Page 1

OF-500 OptiFiber®

PN 1779484

September 2002, Rev. 4 6/06

© 2002-2006 Fluke Corporation. All rights reserved. Printed in USA.

All product names are trademarks of their respective companies.

Certifying OTDR

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke Networks product is warranted to be free from defects in material and workmanship under normal use and service. The warranty

period for the mainframe is one year and begins on the date of purchase. Parts, accessories, product repairs and services are warranted for

90 days, unless otherwise stated. Ni-Cad, Ni-MH and Li-Ion batteries, cables or other peripherals are all considered parts or accessories. The

warranty extends only to the original buyer or end user customer of a Fluke Networks authorized reseller, and does not apply to any product which, in Fluke Networks’ opinion, has been misused, abused, altered, neglected, contaminated, or damaged by accident or abnormal

conditions of operation or handling. Fluke Networks warrants that software will operate substantially in accordance with its functional

specifications for 90 days and that it has been properly recorded on non-defective media. Fluke Networks does not warrant that software

will be error free or operate without interruption.

Fluke Networks authorized resellers shall extend this warranty on new and unused products to end-user customers only but have no authority to extend a greater or different warranty on behalf of Fluke Networks. Warranty support is available only if product is purchased

through a Fluke Networks authorized sales outlet or Buyer has paid the applicable international price. Fluke Networks reserves the right to

invoice Buyer for importation costs of repair/replacement parts when product purchased in one country is submitted for repair in another

country.

Fluke Networks' warranty obligation is limited, at Fluke Networks' option, to refund of the purchase price, free of charge repair, or replacement of a defective product which is returned to a Fluke Networks authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke Networks authorized service center to obtain return authorization information, then

send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke Networks assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke Networks determines that failure was caused by neglect, misuse, contamination, alteration, accident or abnormal

condition of operation or handling, or normal wear and tear of mechanical components, Fluke Networks will provide an estimate of repair

costs and obtain authorization before commencing the work. Following repair, the product will be returned to the Buyer transportation

prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE NETWORKS SHALL

NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, ARISING

FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is held

invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or enforceability of any other provision.

4/04

Fluke Networks

PO Box 777

Everett, WA 98206-0777

USA

Page 3

Table of Contents

Title Page

Overview of Features.................................................................................................... 1

Accessing the Technical Reference Handbook ............................................................ 2

Registration................................................................................................................... 2

Contacting Fluke Networks .......................................................................................... 3

Unpacking ..................................................................................................................... 4

Model OF-500-01...................................................................................................... 4

Model OF-500-02...................................................................................................... 4

Model OF-500-03...................................................................................................... 5

Model OF-500-10...................................................................................................... 5

Model OF-500-13...................................................................................................... 6

Model OF-500-15...................................................................................................... 6

Model OF-500-35...................................................................................................... 7

Model OF-500-45...................................................................................................... 8

Safety Information........................................................................................................ 9

Powering the Tester...................................................................................................... 12

i

Page 4

OF-500 OptiFiber Certifying OTDR

Users Manual

Charging the Battery............................................................................................... 12

Checking the Battery Status.................................................................................... 12

Changing the Language............................................................................................... 14

Removing and Installing the Module.......................................................................... 14

Verifying Operation ..................................................................................................... 15

Basic Features ............................................................................................................... 16

Front Panel Features................................................................................................ 16

Side and Top Panel Features................................................................................... 18

The HOME Screen .................................................................................................... 20

Using the Setup Menus ........................................................................................... 22

Using the Online Help ............................................................................................. 24

Fiber ID Options....................................................................................................... 24

Checking the Tester’s Status ........................................................................................ 25

Preparing to Save Tests ................................................................................................ 26

Cleaning and Inspecting Fiber Connectors and Adapters .......................................... 27

Testing Your Reference Test Cords and Launch Fiber................................................ 28

Using the OTDR ............................................................................................................ 28

About Launch and Receive Fibers........................................................................... 28

Selecting Auto or Manual OTDR Mode.................................................................. 29

OTDR Connection Quality ....................................................................................... 30

Running the OTDR Test........................................................................................... 31

Comparing OTDR Traces.......................................................................................... 38

Cleaning the OTDR Connector..................................................................................... 39

Using the ChannelMap Function................................................................................. 40

Using the FiberInspector Option ................................................................................. 46

Using the Loss/Length Option...................................................................................... 51

About Smart Remotes ............................................................................................. 51

Changing the Connector Adapter .......................................................................... 52

ii

Page 5

Contents

Cleaning the Loss/Length Connectors..................................................................... 54

Cleaning the OUTPUT Connector ....................................................................... 54

Cleaning the INPUT Connector........................................................................... 54

About Setting the Reference................................................................................... 55

Setting the Number of Adapters and Splices.......................................................... 56

Using Mandrels for Testing Multimode Fiber......................................................... 58

Testing in Smart Remote Mode............................................................................... 60

Testing in Loopback Mode ...................................................................................... 66

Testing in Far End Source Mode.............................................................................. 72

Using the Visual Fault Locator...................................................................................... 77

Using the Power Meter Option.................................................................................... 80

Overview of Memory Functions ................................................................................... 84

Memory Capacity and Card Sizes Supported.......................................................... 84

Clearing the Internal Memory................................................................................. 85

About LinkWare and LinkWare Stats Software........................................................... 85

Maintenance ................................................................................................................. 86

Updating the Tester’s Software............................................................................... 86

Updating via the USB or Serial Port ................................................................... 87

Updating via a Memory Card Created with LinkWare ...................................... 88

Optical Connector Care............................................................................................ 89

Replacing Reference Test Cords and Launch Fibers ............................................... 89

Replacing the Battery .............................................................................................. 90

Cleaning.................................................................................................................... 90

Storage .......................................................................................................................... 90

Calibration..................................................................................................................... 91

If Something Seems Wrong.......................................................................................... 91

Getting Help............................................................................................................. 91

Signs of a Bad OTDR Connector .............................................................................. 94

(continued)

iii

Page 6

OF-500 OptiFiber Certifying OTDR

Users Manual

Options and Accessories............................................................................................... 95

Specifications................................................................................................................ 102

Environmental and Regulatory Specifications ....................................................... 102

OTDR Specifications for OFTM-561xB Multimode Modules.................................. 103

Power Meter Specifications..................................................................................... 110

Loss/Length Specifications....................................................................................... 112

Power ....................................................................................................................... 117

Traceable Calibration Period................................................................................... 117

Certifications and Compliance................................................................................ 117

Memory for Test Results.......................................................................................... 117

Serial Interfaces ....................................................................................................... 118

Keyboard Port.......................................................................................................... 119

Video Port for FiberInspector Probe....................................................................... 119

Dimensions (with module and battery installed)................................................... 119

Weight (with module and battery installed) ......................................................... 119

Display...................................................................................................................... 119

Fan............................................................................................................................ 119

FiberInspector Probe Specifications........................................................................ 120

Index

iv

Page 7

List of Figures

Figure Title Page

1. Battery Pack Features........................................................................................................... 13

2. Removing the Module ......................................................................................................... 15

3. Front Panel Features ............................................................................................................ 16

4. Side and Top Panel Features ............................................................................................... 18

5. Home Screen for OTDR with Loss/Length Option .............................................................. 20

6. The SETUP Screen................................................................................................................. 22

7. OTDR Port Connection Quality Gauge................................................................................ 30

8. Equipment for OTDR Testing .............................................................................................. 31

9. Connecting the OTDR to Installed Fiber (no receive fiber)................................................ 33

10. Connecting the OTDR to Installed Fiber (with receive fiber)............................................. 34

11. Connecting the OTDR to Spooled Cable............................................................................. 35

12. OTDR Trace Screen............................................................................................................... 36

13. Cleaning the OTDR Connector ............................................................................................ 39

14. Equipment for ChannelMap Testing................................................................................... 41

15. ChannelMap Test Connections............................................................................................ 43

16. ChannelMap Diagram Features........................................................................................... 44

17. Equipment for FiberInspector Tests .................................................................................... 47

v

Page 8

OF-500 OptiFiber Certifying OTDR

Users Manual

18. Using the FiberInspector Probe........................................................................................... 49

19. FiberInspector Image Examples .......................................................................................... 50

20. SC, ST, LC, and FC Connector Adapters .............................................................................. 52

21. Changing the Connector Adapter ...................................................................................... 53

22. Example of How to Determine the NUMBER OF ADAPTERS Setting................................ 57

23. Wrapping a Reference test cord Around a Mandrel ......................................................... 59

24. Equipment for Loss/Length Testing in Smart Remote Mode............................................. 60

25. Smart Remote Mode Reference Connections .................................................................... 63

26. Smart Remote Mode Test Connections .............................................................................. 65

27. Equipment for Loss/Length Testing in Loopback Mode.................................................... 67

28. Loopback Mode Reference Connections............................................................................ 69

29. Loopback Mode Test Connections...................................................................................... 71

30. Equipment for Loss Testing in Far End Source Mode ........................................................ 72

31. Far End Source Mode Reference Connections ................................................................... 75

32. Far End Source Mode Test Connections ............................................................................. 76

33. Equipment for Using the Visual Fault Locator................................................................... 77

34. Using the Visual Fault Locator ............................................................................................ 79

35. Equipment for Power Meter Tests...................................................................................... 81

36. Connections for Monitoring Optical Power....................................................................... 83

37. Traces Showing Good and Bad OTDR Connectors............................................................. 94

38. Event and Attenuation Deadzone Measurement Methods .............................................. 107

vi

Page 9

List of Tables

Table Title Page

1. International Electrical Symbols.......................................................................................... 9

2. Troubleshooting the Tester................................................................................................. 92

3. Options ................................................................................................................................. 95

4. Accessories............................................................................................................................ 96

5. RS-232 Interface Cable Connections.................................................................................... 118

6. 9-to-25-Pin Adapter ............................................................................................................. 119

vii

Page 10

OF-500 OptiFiber Certifying OTDR

Users Manual

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 11

OF-500 OptiFiber Certifying OTDR

Note

While this manual describes specific operating

procedures for the OptiFiber tester, the fiber

test methods described are provided only as

guidelines. Your test methods may vary.

