Atek Spellman SL150kV Instruction Manual

R

Instruction Manual

High Voltage Power Supply

MODEL :

SERIAL# :

DATE :

SPELLMAN

HIGH VOLTAGE ELECTRONICS

CORPORATION

475 Wireless Blvd.

Hauppauge, New York, 11788

+1(631) 630-3000*FAX: +1(631) 435-1620*

E-mail: sales@spellmanhv.com

SL150kV

Website: www.spellmanhv.com

SL150 SERIES MANUAL 118092-001 Rev A

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Spellman’s SL150kV rack mount high voltage power supply is designed for scientific and industrial OEM applications requiring 150kV at 1200 watts in a compact cable

connected standard sized rack. Models are available in

positive, negative or reversible polarity. The SL150kV is

fully arc and short circuit protected. Excellent regulation

specifications are provided along with outstanding stability

performance. The vacuum encapsulated high voltage

output section assures reliable corona free operation by

eliminating any concerns due to environmental factors.

TYPICAL APPLICATIONS

Electrostatics

HiPot Testing

Semiconductor Processing

Capacitor Charging

OPTIONS

200 200Vac Input Voltage

AOL Adjustable Overload Trip

APT Adjustable Power Trip

AT Arc Trip

BFP Blank Front Panel

CPC Constant Power Control

DPM4 4.5 Digit Panel Meters

EFR External Fault Relay

LL(X) Non-Standard HV Cable Length

(10 standard)

NAD No Arc Detect

NSS No Slow Start

RFR Remote Fault Reset

SS(X) Non-Standard Slow Start

(6 seconds standard)

• CABLE CONNECTED 150kV @ 1200W POWER SUPPLY

• REQUIRES ONLY 8.75˝ (5U) PANEL HEIGHT

• EXTENSIVE ANALOG INTERFACE

• ARC QUENCH/ARC COUNT/ARC TRIP

• COMPREHENSIVE DIGITAL FAULT DIAGNOSTICS

SPECIFICATIONS

Front Panel Controls:

Front Panel Controls Power ON/OFF switch, HV ON

Switch, HV OFF Switch with preset feature, 3.5 digit

backlight digital meters for display of output voltage

and output current,10 turn locking potentiometers with

counting dials for adjustment of both output voltage

and output current.

Front Panel Indicators:

HV ON High Voltage Inhibit

HV OFF Over Current

Voltage Control Mode Over Voltage

Current Control Mode Arc

Interlock Open Regulation Error

Interlock Closed Overtemperature

Input:

220Vac ±10%, 50/60 Hertz

Output Voltage:

0 to 150kV

Output Polarity:

Positive, negative or reversible specify at time of order

Output Current:

8mA

Output Power:

1200W

Voltage Regulation:

Load: 0.01% of rated voltage for a full load change

Line: ±0.01% of rated current over specified input

voltage range

Current Regulation:

Load: 0.01% of rated current ±100µA for full voltage change.

Line: ±0.01% of rated current over specified input

voltage range

Ripple:

0.1% peak to peak of maximum output

Temperature Coefficient:

100ppm/°C.

Stability:

100ppm/hr after a 2 hour warm up, for both voltage and

current regulation

PAGE 1 OF 2

SPELLMAN HIGH VOLTAGE ELECTRONICS CORPORATION

SL150kV

1200W

POWER SUPPLY

www.spellmanhv.com/manuals/SL150KV

Corporate Headquarters

Hauppauge, New York USA

+1-631-630-3000 FAX: +1-631-435-1620

e-mail: sales@spellmanhv.com

www.spellmanhv.com

128062-001 REV. F

Spellman High Voltage is an ISO 9001:2008 and ISO 14001:2004 registered company

For locations worldwide

SL1200

18.12 [460.24]

17.25 [438.15]

JB4

J1

17.00 [431.8 ]

R13 TYP

8.72 [221.48]

0.44

[11.17]

1.48 [37.59]

FRONT VIEW

BACK VIEW

TOP VIEW

19.00 [482.60]

5.75 [146.05]

