Page 1

MULTITECHNOLOGY FLAW DETECTOR: UT, PA, EC, ECA

OmniScan® MX

• Portability

• Modularity

• Color Imaging

• Data Storage

920-117H-EN

Page 2

OmniScan® MX

With thousands of units being used

throughout the world, the OmniScan MX is

Olympus NDT’s most successful portable

and modular phased array and eddy current

array test instrument. The OmniScan family

includes the innovative phased array and

eddy current array test modules, as well as

the conventional eddy current and ultrasound modules, all designed to meet the

most demanding NDT requirements. The

OmniScan MX offers a high acquisition

rate and powerful software features—in a

portable, modular instrument—to efficiently

perform manual and automated inspections.

Rugged, Portable, and

Battery Operated

The OmniScan is built to work in the harshest field conditions. A solid polycarbonatebased casing and rubber bumpers make it a

rugged instrument capable of withstanding

drops and shocks.

The OmniScan is so compact and lightweight (only 4.6 kg, 10.1lb) that it can

be carried easily and handled anywhere,

inside or outside. The OmniScan will run

for 6 hours with its two Li-ion batteries.

Up/Down keys

Menu keys

Scanner interface

Microphone

Help key Parameter keys

Alarm indicator LEDs

SVGA output

Alarm and I/O

Control area

Function keys

On/off switch

Tilt stand

Protective bumpers

User Interface

The highly legible 8.4-inch real-time

display (60-Hz A-scan refresh rate) with an

SVGA resolution of 800 x 600 allows you

to clearly see defects and details under any

light conditions. A scroll knob and function

keys make it easy to browse through and

select functions. A mouse and keyboard

can also be connected for users looking for

a more PC-like interface.

Modular Instrument

The instrument allows you to switch between its different test modules on location.

When a new module is connected, the

instrument detects the module and its supported technology so that the configuration

and test environment are set automatically.

OmniScan Connector

The OmniScan connector has a probe ID

feature that enables physical detection and

recognition of the probe connected to the

instrument.

• Sets the probe to an appropriate

frequency to prevent probe damage.

• Sets C-scan resolution for ECA probes.

• Loads the correct probe parameters.

Eddy current

array module

8-channel

UT module

16:16M

phased array

module

16:128

phased array

module

USB connectors

• Keyboard

• Mouse

• Printer

Ethernet

and serial ports

32:128

phased array

module

Adapters able to connect to probes from other

manufacturers are available.

2

www.olympus-ims.com

Page 3

Setup and Reporting

• Setup storage is compatible with Microsoft Windows

(exportable using a CompactFlash card).

• Complete report setups, including reading configurations, that

can be customized using HTML page layouts.

• Easy report generation, from acquired data to complete report

in seconds

• On-screen interactive help that can be customized for

procedure-oriented setups using HTML script templates

• Setup preview

• Predefined setups

Connectivity, Data Storage, and Imaging

The OmniScan® offers alarm outputs and standard PC ports: USB,

SVGA out, and Ethernet. It offers internal data storage capability

and extended storage via a CF (CompactFlash) card slot as well as

any USB or network storage.

Typical Applications

Girth Weld Inspection

Olympus NDT developed a circumferential weld inspection system for the oil and gas

industry based on the OmniScan PA. This phased array system is qualified to inspect tubes

with diameters ranging from 48 mm to 1524 mm and thicknesses from 5 mm to 25 mm in

compliance with the ASME Boiler and Pressure Vessel Code, Section V. The semiautomated

system offers better inspection speed and detection, and makes interpretation of the indications significantly easier.

Pressure Vessel Weld Inspection

The combination of time-of-flight diffraction (TOFD) and pulse-echo techniques means

that a complete inspection can be performed in a single scan, significantly reducing the

inspection time when compared to conventional raster scanning or radiography. Inspection results are instantly available, allowing you to find problems with the welding equipment and fix it right away. Based on our vast experience in the nuclear and petrochemical

industries, this system includes all the functions that are needed for code-compliant weld

inspections.

Scribe Marks Inspection with No Paint Removal

The Flight Standards Information Bulletin for Airworthiness (FSAW 03-10B), issued in No-

vember 2003, reports damage along fuselage skin lap joints, butt joints, and other areas of

several aircraft caused by the use of sharp tools used during paint and sealant removal.

The OmniScan allows scribe marks inspections to be performed without paint removal,

which is a huge time-saver. The inspections are performed in a single pass using 60º to 85º

SW sectorial scans. The OmniScan PA is now referenced in the Boeing NTM manuals, 737

NDT Manual, Part 4, 53-30-06, July 2005.

Aircraft Fuselage Inspection

The OmniScan ECA (eddy current array) provides the ability to detect hidden corrosion

and cracks in multilayer structures. Currently, material loss of 10% of the lap-splice thickness can be detected in aluminum at a depth of 5 mm. Surface and subsurface cracks can

be detected in the skin, at the fastener, or at the lap-joint edges.

