Page 1

PHASED ARRAY FLAW DETECTOR

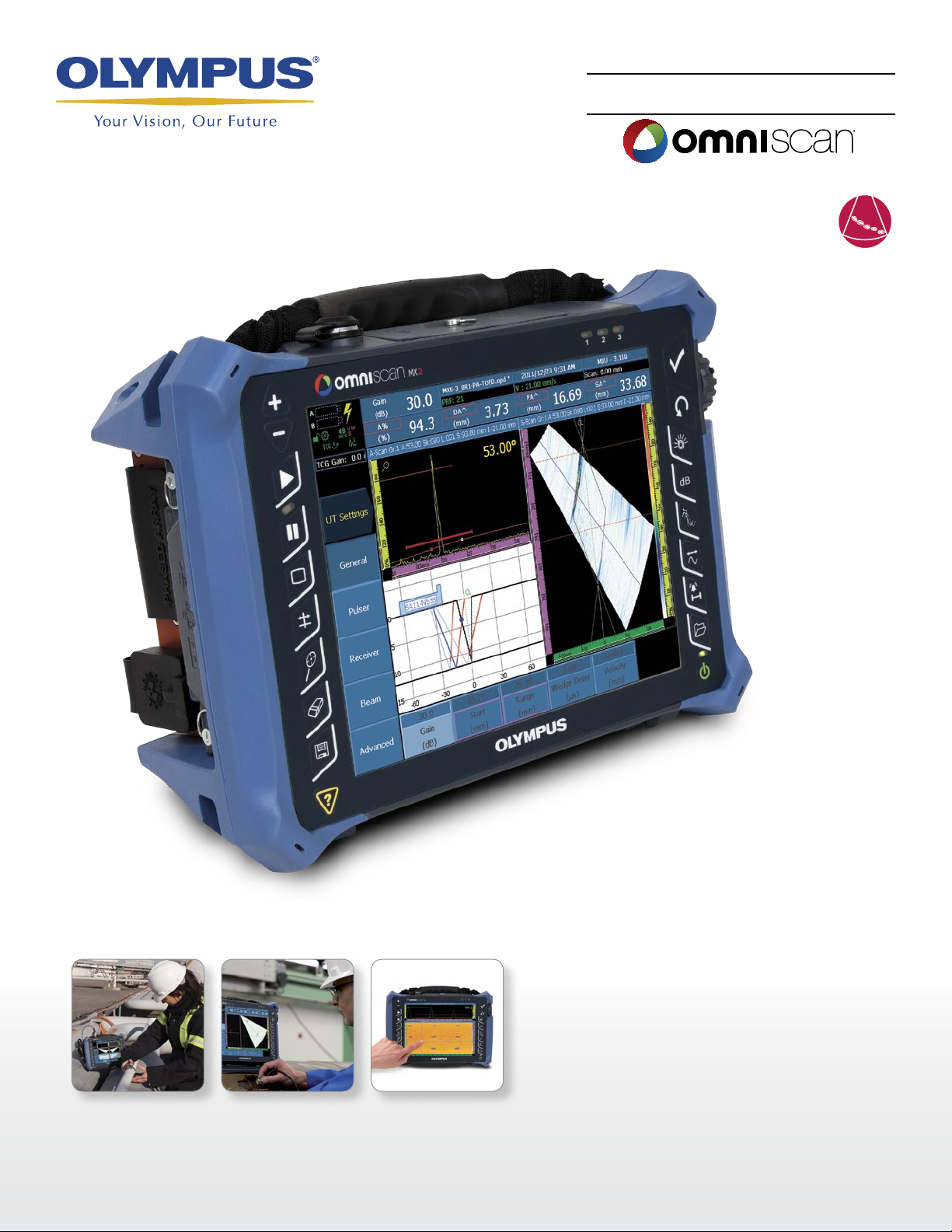

OmniScan® MX2

The Standard in Phased Array, Redefined

• Bright,Large-SizeScreen

• Fast,IntuitiveTouch-Screen

Interface

• AdvancedWeldOverlay

• High-CapacityDataStorage

• FastFileTransfer

• NEWOmniPCAnalysisSoftware

920-218B-EN

Page 2

The Standard in Phased Array, Redefined

The result of over 10 years of proven leadership in

modular NDT test platforms, the OmniScan MX

has been the most successful portable and modular

phased array test instrument produced by Olympus

to date, with thousands of units in use throughout

the world.

