Page 1

NEw

®

OPTALIGN

Laser shaft alignment that meets your needs

PLUS

Series

From the Inventors of

Laser Shaft Alignment

Page 2

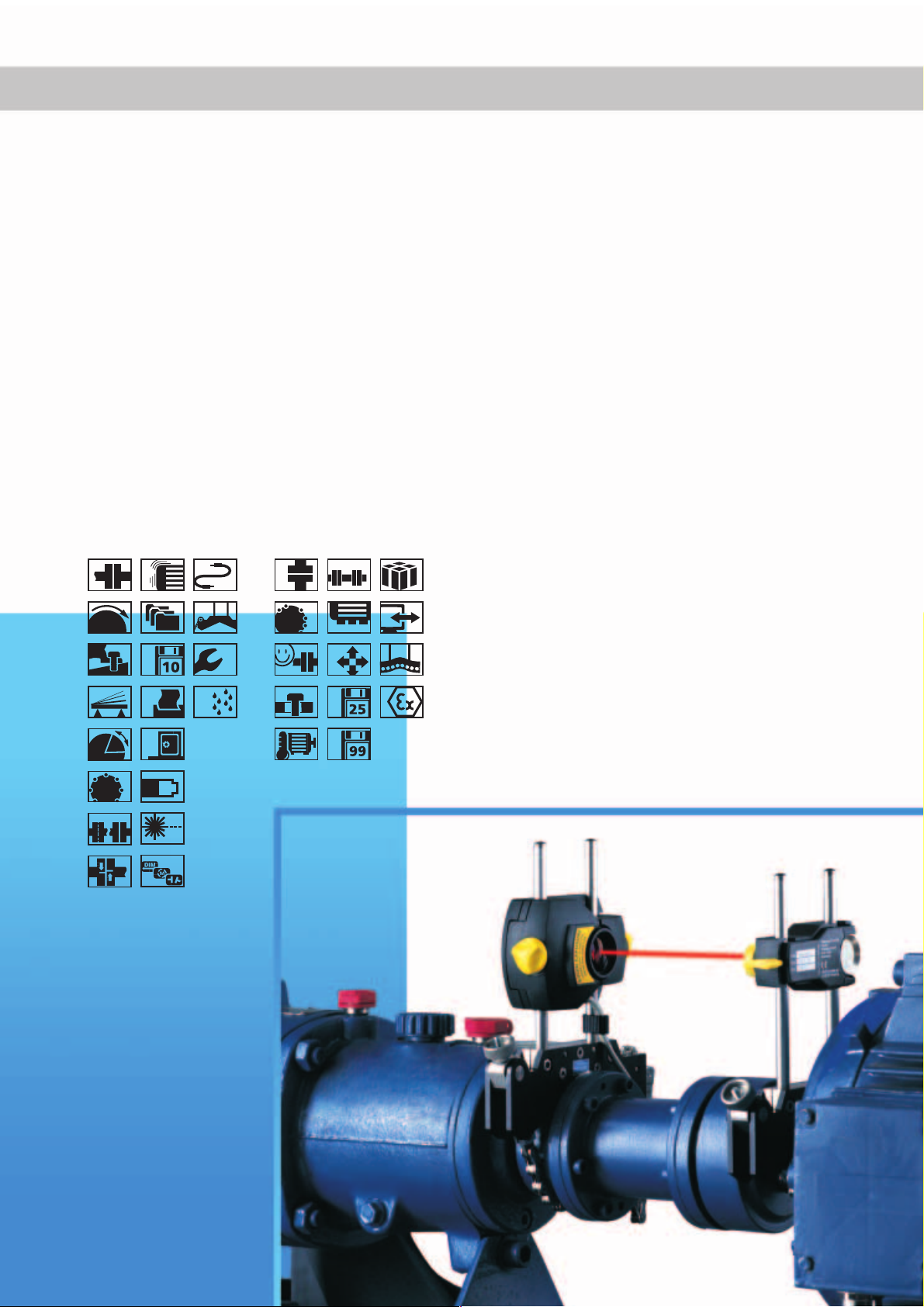

Match your requirements

with OPTALIGN® PLUS Series

Precise shaft alignment pays. Well

aligned couplings reduce bearing

and seal damage, minimize energy

loss, and reduce production downtime. OPTALIGN® PLUS Series offers both precision alignment and

timesaving convenience of laserbased systems. It gives you the

benefits of a dynamic laser shaft

alignment system without stretching the budget.

