Page 1

1

Instruction

Manual

ANALOG TEMPERATURE

CONTROLLERS

SERIES

2000 / 3020

Page 2

2

Page 3

Introduction

Precautions

Congratulations on your purchase of an Athena®Series 2000 or

Series 3020 analog temperature controller. It is a U.L. listed,

1/4-DIN controller for use in a variety of applications. Standard

features include time proportioning with auto-adjusting cycle

time, djustable bandwidth (for on-off to wide band proportioning), and offset (manual reset). Outputs include relay, triac, or

mAdc types.

If you have questions or require any assistance with your controller or with any temperature control problem, please contact

your Athena representative or call technical support at 1-800782-6776. Outside the USA, please call 610-828-2490.

3

After unpacking, inspect the instrument for any physical damage that may have occurred in shipping. Save all packing materials and report any damage to the carrier immediately.

©Copyright 2004, Athena Controls, Inc.

Table of

Contents

Output Configurations 3

Preliminary Instructions 3

Mounting 3

Power Wiring Circuits 4

Thermocouple Wiring Circuits 6

RTD Wiring Circuits 6

Thermocouple Placement 6

Operation 7

Front Panel Layout 8

Output Function Switches 8

Adjustments 9

Maintenance 11

Specifications 12

Ordering Codes 13

Troubleshooting 14

Warranty 16

Unit Repairs 17

Page 4

4

Preliminary

Instructions

Output

Configurations

Type “B” Relay with 7 A at 120 V and 5 A at 240 V

contacts, on-off and time proportioning

Type “F” Signal current, 4-20 mAdc

Type “L” Relay with 7 A at 120 V and 5 A at 240 V

contacts, on-off, reset switch

Type “T” Solid state relay 1 A, 120/240 V resistive

load; 1 A, 120/240 V, 10 A inrush,

inductive load (not U.L. rated)

Type “S” Pulsed 20 Vdc, for driving solid state

relays

Unpacking

Carefully unpack the instrument, inspect for shipping damage. Report any damage to the carrier immediately.

Locating

Select a location for the controller where it will not be subjected to excessive shock, vibration, dirt, moisture or oil. The

ambient temperature of the area should be between 30° and

130° F. (Dust, oil, water resistant cover is available to protect

from harsh environments. Contact factory for details.)