Building on a Solid Basis

This second generation OmniScan MX2 increases

testing efficiencies, ensuring superior manual and

advanced AUT application performance with faster

setups, test cycles, and reporting, in addition to universal compatibility with all phased array and ultrasound modules: past, present and future. Designed

for NDT leaders, this high-end, scalable platform

delivers true next-generation NDT performance.

The OmniScan MX2 offers a high acquisition rate

and new powerful software features for efficient

manual and automated inspection performance—

all in a portable, modular instrument.

Faster Is Better!

Powerstart your day the right way with the

OmniScan MX2. The OmniScan MX2 simplifies

and speeds up the setup process with its new Weld

Overlay software feature, so you can start testing

immediately. Featuring the industry-standard phased

array user interface with faster-than-ever performance, a bigger and brighter 10.4in. screen, new

and unique intuitive touch-screen capabilities, and

faster data transfer, enabling you to get to your next

inspection quicker.

More Rugged than Ever

The OmniScan MX2 is now designed for IP66, and

built to withstand the drops, spills, and abuse that

typically occur in the most demanding inspection

environments.

More than an Instrument

—A Solution Provider

The OmniScan MX2 is an important part of your

inspection solution, and can be combined with

other critical components to form a complete

inspection system. Olympus offers a complete

product range that includes phased array probes,

scanners, analysis software, and accessories, all

of which are integrated and packaged into rapidly

deployable, application-specific solutions for quick

returns on your investment. In addition, Olympus

offers a high-quality calibration and repair service

worldwide, which is backed by a team of phased

array application experts to ensure that you get the

support you need.

