Page 1

SERIES

16C

TEMPERATURE/PROCESS

CONTROLLER

Standard Options and

Digital Communications

User’s Guide

Page 2

© Copyright 2004, Athena Controls, Inc.

Page 3

Table of

Contents

For information and

instructions related to

basic operations, refer

to the Series C

operator’s manual

supplied with your

controller.

Options Wiring Diagrams

Dual Alarm Outputs (Options #10 and #22) 1

Dual Open Collector Alarms (Option #20) 2

Dual 24 Volt DC Alarm Outputs (Option #21) 3

Relay, N.O. Alarm Output (Option #23) 4

RS-232 Communications (Option #30) 5

RS-485 Communications (Option #31) 6

Contact/Digital Input with Alarm

(Options #40, #41, #42) 7

Transducer Excitation (Options #50, #51,

#52, #53) 8

Auxiliary Output (Options #60, #61, #62, #63) 9

Remote Analog Setpoint (Options #80, #81,

#82, #83, #84) 10

Guide to Digital Communications

Remote Communications Options 12

Athena+ Protocol 14

- Message Format 15

- Sample Commands 19

- Request Messages 21

- Response Messages 24

- Communications Parameter List 27

- Auxiliary Commands 31

- Communications Error Codes 34

Page 4

1

Dual Alarm

Outputs

Option #10: Dual Alarm Output, N.O.

Option #22: Dual Alarm Output, N.C.

This optional hardware module provides two alarm drive outputs. LED indicators A1 and A2

are used to indicate alarm conditions as configured in the Alarm Menu.

Option Description:

Option 10: Dual alarm, N.O.

Option 22: Dual alarm, N.C. (Note: NC only when power

is applied to unit; otherwise NO)

Load Limits:

Max. Load Current 1 A rms

Min. Load Current 0.5 mA rms

Power Factor Range 0.2 to 1.0 (can drive small

motors, solenoids, valves, and

contactors)

Max. Surge Current

Non-repeating for 1 second 7.5 A

Max. I2T for fusing (0.01 sec) 4.5 amp-squared seconds (1 A -

ABC1 typical fuse)

Page 5

2

Option #20: Dual Open Collectors, NPN, Isolated

with Clamping Diode

Dual Open

Collector Alarms

Option Description: Dual open collectors, NPN, isolated, with clamping

diode

Recommended operating conditions:

Supply Voltage Pins 13 & 14; 200 working Vdc max. (Never exceed

300 Vdc)

Collector Current 50 mA max.

Specifications:

Saturation Voltage 0.3 Vdc min.

1.2 V max.

Collector-Emitter

Breakdown 300 V min.

Isolation Isolation 300 volts ac/dc output-to-output or output-

to-controller

Page 6

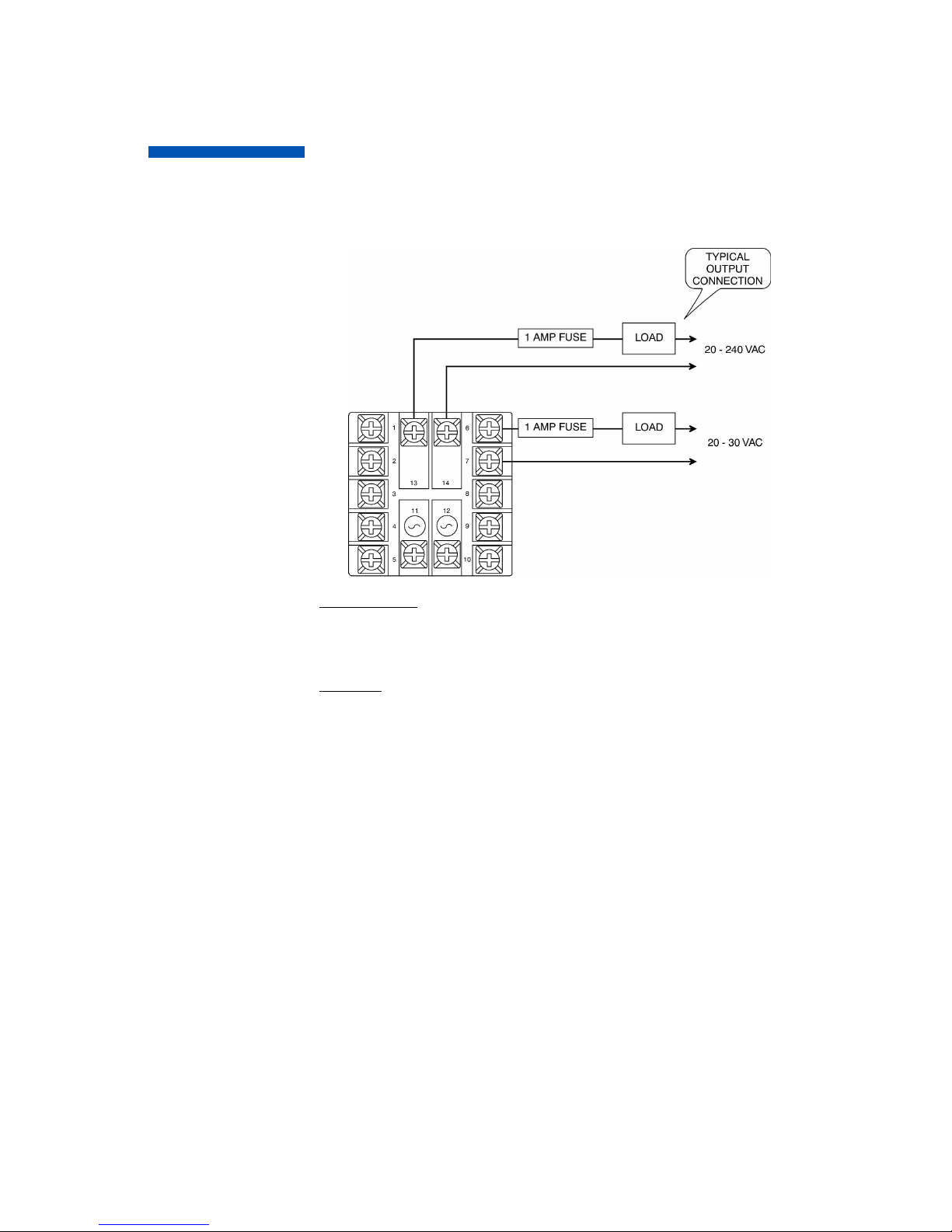

3

Dual 24 Vdc

Alarm Outputs

Option #21: Dual 24 Vdc Alarm Outputs

Option Description: Dual 24 V outputs with clamping diodes

Pins 13 & 7 are connected internally

Source current is limited to 25 mA (1000 ohm

resistor)

Open circuit voltage is 25 volts

Isolation: Isolation 300 volts ac/dc either output to

instrument

Page 7

4

Tungsten Lamp, 360 W 120 Vac

Option Description: NO (Normally open) relay contact is closed when

either alarm is active. Jumpers on the board can be

removed to activate the output for a single alarm only:

JP1 - Alarm A1

JP2 - Alarm A2

The relay life is greater than 100,000 operations at 5 operations per second switching full load.

