’S LIABILITY NO ACTION,

REGARDLESS OF FORM, ARISING OUT OF THE TRANSACTIONS

OF THIS

AGREEMENT MAY BE BROUGHT BY PURCHASER MORE

THAN

ONE YEAR

AFTER THE CAUSE OF ACTION HAS ACCRUED.

SELLER’S MAXIMUM LIABILITY SHALL NOT EXCEED AND BUYER’S

REMEDY IS LIMITEDTO EITHER (i) REPAIR OR

REPLACEMENT

OF

THE DEFECTIVE PART OR PRODUCT, OR AT SELLER’S OPTION (ii)

RETURN

OF THE

PRODUCT AND REFUND

OF THE

PURCHASE

PRlCE, AND

SUCH REMEDY SHALL BE BUYER’S ENTIRE AND

EXCLUSIVE REMEDY.

Page 3

SERIES 6075

AUTO-TUNING

PID

TEMPERATURE CONTROLLER

CONTENTS

PAGE

SECTION 1 GENERAL INTRODUCTION . . . . . . . . . 1

1.1

General Description and Cautions . . . . . . . . . . . . . . . . . . . . . . 1

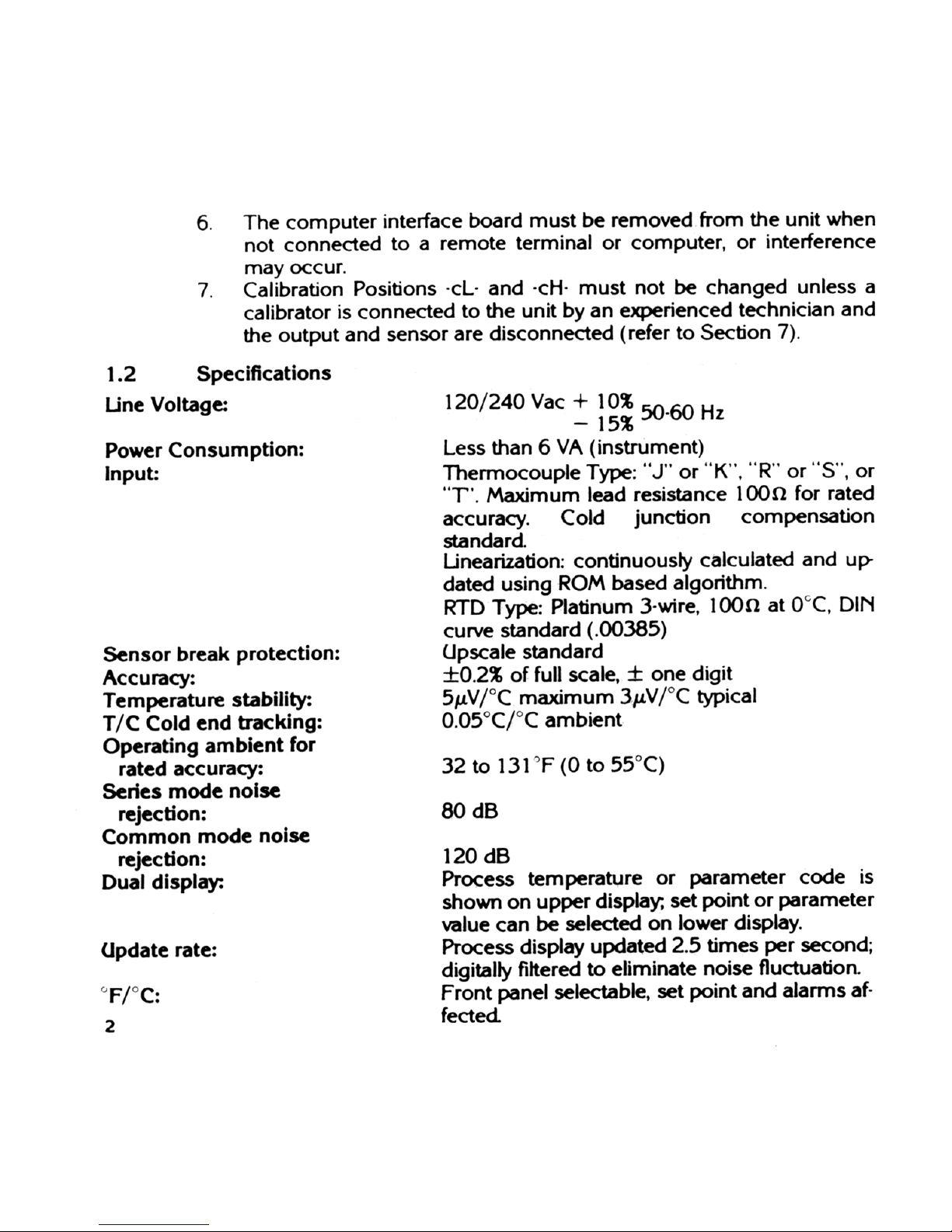

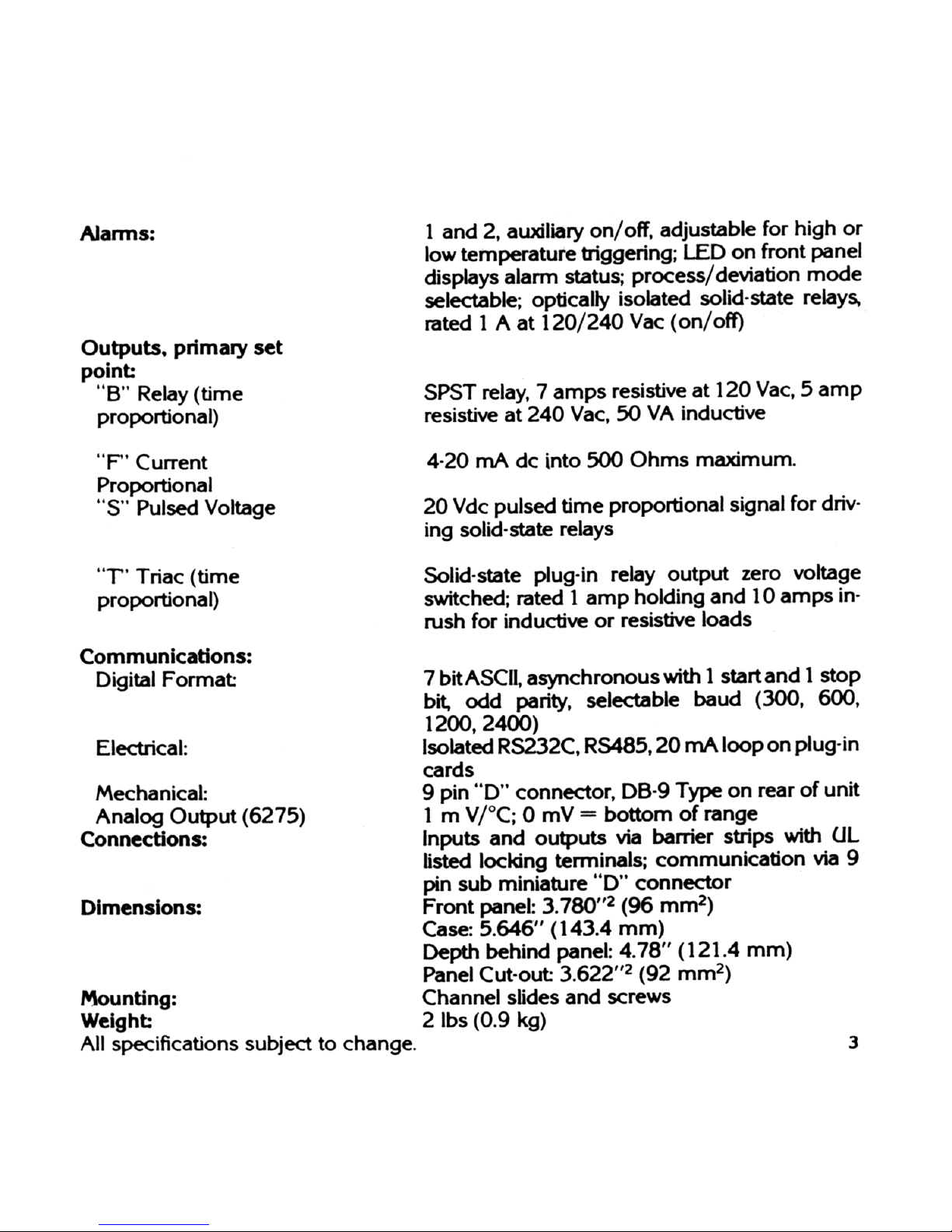

1.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

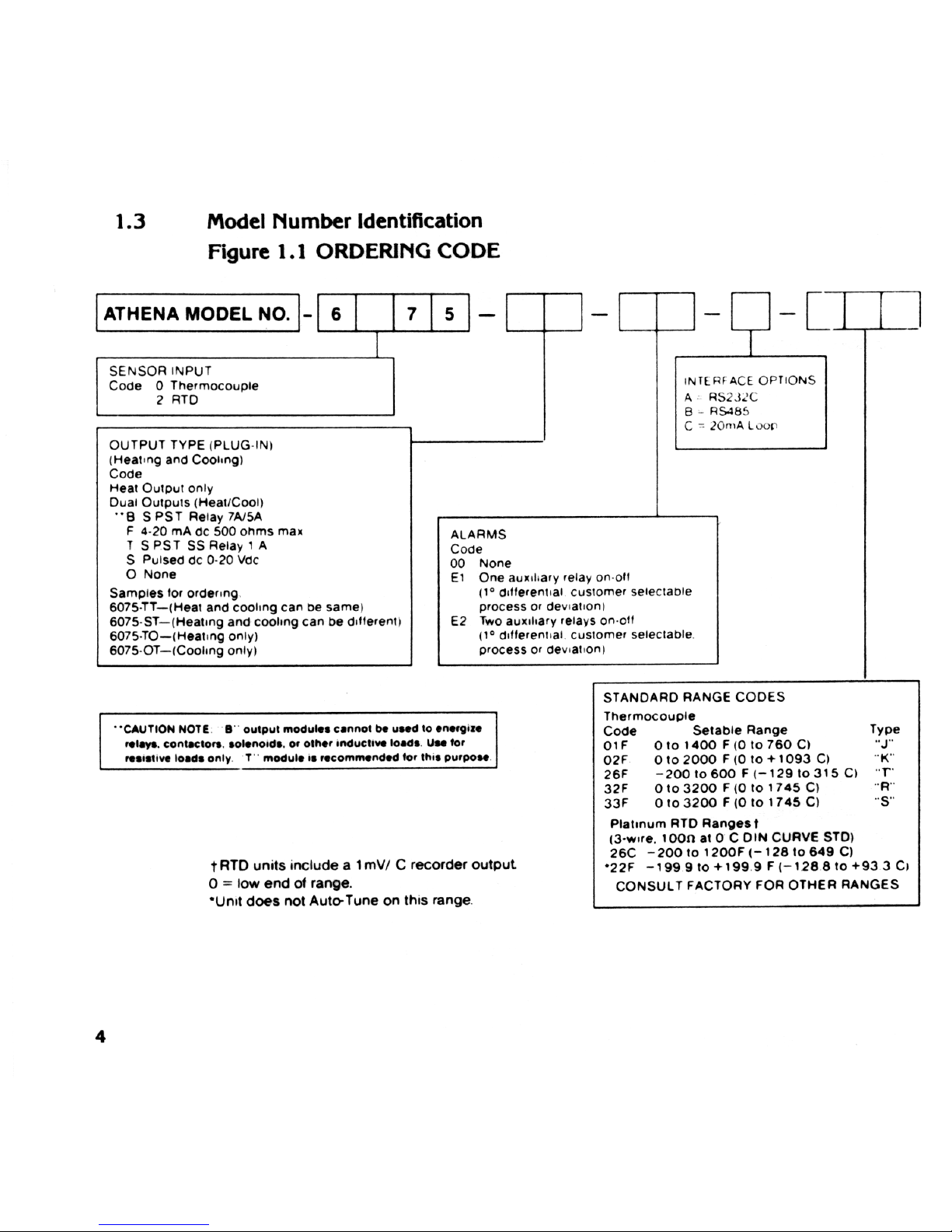

1.3 Model Number Identification . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2 INSTALLATION INSTRUCTIONS . . . . . 5

2.1 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Locating. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Removing Unit. . . . . . . . . . . . . . . . . . . . . . . . . 5

