Page 1

MBITE

Miniature Battery Impedance Test Equipment

■

Determines condition of lead-acid and

NiCd batteries on-line to 2500 Ah

■

Helps to ensure (Improves) critical

equipment back-up and (continuous)

revenue streams

■

Directly measures intercell connection

resistance and voltage

■

Standard and Custom Lead Sets available

■

17% smaller than the previous version

MBITE

Miniature Battery Impedance Test Equipment

DESCRIPTION

The Miniature Battery Impedance Test Equipment, MBITE,

is designed and ideally suited to determine the health of

flooded and sealed lead-acid and Ni-Cd batteries in

telecomm, RR signal and communications, substation,

process control and switchgear, emergency lighting

systems, smaller UPSs, and more. An additional

application is to measure impedance of batteries at the

end of the production line in battery manufacturing plants.

The MBITE is a lightweight, easy-to-use battery tester that

incorporates advanced features for enhanced capabilities

to provide fast, reliable results to determine what further

action may be required to ensure adequate system backup time. After all, measuring batteries is not for the

battery but for the equipment the battery is supporting

whether to ensure revenue streams or to support critical

plant equipment such as oil priming pumps.

In addition to measuring battery impedance and

interconnection resistance, the MBITE also measures

individual dc terminal voltages. Furthermore, since

impedance does not stress the battery, terminal voltages

may be used when they need to be documented. All

three parameters can be stored (up to 1000 lines of

readings) on-board for immediate review at the test site

on the large 31⁄2 digit LCD or from the built-in printer.

The stored data also can be downloaded via the RS-232

connector to a PC using “AVOLink” download software or

other conventional communications packages to

spreadsheet applications for further data interpretation.