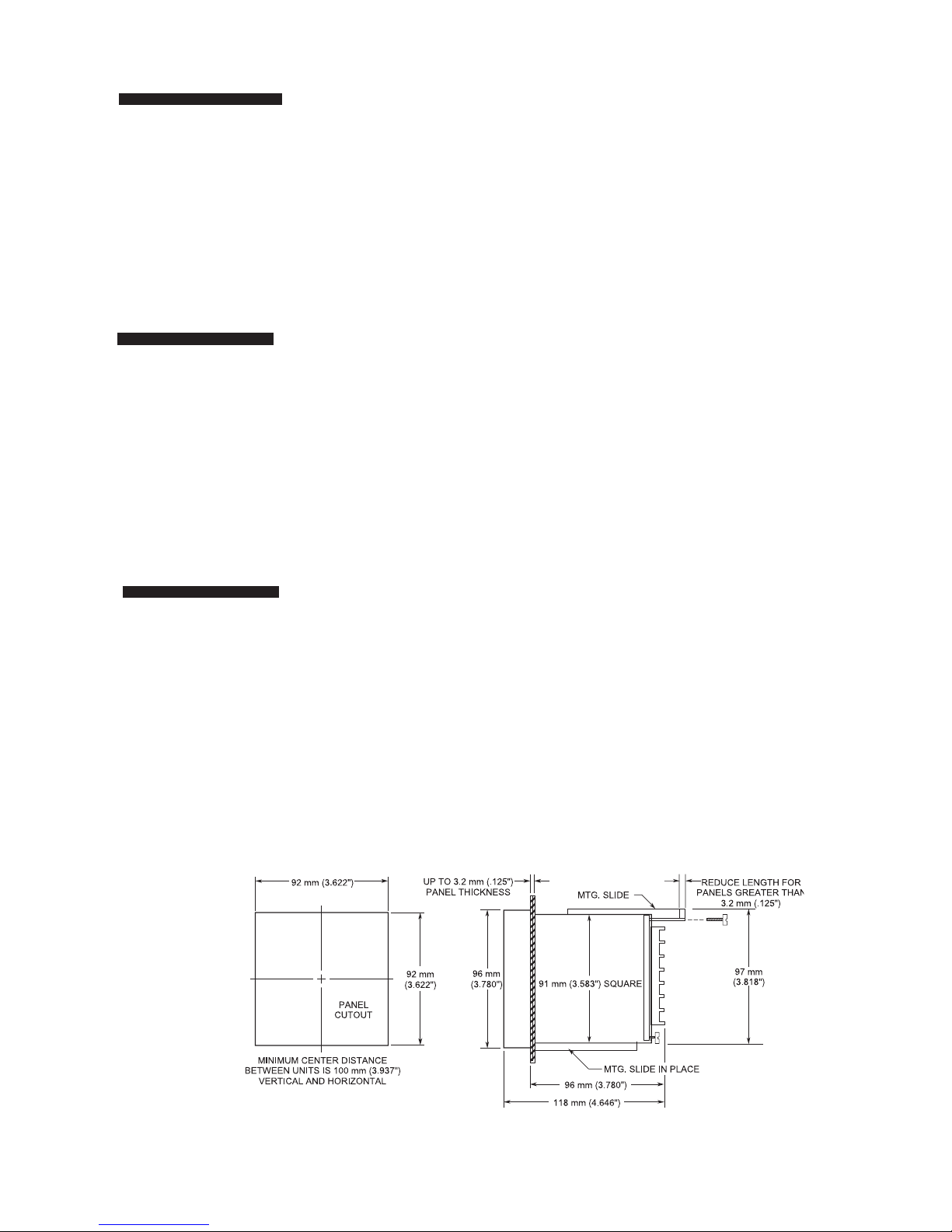

Mounting

Mounting

Mount controller into 92 mm (3-5/8”) square cutout (1/4DIN). See Figure 1 for cutout and case dimensions. The

plug-in controller does not have to be removed from its housing for mounting.

Remove the two screws in the back of the case that hold the

mounting slides, and then remove the slides. Insert case

from front of panel and reinstall the two slides and two

screws. The length of the slides must be reduced if the controller is to be mounted in an extra thick panel. If the controller has been unplugged from its housing, the top of the

housing can be determined by the serial number tag.

Figure 1: Cutout and case dimensions

Page 5

5

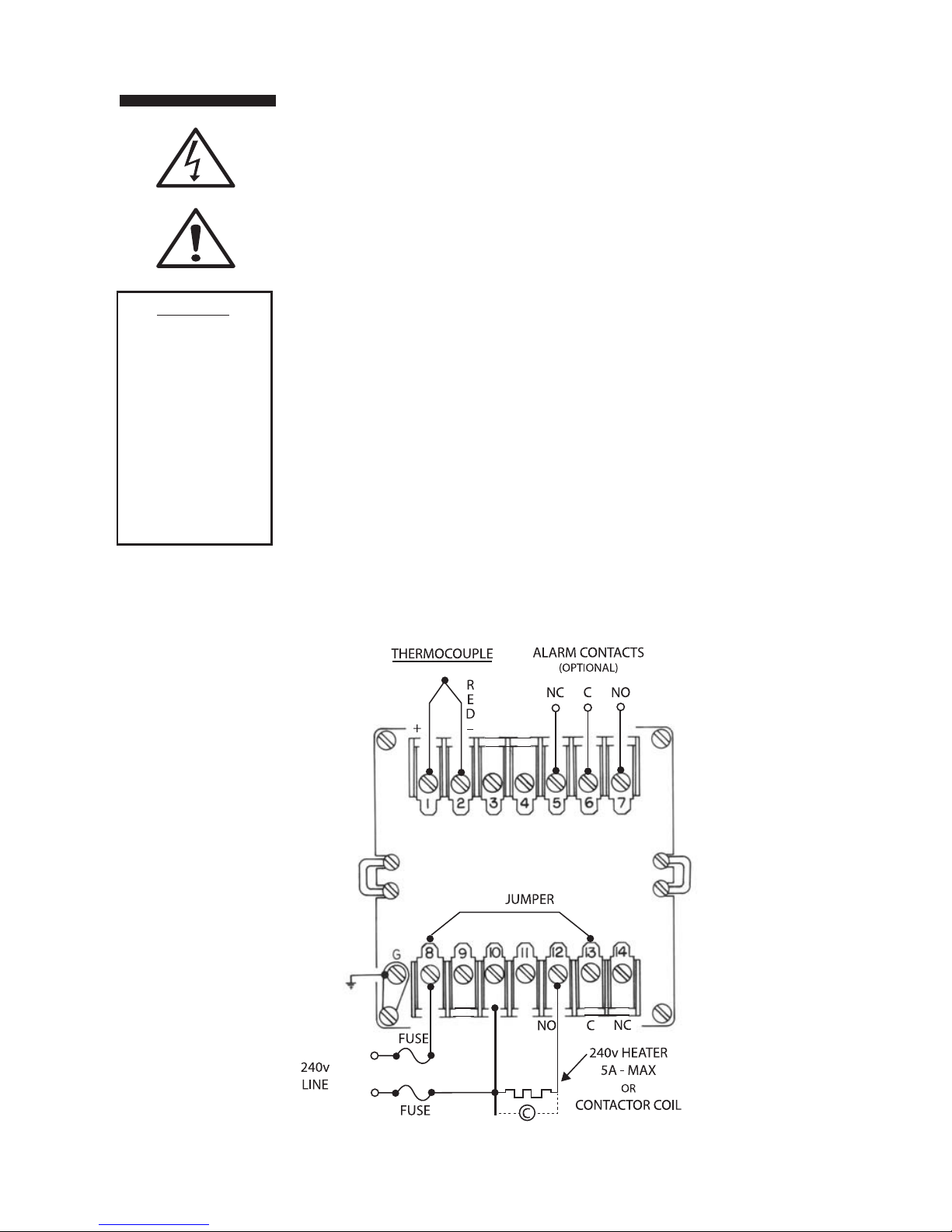

Power Wiring

Circuits

Consult serial tag on the unit and select power wiring diagram for the model specified. All wires are connected to the

terminals on the back of the case. Screw terminals are provided. Make appropriate connections using proper size wire

for rated controller load power circuits. (On -B output model,

use AWG #14 wire; for -F, -S and -T outputs use #14, 16, or

18 wire.) The unit can be supplied with 120 V or 240 Vac,

50/60 Hz. Select proper terminal for the voltage used.

