Atek ADR 10 Operation Manual

OPERATION

MANUAL

Atek ADR 10 Series

HIGH PERFORMANCE

DIGITAL READOUT

[1]

Ingredients

1. ATEK DIGITAL READOUT SYSTEMS........................................................................................................................... 3

1.1. ATEK linear encoder and digital coordinate readout unite usage advantages ................................................. 3

1.2. ATEK Magnetic Linear Encoder ......................................................................................................................... 3

2. TECHNICAL PARAMETERS......................................................................................................................................... 4

3. SYSTEM SETUP .......................................................................................................................................................... 8

3.1. Language Selection ........................................................................................................................................... 8

3.2. Resolution Setup ............................................................................................................................................... 8

3.3. Direction Setup ................................................................................................................................................. 9

3.4. Machine Tool Selection ..................................................................................................................................... 9

3.5. Compansation Selection ................................................................................................................................... 9

3.6. Advanced Settings ............................................................................................................................................. 9

3.6.1. Digit On-Off ............................................................................................................................................. 10

3.6.2. Axis Addition ........................................................................................................................................... 10

3.6.3. 4. Axis Type ............................................................................................................................................. 10

3.6.4. Calculator Decimal Setup ........................................................................................................................ 10

3.6.5. Probe Logic Level Setup .......................................................................................................................... 11

3.6.6. Buzzer Close ............................................................................................................................................ 11

3.6.7. Return to Factory Settings ...................................................................................................................... 11

3.7. Test .................................................................................................................................................................. 11

3.7.1. Display Test ............................................................................................................................................. 11

3.7.2. Eeprom Test ............................................................................................................................................ 12

3.7.3. Keyboard Test ......................................................................................................................................... 12

3.7.4. CPU Test .................................................................................................................................................. 12

3.7.5. Relay Test ................................................................................................................................................ 12

4. Basic Functions ....................................................................................................................................................... 13

4.1. Measurement System Change ........................................................................................................................ 13

4.2. Operation Mode Selection .............................................................................................................................. 13

4.3. Quick Zero Axis Values .................................................................................................................................... 13

4.4. Manuel Value Setting for Each Axis: ............................................................................................................... 13

4.5. Setting Half Value of The Display Value (Milling, Bohrwerk) .......................................................................... 14

4.6. Diameter Mode (Lathe):.................................................................................................................................. 14

4.7. Center Find (Milling, Bohrwerk) ...................................................................................................................... 14

4.8. Simple Calculation on Axis Values:.................................................................................................................. 16

4.9. Undo Function ................................................................................................................................................. 16

4.10. Activate the 4th Axis ................................................................................................................................... 16

4.11. Display Angle on the 4th Axis ...................................................................................................................... 17

[2]

4.12. Sleep Mode: ................................................................................................................................................ 17

5. ADVANCED FUNCTIONS ......................................................................................................................................... 18

5.1. To Find Zero Point of the Machine Tool.......................................................................................................... 18

5.1.1. Ruler Zero Point: ..................................................................................................................................... 18

5.1.2. Mechanical Zero Point: ........................................................................................................................... 19

5.2. Error Compensation Function: ........................................................................................................................ 20

5.2.1. Linear Error Compensation Function: ..................................................................................................... 20

5.2.2. Segmented Error Compansation Function: ............................................................................................. 21

5.3. Travel Limit: ..................................................................................................................................................... 23

5.4. Axis Addition (Lathe, Bohrwerk) ..................................................................................................................... 24

5.5. Shrink Function: .............................................................................................................................................. 25

5.6. Calculator Function: ........................................................................................................................................ 26

5.6.1. To Transfer the Calculated Values To The Axes: ..................................................................................... 26

5.6.2. To Transfer The Axis Values To Calculator: ............................................................................................. 27

5.7. Datum Point Memory: .................................................................................................................................... 28

5.8. Bolt Hole Circle (Divisor) (Milling) ................................................................................................................... 32

5.9. Bolt Hole Line Function (Milling) ..................................................................................................................... 34

5.10. Smooth Radius (Milling) .............................................................................................................................. 36

5.11. Simple Radius (Milling) ................................................................................................................................ 39

5.12. Linear Hole Patterns (Milling) ..................................................................................................................... 41

5.13. Frame Hole Patterns (Milling) ..................................................................................................................... 43

5.14. Rectangular Pocket (Milling) ....................................................................................................................... 45

5.15. Work Piece Angle Measuring (Milling) ........................................................................................................ 47

5.16. Touch Probe (Milling, Bohrwerk) ................................................................................................................ 48

5.16.1. Zero the Axis / Setting Half Value of the Display Value .......................................................................... 48

5.16.2. Find Center .............................................................................................................................................. 49

5.16.3. Measurement .......................................................................................................................................... 50

5.17. Tool Diameter Compansation (Milling) ....................................................................................................... 52

5.18. Tool Storeroom (Lathe) .............................................................................................................................. 53

5.19. Taper Angle Measurement (Lathe) ............................................................................................................. 56

5.20. Digital Filter (Vibration Filter) ..................................................................................................................... 57

5.21. Inclined Z Axis Machining (Milling) ............................................................................................................. 58

5.22. EDM Depth Control Function (Erosion) ...................................................................................................... 60

5.23. HOLD Function ............................................................................................................................................ 62

5.24. Data Transfer by RS – 232 Port ................................................................................................................... 63

[3]

1. ATEK DIGITAL READOUT SYSTEMS

1.1. ATEK linear

encoder and

digital

coordinate

readout unite

usage

advantages

1.2. ATEK Magnetic

Linear Encoder

New 2, 3 and 4 axis available ADR 10 Series Digital Readouts can meet the

application in all machine tools with maximum performance and it includes

features that are essential for increasing productivity. With high-capacity

memory it is possible to save 1000 pcs programs and for the lathes 1000

pcs tool memory. 5 different language choices are existed as Turkish,

English, German, Spanish and Portuguese. Connection opportunity by

contact probe is also available. With 8+1 digit display and standard

resolution values with user designated resolution, ADR10 is designed for

your all requires.

New ADR 10;

- Minimizing production time, increasing productivity.

- Scrap Cost Saving.

- More Accurate Positioning.

- More Quality Parts.

- 80% Reduced Process time.

- Amortizing in a Short Time.

For the best performance please use ATEK Linear Encoders. ATEK MLS

Series magnetic linear scales present to their users high accuracy and

usage advantages. The magnetic systems never influenced negatively from

the environmental conditions as dust, chip, humidity and cutting fluid, they

work without any problem. Because of the contactless working there is no

friction, they have unlimited lead time mechanically, they work without

any mechanical problem and maintenance.

