Page 1

MPRT

Megger Protective Relay Test System

I

The MPRT System consists of a

‘Power Box’, the TouchView Interface™,

and AVTS Software

I

Unique new TouchView Interface (TVI)

simplifies the manual testing of complex

relays

I

Ultra flexible output design provides

up to four-phase voltage and current

or eight-phase current

I

User specified configuration.

Every system is made to order based

on specific customer needs.

I

Includes fully automated testing capability

using AVTS Software (Version 3.0)

MPRT

Megger Protective Relay Test System

DESCRIPTION

The MPRT System is comprised of:

• The ‘Power Box’

• The TouchView Interface (TVI)

• AVTS Software

The ‘Power Box’ is the heart of the system. It employs a

variety of new features including unique Voltage and

Current Generator (VI-Gen) components which have been

combined into one amplifier package. Using multiple

VI-Gens provides the flexibility to deliver four voltages (or

two three-phase open delta voltages) and four currents or

combinations up to eight current channel capability. The

MPRT ‘Power Box’ also incorporates three communication

ports, a new Constant Power Output (CPO) capability and

every one is made-to-order based on each customer’s

individual testing requirements.

The TouchView Interface (TVI) device and AVTS Basic

Software form the brains of the system. The TVI, with its

large full color touch screen allows the user to perform

manual and semi-automatic testing quickly and easily,

using built-in, preset test routines for most popular relays.

Fully automatic testing can also be performed using AVTS

Basic Software which comes with the MPRT System.

APPLICATIONS

MPRT is specifically designed to perform routine testing of

protective relays used in the operation of electric utilities,

power plants and heavy industrials. Other applications

include use in government facilities, harbor and airport

installations, large building complexes and by testing

service companies who are increasingly interested in a

highly flexible, easy-to-use relay test instruments that can

help them improve their job efficiency.

MPRT SYSTEM COMPONENTS

The ‘POWER BOX’

The ‘Power Box’ is ultra flexible, rugged, lightweight and

feature packed. The unique features include:

NEW Constant Power Output (CPO) Capability –

Produces improved power output sustainable through the

entire “power curve” of a test. With a CPO of 200 VA per

current channel and 150 VA per voltage channel it has the

flexibility to test any relay.

Unique VI-Gen Internal Design – The Voltage and

Current Generator (VI-Gen) components have been

combined into one amplifier package. Using multiple

VI-Gens the system has the flexibility to deliver four

voltages (or two three-phase open delta voltages) and four

currents or eight currents for testing multi-phase

differential relays.

Built-in Transducer Testing Capability – Eliminates the

need for additional testing equipment or software. The

MPRT incorporates high accuracy amplifiers, a special

transducer DC input and test algorithms to test transducers

easily and effectively.

Shown without optional adjustable carry handle.

Shown with optional adjustable carry handle.

Page 2

Here’s how easy it is

From the Preset Menu Screen, shown below, the user

simply selects the type of relay to be tested. Built-in test

files are for a wide variety of protective relays, including

Overcurrent, Differential, etc., see following figure.

MPRT

Megger Protective Relay Test System

2

Includes Three Communication Ports – More built-in

flexibility with a protocol choice of IEEE488, RS232 or

Ethernet for high-speed download capability and upgrades

via the internet.

User Specified Configuration – Every system is made to

order based on each customer’s testing requirements and

budget, with an easy and flexible upgrade path.

Output Capabilities for Worldwide Use – Even more

built-in flexibility allows the user to choose from:

I

VI-Gen amplifiers rated at 30A @ 200 VA and

convertible amplifiers rated at 300V or 5A @ 150 VA.

I

VI-Gen amplifiers rated at 15A @ 200 VA and

convertible amplifiers rated at 150V or 5A @ 150 VA.

THE TOUCHVIEW INTERFACE (TVI)

Finally...an easier way to perform manual and semiautomatic relay testing. It’s all done via a unique hand

held controller called the TouchView Interface (TVI). The

most significant feature of the TVI is its ability to provide

the user with a very simple way to manually test even the

most complex relays manufactured today.

Manual operation is simplified through the use of a

built-in computer operating system and the TouchView

Interface, with a large color LCD touch-screen. The TVI

eliminates the need for a computer when testing virtually

all types of relays. Menu screens and function buttons are

provided to quickly and easily select the desired test

function.

Preset Relay Menu Screen

Overcurrent Relay Settings Screen

As an example, touch the ‘Over Current’ button. An

Overcurrent Test Menu Screen, shown below, will be

displayed showing all necessary functions needed to test

that particular type of relay. Next, the user inputs the relay

setting values that will be used to conduct the tests, such

as Relay Tap value and Time Dial value. These values are

used when conducting the pickup and timing tests.

To make it even better, the TVI has both IEEE and IEC

time curve algorithms built-in. By entering the appropriate

values in the setting screen, when the timing test is

conducted, the test results will be automatically compared

to the theoretical values from the time curve that was

selected.

MPRT TouchView Interface

TM

Back view of MPRT.

Page 3

MPRT

Megger Protective Relay Test System

3

As shown in the Overcurrent Settings screen, the IEEE Very

Inverse time curve was selected. If the Test Multiple is

changed, the appropriate theoretical trip time will change

automatically.

The TVI also has the ability to do even more complex tests

and calculations. For example, the MPRT with three

Voltage/Current Modules, can test single-phase, three-phase

open delta, and three-phase wye impedance relays using

the Impedance relay test screen. The user simply selects

different testing applications from a menu screen. For

instance, the Reach Test Settings Screen for an impedance

relay has been selected as shown below.

Impedance Reach Test Settings Screen

It should be noted that not only does the display screen

show values of voltage, current and phase angle, but it

also displays the current value where the relay should pick

up, (different formulas for calculating OHMS are selectable

using the touch-screen to select phase to phase or phase

to ground faults). The user can select ramp current and

hold fault voltage on ramp voltage and hold fault current.

The impedance test screen provides a pre-fault condition

for those relays that require a pre-fault load prior to

applying the fault. The test automatically determines values

like reach, maximum angle of torque, and timing.

Finally, for testing multi-zone relays, the user can select

the Pulse-Ramp method to determine operating points

without needing to defeat the other zone timers. Test

results can be saved to the internal memory for later

download and review.

Also easily test relays not on the Preset Menu

Other types of relays or devices not specifically listed in

the Preset Menu Screen can be tested using one of the

Manual Test screens.

Manual Voltage/Current Test Screen

For example, negative sequence under/over voltage,

reverse phase, phase sequence, and current balance relays

may be tested using the Voltage/Current manual test screen.

In addition, manual control of up to four voltages and

currents, or up to 8 currents is done using this test screen.

Other devices such as auto-synchronizing, frequency

sensitive devices and transducers also have their own

individual manual test screens. The user manually selects

the parameter(s) to be set or adjusted using the touchscreen and ramp outputs using the control knob. Each test

screen has a dynamic enable capability and will either

automatically step from a prefault, to fault, to breaker trip,

to reclose, or automatically ramp frequency at a

preprogrammed Hz/Sec, or time for a given slip frequency,

depending on which screen is in use. In the Manual AutoSynchronizing Test Screen, the advanced closing time and

closing angle are automatically done in the dynamic mode.

In the Manual Test Screen shown above, the pre-selected

outputs are set. The Green color indicates which output(s)

have been selected. When the test is started by pressing

the Start button, the selected output indicators will change

colors from green to red indicating which outputs are

energized. A vector graph indicates the relative phase

angles of all of the outputs. All of the outputs are metered

and displayed to provide real time verification of all of the

selected outputs.