2

www.olympus-ims.comwww.olympus-ims.com

Page 3

Life-Size OmniScan MX2

3

Page 4

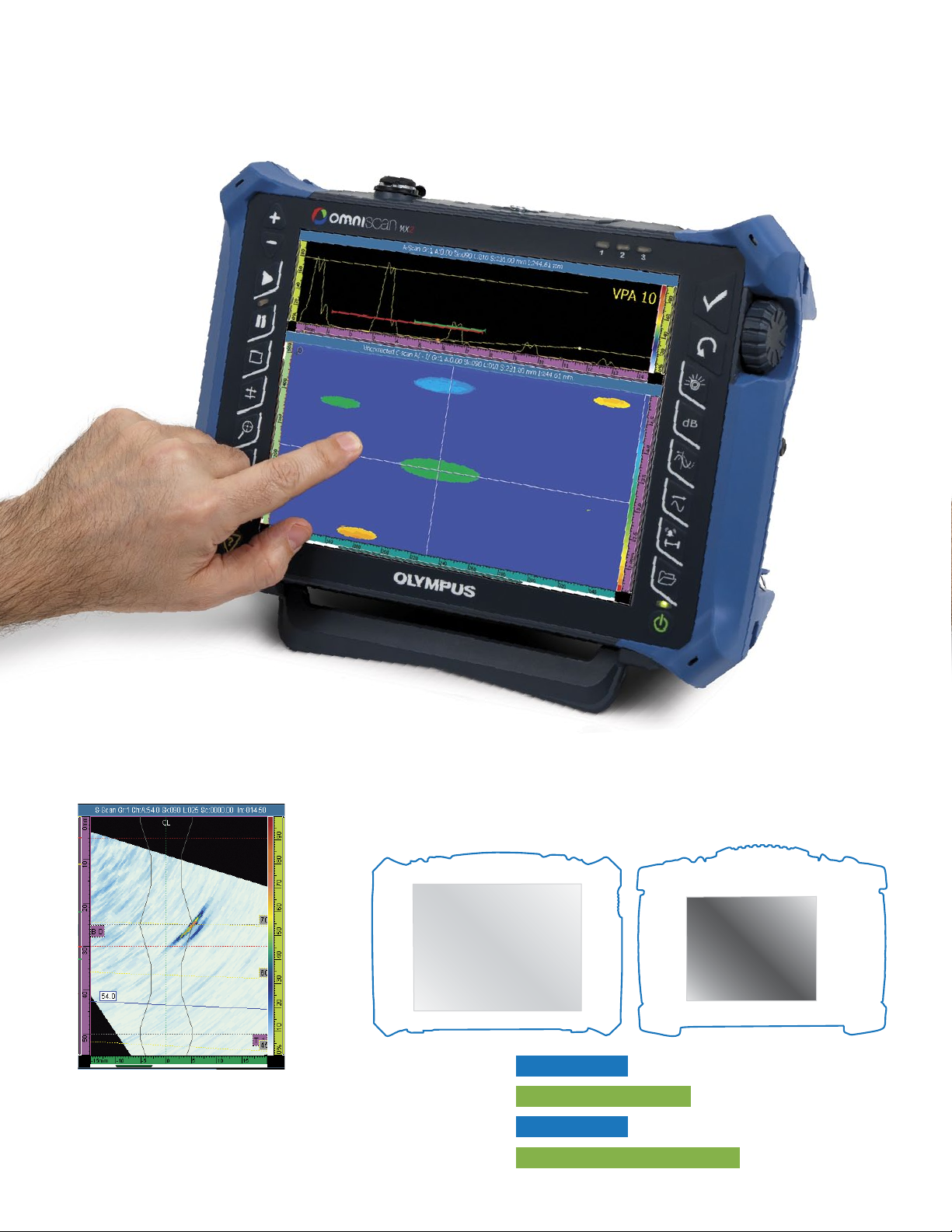

Touch-Screen Interface

The revolutionary touch-screen interface offers simple and quick navigation, enhanced

text input functions, and easier, faster cursor control and gate setup.

Full-Screen Mode

The unique full-screen mode offers operators increased viewing comfort, in addition to better readability at a distance.

This feature can be used in both acquisition and analysis mode.

Bright 10.4 in. Screen

OmniScan MX

Weld Overlay Wizard

The Weld Overlay Wizard facilitates the

creation of industry-standard weld overlays for analysis assistance and volumetric

flaw placement.

OmniScan MX

OmniScan MX2

OmniScan MX

OmniScan MX2

OmniScan MX2

50% larger screen

100% brighter screen

4

www.olympus-ims.comwww.olympus-ims.com

Page 5

Modular Instrument

Backward Compatible. Forward Compatible.

An Evolving Platform for your Growing Needs.

Designed to secure both your current and future phased array investments, the OmniScan MX2 can house any Olympus phased array

module, including the reliable, field-proven models currently available,

and the next-generation modules of the future. Its open architecture also

supports future software updates and phased array module upgrades with

configurations from 16:64M to 32:128 to ensure that your instrument

evolves with your testing needs, and that you get the most from your

investment.

Module Compatibility OmniScan MX2 OmniScan MX

OMNI-M-PA1664M

OMNI-M-PA1664

OMNI-M-PA16128

OMNI-M-PA32128

OMNI-M-PA32128PR

OMNI-M-PA3232 (200V)

OMNI-M-UT

OMNI-M-ECT/ECA

Software Compatibility

MXU-3.X

MXU-2.X setup and data files

TomoView 2.9R12 (or higher)

TomoView Remote Control

1. Data file compatibility

1

1

✔ ✔

✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

✔ ✔

✔

✔

✔ ✔

✔ ✔

✔ ✔

UT2

UT4

UT8

16:64 PA M 16:64 PA

16:128 PA

32:32 PA

32:128 PA

55

Page 6

Setting Up for Success

Touch Screen

The bright 10.4 in. screen with its new, innovative, and revolutionary touch-screen interface improves browsing speed with its userfriendly gate, cursor, and display controls. In addition, the new on-screen text and value input makes devices like mice and keyboards

unnecessary.

Menu Selection and Parameter Settings

Tap once on the screen to quickly navigate through menus, submenus, and parameters.

Zooming and Panning

Gate Selection and Movement

In Gate mode, tap and hold a gate to move it to a new position.

Cursor Selection and Movement

The touch screen’s zooming functions can be used to zoom in on a specific area.

In Cursor mode, tap once on a cursor to select it. Double-tap on a position to move the cursor to the desired location.

Text and Value Input

Double-tap on a parameter to bring up the keyboards or keypad on which values can be

entered. Alphabetic and a numeric keyboards are available.

In Zoom mode, swipe to pan the window contents.

6

www.olympus-ims.com

Page 7

Setup

Group Wizard for All Essential Parameters

• Material selection, with a database for shear and longitudinal

velocities, and configuration of components for flat or curved

surfaces.