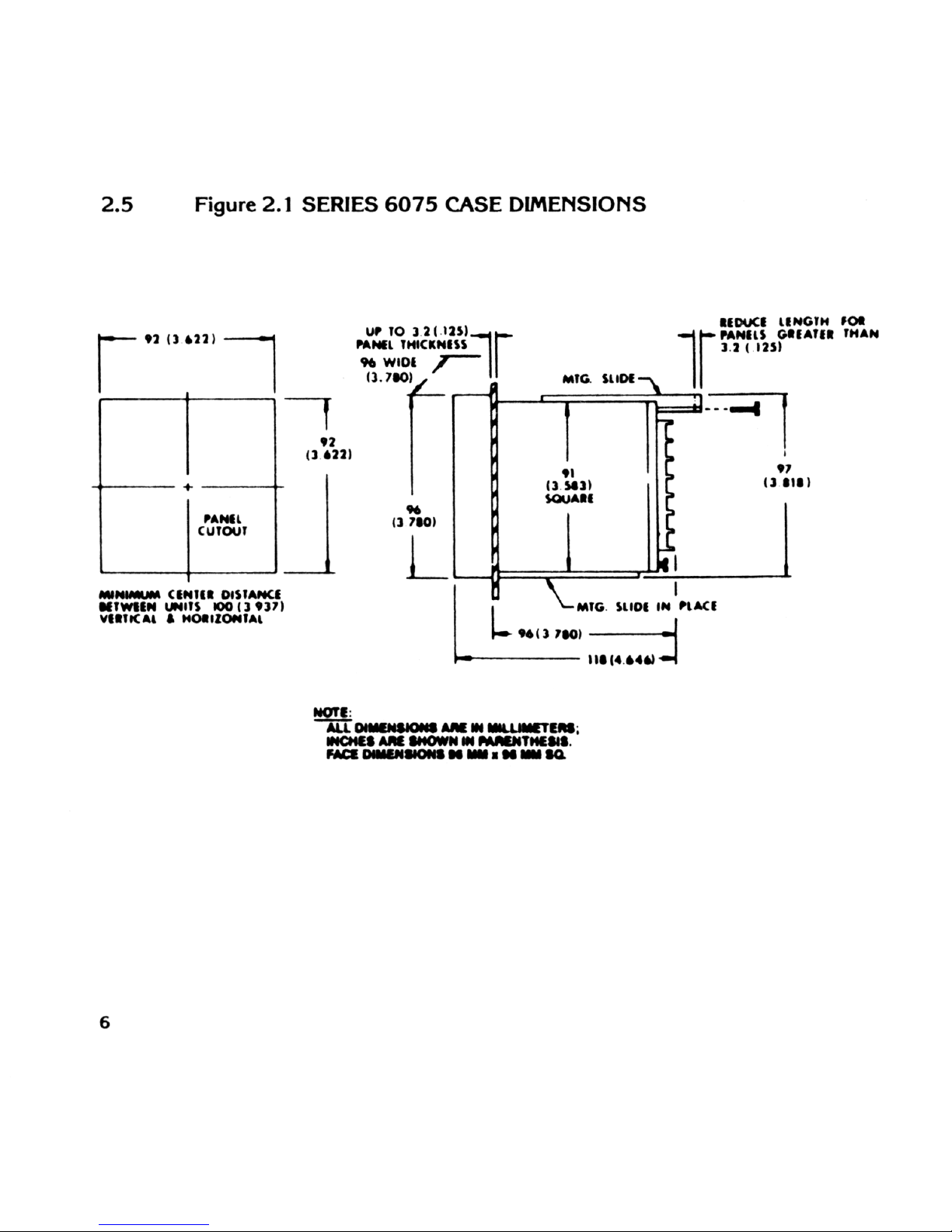

2.5 Case Dimensions. . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION 3 OUTPUT MODULES. . . . . . . . . . . . . . . . 7