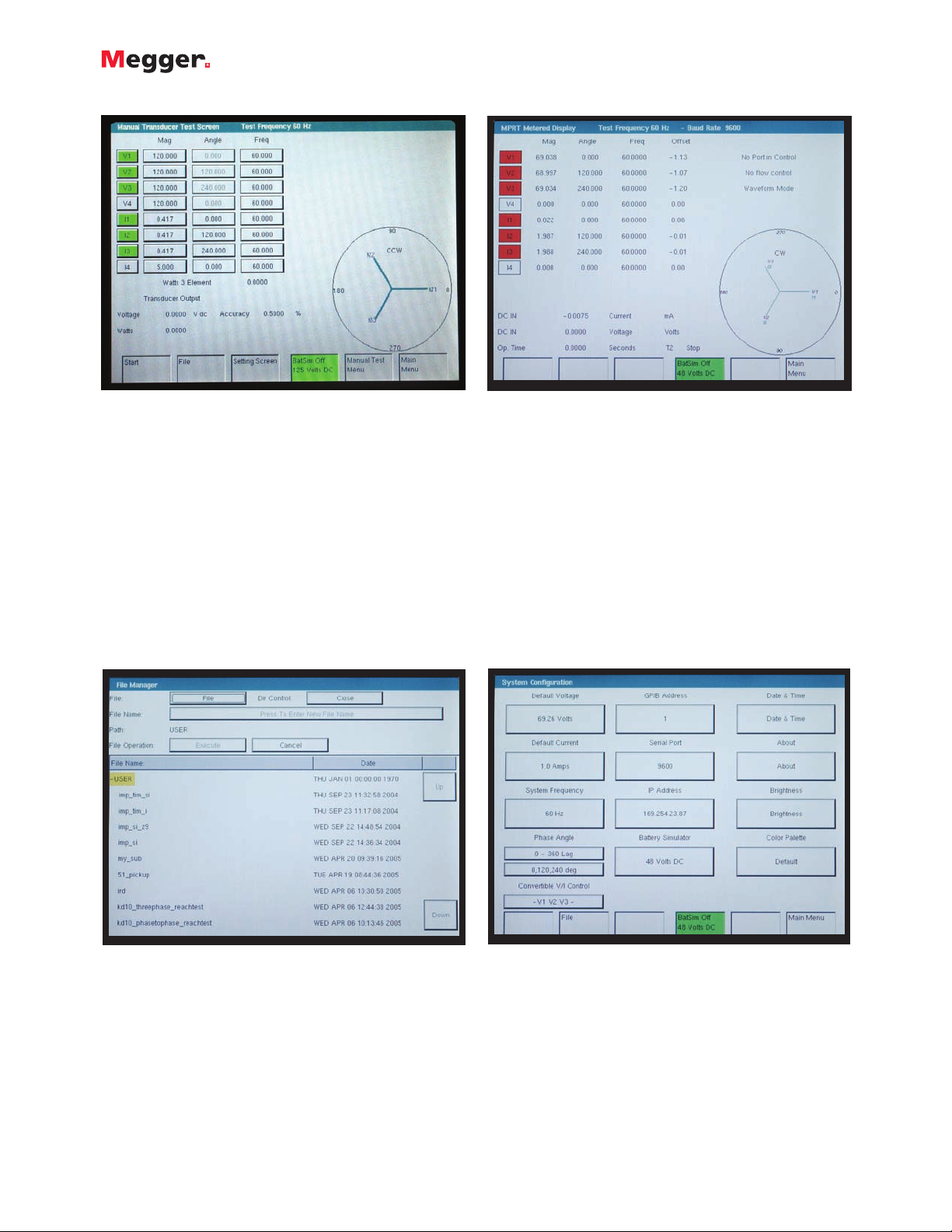

Even perform manual transducer testing

With the built-in transducer test screen, manually testing

transducers has never been easier. The user simply selects

from a pull-down menu, what type of transducer is being

tested and enters information relative to the transducer’s

inputs and outputs. Upon starting the test, the test set

automatically measures and calculates the % error of the

device.

Page 4

MPRT

Megger Protective Relay Test System

4

From any test screen, the user has access to the Test File

Manager Screen. The user can give the test file/result file

any name up to a maximum of 99 characters. Once saved,

the user can recall the test and execute with the

appropriate settings already set, or recall saved test results

to download into the AVTS database for storage or for

printing.

All output values are metered and displayed

When under automatic computer control (with the AVTS

software), the TVI becomes a meter display for all of the

MPRT outputs. The metered values are displayed to

Meter Display Screen

TVI Default Setting Screen

Transducer Test Screen

In the above example, a three-phase, 3 Element Watt

Transducer is being tested. The actual output watts is

calculated based upon the measured values from the

MPRT into the transducer, and the transducer watts

is calculated based upon the measured output

voltage/current from the transducer. A % error is

automatically calculated and displayed. A vector

representation of the voltage and current outputs

is also displayed.

Use the File Manager to organize all test results

The TVI has sufficient internal memory to save hundreds

of test and result files. To manage the tests and results, the

MPRT has a File Manager screen.

File Manager Screen

provide continuous real-time verification of the MPRT

outputs, even when under automatic control.

Output values are displayed with a vector display, which

shows the vector relationship between the output voltage

and currents.

User customized configuration

The user may customize how the unit displays phase

angles (0-360° Lead/Lag or ± 180°), and set default values

of voltages, currents and frequency. The user may also

select a language for prompting the operator. Five

language choices are currently available, English, French,

German, Portuguese and Spanish.

Other default settings include GPIB and IP addresses,

Serial Port settings, Battery Simulator output and screen

background colors.

AVTS SOFTWARE

See page 8 for details regarding AVTS Software.

Page 5

MPRT

Megger Protective Relay Test System

5

FEATURES AND BENEFITS

I

Large Color LCD touch-screen display - The TVI

features an easy to use and read display providing

manual control of the test set, and displays measured

values of voltage, current, along with phase angle and

frequency. Calculated values such as Ohms, Watts, VAR’s

and Power Factor may also be displayed, depending on

the test screen in use. Color contrasts accentuate vital

information. This reduces human error and time in

testing relays.

I

Constant Output Power - The new MPRT employees

new high powered Voltage-Current amplifiers (VI-Gens),

which deliver maximum compliance voltage to the load

constantly during the test. Constant output power in

many cases eliminates the need to parallel current

channels together to test high burden relays.

I

High resolution and accuracy - The TVI has Metered

outputs and a timer to provide extremely high accuracy.

High accuracy extends testing capability to other devices

such as transducers.

I

Internal memory - The TVI provides storage of test

set-up screens and test results. Reduces testing time and

paper work. Saved test results can be downloaded into

the AVTS software database.

I

Steady-State and Dynamic testing capability - The

MPRT provides, either through manual control or

computer control, both steady-state and dynamic testing

of protective relays. This includes programmable

waveforms with dc offset and harmonics.

I

Display screen prompts operator - The TVI features

a display screen that prompts the user with easy to use

function buttons. Single button operation saves time in

testing relays and minimizes human error.

I

Display screen provides five different languages The TVI display screen prompts the user in English,

Spanish, Portuguese, French or German.

I

Output current and voltage sinewaves are generated

digitally - MPRT outputs do not vary with sudden

changes in input voltage or frequency, which increases

test accuracy and reduces testing time.

I

Memory metering - Allows the user to set test currents

and voltages faster. Reduces heating of device under

test.

I

Digital inputs and outputs - MPRT has 10

programmable inputs, and 6 programmable outputs

provide timing and logic operations in real-time with the

output voltage and currents. Binary Inputs can be

programmed, using Boolean logic, for more complex

power system simulations. This provides a low cost,

closed loop, power system simulator.

I

Circuit breaker simulator - MPRT’s binary outputs

provide programmable normally closed and normally

open contacts to simulate circuit breaker operation for

testing reclosing relays. Sequence of operation, timing,

and lockout are easily tested.

I

Performs transient tests - Perform acceptance or

troubleshooting tests by replaying digitally recorded

faults or EMTP/ATP simulations in the IEEE- C37.111,

COMTRADE Standard format.

I

Perform End-to-End tests - Using AVTS software and a

portable GPS satellite receiver, the MPRT performs

satellite-synchronized end-to-end dynamic or transient

tests. Provides precisely synchronized testing of remotely

located complex protection schemes.

I

Wide-ranging output frequency - The output

frequency of the current and voltage channels can be set

for any frequency from dc to 1 kHz. Popular test

frequencies such as 25, 50, 60 and 100 Hz are easily set

and controlled. Provides ultra-flexability to save time

and lower costs.

I

RS-232 serial port - The RS-232 port provides a

computer interface to perform automatic testing.

I

Ethernet port - The Ethernet port provides a highspeed computer interface. This can be used to quickly

download transient waveform data and update test set

firmware via internet.

I

IEEE-488GPIB - The IEEE-488 is an OEM preferred

interface for control of the unit. This interface is

preferred, when using the unit with other IEEE-488

devices. It can also provide high speed downloading of

transient data.

Page 6

MPRT

Megger Protective Relay Test System

6

I

Universal input voltage - Operating from 90 to 264

Vac, 50/60 Hz, the MPRT can use virtually any standard

source in the world.

I

Battery simulator - MPRT’s battery simulator provides

dc output voltages of 24, 48, 125 and 250 Volts.

Eliminates needing a separate dc source for providing

logic voltage for microprocessor-based relays.

I

Immediate error indication - Audible and visual

alarms indicate when amplitude or waveforms of the

outputs are in error.

I

Modular design - Output modules plug-in and slide

out easily for system re-configuration and maintenance.

I

Ancillary Interface - Provides interface to other MPRT

units.