SL150 ANALOG INTERFACE—

JB4 25 PIN MALE D CONNECTOR

PAGE 2 OF 2

DIMENSIONS: in.[mm]

PIN SIGNAL PARAMETERS

1 Power Supply Common Signal Ground

2 External Inhibit Ground = Inhibit, Open = HV ON

3 External Interlock +15Vdc @ open, ≤ 5mA @ closed

4 External Interlock Return Connect to pin 3 to enable supply

5 Current Monitor 0 to 10Vdc = 0 to 100% rated voltage, Zout =10kΩ

6 Voltage Monitor 0 to 10Vdc = 0 to 100% rated voltage, Zout =10kΩ

7 +10Vdc Reference +10Vdc @ 1mA, maximum

8 Remote Current Program Input 0 to 10Vdc = 0 to 100% rated voltage, Zout =10kΩ

9 Local Current Program Output Multi-turn front panel pot for local control capability

10 Remote Voltage Program Input 0 to 10Vdc = 0 to 100% rated voltage, Zout =10kΩ

11 Local Voltage Program Output Multi-turn front panel pot for local control capability

12 EFR (Common) External Fault Relay (Optional)

13

EFR (Normally Open) External Fault Relay (Optional)

14 Local HV OFF OUT +15Vdc @ open, <25mA @ closed, connect to

HV OFF for front panel operation

15 HV OFF Connect to HV OFF OUT for front panel operation

16 Remote HV ON +15Vdc @ 10mA maximum = HV OFF

17 Remote HV OFF Indicator 0 = HV ON, +15Vdc @ 10mA maximum = HV OFF

18 Remote HV ON Indicator 0 = HV OFF, +15Vdc @ 10mA maximum = HV ON

19 Remote Voltage Mode Open collector 50Vdc @ 10mA maximum, ON = Active

20 Remote Current Mode Open collector 50Vdc @ 10mA maximum, ON = Active

21 Remote Power Mode Open collector 50Vdc @ 10mA maximum, ON = Active

22 Power Supply Fault Open collector, 50Vdc @ 10mA maximum

23 +15Vdc Output +15Vdc @ 100mA, maximum

24 Power Supply Ground Signal Ground

25 Shield Return Chassis Ground

Operating Temperature:

0 to 40°C operating

Storage Temperature:

-40 to +85°C storage

Humidity:

20% to 85%, non-condensing

Input Line Connector:

3 conductor 12 AWG 6 ft (1.83m) cable, permanently attached

Output Connector:

A detachable 10 ft (3.05m) shielded HV cable is provided

Cooling:

Forced Air

Dimensions:

8.75”H x 19”W x 22”D rack mount.

(22.23cm x 48.26cm x 55.88cm)

Weight:

89 pounds (40.4kg)

Regulatory Approvals:

Compliant to 2004/108/EC, the EMC Directive

and 2006/95/EC, the Low Voltage Directive.

Specify “P” for positive polarity or “N” for negative polarity, and PN = reversible as

illustrated below.

Sample Model Number: SL150P1200/BFP/LL(20)

Where SL = power supply series, 150 = maximum output voltage in kV,

P = positive output polarity, 1200 = maximum output power (watts), BFP = Blank

Front Panel, LL(20) = 20 foot HV cable.

SPELLM AN HIGH VOLTAGE ELECTR ONICS CORPORATIO N

SL150kV

1200W

POWER SUPPLY

Corporate Headquarters

Hauppauge, New York USA

+1-631-630-3000 FAX: +1-631-435-1620

e-mail: sales@spellmanhv.com

www.spellmanhv.com

128062-001 REV. F

Spellman High Voltage is an ISO 9001:2008 and ISO 14001:2004 registered company

For locations worldwide

IMPORTANT SAFETY PRECAUTIONS

SAFETY

THIS POWER SUPPLY GENERATES VOLTAGES THAT ARE DANGEROUS AND MAY BE FATAL.

OBSERVE EXTREME CAUTION WHEN WORKING WITH THIS EQUIPMENT.

High voltage power supplies must always be grounded.

