Page 1

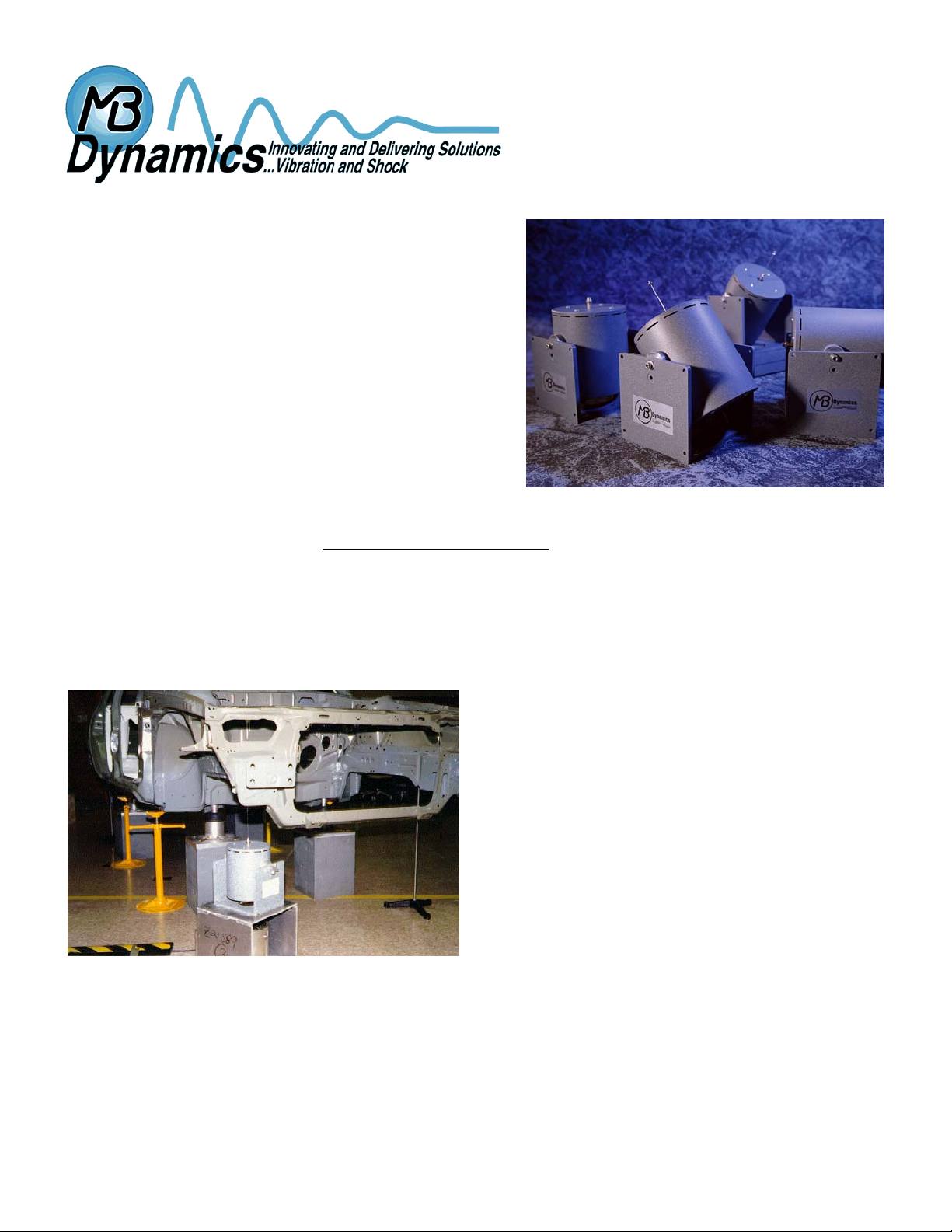

MODAL 50A

Excitation Made Easy!

THE EXCITER - #1 SELLING WORLDWIDE

"The MODAL 50A along with MB's MODAL APPLICATIONS

EXPERTISE have revolutionized modal testing!" This Exciter was

designed by a team of world-respected modal testers, including

University of Cincinnati professors, to eliminate problems

encountered when using traditional shakers for modal tests. The

MODAL 50A slashes setup time to a minimum! Conveniences in

fixturing and setup like the clearance hole through the armature

and shaker and a collet chuck for gripping a threadless stinger

make easy the attachment of the MODAL 50A to a test structure.

50 pounds dynamic force from an Exciter weighing little more than

50 lbs makes it portable and easy to setup by one person.

THE COMPANY - UNIQUELY QUALIFIED

MB's three principals (SDRC alumni) have over seven decades of combined experience performing extensive dynamic

testing - both in the USA and Europe. These experienced test veterans have solved real-world test challenges, and have

helped hundreds of new and experienced modal testers alike properly apply the right excitation source to achieve good

modal data faster! Choosing an MB Modal Exciter gains you access to applications experience unsurpassed in the

marketplace today ... whether you need custom-tailored testing solutions ... on-site consulting ... seminars on theory,

applications, excitation ... practical hints for acquiring valid modal data ... you'll get it with MB Modal Exciters.