*

Connect load and supply voltage per the following table:

Relay, N.O.

Alarm Output

Option #23: Relay, N.O. Alarm Output

Load Type 5 Amp Voltage Limit

Resistive DC 30 Vdc

Inductive DC (L/R = 7 ms) 20 Vdc

Resistive AC 250 Vac

Inductive AC (pF = 0.4) 150 Vac

Motor, AC, 1/6 hp 250 Vac

*

*

Page 8

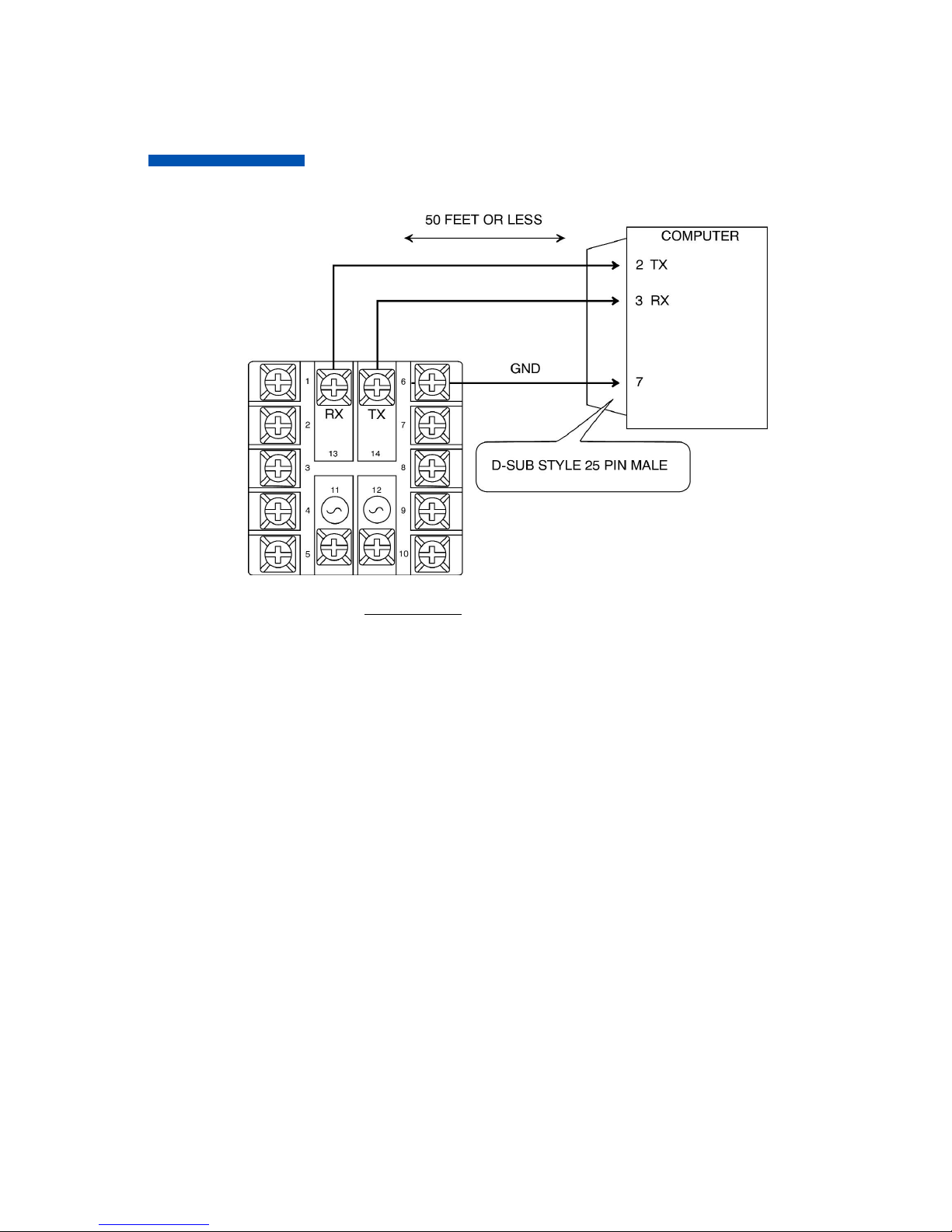

5

RS-232

Communications

Option #30: RS-232 (one-to-one) Communications

Option Description: Provides a one-to-one connection between

the controller and an RS-232 port.

Computers, PLCs, or dumb terminals may

be used to set and access controller data.

Page 9

6

RS-485

Communications

Option #31: RS-485 (one-to-many)

Communications

Option Description: Provides one-to-many communications.

If run exceeds 1000 ft., terminate the controller furthest from the computer by connecting a 120-ohm, 1/4-watt resistor between terminals 13 and 14.

*Converter is supplied with a wallplug-mount power transformer.

Page 10

7

Contact/Digital

Input with Alarm

Option Description: Dual function board (functions unrelated)

a. Output alarm is energized when either A1

or A2 is active.

b. Digital input controls Remote Standby, Ramp-Soak

Run/Hold, OR Second Setpoint Select.

Option 40: Active when switch closed.

Option 41: Active when switch open.

Option 42: Active when 5 V input present

Load Limits:

Max. Load Current: 1 A rms

Min. Load Current: 0.5 mA rms

Power Factor Range: 0.2 to 1.0 (can drive small motors, solenoids, valves,

and contactors)

Max. Surge Current,

Non-Repeating for

1 second: 7.5 A

Max. I2T for fusing (0.01 sec): 4.5 amp-squared secs (1A - ABC1

typical fuse)

