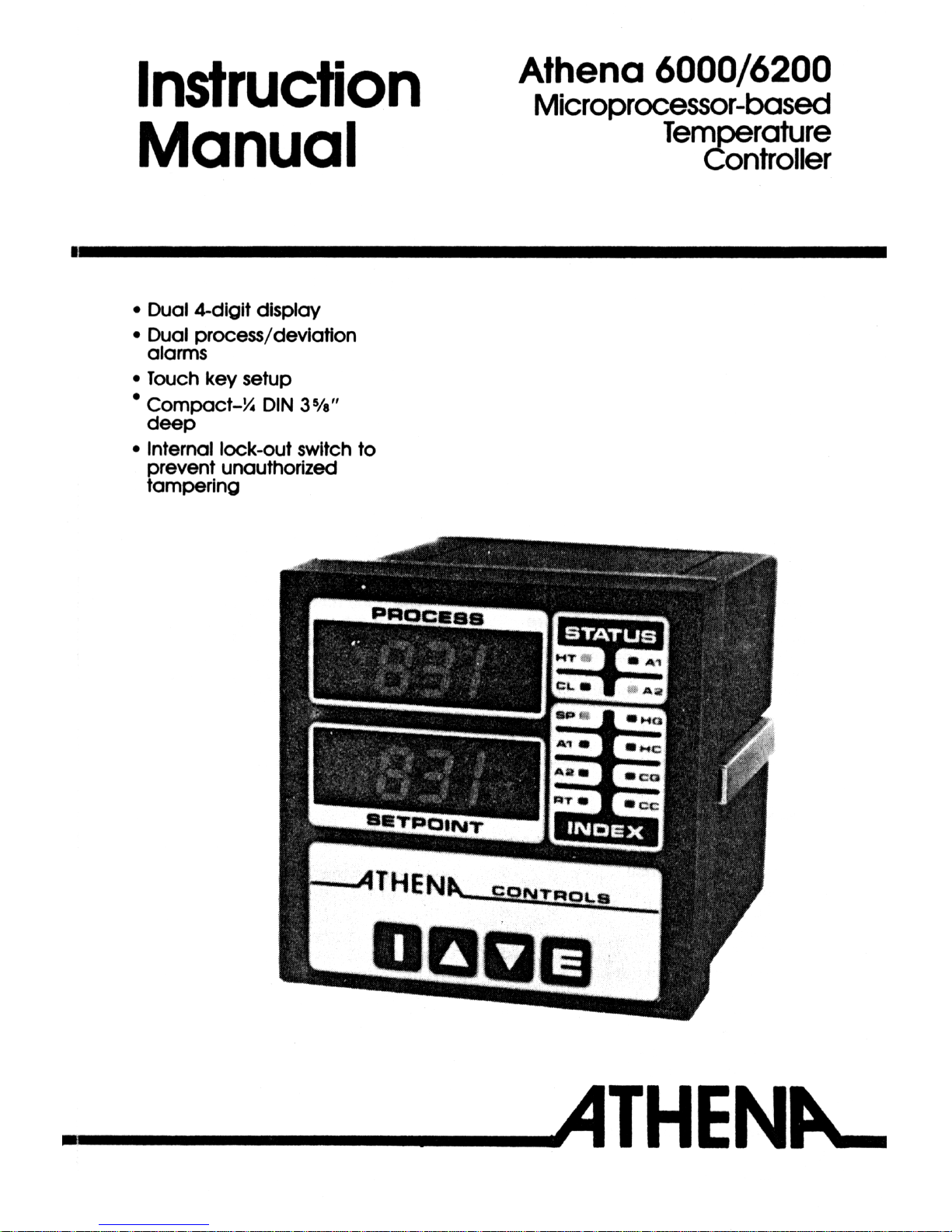

Athena 6000, 6200 Instruction Manual

Athena

6000/6200

Microprocessor-based Temperature Controller

Designed for the user

Athena’s

unique

new

6000

microprocessor-based controller

was developed to satisfy the needs

of actual end users, designers, and

specifiers. Data was gathered on

the temperature controller features,

functions, and performance capabilities that they desired. Then

Athena designed a controller to

satisfy them.

Dual

lndication

Now you can compare process

temperature and setpoint

at a

glance - hands free. This dual

digital

display concept has formerly

only been available in high priced

multifunction process controls.

Microprocessors reduce size,

add extras

By using microprocessor

hardware and a highly sophisticated

software package, Athena designers

and engineers have included more

features than have ever been

available before in a controller this

size. Incorporating two digital

displays, touch-key

operation,

software

linearized

and

stabilized

thermocouple input with 3-mode PID

action heat/cooling control and dual

alarms,

ºF to ºC

conversion,

alarms

that can be energized for temp

rise/fall

and selectable as process

or deviation type, and a program

restart circuit that eliminates

program lock-up due to transient

voltage

spikes

or line voltage

“brown out.” Program automatically

restarts within 2

milliseconds

after

condition passes.