I

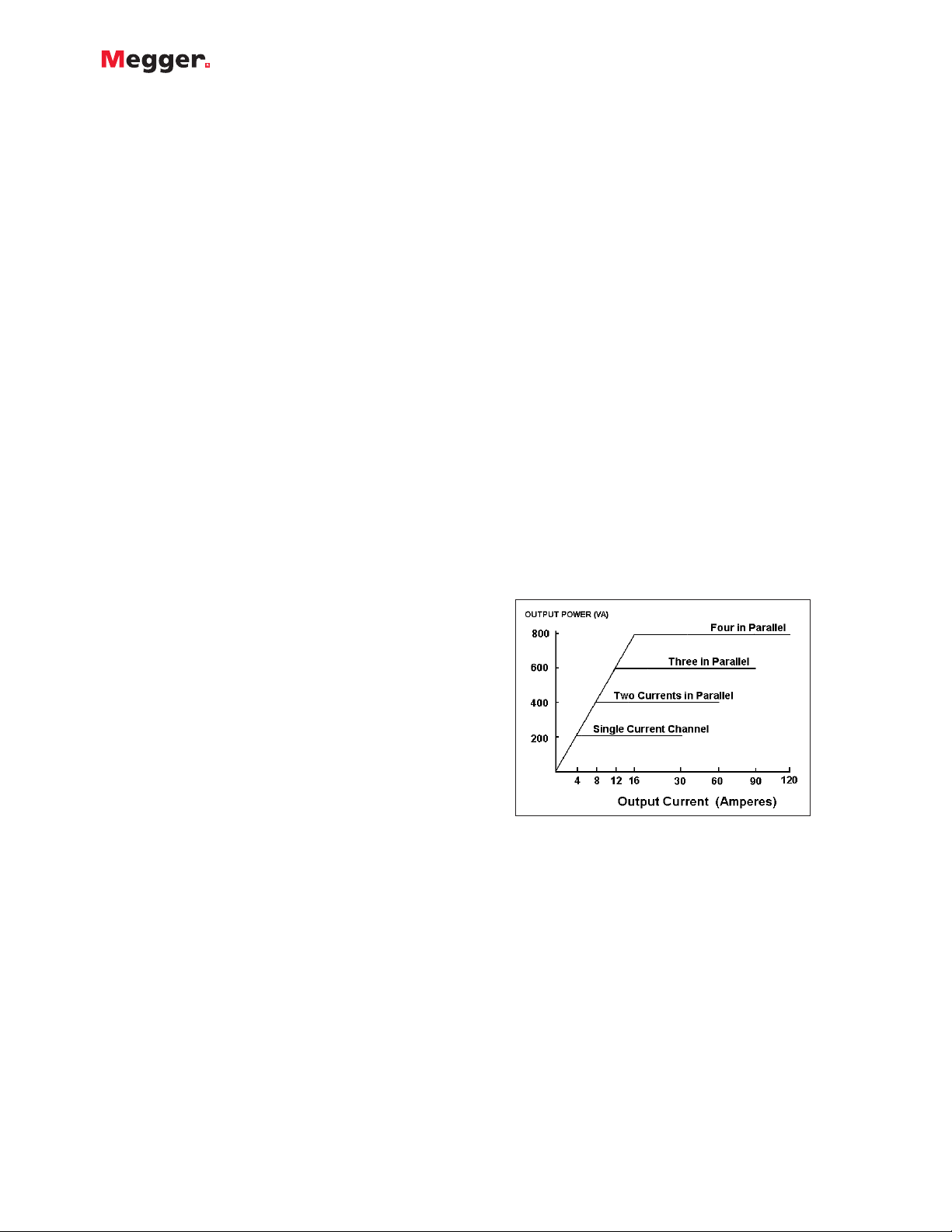

MPRT Model 8430 - Provides up to 300 Volts rms. at

150 VA and 30 Amps rms. at 200 VA per phase. Ample

voltage for testing high instantaneous overvoltage relays.

The current amplifier has high compliance voltage at

low currents for testing ground overcurrent relays. When

configured with four channels, the current amplifiers can

be paralleled to provide a maximum of 120 Amperes at

800 VA, for testing instantaneous overcurrent relays.

With high VA output ratings, the unit can be used for

testing a panel of relays.

I

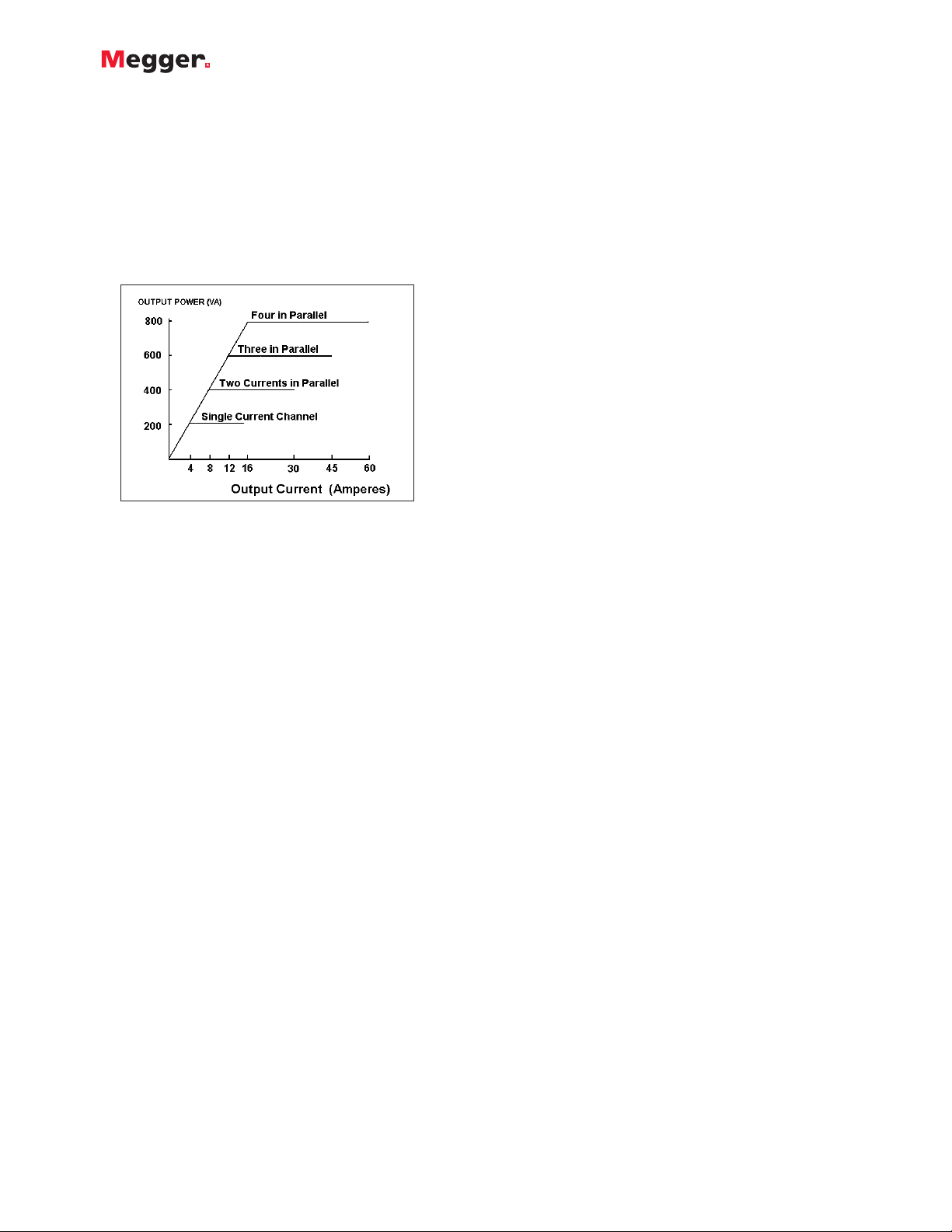

MPRT Model 8415 - Provides up to 150 Volts rms. at

150 VA and 15 Amps rms. at 200 VA per phase. This

lower cost unit is ideal for testing relays used with 1

Amp secondary CT’s. The current amplifier has high

compliance voltage at low currents for testing ground

overcurrent relays. When configured with four channels,

the current amplifiers can be paralleled to provide a

maximum of 60 Amperes at 800 VA, for testing

instantaneous overcurrent relays. With high VA output

ratings, the unit can be used for testing a panel of

relays.

SPECIFICATIONS

Input Power

100 to 240 Volts, ±10%, AC, 1Ø, 50/60 Hz, 2100 VA.

Outputs

All outputs are independent from sudden changes in line voltage

and frequency. This provides stable outputs not affected by

sudden changes in the source. All outputs are regulated so

changes in load impedance do not affect the output. Each output

module consists of one current amplifier, and a voltage amplifier.

The voltage amplifier may be converted to a current source.

Therefore, one amplifier module may be used to test current

differential relays, including harmonic restraint.

Output Current

The following specifications cover both Model 8430 and Model

8415 modules. Outputs are rated with the following:

Model 8430

Per phase:

Output Current Power Max V

4 Amperes 200 VA 50.0 Vrms

7.5 Amperes 200 VA 26.7 Vrms

15 Amperes 200 VA 13.4 Vrms

30 Amperes 200 VA 6.67 Vrms

DC 200 Watts

With two currents in parallel:

Output Current Power Max V

8 Amperes 400 VA 50.0 Vrms

15Amperes 400 VA 26.7 Vrms

30 Amperes 400 VA 13.4 Vrms

60 Amperes 400 VA 6.67 Vrms

With three currents in parallel:

Output Current Power Max V

12 Amperes 600 VA 50.0 Vrms

22.5Amperes 600 VA 26.7 Vrms

45 Amperes 600 VA 13.4 Vrms

90 Amperes 600 VA 6.67 Vrms

With four currents in parallel:

Output Current Power Max V

16 Amperes 800 VA 50.0 Vrms

30 Amperes 800 VA 26.7 Vrms

60 Amperes 800 VA 13.4 Vrms

120 Amperes 800 VA 6.67 Vrms

Power Curve for Model 8430

With two currents in series, the compliance voltage doubles to

provide 4.0 Amperes at 100 Volts.