Typical Wiring Diagrams

-T & -B Outputs

B-Type - 840 W maximum. 120 Vac heater. (Non-inductive

loads only) For larger loads, replace heater connections with

contactor, as required. Maximum inductive load rating is 3 A

at 120 V and 1.5 A at 240 V. The N.C. contacts can be used

for cooling.

T-Type - solid state relay with SPST contacts. The -T units can

handle contactors or resistive loads up to 1 A with 10 A

inrush maximum. For -T units use a 1 A, 250 V fast blow fuse.

-L Output (Limit Controller)

Wiring can be similar to that shown for “B.” The controller’s

relay is de-energized until the reset button on the front panel

is momentarily pressed. The relay will energize if the sensor

temperature is below setpoint. The common and N.C. terminals can be used to indicate alarm condition remotely when

wired to lights, bell, etc.

CAUTION

Possible fire hazard. Because

these controls or

associated equipment may not

always fail safe,

an approved temperature and/or

pressure safety

control should be

used for safe

operation.

Figure 2a: Typical 240 Vac for -B & -T Output

Page 6

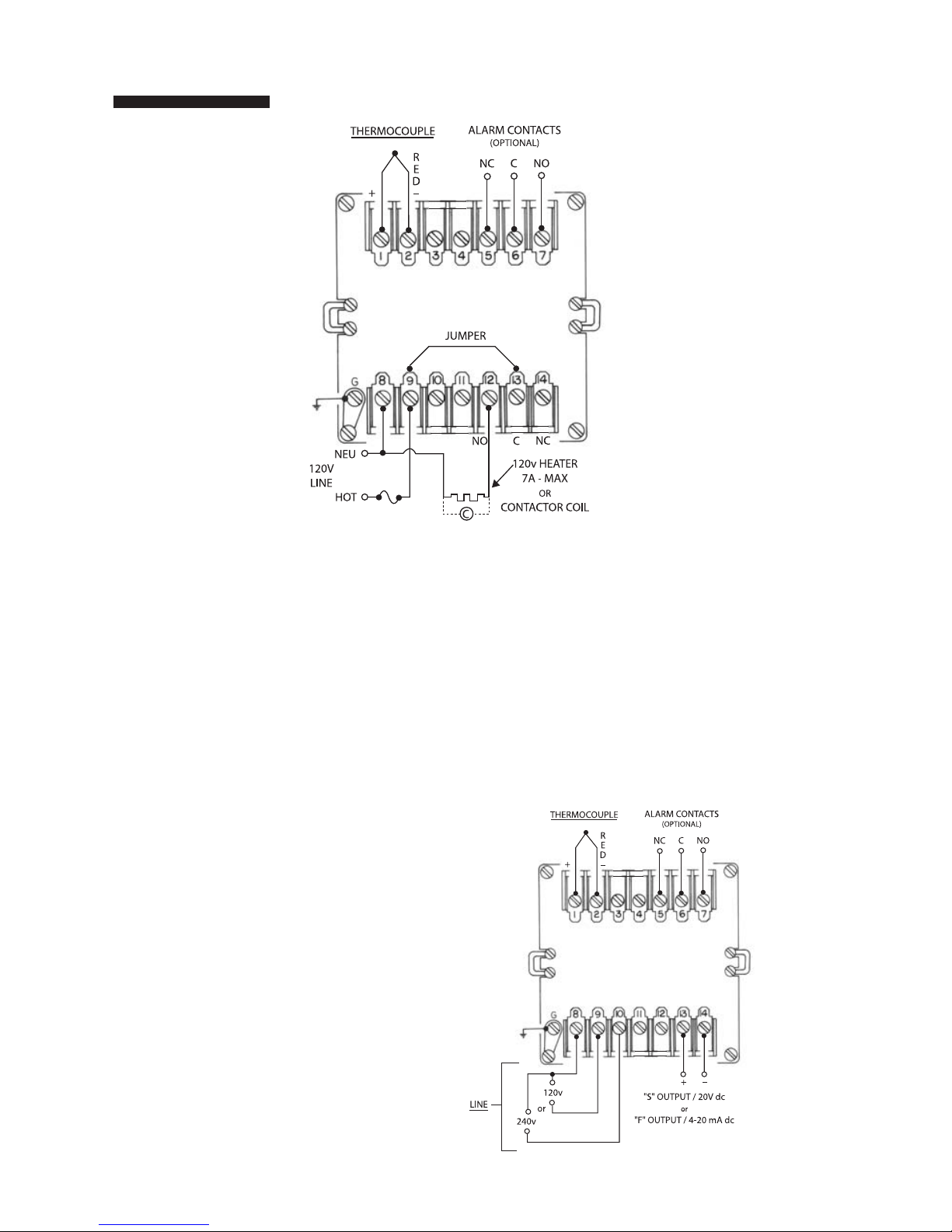

6

Power Wiring

Circuits

Figure 2b: Typical 120 Vac for -B & -T Output

Typical Wiring Diagrams

Figure 3: Typical 120/240 Vac

for -F & -S Output

-F, -S Output - 120/240 Vac

The -F output is 20 mA at the low temperature end of the proportional band and 4 mA at the upper end of the proportional

band. Maximum load resistance is 1000 ohms. The -S output

is a time-proportioned 20 Vdc signal. These controllers cannot be used with a device that does not have an isolated

input. An ungrounded thermocouple must be used if there is

ac leakage or a ground in the input of the device connected

to the controller’s output.