Contact/Digital

Input with Alarm

Options #40, #41, #42: Contact/Digital Input with

Alarm

Input Option Menu

Page 11

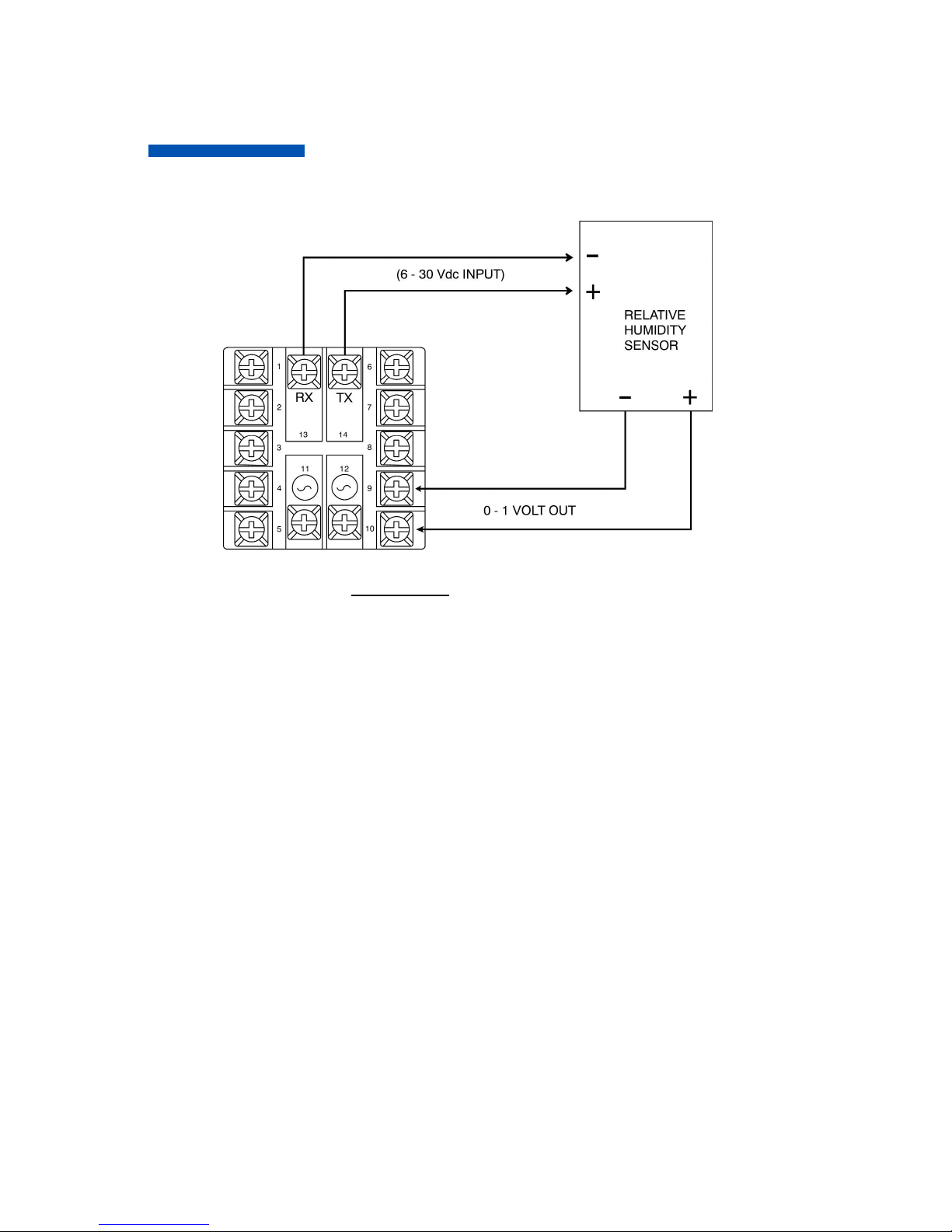

8

Transducer

Excitation

Option #50, #51, #52, #53: Transducer Excitation

Option Description: The transducer excitation option provides power to

remote transducers. The transducer outputs, in turn, provide a signal to the controller input which can be scaled

in the appropriate engineering units.

Option 50: 10 Vdc

Option 51: 12 Vdc

Option 52: 15 Vdc

Option 53: 5 Vdc

All options will provide at least 20 mA. The transducer circuitry is thermally protected

from short circuits.

Page 12

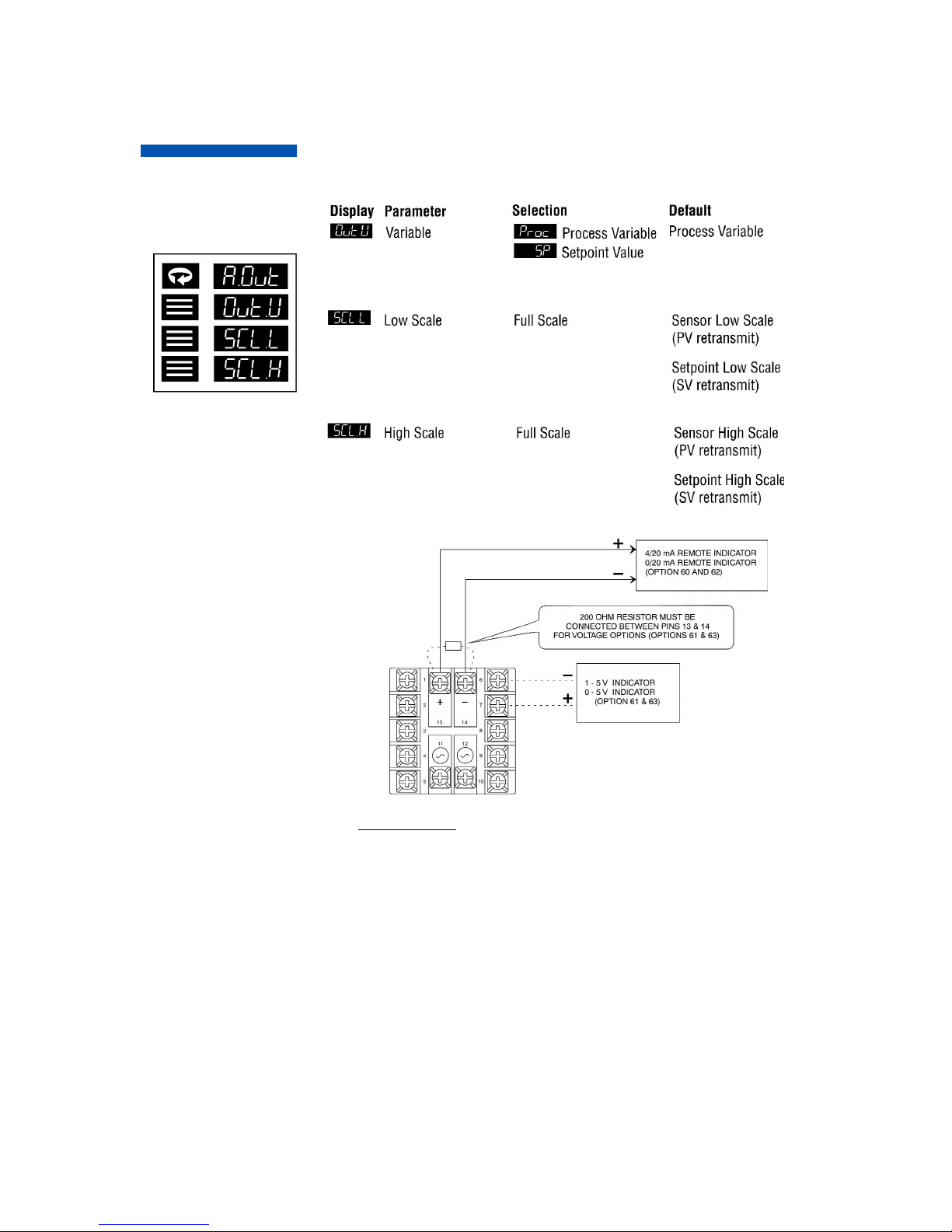

9

Auxiliary Output

Option #60, #61, #62, #63: Auxiliary Output

Auxiliary Output

Input Option Menu

Option #60, #61, #62, #63: Auxiliary Output

Option Description: The Setpoint Variable or Process Variable is

transmitted to a remote device (chart recorders, indicators, data recorders, computers, process

controllers, etc.) with 1 of 4 different interfaces:

Option 60: 4-20 mA

Option 61: 1-5 V

Option 62: 0-20 mA

Option 63: 0-5 V

The output signal is scalable in the Auxiliary Output Menu. Multiple remote indicators

may be driven by the controller. However, current and voltage outputs cannot be used

simultaneously.

For current (mA) options, the remote indicators are connected in series. The sum of

the input resistance for all remote indicators must be less than 400 ohms. For voltage

options, the remote indicators are connected in parallel.

The sum of the currents for all remote indicators must be less than 10 mA.

Page 13

10

Remote Analog

Setpoint

Option #80, #81, #82, #83, #84: Remote Analog

Setpoint

Option Description: Remote setpoints use either voltage or current inputs,

depending on the specified option:

Option 80: 0-5 V

Option 81: 1-5 V

Option 82: 0-20 mA

Option 83: 4-20 mA

Option 84: 0-10 V

The input signal is scalable in the Remote Analog Setpoint Menu. Activation of the

analog setpoint causes the F1 indicator to illuminate. For current (mA) options, the

input resistance is 255 ohms. For voltage input options, the input resistance is greater

than 10K ohms.

*Ground shield at one end, taking care not to run wires next to power circuitry.

Maximum length will be determined by noise performance.

Page 14

11

Series

16C

with

Digital

Communications

Option

Page 15

12

Digital

Communications

Option

Remote Communications Options

RS-232

This method allows bidirectional data transfer via a threeconductor cable consisting of signal ground, receive input and

transmit output. It is recommended for communication distances

less than 50 feet between the computer terminal and the instrument. Note: Multiple instruments cannot be connected to the same

port.

The RS232 port is optically isolated to eliminate ground

loop problems. Typically, “Data Out” of the computer/

terminal connects to the “RCV” terminal. “Data In” connects to the

“XMT” terminal. If shielded cable is used, it should be connected to

the frame ground at one end only. Signal ground is to be connected

at appropriate ground terminals (refer to wiring diagram on next

page).

RS-422

This method allows bidirectional data transfer via a fourwire conductor cable for distances over 50 feet between

the computer terminal and the instrument. A signal ground

wire is not required.

RS-485

The RS485 multipoint capability allows up to 32 controllers to be

connected together in a half-duplex network or up to 100 controllers with an appropriate communications repeater.

Three remote communications options are

available for the 16C

which allow interfacing

to remote devices

utilizing the most

common industry

standards: RS232,

RS422, and RS485.

Page 16

13

Digital

Communications

Option

This method allows bidirectional data transfer over a twisted pair cable. The twisted

pair cable is a transmission line; therefore, terminating resistors are required at the

most distant ends of the line to minimize reflections (typically 120 ohms at each end).

The RS485 circuit is fully optically isolated, eliminating ground loop problems. Parallel

drops from the transmission lines should be kept as short as possible; however, the

line may be daisy-chained at each controller. The polarity of the line is important and

each device will specify an “A” (+) and “B” (-) connection.

Figure 1a. Wiring diagram for

RS-232 digital communications.

Figure 1b. Wiring diagram for

RS-485 digital communications.

Note: Call factory for a

recommended RS485

converter.

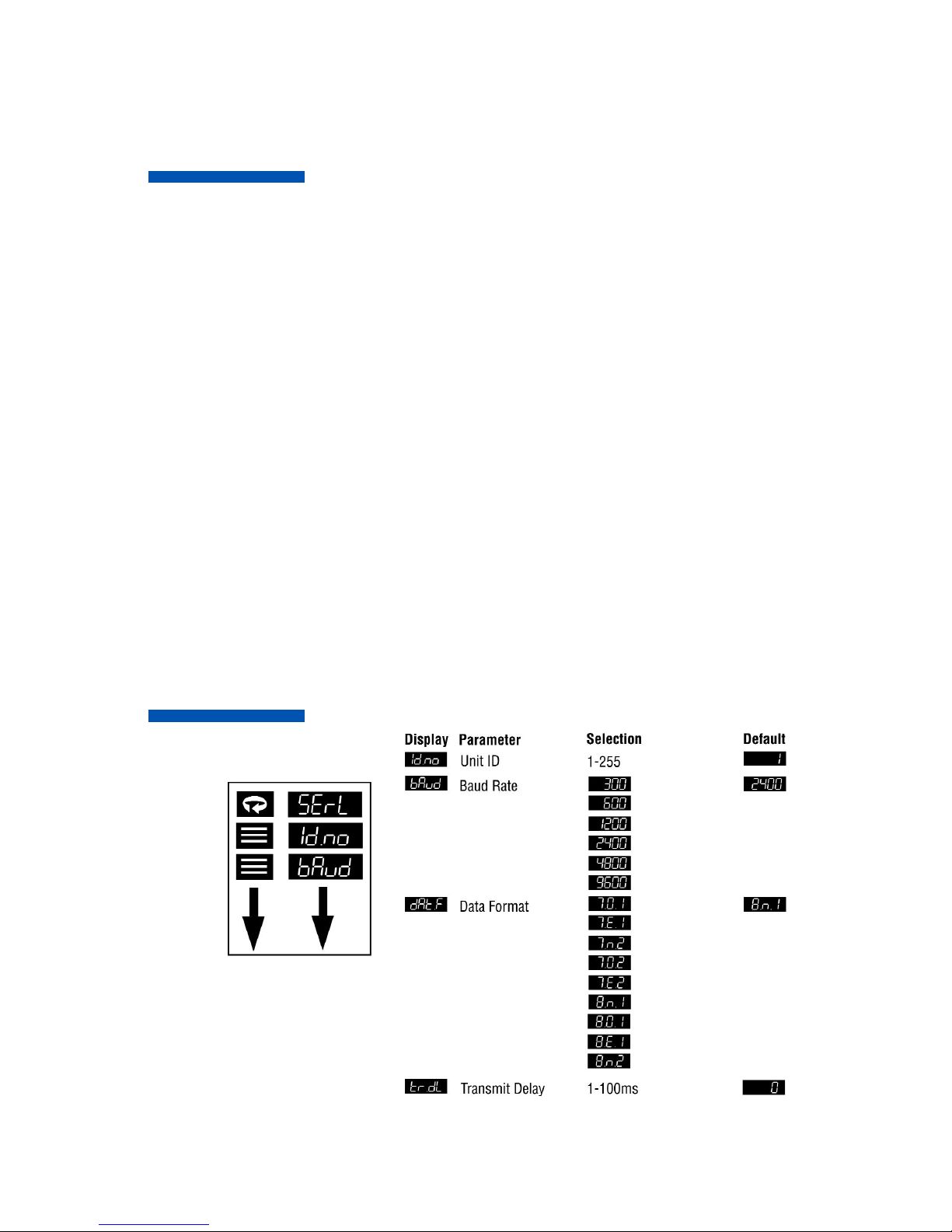

Page 17

14

Athena+ Protocol (Standard)