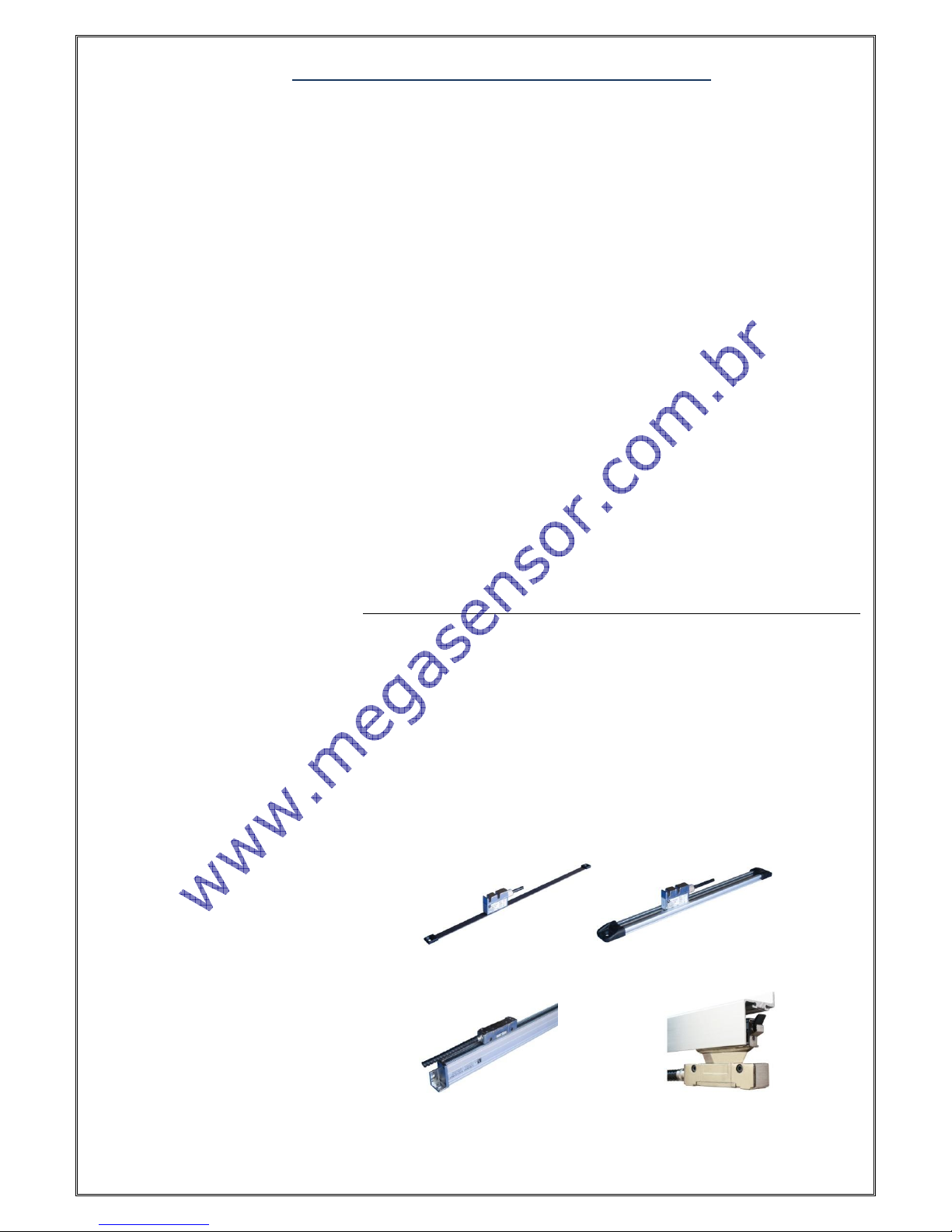

ATEK advice you 4 different magnetic linear encoders:

1. MLS 1 2. MLS 2

3. MLS 3 4. PS 1

[4]

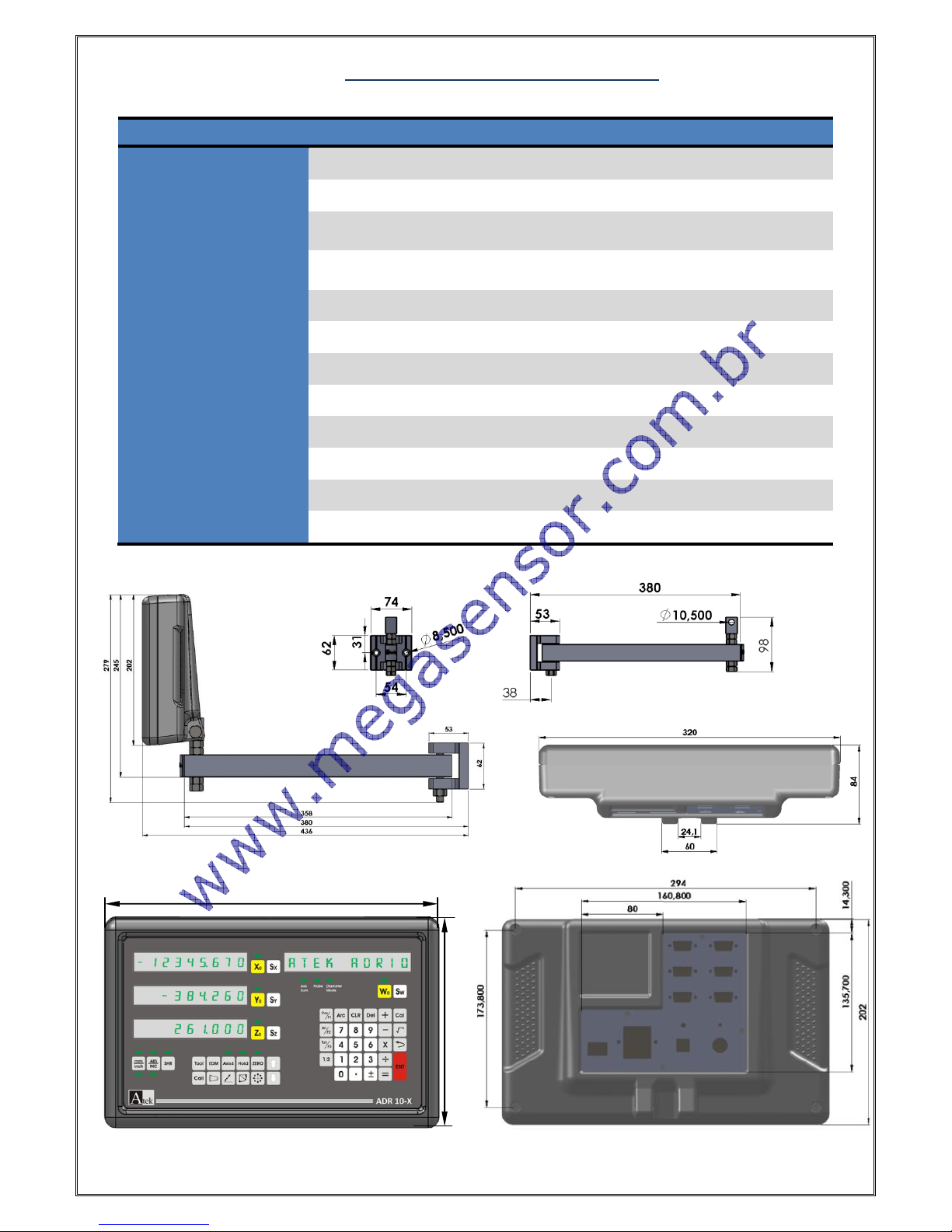

2. TECHNICAL PARAMETERS

TECHNICAL SPECIFICATIONS

Axis Number

2, 3, 4

Display

8 Digit + 1 Sign (-) Digit, Green, Touring (-) Sign

Display Resolution

0.1 µm, 0.2 µm, 0.5 µm, 1 µm, 5 µm, 10 µm, 25 µm

Or the user can designate as requested.

Input Signal

Available Push Pull or TTL

A,B,Z (Line Driver A, B, Z, /A, /B, /Z) Incremental Encoder Signals

Mass

2,7 Kg

Power Supply Voltage

85 – 265 V AC 50/60Hz.

Storage Temperature

- 25 ~ 65 °C

Operation Temperature

-10 ~ 45 °C

Relative Humidity

%20 - %85

Dimensions

( H x W x T )

202mm x 320mm x 84mm

Housing

Aluminum Injection Housing

Diameter Limits

- 99999,999 mm ~ 99999,999 mm

320

202

[5]

Metric / Inch

measurement selection

Absolute / Incremental

Mode Selection

Shrink

X Axis Zero Button

Y Axis Zero Button

Z Axis Zero Button

W Axis Zero Button

X Axis Selection

Y Axis Selection

Z Axis Selection

W Axis Selection

Addition

Multipication

Substraction Button

Division

Square Root Button

Equal

ENTER

Sign Changing Button

½ Function Button

Divisor

4 Axis Activation

Button

Calculator

-

Numeric Buttons

Undo

Sleep Mode

X Axis

(Axis 1)

Y Axis

(Axis 2)

Z Axis

(Axis 3)

Info Screen

and W axis

(Axis 4)

Cosinus Function

Sinus Function

Tangant Function

Tool Enter Button

(Lathe)

Screen Renew Ratio and

EDM Function

User Zeros

Recall (lathe)

Trape Angle and

Eccentricity Measurement

Bolt Hole Line

Radius Functions

Travelling Button

Clear Button

Delete

Arc Trigonometric

Function

Decimal Point button

[6]