Overview of Features

The OF-500 OptiFiber® Certifying OTDR (hereafter

referred to as the tester) is a hand-held Optical Time

Domain Reflectometer (OTDR) that locates and

characterizes reflective and loss events in multimode and

singlemode fibers. The tester is optimized for use on the

shorter fiber runs typically installed in premises (building

and campus) networks. Typical test ranges are up to 7 km

at 1300 nm for multimode fiber and up to 60 km for

singlemode fiber.

The tester offers the following features:

• Automated OTDR trace and event analysis help you

identify and locate faults on multimode (850 nm and

1300 nm; 50 µm and 62.5 µm) and singlemode

(1310 nm and 1550 nm; 9 µm) fiber.

• Displays OTDR results in summary format, as a table

of events, or as an interpretive OTDR trace.

PASS/FAIL results are based on factory-installed limits

or limits you specify.

• ChannelMap

of the connectors and segment lengths in a channel.

• Optional FiberInspector

inspect fiber endfaces and save the images.

function provides an intuitive diagram

Video Probe lets you

1

Page 12

OF-500 OptiFiber Certifying OTDR

Users Manual

• Optional modules add visual fault locator (OFTM-

57xx only), power meter, and loss/length test set

functions to the standard OTDR.

• Interchangeable connector adapters on the input

ports of the loss/length modules allow ISO-compliant

reference and test connections with a variety of

connector types.

• Saves hundreds of test results on a removable

memory card or in internal memory.

• Context-sensitive online help gives you quick access

to operating instructions and fiber troubleshooting

information.

• LinkWare

PC and create professional-quality test reports. The

LinkWare Stats option generates browsable,

graphical reports of cable test statistics.

software lets you upload test results to a

Accessing the Technical Reference Handbook

The OF-500 OptiFiber Technical Reference Handbook

provides additional information on the tester. The

handbook is available on the OptiFiber Product CD

included with your tester and on the OptiFiber product

page on the Fluke Networks website.

Registration

Registering your product with Fluke Networks gives you

access to valuable information on product updates,

troubleshooting tips, and other support services. To

register, fill out the online registration form on the Fluke

Networks website at

www.flukenetworks.com/registration.

2

Page 13

Page 14

OF-500 OptiFiber Certifying OTDR

Users Manual

Unpacking

The OF-500 OptiFiber packages come with the accessories

listed below. If something is damaged or missing, contact

the place of purchase immediately.

Model numbers followed by a "/50M" include

50/125 µm accessories instead of 62.5/125 µm accessories

Model OF-500-01

• OF-500 OptiFiber tester with battery pack

• OFTM-5610B multimode OTDR module

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m, SC/SC

• Protective carrying case for tester

• Carrying strap

• Memory card

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

Model OF-500-02

• OF-500 OptiFiber tester with battery pack

• OFTM-5611B multimode OTDR module with power

meter option

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m, SC/SC

• Two 62.5/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two gray mandrels for 62.5/125 µm fiber with 3 mm

jackets

• Protective carrying case for tester

• Carrying strap

• Memory card

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

4

Page 15

Unpacking

Model OF-500-03

• OF-500 OptiFiber tester with battery pack

• OFTM-5730 singlemode OTDR module

• 9/125 µm singlemode launch fiber (yellow zipper),

130 m, SC/SC

• Protective carrying case for tester

• Carrying strap

• Memory card

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

Model OF-500-10

• OF-500 OptiFiber tester with battery pack

• OFTM-5612B multimode OTDR module with power

meter and loss/length options

• OFTM-5352 FiberInspector Video Probe (250X/400X)

with adapter tip kit

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m , SC/SC

• Two 62.5/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two gray mandrels for 62.5/125 µm fiber with 3 mm

jackets

• Protective carrying case for tester

• Carrying strap

• Soft carrying case for accessories

• Memory card

• USB memory card reader

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

5

Page 16

OF-500 OptiFiber Certifying OTDR

Users Manual

Model OF-500-13

• OF-500 OptiFiber tester with battery pack

• OFTM-5732 singlemode OTDR module with power

meter and loss/length options

• DTX Smart Remote with DTX-SFM2 singlemode fiber

module and interchangeable SC adapter

• OFTM-5352 FiberInspector Video Probe (250X/400X)

with adapter tip kit

• 9/125 µm singlemode launch fiber (yellow zipper),

130 m , SC/SC

• Two 9/125 µm singlemode duplex reference test

cords, 2 m, SC/SC

• Carrying strap

• Hard carrying case for tester

• Soft carrying case for accessories

• Memory card

• USB memory card reader

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

Model OF-500-15

• OF-500 OptiFiber tester with battery pack

• OFTM-5612B multimode OTDR module with power

meter and loss/length options

• DTX Smart Remote with DTX-MFM2 multimode fiber

module and interchangeable SC adapter

• OFTM-5352 FiberInspector Video Probe (250X/400X)

with adapter tip kit

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m , SC/SC

• Two 62.5/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two gray mandrels for 62.5/125 µm fiber with 3 mm

jackets

• OptiFiber carrying strap

• Smart Remote carrying strap

• Soft carrying case for accessories

• Hard carrying case for tester

• Memory card

• USB memory card reader

• USB cable for PC communications

• Mini-B USB cable for OptiFiber Smart Remote

• Two AC adapters

• OptiFiber Users Manual

6

Page 17

Unpacking

• OptiFiber Product Manuals CD

• Smart Remote Users Manual

• Smart Remote Product CD

• LinkWare Software CD

Model OF-500-35

• OF-500 OptiFiber tester with battery pack

• OFTM-5612B multimode OTDR module with power

meter and loss/length options

• OFTM-5732 singlemode OTDR module with power

meter and loss/length options

• OFTM-5352 FiberInspector Video Probe (250X/400X)

with adapter tip kit

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m , SC/SC

• 9/125 µm singlemode launch fiber (yellow zipper),

130 m , SC/SC

• Two 62.5/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two gray mandrels for 62.5/125 µm fiber with 3 mm

jackets

• Two 9/125 µm singlemode duplex reference test

cords, 2 m, SC/SC

• Carrying strap

• Soft carrying case for accessories

• Hard carrying case for tester

• Memory card

• USB memory card reader

• USB cable for PC communications

• AC adapter

• Users Manual

• Product Manuals CD

• LinkWare Software CD

7

Page 18

OF-500 OptiFiber Certifying OTDR

Users Manual

Model OF-500-45

• OF-500 OptiFiber tester with battery pack

• OFTM-5612B multimode OTDR module with power

meter and loss/length options

• OFTM-5732 singlemode OTDR module with power

meter and loss/length options

• DTX Smart Remote with DTX-MFM2 multimode fiber

module and interchangeable SC adapter

• DTX-SFM2 singlemode fiber module and

interchangeable SC adapter

• OFTM-5352 FiberInspector Video Probe (250X/400X)

with adapter tip kit

• 62.5/125 µm multimode launch fiber (gray zipper),

100 m , SC/SC

• 50/125 µm multimode launch fiber (aqua zipper),

100 m , SC/SC

• 9/125 µm singlemode launch fiber (yellow zipper),

130 m , SC/SC

• Two 62.5/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two 50/125 µm multimode duplex reference test

cords, 2 m, SC/SC

• Two red mandrels for 62.5/125 µm fiber with 3 mm

jackets

• Two gray mandrels for 62.5/125 µm fiber with 3 mm

jackets

• Two 9/125 µm singlemode duplex reference test

cords, 2 m, SC/SC

• Carrying strap

• Protective carrying case for accessories

• Hard carrying case for tester

• Protective carrying case for tester

• Memory card reader

• Memory card

• USB cable for PC communications

• Two AC adapters

• Users Manual

• Product Manuals CD

• LinkWare Software CD

8

Page 19

Safety Information

*

W

Safety Information

Table 1 shows the international electrical symbols used

on the tester or in this manual.