3.1 Module Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

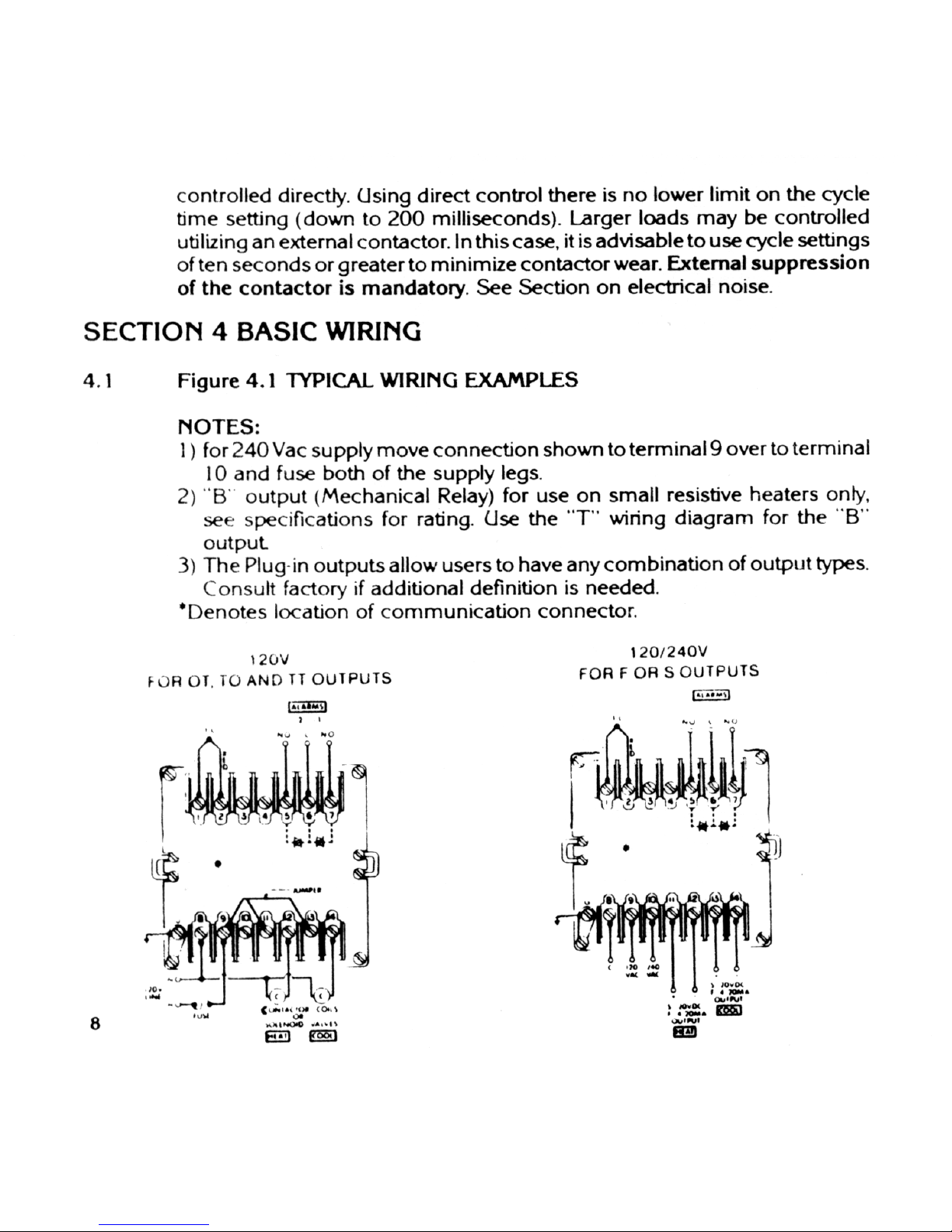

SECTION 4 BASIC WIRING. . . . . . . . . . . . . . . . 8

4.1 Typical Wiring Examples. . . . . . . . . . . . . . . . . . . . 8

4.2 Wiring Thermocouple and RTD Circuits. . . . . . . . . . . . . . 9

SECTION 5 OPERATION. . . . . . . . . . . . . . . . . . . 12

5.1 Front Panel Features. . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.3 Tuning The Controller. . . . . . . . . . . . . . . . . . . . . 20

5.3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.2 Automatic

PlD

Tuning Procedure. . . . . . . . . . . . . . . 20

5.3.2.1 Damping

Settings. . . . . . . . . . . . . . . . . . . 20

5.3.2.2 Operating Instructions. . . . . . . . . . . . . . . . . . . . . 21

5.3.3 Manual Tuning procedure. . . . . . . . . . . . . . . . . . . . . . 22

Page 4

SECTION 6 COMMUNICATIONS . . . . . . . . . . . 26

6.1 Communications Modules . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.1 RS485. . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.2

RS232C. . . . . . . . . . . . . . . . . . . . . . . . . 26

6.1.3 20

mA

Current Loop. . . . . . . . . . . . . . . . . . . 27

6.2

Installing the Communications Modules. . . . . . . . . . . . . 28

6.3 Interface Examples. . . . . . . . . . . . . . . . . . . . . . 30

6.3.1 Read Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3.2 Modify (Temporary). . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3.3 Modify and Store. . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 7 CALIBRATION. . . . . . . . . . . . 33

7.1 Zero and Span Adjustments. . . . . . . . . . . . . . . . . . . . . . . 33

(Factory Set)

SECTION 8 TROUBLESHOOTING. . . . . . . . . . . . 34

8.1 Troubleshooting - General. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.2

Troubleshooting - Communications. . . . . . . . . . . . . . . . 35

FIGURES

1.1

Ordering Code

-

Model Number. . . . . . . . . . . . . . . . 4

2.1

Series

6075 Dimensions. . . . . . . . . . . . . . . . . . . 6

4.1 Wiring Examples. . . . . . . . . . . . . . . . . . . . . . 8

5.1 6075 Front Panel Features. . . . . . . . . . . . . . . . . . 13

5.2

Configuration

Code Chart. . . . . . . . . . . . . . . . . . . 17

5.3 Ziegler

- Nichols Graph. . . . . . . . . . . . . . . . . . . . 23

6.1 Connector Pin Identification. . . . . . . . . . . . . . . . . . . . . 28

6.2 Wiring for

Communications. . . . . . . . . . . . . . . . . . 29

z

Page 5

GENERAL INTRODUCTION

SECTION

1

1.1

General Description and Cautions

Athena Controls, Inc. is proud of the Series 6075 which you will now use It

has been manufactured to our

exacting

production standards, and packed

for

maximum

protection in shipment You will get years of reliable

service

from the unit if the information in the manual is followed regarding location,

adjustments, and general operation.

CAUTlON

High Voltage and High Temperature can cause injury and are a

Fire Hazard. Please read all instructions, have only skilled professionals

wire the unit, and use an approved temperature

and/or

pressure safety control. Even the best components can be

damaged or may not failsafe.

Warning Notes:

1. "B"

Output for resistance load only.

2.

An open thermocouple will disable the INDEX function.

3.

Note also that in units utilizing only heating output the cooling

gain

should be set by user to the equivalent heating gain. The inverse IS

also true.

4.

A unique algorithm in the Model 6075 prevents continual buildup of

oscillation due to grossly misadjusted rate/reset

(-rt-)

or gain. When

this occurs the unit

will

control at some point higher or lower than set

point

outside the proportional band. If this occurs -rt- was probably set

too low and/or gain set too high.

5.

-rt-

sets Rate

(Derivative)

and Reset (Integral) action. The number displayed is the Rate time in seconds. This is tracked by the Reset time in

seconds (1:6 ratio).

Page 6

Page 7

Page 8

Page 9

SECTION 2 INSTALLATION INSTRUCTIONS

2.1

Unpacking

Unpack the instrument and inspect for shipping damage. Report any

damage to the carrier immediitely.

2.2 Locating

Select a

location

for the controller where it will not be subject to excessive

shock vibration, dirt moisture or oil. The ambient temperature of the area

should be between

32º

and 131 ºF (A model

DC-15

dust, oil and water

resis-

tant cover is available to protect from harsh environments.)

2.3

Mounting

Mount the controller into a 92 mm (3

5/8”)

square cutout See figure for the

cutout and case dimensions. The plug-in controller does not have to be

removed from its housing for mounting. Remove two screws that hold the

mounting slides and then remove the slides. Insert case from front panel

and

re-install

the two slides and two screws. Do not over-tighten screws. The

length of the slides must be reduced if the controller is to be mounted in an

extra thick

panel.

If the controller has been unplugged from its housing, the

top of the housing can be determined because it features the serial tag.

2.4

Removing

Unit

The 6075 can be removed

from

its housing by pulling firmly on the black

front bezel. If a communication port is connected, it should be removed

first

Page 10

Page 11

SECTION 3 OUTPUT MODULES

3.1

Module

Description

The Athena 6075 offers field interchangeable output modules. This unique

feature makes it possible to fill output requirements for a variety of

applications with a single controller model.