What is “Series”?

OPTALIGN® PLUS Series is a concept that allows you to design your

own device by acquiring the exact

features you need. The default entry level has the features necessary

for standard horizontal shaft alignment. As job demands grow, additional user benefits can be purchased, enhancing capabilities at

any time.

default features increased benefits

What’s in it for you?

¥ Configure system as you require

¥ Budget for only what you need

¥ Easy to upgrade with new features

¥ Based on the proven OPTALIGN

¥ Intrinsically safe version available

®

PLUS

¥ 20 years laser alignment expertise

Page 3

Alignment condition

determined with only three keys

3. Results

The alignment condition is

displayed with a smiley,

foot correction values, coupling gap and offset.

2. Measure

The auto start / stop capability allows continuous

shaft rotation to start at any

position – in any direction.

1. Dimensions

Enter machine dimensions

as prompted on the display

using the robust keyboard.

A case full of confidence

Like the components inside it, this

lockable, purpose designed case is

rugged and shock proof. Just the

ideal case for industrial environments.

Page 4

Measurement flexibility

Master alignment challenges

OPTALIGN® PLUS Series uses the

patented EZ-Sweep® which allows

minimum and continuous shaft rotation, and eliminates coupling

play effects. Measurement starts

automatically as the shaft is rotated, eliminating any possibility of

user error.

Loaded features

Aligns horizontal machines

Automatic continous

sweep mode

Measures soft foot and

stores the results

Horizontal & vertical ‘Live

Move’ at any 45° position

Overcomes shaft rotation

restrictions

OPTALIGN® PLUS Series has the

features required for standard

alignment. These features translate

into customer benefits by helping

saving time and drastically

reducing unplanned machinery

breakdown.

Continuous sweep mode

This quick and straightforward

measurement mode is ideal

for standard machines and requires a shaft rotation of as

little as 60°.

Static measure mode

For coupled

and uncoupled shafts

Unaffected by backlash

Variable averaging and

deviation band

Measurement files are reusable and can be edited

Save up to 10

measurement files

Print reports directly or

use the printing software

Resume recalls the last file

if it was not saved

Main and reserve battery

UniBeam® enables quick

laser beam adjustment

Static mode

This measurement mode is

used for nonrotatable and uncoupled shafts. Measurement

requires 3 or more of the 8

available measurement positions.

DIM

M

Simple 3-key operation

Only one cable to connect! Eliminates tangling!