3

Page 4

Ultrasound Inspection

Transmitter Receiver

Lower tip

Upper tip

Backwall (+) Lower tip (+) Upper tip (+) Lateral waves (+)

Lateral waves

Backwall reflection

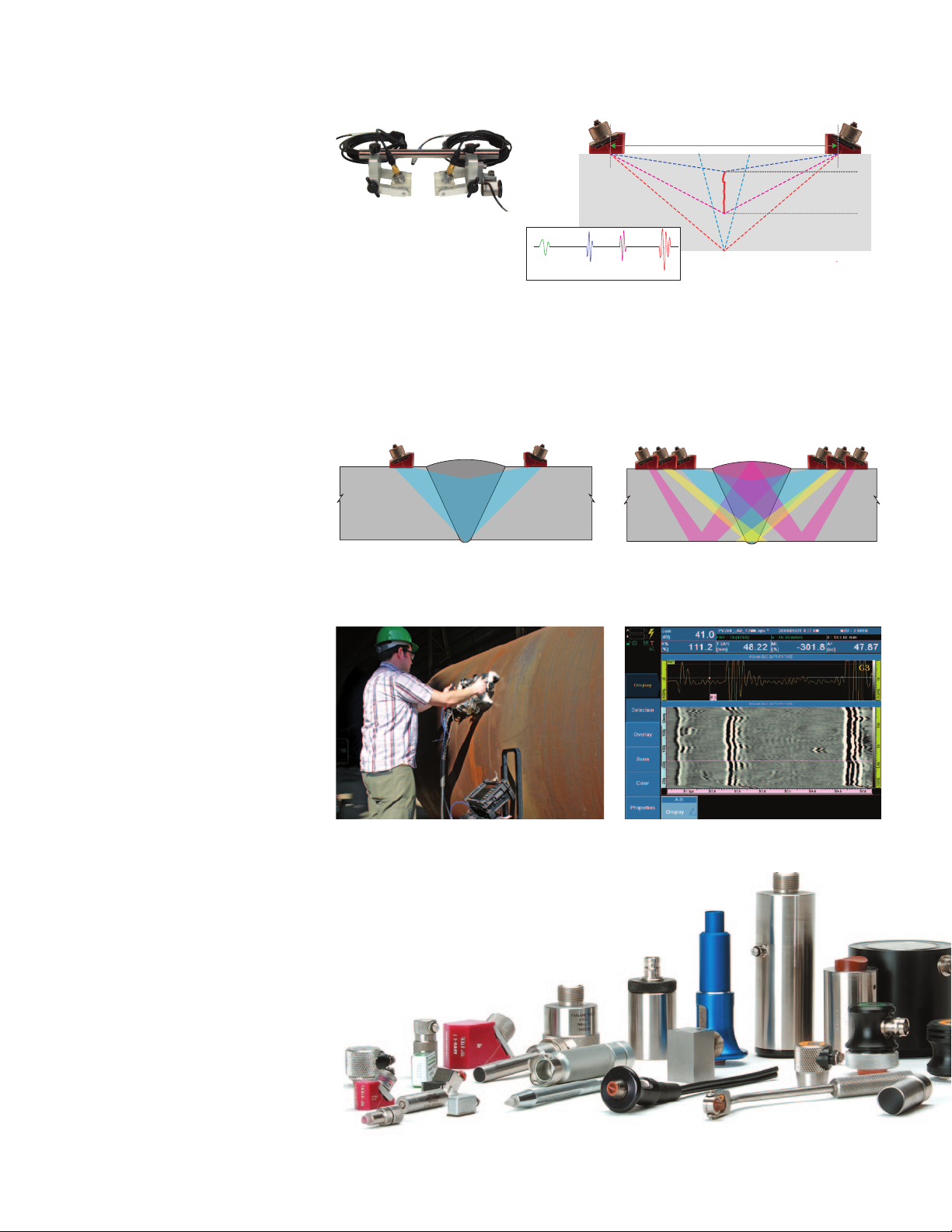

Time-of-Flight Diffraction Testing

Time-of-flight diffraction (TOFD) is a

technique that uses two probes in pitchcatch mode. TOFD detects and records

signals diffracted from defect tips allowing

both detection and sizing. The TOFD data

is displayed in a grayscale B-scan view.

TOFD offers wide coverage and amplitudeindependent sizing complying with the

ASME-2235 code.

• One-line scan for full-volume inspection

• Setup independent of weld configuration

• Very sensitive to all kinds of defects and

unaffected by defect orientation

TOFD and Pulse-Echo Testing

While TOFD is a very powerful and efficient technique, its coverage is limited as

a result of two inspection dead zones: one

dead zone is near the surface, the other is

at the backwall.

The OmniScan® UT allows inspections that

simultaneously combine TOFD with conventional pulse echo. Pulse echo complements TOFD, covering the dead zones.

• TOFD inspection

• 45º pulse echo for weld cap inspection

on either side of the weld

• 60º pulse echo for weld root inspection

on either side of the weld

0-Degree Testing

(Corrosion and Composite)

0-degree testing measures the time-of-flight

and amplitude of ultrasonic echoes reflecting from the part into gates in order to

detect and measure defects.

• C-scan imaging

• Full A-scan recording with C-scan

postprocessing

Ultrasound Transducers

Olympus NDT offers a selection of thousands of transducers in standard frequencies, element diameters, and connector

styles.

