Page 1

P3

Micro-Measurements

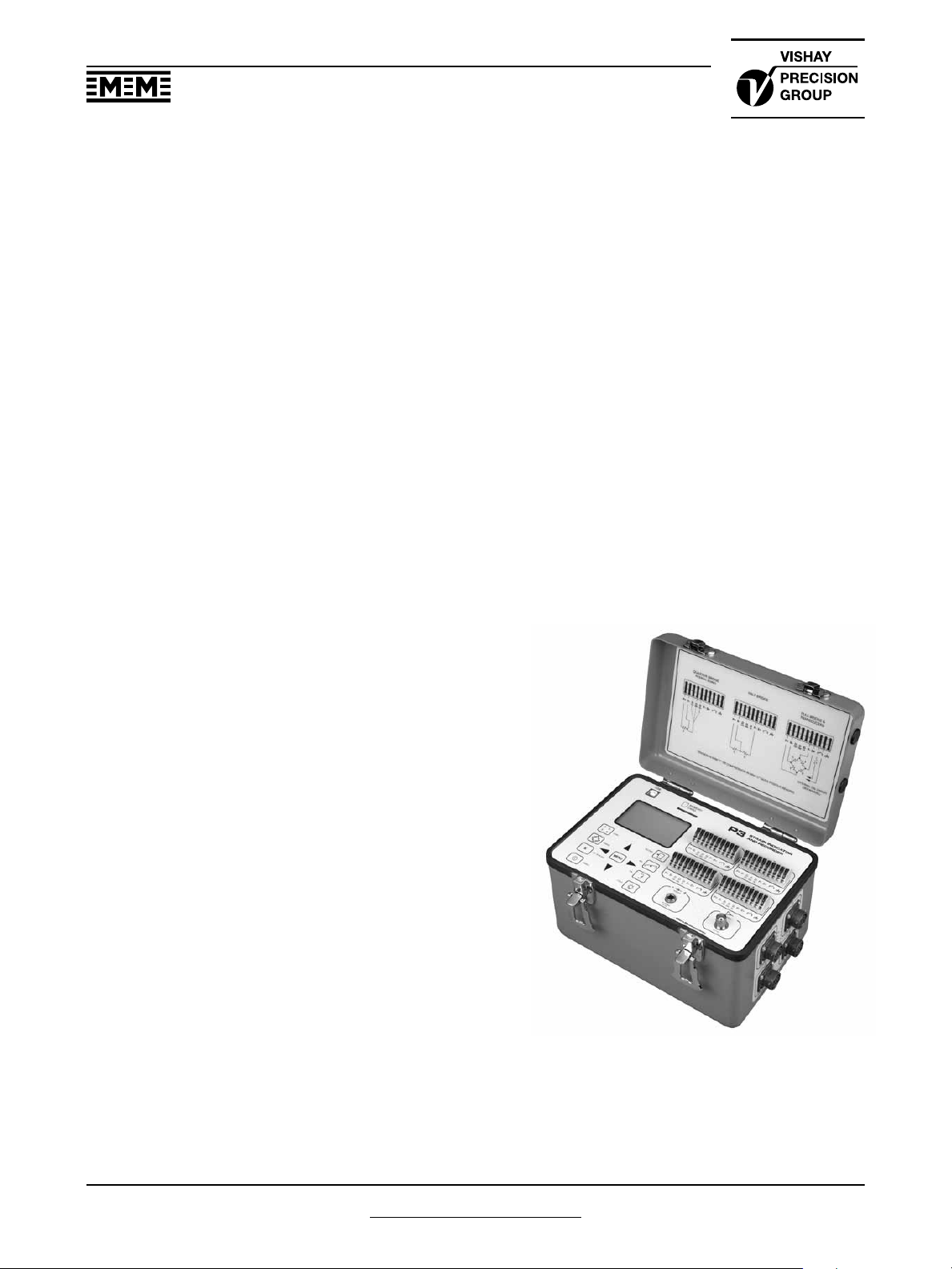

Strain Indicator and Recorder

FEATURES

• Four input channels

• Direct reading LCD display

• On-board data storage

• 0 to 2.5 VDC analog output

• Quarter-, half-, and full-bridge circuits

• Built-in bridge completion

• 120-, 350-, and 1000-ohm dummy gages

• Automatic zero-balancing and calibration

• Intuitive, menu-driven operations

• USB data link

• Operation from keypad or PC

• Portable, lightweight, and rugged

• Battery, USB, or line-voltage power

• Optional 10-pin transducer connectors

DESCRIPTION

The Model P3 Strain Indicator and Recorder is a portable,

battery-operated instrument capable of simultaneously

accepting four inputs from quarter-, half-, and fullbridge strain-gage circuits, including strain-gage-based

transducers. Water-resistant grommets in the hinged

cover allow the lid to be closed with leadwires attached.