Model 8415

Per phase:

Output Current Power Max V

4 Amperes 200 VA 50.0 Vrms

7.5 Amperes 200 VA 26.7 Vrms

15 Amperes 200 VA 13.4 Vrms

DC 200 Watts

With two currents in parallel:

Output Current Power Max V

8 Amperes 400 VA 50 Vrms

15 Amperes 400 VA 26.7 Vrms

30 Amperes 400 VA 13.4 Vrms

Page 7

MPRT

Megger Protective Relay Test System

7

With three currents in parallel:

Output Current Power Max V

12 Amperes 600 VA 50 Vrms

22.5Amperes 600 VA 26.7 Vrms

45 Amperes 600 VA 13.4 Vrms

With four currents in parallel:

Output Current Power Max V

16 Amperes 800 VA 50 Vrms

30 Amperes 800 VA 26.7 Vrms

60 Amperes 800 VA 13.4 Vrms

Battery Simulator

The battery simulator provides the following DC output:

24, 48, 125 or 250 Volts at 60 Watts. Voltage output is controlled

via the Touch-View Interface, or through AVTS software.

Metering

Measured output quantities such as AC Amperes, AC Volts, DC

Volts or DC Amperes, and Time may be simultaneously displayed

on the large, variable contrast, color LCD touch screen. The

memory feature of the metering provides fast and accurate preset

of test values. The AC and DC outputs display the approximate

voltage/current output prior to initiation of the outputs. This

provides a fast, easy method for preset of outputs. Other values

that may be displayed, depending on which test screen is in view,

are phase angle, frequency, Ohms, Watts, VARS and Power Factor.

All Accuracies stated are from 10 to 100% of the range at 50/60 Hz.

AC Voltage Amplitude

Accuracy: ±0.05% typical, 0.1% guaranteed.

Resolution: .0001/.001/.01

Measurements: True RMS

AC Current Amplitude

Accuracy: ±0.05% typical, 0.1% or ±20 mA, which ever is greater,

guaranteed.

Resolution: .0001/.001/.01

Measurements: True RMS

DC Voltage Amplitude

Accuracy: ±0.1% typical, 0.25 % guaranteed.

Resolution: .0001/.001/.01

Measurements: True RMS

DC Current Amplitude

Accuracy: ±0.1% typical, 0.25 % or ±20 mA, which ever is greater,

guaranteed.

Resolution: .0001/.001/.01

Measurements: True RMS

Convertible Source in AC Current Mode

Accuracy: ±0.05% typical, 0.1 % or ±12.5 mA,

which ever is greater, guaranteed.

Resolution: .0001

Measurements: True RMS

Phase Angle

Ranges 0.01 to 359.99 degrees, Counter Clock Wise,

or Clock Wise rotation, or ±0.01 to ±180.00 degrees

Accuracy: ± 0.02° typical

± 0.25° at 50/60 Hz max

Frequency:

The output modules provide a variable frequency output with the

following ranges and accuracy.

Ranges

DC

0.001 to 1000.000 Hz

Output amplifiers can provide transient signals with a range of

DC to 10 kHz for transient playback.

Resolution: .001 Hz

Frequency Accuracy:

2.5 ppm typical

25 ppm 0° to 50° C, at 50/60 Hz

Total Harmonic Distortion:

Less than 0.1% typical,

2% maximum at 50/60 Hz.

Power Curve for Model 8415

With two currents in series, the compliance voltage doubles to

provide 4.0 Amperes at 100 Volts.

AC Voltage Output

The following specifications cover both the Model 8430 and 8415

modules. Outputs are rated with the following Ranges:

Model 8430

Per phase:

Output Volts Power Max I

30 Volts 150 VA 5 Amps

150 Volts 150 VA 1 Amp

300 Volts 150 VA 0.5 A

DC 150 Watts

With two voltages in series:

Output Volts Power Max I

60 Volts 300 VA 5 Amps

300 Volts 300 VA 1 A

600 Volts 300 VA 0.5 A

With three converted sources in parallel:

Output Current Power Max V

15Amperes 450 VA 30 Vrms

Model 8415

Per phase:

Output Volts Power Max I

30 Volts 150 VA 5 Amps

150 Volts 150 VA 1 Amp

DC 150 Watts

With two voltages in series:

Output Volts Power Max I

60 Volts 300 VA 5 Amps

300 Volts 300 VA 1 A

With three converted sources in parallel:

Output Current Power Max V

15Amperes 450 VA 30 Vrms

Page 8

MPRT

Megger Protective Relay Test System

8

Power

The Watts displayed is the calculated value based on the displayed

formula. Nine different formulas are available.

Range: 0 to 15 kW

Accuracy: ± 0.525 % of VA ±1 least significant digit

The DC IN input terminals

Range:

0 to ±10 V DC

0 to ± 20 mA DC

Accuracy: ±0.02% Typical

±0.05% Max

Resolution: .0001/.001

Measurements: Average

Timer-Monitor

The Timer-Monitor (Binary Inputs) are designed to monitor and

time-tag inputs, as a sequence of events recorder. In addition, the

binary input controls enable the user to perform logic AND/OR

functions on the inputs, and conditionally control the binary

output relays to simulate circuit breaker, trip, reclose and carrier

control operation in real-time. The Timer function displays in

Seconds or Cycles, with the following range and resolution:

Seconds: 0.0001 to 99999.9

(Auto Ranging)

Cycles: 0.01 to 99999.9

(Auto Ranging)

Accuracy: ±0.001% of reading, typical. ±2 least significant digit,

±0.005% of reading from 0 to 50° C maximum.

Binary Inputs- Start/Stop/Monitor Gates

10 identical, independent, galvanically isolated, Start/Stop or

Monitor circuits are provided. To monitor operation of relay

contacts or trip SCR, a continuity light is provided for each input

gate. Upon sensing continuity the lamp will glow and a tone

generator will sound. In addition to serving as Timer/Monitor

inputs, the Binary Inputs may be programmed to trigger binary

output sequence(s). Binary Inputs can also be programmed using

Boolean logic for more complex power system simulations.

Input Rating: up to 300 V AC/DC

Binary Output Relays

6 identical, independent, galvanically isolated, output relay

contacts accurately simulate relay or power system inputs to

completely test relays removed from the power system. Binary

outputs simulate normally open / normally closed contacts for

testing breaker failure schemes. Outputs can be configured to

change state based on binary input logic (Boolean logic is

available for more complex simulations), or a specified time delay

after a logic input condition.

Contact Rating: Up to 400 Volts peak, AC/DC, 1 Amp

continuous, 3 Amps Max.

Waveform Generation

Each output channel can generate a variety of output waveforms

such as: DC; sinewave; sinewave with percent harmonics at

various phase angles; half waves; square waves with variable duty

cycles; exponential decays; periodic transient waveforms from

digital fault recorders, relays with waveform recording capability

or EMTP/ATP programs, which conform to the IEEE C37.111

COMTRADE standard format. In addition, each output channel has

input BNC connector for amplification of external analog signals.

Waveform Storage

Each output channel can store waveforms for playback on

command. End-to-end playback of stored waveforms is possible,

when triggered externally by a GPS receiver. Each channel can

store up to 256,000 samples.

Protection

Voltage outputs are protected from short circuits and prolonged

overloads. Current outputs are protected against open circuits and

overloads.

Ancillary Interfaces

On the back panel of the MPRT are the RS-232, Ethernet, IEEE488 GPIB, Trigger In, Trigger Out, Clock In, and Clock Out.

Temperature Range

Operating: 32 to 122° F (0 to 50° C)

Storage: -13 to 158° F (-25 to 70° C)

Relative Humidity: 5 - 90% RH, Non-condensing

Dimensions

Unit Enclosure

17.2 W x 8.75 H x 18.5 D* in. (430 W x 218 H x 463 D mm)

*Includes 2.5” depth of floor stand-offs

Weight

Weight varies depending on the number of output modules in the

system. The weights shown below are for a complete three-phase

test system.

Model 8415: Model 8430:

41.8 lb. (18.9 kg) 41.8 lb. (18.9 kg)

Safety, EMC, RFI and ESD Conformance

IEC 61010-1, Amendments 1 and 2, EN 50081-2, EN 50082-2,

EN 61000-3-2, 61000-3-3, IEC 61000-4-2/3/4/5/6/8/11.

Shock, Vibration and Temperature

To simulate the worst field conditions the unit was tested in

accordance with Military Standard MIL-STD-810 for temperature,

humidity, shock, and vibration.

Enclosure and Transit Cases

The unit comes mounted in a rugged enclosure for field

portability. There are three versions of the enclosure. The L

version has carry handles on the sides for easy mobility, and a

carry strap that connects to the chassis. Small fold up feet built

into the bottom of the chassis serve to tilt the face of the unit up

when operating on a bench top. The enclosure has vertical standoffs on the back that allows the unit to be operated vertically off

the floor. The H version is the same as the L with an additional

MPRT in optional softsided case.

One-piece hardsided case.

Two-piece hard-sided case.