APPLICATIONS EXPERTS - BEHIND EVERY EXCITER

The MODAL 50A (and multiples thereof) is ideal for exciting

structures smaller than say, a full-size automobile. Total

vehicle modal tests on anything larger (truck, jet, even a

space shuttle) requires multiple MODAL 50A's or the MODAL

250A.

Modal testing of structures needs an Exciter that is highly

portable and easy to setup and operate. The lightweight,

compact MODAL 50A was designed with these needs in

mind. A center bore extending through the armature,

housing, trunnion base, and inertial masses allows a stinger

to be easily positioned along its axis. It may then be placed

as close to the test article as desired and the chuck tightened

down to grip the stinger firmly. The stinger need not be cut

off, thus retaining flexibility for future use in different

orientations and applications.

The ideal stinger would be infinitely stiff in the axial direction and have no bending stiffness. Since this is not possible, it

can be approached with a pre-loaded thin wire. Replacing the 1/8" stinger with piano wire is easy by simply changing one

of the collets provided in the Accessory Kit. Once installed, the wire can be pre-loaded using bungy cord and a small

block pulley. An oscillatory force of 50 pounds keeps the tension in the stinger while delivering peak dynamic force. This

virtually eliminates measurement errors due to bending moments and side loads that can result when using compression

loading of traditional stingers.

25865 Richmond Rd · Cleveland OH 44146 · 216-292-5850 · fax 216-292-5614 · email mbd@mbdynamics · www.mbdynamics.com

Page 2

EASY TO FIXTURE & SETUP -- SLASHES SETUP TIME

• Clearance hole through armature and shaker allows unlimited

positioning along the axis of the stinger

• Collet chuck with clearance hole through armature and shaker

provides easy attachment of "one size fits all" stinger

• 'Piano wire' minimizes cross-axis measurement errors; allows

large static force to be applied without derating 50 lb dynamic

force

• Quick disconnect turnbuckles for adjustable suspension and

easy, 6 dof positioning

• Lightweight shaker, easy-mount inertial masses/accessories

allows one-man setup and portability to remote locations

• Trunnion base with two hand-knobs and three screw feet allow

adjustment to virtually any excitation angle

• Quick connect/disconnect of additional mass supplies large

inertial restraint for low frequency tests

UNIVERSAL -- NO NEED FOR 2 LBS FORCE OR 6" STROKE SHAKERS

• 1" stroke - sufficient for flexible structures and low frequency "suspended shaker" tests

• 50 pounds dynamic force - enough for large test articles such as mid- to full-size automobile

• Lightweight armature (<0.4 lb) enables testing small items

• Broad usable frequency range (1-4000 Hz) handles almost every modal survey

• Ideal for multi-shaker random, single-point random, multi-point sine dwell, and even burst random

ACCURATE -- FEWER MEASUREMENT ERRORS DUE TO FIXTURING

• The 'current mode' of MB's SS250VCF amplifier virtually eliminates mass loading of very small test items

• Lightweight armature minimizes mass loading - dramatically reduces force drop-off at resonances of the test specimen

• Low armature axial suspension stiffness (<15 lbs/in) assures shaker dynamics are decoupled from the test specimen’s

• Ultra thin stinger decouples force inputs in all directions except the driven axis - avoids "cross axis" error in force

measurement

• Applies/Maintains pre-loaded tension to the stinger, eliminating buckling problems - results in superior forcing function!

ACCESSORY KIT

Includes chucks, turnbuckles, nuts, bolts, bolt-on masses, wrenches for bolt-on masses, stingers, user's manual, and

extra storage for your stingers and load cells

SPECIFICATIONS

STROKE 1" peak-peak (continuous duty)

1.1" between stops

FORCE OUTPUT Convection Cooling:

Shop Air by User:

Portable Cooling:

STINGER ATTACHMENTS Chuck and assortment of collets handles wire sizes from .020" to .125"

SHAKER ATTACHMENTS (for mounting) Floor: adjustable trunnion base & screw feet. Suspended: multiple

TEST SPECIMEN STATIC PRE-LOAD Capable of tensioning stinger in excess of 50 pounds

WEIGHT Shaker with trunnion base: 55 pounds

BOUNCE MODE OF 'LARGE INERTIAL

CONFIGURATION' ON ARMATURE SUSPENSION

DIMENSIONS 11 ½" H (to top of collet chuck with feet retracted) 7 ½" x 9 ¼" footprint

DRIVE CABLE LENGTH 30’ standard (100’ cable available as option)

Specifications subject to change without notice 0297

25 pounds (peak)

50 pounds (peak)

50 pounds (peak) - optional

turnbuckles

Approx. 1 Hz

Loading...

Loading...