Communications

Option Menu

Athena+ Protocol

The Athena+ Protocol provides an easy way to query and

modify controller parameters using a personal computer and the

optional digital communications option of the 16C.

In this manual, the word “host” refers to the personal computer

that’s communicating with the controllers in the serial link, and the

word “slave” refers to the controllers themselves.

All transactions between the host and the slaves are done with

messages consisting of only printable ASCII characters. There are

only two primary types of messages: Requests

and Responses. Messages coming from the host are called

requests and messages coming from the slaves are called

responses.

With the exception of a broadcast request, for every request sent

from the host, the slave will send back a response. If a slave does

not respond within 100 milliseconds, then the request can be considered lost.

A broadcast request is a request having an ID of ‘00’ (see Message

Formats on next page). It is used to address all slaves on the network. All slaves on the network will perform the actions requested

in a broadcast message. However, a response message will not be

returned. Therefore, the host can only broadcast Write or Auxiliary

Command Requests. All slaves will ignore all Read Broadcast

Requests.

Digital

Communications

Option

Page 18

15

Message Formats

All Athena+ messages adhere to the general format of:

[START CHAR][ID][ZONE][TYPE][PARAM][ERROR]

[DATA][CHKSUM][END CHAR]

START CHAR

This is a single character which designates the start of the message. For a Request message, this character is the ASCII ‘$’ and

for a Response message, this character is the ASCII ‘%’.

ID

This is a two-character ID identifying the receiving controller.

Controller IDs go from 1-255 inclusively and all slaves in the network must have unique IDs. The ID number of ‘00’, when used in a

request, designates a broadcast message that is used to address

all controllers in the network. See the section Request Message for

an explanation of the broadcast message.

In order to represent 255 with just two ASCII characters, a number

system known as the Message Code Numbering System is used.

In this system, the most significant digit is represented with the

numbers 0-9 and the letters A-Z and the least significant digit is

represented with the numbers 0-9. The numbers 0-9 have the

Digital

Communications

Option

Page 19

16

same values as their decimal

counterparts and the letters A-Z have the values of 100 - 350 inclusively in increments of 10.

Example:

Message Code Value = Decimal Value

00 0 + 0 = 00

99 90 + 9 = 99

A0 100 + 0 = 100

A2 100 + 2 = 102

B8 110 + 8 = 118

P5 250 + 5 = 255

Zone

This is a two character ID identifying the Zone number in multizone capable controllers. For the 16C, this number must be 01.

Digital

Communications

Option

Page 20

17

Type

This is a single character identifying the type of message. The following table lists the type characters for all messages.

TYPE character Message Type

R Read Request or Read

Response Returning a

Positive Result

r Read Response Returning a

Negative Result

W Write Positive Value Request

and Response

w Write Negative Value Request

and Response

A Auxiliary Command

For further information, see following sections on the

different message types.

Digital

Communications

Option

Page 21

18

PARAM

This is a two character, message specific, parameter ID. For a

Read/Write Request or Response message, this ID identifies the

controller parameter. For an Auxiliary Command Request or

Response message, this ID specifies the command.

STATUS

This is a single-character field used in all response messages, containing a status code specifying the status of the request message

received.

DATA

This field contains the ASCII representation of the value of the

parameter. For the Auxiliary Request or Response messages, this

field either contains the ASCII representation of a numeric value or

just ASCII data. The length of this field depends on the message

type. The discussion on the specific message types gives the exact

requirements for this field.

All ASCII representations of numeric values must be done using

the characters ‘0’-‘9’, and ‘.’. Any use of other ASCII characters,

including‘ ‘ and ‘-’ will result in a bad message. Negative numbers

CANNOT be represented by preceding the number with ‘-’ character. Instead, a special message type is used. See subsequent sections for more information.

Digital

Communications

Option

Page 22

19

Digital

Communications

Option

IMPORTANT:The data field in the Read and Write Request and

Response messages must and will only contain the

characters ‘0’-’9’, and the decimal point ‘.’. All other characters are

considered illegal. When the data field is listed as Unused or

Ignored in an auxiliary command, it does not mean that the field

can be skipped when sending in the request message. Instead, this

field must be padded with any 10 alphanumeric (only letters and

numbers are allowed) ASCII characters.

Figure 2. Sample Communications Commands

Figure 3. Requesting a Parameter from a Controller

Page 23

20

Examples of valid numeric representations for a

6 character data field:

Numeric Value ASCII Representation

3 3.0000

000003

003.00

100 100.00

0100.0

000100

3.2 003.20

0003.2

Examples of invalid numeric representations for 6 character data

field: (B represents a blank, or a space, character)

Numeric Value Bad ASCII Representation Why?

3 BBBBB3 Leading blanks

are not allowed.

3.0BBBB Trailing blanks

are not allowed.

-3.2 -3.20000 ‘-’ is not

allowed.

Digital

Communications

Option

Page 24

21

CHKSUM

This is a two character Message Code Numbering System, representing the sum of all the ASCII values of all the characters

(excluding the START, CHAR, the END CHAR, and the CHKSM

themselves) in the message. The sum is computed using the following formula:

CHKSM = SUM(All Message Characters)%256

% represents the modulus operator.

END CHAR

This is a single character designating the end of the message. For

all messages, the character used is <CR>, the carriage return.

Request Messages:

Request Messages are sent from the host to the slaves. Each

request will have an ID identifying the intended recipient of the

request. If the ID is ‘00’ (zero), then the request is a broadcast

message. All slaves will perform the action requested in the broadcast request. However, a response message will not be returned.

Therefore, it only makes sense to send Write or Auxiliary

Command Requests as broadcast requests. There are three types

of Request Messages: Read, Write, and Auxiliary Commands.