Page 9

MPRT

Megger Protective Relay Test System

9

extra large adjustable carry handle that can also be used to tilt the

face of the unit up. The H version does not come with a carry

strap. Both units may be carried in the optional soft sided carry

case, Part Number 684011. The soft sided case has approximately

1 inch thick padding, which provides moderate protection against

rain, dust, vibration and shock. For higher level transit protection,

optional custom made hard sided transit cases are available. The

one piece transit case, part number 684019, provides protection

for the MPRT and the Touch View Interface, as well as provides

storage facilities for the power cord, interface cables and test

leads. The case has built-in wheels and a telescoping handle. The

two piece hard sided transit case also has built-in wheels and a

telescoping handle, part number 674002. The two piece hard

sided transit case was specifically designed to reduce the size and

weight for those who use commercial airlines. Therefore, only the

L version will fit in the two piece case (the H version is heavier

by about 2.2 pounds or 1 kg). The larger of the two pieces is

designed to carry the MPRT. The second smaller case has storage

space for the TVI, power cord, interface cables and test leads. The

weight of a 3 channel MPRT unit in the two piece transit case is

approximately 66 pounds or 29.7 kg. The weight of the second

case with test leads will vary depending on the number of test

leads stored. Typically the weight will be about 27 pounds or 12.2

kg. The last version of the unit enclosure is the R version, or rack

mount version. The R version includes rack mounting hardware to

fit a standard 19 inch rack.

AVTS

Advanced Visual Test

Software Version 3.0

DESCRIPTION

AVTS is a Microsoft

®

Windows®98/ME/NT4.0/2000/XP

®

software program designed to manage all aspects of

protective relay testing using the new Megger MPRT or

older PULSAR relay test sets. More flexibility has been

added as well as some new and powerful features.

AVTS 3.0 comes in three different levels:

I

Basic

I

Advanced

I

Professional

Every MPRT unit comes with AVTS Basic.

The Basic version includes Online Vector, Ramp and ClickOn-Fault controls with the ability to import, save and execute

test modules. In addition, the Basic version includes enhanced

Relay Test Wizards, including new wizards not previously

available.

The Advanced version includes the Test Editor, Dynamic

Control, Modbus, One-Touch Test, SS1 Converter, End-toEnd test macros and basic programming Tools for creating

and editing test modules.

The Professional version includes all of the features of

the Basic and Advanced versions plus some new and

powerful features. It includes the DFR Waveform Viewer

and editor, and Waveform Digitizer.

APPLICATIONS

Using the Online Ramp Control, traditional steady-state

tests are easily performed with AVTS by simply applying

test quantities to the device under test and automatically

ramping the current, voltage, phase angle or frequency.

Using either the Online Ramp, Vector or Dynamic Controls,

Dynamic tests can easily be performed. The dynamic test

includes setting a prefault condition and allowing the

software to automatically test/search for the operating

characteristic of the relay by selecting one of several

available methods. Using Test Wizards or Test Modules,

fault types are selected from a pull-down window.

Operating characteristics for virtually any type of relay are

easily defined using Mho circles, Lenticular, Tomato

characteristics, or a combination of lines, line and slope,

time and amplitude, calculated value or theoretical object

(a time-current curve may be scanned into the program

using the digitizer feature in either the Advanced or

Professional versions of AVTS).

The AVTS Test Screen enables the user to view test values

(both theoretical and actual) on one screen. For example,

the figure above shows test values, both theoretical and

actual results, all on one screen.

The chart on the following page provides an easy

reference showing the features of each version of AVTS

Software.

Page 10

10

Online Vector Control

Online Ramp Control

On-Line Click On Fault

RIO File Format

DFR Playback

Fault Calculator

Import, Save, and

Execute Test Modules

Overcurrent Wizard

Over/Under Voltage

Wizard

Distance Wizard

Differential Wizard

Directional Wizard

Transducer Testing

with Touch-View

Interface or AVTS software

Test Editor

Dynamic Control

Basic Programming

Tool

One-Touch Test™

Modbus

SS1 File Converter

Import Aspen Relay

Database

®

End-to-End Test Macro

Waveform Digitizer

DFR Waveform Viewer

and Playback

The Online Vector Control allows the user to have direct control of the Relay Test System. Up to sixteen

vector states may be created and sequenced back through the test system.

Preramp (prefault), Ramp 1 and Ramp 2 are available for use to be played back through the test system.

Automatically Ramp or Pulse Ramp outputs. PulseRamp provides the capability to determine reach points

on multi-zone distance relays without having to defeat the zone timing elements, and provides pre-fault

load conditions for relays that require it. Enable timer control with either ramp. PulseRamp is available

down to the basic level.

The user can define the type of operating characteristic using the AVTS Theoretical Control or Import files

in the RIO file format, then click at a point on the characteristic that they wish to test for, either as a Shot,

a Check Point or using the Search features. If using the Search the test will progress down a line, using

click and drag, either as a ramp or a pulse ramp looking for the relay to operate. Test results appear in

the RX diagram along with the theoretical operating characteristic of the relay.

Used to download relay characteristic settings from certain manufacturers microprocessor based relays for

full automatic testing using Click-On-Fault either On Line or in the Test Editor Screen.

Import and execute relay test modules, which contain DFR playback files created using the DFR Waveform

Viewer Tool.

Calculate fault values for Ø-Ø, Ø-N, and 3 Ø faults. Use line voltage, line Z and angle, relay volts and

angle, relay amps and Z0/Z1.

Import relay test files and execute selected tests. Save results to built-in Microsoft Access compatible data

base, and print results.

Provides automatic testing of overcurrent relays, including pickup, timing characteristic using IEEE / IEC

formulas, Instantaneous, DC target and seal-in tests.

Provides automatic testing of over and under voltage relays, including pickup, timing characteristic and DC

target and seal-in tests.

Provides automatic testing of distance relays. Ø-Ø, Ø-G, and 3 Phase faults are available. Test result

graphics are displayed in an R X plane.

Provides automatic testing current differential relays, including pickup, slope (includes capability to control

up to 8 currents for differential characteristic), and 2nd, 3rd and 5th harmonic restraint tests on transformer

differential relays.

Provides automatic testing capability of directional elements.

Use the TVI to do manual testing of all types of transducers. Results maybe saved to the internal memory,

downloaded to AVTS and printed later. AVTS users may create a test for any type transducer using the Test

Editor Screen and the Analog Input control tool.

Provides editing tools for modifying tests.

Accessed through the Test Editor Screen, the Dynamic Control provides dynamic multi-state testing of

relays with more flexibility and choices than Vector Control. A "state" can be voltage(s), current(s), phase

angle(s), timers, start and stop the analog recorder, set Boolean logic for the binary inputs, set binary

output(s), or even use variables to set values. The test transitions from one state to another after a

programmed time delay of either milliseconds or cycles, or after a trigger condition. In addition, the

Dynamic Control allows the user to easily build harmonic waveforms with frequencies up to 1000 Hz. In

conjunction with the Dynamic Control the Capture feature may be used to measure and display the output

analog waveforms, binary inputs and outputs to evaluate the dynamic test results in a graphic form.

Provides control tool in the Test Editor. Basic programs can be written using the test system command set

for special testing applications.

Test Editor control tool, used in conjunction with specific Megger Test Modules, to download relay settings

(into the AVTS settings screen) from microprocessor based relays for full automatic one-touch testing.

Used in conjunction with specific Megger Test Modules to automatically download relay settings (into the

AVTS setting screen) from microprocessor based relays, which use the Modbus protocol, for full automatic

one-touch testing.

SS1 files are generated using Power System Simulation software programs by Electrocon®CAPE™ or Aspen

One-liner®. By modeling the power system and using the SS1 files, the relay can then be tested

dynamically using realistic system test scenarios.

Capability to import relay settings directly from Aspen Relay Database

®

“End-to-End” testing is used to describe the testing of an entire line protection scheme. This includes all

protective relays, interface equipment, and any communication equipment.

Provides digitizing tools to create digital time curves for old electromechanical relay time curves (that do

not fit any time curve algorithm) up to the most complex relay operating characteristics. Good for

digitizing scanned waveforms (like from a light-beam chart recorder).

Import, view, modify and replay Digital Fault Recordings or EMTP/ATP simulations that are in the

COMTRADE file format.

III

III

III

III

III

III

III

III

III

III

III

III

II

II

II

II

II

II

II

II

II

I

I

AVTS 3.0

Basic

Advanced

Professional

Feature

Description

NEW

NEW

NEW

NEW

NEW

Page 11

MPRT

Megger Protective Relay Test System

11

Aux Contact Check Box- will close an “aux” binary

output contact conditional with change from one vector

state to another.

Edit Custom Prefix Command- available for each vector

state and allows entry of a formula, Relay Test System

syntax, or other controlling variable for that selected vector

state.

Zoom- enlarges the polar vector diagram to the full

dimensions of the dialog box.

Favorites - save a single vector, or a set of multiple

vectors, with all the parameters to a desired name for

recall at a later time in the Online Vector Control (Basic

Version) or the Test Editor Vector Control (requires

Advanced version). Save to the name placed in the edit

field will retain only the selected vector(s) in the vector

list. The Edit Customs Prefix Commands are saved along

with the generator parameters.

Set to Variables - selection replaces the numeric values

for all the vector parameters to known default variable

names. This function is more commonly used for the

Vector Control used within a test development in the Test

Editor (Advanced Version), where the variable names are

given values in the Settings Screen, Variable Watch edit

field (a powerful programming tool in the Advanced

version) in the Test Screen, or in another control in the

Test Editor (Advanced version) Screen prior to the Vector

control.