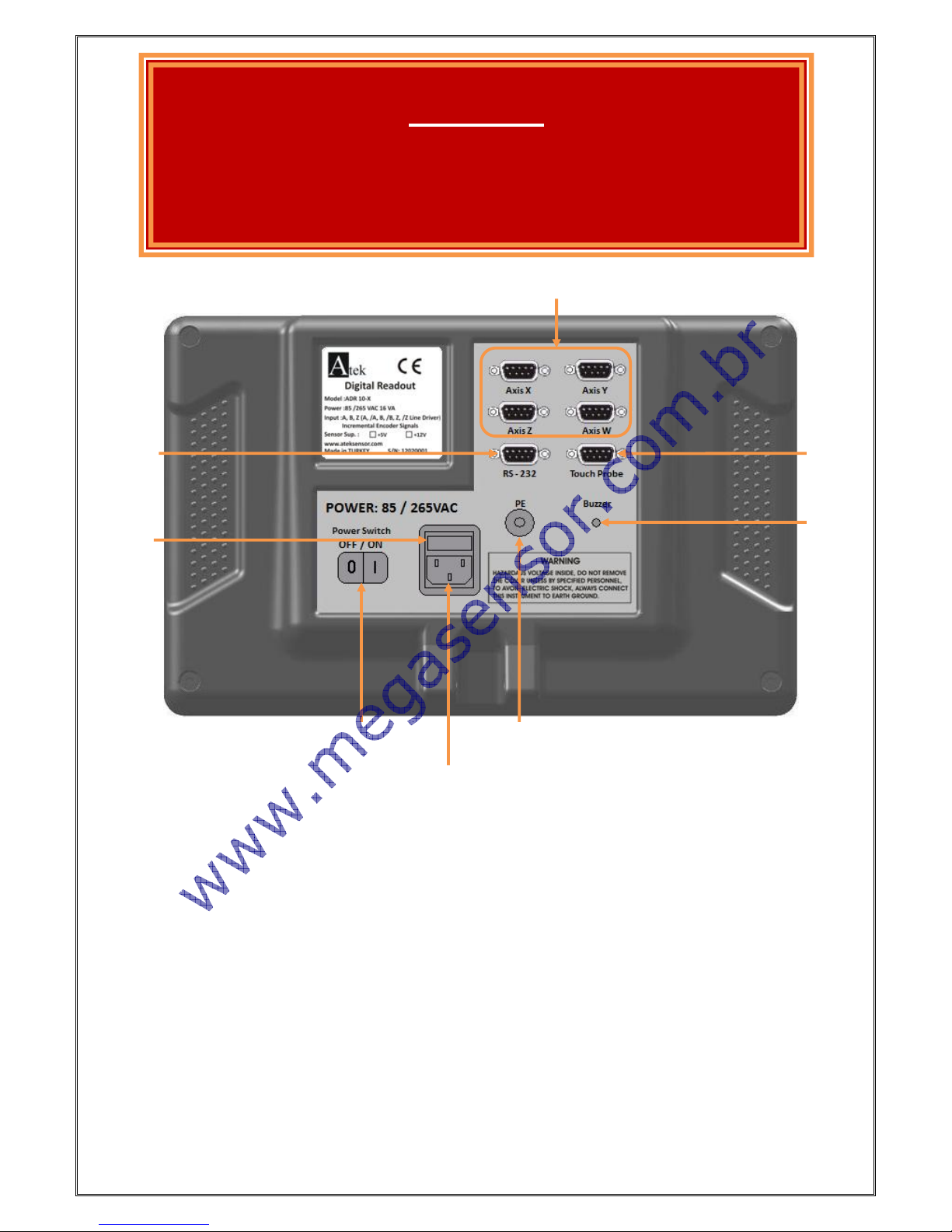

While Connection;

Never Make Connection Under Energy.

Check the On / Off Switch is “Off”.

Check the power voltage if convenient values.

Use only the power cable which is given with the product.

Check the grounding connections.

Don’t use in strong magnetic field.

Don’t use in high temperature and humidity environments.

Install the display as vertical in the high which user can use the keyboard and see the screen.

Note: 4 Axis ADR 10-4 Type DRO Gear Panel Wiev.

Contact

Probe

connection

Encoder

Connection

RS -232

Connection

Ground

Connection

Buzzer

Voice

Power Cable

Connection

On / Off

Switch

1A Insure

WARNING!

While installation of the device please switch all

machine energy off and fallow the manual directions.

[7]

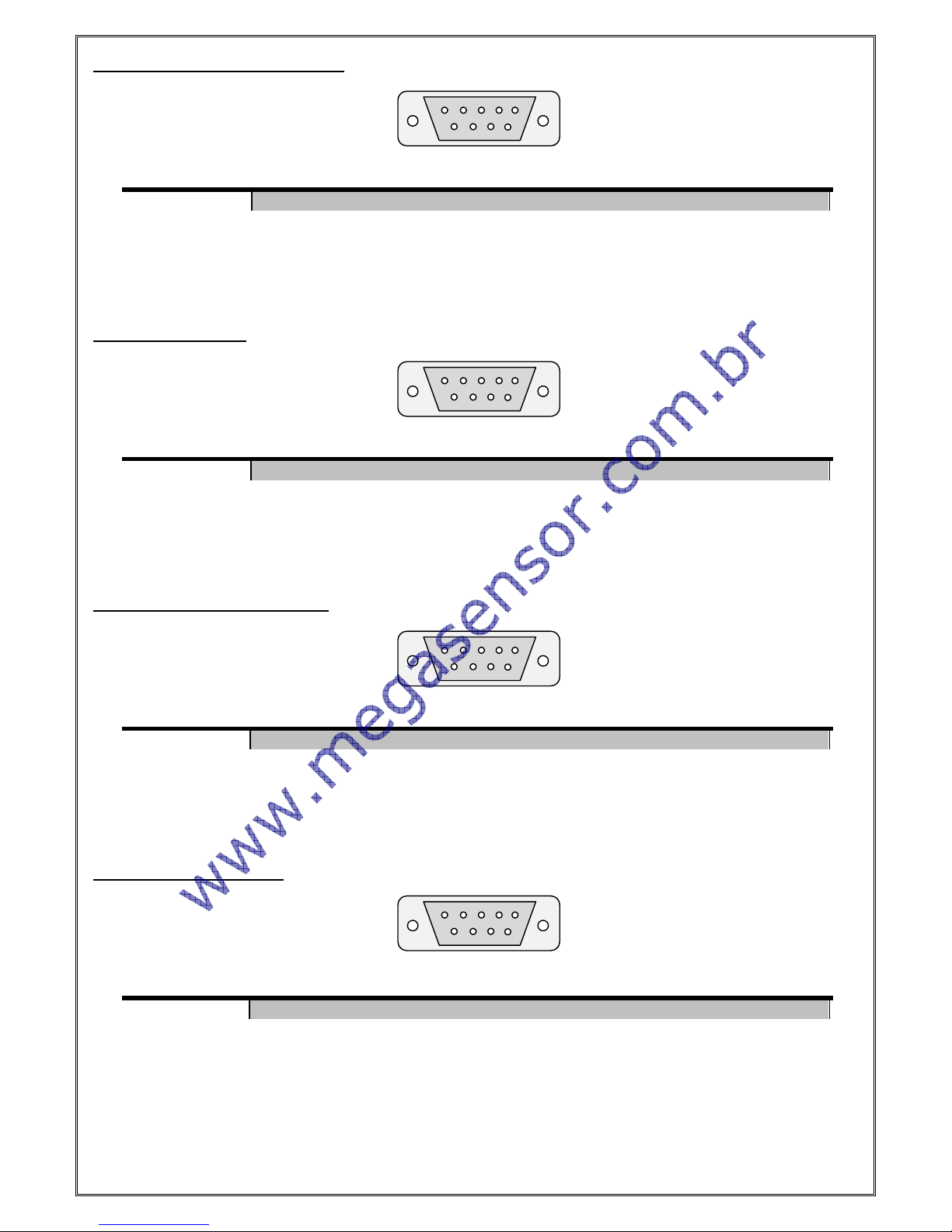

Encoder Connections (Differential)

Encoder Connections

RS – 232Output Port Connection

Contact Probe Connection

Note: While using single contact probe “Signal-” pin must be empty.

Pin Number

1 2 3 4 5 6 7 8 9

Signal

A

/B

+V

0V

/A B /Z

Z

Shield

Pin Number

1 2 3 4 5 6 7 8 9

Signal

A

Empty

+V

0V

Empty

B

Empty

Z

Shield

Pin Number

1 2 3 4 5 6 7 8 9

Signal

Empty

Rx

Tx

Empty

0V

Empty

Empty

Empty

Shield

Pin Number

1 2 3 4 5 6 7 8 9

Signal

Empty+

Empty

+V

0V

Signal-

Empty

Empty

Empty

Shield

1 2 3 4 5 6 7 8 9

1

2 3 4

5

6 7 8

9

1

2 3 4

5

6 7 8

9

1 2 3 4 5 6 7 8 9

[8]