• Contact and immersion transducers

• Dual transducers

• Angle-beam transducers and wedges

• Replaceable delay line transducers

• Protected face transducers

• Normal incidence shear-wave

transducers

Transmitter Receiver

Lateral waves

Upper tip

The TOFD hand scanner is a small, lightweight, efficient, low-cost, and versatile

weld inspection solution.

It can accommodate a full range of probes

and wedges, including the CentraScan™

composite product line.

Weld inspection using TOFD. Weld inspection using combined TOFD and pulse echo

HSMT-Flex scanner used for TOFD applications (PV-100).

General view of TOFD setup for linear weld inspection showing

lateral wave, backwall echo, and diffracted signals on the A-scan.

TOFD

60º SW

45º SW

Transmit

PE

PE

(PV-100).

Weld inspection with TOFD.

Lower tip

Backwall reflection

TOFD

Receive

60º SW

45º SW

PE

PE

4

www.olympus-ims.com

Page 5

Ultrasound Software

Full-Featured C-Scan

• Monitors amplitude, peak position, crossing level position,

and thickness on each gate.

• Automatic gate synchronizes from previous gate for higher

dynamic range of thickness.

• A-scan data storage and C-scan postprocessing capabilities

Step-by-Step Calibration Wizards

All calibration procedures are guided using step-by-step wizards.

Multiple A-scan display.

Indoor/outdoor color schemes for

improved readability in all conditions.

• Sound velocity calibration

• Wedge delay calibration

• TOFD calibration

• TCG calibration

• Encoder calibration

TOFD Option

• Optional IF gate for surface-following synchronization or

measurement gate, or TCG/DAC curves

• Positive or negative gate on RF signal (independent for each

gate)

• Eight completely configurable alarms on single-gate events

or multiple-gate events, filter for n occurrences from one or

multiple channels

• Customizable color palette for amplitude and thickness

C-scans

• Adjustable 256-level color palette

• 2-axis mechanical encoding with data-acquisition

synchronization on mechanical movement

• Optional data library to access A-scans and/or C-scans on PCs

for custom processing

Full-Featured B-Scan

• Easy-to-interpret cross-sectional view of inspected part

• Excellent display of corrosion mapping for boilers, pipes, and

storage tanks

• Visual identification of acquired thickness values

• Encoded TOFD capability for amplitude-independant defect

sizing

Full-Featured A-Scan

• Color-selectable A-scan display

• Reject mode

• Hollow mode

• Peak-hold mode (always keeps the signal that shows the

maximum amplitude in gate A)

• Gate threshold-level crossing (changes the color of the curve

that is over the gate level)

• 60 Hz A-scan refresh rate with overlays of envelope and peak

inside the gate

• B-scan encoded data imaging and storage

• Grayscale color palette, adjustable for brightness and contrast

• 100 MHz A-scan digitizing

• TOFD calibration wizard, online and offline

• Hyperbolic cursor and reading for TOFD sizing

• Lateral wave resynchronization

Live switching between conventional

UT and phased array UT

5

Page 6

Transmitting

delays

Receiving delays

and sum

Probe elements

Pulses

Incident wave front

Reflected wave front

Trigger

Flaw

Flaw

Echo signals

Emitting

Acquisition unit

Receiving

Phased array unit

Phased Array Inspection

Phased Array Technology

Phased array technology enables the

generation of an ultrasonic beam where

parameters such as angle, focal distance, and focal point size are controlled

through software. Furthermore, this beam

can be multiplexed over a large array.

These capabilities open a series of new

possibilities. For instance, it is possible to

quickly vary the angle of the beam to scan

a part without moving the probe itself.

Phased arrays also allow replacing multiple probes and mechanical components.

Inspecting a part with a variable-angle

beam also maximizes detection regardless

of the defect orientation, while optimizing

signal-to-noise ratio.

Benefits of Phased Arrays

Phased array technology offers the following benefits:

• Software control of beam angle, focal

distance, and spot size

• Multiple-angle inspection with a

single, small, electronically-controlled

multielement probe

• Greater flexibility for the inspection of

complex geometry

• High-speed scans with no moving

parts

To generate a beam, the various probe elements are pulsed at slightly different times. By precisely controlling the delays between

the probe elements, beams of various angles, focal distances, and focal spot sizes can be produced. The echo from the desired

focal point hits the various transducer elements with a computable time shift. The signals received at each transducer element

are time-shifted before being summed together.

Multiple-angle inspection with one multielement probe.

Wedge and

phased array

probe

11 angles

Greater flexibility for the inspection of complex geometry.

Phased Array Probes

Olympus standard phased array probes are

divided into three categories:

• Angle beam probes with external

wedges (1) (2)

• Angle beam probes with integrated

wedge (3)

• Immersion probes (4)

Numerous accessories, such as encoders (5)

are also available.

6

The use of phased array probes enables one-line scanning

and eliminates one axis of a two-axis scan.

Active group

16

1

Scanning direction

High-speed scans with no moving parts.

Compared to a wide, single-element transducer, phased

array technology offers a much higher sensitivity due to the

use of a small focused beam.