• A group copy option in the Wizard for fast creation of

symmetrical two-probe inspections.

• Wedge selection from a database of Olympus wedges.

• Auto probe detection.

• Scanner configuration with offsets, skews, and probe positions.

• Wizard guidance for phased array, conventional UT, and

TOFD channels.

• Detailed interactive and illustrated help menu for every step in

the Wizard.

• Weld Overlay and RayTracing: step-by-step Wizard to

configure the weld geometry.

Setup Speed

OmniScan MX

Scan plan adjustment using the Focal Law Wizard.

OmniScan MX2

50% faster

S-Scan and A-Scan Display Refresh Rate

OmniScan MX

OmniScan MX2

300% better

Calibration

Code-Compliant Calibration

The Calibration Wizards ensure that every focal law in every

group is the direct equivalent of a single-channel conventional

flaw detector.

Calibration Wizards

• Guide the user step-by-step through Velocity, Wedge Delay,

Sensitivity, TCG, DAC, AWS, and DGS calibrations.

• Enable experimental or theoretical sensitivity, and TCG curves

based on two, three, or all beams for a real or interpolated

calibration.

• Offer a simple, easy-to-use interface that enables all focal laws

to be visualized simultaneously for a particular calibration

task.

• Features an interactive help menu with detailed graphics and

definitions, which is available in each step of each Wizard.

UT parameter adjustment using the touch-screen software keypad.

Sensitivity calibration for a defined section in a sectorial scan.

Sensitivity calibration for all beams in a sectorial scan.

7

Page 8

Acquisition

• A scan menu for quick and easy configuration of inspection

parameters for manual, one-line, raster, and helicoidal scans.

• Multiple encoder modes, including Clock, Quadrature, and

Clicker.

• C-scan configuration for amplitude and position C-scans, and

display setup.

• Data storage options for full A-scans, S-scans, and/or C-scans.

• Preconfigured display layouts for easy inspection preparation.

• PRF auto adjustments for optimized, maximum speed, or

manually-controlled settings.

• Data storage options for flash card or USB media devices.

• Real-time data acquisition displays, with the ability to rewrite

data in both scan directions when using an encoder.

• Easy to interface with encoded scanners.

• Different gate-synchronization capabilities.

Pulse Repetition Frequency (PRF)

OmniScan MX

Top: Data acquisition

displaying TOFD.

Right: Data acquisition

displaying two phased

array channels and

TOFD.

OmniScan MX2

40% better

Saving Inspection Data File to USB (speed)

OmniScan MX

OmniScan MX2

Up to 400% better

Maximum File Size (Mb)

OmniScan MX

OmniScan MX2

160 Mb

300 Mb

Flawless Data Management

An SD Card is used to store data for easy transfer to a computer.

The SD card can also be inserted and removed without having

to reboot the unit. In addition, data can be transferred to external media using the USB 2.0 port. The OmniScan MX2 provides

data transfer speeds up to 400% faster than the OmniScan MX

(depending on the device used).

Analysis

• An extensive display menu for preconfigured multigroup and

multiprobe inspection layouts.

• Data, reference, and measurement cursors for defect sizing

and reporting.

• Extensive Readings database for trigonometry, flaw statistics on

axes, volumetric position information, code-based acceptance

criteria, corrosion mapping statistics, etc.

• All Readings are available online, and are also available off-

line when full A-scans are saved in data files.

• Linked displays for interactive analysis of A-scans, B-scans,

S-scans, and C-scans for multigroup and multiprobe

inspections.

• Optimized preconfigured layouts for quick and simple length,

depth, and height sizing of flaws for code-based or non-codebased inspections.

• Interactive off-line gate repositioning.

Weld inspection

display showing the

position of indications

in the RayTracing

display.

8

www.olympus-ims.com

Page 9

p

O

Data Analysis with OmniPC

This new software is the most efficient and affordable option for OmniScan data analysis,

and features the same analysis tools provided in the OmniScan onboard software, with the

added flexibility of running on a personal computer.

• Optimized use of your OmniScan: The OmniScan unit can now be used strictly for

scanning while analysis is performed simultaneously on a personal computer.

• Affordable software.

• Same user interface as the OmniScan. An inspector with training on the OmniScan is

automatically qualified to use the OmniPC.

• Compatible with extra large screens for increased visibility during analysis.