3. SYSTEM SETUP

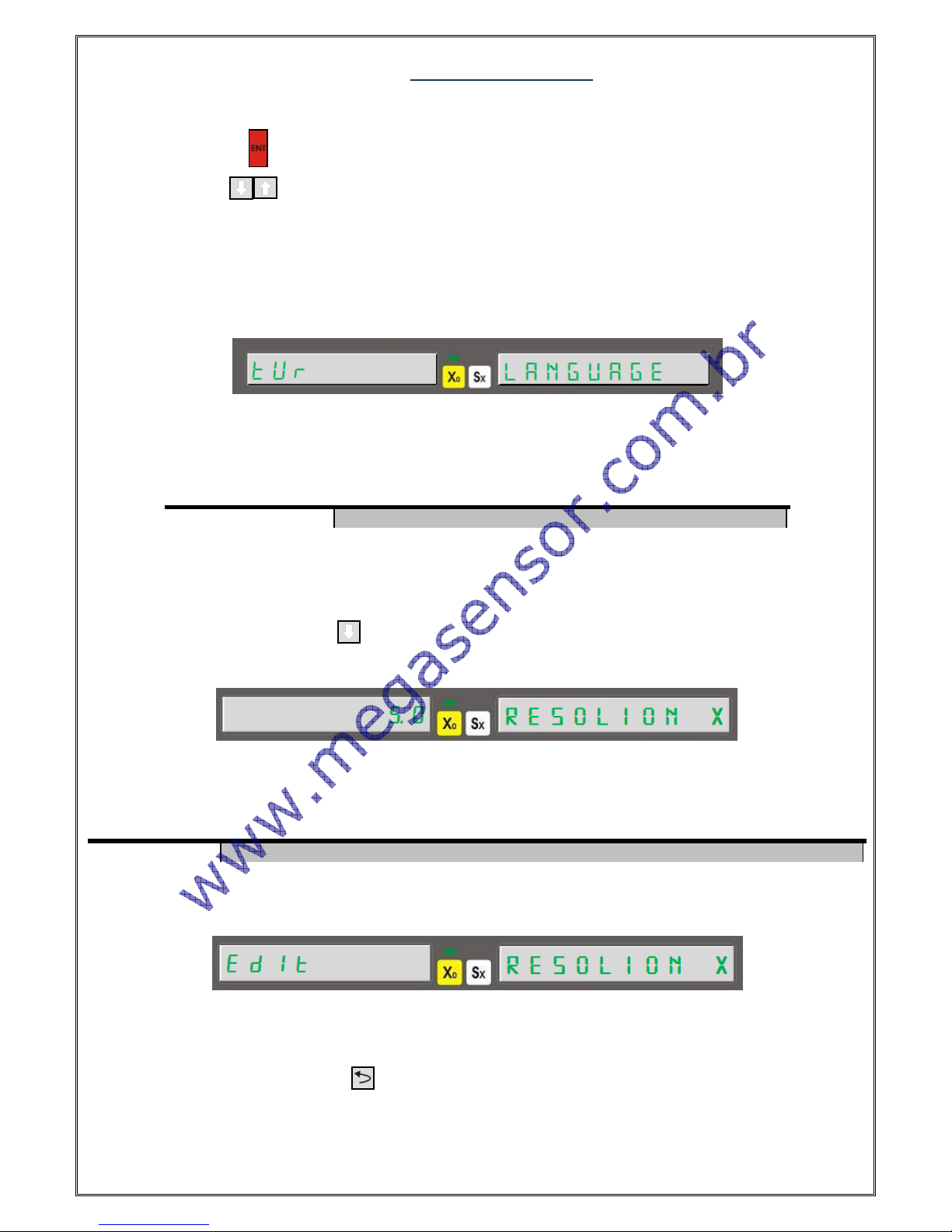

To enter system setup, when ADR-10 first energized (power connections completed and on/off switch turned “on”)

press “ENTER” button ( ) for a while. You will see “LANGUAGE” word as first when you are in system setup menu.

For MENU traveling buttons can be used.

3.1. Language Selection

It is the first selection of system setup. The numeric buttons can be used for language selection.

In data display “LANGUAGE” and in X axis display language options are written. Language selection can be done by

numeric buttons. After selection please press “ENTER” to save.

3.2. Resolution Setup

After selection language, by pressing button you can enter the resolution setup for X axis. The included

resolution options are displayed as first.

In data screen “RESOLION X” words are seen while the resolution value is seen on X axis. To save the resolutions

please press to enter.

* “9” button is used for user determinate resolution.

To enter user determinate resolution after pressing “9” button please press “ENTER” button. To enter a value press

“Sx” button and enter the resolution value and press enter to save.

You can turn to system setup menu by button.

For the other axes you can repeat the same operation for resolution setup.

Numeric Button

0 1 2 3 4

Language Option

Turkish

English

German

Spanish

Portuguese

Numeric Button

0 1 2 3 4 5 6 7 8

9

Resolution

5 µm

1 µm

2 µm

10 µm

25 µm

0,1 µm

0,2 µm

0,5 µm

*

[9]

Using 4th Axis For Angle Display

For angle measurement with 4th axis (W axis) when you are in “RESOLION W” please press “9” button and press

“ENTER” to enter the pulse number of the encoder. Press “ENTER” again to save. After this in “ADVANCED” menu “W

TYPE” option must be select as 1 – rotary. “ADVANCED” menu will be told detailed in the fallowing pages.

3.3. Direction Setup

It determinates the measuring direction according to encoder movement direction.

For positive measuring direction press “1” button. You will see “1” value in X axis. For negative measuring

direction, please press “0” button. “-1” value will be seen on X axis. Press “ENTER” to save.

You can repeat the same buttons for the other axes.

3.4. Machine Tool Selection

This menu is used to select the type of the machine tool which Digital Readout used on.

Please press “ENTER” button after machine tool selection.

3.5. Compansation Selection

Compansation selection is setup by system setup menu.

By up-down button the “COMPNSTN” writing is found please select linear compensation by “0” button and select

segmented compensation by “1” button. Save the selected compensation by pressing “ENTER” button.

3.6. Advanced Settings

You can receive to Advanced Settings by “ System Setup” menu.

After seeing “ADVANCED” writing press “ENTER” to enter the menu.

Numeric Button

0 1 2 3 4

Machine Type

Milling

Lathe

Grinding

Bohrwerk

Spark

Erosion

[10]

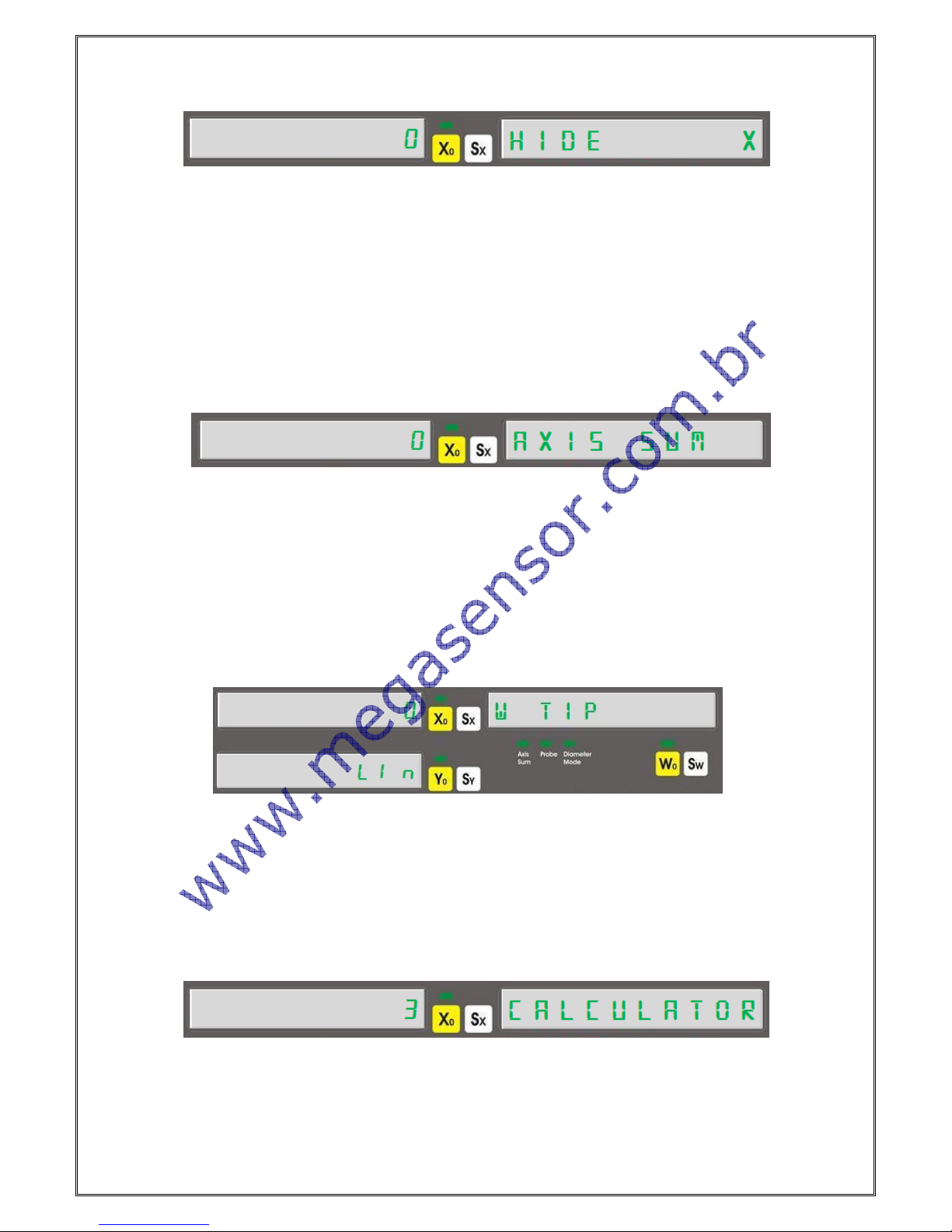

3.6.1. Digit On-Off

It is in the “Advanced Setting” menu.