Digital

Communications

Option

Page 25

22

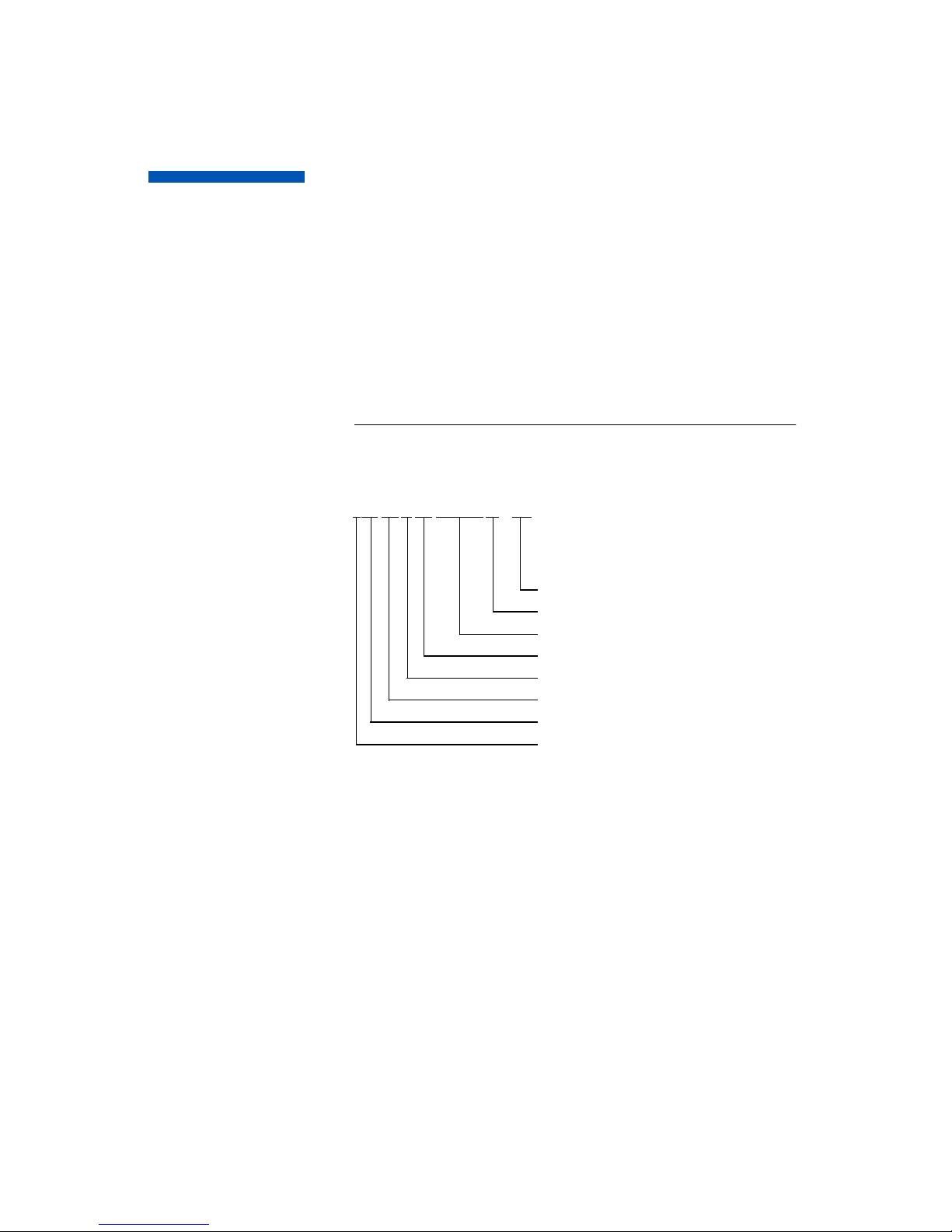

The Read Request:

The Read Request is used to query parameter values and it has

the following message format:

[START CHAR][ID][ZONE][TYPE][PARAM][CHKSUM][END CHAR]

Field Description: TYPE Must contain the uppercase letter ‘R’.

Request Message Description

$Ø1Ø1RØ5C1<CR> Queries the value of the Process Variable

of Controller #1.

$Ø1Ø1RØ9C5<CR> Queries the value of the EEPROM

Setpoint 1 of Controller #1

$Ø2Ø1RØ9C6<CR> Queries the value of the EEPROM

Setpoint 1 of Controller #2.

END CHAR

CHKSUM

PARAM

TYPE

ZONE

ID

START CHAR

Digital

Communications

Option

Examples of the responses to these requests are given

in later sections on Response Messages.