4

1

3

2

128

5

www.olympus-ims.com

Page 7

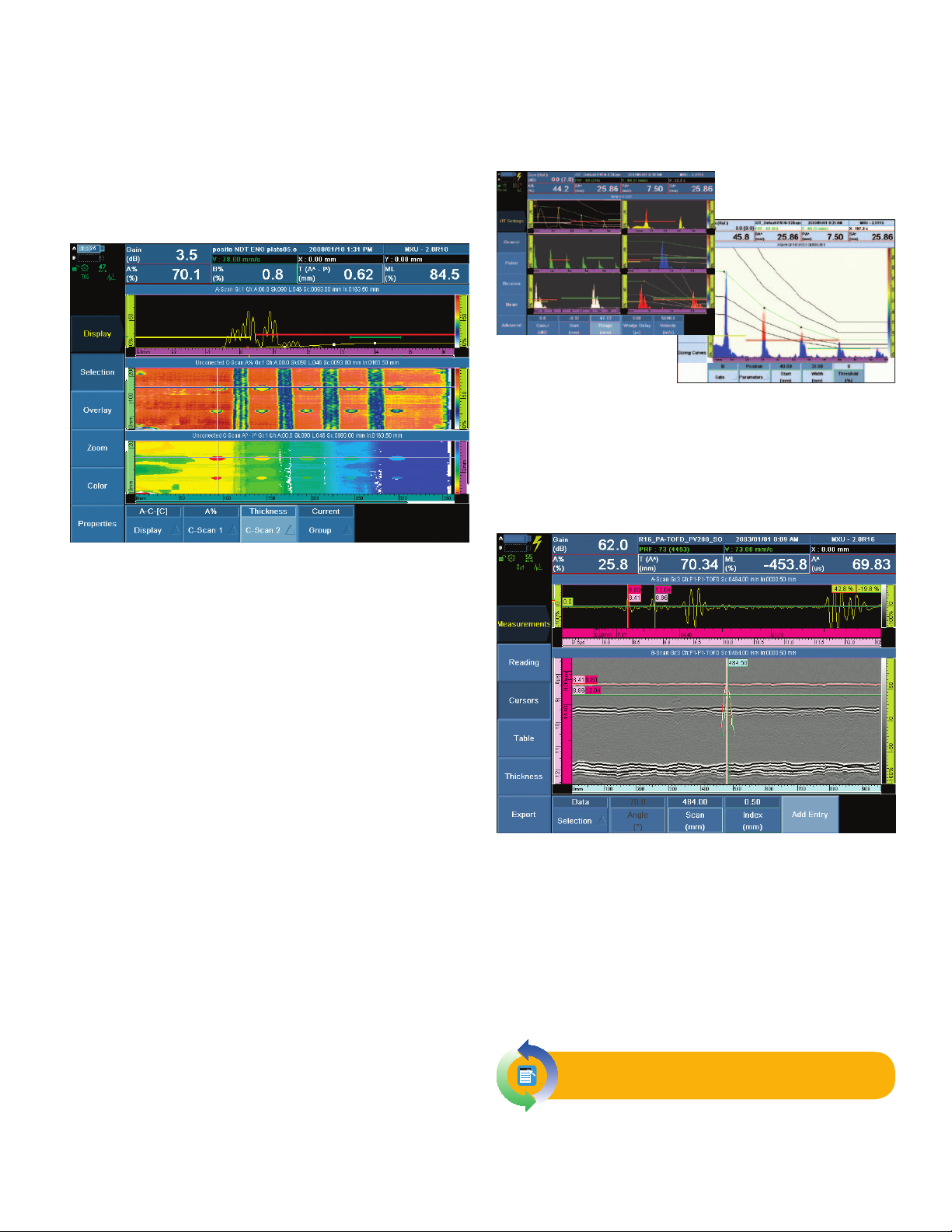

Phased Array Software

Full-Featured A-Scans, B-Scans, and C-Scans

B-scan display

A-scan and C-scan displays

The OmniScan® PA builds upon the OmniScan UT feature set and

offers full-featured A-scan, B-scan, and C-scan displays.

Full-Featured Sectorial Scan

Wizards for Groups and Focal Laws

• The Group Wizard allows you to enter all probe, part, and

beam parameters, and generate all focal laws in one step

instead of generating them with each change.

Examples of the Focal Law Wizard

• The step-by-step approach prevents the user from missing a

parameter change.

• Online help provides general information on parameters to be

set.

Multiple-Group Option

It is now possible to manage more than one probe with two different configurations: different skews, different scanning types,

different inspection areas, and other parameters.

Sectorial scan display

Real-time data processing

• Real-time volume-corrected representation

• Higher than 20 Hz refresh rate (up to 40 Hz)

Advanced Real-Time Data Processing

• Real-time data interpolation to improve spatial representation

of defects during acquisition of data

• User-selectable high-pass and low-pass filters to enhance

A-scan and imaging quality

• Projection feature allows the operator to view vertically

positioned A-scan simultaneously with sectorial scan image.

Calibration Procedures and Parameters

All calibration procedures are guided by a step-by-step menu

using Next and Back navigation.