You can determine the closed digit number by “Hide X” menu . You can close digit numbers up to 5 digits. Please

enter the digit number which will be closed by keyboard and press “ENTER” to save

Please repeat the same way for the other axes.

3.6.2. Axis Addition

Only for lathe and bohrwerk machine tools the axis addition can be used.

You can use this option by “Advanced Setting”

by“1” button you can active and “0” button you can passive. On lathes it adds and Z axis. On bohrwerk machine tools

it adds Z and W axis.

In this menu if addition is active, on lathes Z axis , on Bohrwerks W axis can’t be change by manuel.

3.6.3. 4. Axis Type

The encoder type which will be used on 4. axis means W axis must be enter.

If a rotary encoder will be used press “1” button. On X axis “1” writing and on Y axis “rot” writing will be seen. If a

linear encoder will be used “0” button must be pressed. On X axis “0” writing and on Y axis “Lin” writing will be seen.

3.6.4. Calculator Decimal Setup

This menu determines the decimal number of the calculations on the calculator.

3 or 4 digits can be seen after point. The decimal number can be enter by keyboard. After press “ENTER” to save the

value.

[11]

3.6.5. Probe Logic Level Setup

It can be needed to change according to used probe.

If there is a signal after probe contact (High-Active) must change as “1”, if there is no any signal (Low-Active) must

be change as “0”. Press “ENTER” to save.

3.6.6. Buzzer Close

Buzzer voice can be closed by this menu.

It can be closed by “1” button and can be opened by “0” button.

3.6.7. Return to Factory Settings

It is used to reset all functions changes.

In the menu to return factory settings please press to “Enter” button. “SURE” writing is seen. Press again to

“ENTER”. “WAIT” writing is seen and after a while it turns to fabric setup.

3.7. Test

In system setup menu the device can be tested. You can make display, eeprom test, CPU test, and Relay Test.

Press “Enter” button to enter the menu.

3.7.1. Display Test

It exist in test menu. It can be active by “ENTER” button.

After pressing “Enter” button it clicks all the LED and display segments. Only “Probe” LED can’t be test. To stop the

testing press button.

[12]

3.7.2. Eeprom Test

If Eeprom Works correct when you press “ENTER” button you will see “1” writing.

3.7.3. Keyboard Test

It exist in test menu. You can active it by “ENTER” button.

After activation you have to see different number by for each pressed buttons. To turn back press button.

3.7.4. CPU Test

When you press “Enter” button CPU data can be seen.

On X axis, it shows drawer speed in Hertz unit, on Y axis drawer flash memory in Byte unit , on Z axis RAM in byte

unit.

3.7.5. Relay Test

By pressing “Enter” button this test can be done.

For each “ENTER” pressing the relay will be push and pull.

[13]

4. Basic Functions

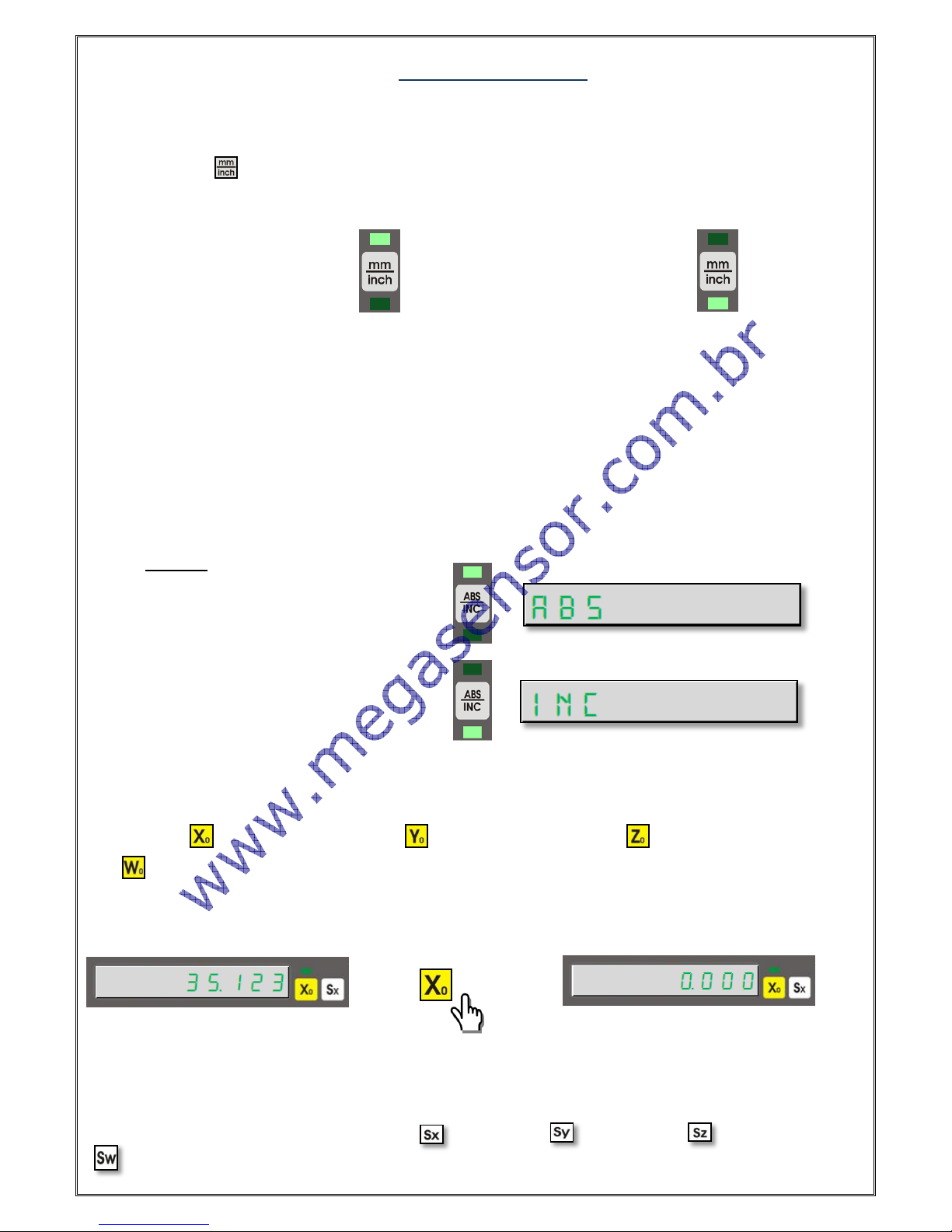

4.1. Measurement System Change

By the button on the keyboard the measurement unit as Metric or Inch system can be selected.

Fort his operation button is used. For each pressing the measurement system is changed. The used

measurement systems can be transfer to the user by LED’s.

Example:

Using Metric Measurement System Using Inch Measurement System

4.2. Operation Mode Selection

Operation Mode can be selected by ABS/INC button on the keyboard. 2 different coordinate display systems are

supported.

- Absolute Operation Mode

- Incremental Operation Mode

For each pressing the operation mode is changed. The used measurement system is transfer to user by

LED’s. In the same time it is showed on data display.

Example:

Using Absolute Operation Mode

Using Incremental Operation Mode

4.3. Quick Zero Axis Values

Axis values can be zero by the zero buttons of the ach axes.

To zero X axis button is used, To zero Y axis button is used, to zero Z axis, button is used and to zero W

axis button is used.

Example: To zero X axis;

4.4. Manuel Value Setting for Each Axis:

It is used to setting value to the axes as manuel.

The axis which will be value setting should be selected by the “Axis Selection Button, the value should be set and

ENTER button should be pressed. To select X axis , to select Y axis to select Z axis and to select W axis

nx button should be pressed and enter is pressed.