Page 7

7

Thermocouple

Wiring Circuits

Use thermocouple and extension wire that conforms to the

appropriate thermocouple type specified on the serial number

tag. In thermocouple circuits, the negative lead is colored red.

Extension wires must be of sufficient size so that on long runs

the thermocouple circuit resistance does not exceed 100

ohms.

Do not run thermocouple leads in the same conduit as the

power lines. If shielded thermocouple wire is used, terminate

the shield only at the controller end using the corner screw

provided for that purpose.

Standard Thermocouples

I.S.A. Type Materials Color Code

(U.S.A.)

J Iron-Constantan (I/C) White (+)/Red(-)

K Chromel-Alumel (C/A) Yellow (+)/Red (-)

T Copper-Constantan Blue (+)/Red (-)

RTD Wiring

Circuits

Thermocouple

Placement

The 2002 and 3220 units are designed for 100 ohm platinum

RTDs. Two-wire RTDs are connected to terminals -1 and -2

with a jumper connecting 2 to 3. Keep leads short and use

heavy gauge copper extension wires if necessary, to minimize

lead resistance. For long runs 3-wire RTD should be used and

wire gauge should be sufficient that resistance does not

exceed 10 ohms.

DO NOT RUN RTD LEADS IN THE SAME CONDUIT AS POWER LINES.

If shielded RTD wire is used, terminate the shield only at the

controller end, using the corner screw provided for that purpose.

Proper thermocouple placement can eliminate many problems in the system. The probe should be placed so that it can

detect any temperature change with little thermal lag. In a

process that requires fairly constant heat output, the probe

should be placed close to the heater. In processes where the

heat demand is variable, the probe should be close to the

work area. Some experimenting with probe location can often

provide optimum results.

In a bath process, the addition of a stirrer will help to eliminate

lags. Since the thermocouple is basically a point measuring

device, putting more than one thermocouple in parallel will

provide an average temperature reading and produce better

results in air-heated processes.

NOTE: RTDs

tend to be shock

sensitive and

require extra care

in handling and

installation

Page 8

8

Operation

The typical control system contains the sensor, controller (2000/3020)

and the process (load). The sensor produces a small signal proportional to the measured temperature of the process. This signal is

amplified by the controller, where it is compared with setpoint temperature. If the temperature of the sensor is below setpoint, the output circuitry will be actuated to apply power to the process. This is

indicated by means of an LED light in the lower center of the front

panel. The deviation meter will swing to the extreme left. It will remain

there until the temperature of the probe rises to within 50 °F of setpoint, and then will continue to rise to the null point (zero degree

deviation). The deviation meter accurately displays the difference

between the probe’s (process) temperature and the desired setpoint

temperature.

-B - Relay Output

The “B” output is a relay rated at 7 A, 120 Vac and 5 A, 240 Vac.

These contacts can be wired to provide power to a heater within the

above rating. A contactor can be operated to handle a larger load.

Solenoids can be operated to control oil or gas heaters.

The controller operates as a narrow band controller when the band

adjustment is set at the narrow position. As the band is widened, the

unit becomes a time-proportioning controller, which provides close

temperature control. The percentage of the time when the relay is

energized is varied by the controller to meet the load requirements.

Maximum cycle time setting is 15 seconds.

-F - Current Output

Current proportional output of the -F unit is a 4 to 20 mAdc signal into

1000 ohm maximum. This output can be used to drive power controllers, motor positioners or electropneumatic actuators.

-S - Pulsed Voltage Output

This output is similar to the -F output with the exception of a pulsed

time base rather than a fully proportional current output signal. This

output is designed to drive solid state contactors.

-L - Limit Control Output

The -L output unit is designed as a high limit controller and is a variation of the -B output controller. The time proportioning circuit, along

with the proportional band and offset (manual reset) adjustments,

have been eliminated. A reset pushbutton has been added to the

front panel and extends beyond the door. When power is applied, the

controller will energize except for the output relay, which will operate

after the reset button is pushed. The green LED indicates the safe or

non-alarm condition. When the measured temperature exceeds the

setpoint, the relay will de-energize and the green LED will turn off.

Lights or horns can be driven directly, because the SPDT relay contacts are rated 7 A at 120 Vac or 5 A at 240 Vac.

-T - Solid State Output

The -T output unit has a solid state relay with SPST contacts rated at

1 A, 120/240 Vac (10 A inrush maximum). These contacts can be

wired to provide power to a heater within the above ratings, and a

contactor can be added to handle larger loads. Solenoids can be

operated to control oil or gas heaters.