Table 1. International Electrical Symbols

X

W

*

Warning: Risk of fire, electric shock, or personal

injury.

Warning or Caution: Risk of damage or

destruction to equipment or software. See

explanations in the manuals.

Warning: Class 1 laser (OUTPUT port). Risk of eye

damage from hazardous radiation.

Do not put products containing circuit boards

~

into the garbage. Dispose of circuit boards in

accordance with local regulations.

To avoid possible eye damage caused by

hazardous radiation and to avoid possible fire,

electric shock, or personal injury:

• Never look directly into optical connectors.

Some sources produce invisible radiation that

can permanently damage your eyes.

• Never run any tests that activate the tester’s

outputs unless a fiber is attached to the output.

• Do not open the case; no user-serviceable parts

are inside.

• Do not modify the tester.

• Do not use magnification to view the optical

outputs without proper filtering.

• Use of controls, adjustments, or procedures not

stated herein might result in hazardous

radiation exposure.

• Use only the ac adapter provided to charge the

battery or power the tester.

• Do not use the tester if it is damaged. Inspect

the tester before use.

Warning

9

Page 20

OF-500 OptiFiber Certifying OTDR

Users Manual

• If this equipment is used in a manner not

specified by the manufacturer, the protection

provided by the equipment may be impaired.

WCaution

To avoid damaging the tester or cables under

test and to avoid data loss:

• Always turn the tester off before removing or

installing a module.

• Never connect the OTDR port to an optical

source. Doing so can damage the OTDR

receiver.

• Never connect the tester to an active network,

except when using the power meter. Doing so

causes unreliable test results and can disrupt

network operations.

• If the tester shows an error because the power

reading is too high, immediately disconnect the

source from the tester. The tester is not

designed for measuring higher power levels,

such as produced by CATV, optical amplifiers,

and cellular systems.

• Avoid touching reflective surfaces (such as

metal) to the end of a fiber cable plugged into

the OTDR when the OTDR is operating. An

open fiber connector end face has about a 4%

reflection. Holding a reflective surface near the

connector end face may cause much greater

than a 4% reflection, which may damage the

photodetector in the OTDR.

• Use proper cleaning procedures to clean all

fiber connectors before every use. Neglecting

this step or using improper procedures can

cause unreliable test results and may

permanently damage the connectors.

• Use a Fluke Networks FiberInspector Video

Microscope to periodically inspect the OTDR

and loss/length option’s OUTPUT connectors for

scratches and other damage.

10

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 21

Safety Information

• Read the instructions for splice machines before

using the OTDR to monitor splicing procedures.

The OTDR can interfere with the light injection

detection techniques used by some splicers.

• To avoid unreliable test results, connect the ac

adapter or replace the battery as soon as the

low battery indication appears.

• You may use a PC to move or copy test record

(.tst) files from a memory card, but do not

rename the .tst files. Doing so may result in loss

of data.

• Never remove the memory card while the

memory card’s LED is on. Doing so can corrupt

the data on the card.

11

Page 22

OF-500 OptiFiber Certifying OTDR

Users Manual

Powering the Tester

You can power the tester with the ac adapter included or

with the removable lithium ion battery pack.

I to turn the tester on.

Press

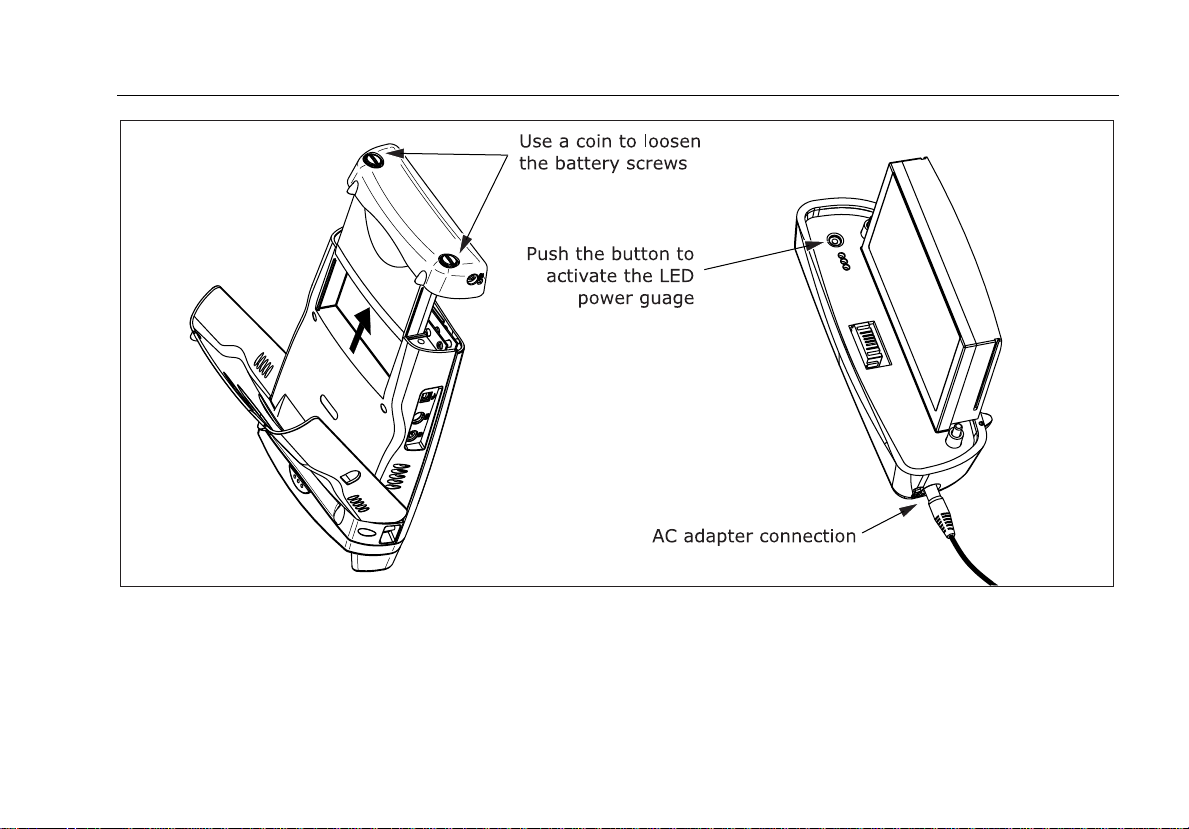

Charging the Battery

Before you rely on battery power for the first time,

charge the battery for about 2 hours with the tester

turned off.

You can also charge the battery when it is detached from

the tester, as shown in Figure 1.

A fully-charged battery lasts about 8 hours during typical

use. The battery typically takes about 4 hours to fully

charge when the tester is turned off.

Notes

You do not need to fully discharge the battery

before recharging it.

The battery will not charge if its temperature is

outside the range of 32 °F to 113 °F (0 °C to

45 °C).

Checking the Battery Status

Many of the tester’s screens show a battery status icon

( ) near the lower-right corner.

To see more information about the battery status, press

F; then select Battery Status. Press H for detailed

information about the battery status screen.

12

Page 23

Powering the Tester

ajt20f.eps

Figure 1. Battery Pack Features

13

Page 24

OF-500 OptiFiber Certifying OTDR

Users Manual

Changing the Language

To change the tester’s language, do the following:

1 Press

2 Press

3 Press

4 Use ML to select the desired language; then press

5 Restart the tester to apply the new language.

Additional languages for the tester may be available

with software updates available on the Fluke Networks

website. Use LinkWare software to install or remove

languages. See “Updating the Tester’s Software” on

page 86 for details.

S.

N once to select the System tab.

L to select LANGUAGE; then press t.

t.