Module Type B: This

7A/5A

relay (at

120/240 Vac)

is used for driving

resis-

tive

heaters.

NOTE:

Do not use this output module with mechanical

contactors

because they generate an excessive

EMI

field which can interfere

with the

6075’s

microprocessor, Instead, we recommend

“T’

output modules for this application

Module Type

F: This 4-20mA

output module can deliver full output to loads

having an input impedance of 500 Ohms or less. The cycle time setting

must be ZERO for smooth current output.

Module Type S: Similar to

F.

but pulsed 20 Vdc output

for

driving solid state

relays.

Up

to 6 (input series connected) solid state relays can be used.

Cycle

time can be set to optimize the load response time

requirements.

“F’ & “S”

MODULE

NOTE:

A

push-on

terminal is

utilized

as a return for ground

currents

of

the

milliamp

source. It is connected internally by the mating lug

on the circuit board. To avoid ground loops, drive floating

(ungrounded) loads.

Module Type T:

This solid state relay is capable of 1

amp at 120/240 Vac.

It is

zero voltage switched and

optically

isolated from the drive signal. With it

resistive loads up to

I20

watts at

I20 Vac

and 240 watts at 240

Vac

may

be

Page 12

Page 13

Page 14

Standard Thermocouples

I.SA.

Type

Materials

Color Code

J

Iron-Constantant (I/C)

White( +

)

Red(

-

)

K

Chromel-Alumel

Yellow( +

)

Red(

-

)

T

Copper-Constanan

Blue( +

)

Red( -

)

Platinum-Platinum

13%Rhodium

-

Platinum-Platinum 10%

Rhodium

-

Wiring RTD Circuits

6275 units are designed for 100 Ohm Platinum

RTD’s 2-wire RTD’s

are

connected to terminals 1 and 2 with a jumper connecting 2 to 3. Keep leads

short and use heavy gauge

copper

extension wires if necessary, to minimize

lead resistance. For long runs

3-wire

RTD should be used and wire gauge

should be sufficient that resistance does not exceed 10 Ohms. An error of

0.2ºF

will result for each additional 10 Ohms Per lead

DO NOT RUN RTD LEADS IN IN THE SAME CONDUIT AS POWER LINES.

If shielded RTD wire is used, terminate the shield only at the controller end,

using the comer screw provided for that purpose.

NOTE

RTDs

tend to be shock sensitive and require extra care in handling

and installation.

THERMOCOUPLE PLACEMENT

(or RTD)

Proper thermocouple placement can eliminate many problems in the system. The probe should be placed so that it can detect any temperature

change with minimal thermal lag. In a process that requires fairly constant

heat output, the probe should be placed close to the heater. In processes

where heat demand is variable, the probe should be close to the work area.

Some experimenting with probe location is often needed to find its

optimum Position.

A WORD ON ELECTRICAL NOISE

Microprocessor are essentially small computers. As such they can

randomly be interferred with by large electrical spikes, even with elaborate

10

R

S

Page 15

watchdog circuits and filtering built into the unit Contacts and coils must be

suppressed! One very effective filter is a

.1 ufd/600V

capacitor in series with a

100 Ohm,

1/2

watt (min.) resistor. This network must be put on all contacts,

especially across hard contacts that are switching coils and across the coils

themselves. The filter should be placed as close to the noise source as

Possible

i.e.

right on a

contactors

coil etc.

Other recommended practices include:

* Run sensor wires separately, shield if possible and ground only one end

of the shield.

* Install

.01 ufd/100V

or greater capacitors from each sensor terminal to

case ground (the green screw).

* Connect each unit’s ground (the green case screw) directly to the machine

(ground). Do not connect it to the panel Paint and corrosion can cause

poor

signal transmission Do not connect ground wires in series from

unit to unit Ground wires must be connected from each unit directly

to ground

* Make sure the machine is connected to earth ground Do not assume

it is.

11

Page 16

SECTION 5 OPERATION

5.1

Front Panel Features

Touch Key and Indication Operation Layout

1.

2.

3.

4.

5.

6.

7.

Process Temperature or Parameter code is viewed on the upper

display.

Set Point or Parameter setting is viewed on the lower display. Degrees F

and C is also displayed.

Set Point

Key:

Allows user to return to set point

ENTER/TUNE

Key:

Enters a selected value into nonvolatile memory.

Also initiates Auto-Tuning when used in the correct sequence.

Up and Down Keys: Raises and lowers setting respectively. 2 Step scan

rate: Slow and Faster (after 5 seconds).

Index

Key:

Selects Parameters to be addressed

STAND-BY/CANCEL

Key:

Disables outputs. Unit is put in idle mode.

LED above

switch

lights in STAND-BY mode. STAND-BY is also used

as the position from which AUTO-TUNE is accessed. If the key is

pressed during Auto-Tuning the unit will cancel the

Auto-Tuning

pro-

cedure and return to the STAND-BY

mode.

8.

Receive (RX) and

transmit

(TX) lights: Indicate a signal is present at the

communication

port

tights only

momentarily

9.

Heat (HT) a

nd

CooI

(CT) Output

Lighk

Lights when output drive signal

is present

10.

Alarm Lights (A1 and A2): Lights when unit is in alarm. (programmable

Hi, Low, process or deviation.)

12

Page 17

Page 18

5.2

Basic Series 6075 Setup

1.

The 6075 has dual-input ranges which allow selection of one of two

ranges and T/C types, by simply moving the position of the internal

jumper.

To set unit to proper range, remove unit from case and position jumper on

top board. Front position is range A, rear position is range B, grouped

s

offered.

A = 01F No Jumper = 26F A = 33F A = 22F No Jumper = 22C

B = 02F

B = 32F B = 26C

Consult Serial Tag for actual range and sensor type ordered. Ranges

are defined in Section

1.3,

Model Number Identification.

The Series 6075 is shipped from the factory with the following settings:

SP = 100 CG = 30 Id = 01

A1 = 105 CC = 05 (F=00) bd = 02

A2 = 95 cd = 08 cL = Range dependent

rt = 00 AT = 00 cH = Range dependent

HG = 30 cF = 08 (05 for ºC ranges)

HC = 05 (F=00) ct ct = 00

14

Page 19

2. .