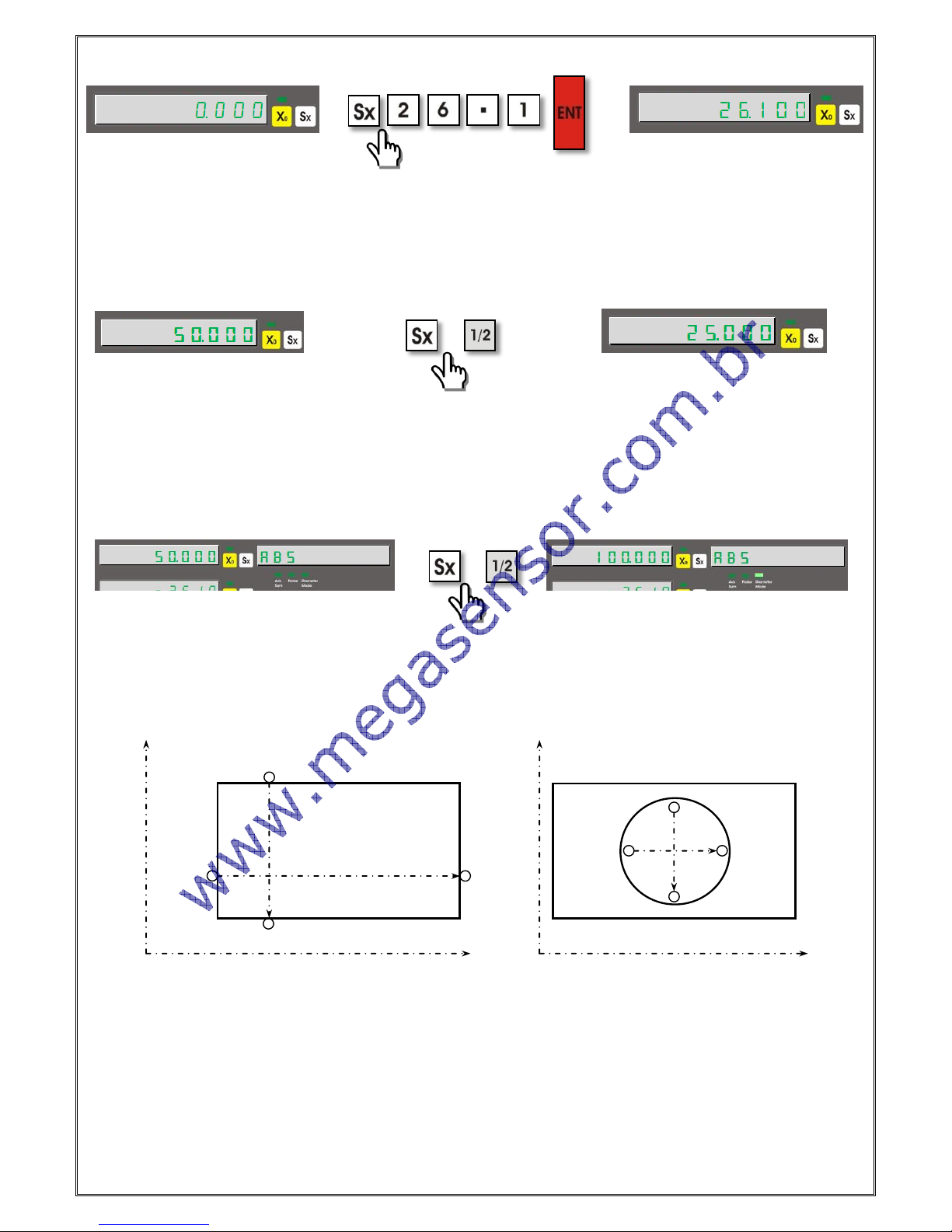

[14]

Example: To setting 26.100 mm for X axis;

4.5. Setting Half Value of The Display Value (Milling, Bohrwerk)

With the included keyboard you can get the half value of the axis you want. Firstly the select the axis which you want

to get half value and press ½ function button.

Example: To get half value of the X axis which shows 50.000;

4.6. Diameter Mode (Lathe):

With this mode, designed for lathe machines the measured value is showed as 2 times. It is valid on X axis. To

activate this function X axis is selected and½button is pressed. When the function is active “Diameter Mode” LED

signs.

Example: On X axis which shows 50.000 value to activate diameter mode;

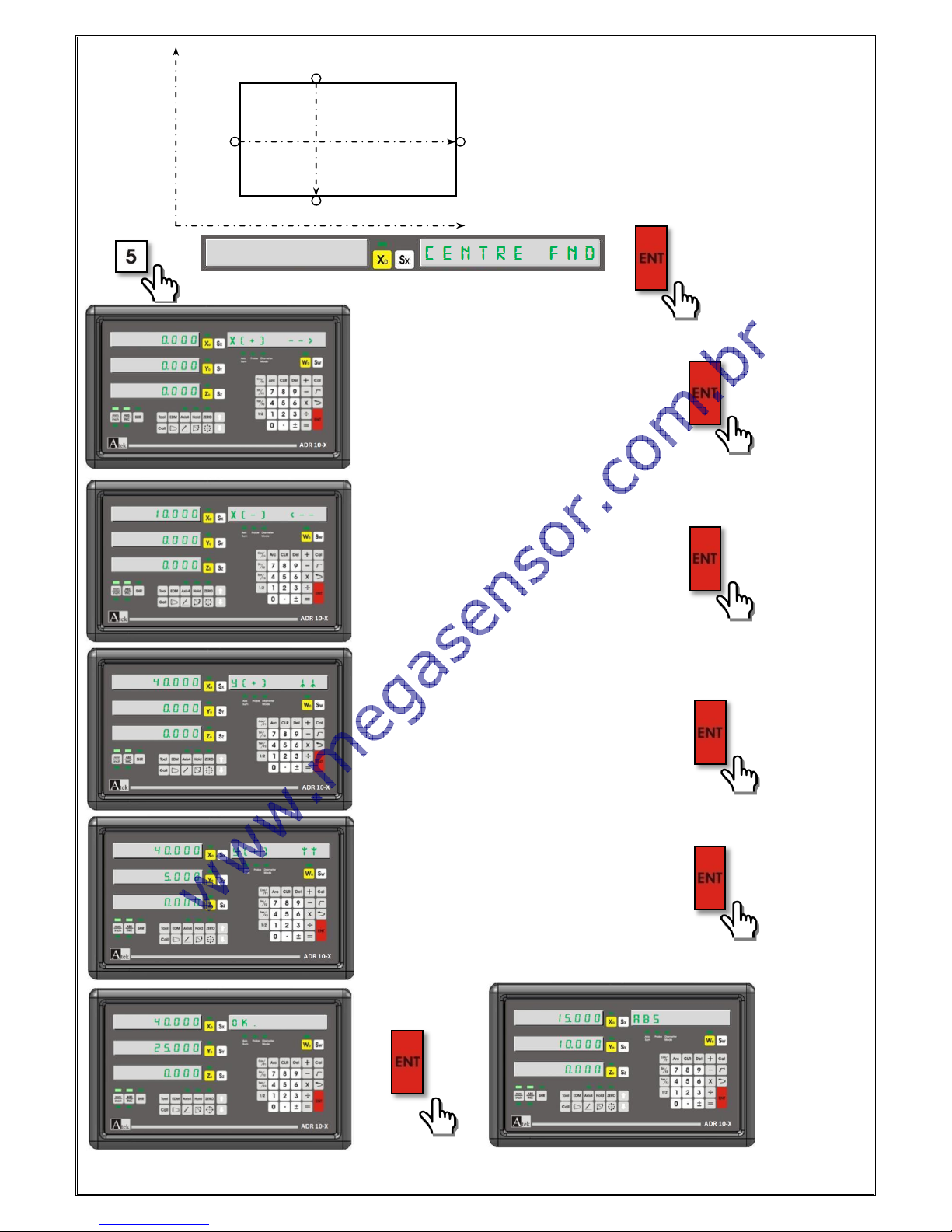

4.7. Center Find (Milling, Bohrwerk)

It is used to find centre of the work piece on XY plane according to teached points. The 4 point of the work piece

must be teached.

Please press “5” button and press enter to enter the function. Contact the tool edge on the first point on X axis as

“Position 1” and press enter to save. Contact the tool edge on Point 2 for position 2 and press enter. For 3 point

contact the tool edge to Point 3 on Y axis for position 3 and press enter. As last contact the tool edge for Point 4 and

press enter to save. You will see “OK” writting on the screen. When you press enter you will see the coordinates to

find the centre by moving. When you move the table up to make zero the coordinates you will be found the centre.

X

Pozisyon 4

Pozisyon 3

Pozisyon 1

Pozisyon 2

Pozisyon 4

Pozisyon 3

Pozisyon 1

Pozisyon 2

X

Y

Y

[15]

Example:

When you move up to reset axis value zero you can find the centre of the work piece.

To find the centre of the drawing on the

left.