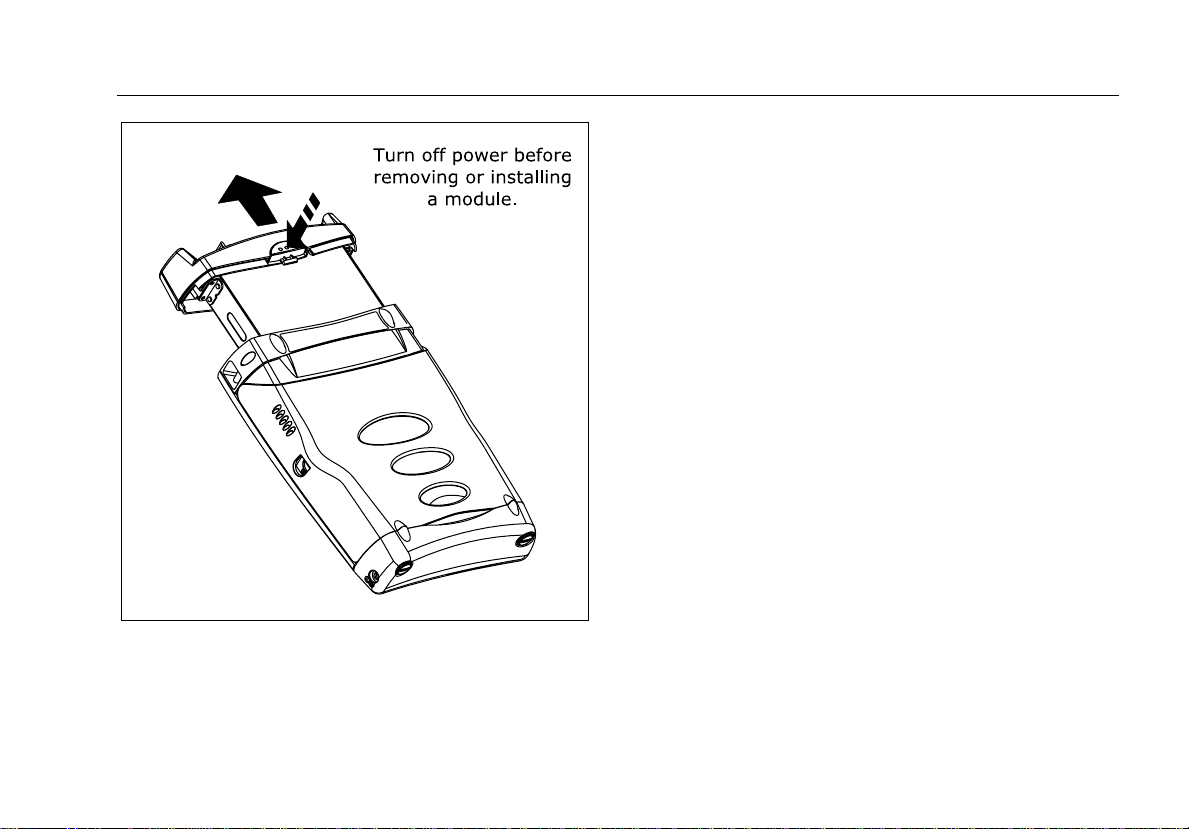

Removing and Installing the Module

The tester’s capabilities depend on which test module is

installed. Figure 2 shows how to remove the module.

WCaution

To avoid corrupting the tester's software,

always turn the tester off before removing or

installing a module.

14

Page 25

Verifying Operation

Verifying Operation

The tester performs a basic self-test when you turn it on.

If the tester reports an error or does not turn on, refer to

“If Something Seems Wrong” on page 91.

The tester shows the model number of the installed

module in the upper-right corner of the screen. If the

screen shows No Module Installed, Problem with

Module, or The module needs a software update refer to

“If Something Seems Wrong” on page 91.

Figure 2. Removing the Module

ajt56f.eps

15

Page 26

OF-500 OptiFiber Certifying OTDR

Users Manual

Basic Features

The following sections describe the tester's basic features

and introduce the tester's menu system.

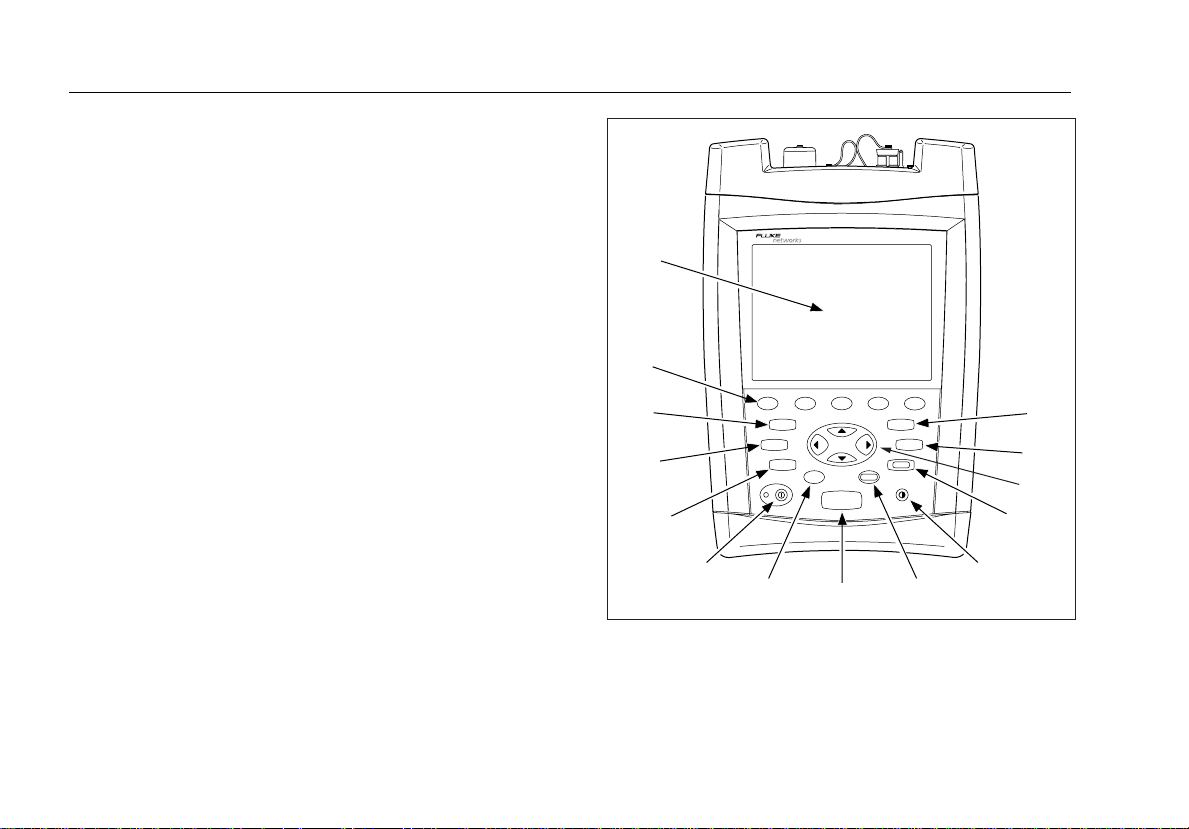

Front Panel Features

Figure 3 describes the tester’s front panel features.

16

A

N

M

L

K

F1

FUNCTIONS

SETUP

FIBER

INSPECTOR

F2

HELP

F4 F5

F3

SAVE

ENTER

TEST

J

I

Figure 3. Front Panel Features

H

OPTIFIBER

VIEW

RECORDS

EXIT

G

F

E

B

C

D

ajt12f.eps

Page 27

Basic Features

A

LCD display with backlight and adjustable brightness.

B s: Saves test results on the removable memory

card or in internal memory.

I H: Shows a help topic related to the current screen.

To see the help index, press

H again.

J I: On/off key.

C v: Shows the test records saved on the memory

card or in internal memory.

D K N L M: Navigation keys let you move the cursor

or highlighted area on the screen and increment or

decrement alphanumeric values.

E e: Exits the current screen.

F J: Lets you adjust the display brightness.

G t: Selects the highlighted item on the screen.

H T: Starts the currently selected fiber test. The test

that will run is shown in the upper-left corner of the

display. To change the test, press

from the HOME screen or select a test from the

FUNCTIONS menu.

A Change Test

Figure 3. Front Panel Features (cont.)

K f: Activates the optional FiberInspector video

probe, which lets you inspect fiber endfaces and save

the images with test results.

L F: Shows a list of additional test, configuration,

and status functions.

M S: Shows the menus you use to configure the

tester.

N A B C D E: The five softkeys provide

functions related to the current screen. The current

functions are shown on the screen above the keys.

17

Page 28

OF-500 OptiFiber Certifying OTDR

Users Manual

Side and Top Panel Features

Figure 4 describes the tester’s connectors and other

features on the side and top panels.

Figure 4. Side and Top Panel Features

ajt14f.eps

18

Page 29

Basic Features

A

Connector for the ac adapter. The LED turns on when the

adapter is connected to ac power.

B USB port for uploading test reports to a PC and

downloading software updates from a PC to the tester.

See the LinkWare documentation for details on using the

USB port.

C Six-pin mini DIN connector for an optional external PS2

keyboard.

D Eight-pin mini DIN connector for the optional

FiberInspector video probe.

E Fan vents.

F RS-232C serial port for uploading test reports to a PC and

downloading software updates from a PC to the tester.

See the LinkWare documentation for details on using the

serial port.

G Slot for the removable memory card. The LED lights when

the tester is writing to or reading from the memory card.

H Multimode (MM) or singlemode (SM) label for the module.

Figure 4. Side and Top Panel Features (cont.)

I OFTM-57xx: Connector for the visual fault locator.

J OTDR connector adapter (SC is standard). The LED

lights when the laser is active.

K OFTM-5612B/5732: Loss/length output port (SC).