Range of Adjustments (Parameters)

All

parameters are accessed by pressing the INDEX key. They

are

listed

in

the order they are displayed when the

lNDEX

key is pressed.

The front panel of the Model 6075 contains a lower display of 5 digits

which displays the set point temperature, the other parameter values

and degrees F or C. The upper display consists of 4 digits which display

the

process

value or the

parameter

abbreviations;

e.g. -A1-

identifies

Alarm

1.

As the INDEX key is pressed the second column

abbreviations

appear in the upper display. To the right of the ENTER Key is an

EXIT

Key

labelled

‘SET POINT’ which allows the user to EXIT parameters 2

thru 16 back to parameter # 1 (set point).

After

changing a value the

ENTER Key must be pressed. This enters the new value in memory. If it

is

not

pressed

and power is removed, the last value entered for that

parameter

will

be set up for that parameter.

DlSPLAYED

NUMBER

CODE

PARAMETER

RANGE

0

Process Temperature

Zero to span of

unit

(ºF

or ºC)

1

Set Point

Zero to span of

unit

(ºF

or

ºC)

2

-A1-

Alarm One

Zero to span of

unit (ºF or ºC)

3

-A2-

Alarm Two

Zero to span of

unit

(ºF

or

ºC)

4

-rt-

Rate/Reset

(1:6

ratio)

0 to 255 Seconds

5

-HG-

6

-HC-

7

-CG-

8

-CC-

9 cd-

Heat Gain

Heat Cycle Time

Cool Gain

Cool Cycle Time

Access Code

(See Note

6)

(See Note 2)

0 to 120 Seconds

(See Note 7)

0 to 400

(See Note 2)

0 to 120 Seconds

(See Note 7)

0 to 255

(See Note 3)

15

-

-

1 to 400

Page 20

Locally Adjustable only (Not by Remote Keyboard)

10

-At-

Auto-Tune Damping

0=Low,

1

=normal,

2=High

11

-cF-

Configuration

0 to15

(See Note 4)

12xx

-ct-

Cooling Type

0-Oil or none,

1

-Air, 2-Water

13

-Id-

Unit ID CODE 0 to 99

(See Note 5)

14

-bd-

Baud Rates

300(0),600(

1)

1200(2), 2400(3)

15

-cL-

Calibration, Low

±3% Span

(ZERO)

(°F/ºC)

16

-cH-

Calibration, High

±3% Span

(SPAN)

(ºF/ºC)

xx

Not on RTD units

When setting up the unit for the first time, push the “STAND BY" key

(LED above button is on), and the unit will be placed into an idle condition. Outputs and alarms will be off. On completion of

inital

setup, push

the key again (LED

off)

for normal operation.

press the INDEX key until parameter #9 (-cd-) appears in the process

display area.

a.

Set

14 in lower display to gain access to configuration code, by

pressing the up or down arrow and then pressing the

ENTER

key.

press the INDEX key until parameter

#11 (-cF-)

appears in the process

display area.

a. Refer to the configuration code chart and select a number that

represents the desired configuration of thealarms and display

units

e.g., #06 = ºF, Deviation Alarms Alarm 1=Low Acting, Alarm

2=High

Acting.

b. Set this number into the lower display, using the keys

c.

press the ENTER key.

16

Note: Changing temperature scale requires

re-setting

of all points.

3.

4.

5.

Page 21

Page 22

pressed the INDEX key, the unit

will

advance to the High and Low

Calibration

positions.

but index no further until the SETPOINT

key is

depressed.

CAUTION: DO NOT CHANGE THE

CALIBRATION

LOW

[cL(Zero)]

OR

CALlBRATlON

HIGH

[cH(Span)]

ADJUSTMENT

UNLESS YOU INTEND TO, ARE QUALIFIED AND HAVE

A

CALIBRATION

TEST SETUP CONNECTED.

9.

Press Index and Alarm One (Al) appears in the upper display area. If

this option is installed. set in the desired temperature value, then

press ENTER.

10.

Repeat

for

(-A2-)

Alarm two, if installed

11.

Refer to the

section

on tuning the 6075 for the remainder of the

settings.

NOTE: When finished entering all parameters return to

-cd-

using the

INDEX key. Select the level of security desired and enter the appropriate

value into memory.

#1 -

Allows changes to set point

only.

#8 -

Allows changes to first nine parameters

only.

#14 -

Allows changes to 9 parameters and calibration constants.

NOTE: Any other value only allows changes to

-cd-

Reference Notes

NOTE 1: Parameters

#

10 thru # 16 are accessed from the front panel only,

and can not be set from a remote terminal

NOTE 2: The gain value

(-HG-&-CG-)

is multiplier used to increase the

sen-

sitivity of the controller according

to the

formula: Output = Gain (E + I + D)

where E

=

Error. I = Integral. D= Derivative, Its relationship to proportional

band is as follows:

Unit

Span

PROP BAND =

=

Heat Gain (HG) or Cool

Gain (CG)

Note that proportional band is an inverse function of gain, The range of

18

adjustment is 0 to 400 for Heat. 0 to

400

for Cool.

___________________

Page 23

SPECIAL

NOTE:

For Units utilizing only heating output, the cooling gain should be

set by the user to the equivalent heat

gain.

The inverse is also true.

Setting CG to 0 initiates an on-off (narrow deadband) output for

cooling, which is recommended for cooling-only applications.

Setting

HG

to 0 disables the Heat output.

NOTE 3: The access code is a number stored in ROM that upon entering in

location

-cd-

allows user access to change parameters. Depending on the

code entered the user may then alter calibration and configuration of the

controller. When this is accomplished the code may be changed to prevent

tampering with critical

values. When

the number

is"

1" only the set point can

be changed. When the number is ”8”, changes are allowed to the first nine

parameters. When the number is

“14”

all

settings

can be altered. When

neither

1, 8

or 14 are entered only the access code can be altered.

NOTE 4: The configuration code allows the user to configure the alarms for

process/deviation, high or low energizing. The code also selects ºF or

ºC

operation of the unit. SEE THE

CONFIGURATlON

CODE CHART.

NOTE 5:

-Id-

is the unit identification code. It is variable from 00 thru 99 and

is used with the communications interface to allow a remote

device

to iden-

tify which controller it is communicating with.

NOTE 6: Setting RT to 0 disables rate and reset

action

for

proportional

only

control. This will cause an offset between set point and process

termperature.