NOTE: To reach

the plug-in module,

push reset button

while opening the

door, and then

remove two (2)

screws.

Page 9

9

Front Panel Layout

Layout of the front panel is shown below. To reach the adjustments, swing the top of the door forward and down. The proportional band adjustment is on the right side and sets the

gain of the controller. The offset (manual reset) adjustment is

on the left and corrects for offsets from the setpoint temperature. The output indication (LED) can be seen through a window in the door.

Units ordered with Option A (3-Mode PID) will not have a

manual reset adjustment. Instead, these units have an automatic rate adjustment on the front panel and an automatic

reset selector switch inside the unit.

Output Function

Switches

Output Function Switch Chart

Figure 5: Output Function Switch Chart

NOTE:

—SWITCH NO. 4 IN “ON” POSITION IS FOR: “B” OR “T” OUTPUTS WHEN DRIVING MECHANICAL

DEVICES, E.G., CONTACTORS.

—SWITCH NO. 4 IN “OFF” POSITION IS FOR “T”, “F”, OR “S” OUTPUTS WHEN DRIVING DEVICES

THAT CAN WITHSTAND RAPID CYCLING, E.G., SOLID STATE DEVICES, SOLENOIDS, ETC.

Page 10

10

Output Function

Switches

How to Configure Output Function Switches

There is a switch assembly on the bottom board (see bottom

board illustration). This four-position switch regulates cycle

time and output selection. It is factory-configured for the plugin output ordered. Check the output function chart to make

sure the configuration is correct for your application. Figure 5.

Switches 1&2: These switches act together to select either

proportional current output or one of the time

proportioning cycle times. (See the output

function switch chart.) Use longest times to

get best relay life expectancy. If meter shows

temperature swings following each “on” cycle,

select a faster time to reduce “ripple.”

Switch 3: Selects either on/off or proportional action.

“On” provides proportional action. “Off” provides on/off action.

Switch 4: Selects output for either mechanical or solid

state relays.

On: Provides slow proportional times for

mechanical relays

Off: Provides 20 mAdc when used with the “F”

module or fast time proportioning times

when used with “S” or “T” modules.

NOTE: Switch 4 changes the cycle times in conjunction with

switches 1 and 2. Check output function switch chart.

NOTE:

Reconfigured or

field-modified units

should always be

checked to assure

that output switch

positions are correct.

Proportional Band Adjustments for All Outputs

The proportional band adjustment widens or narrows the

band over which proportional action occurs. Too narrow a

band can cause the temperature to swing about the setpoint.

This can be seen on the deviation meter. Too wide a band

can cause an error between the setpoint and the actual temperature (droop error) as measured at the sensor.

Proper setting of this adjustment is the point where the temperature swings just stop. When adjusting the proportional

band control, do so in small increments, allowing time

between each adjustment for the process to stabilize.

Turning the adjustment in a clockwise direction widens the

proportional band and should reduce swings to straight line

control with most processes.

Offset (Manual Reset)

After the proportional band is set, the process temperature

may stabilize at a point other than the setpoint, high or low, as

shown on the deviation meter. This can be corrected with the

offset (manual reset) adjustment. If the deviation meter indicates a low temperature, turn the offset (manual reset) adjustment clockwise (+ direction) until the deviation meteris at

zero. Turn the offset (manual reset) adjustment counter-clock-

Adjustments

Page 11

11

wise (- direction) for high temperature as indicated by the

deviation meter.

NOTE: If close control cannot be obtained after carefully

repeating the above procedures, check to see if the thermocouple probe is in good contact with the heated process, and

if the heaters are correctly sized for the application.

Applications involving large changes in setpoint operating

temperature, or large load changes, will require readjustment

of the proportional band and offset (manual reset) pots.

How to Set the Alarm

Deviation alarms are triggered when the temperature deviates from the setpoint by a predetermined amount. Units can

be ordered with either high, low, or high/low alarms.

1. Turn the adjustment clockwise to widen the span

between the process setpoint and the alarm, or

counterclockwise to narrow it. (Full clockwise

should be about 50 °F (30 °C) from setpoint. Full

counterclockwise should be only 5 °F (3 °C) from

setpoint.

2. To check the actual alarm point, simply change

the setpoint until the deviation meter reads zero.

Then move it downward (for high alarm) or

upward (for low alarm). When the alarm is triggered, check the deviation meter -- it will show

deviation in the amount you’ve set on the alarm.

Optional 3-Mode (PID)

How to Set Reset, Proportional Band, and Rate

Auto reset action automatically, but slowly, corrects droop

error in proportionally controlled processes. Ideal reset time

is one half the period of oscillation of the process. Slower settings are safe, but sluggish. Faster settings will cause continuous oscillation.

1. For slow processes, move switches 1 and 2 off,

set rate slow, proportional band wide, and go to

Step 4. Otherwise:

2. Set reset time (internal switches are indicated on

automatic reset switch chart below). Use the

fastest time (0.8 minutes) for very fast processes,

1 minute for most others, as a first try.

3. Set the proportional band to full wide (270°

clockwise). Make sure rate is full fast, turned full

clockwise, as well.)

4. Plug controller in, turn your process on.

5. Observe warm-up. If the process overshoots setpoint and cycles in continually decreasing waves

Adjustments

Page 12

until it finally stabilizes, the reset time is correct.