Transmits optical signals for loss/length tests.

L OFTM-5731/5732/5611B/5612B: Loss/length input

port with interchangeable connector adapter (SC is

standard). Receives optical signals for power

measurements and loss/length tests.

*

W

Never look directly into optical connectors.

Some sources produce invisible radiation that

can permanently damage your eyes.

Warning

M Laser safety label (shown below).

CAUTION

ajt72f.eps

19

Page 30

OF-500 OptiFiber Certifying OTDR

Users Manual

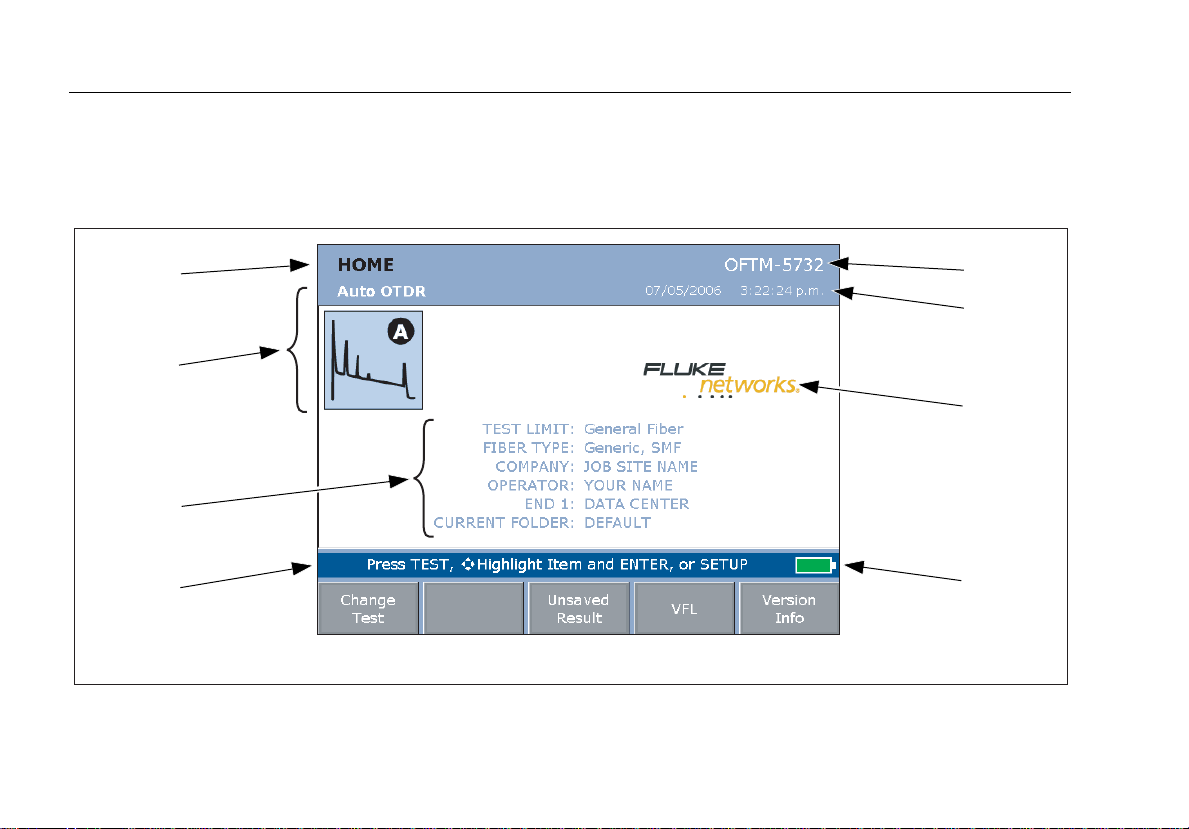

The HOME Screen

The HOME screen shows important test and job settings

you might need to change to configure the tester for your

needs. Figure 5 describes a typical home screen.

L

K

J

I

H

Figure 5. Home Screen for OTDR with Loss/Length Option

G

F

E

A

B

C

D

ajt13f.eps

20

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 31

Basic Features

A

Model number of the installed module.

B The current date and time.

I Action prompts. For most screens, this area prompts

you on what keys to press.

J Important test and job settings. To change these

C Owner’s logo. See the OptiFiber Technical Reference

Handbook (on the Product Manuals CD) or the LinkWare

online help for information on changing the logo.

D Battery status icon. For more information about the

battery, press F; then select Battery Status.

E Press E to see the hardware and software versions and

calibration dates for the tester and the installed module.

F Press D VFL to activate the visual fault locator.

G If the last test run was not saved, you can press

settings, use KLMNto highlight a setting; then

t. Selecting TEST LIMIT or FIBER TYPE lets

press

you change the item. Selecting the limit’s or type’s

name lets you see that item’s settings. You may also

access the tester’s settings by pressing

S.

K The test mode, which determines what type of test

will run when you press T. The available modes

depend on which module is installed. To change the

test mode, press A Change Test.

L The name of the current screen.

C Unsaved Result to see the test’s results.

H Press A Change Test to switch test modes. See K.

Figure 5. Home Screen for OTDR with Loss/Length Option (cont.)

21

Page 32

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the Setup Menus

To access the tester’s settings, press S. Figure 6

introduces the SETUP menus.

C

Figure 6. The SETUP Screen

A

B

ajt17f.eps

22

Page 33

Basic Features

A The settings available on the current tab.

Note

To see details about a setting, highlight the

setting; then press H.

B Use D Tab and E Tab to move among tabs on

the SETUP screen.

C Tabs for the setup menus:

• Job settings apply to the fiber installation you are

testing and are stored with saved test results. Use

these settings to identify the job site, set up cable ID

lists, and identify which end of the cabling you are

testing.

• System settings let you localize the tester and set

other user preferences, such as the power down

timeout and camera type.

Figure 6. The Setup Screen (cont.)

• The Cable tab lets you select the type of fiber cable you

will test and define some cable characteristics for

loss/length tests. You can also change the index of

refraction if you do not want to use the default values.

Note

Select a fiber type before selecting a test limit. The

fiber type determines which test limits are available.

• The OTDR tab lets you select a test limit and wavelength

for OTDR tests and enable launch fiber compensation. You

can also change settings for Manual OTDR mode.

• The Loss/Length tab appears if the installed module

includes the loss/length or power meter option (you can

run loss tests in Far End Source mode with the power

meter option). Use this tab to configure the loss/length

test. See “Using the Loss/Length Option” on page 51 for

details.

Different or additional tabs may be available depending on

the installed module.

23

Page 34

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the Online Help

When you press H, the tester shows a help topic that

relates to the current screen. Blue, underlined words are

links to other topics.

Note

The help files are stored in the mainframe

(rather than the module) and may describe

features not present in the installed module

To go to a linked topic (blue, underlined words), use the

left or right arrow keys to highlight the words; then press

t.

To see an index of all help topics, press

are in the help system.

H any time you

Fiber ID Options

You can create or select fiber IDs as follows:

• You can create an ID after you press s. You can

also highlight a used or unused ID in a list; then press

t to edit it into a new ID. The next time you press

s, the tester increments the last character of the

ID you created (the auto increment feature).

• You can create a list of sequential fiber IDs by

configuring a template on the Job tab in Setup.

Select the IDs from the AUTO SEQ IDs list after you

press s.

• You can create ID lists in LinkWare software; then

download them to the tester. Select the IDs from the

DOWNLOAD IDs list after you press s.

• After you press

assigned to a record stored in the current folder. This

lets you overwrite existing results or add new results

to an existing record. Select the ID from the IDs IN

CURRENT FOLDER list after you press

s, you can use an ID already

s.

24

Page 35

Checking the Tester’s Status

Checking the Tester’s Status

The following steps help you verify that the tester is ready

for use.

Checking the Tester’s Status

Check the battery status

Look at the battery icon in the lower-left corner of the

screen or press

A fully-charged battery lasts about 8 hours during

typical use.

Check the space available on the memory card

Insert the memory card you will use, press

select Memory Status.

To see the status of the internal memory, press

A from the MEMORY STATUS screen.

F; then select Battery Status.

F; then

To view or delete stored records, press

To format the memory card press F; then select

Format Memory Card.

Verify that the installed module can run the tests you

need

The module’s model number is shown in the upperright corner of the screen.

To review module capabilities, press H twice; then

select “modules” in the OptiFiber online help index.

v.

25

Page 36

OF-500 OptiFiber Certifying OTDR

Users Manual

Preparing to Save Tests

The following steps summarize how to configure settings

that apply to saved test results.

Preparing to Save Tests

Set up a job folder

1 Insert a memory card into the tester.

2 Press

3 Select an existing folder on the memory card, or

Enable or disable the SAVE WARNING

Press

tab to enable or disable the warning about an unsaved

test.

Enter COMPANY and OPERATOR names on the Job

tab

COMPANY is the customer name, job site, job work

order, or other job identifier.