NOTE 7: Set the heat cycle

(-HC-)

and cool cycle

(-CC-)

according to power

handler being used. 0

for "F" (4-20mAdc)

outputs,

5-20

for

contactors

and

solenoids. Setting HC or CC to 0 initiates 200 millisecond

timebase

for fast

cycling of the

respective

output. Use with external solid state relays

(“S"

Modules) or

SCR

Power Controllers

("F"

Modules).

19

Page 24

5.3

Tuning the Controller

5.3.1

Introduction

5.3.2

The Series 6075 is a state-of-the-art automatic tuning PlD temperature controller. The user has the option of automatically selecting the controller’s

PlD

settings or manually setting the unit as desired.

Tuning a

3-Mode

controller involves three (3) major adjustments;

proportional Band (Gain), Rate (Derivative) and Reset (lntegral) action. Athena has

simplified the adjustment procedure with the incorporation of the Rate and

Reset settings into one adjustment

"RT"

which is displayed in seconds of

Rate time. The Reset time is automatically set at six (6) times the displayed

Rate values.

Automatic

PlD

Tuning procedure

NOTE FOR OPTlMUM RESULTS

Set point must be a minimum of 100°F above the starting or

ambient

temperature when tuning is initiated for accurate tuning. Less than

100ºF may not yield effective tuning settings.

Multi-zone applications require Auto-Tune units on each zone and

simultaneous warmup.

Loss of power or a turn-off during the

Auto-Tune

cycle requires a restart

from ambient (or at least

I00ºF

rise to set point) for reliable

PlD

values.

Change of state processes, i.e. solid to liquid or liquid to gas, may

introduce erroneous tuning parameters during process warmup.

Tuning should be done after the change has

occured

5.3.2.1

Damping Settings

Heat Damping Choices (“-At-“: position # 10)

To allow the controller to provide automatic tuning for a wide variety of processes that may exhibit varying heating characteristics and/or varying heat-

ing capabilities, the controller offers three damping choices:

00 Low Damping - For processes that (any combination of the following)

-

are adequately powered with excellent coupling between heater and

probe.

20

-

require quick response and the tightest possible temperature control

is desired

1.

2.

3.

4.

Page 25

5.3.2.2

01

02

Normal Damping

-

For processes that: (any combination of the

following)

- have heaters that are properly sized.

- have good coupling between heater and probe.

- are considered standard with moderate lags and response time.

High Damping - For processes that (any combination of the fol-

lowing)

- are overpowered

- have multiple lags

- are poorly coupled between the heater and probe

COOL (“ct-“: position #12) (Not On RTD Units)

When using the controller on heating and cooling applications, such as

extruders, the

"ct"

number allows setting of the controller for the type of

cooling used:

00 -

Oil cooling (Use this Setting if No cooling is used)

01 - Air cooling - Forced air

02 - Water cooling (above

212ºF set point)

Operating

Instructions (Read “Damping Settings” before proceeding)

How to Start the Automatic Tunina procedure

STEP 1: Energize the unit and Proceed immediately to step 2.

STEP 2: Place the unit on standby by pushing the stand-by button. LED

above button will light Auto-tune can

only

be accessed from the

stand-by position.

STEP 3: Index down and enter access code, position 9, then press set

point

STEP 4: Index down and enter all settings per section 5.2 Basic Setup. e.g.

set point Al, A2, HC, CC, AT, cF, ct, Id, bd, and press set point RT,

HG, and CG will be set by controller during Auto-Tuning.

STEP 5: Index down to

“-At-“.

21

Page 26

STEP 6:

When

ready to

start Auto-Tuning

calculation

of

PlD settings

press

the “Enter/Tune” button. The displays will return to process and

set point displayed. The F/C digit will blink while tuning is in process.

Upon completion of tuning, the digit will stop blinking. TO

stop the Auto-Tuning press

standby/cancel.

NOTE:

Series 6275, RTD input will not

Auto-Tune

when the decimal point

range is used. If tenth degree range is desired either auto tune on

the other range and then move the range jumper or use manual

tuning methods.

How to override automatic tuning

parameters

(Also refer to Ziegler-

Nichols Tuning Method)

It is possible to set or fine tune the three mode parameters manually.

To manually enter parameters

1)

Press Index button until

"Rt"

(Rate),

"HG"

(Heat Gain) or

CG

(Cool

Gain)

are displayed.

2) Enter new parameter

setting

desired using the up/down buttons.

3) Press the “Enter” key.

The new parameters will now take control of the process.

5.3.3 Manual Tuning procedure

The following procedure can be used for fine tuning after or instead of Auto-

Tuning.

Ziegler-Nichols

PID

Tuning Method

This has long been an accepted method of tuning

PID (3 Mode)

controllers

using a minimum of time and set up to reach effective tuning parameters.

Before

proceeding make sure the basic unit setup is done as discussed in

section 5.2.

22

Page 27

Page 28

4. Press STAND-BY again and temperature will begin to rise. When the process rises to the desired set point it will probably oscillate. Periodically

decrease the Gain (lower the HG number) until a small constant oscillation is obtained. Reducing the Gain by steps of one half (1/2) the previous

-HG- setting

is an acceptable method to obtain the desired small

oscilla-

tion. Note time between oscillations in seconds (“T” on Figure 5.3).

5.

Decrease the Heat Gain to 60% of the value obtained in the previous step.

The Gain is now tuned. Enter the same number in the Cool Gain.

6.

The best rate time (-RT-) setting is one-eighth (1/8) the time in seconds of

one cycle (see cycle time "T" in Figure 5.3). This will give a conservatively

tuned system. If faster response and/or faster rise to set point is desired

one-twelth (1 /12) of "T" may be used. Note that faster settings may yield

instability and temperature overshoots on startup. Remember that the

reset automatically tracks the rate (-rt-) adjustment

7.

Connect cooling apparatus Observe control stability.

8. If oscillation occurs lower the cool gain number. If cooling is sluggish

raise the cooling gain number.

NOTE: In order to observe changes in process temperature, especially as

they relate to time, it is helpful to use a temperature recorder in conjunction

with all tuning and parameter setting procedures.

TUNING HINTS

1.

Once the optimum -rt- and -HG- have been set into the unit, cold start tests

of the process should be tried. Remember that start-up and running

parameters will usually be different and it is desirable to adjust both gain

(HG) and rate/reset (RT) ±25% to strike a balance between good startup

and running settings.