Online Ramp Control

The Online Ramp Control, launched from the AVTS

Tools menu item, allows the user to have direct real time

control of the Relay Test System. This control is very

similar to the Online Vector Control. However, where the

A

VTS BASIC VERSION

There are three versions of AVTS software. The Basic

version is included with each MPRT unit. The

Advanced and Professional versions are optional. The

Basic version includes online Vector, Ramp and Click-OnFault controls, relay testing wizards for most types of

relays, the ability to import, save and execute relay specific

test modules created either by Megger or someone else

with either an Advanced or Professional version of AVTS

3.0. Basic can also playback a DFR file created using the

Professional version of AVTS. The following describes the

features of the Basic version of AVTS 3.0.

Online Vector Control

The Online Vector Control, launched from the AVTS

Tools menu item, allows the user to have direct control of

the Relay Test System. Up to sixteen vector states may

be created and played back through the Relay Test

System. A timer control is available to enable starting

the Relay Test System timer at the execution of any one of

the vector states. The timer stop is typically controlled by

an action from one of a device’s outputs connected to the

appropriate Relay Test System timer stop gate. The

default view of the Online Vector Control remains visible

during all use of the control.

For manual ramping of amplitudes and phases, a

gang control is available through the selection of the

vectors (Relay Test System amplifiers) to be controlled.

The vectors to be controlled in gang are selected by using

the mouse to grab and alter the vector(s) parameters.

Vector selection is made by clicking on a vector channel

name to highlight that vector with its parameters. Should

it be desired to simultaneously control more than one

vector, the user will need to click on the wanted vectors

while holding the keyboard Ctrl key down to highlight all

of the selected vectors. The user may then select from the

‘Dragging Parameters’ box whether the amplitudes

and/or phases of the selected vectors are to be active.

Once selected, the user can grab the tip of any of the

selected vectors in the polar graph and, while holding the

left mouse button down, move the vector(s). The values

of the vector(s) will change graphically and numerically,

and simultaneously pass the new values directly to the

corresponding Relay Test System amplifiers. Some other

unique features are:

vector control sequences through up to 16 different states,

the Ramp Control provides automatic ramping of selected

outputs to do pick-up or drop outs tests of amplitude,

phase angle or frequency. Pre-ramp, Ramp 1 and Ramp 2

are available for use to be played back through the Relay

Test System. A timer control is available to enable starting

the Relay Test System timer at the execution of either of

the ramp states. The timer stop is typically controlled by

an action from one of a device’s outputs connected to the

timer stop gate.

Page 12

RIO File Import

In association with the Click-On-Fault test screen, Megger

has also included a feature called RIO Import. RIO is a file

format that defines the operating characteristic of specific

relays. Customers who already have RIO files for their

relays can import them into the Click-On-Fault RX diagram

ready to test. Shown below is a RIO file import for a SEL

321 relay. Six shot test points are defined.

Test Wizards

All versions of AVTS software come with test wizards. The

wizards walk the user through a step by step procedure to

create a relay specific test(s). Wizards are available for the

most common types of relays such as, Overcurrent,

Over/Under Voltage, Frequency, Differential, Distance,

Synchronizing and Directional. The following is a brief

description of each test wizard.

Overcurrent Wizard - Provides automatic pickup,

instantaneous pickup and timing. IEEE and IEC time curve

algorithms are provided for automatic evaluation of the

results. Digitized time curves for various

electromechanical overcurrent relays are also available.

For North American relays, a dc target and seal-in test is

available. A test report will provide pass/fail information of

the test results.

MPRT

Megger Protective Relay Test System

12

Similar to Online Vector Control, Online Ramp Control

provides manual ramping of amplitudes and/or phases.

The gang control is similar through the selection of the

vectors (Relay Test System amplifiers) to be controlled.

The outputs to be controlled in gang are selected by using

the mouse to grab and alter the parameters (see Online

Vector Control for more details). Another feature of the

Online Ramp Control is the ability to do Pulse Ramping.

One advantage of Pulse Ramping is the capability to

determine reach points on multi-zone distance relays

without needing the defeat the zone timing elements. For

relays which require a prefault load condition prior to

applying a fault value, the Online Ramp Control has a Preramp (Pre-fault) state. This feature allows the user to apply

the appropriate load values before Pulse Ramping begins.

After applying a fault value the Ramp Control returns to

the Pre-ramp state before the next value is applied. Many

of the same features in the Online Vector Control are also

available in the Ramp Control, such as the Zoom, Set

Variables and Favorites.

On-Line Click-On-Fault Control

Online Click-On-Fault, launched from the AVTS Tools

menu item, allows the user to quickly test impedance relay

characterisitcs. The user can define the type of operating

characteristic using the AVTS Theoretical Control, where

the user can select a Mho circle, Ellipse, Tomato or

virtually any operating characteristic. Characteristics can

also be predefined and imported using either the

Theoretical Object File Import or RIO File Import. To test

the user simply selects the type of fault desired (Line to

Earth, Line to Line etc) and clicks to set a test point, either

as a Shot, a Check Point or using the Search. Multiple test

points maybe selected and the software will automatically

calculate the appropriate test currents and phase angles

based upon the Settings and the Fault Type selected. In

the Settings screen the user can define Constant Voltage,

Constant Current or Constant Source Z (defined by Source

Z, Source Angle and K). If using the Search the test will

progress down a line, using click and drag, either as a

ramp or a pulse ramp looking for the relay to operate.

Test results are automatically displayed for each test point.

Click-On-Fault Test Screen with Multi-Zone Mho Distance Relay

Click-On-Fault RIO Import of SEL 321 Characteristic

Over/Under Voltage Wizard - Provides automatic pickup

and timing. A test report will provide pass/fail information

of the test results based on user input.

Page 13

MPRT

Megger Protective Relay Test System

13

Typical Phase to Phase Characteristic Test

Test History for IAC77 Relay

Resized Differential Slope Test Screen

Differential Wizard - Perform automatic winding pickup,

differential characteristic (slope) test and harmonic restraint

tests. In the figure below, the test result screen was resized

using the mouse and the windows drag and drop feature.

This allows the operator to more closely examine test

points and results. The user may then generate a test

report with the test results showing pass/fail based upon

input by the user.

Distance Wizard - Perform automatic reach, max angle of

torque and characteristic tests on single phase, three phase

open delta or three phase Y connected relays. User may

choose between fixed voltage and vary current or fix

current and vary voltage. In addition, the user may select

mho, lens, tomato or other basic distance characteristics

using a pull-down menu. The test report will provide

pass/fail information based upon user data input.

Directional Wizard - Perform automatic pickup test on

directional elements. A report will provide test result.

Import, Save, Execute Test Modules

AVTS Basic users can import test modules generated by

Megger, or someone else using the Advanced or

Professional versions of AVTS. The user can execute the

tests, save results and print results. In addition, users can

playback a Digital Fault Record, which has been generated

by the Professional version of AVTS 3.0.

Database

The database is Windows Access compatible. Data is saved

in a conventional tree format to facilitate ease of use.

The following figure illustrates the AVTS navigator Relay

tab when AVTS is opened for use. The Relay has been

expanded to illustrate the Organization.

The Organization is the method used to geographically

locate the relays installed in this database.

This example has the Organization tree by Region, then

Substation, then Line, then panel and finally the relay in

the panel. The relays installed are then listed under that

location. As part of the installation process of AVTS, the

default Organization tree comes with three levels and may

either be accepted or a new Organization tree may be

edited with up to five levels.

In addition to showing the location of the relays in your

system, it can also be used to look at the historical test

records of any individual relay. By clicking on the box, it

expands the selected relay’s test history.

Test Reports

Individual test results can be viewed by double clicking on

the desired result file. The test report can either be printed,

or exported to Microsoft Word for user customized report

generation using company logo, company standard format etc.

Page 14

MPRT

Megger Protective Relay Test System

14

Fault Calculator

The Fault Calculator allows the user to automatically

calculate fault quantities for phase-to-phase, phase-toground and three-phase faults. The user inputs variables

for: line voltage, line Z with angle, relay volts with angle,

relay amps and Z0/Z1. The Z0/Z1 system impedance ratio

is applied to both the source Z and the line Z for all faults

which include ground.

A

VTS ADVANCED VERSION

The Advanced version includes all of the features

previously described for the Basic version. In addition, it

includes the very powerful Test Editor, Connection Editor,

Dynamic Control, Analog Recorder, Basic Programming

Tool, Modbus communications, SS1 File Connector, End-toEnd test macros, One-Touch test macros and generic preconstructed relay test modules. Advanced users can also

playback a DFR file created by someone using the

Professional version of AVTS. The following describes the

additional features of the Advanced version of AVTS 3.0.

Connections Editor

A picture is worth a thousand words. It seems like modern

relays need a thousand connections today, so the

Connections Editor is ideal to show how to connect the

test system to the device under test. Powerful graphic tools

are available to show test connections (see following

Figure).

Test Editor Window

Adjusting Ramp Control- Current Increment

Test Editor

The real power of AVTS is in the Test Editor window. No

more complicated test macros to write or edit. Instead, the

user selects from a variety of icons representing various

test macro functions. For example, in the following Figure,

certain icons are selected and connected using the mouse.

The software takes care of the rest. No more theoretical

characteristic macros to write either. Simply click on the

appropriate icon and drop into the test editor window.