S; then select CURRENT FOLDER on the

Job tab.

press

A New Folder to create a new folder.

S; then select SAVE WARNING on the System

Create a list of sequential fiber IDs (See “Fiber ID

Options” on page 24 for other ID options.)

1 Select AUTO SEQ TEMPLATE on the Job tab.

2 Press

3 Press

4 Press

Identify the ends of the cabling

1 Enter names for END 1 and END 2 on the Job tab.

2 Set THIS END to the end you will test from first.

A Change Template to select an ID

template.

B Edit Start or C Edit Stop to create the

start and stop IDs; then press E Sample List to

see what the list will look like.

s when you are finished.

For example, one end could be TELECOM ROOM

and the other could be WORK AREA.

OPERATOR is the name of the OptiFiber user.

26

Page 37

Cleaning and Inspecting Fiber Connectors and Adapters

Cleaning and Inspecting Fiber Connectors and Adapters

Always clean and inspect fiber connectors before making

connections. Use 99 %-pure isopropyl alcohol and

optical-grade wipes or swabs to clean fiber connectors as

follows:

WCaution

See pages 39 and 52 for instructions on cleaning

the tester's OTDR and loss/length connectors.

• Connector ends: Wipe the end of the ferrule with a

swab or wipe lightly moistened with alcohol. Dry

with a dry swab or wipe.

• Bulkhead adapters:

1 Touch the tip of a lint-free foam swab to an

alcohol-soaked cleaning pad.

2 Push the swab into the adapter; twist it around

3 to 5 times against the endface, then remove

and dispose of the swab.

3 Dry the endface with a dry, lint-free swab by

twisting it around in the adapter 3 to 5 times.

• Inspect connectors with a fiber microscope, such as

the Fluke Networks FiberInspector Video Probe

before making connections. See “Using the

FiberInspector Option” on page 46 for details.

• Periodically clean fiber adapters with a swab and

alcohol. Dry adapters with a dry swab before use.

• Always cover unused connectors with dust caps or

plugs. Clean dust plugs periodically with a swab or

wipe and alcohol.

27

Page 38

OF-500 OptiFiber Certifying OTDR

Users Manual

Testing Your Reference Test Cords and Launch Fiber

You should test your reference test cords and launch

fiber before each job. Use another set of known-good

cords to set a reference and run an Autotest on each cord

and launch fiber. Use Smart Remote mode to test two

cords at a time, or Loopback mode to test one cord.

You should also use a fiber microscope, such as the

FiberInspector video probe, to inspect the reference test

cord and launch fiber connectors for damage at least

once a day.

Using the OTDR

The OTDR helps you identify and locate faults on fiber

cabling. It also measures length, event loss, and overall

loss of the cabling and provides PASS/FAIL results based

on a selected test limit.

About Launch and Receive Fibers

Launch and receive fibers let the tester measure the loss

and reflectance of the first and last connectors in the

cabling, and include those connectors in ORL (optical

return loss) measurements. Without launch and receive

fibers, no backscatter is available before the first

connector and after the last, so the tester cannot

measure the connectors’ characteristics.

If the first or last connection in the cabling is bad, and

you do not use launch and receive fibers, the OTDR test

may pass because it does include measurements from the

bad connection.

28

Page 39

Using the OTDR

OVERALL LOSS and FIBER LENGTH include the loss and

length of the launch and receive fibers, unless you use

the launch/receive fiber compensation function. See the

online help or the Technical Reference Handbook for

details on launch fiber compensation.

Fluke Networks recommends that you use launch and

receive fibers. You should also use launch/receive fiber

compensation to remove the effects of these fibers from

the OTDR measurements.

Note

Avoid using hybrid patch cords to connect to the cabling

under test. Connect the launch and receive fibers directly

to the cabling under test, using a launch fiber with the

appropriate connectors. This provides the best view of

the connectors at the ends of the cabling. Hybrid launch

fibers with various connector styles are available from

Fluke Networks.

Selecting Auto or Manual OTDR Mode

Note

You should use Auto OTDR mode when

certifying cabling with the OTDR.

From the HOME screen, press

Auto OTDR or Manual OTDR from the popup menu.

In Auto OTDR mode, the tester automatically selects

settings based on the length and overall loss of the

cabling. This mode is the easiest to use, provides the most

comprehensive view of the events on the cabling, and is

the best choice for most applications.

Manual OTDR mode lets you change settings to optimize

the OTDR for displaying specific events. See the online

help or the Technical Reference Handbook for details.

A Change Test. Select

29

Page 40

OF-500 OptiFiber Certifying OTDR

Users Manual

OTDR Connection Quality

When you run an OTDR test, the tester determines the

quality of OTDR port connection (Figure 7).

If the gauge is in the Poor range, you should clean the

OTDR port and the fiber connector. Use a video

microscope, such as the FiberInspector video probe, to

inspect the port and fiber connector for scratches and

other damage. If a connector on the tester is damaged,

contact Fluke Networks for service information.

A poor OTDR connection increases the connector’s

deadzone, as shown in Figure 37 on page 94. The

deadzone can hide faults near the OTDR connector.

A poor connection also decreases the light available for

testing the fiber. The weakened test signal causes a

noisier trace, poor event detection, and decreased

dynamic range.

The port connection quality rating is saved with OTDR

result details.

Figure 7. OTDR Port Connection Quality Gauge

ajt67f.eps

30

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 41

Using the OTDR

Running the OTDR Test

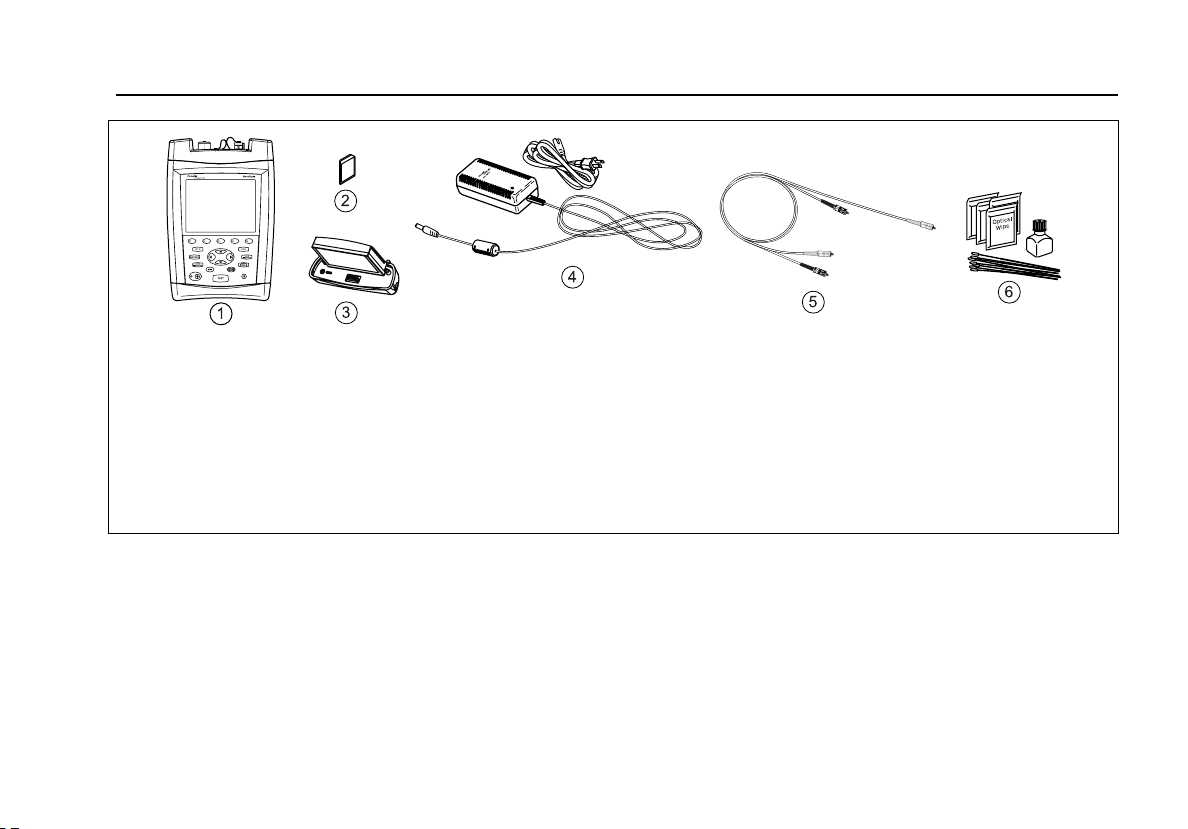

Figure 8 shows the equipment needed for using the

OTDR.

A Tester with OFTM-56xxB or OFTM-57xx module

B Memory card (optional)

C Spare battery pack (optional)

D AC adapter with line cord (optional)

Figure 8. Equipment for OTDR Testing

ajt42f.eps

E Launch fiber and receive fibers. Match the fiber to be

tested. Match cable connectors at one end when

possible.