Then proceed to Step 7. If it continues to oscillate,

reset it to short, continue with Step 6.

6. Set reset switches to the next slowest time.

Repeat Step 5. Continue changing settings until

the process stabilizes.

7. Turn proportional band pot 1/4 turn toward nar-

row (counterclockwise). Process could begin to

oscillate again. If it doesn’t, proceed to step 8. If it

oscillates, back up 1/8 turn clockwise.

8. Tighten proportional band by turning the pot

counterclockwise. Observe the process. If oscillation continues, widen back by 1/8 turn. Continue

until the process stabilizes.

9. Set the rate. Rate action responds to sudden load

changes and anticipates power output requirements. It also helps to eliminate overshoot on startup. Rate should be approximately 1/6 of reset time.

If the reset time is 0.8 minutes, the rate should be

turned clockwise. For 1 minute, mid-position. For 2

minutes, it should be at least 3/4 full; for 4 minutes

full slow.

10. Turn the process off to cool, then start up

again observing the warm-up curve. If it takes

the process too long to reach the setpoint, make

the rate faster by turning it back clockwise. If, on

the other hand, it overshoots the setpoint by an

amount that is not acceptable, slow the rate by

turning the pot counterclockwise.

Adjustments

NOTE:

Each

process will tolerate

differing warm-up

curves. Often, a fast

warm-up is more

important than the

elimination of overshoot. If it is important to eliminate

overshoot, a slower

setting should be

used, but it will also

add to the time it

takes the process to

reach the setpoint.

In general, it is

best to maintain the

tightest parameters

possible (narrow

proportional band,

faster reset, faster

rate) that still deliver

optimal process

response.

Maintenance

11. Fine tuning. If, after having established parameters, you’d like to improve response, it can be

accomplished by a simple “trial and observation”

technique.

A. Change a parameter (either rate or proportional

band) by a significant value (the pots generally

need to be moved 30° to produce an effect).

B. Change the setpoint.

C. Observe the way the process responds

-- if response is improved (i.e., faster rise, less

overshoots, faster stabilization at setpoint),

retain the new value. If not, return the old value.

D. Try another parameter.

Some preventive maintenance steps on the controllers are:

1. Keep the controller fairly clean, and protect it from

dirt, oil, and corrosion. An optional dust cover is

available for use in hostile environments.

2. Periodically recheck all electrical connections.

CAUTION:

Since the front

panel and the

meter face are

plastic, do not

use solvents to

clean them.

12

Page 13

13

Specifications

Supply Voltage: 120/240 Vac, +10% -15%, 50/60 Hz

Setpoints:

Series 2000

: Analog - single-turn

potentiometer, 270° rotation

Series 3020

: Mechanical digital

potentiometer

Setpoint Repeatability: +/-0.3% of span (Series 2000)

Setpoint Resolution:

Series 2000

: 0.2% of span

Series 3020

: 1 °F or °C

Input: Thermocouple Types J, K, T, R (Series 2000)Types J, K

(Series 3020), range dependent.

Maximum lead resistance 100 ohms for rated accuracy;

cold junction compensation standard. RTD input 100 ohms

platinum at 0°C, DIN (.00385) curve.

Thermocouple

Break Protection: Built-in, failsafe, open sensor, output zero;

Meter units – upscale indication

Cold Junction

Compensation: Automatic electrical

Accuracy: +0.5% of span at calibration points

Indication,

Temperature: Deviation meter +50 °F (+30 °C) of setpoint

Load: LED on when power is supplied to load

Proportional Band: On/off or nominal 5 °F - 50 °F (3 °C - 30 °C)

Offset (Manual Reset): Adjustable over 100% of proportional band

Rate (Derivative): 0.5 to 25 seconds

Reset (Integral): 0.7, 1, 2 or 4 minutes via internal

DIP switches

Alarm: 3 A at 120 Vac

Output: B - SPDT Relay, non-inductive rated

7A/5A max at 120/240 Vac, 50 VA inductive

F - 4 to 20 mAdc into 1000 ohms max load

L - SPDT Relay, non-inductive rated

7A/5A max at 120/240 Vac, 50 VA inductive

S - 20 Vdc into 1000 ohm maximum load

T - 1 A solid-state relay; 10 A max. inrush

Ambient Temp Range: 30° to 130 °F (0 to 55° C)

Weight: 1 lb, 9 oz (709 g)

All specifications subject to change.

Page 14

14

Ordering Codes

Alarms Code

B = High alarm only

C = Low alarm only

D = High and low alarm

0 = None

Control Options

Code

0 = Proportional

(Standard)

A = 3-mode (PID)

Athena’s ZC/PC solid state

contactors, and Series 91 and

93 or Series 19 and 39 SCR

power controllers, can be

added to boost ac load

switching capacity.

The deviation meter spans a

range of +5° and reads in

increments of 0.5°.