• Intuitive keyboard shortcuts have been added to boost productivity levels

during file analysis.

• The inspector can validate the parameters used for inspection.

OmniPC is the perfect choice for performing analysis with most applications, including composite, corrosion, and weld inspection with up

to three groups.

OmniPC and TomoView Feature Comparison

OmniPC 3.1 TomoView Analysis

Ray tracing

Offline peak selection in gates

Metric and imperial units

Multigroup combined display (PA, UT, and TOFD)

Ability to zoom in and out of the display

Predefined weld overlay display

Selectable information groups (readings)

Standard Analysis

Off-line data management and processing

Indication-table tools

Built-in report generator (customizable)

Ability to modify/create color palettes

Volumetric merge tool (automatic or manual)

Software gain adjustment

Advanced layout tools

Zone tool for statistical measurements

3-D cursor

Ability to open multiple files simultaneously

Merge tool (data files and C-scans)

Advanced off-line data management and processing

Signal-to-noise ratio (SNR) analysis tool

Advanced Analysis

Hysteresis correction

Ability to export data groups to .txt files

FFT calculation

Microsoft Excel Exchange

Acoustic field simulation (AFiSiMO)

√

√

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√

√

√

√

√

√

√

√

√

√

√

√

√

√

99

Page 10

11-01-13 10:20

Page 1 of 9

OmniScan Report

Report Date Report Version File Name Inspection Date Inspection Version Save Mode

2011 / 01 / 11 MXU - 3.0B4T12 PV200steph2.opd 2010 / 12 / 20 MXU - 3.0B4T10 Inspection Data

OmniScan Type OmniScan Serial # Module Type Module Serial # Calibration Due Data File Name

N/A OMNI- EQUX251C AMP127 OMNI-2037 2011/8/12 File####

Group 1

Setup

A:70.00 Sk:090 L:001

Beam Delay Start (Half Path) Range (Half Path) Max. PRF Type Averaging Factor

22.1 us 11.70 mm 61.40 mm 35 PA 1

Scale Type Scale Factor Video Filter Pretrig. Rectification Filter

Compression 12 Off 0.00 µs FW None 0.50 - 19.00 MHz

Voltage Gain Mode Wave Type Sound Velocity Pulse Width

40 (Low) 40.35 dB PE (Pulse- Echo) Shear 3240.0 m/s 100.00 ns

Scan Offset Index Offset Skew C-scan time resolution

-81.00 mm -21.50 mm 90.0º 10.0 ns

Gate Start Width Threshold Synchro.

I 0.00 mm 11.00 mm 20.00 % Pulse

A 7.00 mm 15.00 mm 50.00 % Pulse

B 72.71 mm 11.00 mm 30.00 % Pulse

TCG Point Number Position (Half Path) Gain

1 0.00 mm 0.0 dB

2 11.98 mm 1.2 dB

3 17.88 mm 5.0 dB

Calculator

Element Qty. Used First Element Last Element Resolution Wave Type Material Velocity

16 1 32 1.0 Shear 3240.0 m/s

Start Angle Stop Angle Angle Resolution Focal Depth Law Configuration

70.00º N/A N/A 12.00 mm Linear

Technician Name ____________________________________________________________________________________________________________________

Technician Signature ____________________________________________________________________________________________________________________

Contractor ____________________________________________________________________________________________________________________

Date ____________________________________________________________________________________________________________________

Page 9 of 9

Indication # Scan Index Group Channel A% DA^ ViA^ VsA^ A% DA^ U(m -r) S(m-r)

1 109.00 mm -11.63 mm 2 55.00º 67.7 % 5.60 mm -1.77 mm 109.00 mm 67.7 % 5.60 mm 6.84 mm 33.00 mm

Comments

-

The RayTracing is only a graphical representation of the readings approved by the operator.

Reporting

The OmniScan MX2 is designed to inspect, analyze, and generate

reports directly on the instrument, or off-line on a computer.

• The reports created on the OmniScan include an indication

table that can be customized with additional readings and

comments specific to each indication.

• RayTracing tools are included to represent indication positions

on the weld profile.

• Option to include a high-resolution image of the current

display in the report.

• The autogenerated report contains relevant parameters for the

instrument, software, calibration, UT parameters, phased array

parameters, scanner setup, and flaw reporting.

• Up to eight readings from the original setup can be displayed

using the touch screen’s simple toggle operations.