F Fiber cleaning supplies

31

Page 42

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the OTDR

1 Select Auto OTDR mode: On the HOME screen, press

A Change Test; then select Auto OTDR.

2 Compensate for the launch/receive fibers, if desired:

F; then select Set Launch Fiber Compensation.

Press

Press H for details on the compensation screens.

3 Choose settings for the fiber to be tested. Set the

following on the Cable tab:

• FIBER TYPE: Select the fiber type to be tested.

• MANUAL CABLE SETTINGS (index of refraction

and backscatter coefficient): Disable to use the

values defined in the selected fiber type, which are

suitable for most applications.

4 Configure the OTDR test. Press

following on the OTDR tab:

• TEST LIMIT: Select an appropriate limit.

• WAVELENGTH: Select one or both wavelengths.

• LAUNCH COMPENSATION: Enable if you want to

use the launch fiber compensation settings.

• OTDR PLOT GRID: Enable to see a measurement

grid on the OTDR plot.

S; then select the

5 Clean the connectors on the launch fiber and the fiber

to be tested.

6 Clean all connectors that will be used.

7 Connect the tester's OTDR port to the cabling, as shown

in Figure 9, 10, or 11.

8 Press

9 To save the results, press

For bi-directional testing, do the following:

1 Set THIS END to END 1 on the Job tab in Setup.

2 Test all the cabling from END 1.

3 Change THIS END to END 2; then test all the cabling

T to start the OTDR test. Figure 12 describes

the OTDR trace screen.

s, select or create a fiber

ID; then press

from the other end. Save the results with the same fiber

IDs as results from the first test direction. The ID will be

in the IDs IN CURRENT FOLDER list.

s again.

32

Page 43

Using the OTDR

Figure 9. Connecting the OTDR to Installed Fiber (no receive fiber)

ajt32f.eps

33

Page 44

OF-500 OptiFiber Certifying OTDR

Users Manual

34

Figure 10. Connecting the OTDR to Installed Fiber (with receive fiber)

ajt01f.eps

Page 45

Using the OTDR

Figure 11. Connecting the OTDR to Spooled Cable

ajt33f.eps

35

Page 46

OF-500 OptiFiber Certifying OTDR

Users Manual

A

B

36

N

M

L

K

HIJ

Figure 12. OTDR Trace Screen

G

F

C

D

E

ajt16f.eps

Page 47

Using the OTDR

A

Wavelength for the trace and the End setting on the

Job tab in SETUP. If the test ran at two wavelengths,

A to switch wavelengths. You can set the

press

wavelengths on the OTDR tab in Setup.

B Magnification factors for the trace. See the online help

for details on zooming.

C The distance (m or ft) and the power loss (dB) between

the cursor and the measurement marker (M).

D OTDR plot grid. You can enable or disable the grid on

the OTDR tab in SETUP.

E PASS/FAIL status appears if the cursor is on an event.

The status may refer to the event or the fiber segment

before the event. If the event looks ok, press C View

Details from the EVENT TABLE screen or the

SUMMARY screen to see results for the segment.

F Press E to change the arrow keys’ function from

moving the cursor to zooming to moving the trace if

trace overlay is active (page 38). The navigational cue

above the softkey labels describes the arrow keys’

current function.

Figure 12. OTDR Trace Screen (cont.)

G Key for setting and clearing the measurement cursor.

H Moves the cursor to the next event on the trace. If you

use K to move the cursor, C changes to Previous

Event and moves the cursor to the previous event.

I Displays the event table.

J For dual-wavelength tests, press A to switch

wavelengths.

K Event information appears if the cursor is on an event.

Otherwise, the distance to the cursor is shown.

L Scale for the distance along the cabling under test.

Tip: The distance scale represents the distance along the

fiber, which may be different from the distance along

the cable jacket. To adjust the length measurements

to represent cable jacket length, change the index of

refraction until the measured length matches the

jacket length.

M Measurement marker and cursor.

N Decibel scale for the OTDR backscatter.

37

Page 48

OF-500 OptiFiber Certifying OTDR

Users Manual

Comparing OTDR Traces

The trace overlay function lets you see two OTDR traces

at the same time. This lets you do the following:

• Compare a link’s current trace with a past trace to

see if the link has changed.

• Compare traces from links in the same run to check

for differences.

To compare two traces, do the following:

1 Run an OTDR test; then press

or

View an OTDR trace from a saved record.

This trace is the Comparison Trace.

2 Press

3 Select New Reference Trace.

4 On the VIEW RECORDS screen, select a record. Only

5 Press

F. This brings up the OTDR FUNCTIONS

menu.

records with OTDR traces are shown.

The test’s trace becomes the Reference Trace on the

OTDR FUNCTIONS menu.

e.

A View Trace.

The reference trace stays on the plot until you turn off

the trace overlay function.

38

Page 49

Cleaning the OTDR Connector

Cleaning the OTDR Connector

Note

Typically, the OTDR connector requires cleaning

only if it has been touched.

Use a dry, optical-grade wipe to clean the OTDR

connector. Figure 13 shows how to remove the OTDR

adapter to access the connector ferrule.

The OTDR port connection quality screen helps you

determine when the OTDR connector needs cleaning. See

page 30.

If the connector is very dirty, wipe the end of the ferrule

with an optical-grade wipe lightly moistened with 99 %pure isopropyl alcohol. Dry with a dry wipe.

Figure 13. Cleaning the OTDR Connector

ajt71f.eps

39

Page 50

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the ChannelMap Function

The ChannelMap function creates a map of the cabling

under test. The map shows the fiber links and

connections in the cabling. This function is optimized for

resolving connections as close as 1 m apart on multimode

fiber and 2 m apart on singlemode fiber.

Reflective events that do not appear to be connectors are

not shown on the map. Loss events are also not shown.

Note

Since the ChannelMap function identifies only

reflections, it is not appropriate for finding fusion splices

or angled physical contact (APC) connectors.

Figure 14 shows the equipment needed for ChannelMap

tests.

40

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com

Page 51

Using the ChannelMap Function

ajt48f.eps

A Tester with OTDR module

B Memory card (optional)

C Spare battery pack (optional)

E Launch fiber or patch cord. Match fiber to be tested.

Match cable connectors at one end. SC at the other

end.

F Fiber cleaning supplies

D AC adapter with line cord (optional)

Figure 14. Equipment for ChannelMap Testing

41

Page 52

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the ChannelMap Function

1 Select ChannelMap mode: On the HOME screen, press

A Change Test; then select ChannelMap.

2 Select a fiber type on the Cable tab in Setup. You do

not need to select a test limit for ChannelMap tests.

3 Clean the connectors on the launch fiber or patch cord

and the channel to be tested.

4 Connect the launch fiber to the OTDR port and the

channel to be mapped. Refer to Figure 15.

5 Press

6 To save the results, press

T. Figure 16 describes the features of the

ChannelMap diagram.

s, select or create a fiber

ID; then press s again.

42

Page 53

Using the ChannelMap Function

Figure 15. ChannelMap Test Connections

ajt55f.eps

43

Page 54

OF-500 OptiFiber Certifying OTDR

Users Manual

A

44

F

E

Figure 16. ChannelMap Diagram Features

B

C

D

ajt25f.eps

Page 55

Using the ChannelMap Function

A

The length of the channel, including the launch fiber.

Note

The FIBER LENGTH shown is the actual length of

the channel rounded to the nearest meter or foot

(not the sum of the displayed segment lengths).

B The far end of the channel. The name is set by the

END 1 or END 2 setting on the Job tab in Setup.

C The length of a segment or patch cord rounded to the

nearest meter or foot.

D Press D to add a comment to the ChannelMap

results.

E A reflective event, usually a connector. Could also be a

mechanical splice or a reflective fault such as a sharp

bend or a crack in the fiber.

F The near end of the channel. The name is set by the

END 1 or END 2 setting on the Job tab in Setup.

Figure 16. ChannelMap Diagram Features (cont.)

45

Page 56

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the FiberInspector Option

The OFTM-5352 FiberInspector Video Probe connects to

an OptiFiber fiber tester to let you inspect the ends of

fiber optic connectors. The probe's 250X and 400X

magnifications reveal dirt, scratches, and other defects

that can cause poor performance or failures in fiber optic

networks.

The 250X magnification shows dirt and other defects on

the fiber endface and surrounding ferrule. The 400X

magnification allows a more detailed inspection of the

cladding and core.

Figure 17 shows the equipment needed for using the

FiberInspector probe.

46

Page 57

Using the FiberInspector Option

ajt43f.eps

A OptiFiber tester

B Memory card (optional)

C Spare battery pack (optional)

E FiberInspector probe with adapter cable and

appropriate adapter tip

F Fiber cleaning supplies

D AC adapter with line cord (optional)

Figure 17. Equipment for FiberInspector Tests

47

Page 58

OF-500 OptiFiber Certifying OTDR

Users Manual

Using the FiberInspector Probe

1 On the System tab in Setup, set CAMERA TYPE to match

the magnification you will use. This selects the correct

size for the core size scale.