Pre-assembled brackets

for quick mounting

Rugged and robust control unit resists shock

Industrial-strength waterresistant housings

Page 5

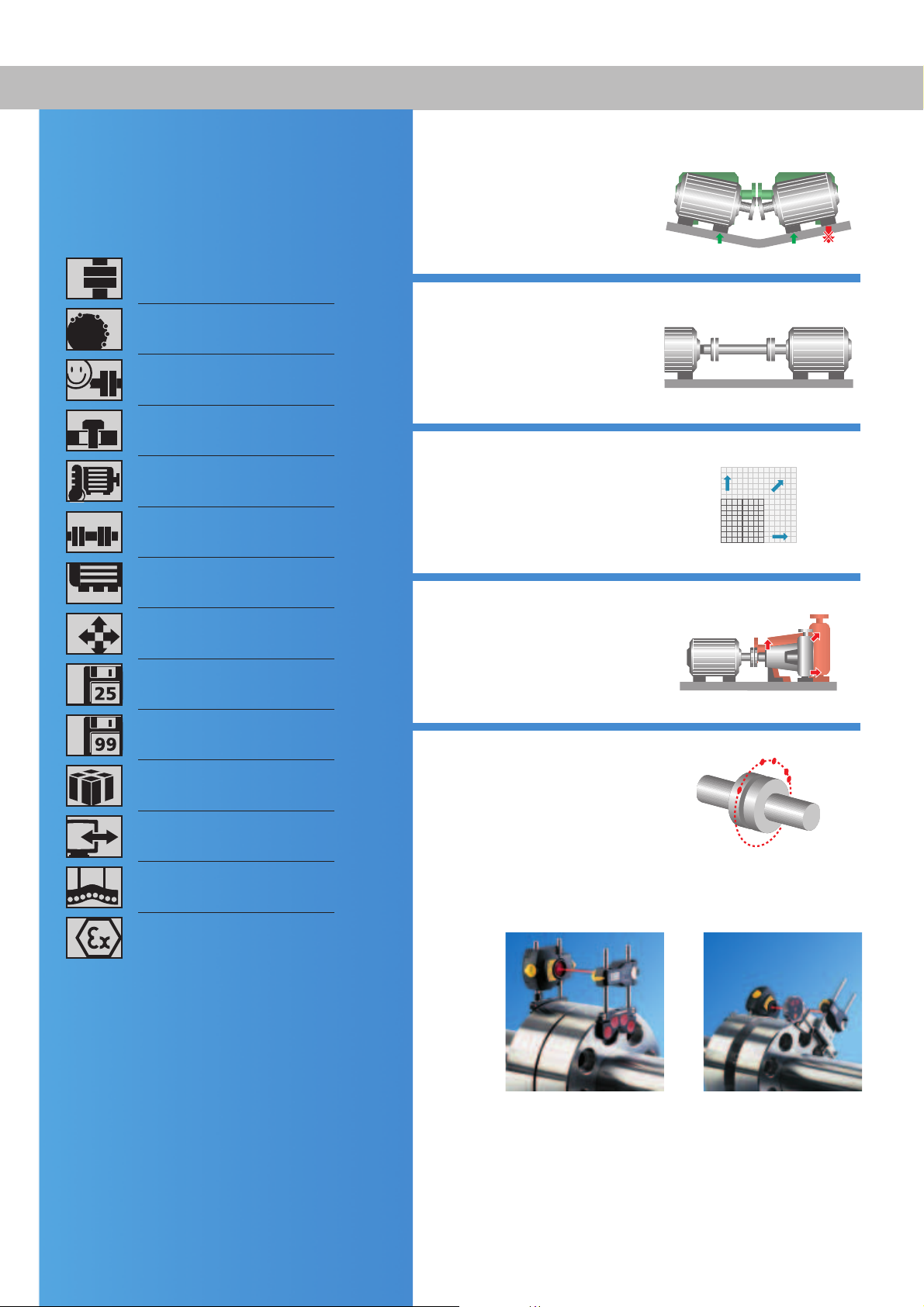

Powerful capabilities

Vertical

machine alignment

Movement restrictions

Problems arising from basebound or bolt-bound feet are

resolved by redefining fixed

feet.

Multipoint mode for

shafts on all bearings

TolChek® determines

alignment condition

Static feet handles movement restrictions

Ability to enter targets

and thermal growth

Ability to select spacer

shaft improving accuracy

Determine alignment condition of 6-foot machines

InfiniRange® extends

measurement range

Save up to 25

measurement files

Save up to 99

measurement files

Acquire all the above

features in one go

OPTALIGN® PLUS Explorer

for full editing capabilities

Choose coupling type

Accuracy of results is ensured

as the type of coupling used is

taken into account and the

true offsets are calculated at

the real coupling planes.

InfiniRange

The detector measurement

area is automatically extended

to allow alignment of grossly

misaligned machines and for

long spans.

Thermal growth

Thermal growth at the feet

and at the coupling can be

input for both machines to

take into account thermal and

dynamic load growth.

Multipoint mode

For shafts that are mounted

on all types of bearings. Measurement requires 3 points or

more at any position over 60°

rotation.

®

Optional brackets for any

application

Intrinsically safe version for

explosive environments

Make OPTALIGN® PLUS Series a

most versatile laser shaft alignment

system by configuring it with useful features that handle thermal

growth, 6-feet machines and vertical machines among others.

A most versatile bracket

The compact magnetic bracket

ALI 2.112 SET mounts quickly

and is straightforward to use.

Its powerful magnets fit onto

nearly any flat coupling surface

enabling rigid mounting in a

matter of seconds. It’s ideal for

machines with large coupling

flanges.