Page 26

23

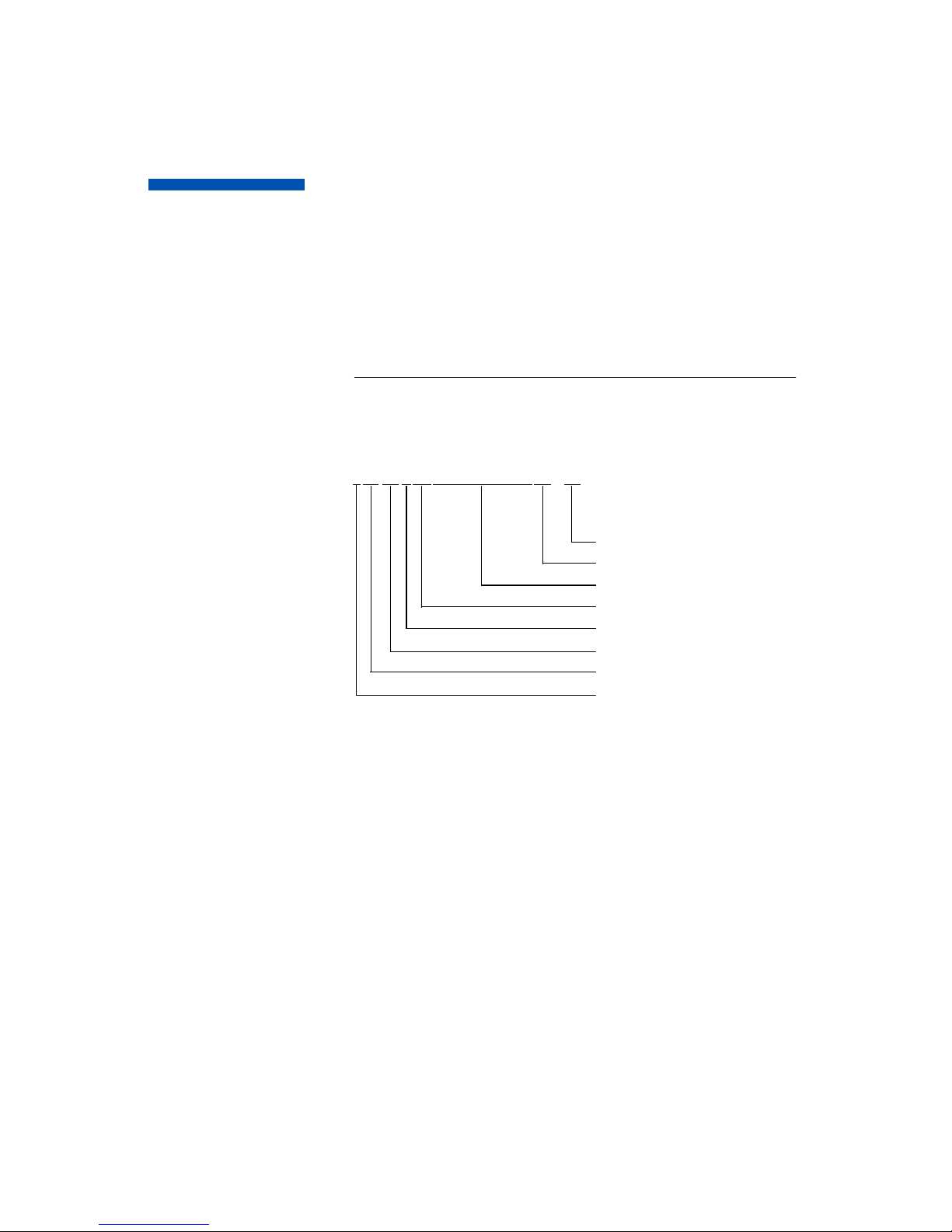

The Write Request:

The Write Request is used to modify parameter values and it has

the following message format: [START CHAR][ID][ZONE]

[TYPE][PARAM][DATA][CHKSUM][END CHAR]

Field Description: TYPE This field must contain one of the following

two characters.

W– Value in DATA is a positive value.

w– Value in DATA is a negative value.

DATA A six-character ASCII representation of a

numeric value.

Request Message Description

$Ø1Ø1WØ91Ø.123G7<CR> Change both the RAM and EEPROM

copies of Setpoint #1 in controller #1

to the value of 10.123

$Ø1Ø1w1Ø1Ø.123J1<CR> Change only the RAM copy of

setpoint #1 in controller #1 to

the value of -10.123 (notice the

lowercase ‘w’).

END CHAR

CHKSUM

DATA

PARAM

TYPE

ZONE

ID

START CHAR

Digital

Communications

Option

Page 27

24

Response Messages:

Response Messages are replies to the requests sent from the host.

For each request received, the slave will reply back with

a response.

For all requests, the Athena+ Protocol specifies a maximum

response time of 100 milliseconds. If a response is not received

after 100 milliseconds, that request can be

considered lost.

There are three types of Response Messages: Read, Write,

and Auxiliary Commands.

The Auxiliary Command Request:

The Auxiliary Command Request is used to issue commands to the

controllers and it has the following message format:

Field Description: TYPE This field must contain the uppercase

letter ‘A’

DATA A ten-character ASCII representation of a

numeric value or 10 alphanumeric ASCII characters.

Request Message Description

$Ø1Ø1AØ1XXXXXXXXXXL2<CR> Tell controller #1 to load

all parameters with their

defaults. The 10 X’s are

padding characters.

$Ш2Ш1AШ2ШШШ1.ШШШШШ69<CR> Tell controller #2 to

perform a low RTD

calibration.

END CHAR

CHKSUM

DATA

PARAM

TYPE

ZONE

ID

START CHAR

Digital

Communications

Option

Page 28

25

The Read Response:

The Read Response will be sent in response to a Read Request.

Some examples:

Request Message Description

%Ø1Ø1RØ5Ø21.123K8<CR> The value of the Process

Variable is 21.123 Degrees C.

%Ø2Ø1R1Ø1G7<CR> A serial transmission has

occurred: Framing Error

%Ø1Ø1rØ9Ø21.ØØØN8<CR> The value of the EEPROM

setpoint #1 is -21 Degrees C

(notice the lowercase ‘r’).

END CHAR

CHKSUM

DATA

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

Digital

Communications

Option

Page 29

26

The Auxiliary Command Response:

The Auxiliary Command Response will be sent in response to an

Auxiliary Command Request.

Some examples are:

Request Message Description

%Ø1Ø1AØ1ØXXXXXXXXXXØ4<CR> Default load all para-

meters has started.

%Ш2Ш1AШ2ШШ.ШШШШШШШШB6<CR> RTD low calibration

on controller #2 has

started.

END CHAR

CHKSUM

DATA

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

The Write Response:

The Write Response will be sent in response to a Write Request.

Some examples:

Request Message Description

%Ø1Ø1WØ93I1<CR> A serial transmission error

has occurred: Parity error.

Write failed.

%Ø1Ø1w1ØØK2<CR> RAM copy of setpoint #1

modified successfully.

END CHAR

CHKSUM

STATUS

PARAM

TYPE

ZONE

ID

START CHAR

Digital

Communications

Option

Page 30

27

Digital

Communications

Option

Parameter Parameter

Number Description Number Description

1 Controller Type 19 Manual Control

2 Software Version 2 Percentage

3 Communications 2Ø Output 1 Deadband

Version 21 Output 1 Hysteresis

4 Status Byte 22 Output 1 Proportional

5 Process Value Band

6 Operating Mode 23 Output 2 Proportional

7 Access Level Band

8 Contact/Digital 3Ø Rate/Derivative Action

Input State 32 Reset/Integral Action

9 Setpoint - RAM, 34 Manual Reset/

EEPROM Internal Action

1Ø Setpoint - RAM 37 Output 2 Deadband

Only 38 Output 2 Hysteresis

11 Second Setpoint - 39 Autotune Damping

RAM, EEPROM 4Ø Recipe Option

12 Second Setpoint - 41 Single Setpoint Ramp

RAM Only Time

13 Remote Analog 42 Ramp Time 1

Setpoint 43 Ramp Time 2

14 Recipe Setpoint 44 Ramp Time 3

16 Output 1 Percentage 45 Ramp Time 4

17 Output 2 Percentage 46 Ramp Time 5

18 Manual Control 47 Ramp Time 6

1 Percentage 48 Ramp Time 7

Table 1. Communications Parameter List (Athena+ Protocol)