Possible Configurations for Multiple-Group Inspection

A Use one single phased array probe of 64 or more elements and

create 2 different groups:

Linear scan at 45º to cover the upper part

using skips on the bottom surface

Linear scan at 60º to cover the lower part

B Use one single phased array probe of 64 or 128 elements and

create 2 different groups:

Linear scan at 0º at low gain

Linear scan at 0º at higher gain

C Use one phased array probe of 64 or 128 elements and create

3 different groups:

Linear scan at 45º to cover the upper part

using skips on the bottom surface

Linear scan at 60º to cover the lower part

Sectorial scan from 35º to 70º to increase

probability of detection

D Use two phased array probes of 16 or 64 elements and create 2

different groups:

Sectorial scan from 35º to 70º for inspec-

tion from left side of the part using skips

on the bottom surface

Sectorial scan from 35º to 70º for inspec-

tion from right side of the part using skips

on the bottom surface

Example of sensitivity

calibration

7

Page 8

Eddy Current Inspection

Eddy Current Technology

Eddy current testing (ECT) is a method for

the inspection of metallic parts. The probe,

excited with an alternating current, induces

an eddy current in the part being inspected.

Any discontinuities or material property

variations that change the eddy current flow

in the part are detected by the probe as a

potential defect.

Over the years, probe technology and data

processing have continuously progressed

so that the eddy current technique is now

recognized to be fast, simple, and accurate.

This is why the technique is widely used in

the aerospace, automotive, petrochemical,

and power generation industries in the detection of surface or near-surface defects in

materials such as aluminum, stainless steel,

copper, titanium, brass, Inconel, and even

carbon steel (surface defect only).

Benefits of Eddy Currents

Eddy currents offers the following benefits:

• A quick, simple, and reliable inspection

technique to detect surface and nearsurface defects in conductive materials

• Can be used to measure the electrical

conductivity of materials.

• Measurement of nonconductive

coatings

• Hole inspection with the use of a high-

speed rotating scanner and surface

probe

Eddy Current Probes

Olympus NDT standard eddy current

probes are available in different configurations:

• Bolt hole probes

• Surface probes, in various shapes and

configurations

• Low-frequency Spot and Ring probes

• Sliding probes

• Wheel probes

• Conductivity probes

• Speciality probes made for specific

applications

Reference standards with EDM notches can

be manufactured according to the application specifications.

Probes used to perform eddy current inspections are made with a copper wire wound to form a coil. The coil shape can vary to

better suit specific applications.

1. The alternating current flowing through the coil at a chosen frequency generates a

2. When the coil is placed close to an electrically conductive material, an eddy current is

3. If a flaw in the conductive material disturbs the eddy current circulation, the magnetic

Surface preparation is minimal. Unlike liquid penetrant or magnetic particle inspection, it is unnecessary to remove the paint from

the surface to inspect the parts.

a

magnetic field around the coil.

induced in the material.

coupling with the probe is changed and a defect signal can be read by measuring the

coil impedance variation.

b

c

8

www.olympus-ims.com

Page 9

Eddy Current Software

Probe Characterization

Raw -Group 1

OmniScan Report

Report Date Report Version Setup File Name Inspection Date Inspectio n Version

2008 / 07 / 17 MXE - 2.0R1 MXE ECT_DEMO.oes 2008 / 07 / 17 MXE - 2.0R1

OmniScan Type OmniScan Serial # Module Type Module Serial # Calibration Due

OmniScan MX OMNI-1684 OMNI-M-ECA4-32 OMNI-4104 2007 / 10 / 31

# laireS eborPledoM eborP

4CH,1Chan,8Freq N/A

.ytQ tnemelEnoitatoRniaGecnerefeRycneuqerFegatloV

1 0.353Bd 0.29lanretnIzHk 8.94V 0.2

F fffotuC1qerF ffotuCstnioP fo .oNepyT retliFretliF req2

A/NA/NA/NenoN1 retliF

A/NA/NA/NenoN2 retliF

Calibration not finished.

PP PIPP PSPP ØPP A

mmsºV

Notes

Technician Name ____________________________________________________________________________________________________________________

Technician Signature ____________________________________________________________________ ____________________________________ ____________

Contractor ____________________________________________________________________ ____________________________________ ____________

Date ____________________________________________________________________ ____________________________________ ____________

Impedance Plane and Strip Chart Display

• User-selectable screen persistence

• Reference signal overlays can be kept on the screen for easier

signal interpretation.

• Freeze mode allows signal rotation and gain adjustment

without having to hold the probe on the part.

• Zoom and Best Fit functions

C-Scan Surface Mapping

• Support of two encoder inputs to connect various scanners

• Real-time C-scan mapping display with impedance plane and

strip chart view

Multifrequency Operation and Automatic

Mixing Capability

• Up to 8-frequency operation (1 channel: 8 frequencies; 2

channels: 4 frequencies; 4 channels: 2 frequencies)

• Automatic mixing capability

Advanced Real-Time Data Processing

• Three alarms can be defined with various shapes to activate

LED, buzzer, or TTL output.

• High-pass, low-pass, and specialized filters (IIR and FIR

filtering available

Alarms

Alarm zone in impedance plane on the OmniScan® ECT.