Position 4

Position 3

Position 1

Position 2

Y

Tool edge is bringed to

“Position 1”

Tool edge is bringed to

“Position 2”

Tool edge is bringed to

“Position 3”

Tool edge is bringed to

“position 4”

[16]

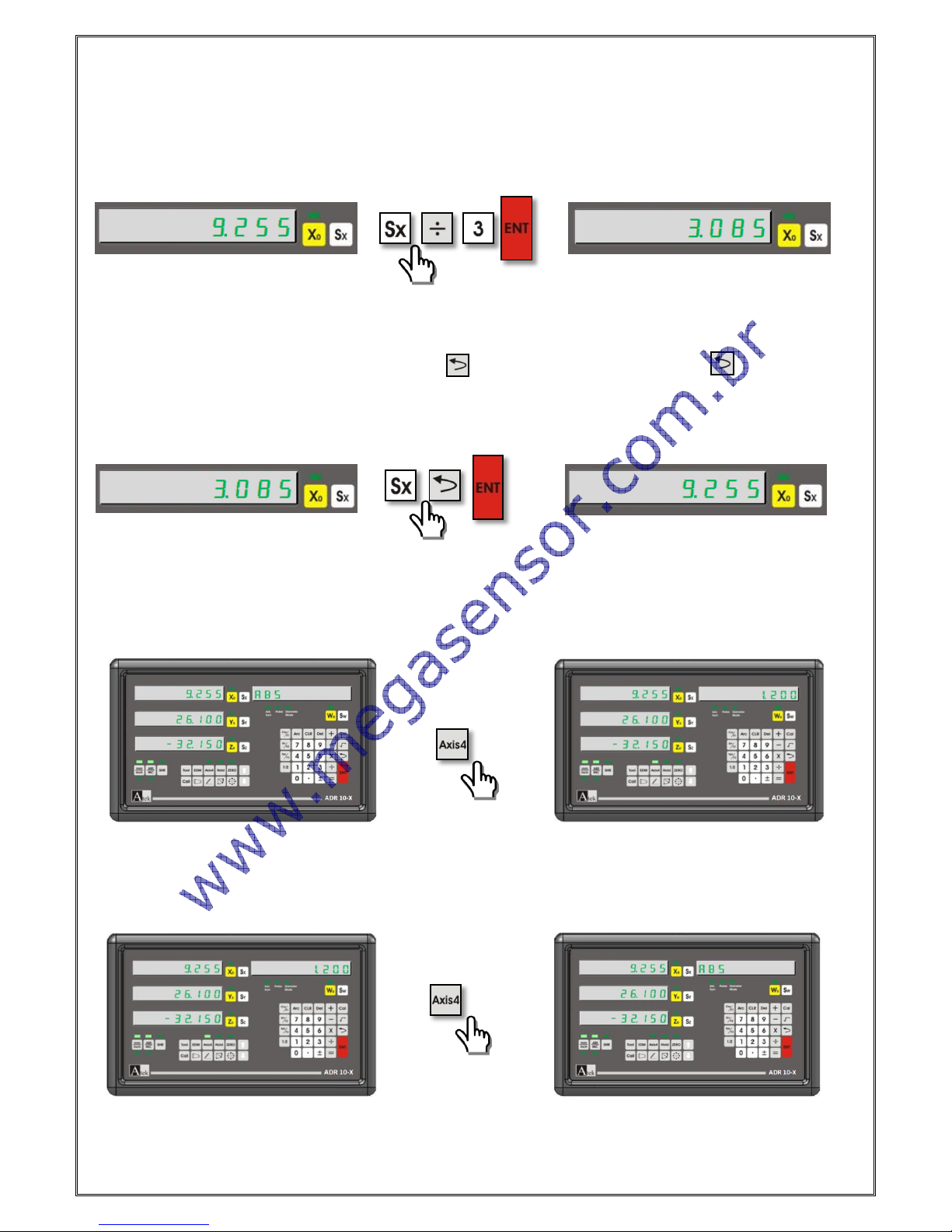

4.8. Simple Calculation on Axis Values:

It is possible to make simple calculation as addition, subtraction, division and multiplication on axis values. It can be

done without activation of calculator. Firstly the axis which the calculation will be done must be selected. Press the

calculation button (+,-,/,* ). And then;

Example: To divide by 3 the X axis value;;

4.9. Undo Function

After transferring the axis value as manuel or after making simple calculations to return the last value this function is

used. For this function firstly select the axis and press button and press enter. If you press button again you

will be canceled the operation.

Example: To turn to old values on X axis;

4.10. Activate the 4th Axis

In 4 axis digital readouts you can activate or deactivate the 4th axis. The axis 4 button is used for this operation

Example: To activate the 4th axis;

Example: To deactivate the 4th axis;

[17]

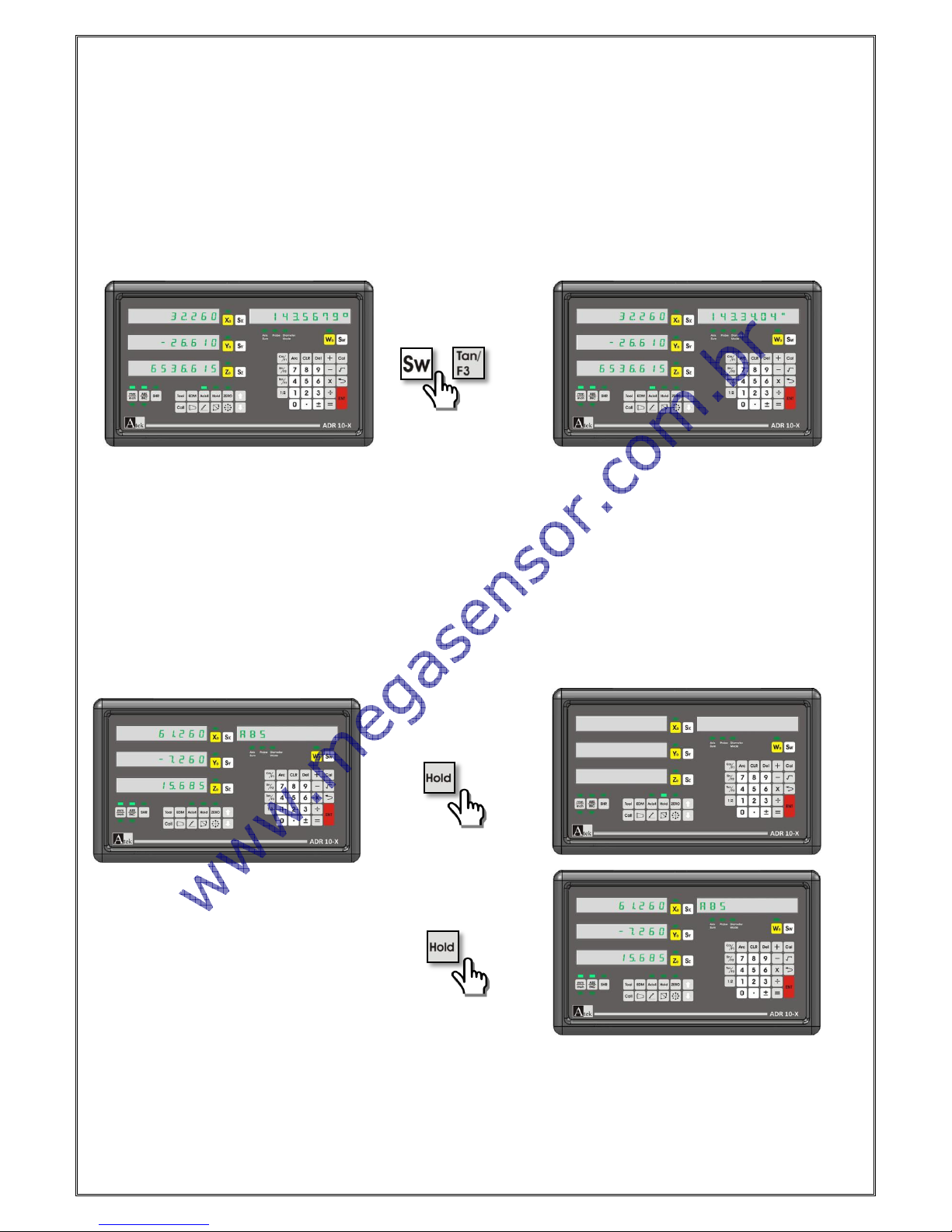

4.11. Display Angle on the 4th Axis

To display angle on 4th axis by “system setting“menu the encoder pulse number must be entered as W resolution.

And again by “system setting “menu, rotary type must be selected. You can also see the this setting on system

setting as detailed.

The angle can be set as Degree or Degree.minute.second. To make passing please press “Sw” button and “Tan/F3”

button accordingly.

Example: To Change Degree Angle as Degree.minute.second;

4.12. Sleep Mode:

When the screen is on sleepy mode all the buttons are turned off except “HOLD” button. By this way 3th Person

interfere will be prevented. Although the buttons are turned off, the signals will be process. If you change the table

place it senses this changing and if in the normal mode it use the last position.