2 Use the adapter cable provided to connect the probe to

the video input jack on the side of the tester.

3 Screw an adapter tip that matches the connector type

being inspected onto the fiber probe.

4 Clean the connector to be inspected.

5 Press

f. If the message “Camera Image

Unavailable” appears check the connections between

the probe and the tester.

6 Place the probe on the fiber connector. Turn the larger

ring on the probe to focus the image. Turn the smaller

ring to change magnification. Refer to Figure 18.

The tester’s softkeys provide additional functions. Press

A More to see other softkey functions.

7 To save the image, press

ID; then press s again.

Figure 19 shows some typical FiberInspector images.

s, select or create a fiber

48

Page 59

Using the FiberInspector Option

ajt57f.eps

Figure 18. Using the FiberInspector Probe

49

Page 60

OF-500 OptiFiber Certifying OTDR

Users Manual

50

far end

Wiped with fingertip

Figure 19. FiberInspector Image Examples (250X on multimode fiber)

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

Alcohol drying

Dirty patch panel connector

(left uncovered)

FAX 781.665.0780 - TestEquipmentDepot.com

Dirt on coreClean, with light at

Scratched, needs polishing

ajt23f.eps

Page 61

Using the Loss/Length Option

Using the Loss/Length Option

The loss/length measurement option provides the

following features, in addition to the OTDR module

features described earlier:

• Measures optical power loss, length, and propagation

delay on dual-fiber cabling. Provides PASS/FAIL results

based on limits you enter or on factory-installed

limits.

• FindFiber

optical connections.

The loss/length option is available with OFTM-56x2B and

OFTM-5732 modules.

feature helps you identify and verify

About Smart Remotes

You can use the following as the remote for loss/length

testing and FindFiber tests in Smart Remote mode:

• A second OptiFiber tester with the loss/length option

• A Fluke Networks DTX Series CableAnalyzer™ smart

remote with a multimode or singlemode fiber

module. The DTX remote can also be used as a

manually-controlled source for testing in Far End

Source mode. You can buy a DTX smart remote

separately for this purpose. See the Fluke Networks

website or contact Fluke Networks for details.

Note

The OptiFiber tester must have software version

1.8.8 or later to work with a DTX-xFM2 smart

remote. OptiFiber software updates are available

on the Fluke Networks website.

51

Page 62

OF-500 OptiFiber Certifying OTDR

Users Manual

Changing the Connector Adapter

You can change the module's input connector adapter

(Figure 20) to connect to SC, ST, LC, and FC fiber

connectors. Additional adapter styles may be available.

Check the Fluke Networks web site for updates.

WCaution

• Cover all connectors with dust caps when not in

use.

• Store extra connector adapters in the canisters

provided.

• Do not touch the photodiode lens (see Figure

21).

• Do not overtighten the adapter or use tools to

tighten the adapter.

To install a connector adapter, refer to Figure 21and do

the following:

1 Locate the slot in the module connector and the key

on the adapter ring.

2 Holding the adapter so it does not turn in the nut,

align the adapter's key with the module connector's

slot and slide the adapter onto the connector.

3 Screw the nut onto the module connector.

amd37f.eps

Figure 20. SC, ST, LC, and FC Connector Adapters

52

Page 63

Using the Loss/Length Option

Figure 21. Changing the Connector Adapter

ajt61f.eps

53

Page 64

OF-500 OptiFiber Certifying OTDR

Users Manual

Cleaning the Loss/Length Connectors

Always clean and inspect fiber connectors before making

connections. Use 99 %-pure isopropyl alcohol and opticalgrade wipes or swabs to clean the connectors as follows:

Cleaning the OUTPUT Connector

1 Touch the tip of a 2.5 mm lint-free foam swab in

alcohol; then touch the swab to an alcohol-soaked

cleaning pad.

2 Push the swab into the adapter; twist it around 3 to 5

times against the endface, then remove and dispose

of the swab.

3 Dry the endface with a dry swab by twisting it around

in the adapter 3 to 5 times.

4 Inspect the connector regularly with a fiber

microscope, such as the Fluke Networks

FiberInspector Video Microscope.

Cleaning the INPUT Connector

Note

Typically, the input connector requires cleaning

only if it has been touched.

1 Remove the connector adapter to expose the

photodiode lens (see Figure 21).

2 Use the method described under "Cleaning the

Output Connector" above to dampen a swab with

alcohol.

3 Twist the damp swab around against the lens 3 to 5

times; then twist a dry swab around against the lens 3

to 5 times.

54

Page 65

Using the Loss/Length Option

About Setting the Reference

Setting a reference lets the tester automatically subtract

out the losses due to reference test cords and the main

and remote tester.

Note

Always let your test equipment warm up for 5

minutes before setting a reference.

For the most accurate test results, you should set the

reference at these times:

• At the beginning of each day using the remote end

setup (Figures 25 through 32) you will use that day.

The tester reminds you to set the reference if the

reference is more than 12 hours old.

• Anytime you reconnect a reference test cord to the

tester or other source.

• Anytime the tester warns you that the reference is

out of date.

The tester requires you to set the reference at these

times:

• Anytime you change the loss/length module in the

main or remote tester.

• Anytime you start using a different remote tester.

• Thirty days after the reference was previously set.

The tester warns you if the reference value is outside of

an acceptable range.

To see the reference information for the current remote

end setup, select Set Loss/Length Reference from the

Functions menu; then press

See the sections "Testing in Smart Remote Mode",

"Testing in Loopback Mode", and "Testing in Far End

Source Mode" for details on setting the reference for

each mode.

A View Settings.

55

Page 66

OF-500 OptiFiber Certifying OTDR

Users Manual

Setting the Number of Adapters and Splices

The NUMBER OF ADAPTERS and NUMBER OF SPLICES

settings are on the Loss/Length tab in Setup. These

settings do not apply to all test limits.

Test limits that include maximum values for the loss per

km, loss per connector, and loss per splice use a

calculated limit for loss. Only limits with all three values

use a calculated loss limit. The OVERALL LOSS value

should be N/A in these limits. If a loss value is entered, it

is ignored.

To see the limit’s values, select TEST LIMIT on the

Loss/Length tab; then press

If the selected limit uses a calculated loss limit, enter the

number of adapters and splices that will be added to the

fiber path after the reference is set.

Figure 22 shows an example of how to determine the

NUMBER OF ADAPTERS setting.

A View Limit.

56

Page 67

Using the Loss/Length Option

Figure 22. Example of How to Determine the NUMBER OF ADAPTERS Setting

ajt22f.eps

57

Page 68

OF-500 OptiFiber Certifying OTDR

Users Manual

Using Mandrels for Testing Multimode Fiber

You should use mandrels when testing multimode fiber.

Mandrels can improve measurement repeatability and

consistency. They also allow the use of LED light sources

to certify 50 µm and 62.5 µm fiber links for current and

planned high bit-rate applications, such as Gigabit

Ethernet and 10 Gigabit Ethernet.

The gray mandrels included with some OptiFiber models

are compliant with TIA/EIA-568-B for 62.5 µm fiber with a

3 mm jacket.

Mandrels for 50 µm fiber are available from Fluke

Networks. Refer to the appropriate standard for mandrel

requirements if you follow other standards. The OF-500

Technical Reference Handbook provides a partial list of

mandrel requirements for TIA and ISO standards.

Figure 23 shows how to wrap the fiber around a

mandrel. Place mandrels on the tester’s output fibers, as

shown in Figures 25 through 32.

In the reference and test connection diagrams shown on

the tester, mandrels are indicated by a loop in the fiber.

58

Page 69

Using the Loss/Length Option

ajt02f.eps

Figure 23. Wrapping a Reference test cord Around a Mandrel

59

Page 70

OF-500 OptiFiber Certifying OTDR

Users Manual

Testing in Smart Remote Mode

Use Smart Remote mode to test and certify dual-fiber

cabling. In this mode, the tester measures loss, length,

and propagation delay on two fibers at two wavelengths

in one or both directions.

A Tester with OFTM-5612B or OFTM-5732 module and

smart remote (DTX remote shown). Match connector

adapters to the connectors in the link.

B Memory card (optional)

C Spare battery pack (optional)

D Two ac adapters with line cords (optional)

Figure 24 shows the equipment needed for testing in

Smart Remote mode.

ajt44f.eps

E Two duplex reference test cords. Match the fiber to be

tested. Connectors for the tester and remote outputs

must be SC. For the others match the connectors in the

link.

F Two mandrels. Recommended when testing multimode

fiber. See page 58.

G Fiber cleaning supplies

60

Figure 24. Equipment for Loss/Length Testing in Smart Remote Mode

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176

FAX 781.665.0780 - TestEquipmentDepot.com