What may have taken days or weeks to “write” using basic

programming now takes only minutes!

In addition, the test wizards automatically assemble and

connect the appropriate icons for you. All you need to do

is edit the appropriate control function to meet your

specific needs. For example, using a right-mouse click on

the Ramp Control Icon (in the Test Editor work screen),

and then clicking on the Increment button, the user is able

to adjust the increment value of each current increment for

a pickup test.

Connections Editor Screen provides relay test connections details

The Connections Images toolbar contains ten available

icons for the user to define each as an image bitmap to

import into the connection editor screen. This can include

schematic internal diagrams of the relays, or other helpful

information. Pictures of other test sets may also be used

for illustration.

Page 15

MPRT

Megger Protective Relay Test System

15

Dynamic Control Screen

The Dynamic Control, accessed from the Test Editor

Screen, provides the user an easy means of settings up

multi-state dynamic tests that are normally associated with

trip and reclosing schemes. The figure above shows an

example test setup using the Dynamic Control.

A “state” can be voltage(s), current(s), phase angle(s),

timers, start and stop the analog recorder, set Boolean

logic for the binary inputs, set binary output(s), or even

use variables to set values. The test transitions from one

state to another after a programmed time delay of either

milliseconds or cycles, or after a trigger condition. In

addition, the Dynamic Control allows the user to easily

build harmonic waveforms with frequencies up to 1000

Hz. In conjunction with the Dynamic Control the Capture

feature may be used to measure and display the output

analog waveforms, binary inputs and outputs to evaluate

the dynamic test results in a graphic form.

Dynamic Analog Recorder

In association with the Dynamic Control is an analog

recorder, which not only records the action of the binary

inputs and outputs, but it also records the actual analog

waveforms of the outputs. For example, after running a

reclosing sequence press OK to view the waveform

capture screen. When the Waveform Capture screen

comes up, press the Lightning Bolt button. This will load

the data from the MPRT resulting in something like the

following example.

General Electric UR G60 Modbus Device Setting Screen

Dynamic Control

The user can view the actual outputs waveforms as well as

any selected binary inputs and or binary output contacts.

This capability also will work with Multi-State or State

Sequence Playback. It should also be noted that the user

can record the complex waveforms that they applied using

the harmonic waveform generator in the dynamic control.

Basic Programming Tool

The Basic Programming Tool provides a means to either

import older test macros into AVTS and execute legacy test

files, or to send the test system syntax commands to do

special test applications not covered by the standard test

modules, generic test modules, wizards, DFR playback,

vector control, ramp control or dynamic control. These

commands can be issued from the Basic Tool icon as part

of a special test file.

Modbus Communications

AVTS now has the capability to communicate with relays

via the Modbus protocol. This allows the AVTS user the

ability to automatically download relay settings from the

relay via the Modbus addressing scheme into the AVTS

relay setting screen. In addition AVTS can now monitor the

relay protection or metering elements via the Modbus

communications. This means the user will not need to

change the relay outputs, thus test the relay without

making any changes to the relay what so ever. Instead of

the user having to read the meter values and manually

input them into a result screen the software can now read

the values automatically. This feature combined with the

Sequence Test feature can mean fully automatic testing

without user intervention. As an example, the General

Electric UR Model G60 relay device settings screen can be

seen in the following figure. Note the Modbus address for

each setting in the relay is defined in the Device Setting

screen. Once the device setting screen is created for the

relay, test files may be created.

Dynamic Recorder Screen for Single Phase Multi-Shot Reclosing Relay

Page 16

MPRT

Megger Protective Relay Test System

16

SS1 File Converter

End-to-End Test Capability

End-to-end testing usually involves the coordinated

playback of a digital fault recorder (DFR) record by the

test equipment. However, there are occasions when a

user- defined single or multi-state data playback may be

desired. End-to-End tests are run by using a special macro

in AVTS Advanced and Professional. The macro will allow

the user to select the test file (DFR recording) which is

then loaded into the test system. The test system then

waits for a GPS trigger pulse to begin playing back the

recording. If the user desires to perform a state playback

rather than a DFR playback, the user simply constructs a

test utilizing the Data and End To End macros. The Data

macro can be edited and allows the user to specify the

voltage and current generator states and time durations for

playback. A typical End-to-End test setup would look like

the following figure.

SS1 File Converter

SS1 files are generated using Power System Simulation

software programs by Electrocon® CAPE™ or Aspen Oneliner® .By modeling the power system and using the SS1

files, the relay can then be tested dynamically using

realistic system test scenarios. The SS1 File Converter will

read the SS1 file and create a dynamic state sequence

playback file. This file can be used in two ways. The first

method of use is as a standard dynamic test. One

application is the testing of impedance relays. By modeling

the power system using simulation software, the relay can

then be tested dynamically using realistic system test

scenarios. The dynamic test can be used stand alone or as

part of a more complex test module. The other application

is as an End-to-End playback file, similar to a DFR

playback file.

Typical End-to-End Test with MPRT

Log-in for SEL-321 Scripted Test Module

One-Touch Test

TM

The One-Touch Test utilizes a Visual Basic®Script Control

tool that is only available in the Advanced and

Professional version of AVTS 3.0. The script file works with

Megger Test Modules that have been specifically created to

make use of this feature, see AVTS Test Modules. The

Script file allows AVTS software to communicate to a

microprocessor-based relay via ASCII text serial

communication, and download the relay settings into the

AVTS relay Setting Screen automatically. Then, using the

Group Execute feature in AVTS, automatically test the relay

to the actual relay settings with one touch of the mouse

button.

Page 17

MPRT

Megger Protective Relay Test System

17

DFR Test Editing Dialog Screen

Waveform Viewer is invoked from the Tools menu, the

screen called DfrWaveView dialog box will appear.

From this dialog box a user can convert digital fault

recorder data, in COMTRADE format, to hexadecimal files

compatible with the Test System waveform generators,

select the channels and ranges to be uploaded, and upload

and output the waveforms.

In addition, special editing capabilities allow the user to

replicate the prefault data for as many cycles as desired to

insure that the device under test is properly polarized prior

to applying the fault. Timing maybe started in conjunction

with the fault application, thus timing the replay event.

Due to the wide operating bandwidth of the test system,

there is no degrading of the recorded samples thus high

fidelity of the playback waveforms is insured.

Import Relay Settings From Aspen Database

Westinghouse CO-9 Digitized Time-Current Curves

Import Aspen Relay Database

®

In addition, relay settings may also be imported from other

databases. For example, relay settings from the Aspen

Relay Database

®

can be seen in the figure below.

A

VTS PROFESSIONAL VERSION

The Professional version includes all of the features

previously described for the Basic and Advanced versions.

It also includes special testing and editing tools for

playback of Digital Fault Records or EMTP/ATP simulations

that are in the IEEE C37.111 COMTRADE format. In

addition, it includes the Waveform Digitizer.

Waveform Digitizer

The AVTS Waveform Digitizer Tool enables the user to

digitize waveforms and export them to a COMTRADE*.cfg

and *.dat files for playback through the Test System.

Waveforms from old strip chart recorders, hand drawn

waveforms, and waveforms created by oscillographic

functions of the modern microprocessor and numerical

relays; any waveform that can be represented in a *.bmp

format can be digitize. In addition, electromechanical relay

analog time curves, that do not fit numerical algorithms,

can be scanned into AVTS. The digitizer can be used to

create a virtual time curve to be used in the timing test.

For example, AVTS software comes with numerous analog

curves already digitized and ready for use.

DFR Waveform Viewer and Playback

In addition to performing the steady-state testing, it is

increasingly becoming a popular practice to perform

dynamic and transient testing on protective relays. AVTS

DFR Waveform Viewer has the capability of playing back

transient waveform data to the Test System waveform

generators. In other words, it can recreate a fault

(waveforms...) recorded by a Digital Fault Recorder or

simulated fault using EMTP/ATP programs. When DFR

Page 18

MPRT

Megger Protective Relay Test System

18

AVTS TEST MODULES

Complex Testing Simplified

Megger has developed a wide variety of relay specific test

modules from different relay manufacturers. AVTS Basic

Software users can import these test modules, execute,

save and print results. Using the Advanced version of

AVTS 3.0, users may copy, paste, rename and modify

existing test modules to create new relay test modules,

which have similar operating characteristics. Contact your

local Megger sales office for an up-to-date listing of the

available test modules.

AVTS Professional Waveform Viewer Screen

Time Saving

Each relay test module is an extremely valuable product

for any relay test technician or engineer. It provides the

user with a quick, easy way to test a specific relay to the

relay manufacture’s specifications, as well as eliminates the

time and costs associated with users having to create their

own test routines.

One-Touch Test Modules

One-Touch Test modules are currently available for a

variety of relays. One-Touch Test requires the AVTS

Advanced or Professional version to execute the

communication link between AVTS and the relay under

test, as well as automatically download relay settings. If

you have AVTS Professional, don’t forget to ask if the test

module you are interested in has the One-Touch Test

capability. Test modules, which are One-Touch capable,

save the user time, money and removes the possibility of

human error when having to read over 100+ relay settings.