• Full range of user-selectable alarms (pie, rectangular, ring)

• Simple and quick to set up

• Full control of alarm output

Eddy Current Reports

• Simple and fast report generation

• HTML reporting format for flexibility can be quickly e-mailed

and viewed on any Web browser.

• Predefined and user-customizable reports

Live switching between eddy current

and eddy current array

9

Page 10

Eddy Current Array Inspection

Eddy Current Array Technology

Eddy current array (ECA) technology

provides the ability to electronically drive

and read several eddy current sensors

positioned side by side in the same probe

assembly. Data acquisition is made possible

through the use of multiplexing, which

avoids mutual inductance between individual coils.

The OmniScan® ECA test configuration

supports 32 sensor coils (up to 64 with an

external multiplexer) working in bridge or

transmit-receive mode. The operating frequency ranges from 20 Hz to 6 MHz with

the option of using multiple frequencies in

the same acquisition.

Benefits of Eddy Current Arrays

Compared to single-channel eddy current

technology, eddy current array technology

provides the following benefits:

• Dramatically reduces inspection time.

• Covers a large area in a single pass.

• Reduces the complexity of mechanical

and robotic scanning systems.

• Provides real-time cartography of the

inspected region, facilitating data

interpretation.

• Is well suited to complex part geometry.

• Improves reliability and probability of

detection (POD).

Multiplexing principle between elements. Coils are shown for illustration purposes only.

Eddy Current Array Probes

Olympus NDT manufactures ECA probes

for a wide range of applications. Probes

can be designed to detect a specific type of

flaw or to follow the shape of the part being

inspected. Standard designs are available

to detect defects such as cracks and pitting,

and subsurface defects such as cracks in

multilayer structures, as well as corrosion.

Eddy current array probes can replace one axis of a two-axis scan and offer greater flexibility

in the eddy current setup.

Probes can be made in different shapes and sizes to follow,

with ease, the contour of the part under inspection.

ECA technology is invaluable in aerospace maintenance

applications

Transmit-receive probe for corrosion detection down to 6 mm (0.25 in.)

in aluminum

10

Transmit-receive probe for surface-crack detection shown

with optional encoder

Absolute probe for surface crack detection

www.olympus-ims.com

Page 11

Eddy Current Array Software

Simple Acquisition and Analysis Displays

Acquisition display

Analysis display

• Data acquisition in a C-scan view for quick and efficient

defect detection

• Data selection in Analysis mode to review the signal in the

impedance plane and strip charts

• Amplitude, phase, and position measurement

• Adjustable color palette

• Large impedance plane and strip chart views to

accommodate conventional single-channel ECT probe

inspection

Calibration Wizard

Automatic Probe Detection and Configuration

• C-scan parameters and multiplexing sequence are

automatically set when the probe is connected.

• Frequency range protection to avoid probe damage

Subtraction Tools in Analysis Mode

This function can be used to remove the lift-off variation that is

shown between adjacent channels.

Advanced Real-Time Data Processing

Before interpolation

After interpolation

• Real-time data interpolation to improve the spatial

representation of defects

• When working with two frequencies, a MIX signal can be

generated to remove unwanted signals (for example, lift-off,

fastener signals, etc.).

• Several filters can be applied to the data such as high-pass,

low-pass, median, and averaging filters. The illustrations

below represent an application where cracks are located at

the edge of a lap-joint which has a sharp thickness variation.

The filtered data may improve detection, especially for small

cracks.

Fastener inspection using two frequencies and a dual C-scan display.

• Step-by-step process

• All the channels of a group are calibrated simultaneously,

each channel having its own gain and rotation.

• Amplitude and phase can be set on different reference flaws.

Alarms

• Three alarm outputs can combine LED, buzzer, and TTL

output.

• Various alarm zone shapes can be defined in the impedance

plane (sectorial, rectangular, ring, etc.).

11

Without filter

With high-pass

digital filtering

www.olympus-ims.com

Page 12

OmniScan Specifications

OmniScan MX Specifications

Overall dimensions

(W x H x D)

Weight

Storage devices

Data file size 160 MB

USB ports 3

Speaker out Yes

Microphone input Yes

Video output Video out (SVGA)

Video input Video input (NTSC/PAL)

Ethernet 10/100 Mbps

Encoder

Digital input 4 digital TTL inputs, 5 V

Digital output 4 digital TTL outputs, 5 V, 10 mA

Acquisition on/off switch Remote acquisition enable TTL, 5 V

Power output line

Alarms 3 TTL, 5 V, 10 mA

Analog output 2 analog outputs (12 bits) ±5 V in 10 kΩ

Pace input 5 V TTL pace input

Display size 21 cm (8.4 in.) (diagonal)

Resolution 800 pixels x 600 pixels

Number of colors 16 million

Type TFT LCD

Battery type Smart Li-ion battery

Number of batteries

Battery life

DC-in voltage 15 V to 18 V (min. 50 W)

Environmental specifications

Operating temperature range

Storage temperature range –20°C to 70°C (–4ºF to 158ºF)

Relative humidity

321 mm x 209 mm x 125 mm

(12.6 in. x 8.2 in. x 5.0 in.)