Designed for use in a wide variety of physical test and

measurement applications, the P3 functions as bridge

amplifier, static strain indicator, and digital data logger.

The Model P3 Strain Indicator and Recorder, utilizing a

large LCD display for readout of setup information and

acquired data, incorporates many unique operating

features that make it the most advanced instrument of

its kind. An extensive, easy-to-use menu-driven user

interface operates through a front-panel keypad to readily

configure the P3 to meet your particular measurement

requirements. Selections include active input and output

channels, bridge configuration, measurement units, bridge

balance, calibration method, and recording options,

among others.

Standard sensor input connection is via eccentric-leverrelease terminal blocks. Optional transducer connection

is available via side-mounted bayonet locking circular

connectors.

Data, recorded at a user-selectable rate of up to 1 reading

per channel per second, is stored on a removable flash

card and is transferred by USB to a host computer for

subsequent storage, reduction and presentation with the

supplied software.

The P3 can also be configured and operated directly from

your PC with a separate software application included

with each instrument. Additionally, a full set of ActiveX

components is provided for creating custom applications

in any language supporting ActiveX.

A highly stable measurement circuit, regulated

bridge excitation supply, and precisely settable gage

factor enable measurements of ±0.1% accuracy and

1 microstrain resolution. Bridge completion resistors of

120, 350 and 1000 ohms are built in for quarter-bridge

operation. Also, input connections and switches are

provided for remote shunt calibration of transducers and

full-bridge circuits.

The P3 operates from two readily available D cells.

Battery life depends upon mode of operation but ranges

up to 600 hours of continuous use for a single channel. It

can also be powered by connection to an external battery

or power supply, a USB port on a PC or with an optional

external line-voltage adapter, the Model P3-A105.

www.micro-measurements.com

6

For technical questions, contact

micro-measurements@vishaypg.com

Document No.: 11102

Revision: 06-May-2011

Page 2

Micro-Measurements

Strain Indicator and Recorder

P3

P3

HARDWARE SPECIFICATIONS

All specifications nominal or typical at +23°C unless

noted.

Inputs

Eccentric-lever-release terminal blocks accept up to four

independent bridge inputs. Accommodates 16-28 AWG

(1.3 to 0.35 mm diameter) wire.

The Transducer Option includes four 10-pin bayonet

locking circular connectors mounted on the side of the

case and wired in parallel to the lever-release terminal

blocks. The supplied mating connector has a 0.046 inch

(1.17 mm) diameter solder well.

Bridge Configurations

Quarter-, half-, and full-bridge circuits. Internal bridge

completion provided for 120Ω, 350Ω and 1000Ω quarter

bridges, 60 to 2000Ω half or full bridge.

Display

Full dot-matrix structure with 128 dots x 64 dots FSTN

positive, gray transflective LCD with backlight. Display

update is twice a second.

Data Conversion

High-resolution sigma-delta converter. 60 Hz or 50 Hz

noise rejection. User selectable.

Basic Range

±31,000 microstrain (±1 microstrain resolution) at Gage

Factor = 2.000

Accuracy

±0.1% of reading ±3 counts. (Normal mode operation at

Gage Factor = 2.000)

Gage Factor Settings

Range 0.500 to 9.900

Balance

Single key operation to initiate automatic software

balance

Bridge Excitation

1.5 VDC nominal. Readings are fully ratiometric, and not

degraded by variation in excitation voltage

Communication Interface

Universal Serial Bus with type B connector. Used for

transferring stored data and firmware.

Data Storage

Media: Removable Secure Digital or Multimedia Card

(2GB max).

Data Recording Rate: 1 reading per second

maximum.

Calibration

Shunt calibration across each dummy resistor to simulate

5000 microstrain (±0.1%). Remote calibration supported

via accessible switch contacts at input terminal block.