Do not touch connections unless the equipment is off and the

Capacitance of both the load and power supply is discharged.

Allow five minutes for discharge of internal capacitance of the power supply.

Do not ground yourself or work under wet or damp conditions.

SERVICING SAFETY

.

Maintenance may require removing the instrument cover with the power on.

Servicing should be done by qualified personnel aware of the electrical hazards.

WARNING note in the text call attention to hazards in operation of these units

that could lead to possible injury or death.

CAUTION notes in the text indicate procedures to be followed to avoid possible

damage to equipment.

Copyright © 2000, Spellman High Voltage Electronics Corporation. All Rights Reserved.

This information contained in this publication is derived in part from proprietary and patent data. This information has

been prepared for the express purpose of assisting operating and maintenance personnel in the efficient use of the

model described herein, and publication of this information does not convey any right to reproduce it or to use it for

any purpose other than in connection with installation, operation, and maintenance of the equipment described.

118004-001 REV. B

Table of Contents

PAGE

1. INTRODUCTION

1.1 Description of the SL150.....................................................................................1

1.2 Standard Features.................................................................................................2

1.2.1 Remote Operating Features ..................................................................2

1.2.2 System Status and Fault Diagnostic Display........................................2

1.3 Options.................................................................................................................3

1.4 Interpreting the Model Number...........................................................................4

2. INSPECTION & INSTALLATION

2.1 Initial Inspection ..................................................................................................5

2.2 Mechanical Installation........................................................................................5

3. OPERATING INSTRUCTIONS

3.1 Operation .............................................................................................................7

3.2 Standard Features.................................................................................................8

4. PRINCIPLES OF OPERATION

4.1 Chassis .................................................................................................................17

4.2 High Voltage Transformer...................................................................................18

4.3 High Voltage Assembly.......................................................................................18

4.4 Control/Power PWB ............................................................................................18

4.5 Front Panel Assembly..........................................................................................18

4.6 Options.................................................................................................................18

5. OPTIONS

5.1 Adjustable Overload Trip ....................................................................................19

5.2 200Vac Single Phase Input .................................................................................19

5.3 No Slow Start ......................................................................................................19

5.4 Non-Standard Slow Start .....................................................................................19

5.5 Extra Length Output Cable..................................................................................19

5.6 Arc Trip Option ...................................................................................................19

5.7 Reversible Polarity Option...................................................................................19

5.8 Adjustable Power Trip/Constant Power Control.................................................19

5.9 External Fault Relay Option................................................................................20

5.10 NAD Option.........................................................................................................20

5.11 RFR Option..........................................................................................................20

5.12 Custom Design Models........................................................................................20

SL150 MANUAL I 118093-001 REV B

6. MAINTENANCE

6.1 Periodic Servicing................................................................................................23

6.2 Performance Test.................................................................................................23

6.3 High Voltage Dividers.........................................................................................23

7. REPLACEMENT PARTS

7.1 Replacement Parts................................................................................................24

7.2 Correspondence and Ordering Spare Parts ..........................................................24

8. FACTORY SERVICE

8.1 Warranty Repairs.................................................................................................25

8.2 Factory Service Procedures .................................................................................25

8.3 Ordering Options and Modifications...................................................................25

8.4 Shipping Instructions...........................................................................................25

LIST OF FIGURES

Figure 2.1 SL150 Dimensions......................................................................................6

Figure 3.1 SL150 Typical Operating Set Up................................................................10

Figure 3.2A Wiring Diagram for Remote Programming via Voltage Source ................12

Figure 3.2B Wiring Diagram for Remote Programming via External Resistance..........12

Figure 3.3 Remote Monitor Test Point Designations...................................................13

Figure 3.4 Remote Control of High Voltage On and Off ............................................13

Figure 3.5 External Inhibit Interface Circuit................................................................14

Figure 3.6 External Interlock Interface Circuit............................................................14

Figure 3.7 Remote High Voltage On and Remote High Voltage off Indicator Circuit.... 15

Figure 3.8 Remote Indicators Interface............................................................................ 16