4.6 kg (10.1 lb), including module and

one battery

Data storage

CompactFlash card, most standard USB

storage devices, or through fast Ethernet,

internal 32-MB DiskOnChip

I/O ports

I/O lines

2-axis encoder line (quadrature, up,

down, or clock/direction)

5 V, 500 mA power output line (shortcircuit protected)

Display

Power supply

1 or 2 (battery chamber accommodates

two hot-swappable batteries)

Minimum 6 hours with two batteries;

minimum 3 hours per battery under

normal operating conditions

0°C to 40°C; 0°C to 35ºC with 32:128 PA

(32ºF to 104ºF; 32ºF to 95ºF with

32:128 PA)

0% to 95% noncondensing. No air

intake; splashproof design.

Ultrasound Module Specifications

Overall dimensions

(W x H x D)

Weight 1 kg (2.2 lb)

Connectors LEMO 00 (2, 4, or 8)

Number of pulsers 2, 4, or 8

Pulse output

Pulse width

Fall time Less than 7 ns

Pulse shape Negative square wave

Output impedance Less than 7 Ω

Number of receivers 2, 4, or 8

Receiver gain range 0dB to 100 dB, by steps of 0.1 dB

Maximum input signal 20Vp-p (screen at 128%)

Minimum sensitivity 200µVp-p (screen at 128%)

Noise referred to input 160µVp-p (26µV RMS) (128%)

Input impedance 50 Ω

Input filter

(100% bandwidth)

System bandwidth 0.25MHz to 32 MHz (–3 dB)

Rectifier Both, positive, negative

Mode

Smoothing Digital

Number of points 16

DAC range Up to 40 dB

Maximum gain slope 20 dB/µs

A-scan acquisition rate 6000 A-scans/s (512-point A-scan)

Maximum pulsing rate 1 channel at 12 kHz (C-scan)

Real-time averaging 2, 4, 8, or 16

Quantity 3: I (synchro), A and B (measure)

Synchronization

A-scan recording (TOFD)

C-scan type data recording

Refresh rate 60 Hz

On time 1 Hz to 12 kHz

On encoder

Number of alarms 3

Conditions Any logical combination of gates

Signal Amplitude or TOF of gate A or B

244 mm x 182 mm x 57 mm

(9.6 in. x 7.1 in. x 2.1 in.)

Pulser

50 V, 100 V, 200 V, 300 V ±10%

(variable pulse width)

Adjustable from 30 ns to 1000 ns ±10%,

resolution of 2.5ns

Receiver

Centered at 1 MHz (1.5 MHz),

centered at 2 MHz (2.25 MHz),

centered at 5 MHz (4 MHz),

centered at 10 MHz (12 MHz),

centered at 15 MHz,

centered at 20 MHz;

0.25MHz to 2.5 MHz, 2MHz to

25MHz BB

PE (pulse-echo), PC (pitch-catch), TT

(through-transmission). In PC mode the

maximum number of pulsers equals the

number of channels divided by 2.

DAC

Data acquisition

Data processing

Gates

I, A, B referenced on main bang; A and

B referenced on gate I (post-synchronization)

Data storage

6000 A-scans/s (512-point A-scan)

(3 MB/s transfer rate)

12000 (A1, A2, A3, T1, T2, T3) (3 gates)

12 kHz

(lower frequency for corrosion mapping)

Data visualization

Data synchronization

On 1 or 2 axes divided into 1 to 65536

steps

Alarms

12

Page 13

Eddy Current Modules Specifications

Eddy Current Array Eddy Current

Overall dimensions

(W x H x D)

Weight 1.2 kg (2.6 lb)

Connectors

Number of channels

Probe recognition Automatic probe recognition and setup

Number of generators 1 (with internal electronic reference)

Maximum voltage 12 Vp-p into 10 Ω

Operating frequency 20 Hz to 6 MHz

Bandwidth

Number of receivers 1 to 4

Maximum input signal 1 Vp-p

Gain 28dB to 68 dB

Number of generators

Maximum voltage 12 Vp-p into 50 Ω

Number of receivers

Maximum input signal 1 Vp-p

Digitizing frequency 40 MHz

Acquisition rate

A/D resolution 16 bits

Phase rotation 0° to 360° with increments of 0.1°

Filtering

Channel processing Mixing

Maximum file size

On internal clock 1 Hz to 15 kHz (single coil)

External pace Yes

On encoder On 1 or 2 axes

Number of alarms 3

Alarm zone shape Pie, inverted pie, box, inverted box, and ring

Output type Visual, audio, and TTL signals

Analog outputs 1 (X or Y)

244 mm x 182 mm x 57 mm

(9.6 in. x 7.1 in. x 2.1 in.)

1 OmniScan® connector for eddy current

array probes

1 19-pin Fischer eddy current probe connector

1 BNC connector

32 channels with inter-

nal multiplexer

64 channels with external multiplexer

Generator

8 Hz to 5 kHz (in single coil). Inversely proportional to the time-slot duration and set by the

instrument in multiplexed mode.