Page 19

Model Number MPRT

Preset Configuration

84 = Maximum Configuration of up to

8 Currents & 4 Voltage Outputs

Output Power Selection

Enter 15 = Lower Output 15 Amps / 150 Volts

per amplifier channel

Enter 30 = Higher Output 30 Amperes / 300

Volts per amplifier channel

Enter R = Rack-mount Option. Unit comes with

hardware for rack mount in 19 in rack

Enter L = Light weight enclosure with two side

carry handles

Enter H = Lightweight enclosure with two side

carry handles AND large handle

Amplifier Output Modules

Enter 1, 2, 3 or 4 for the number of customer

selected amplifier modules required

Enter 0 for no customer selected amplifier modules

T = Base Unit with Touch View Interface

F = Base Unit with Floating Outputs and TVI

Pre-Set Frequency Output Option

Enter 5 = Unit comes pre-set with output frequency of 50 Hz

Enter 6 = Unit comes pre-set with output frequency of 60 Hz

Power Cord Option

Enter A = North American Power Cord

Enter I = International Power Cord comes with jacket strip

international color coded wires ready for installation of desired

connector.

Enter E = Continental Europe Power Cord comes with CEE 7/7

Schuko plug.

Transit Case Options

Enter 0 = No carry case

Enter 1 = Soft-sided carry case

Enter 2 = Hard-sided transit case

Enter 3 = 2 Piece hard-sided transit case

ORDERING INFORMATION STYLE NUMBER IDENTIFICATION

84 T

*

MPRT

Megger Protective Relay Test System

19

*NOTE: If you order 3 (2 piece hard-sided transit case),

you must order L (the MPRT with the two side

carry handles only).

Page 20

MPRT

Megger Protective Relay Test System

Item (Qty) Cat. No.

Popular Configurations

Model 8415, three-phase unit with soft-sided

carry case and North American power cord 8415-L3T6A1

Model 8415, three-phase unit with soft-sided

carry case and Continental Europe power cord 8415-L3T5E1

Model 8415, three-phase unit with soft-sided

carry case and International power cord 8415-L3T5I1

Model 8430, three-phase unit with extra

carry handle, soft-sided carry case and

North American power cord 8430-H3T6A1

Model 8430, three-phase unit with extra

carry handle, soft-sided carry case and

Continental Europe power cord 8430-H3T5E1

Model 8430, three-phase unit with soft-sided

carry case and International power cord 8430-L3T5I 1

AVTS, Advanced Version 544245

AVTS, Professional Version 544246

Included Accessories

Model 8415 and 8430 Base Unit

Power Cord - Depending on the style number,

the unit will come with one of the following

Line cord, North American (1 ea.) 801046

Line cord, Continental Europe with CEE 7/7

Schuko Plug (l ea.) 15021

Line cord, International color coded wire (1 ea.) 14525

Instruction manual (1 ea.) 710000

TouchView Interface (1 ea.) 710004

Cable Assy, Hand-Held Controller (1 ea.) 620001

RS-232 , Straight 9-pin, male/female,

Cable Assy. (1 ea.) 16350

Test lead, red, 200 cm, use with voltage/current

(up to 15Amps) outputs and timer (3 ea.)* 684000

Test lead, black, 200 cm, use with voltage/current

(up to 15Amps) outputs and timer (3 ea.)* 684001

Lug adapter, red, 6.2 mm, use with voltage

outputs and timer (3 ea.)* 684002

Lug adapter, black, 6.2 mm, use with voltage

outputs and timer (3 ea.)* 684003

Lug adapter, red, 4.1 mm, use with voltage

outputs and timer (3 ea.)* 684004

Lug adapter, black, 4.1 mm, use with voltage

outputs and timer (3 ea.)* 684005

Alligator clip, red, use with voltage outputs

and timer (3 ea.)* 684006

Alligator clip, black, use with voltage

outputs and timer (3 ea.)* 684007

Ethernet Crossover cable (1 ea.) 620094

Carry Strap (1 ea.) (L Unit only) 684024

ORDERING INFORMATION

20

Item (Qty) Cat. No.

Model 8415 Voltage/Current Output Module

Each output module will come with the following,

Test lead, red, 200 cm, use with voltage / current (up to

15Amps) outputs and timer (2 ea.)* 684000

Test lead, black, 200 cm, use with voltage/current

(up to 15Amps) outputs and timer (2 ea.)* 684001

Lug adapter, red, 6.2 mm, use with voltage

outputs and timer (2 ea.)* 684002

Lug adapter, black, 6.2 mm, use with voltage

outputs and timer (2 ea.)* 684003

Lug adapter, red, 4.1 mm, use with voltage

outputs and timer (2 ea.)* 684004

Lug adapter, black, 4.1 mm, use with voltage

outputs and timer (2 ea.)* 684005

Alligator clip, red, use with voltage outputs

and timer (2 ea.)* 684006

Alligator clip, black, use with voltage outputs

and timer (2 ea.)* 684007

Model 8430 Voltage/Current Output Module

The higher current output module includes 6 mm test leads

that are specially made for the higher current of the Model

8430 output module. Each output module will come with

the following,

Test lead, red, 200 cm, use with voltage output

and timer (1 ea.)* 684000

Test lead, black, 200 cm, use with voltage output

and timer (1 ea.)* 684001

Test lead, red, 6 mm dia., 150 cm long,

use with current output (1 ea.)* 15923

Test lead, black, 6 mm dia., 150 cm long,

use with current outputs (1 ea.)* 15924

Lug adapter, red, 6.2 mm, use with voltage

outputs and timer (2 ea.) v 684002

Lug adapter, black, 6.2 mm, use with voltage

outputs and timer (2 ea.)* 684003

Lug adapter, red, 4.1 mm, use with voltage

outputs and timer (2 ea.)* 684004

Lug adapter, black, 4.1 mm, use with voltage

outputs and timer (2 ea.)* 684005

Alligator clip, red, use with voltage outputs

and timer (1 ea.)* 684006

Alligator clip, black, use with voltage outputs

and timer (1 ea.)* 684007

Additional Optional Accessories

Rugged, hard-sided transit case (1ea) 684019

Soft-sided transit case (1 ea.) 684011

Two-piece, hardsided, lightweight

transit case (L unit only) 674002

* Test leads, lugs and clips have a CATII or better

insulation rating

Page 21

MEIU

MPRT EPOCH Interface Unit

21

MEIU

MPRT EPOCH Interface Unit

ORDERING INFORMATION

DESCRIPTION

The MEIU is a small, light-weight, field portable, interface

unit specifically designed to control Multi-Amp EPOCH-II

®

and EPOCH-20®units with the Megger MPRT relay test

system. The combination of the MPRT and the

EPOCH-II/20 units provides a very powerful test capability.

A single EPOCH-II/20 unit can provide a maximum of 170

Amperes, at 1,000 VA/600 VA, for simulating single phase

to ground faults. With a three channel MPRT unit, the

MEIU can interface and control up to three EPOCH-II/20

units either manually from the MPRT Touch View Interface

or through the AVTS software. With three EPOCH-II/20

units, three-phase fault simulations of up to 170 amperes

per phase are possible. The combination of a three

channel MPRT, the MEIU and three EPOCH-II/20 units can

provide 6 currents for testing three-phase current

differential protection schemes.

SPECIFICATIONS

MEIU Input Port:

21 pin D-connector connects the MEIU to the MPRT EPOCH

interface connector.

MEIU Output Ports:

Three (3) each 15 pin D-connectors connect the MEIU to

the EPOCH -20 units, or the to the EPOCH-II units.

Temperature Range:

Operating: 32 to 122° F Storage: -13 to 158° F

(0 to 50° C) (-25 to 70° C)

Relative Humidity:

90% RH, Non-condensing

Dimensions:

6.0 W x 1.75 H x 6.375 D in.

152.4 W x 44.45 H x 161.9 D mm

Weight:

0.80 lbs. (0.36 kg)

Enclosure

The unit comes mounted in a rugged enclosure for field

portability. A padded soft-sided carry case is provided.

The following are abbreviated specifications for the EPOCH-II and

EPOCH-20 High Current Units. For complete specifications of

these units refer to the EPOCH-II or EPOCH-20 bulletins.

Item (Qty) Cat No.

MEIU, MPRT EPOCH Interface Unit 801050

Model MEIU Includes

Instruction Leaflet (1 ea) 710017

MPRT to MEIU Interface Cable (1 ea.) 620081

EPOCH-20 Interface Cable (1 ea.) 15821

EPOCH-II Interface Adapter (1 ea.) 15833

Carry Case (1 ea.) 14574

Page 22

UK

Archcliffe Road, Dover

CT17 9EN England

T (0) 1 304 502101

F (0) 1 304 207342

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1019 USA

T 1 800 723 2861

T 1 214 333 3201

F 1 214 331 7399

OTHER TECHNICAL SALES OFFICES

Norristown USA, Toronto CANADA,

Mumbai INDIA, Trappes FRANCE,

Sydney AUSTRALIA,

Madrid SPAIN and

The Kingdom of BAHRAIN.

ISO STATEMENT

Registered to ISO 9001:1994 Reg no. Q 09250

Registered to ISO 14001 Reg no. EMS 61597

MPRT_AVTS3.0_DS_en_V18

www.megger.com

Megger is a registered trademark

MPRT

Megger Protective Relay Test System

Loading...

Loading...