Figure 5.1

Figure 5.2 Reverse Polarity Option

Adjustable Power Remote Interface Control..............................................21

...............................................................................22

LIST OF TABLES

Table 1.1 SL150 Options............................................................................................3

Table 3.1 Rear Panel Interface 25 pin Mini D............................................................11

A. Specification Controls (Custom Models Only)

SL150 MANUAL II 118093-001 REV B

APPENDIX

Chapter 1

INTRODUCTION

1.1 Description of the SL150

he SL150 voltage power supply provides very well

regulated, low ripple high voltage in a highly

T

efficient, compact design. The improvements in size

and performance over traditionally designed high voltage

power supplies are due to the resonant topology and

unique control circuitry of the SL design. A proprietary

control system maintains high frequency over the

operating output range. High frequency operation allows

a dynamic response time of less than 5 milliseconds, and

one of the lowest ripple specifications in the industry at

this power level. The combination of proprietary control

system and proprietary protection circuitry enables the

supplies to operate under arcing and extreme transient

conditions without damage or interruptions.

The DC output voltage and current are continuously

adjustable from zero to the maximum rating via two front

panel ten-turn locking potentiometers. These high

voltage power supplies have 0.005% load regulation,

0.005% line regulation, and 0.1% p-p ripple.

The supplies operate from either a 200 (option) or 220

Volt, single phase AC line. Other line voltages are

available. Options are listed in Table 1.1 and are

described in Section 5. Custom designed units to meet

special needs are also available.

SL150 MANUAL 1 118093-001 REV B

1.2 Standard Features

The SL150 incorporates several standard features

designed to optimize user satisfaction and safety.

SLOW START: This feature provides a gradual

increase in high voltage until the preset operating

point is reached. The slow start time is factory set

for 6 seconds. Other slow start times are available as

an option.

ARC DETECT / ARC QUENCH / ARC COUNT:

These features allow the user to tailor the power

supply to meet specific needs in dynamic load

applications. If an arc occurs, the output is inhibited

for approximately one second, then the output is

ramped up to the preset level with the slow-start

circuitry. See Chapter 3 for operating details and

information for user customization of these features.

INTERNAL FAULT PROTECTION: The SL

Series continually monitors internal circuits critical to

the proper operation of the power supply. In the

event that one of these circuits does not function

correctly, the fault detection circuit latches the

appropriate fault on the front panel display and turns

off the output and reverts the unit to the POWER

DOWN mode.

INDICATOR LAMPS: LINE POWER, HIGH

VOLTAGE OFF AND HIGH VOLTAGE ON

indicators.

OUTPUT CABLE: All models are provided with a

ten foot shielded high voltage output cable. The

cables are designed with a plug arrangement so that

they can be easily removed from the mating

receptacle located on the rear of the chassis.

1.2.1 Remote Operating Features

REMOTE PROGRAMMING: Allows remote

adjustment of the output voltage and current via an

external voltage source. The output power is also

remotely controllable when the CPC or APT option

is ordered, TB1 only.

REMOTE MONITOR: Allows remote monitoring

of the output voltage and current.

REMOTE HIGH VOLTAGE CONTROL:

Allows remote control of HIGH VOLTAGE ON and

HIGH VOLTAGE OFF. Signals are also provided

for remote indication of HV ON or HV OFF status.

EXTERNAL INHIBIT: A control signal that will

inhibit the high voltage output is provided on the

external interface. A logic low, ground, will inhibit

the high voltage output an d a logic high, open, will

restore the high voltage output to the preset level.

NOTE: The External Inhibit circuit should NOT be used

for protection against injury or for safety interlock.

See External Interlock for this type of safety control.

EXTERNAL INTERLOCK: Interlock connections

are provided on the external interface on the rear of

the chassis for connection to a safety switch. The

unit will not operate unless the interlock circuit is

closed. During high voltage operation, opening the

interlock circuit will cause the High Voltage to shut

off. This circuit should be used for safety interlock

circuits.