PID

Control

Three mode (Proportional,

lntegral, and Derivative) action

eliminates offset (droop) as cooling

and heating requirements change in

the process, and provides fast

output response to rate of change

and reduces temperature overshoot

and undershoot.

Thermocouple linearization

The 6000 has a program to

linearize signal input from the

thermocouple. Without it, temperature controllers have accurate

temperature indication over only

certain

portions of the scale.

Contents

General:

Introduction

Configuration:

Output Forms

Alarm Types

ºC/°F

Installation

lnstructlons:

Unpacking

Locating

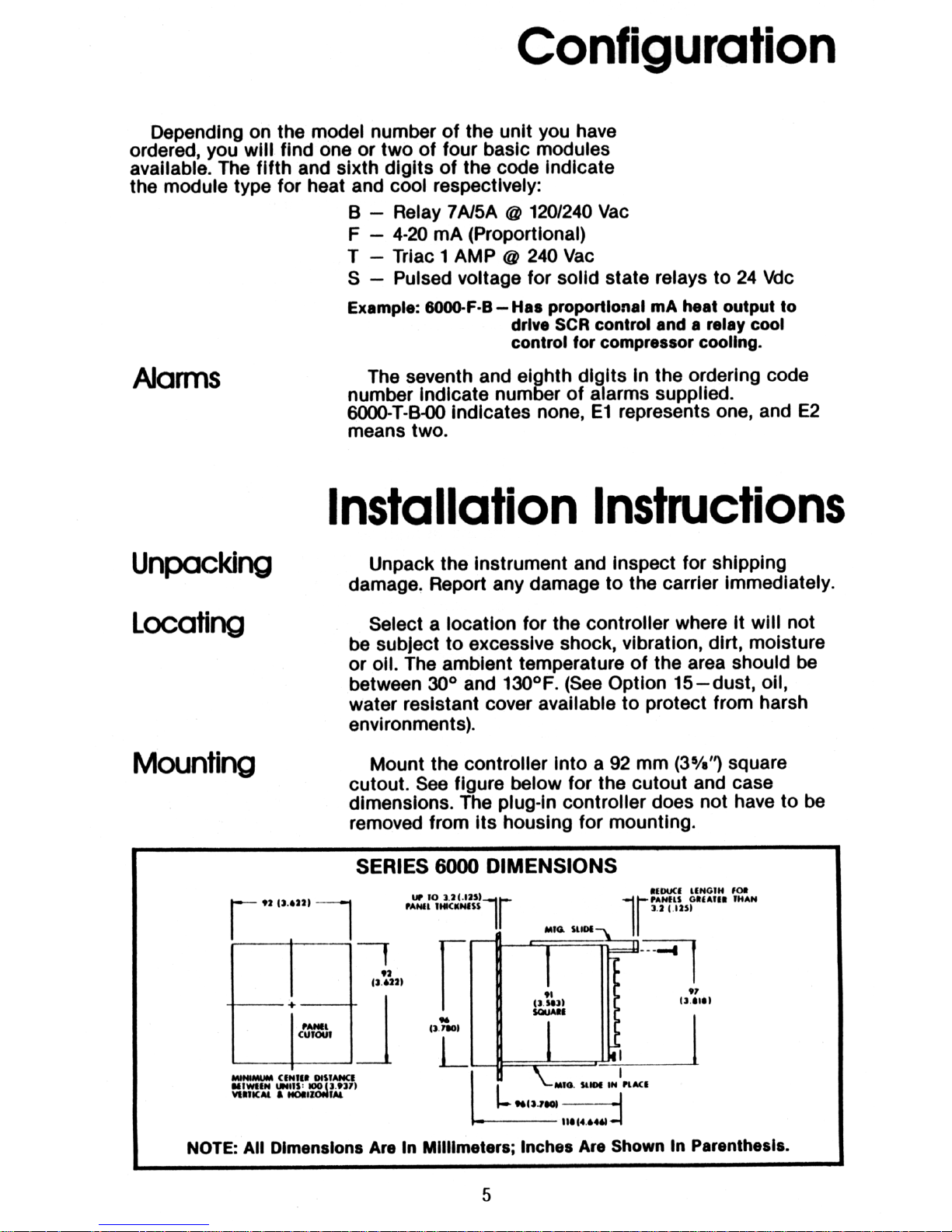

Mounting

Terminal Designations

Output Modules

Wiring Examples

Internal

Switches

Thermocouple lnstallation

PAGE

2

4-5

4-5

4-5

5

5

5

6

6-7

6-9

10

11

Operating Instructions:

Control Panel Description

Start-up

Parameter Entry

Heat Galn Setting

Rate

Setting

Examples

Cool Gain

Setting

Trouble Shootlng

Repairs and Warranty

PAGE

13

13

13-14

15

15

15

15

16

16

2

Specifications

Inputs:

Line

Voltage

Sensor

Power

consumption:

Ranges

available:

Accuracy:

Temperature

stability:

Cold end

tracking:

Operating ambient

for

rated accuracy:

Maximum lead

resistance for rated

accuracy:

Series

mode noise

rejection:

Common mode

noise

rejection:

T/C break

protection:

Dual display:

Display update rate

and filtering

ºF/ºC:

Alarm 1 & 2:

Outputs:

- B

Relay (time

proportioning)

-F Current

proportional

-S Pulsed

voltage

-T

Triac

(time

proportional

-

E1 & E2

Auxiliary

alarm relays

(on/off)

Filtered

LED

display:

T/C linearization:

Connections:

Dimensions:

Mounting:

Weight:

Recorder output:

(RTD

only)

120/240

Vac

50,60

Hz

T, J or K thermocouple or Platinum 100Ω at 0°C

Less than 6 VA (Instrument)

J couple 0-1400°F (0-760%)

K couple 0-2000°F (0-1093ºC)

±1 digit of full scale

5 µV/ºC Max 3 µV/ºC typ.

0.05ºC/°C ambient

0 to 55%

Thermocouple: 100Ω

RTD: 10Ω/lead

60 dB

120 dB

upscale standard

Process temp displayed continuously; setpoint or other

parameters updated on lower display

Greater than 5 times per second.

Analog and digital filtering techniques increase stability of

process & display.

Internal switch selection-process, setpoint and alarms

affected.

Adjustable over full range of control. LED displays alarm

status. 3 amp relay at 120 Vac normally open contact.

Reverse acting relay by switch selecting or low alarms.

Process/deviation mode selectable (internal switch).

Available heating only or heat/cool

SPST relay 7 amps resistive at 120 Vac, 5 amp resistive

at 240 Vac, 50 VA inductive

4-20 mAdc into 500 ohm max.

0-20 Vdc pulsed time proportioning signal for driving solid

state relays 500 ohms maximum input impedance

Solid state plug-in triac output. Rated 1 amp holding &

10 amps inrush

SPST relays, rated 3 amps at 120

Vac

4 digits for process, 4 digits for parameters.

Continuously calculated and updated using rom based

algorithm.

Inputs and outputs vla barrier strips with U.L. approved

Iocking sems terminals.

Front panel: 96mm x 96mm x 22mm

Case: 92mm x 92mm x 118mm

Depth behind panel: 96mm (approx. minus panel thickness)

Channel slides and screws

2 lb

1 mV/ºC for degree reading unit

0.1 mV/ºC for 1 10 degree reading unit

3

+10

-15%

Front Panel Adjustments

Touch Key

Index:

Allows the following adjustments to be selected.

1) set

point temperature 0 to span

2) alarm one temperature setting 0 to span

3) alarm two temperature setting 0 to span

4) rate with tracking reset (1:6ratio) ** 0 to 120 sec

5) heat gain *** 1 to 400

6) heat cycle time * 1 to 120 sec

7) cool gain *** 1 to 400

6) cool cycle time * 1 to 120 sec

up/down keys: increases/decreases values of above adjustments

writes selected values to

nonvolatile

memory

Enter:

Internal switches/jumpers

A) 4 position dip switch

1) selects ºF/°C display

2) selects energized alarm two on hi/low (dev + / dev -) temperature

3) selects energized alarm one on hi/low (dev + / dev -) temperature

4) selects process or deviation alarm function

B) 2 position dip switch

1) selects reduced rate gain

2) locks out front panel parameter entry excepting set point

NOTES: *** setting to zero disables output

* setting to zero initiates 60 millisecond timebase for ultra fast cycling.

Use with external solid state relays.

**Setting to zero disables reset and rate actlon for proportional only control.

To order see price sheet C-5-82

General

Congratulations on

purchasing

an

outstanding

temperature controller Ingenious use of

microprocessor technology has given you an

economical, compact controller that:

1.

2.

3.

4.

5.

Accurately measures, linearizes and displays

temperature in

ºF

and

ºC.

Digitally

enters and displays control and alarm set

points

as well as heat and cool

gains,

cycle times,

and user simplified rate and reset action.

Can be switched

configured

for

high

and low

process alarms or deviation

alarms.

Can be field converted from relay output “B”, to

solid state relay "T" to solid state relay driver "S"

or to a 4-20 MA output SCR driver "F", with

independent outputs for heat and cool.

Will remember its “entered” settings after power

failure or shut-off and not “Go To Sleep”.

CAUTION: HIGH VOLTAGE AND HIGH TEMPERATURES CAN

CAUSE INJURY AND ARE A FIRE HAZARD. PLEASE READ

ALL INSTRUCTIONS, HAVE ONLY SKILLED PROFESSIONALS

WIRE THE

UNIT,

AND USE AN APPROVED TEMPERATURE

AND/OR PRESSURE SAFETY CONTROL. EVEN THE BEST

COMPONENTS CAN BE DAMAGED OR MAY NOT FAIL SAFE.

4

x

Loading...

Loading...