Generally higher settings of -rt- will give more controlled start-ups with

less overshoot lower values will give faster recovery from process upsets

Higher gain settings will give tighter control of the running process. but

may give more overshoot on start-up.

24

Page 29

Page 30

SECTION 6 COMMUNICATIONS

6.1 Communications Modules

Optional plug-in modules are available for the Series 6075 to allow interfac-

ing to the most common industry standards. A brief description of each type

follows.

6.1.1

RS485

RS485 is a specification standard for balanced voltage digitial interface cir-

cuits published by the EIA.

It was published in 1983 as an upgrade of RS422A electrical specifications,

with emphasis given to the application of multipoint systems. The interface

circuits used in

the Athena Model 6075 meet the electrical characteristics of

the RS485 standard.

The RS485 multipoint capability allows up to thirty-two (32) units to be con-

nected together in a half duplex network More can be added with the use of

“repeaters” such as the Athena Model CC.1 interface box

This module allows

bi-directional

data transfer over a shielded twisted pair.

The

twisted

pair

is a

transmission line

with

drops to communicating devices.

Since it is a transmission line, terminating resistors are required at the most

distant ends of the line to minimize reflections. (Typically 60 ohms from

each line to signal ground).

The Model 6075 RS485 module is fully optically

isolated, eliminating ground loop problems, Parallel drops from the

transmission line should be kept as short as possible. Alternately the line

could be daisy chained at each DB-9 connector. Note that the polarity of the

line is important and each device will

specify an

“A” and ”B”

connection. On

the 6075 RS485 module, “A" is pin 8 and 4; “B” is pin 7 and 3 and com-

munications ground is available on pins

1,2,

and 6. Frame ground is pin 5

and 9.

6.1.2 RS232C

The RS232C is a standard that was published in 1968 by the “Electronic

Industries Association” (ElA). The RS is an acronym for Recommended

26

Page 31

Standard and the 232 is the identification number for that particular Standard. The C designates the last revision made to the RS232 standard. The

purpose of this standard is to define the electrical characteristics for the

interfacing of ”data terminal equipment” and “data communications equip

ment”. The standard providesvoltage ranges for data and control signals to

provide proper transmission.

This module allows bi-directional data transfer via a three conductor cable

consisting of signal ground (pin 7). receive (input, pin 2) and transmit (out-

put, pin 3). It is recommended for less than fifty feet between computer/

terminal and instrument Note that multiple instruments cannot be tied to

the same port The module is optically isolated to eliminate ground Ioop

problems. Note that in a typical installation, “data out” of the computer/

terminal connects to "receive data" of the 6075 and "receive data" of the

computer/terminal connects to *‘data out” of the 6075. If shielded cable is

used it should be connected to frame ground at one end only. Signal ground

is connected at both ends. The RS232 module is configured for active

operation.

6.1.3 20 mA

Current

Loop

This module allows bi-directional data transfer via a current loop with each

instrument series connected within the loop (10 Units Maximum). The mod-

ule is “passive” i.e. an external current source is required. This is usually

available at the computer/terminal. Typically the receive and transmit section of each instrument is series connected and inserted into the loop:

however a separate loop for receive and transmit may be used in the event

there is insufficient headroom in the energizing supply. For series transmit

and receive approximately two volts of headroom is taken for each instru-

ment on line. For operation with separate loops, approximately 1.5 volts is

taken for receive and 0.5 volts for transmit Care must be observed to insure

the polarity of connections is correct because current will still flow in the loop

if polarity is reversed making troubleshooting difficult Wiring connections

are: pin 3 = Transmitting Position (+), pin 4 = Transmit (-), pin 7 =

Receive (+), pin 8 = Receive

(-),

pins 5 and 9 are Frame Ground.

27

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

SECTION 7 CALIBRATION

WARNING: These adjustments are factory set and should only be changed by a

qualified

person

using

calibrated equipment. Adjustment is not necessary during

the life of these

controllers.

7.1

Zero

(-cL-)

and Span

(cH)

Calibration

1.

2.

3.

4.

5.

Unlock access to the calibration constants by entering the unlock

number (14) into location 9 (-cd-).

Use a tempemture calibmtor with a range appropriate for the unit to be

calibrated. Set in the value for low scale calibration, e.g. (1 % of range).

Step to -cL- (calibmte low [ZERO]) using tie index key on the 6075.

press the up/down keys on the 6075 until both instruments agree

press the ‘ENTER’ key.

Set in a value on the calibrator equivalent to the high-end capability of

the unit under test e.g. (95% of range).

Step to -cH- (calibrate high [SPAN]) using the INDEX key.

Press the up/down keys on the 6075 until both instruments agree.

Press the "ENTER" key.

Repeat steps2 thru 7 until readings agree. Some interaction between

Zero(-cL-) and Span (-cH-) calibration usually occurs

Lock out configumtion access, if desired, and return to set point by

pressing "SET POINT" key.

NOTE: Pressing index continuously selects -cH- or -cL- (Span and Zero) in

the calibrate mode to faciliite testing. Exit this mode by pressing the ‘SET

POINT" key.

33

6.

7.

8.

9.

Page 38

SECTION 8 TROUBLESHOOTING

8.1

Troubleshooting -

General

Symptom

Display does not

light

up.

Process display shows

(- - -)

or

‘HHHH’

Probable Cause &

Corrective Action

No power, blown fuse.

Process display shows LLLL or

counts down scale when

temperature is rising.

About 30% error.

No heat

Display

blinks;

entered values

change.

Open thermocouple circuit Shorting terminals 1

and 2 should indicate temperature at back of case.

Repair or replace thermocouple.

Check for reversed thermocouple.

Wrong thermocouple type connected or internal

range jumper in wrong position. Check serial tag for

sensor type and then check probe. Consult manual

for jumper location for desired range and then

check unit and sensor.

Incorrect heater wiring, wrong output module.

Check for cause and correct the components

Electromagnetic interference

(EMI).

To

eliminate

high voltage spikes, separate sensor

and controller wiring from “dirty” power lines.

Ground heated devices. Suppress all coils and contacts.

See section on Electrical Noise.

34

Page 39

ATHENL

Athena Controls, Inc.

5145

Campus Drive Plymouth

Meeting,

PA

19462

Tel:

(610) 828-2490

Fax:

(610)

828-7084

Loading...

Loading...