Sensor Input Code

0 = Thermocouple

2 = RTD

STANDARD RANGE CODE

Thermocouple

Code Set Range Type

14F 100 to +400°F “T”

03F 0 to +300°F “J”

04F 0 to +400°F “J”

13F -100 to +350°F “J”

16F 100 to +600°F “J”

08F 0 to +800°F “J”

01F 0 to +1000°F “J”

03C 0 to +300°C “J”

05C 0 to +500°C “J”

51F 500 to +1500°F “K”

02F 0 to +2000°F “K”

25F 0 to +2500°F “K”

01C 0 to +1000°C “K”

30F 0 to +3000°F “R”

R

TD (3-wire, 100 ohms)

R26 -200 to +600°F

R81 80 to +120°F

R30 0 to +300°F

R60 0 to +600°F

R10 0 to +1000°F

R11 -100 to +100°C

R23 200 to +300°C

R06 0 to +600°C

Special Options

(Consult Factory)

2

0

0

Output type (Plug-In) Code

B = SPDT Relay, 5 A/7 A

F = 4-20 mAdc

T = SPST SS Relay, 1 A

S = Pulsed 20 Vdc

L = Limit Control

Alarms Code

B = High alarm only

C = Low alarm only

D = High and low alarm

Control Options

Code

0 = Proportional

(Standard)

A = 3-mode (PID)

Athena’s ZC/PC solid state

contactors, and Series 91 and

93 or Series 19 and 39 SCR

power controllers, can be

added to boost ac load

switching capacity.

Sensor Input

Code

0 = Thermocouple

2 = RTD

STANDARD RANGE CODE

Thermocouple

Code Set Range Type

01F 0 to +999°F “J”

05C 0 to +500°C “J”

02F 0 to +1999°F “K”

R

TD (3-wire, 100 ohms)

R06 0 to +600°C 100 ohm

R10 0 to +999°F 100 ohm

Special Options

(Consult Factory)

3 2

0

Output type (Plug-In) Code

B = SPDT Relay, 5 A/7 A

F = 4-20 mAdc

T = SPST SS Relay, 1 A

S = Pulsed 20 Vdc

Page 15

15

Symptom

Controller dead. No output

light, no meter deflection

Probable Cause

- No line voltage input

- Open PC board to backplate connector (defective connector)

- Open power transformer

Symptom

No output, step 1 ok, meter

nulls at ambient

Probable Cause

- External backplate

jumper missing (all models except “S” and “F”)

- Defective relay

- Open heater or heater circuit wiring

Symptom

No output, meter reads full

scale positive, no heat

Probable Cause

- Open thermocouple or

T/C wiring

Symptom

Full output, no control.

Ouput light stays on.

Probable Cause

- Thermocouple connections reversed

- T/C lead wires shorted

between T/C

and control

Symptom

Full output, no control.

Output light goes off. Meter

goes upscale.

Probable Cause

- Relay contacts welded

closed

Troubleshooting

Check

Verify 120/240 Vac, 50/60 Hz input voltage. Check

heater for shorts. Look for open breakers or open

external fuse. Remove input power. Check continuity

through power transformer primary. With ohmmeter,

read between pins: 8 and 9 for 225 or 450 ohms

+/-10% and 8 and 10 for 680 or 1000 ohms +/-10%

Corrective Action

- Replace heater, if shorted

- Restore power

- Replace either power transformer or backplate

connector

Check

If no readings in either step above, remove controller

from housing and repeat resistance measurements as

above, but directly on PC board lands corresponding

to pins 8, 9, and 10. Correct readings indicate open

PC board to backplate connector problem. Incorrect

readings indicate power transformer problems.

Visually inspect relay contacts.

Heater continuity and wiring.

Corrective Action

- Install jumper

- Replace relay if contacts are worn or dirty

- Replace open heater, correct defective wiring

Check

T/C continuity. Disconnect T/C connections from

instrument. Measure T/C circuit resistance. Ohmmeter

should read 100 ohms or less.

Corrective Action

- Replace T/C. Correct defective wiring

Check

Connection polarity. T/C wires are color-coded. Red is

the negative (-) lead. (for U.S.A.) T/C lead wiring.

Corrective Action

- Connect correctly

- Repair or replace

Check

Disconnect power and load. Measure resistance

between pins 12 and 13. Should read infinity.

Corrective Action

- If resistance reading is near 0 ohms, replace relay

Page 16

Troubleshooting

Symptom

Process control temperature differs from setpoint when read

with an external pyrometer.

Deviation meter nulls and

process is stable.

Probable Cause

- T/C lead wires shorted close

to process

- Wrong type of T/C being used,

etc.

- Standard electrical wiring

being used in place of T/C

wire

- Gradient error

Symptom

Temperature overshoots, or

oscillates.

Probable Cause

- Process overpowered

- Bandwidth too narrow

- Process or sensor lag

Symptom

Process control temperature

stabilizes above or below setpoint as read on deviation

meter.

Probable Cause

- Offset (manual reset) incorrectly adjusted

- Partial short to ground in

heater when used on 240 V

line

- No output from suspect con-

trol

- Controller reading other zones

of multi-controlled process

- Full output from suspect con-

trol

- Apparent stabilization from

other zones of multi-controlled

process

- Improperly sized heater

NOTE: Fuse blowing is not caused by

the controller. Blown fuses are caused

by shorts in the heater circuit, and

must be corrected to prevent damage

to the controller.