In the brake times and after works the device can be sleepy mode until beginning to work again.

You can pass “Sleepy Mode” by “HOLD” button and it is possible to exit by the same “HOLD” button.

Example: To pass to “Sleepy” mode and to exit;

[18]

5. ADVANCED FUNCTIONS

5.1. To Find Zero Point of the Machine Tool

It is used not to lost time by measuring the work pieces one by one. The zero point will not be deleted after energy

cuttings. But for the high accuracy it will be better to revise for each new starts.

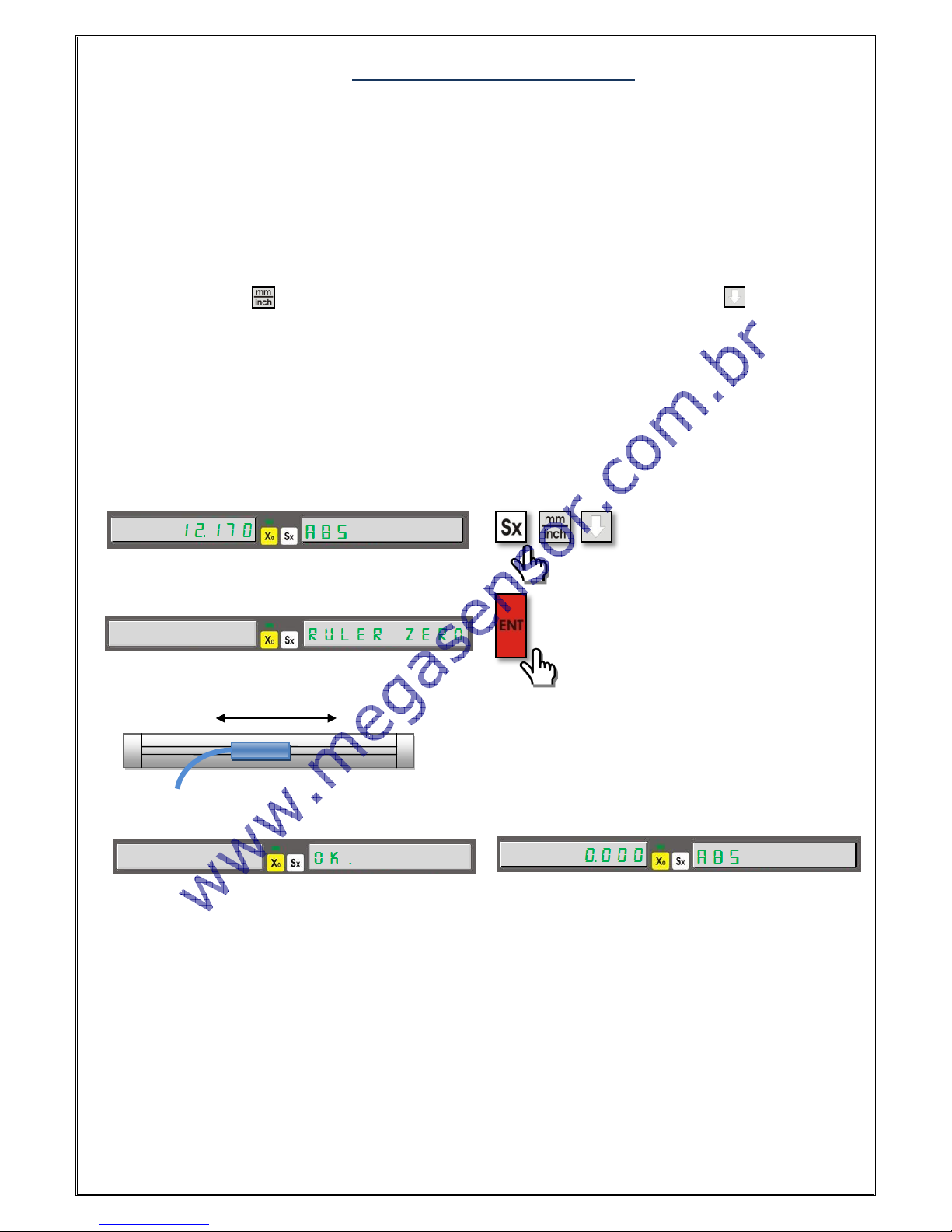

5.1.1. Ruler Zero Point: To set the ruler zero press the button which selects the axis and press the

button . You will see the compensation screen. To pass this screen press button. On the

information Screen you will see the “RULER ZERO” writing. Please press enter and move the scale to

see “OK” writing on the screen and you will exit in one second from the function.

Example: To find ruler zero point on X axis;

The zero point will be found by these steps.

Move the scale to find the zero point

[19]

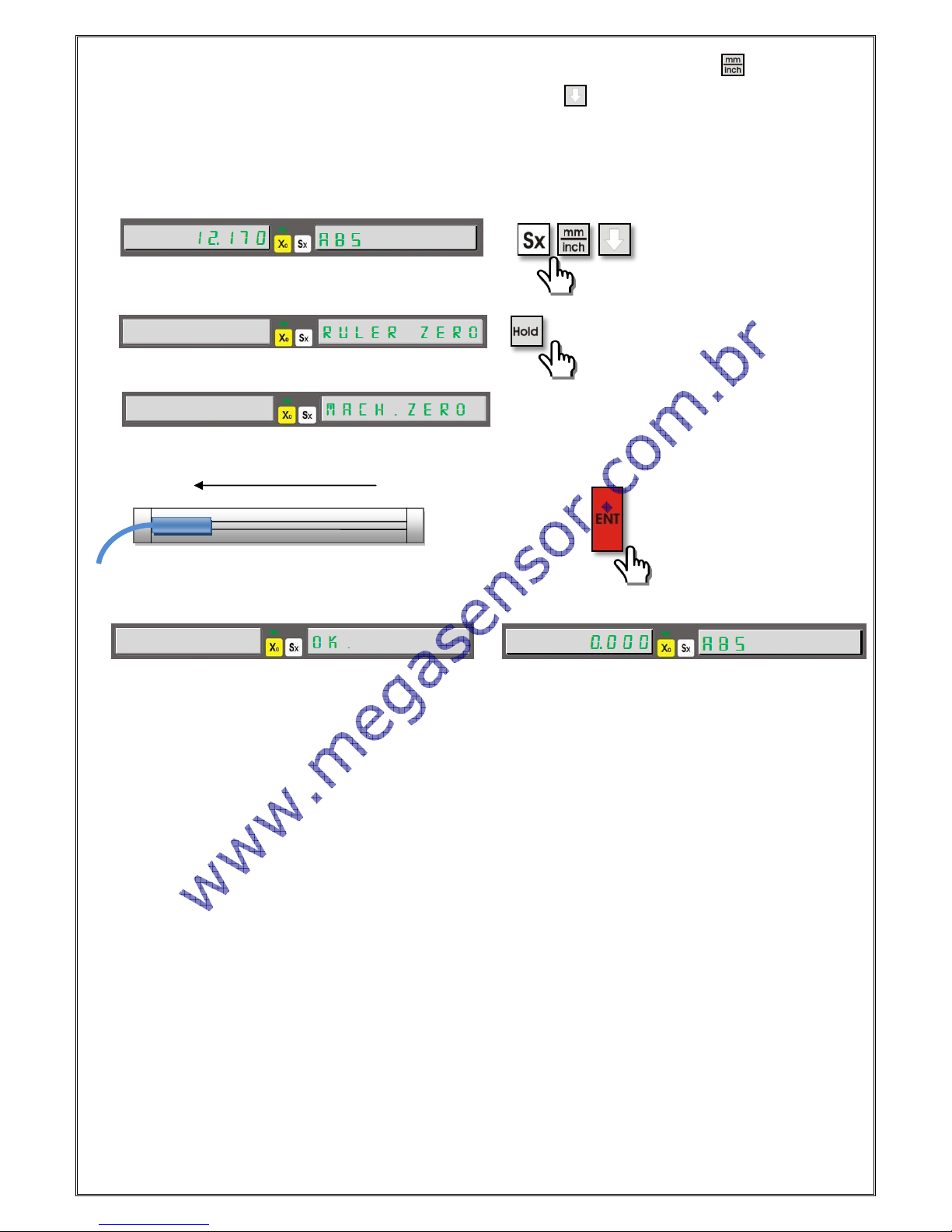

5.1.2. Mechanical Zero Point: Please select the axis which will be zero and press button. You will

see the compensation screen. To pass please press button. When you see “RULER ZERO”

writing press “HOLD” button. Then you will see “MACH. ZERO” writing. Move the scale the end point

of left side and press “ENTER” to save.

The mechanical zero point will be found by these steps.

Move the

scale to end

of left side

Loading...

Loading...