1.2.2 System Status and Fault

Diagnostic Display

“Dead Front” type indictors are provided to give the user

complete indication of system operation and fault

conditions. If a fault occurs, the power supply will revert

to the POWER DOWN mode. This is indicated by both

the HV ON and HV OFF lamps turning off. To reset,

depress the HV OFF switch.

VOLTAGE (CONTROL): Indicates the output

voltage regulator circuit is maintaining voltage

regulation.

CURRENT (CONTROL): Indicates the output

current regulator circuit is maintaining current

regulation.

POWER (CONTROL): Indicates the output power

regulator circuit is maintaining power regulation

(optional).

HV INHIBIT: Indicates that the high voltage

supply is being inhibited by either the EXTERNAL

INHIBIT or internal protection circuitry.

NOTE: Output power remote monitor is included with

the CPC and APT options, TB1 only.

SL150 MANUAL 2 118093-001 REV B

INTLK CLSD: Indicates the EXTERNAL

INTERLOCK connections are in the closed position.

This also indicates closure of internal power supply

interlocks.

INTKL OPEN: Indicates the EXTERNAL

INTERLOCK connections are in the open position.

This also indicates opening of internal power supply

interlocks.

OVERVOLT: Indicates the overvoltage protection

circuitry has caused the power supply to turn off.

Overvoltage protection is internally set to 110% of

the rated output voltage.

OVERCURR: Indicates the output current has

exceeded the programmed current trip level when the

AOL (Adjustable Overload Trip) or the OL

(Overload Trip) options are installed.

OVERPOWER: Indicates the output power has

exceeded the internally set level or the remote

programmed level if the optional circuitry is

installed.

ARC: Indicates that an arc has occurred within the

previous one second or that the ARC COUNT/TRIP

has shutdown the power supply.

RGLT ERR: Indicates a failure in the voltage,

current or power regulation circuitry. This fault

usually occurs when there is a lack of output power

to maintain regulation.

The options available are listed in Table 1.1. See Section

5 for more information on these options along with

operating and set-up instructions. With few exceptions,

these options and modifications can be retrofitted to your

power supply at the factory in a short time. For price and

retrofit arrangements, contact the Spellman Sales

Department.

1.3 Options

AOL Adjustable Overload Trip (0-103%)

APT Adjustable Power Trip

AT Arc Trip

CPC Constant Power Control

SS(x) Non-Standard Slow Start

NSS No Slow Start

LR Low Ripple (0.05% p-p)