• Reports are stored and viewed on the instrument, and can also

be saved as HTML documents for use on a computer.

• Reports are fully customizable and come with several

preconfigured templates.

Advanced Data Acquisition and Analysis with TomoView

TomoView™ is the perfect PC-based complement to

the OmniScan® family of instruments, and seamlessly

imports OmniScan files for advanced processing and

analysis in TomoView.

• Displays volume-corrected views that are fully

customizable and come with several preconfigured

templates.

• Imports and merges several data files. For simplified

interpretation, several groups are merged into one.

• Corrects potential operator errors in acquisition

parameters (incorrect skews, index offsets, etc.) by

reading back raw acquisition data without altering

original data.

Advanced Inspection Tools

TomoView offers advanced inspection tools to simulate,

test, and prepare setups for the OmniScan.

• 2-D matrix

• Pitch-and-catch, tandem

• Advanced focusing

Advanced Analysis Tools

• The TOFD Manager performs TOFD calibration,

lateral wave straightening, lateral wave removal, and

the synthetic aperture focusing technique (SAFT).

• C-Scan Merge: Merges C-scans based on minimum

or maximum amplitude, or time-of-flight (TOF).

• Signal-to-noise ratio (SNR): On a C-scan, this tool

calculates and displays areas in which SNR is above

and/or below a certain threshold.

Reporting

Creating a report in TomoView takes just a few clicks.

Defects can be added into the indication-table database,

the indication table can be customized with additional

readings, and you can add comments specific to each

indication.

TomoView offers advanced post-processing of OmniScan

data. Illustrated here: weld overlay, multiple sector scans,

multibeam C-scans, and merging of A-scans with Top and

End views (the latter with rebound display).

Dual matrix PA probe (TRL).

Indication table built from composite inspection data.

10

www.olympus-ims.com

Page 11

Typical Applications

Girth Weld Inspection

The OmniScan PA is at the heart of the Olympus manual and

semiautomated circumferential weld-inspection solutions developed

for the oil and gas industry. These phased array systems, which are

certified for tube inspection in compliance with ASME, API, and other

code criteria, offer superior inspection speed and detection, and

facilitate interpretation of indications.

Pressure Vessel Weld Inspection

A complete inspection of pressure vessel welds can be performed in a

single scan using an OmniScan PA and a motorized scanner such as

the WeldROVER. By combining TOFD and PA in a single inspection

pass, a significant reduction in inspection time can be achieved as

compared with conventional raster scanning or radiography. Furthermore, inspection results are available immediately, enabling you to

detect problems with welding equipment and fix them right away.

Weld Inspection of Small-Diameter Pipes

When coupled with the COBRA manual scanner, the OmniScan flaw

detector is capable of inspecting pipes ranging from 0.84in. OD to

4.5in.OD. With its very slim design, this manual scanner is able to

inspect pipes in areas with limited access. Adjacent obstructions such

as piping, supports, and structures can be as close as 12mm (0.5in.).

Manual and Semiautomated Corrosion Mapping

The OmniScan PA sytem with the HydroFORM scanner is designed to

offer the best inspection solution for detecting wall-thickness reductions resulting from corrosion, abrasion, and erosion. In addition, it

detects mid-wall damage such as hydrogen-induced blistering and

manufacturing-induced laminations, and easily differentiates these

anomalies from loss of wall thickness.

For this application, phased array ultrasound technology offers superior inspection speed, data point density, and detection.

Composite Inspection

Parts made of laminate composite materials pose an inspection challenge due to their various shapes and thicknesses.

Olympus offers complete solutions for the inspection of carbonfiber-reinforced polymer structures. These solutions are based on the

OmniScan flaw detector, the GLIDER™ scanner, and dedicated probes

and wedges designed for CFRP flat panel and radius inspection.