Check

Check T/C lead wires at back of probe

Wire color indicates type of T/C

Verify type of wire

Corrective Action

- Replace defective wiring

- Install correct T/C for temperature range of instrument. See instrument serial number tag for T/C type.

- Run only T/C wire between process and controller.

- Use electronic indicator in parallel with suspect

instrument’s T/C input.

Check

Check bandwidth

Loose heater or sensor fit. Poor

relative location.

Corrective Action

- Reduce total heater power

- Widen band

- Improve fit, locate closer together

Check

Offset (manual reset)

Heater to ground resistance

Design parameters for process heat required

Corrective Action

- Adjust (+) to increase controlled temp. (-) to

decrease temp.

- Replace defective heater

16

Page 17

17

Two-Year Limited Warranty

THIS EQUIPMENT IS WARRANTED TO BE FREE FROM DEFECTS OF

MATERIAL AND WORKMANSHIP. IT IS SOLD SUBJECT TO OUR

MUTUAL AGREEMENT THAT THE LIABILITY OF ATHENA CONTROLS, INCORPORATED IS TO REPLACE OR REPAIR THIS EQUIPMENT AT ITS FACTORY, PROVIDED THAT IT IS RETURNED WITH

TRANSPORTATION PREPAID WITHIN TWO (2) YEARS OF ITS PURCHASE.

THE PURCHASER AGREES THAT ATHENA CONTROLS, INCORPORATED ASSUMES NO LIABILITY UNDER ANY

CIRCUMSTANCES FOR CONSEQUENTIAL DAMAGES RESULTING

FROM ITS USE OR FROM IMPROPER HANDLING OR PACKAGING

OF SHIPMENTS RETURNED TO THE FACTORY.

COMPONENTS WHICH WEAR OR WHICH ARE DAMAGED BY MISUSE ARE NOT WARRANTED. THESE INCLUDE CONTACT POINTS,

FUSES, ELECTROMECHANICAL RELAYS, AND TRIACS. UNITS

WHICH HAVE BEEN MODIFIED BY A CUSTOMER IN ANY WAY ARE

NOT WARRANTED.

Other than those expressly stated herein, THERE ARE NO OTHER

WARRANTIES OF ANY KIND, EXPRESS OR IMPLIED, AND SPECIFICALLY EXCLUDED BUT NOT BY WAY OF

LIMITATION, ARE THE IMPLIED WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY.

IT IS UNDERSTOOD AND AGREED THE SELLER’S LIABILITY

WHETHER IN CONTRACT, IN TORT, UNDER ANY WARRANTY, IN

NEGLIGENCE OR OTHERWISE SHALL NOT EXCEED THE RETURN

OF THE AMOUNT OF THE PURCHASE PRICE PAID BY THE PURCHASER AND UNDER NO CIRCUMSTANCES SHALL SELLER BE

LIABLE FOR SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE PRICE STATED

FOR THE EQUIPMENT IS A CONSIDERATION IN

LIMITING SELLER’S LIABILITY. NO ACTION, REGARDLESS OF

FORM, ARISING OUT OF THE TRANSACTIONS OF THIS AGREEMENT MAY BE BROUGHT BY PURCHASER MORE THAN ONE YEAR

AFTER THE CAUSE OF ACTION HAS ACCRUED.

SELLER’S MAXIMUM LIABILITY SHALL NOT EXCEED AND BUYER’S

REMEDY IS LIMITED TO EITHER (i) REPAIR OR REPLACEMENT OF

THE DEFECTIVE PART OR PRODUCT, OR AT SELLER’S OPTION (ii)

RETURN OF THE PRODUCT AND REFUND OF THE PURCHASE

PRICE, AND SUCH REMEDY SHALL BE BUYER’S ENTIRE AND

EXCLUSIVE REMEDY.

THE SPECIFICATIONS PUT FORTH IN THIS MANUAL ARE SUBJECT

TO CHANGE WITHOUT NOTICE.

Warranty

Page 18

Unit Repairs

It is recommended that units requiring service be returned to an

authorized service center. Before a controller is returned for service,

please consult the service center nearest you. In many cases, the

problem can be cleared up over the telephone. When the unit needs

to be returned, the service center will ask for a detailed explanation of

problems encountered and a Purchase Order to cover any charge.

This information should also be put in the box with the unit. This

should expedite return of the unit to you.

This document is based on information available at the time of its

publication. While efforts have been made to render accuracy to its

content, the information contained herein does not purport to cover all

details or variations in hardware, nor to provide for every possible

contingency in connection with the installation and maintenance.

Features may be described herein which are not present in all hardware. Athena Controls assumes no obligation of notice to holders of

this document with respect to changes subsequently made.

Proprietary information of Athena Controls, Inc. is furnished for customer use only. No other use is authorized without the written permission of Athena Controls, Inc.

Repairs

18

Page 19

19

Page 20

900M002U00 Revision B

Athena Controls, Inc.

5145 Campus Drive

Plymouth Meeting, PA 19462 USA

Tel: 610-828-2490

Fax: 610-828-7084

Toll-Free in USA: 1-800-782-6776

techsupport@athenacontrols.com

athenacontrols.com

For free technical assistance in the USA,

call toll free 1-800-782-6776 or

e-mail techsupport@athenacontrols.com

Loading...

Loading...