DPM4

PN Reversible Polarity

LL (x) Extra Length Output Cable in Feet

EFR External Fault Relay

BFP Blank Front Panel

NAD No ARC Detect

RFR Remote Fault Reset

4 1/2 Digit 1 Least Significant Digit Panel Mtr

Table 1.1 SL150 Options

Note: APT/CPC cannot be combined with EFR

SL150 MANUAL 3 118093-001 REV B

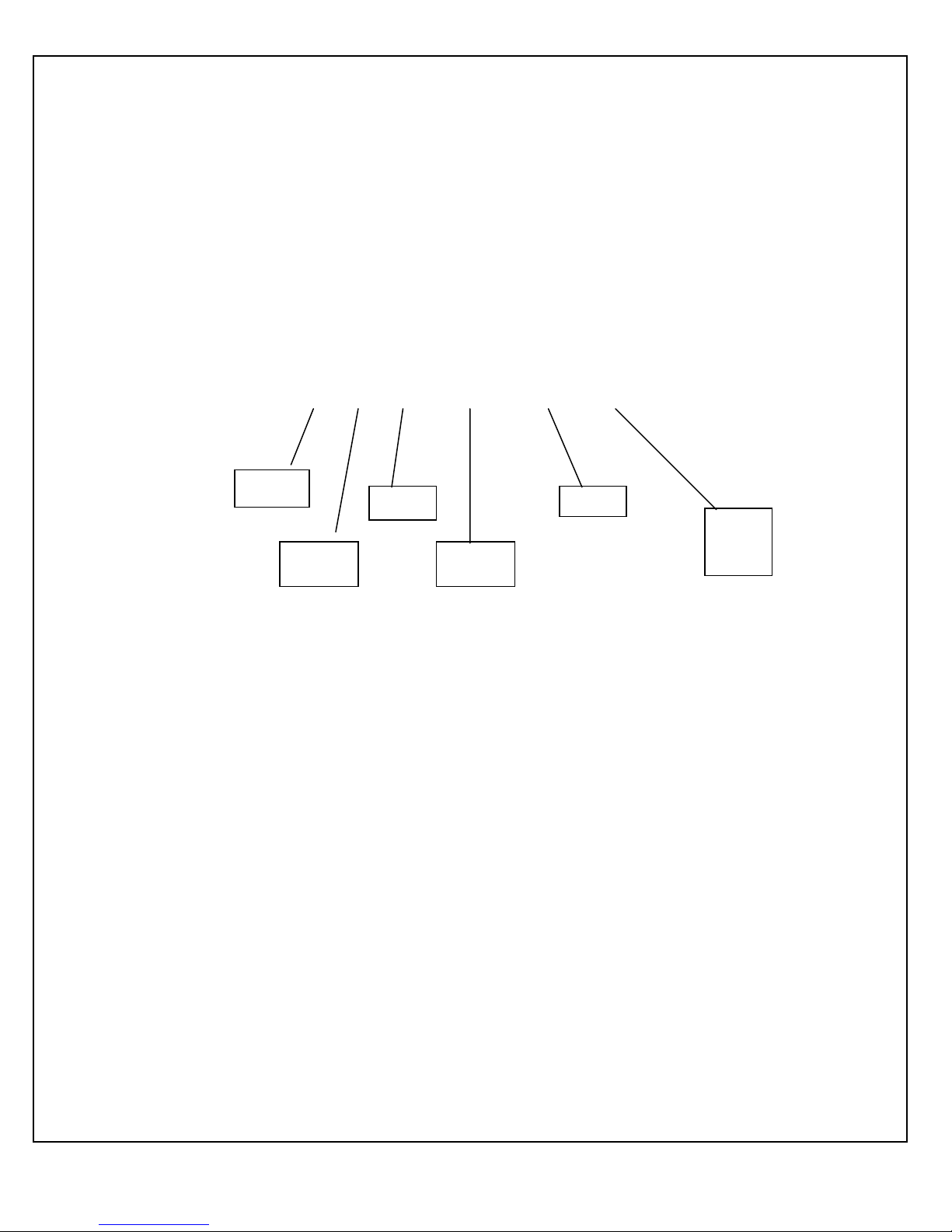

1.4 Interpreting the Model Number

The model number of the power supply describes its

capabilities. After the series name is:

1. the maximum voltage (in kV).

2. the polarity of the unit: positive (P), nega tive (N) or

reversible (PN).

3. the maximum output (in watts).

4. the option codes for all options that are included.

Custom units have an X number after the option codes.

SL 150 P 1200 / AOL / X (#)

Series

Name

Maximum

Voltage

Polarity

Maximum

Option

Custom

“X”

Number

Power

SL150 MANUAL 4 118093-001 REV B

Chapter 2

INSPECTION & INSTALLATION

nitial inspection and preliminary checkout procedures

are recommended. For safe operation, please follow

I

the step-by-step procedures described in Chapter 3,

Operating Systems.

2.1 Initial Inspection

Inspect the package exterior for evidence of damage due

to handling in transit. Notify the carrier and Spellman

immediately if damage is evident. Do not destroy or

remove any of the packing material used in a damaged

shipment.

After unpacking, inspect the panel and chassis for visible

damage.

Fill out and mail the Warranty Registration card

accompanying the unit. Standard Spellman SL Series

high voltage power supplies and components are covered

by warranty. Custom and special order models (with an

X suffix and the model number) are also covered by

warranty.

2.2 Mechanical Installation

Units in the SL Series have front panel holes for standard

EIA rack mounting. The rack must allow rear access for

cable connections. Units are fully enclosed and are

suitable for bench or table top operation. Standard unit

dimensions are shown in Figure 2.1.

SL150 MANUAL 5 118093-001 REV B

Loading...

Loading...