11

Page 12

OmniScan MX2 Specifications

OmniScan MX2 Mainframe Specifications

Overall dimensions

(W x H x D)

Weight 5 kg (11 lb), including module and one battery

Data Storage

Storage devices

Data file size 300 MB

I/O Ports

USB ports 3

Speaker out Yes

Video output Video out (SVGA)

Ethernet 10/100 Mbps

I/O Lines

Encoder

Digital input 4 digital TTL inputs, 5 V

Digital output 4 digital TTL outputs, 5 V, 15 mA

Acquisition on/off

switch

Power output line

Alarms 3 TTL, 5 V, 15 mA

Analog output 2 analog outputs (12 bits) ±5 V in 10 kΩ

Pace input 5 V TTL pace input

Display

Display size 26.4 cm (10.4 in.) (diagonal)

Resolution 800 pixels x 600 pixels

Brightness 700 cd/m

Number of colors 16 million

Type TFT LCD

Power Supply

Battery type Smart Li-ion battery

Number of batteries

Battery life Minimum 6 hours with two batteries

Environmental Specifications

Operating temperature

range

Storage temperature

range

Relative humidity

Shockproof rating Drop-tested according to MIL-STD-810G 516.6

325 mm x 235 mm x 130 mm

(12.8 in. x 9.3 in. x 5.1 in.)

SDHC card, most standard USB storage devices,

or fast Ethernet

2-axis encoder line (quadrature, up, down, or

clock/direction)

Remote acquisition enabled TTL, 5 V

5 V, 500 mA power output line

(short-circuit protected)

2

1 or 2 (battery chamber accommodates two

hot-swappable batteries)

0°C to 45°C; 0°C to 35ºC with 32:128 PA

(32ºF to 113ºF; 32ºF to 95ºF with 32:128 PA)

–20°C to 60°C (–4ºF to 140ºF) with batteries

–20°C to 70°C (–4ºF to 158ºF) without batteries

0% to 85% noncondensing

No air intake; designed for IP66

Phased Array Module Specifications (Applies to OMNI-M-PA32128)

Overall dimensions

(W x H x D)

Weight 1.2 kg (2.6 lb)

Connectors 1 OmniScan connector for phased array probes

Number of focal laws 256

Probe recognition Automatic probe recognition

Pulser/Receiver

Aperture 32 elements

Number of elements 128 elements

Pulser

Voltage 45 V or 90 V per element

Pulse width Adjustable from 30 ns to 500 ns, resolution of 2.5ns

Pulse shape Negative square wave

Output impedance Less than 30 Ω

Receiver

Gain 0dB to 74 dB, maximum input signal 1.25Vp-p

Input impedance 50 Ω

System bandwidth 0.53MHz to 21 MHz (–3 dB)

Beamforming

Scan type Sectorial and linear

Group quantity Up to 8

Active elements 32

Elements 128

Data Acquisition

Digitizing frequency 100 MHz (10 bits)

Maximum pulsing rate Up to 10 kHz (C-scan)

Data Processing

Number of data points Up to 8,000

Real-time averaging 2, 4, 8, 16

Rectifier RF, full wave, halfwave +, halfwave –

Filtering

Video filtering Smoothing (adjusted to probe frequency range)

Data Visualization

A-scan refresh rate Real time: 60 Hz

Data Synchronization

On internal clock 1 Hz to 10 kHz

On encoder On 1 or 2 axes

Programmable Time-Corrected Gain (TCG)

Number of points 16 (1 TCG curve per channel for focal laws)

Alarms

Number of alarms 3

Conditions Any logical combination of gates

Analog outputs 2

244 mm x 182 mm x 57 mm

(9.6 in. x 7.1 in. x 2.1 in.)

Low-pass (adjusted to probe frequency), digital filtering

(bandwidth, frequency range)

Compatible with the Following Inspection Codes:

The OmniScan MX2 is compatible with standard industry inspection codes, including, but not limited to:

ASME Section V, Article 4 AWS

All ASME phased array code cases API 1104 and API RP2X

ASTM E2700-09 CEN EN 583-6

ASTM E2491-06 BSI BS7706

… and more

48 Woerd Avenue, Waltham, MA 02453, USA, Tel.: (1) 781-419-3900

12569 Gulf Freeway, Houston, TX 77034, USA, Tel.: (1) 281-922-9300

505, boul. du Parc-Technologique, Québec (Québec) G1P 4S9, Tel.: (1) 418-872-1155

1109 78 Ave, Edmonton (Alberta) T6P 1L8

www.olympus-ims.com

info@olympusNDT.com

OmniScan_MX2_EN_201203• Printed in Canada • Copyright © 2012 by Olympus NDT.

*All specications are subject to change without notice.

All brands are trademarks or registered trademarks of their respective owners and third party entities.

isISO9001and14001certied.

Loading...

Loading...