Receiver

Internal multiplexer

32 (4 simultaneously

on 8 time slots; up

to 64 with external

multiplexer)

4 differential receivers

(8 time slots each)

Data acquisition

1 Hz to 15 kHz (in single coil). The rate can

be limited by the instrument’s processing

capabilities or by delays set by the multiplexed

excitation mode.

Data processing

FIR low-pass, FIR high-pass, FIR band-pass,

FIR band-stop (adjustable cutoff frequency),

median filter (variable from 2 points to 200

points), mean filter (variable from 2 points to

200 points)

Data storage

Limited to available internal flash memory:

180 MB (or 300 MB optional)

Data synchronization

Alarms

N/A

4 channels

N/A

Phased Array Module Specifications

(Applies to OMNI-M-PA16128)

Overall dimensions

(W x H x D)

Weight 1.2 kg (2.6 lb)

Connectors

Number of focal laws 256

Probe recognition Automatic probe recognition and setup

Aperture 16 elements*

Number of elements 128 elements

Voltage 80 V per element

Pulse width

Fall time Less than 10 ns

Pulse shape Negative square wave

Output impedance Less than 25 Ω

Gain

Input impedance 75 Ω

System bandwidth 0.75MHz to 18 MHz (–3 dB)

Scan type Azimuthal and linear

Scan quantity Up to 8

Active elements 16*

Elements 128

Delay range transmission 0µs to 10 µs in 2.5-ns increments

Delay range reception 0µs to 10 µs in 2.5-ns increments

Digitizing frequency 100 MHz (10 bits)

Maximum pulsing rate Up to 10 kHz (C-scan)

Acquisition depth

Number of data points Up to 8000

Real-time averaging 2, 4, 8, 16

Rectifier RF, full wave, halfwave +, halfwave –

Filtering

Video filtering Smoothing (adjusted to probe frequency range)

A-scan recording (TOFD)

C-scan type data recording I, A, B, up to 10 kHz (amplitude or TOF)

Maximum file size

A-scan refresh rate Real time: 60 Hz

Volume-corrected S-scan Up to 40 Hz

On internal clock 1 Hz to 10 kHz

On encoder On 1 or 2 axes

Programmable time-corrected gain (TCG)

Number of points 16 (1 TCG curve per channel for focal laws)

Number of alarms 3

Conditions Any logical combination of gates

Analog outputs 2

* Models 16:16, 16:16M, 16:64M, 32:32, and 32:128 also available

244 mm x 182 mm x 57 mm

(9.6 in. x 7.1 in. x 2.1 in.)

1 OmniScan connector for phased-array

probes

2 BNC connectors (1 pulser/receiver,

1 receiver for conventional UT) (BNC not

available on models 32:32 and 32:128)

Pulser/Receiver

Pulser

Adjustable from 30 ns to 500 ns, resolution

of 2.5 ns

Receiver

0dB to 74 dB, maximum input signal

1.32Vp-p

Beamforming

Data acquisition

29 meters in steel (L-wave), 10 ms with compression. 0.24 meter in steel (L-wave), 81.9 µs

without compression

Data processing

Low-pass (adjusted to probe frequency), digital

filtering (bandwidth, frequency range)

Data storage

6000 A-scans per second (512-point, 8-bit

A-scan)

Limited to available internal flash memory:

180 MB (or 300 MB optional)

Data visualization

Data synchronization

Alarms

www.olympus-ims.com

13

Page 14

Olympus NDT Training Academy

The unique Olympus NDT Training Academy offers comprehensive courses in phased array technology and applications. Courses range

from a two-day “Introduction to Phased Array” program to a two-week, in-depth “Level II Phased Array” course. In all cases, students

experience practical training using the portable OmniScan® phased array unit.

Courses are currently being offered in training facilities at participating companies as well as at customer-determined locations worldwide. Customized courses can also be arranged.

Check the latest course schedule at www.olympus-ims.com.

OmniScan Data Analysis with TomoView

TomoView™ is the perfect companion for the OmniScan® family of instruments. Seamlessly import OmniScan files for advanced processing and analysis in TomoView.

• Import OmniScan data files and display volume-

corrected views as well as multiple B-scan views.

• Correct potential operator errors in acquisition

parameters (incorrect skew, index offsets, etc.) by

reading back raw acquisition data without altering

original data.

• Import and merge several OmniScan data files.

For simplified interpretation, merge several groups

into one.

TomoView offers advanced post-processing of

OmniScan data. Illustrated here: weld overlay, multiple

sector scans, multibeam C-scans, and merging of

A-scans with Top and End views (the latter with

rebound display).

www.olympus-ims.com

info@olympusNDT.com

48 Woerd Avenue, Waltham, MA 02453, USA, Tel.: (1) 781-419-3900

12569 Gulf Freeway, Houston, TX 77034, USA, Tel.: (1) 281-922-9300

505, boul. du Parc-Technologique, Québec (Québec) G1P 4S9, Tel.: (1) 418-872-1155

1109 78 Ave, Edmonton (Alberta) T6P 1L8

OmniScan_MX_EN_201005• Printed in Canada • Copyright © 2010 by Olympus NDT.

*All specifications are subject to change without notice.

All brands are trademarks or registered trademarks of their respective owners and third party entities.

is ISO 9001 certified.

Loading...

Loading...