Analog Output

BNC connector. 0 to 2.5V maximum output. Device

impedance of 2000Ω or greater. 480 samples/second

DAC output update rate.

Power

Internal battery pack using two “D” cells. Battery life up

to 600 hours (single channel, normal mode.) Can also

be powered from USB or by external battery or other

power source of 6 to 15 VDC. AC adapter optional

(Model P3-A105).

Operational Environment

Temperature 0 to + 50°C. Humidity up to 90% RH,

noncondensing

Document No.: 11102

Document No.: 11102

Revision: 06-May-2011

Revision: 06-May-2011

For technical questions, contact

micro-measurements@vishaypg.com

www.micro-measurements.com

7

Page 3

P3

Micro-Measurements

Strain Indicator and Recorder

FIRMWARE FEATURES

Display Update Rate

2 readings per second

Recording Rates

Up to 64 data files

Automatic recording

1 reading every 1 to 3600 seconds

Individually selectable per channel

Manual recording

Automatic date/time stamping

Scaling

Automatic scaling for microstrain, based upon gage

factor, with nonlinearity correction based upon bridge

type

Automatic calculation of mV/V

Linear scaling for other engineering units

Units

με

mV/V lbf m deg

psi lb s rad

ksi kg A oz

GPa in N mV

MPa mm V m/s

Pa mil Ohms ton

Bridge Types

Quarter bridge

Half bridge, adjacent arms, equal and opposite strains

Half bridge opposite arms equal strains

Shear bridge, 2 active arms

Poisson half bridge

Full bridge 4 fully active arms

Shear bridge, 4 active arms

Full bridge, Poisson gages in opposite arms

Full bridge, Poisson gages in adjacent arms

Undefined full bridge

Undefined half bridge/quarter bridge

g rpm hp

2

Software Adjustable Contrast

Operating Modes

Normal mode

Analog output (any one of four channels)

Data Link

USB interface

Windows-based P3 software provided for control and

data storage

No device driver required (treated as an HID device)

Real-time Clock

System Calibration/Verification

Requires Model 1550A Strain Indicator calibrator or other

compatible calibrator

Calibration date stored in flash memory

Firmware Upgradeable

View Showing

Optional Transducer

Input Connectors

Bridge Balance

Automatic

Manual offset adjust

Disabled (Raw offset)

Backlight Control

Programmable on time while in run mode

5, 15 or 60 seconds

Manual off/on

If illuminated, backlight will remain illuminated while

operating menus

www.micro-measurements.com

8

For technical questions, contact

micro-measurements@vishaypg.com

Document No.: 11102

Revision: 06-May-2011

Page 4

Legal Disclaimer Notice

Legal Disclaimer Notice

Vishay Precision Group

Disclaimer

ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their

behalf (collectively, “Vishay Precision Group”), disclaim any and all liability for any errors, inaccuracies or

incompleteness contained herein or in any other disclosure relating to any product.

The product specifications do not expand or otherwise modify Vishay Precision Group’s terms and conditions of

purchase, including but not limited to, the warranty expressed therein.

Vishay Precision Group makes no warranty, representation or guarantee other than as set forth in the terms

and conditions of purchase. To the maximum extent permitted by applicable law, Vishay Precision Group

disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and all liability,

including without limitation special, consequential or incidental damages, and (iii) any and all implied

warranties, including warranties of fitness for particular purpose, non-infringement and merchantability.

Information provided in datasheets and/or specifications may vary from actual results in different applications

and performance may vary over time. Statements regarding the suitability of products for certain types of

applications are based on Vishay Precision Group’s knowledge of typical requirements that are often placed on

Vishay Precision Group products. It is the customer’s responsibility to validate that a particular product with the

properties described in the product specification is suitable for use in a particular application.

No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or by

any conduct of Vishay Precision Group.

The products shown herein are not designed for use in life-saving or life-sustaining applications unless otherwise

expressly indicated. Customers using or selling Vishay Precision Group products not expressly indicated for use

in such applications do so entirely at their own risk and agree to fully indemnify Vishay Precision Group for any

damages arising or resulting from such use or sale. Please contact authorized Vishay Precision Group personnel

to obtain written terms and conditions regarding products designed for such applications.

Product names and markings noted herein may be trademarks of their respective owners.

Document No.: 63999

Document No.: 63999

Revision: 27-Apr-11

Revision: 27-Apr-11

www.vishaypg.com

1

Loading...

Loading...