It turns when shafts can’t

When one or both shafts cannot be rotated for measurement, the sliding magnetic

bracket ALI 2.230 comes to the

rescue. It glides around the

outside of the coupling or shaft

end from one measurement

position to the next, providing

an elegantly simple solution.

Page 6

PC software for advance job setup,

archival, reporting

• Supports two-way communication between device and a PC

• Set up alignment jobs in advance

• View alignment results

• Optimise alignment corrections

• Copy measurement files into an

archive

• Print out customised alignment

reports with company logo

• Long names in a tree structure

for company, plant, section and

machine

• Drag and drop files to other

documents, e.g. eMail, MS Word

• Measurement reports in HTML

format can be sent using email

and opened using any browser

OPTALIGN®PLUS Series technical data

Transducer

Measurement principle Coaxial, reflected laser beam

Environmental protection IP 67 (submersible, dustproof)

Ambient light protection yes

Temperature storage -20°C to 80°C / -4°F to 176°F

operating 0°C to 55°C / 32°F to 131°F

Dimensions approx. 107 x 70 x 49 mm

Weight: only about 177g / 6½ oz.

Laser

Laser Ga-Al-As semiconductor laser

Wavelength (typical) 675 nm (red, visible)

Safety class Class 2; FDA 21CFR 1000 and 1040

Beam power < 1 mW

Safety precautions Do not look into laser beam

Detector

Measurement area unlimited, dynamically extendible

Resolution 1 µm

Accuracy (av.)

Inclinometer

Measurement range 0° to 360°

Resolution

Reflector

Type 90° roof prism

Accuracy (av.)

Environmental

protection IP 67 (submersible, dustproof)

Temperature:

storage -20°C to 80°C / -4°F to 176°F

operating -20°C to 60°C / -4°F to 140°F

Dimensions: approx. 100 x 41 x 35 mm

Weight: approx. 65g / 2½ oz.

4 1/4" x 2 3/4" x 2"

(U.S. Patent 6,040,903 )

> 98%

<1°

> 99%

4" x 1 5/8" x 1 3/8"

OPTALIGN® is a registered trademark of PRÜFTECHNIK Dieter

Busch AG. No copying or reproduction of this information, in any

form whatsoever, may be undertaken without express written

permission of PRÜFTECHNIK AG. The information contained in

this leaflet is subject to change without further notice due to the

PRÜFTECHNIK policy of continuous product development.

PRÜFTECHNIK products are the subject of patents granted or

pending throughout the world.

© Copyright 2004 by PRÜFTECHNIK AG.

Control Unit

Display fixed-segment LCD display

Display dimensions approx. 94 x 73 mm / 3 3/4" x 2 7/8"

Keyboard robust, flat, greaseproof keyboard

Environmental IP 65 (water spray resistant, dustproof protection except for sealed battery compartment);

Operating temp. 0°C to 55°C / 32°F to 131°F

Main power supply 6 x 1.5V IEC LR6 ("AA") batteries

Backup power supply 1 x 9V IEC 6LR61 battery

Battery life (alkaline) 25 hours on main batteries plus 3 hours on

Interfaces 1 x sensor; 1 x printer/PC (serial)

Dimensions approx. 145 x 290 x 67 mm

Weight w/o batteries approx. 1.1 kg / 2.4 lb.

Carrying case

Standard ABS, drop tested (2 m / 6 1/2ft.)

Case dimensions approx. 470 x 400 x 195 mm

Weight, including

all standard parts only about 6.8 kg / 15.2 lb.

Options

Intrinsic safety EEx ib IIC T4

Certificate number TÜV 01 ATEX 1730

fully electrically insulated

(even rechargables)

reserve battery - based upon an operating

cycle of 25% measurement, 25%

computation and 50% ‘sleep mode’

5 3/4" x 11 1/2" x 2 3/4"

18 1/2" x 15 3/4" x 7 3/4"

Visit us at www.pruftechnik.com

Printed in Germany ALI 9.567.03.04.0G

PRÜFTECHNIK Alignment Systems

Oskar-Messter-Straße 15

D-85737 Ismaning, Germany

www.pruftechnik.com

Phone: +49 (0)89 99 61 60

Fax: +49 (0)89 99 61 61 00

eMail: info@pruftechnik.com

II 2 G

From the inventors of laser shaft alignment

Loading...

Loading...