Page 31

28

Digital

Communications

Option

Table 1. Continued

Parameter Parameter

Number Description Number Description

49 Ramp Time 8 73 Soak Time 8

5Ø Ramp Event 1 74 Soak Event 1

51 Ramp Event 2 75 Soak Event 2

52 Ramp Event 3 76 Soak Event 3

53 Ramp Event 4 77 Soak Event 4

54 Ramp Event 5 78 Soak Event 5

55 Ramp Event 6 79 Soak Event 6

56 Ramp Event 7 8Ø Soak Event 7

57 Ramp Event 8 81 Soak Event 8

58 Soak Level 1 82 Recycle Number

59 Soak Level 2 83 Holdback Band

6Ø Soak Level 3 84 Termination State

61 Soak Level 4 85 Power Resume

62 Soak Level 5 86 Input Bias

63 Soak Level 6 87 Input Low Scale

64 Soak Level 7 88 Input High Scale

65 Soak Level 8 89 Lower Setpoint Limit

66 Soak Time 1 9Ø Upper Setpoint Limit

67 Soak Time 2 91 Input Filter

68 Soak Time 3 92 Input Type

69 Soak Time 4 94 Output 1 Type

7Ø Soak Time 5 95 Output 1 Action

71 Soak Time 6 96 Output 1 Alarm

72 Soak Time 7 Action

Page 32

29

Digital

Communications

Option

Table 1. Continued

Parameter

Number Description

B6 TC/RTD Decimal Position

B7 Linear Decimal Position

B8 Display Filter

B9 Display Units

C1 Display Blanking

C2 Alarm 1 Action

C3 Alarm 1 Operation

C4 Alarm 1 Delay

C5 Alarm 1 Inhibit

C6 Alarm 1 Process Setpoint

C7 Alarm 1 Deviation Setpoint

C8 Alarm 2 Action

C9 Alarm 2 Operation

DØ Alarm 2 Delay

D1 Alarm 2 Inhibit

D2 Alarm 2 Process Setpoint

D3 Alarm 2 Deviation Setpoint

D4 Communication Protocol

D5 Communication ID

D6 Communication Baud Rate

D7 Communication Data Format

D8 Communication

Transmit Delay

E1 Output 1 Failsafe %

E2 Output 2 Failsafe %

Parameter

Number Description

97 Output 1 Alarm Operation

98 Output 1 Alarm Delay

99 Output 1 Alarm Inhibit

AØ Output 1 Process

Alarm Setpoint

A1 Output 1 Deviation

Alarm Setpoint

A2 Output 1 Cycle Time

A3 Output 1 Low Limit

A4 Output 1 High Limit

A5 Output 2 Type

A6 Output 2 Action

A7 Output 2 Alarm

Action N/A

A8 Output 2 Alarm Operation

A9 Output 2 Alarm

Delay N/A

BØ Output 2 Alarm Inhibit

B1 Output 2 Process

Alarm Setpoint

B2 Output 2 Deviation

Alarm Setpoint

B3 Output 2 Cycle Time

B4 Output 2 Low Limit

B5 Output 2 High Limit

Page 33

30

Parameter

Number Description

E3 Loop Break Time

E4 Highest Reading

E5 Lowest Reading

E8 Option Selection N/A

E9 TC Zero Calibration

FØ TC Span Calibration

F1 RTD Zero Calibration

F2 RTD Span Calibration

F3 Low-Voltage Zero

Calibration

F4 Low-Voltage Span

Calibration

F5 High-Voltage Zero

Calibration

F6 High-Voltage Span

Calibration

F7 Current Zero Calibration

F8 Current Span Calibration

G1 Auxiliary Output Variable

G2 Auxiliary Output

Scale Low

G3 Auxiliary Output

Scale High

G5 RAS Scale Low

G6 RAS Scale High

Digital

Communications

Option

Table 1. Continued

Parameter

Number Description

G7 Contact/Digital

Switch Function

H2 Autotune State

H3 Recipe State

H5 Current Recipe

Segment

H6 Active Setpoint

H7 Resume Exhaustion

Flag

F4 Low-Voltage Span

H8 LED Status Indicator

H9 RTD (with decimal

support) Zero Calibration

I

Ø RTD (with decimal

support) Span Calibration

Page 34

31

Auxiliary Commands:

Command: Load Parameter Defaults

Parameter #: 01

Description Restore all menu parameters to their

default values.

Request Data Field: Ignored.

Response Data Field: Ignored.

Command: Perform Process Low Calibration

Parameter #: 02

Description: Performs a Low Calibration. The

data field in the request message

specifies the process. Make sure the

prerequisite for the calibration is

satisfied before issuing a calibration

command. For instance, the RTD

calibration command must only be

used when the input sensor type is

chosen as RTD or RTD w/ Decimal.

Digital

Communications

Option

Page 35

32

Request Data Fields: A 10 character ASCII representation

of a numeric value specifying what

to calibrate.

0 - Thermocouple

1 - RTD, Resistive Thermal Device

2 - Linear

3 - RAS, Remote Analog Setpoint

Response Data Field: Ignored.

Command: Perform Process High Calibration

Parameter #: 03

Description: Performs a High Calibration. The data

field in the request message specifies

the process. Make sure the prerequisite for the calibration is satisfied

before issuing a calibration command

For instance, the RTD calibration

command must only be used when the

input sensor type is chosen as RTD or

RTD w/ Decimal.

Request Data Field: A 10 character ASCII representation

of a numeric value specifying what

to calibrate.

Digital

Communications

Option

Page 36

33

0 - Thermocouple

1 - RTD, Resistive Thermal Device

2 - Linear

3 - RAS, Remote Analog Setpoint

Command: Retrieve Display

Parameter #: 05

Description: Retrieves the string currently dis-

played on the slave’s display. The data

field in the request message specifies

which display and the data field in the

response message contains the string.

Request Data Field: A 10 character ASCII representation

of a numeric value specifying which

display to retrieve data from.

0 - Lower Display

1 - Upper Display

Response Data Field: The ASCII string.

Command: Clear Latched Alarms

Parameter #: 10

Description: Clear all latched alarms.

Request Data Field: Ignored.

Response Data Field: Ignored.

Digital

Communications

Option

Page 37

34

Table 2. Communications Error Codes Returned.

Code Description

0 No error.

1 Framing error.

2 Hardware error.

3 Parity error.

4 Bad character in the TYPE field.

5 Bad message. Message cannot be understood.

6 Bad checksum. The checksum received did not

match the checksum of the message.

7 Bad zone ID.

8 Bad auxiliary command ID. The auxiliary command

is not supported in this controller.

9 Bad parameter ID. The parameter is not supported

in this controller.

A Bad data. Bad representation in the data field or

data is out of range.

B Attempt to write to a read only parameter.

C Cannot write to a parameter because it’s in use.

Digital

Communications

Option

Page 38

35

Communications

Option Menu

Option “ED” – SPI Protocol

Page 39

NOTES

Page 40

For technical assistance, call toll free

1-800-782-6776 (in the U.S.)

or

610-828-2490

(from anywhere in the world),

or

e-mail: techsupport@athenacontrols.com.

Athena Controls, Inc.

5145 Campus Drive

Plymouth Meeting, PA 19462 USA

Toll-free: 800.782.6776

Tel: 610.828.2490

Fax: 610.828.7084

techsupport@athenacontrols.com

athenacontrols.com

900M012U00 REV “C” - 05022005

Loading...

Loading...