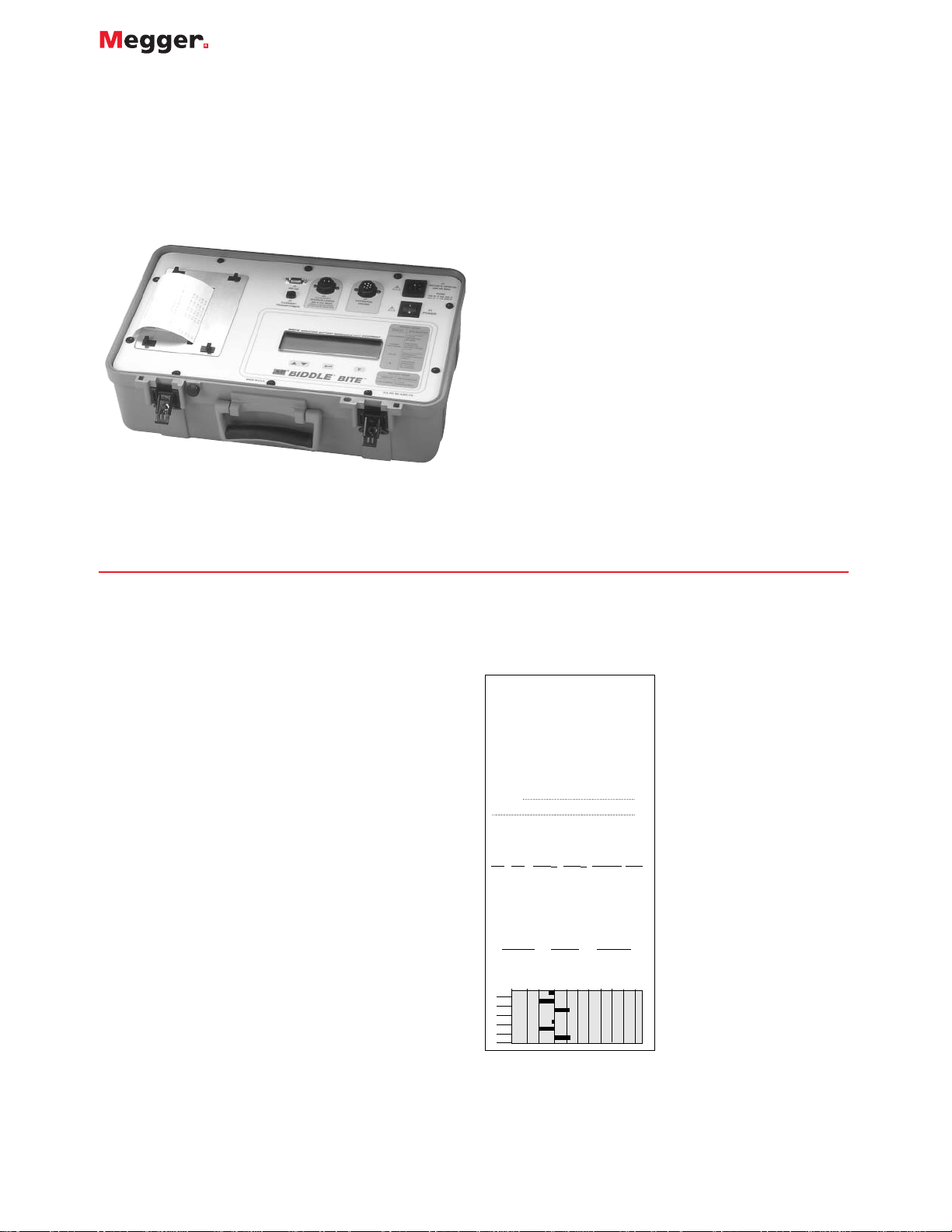

The Battery Analysis Report (see Figure 1) prints out cell

number, battery impedance, interconnection resistance,

cell dc voltage, date and time at which cell impedance is

recorded, total test current, and cell impedance summary

including graphical analysis. The printed header has space

to record user, location and cell IDs using the Bar Code

Wand listed in Optional

Accessories.

Unlike load cycle testing,

which involves substantial

downtime and performed

periodically, the MBITE

requires no battery discharge.

With a test time of less than

30 seconds per cell, it

measures internal cell

impedance, dc terminal

voltage and intercell

connection resistance without

taking batteries off-line. The

MBITE, like the original BITE,

is used to find weak cells due

to sulphation, post-seal

corrosion, and poor top lead

and intercell connections.

The test results, along with

user-supplied information

such as ambient temperature

and system ac ripple current,

will provide sufficient

information to evaluate the

overall battery system.

Figure 1.The Battery Analysis

Report (with Loc ID, User ID,

Notes, Cell ID filled-in)

Battery Analysis Report

Location ID:

USA Mobile Comm Site 37W Str 1A

User ID:

John Doe

Average Test Current: 0.98

Notes:

23-FEB-2000

TST Cell Zb mΩ RS mΩ Volts DC Time

001 1A01 2.46 0.356 6.18 10:56

002 1A02 2.34 0.359 6.23 10:57

003 1A03 2.65 0.341 6.23 10:57

004 1A04 2.47 0.355 6.18 10:58

005 1A05 2.34 0.337 6.23 10:58

006 1A06 2.65 0.347 6.23 10:58

Cell Impedance Summary

Minimum

001

002

003

004

005

006

Average Maximum

2.34 2.48 2.65

Percent Deviation from Average

-10 0 10 20 30

Page 2

Why Measure Batteries at all?

Measuring batteries is not for the battery but for the

equipment the battery is supporting whether to ensure

revenue streams as in wireless phone service or to support

critical plant equipment such as oil priming pumps. In a

sense, it is insurance that the MBITE provides and peaceof-mind knowing that the batteries are in good health.

APPLICATIONS

The MBITE measures impedance values and dc voltage for

flooded and sealed lead-acid and nickel-cadmium cells.

This information aids the operator to determine cell

replacement criteria based on impedance trends. The

MBITE also identifies weak cells in a battery string and

pinpoints unsatisfactory intercell and/or intertier

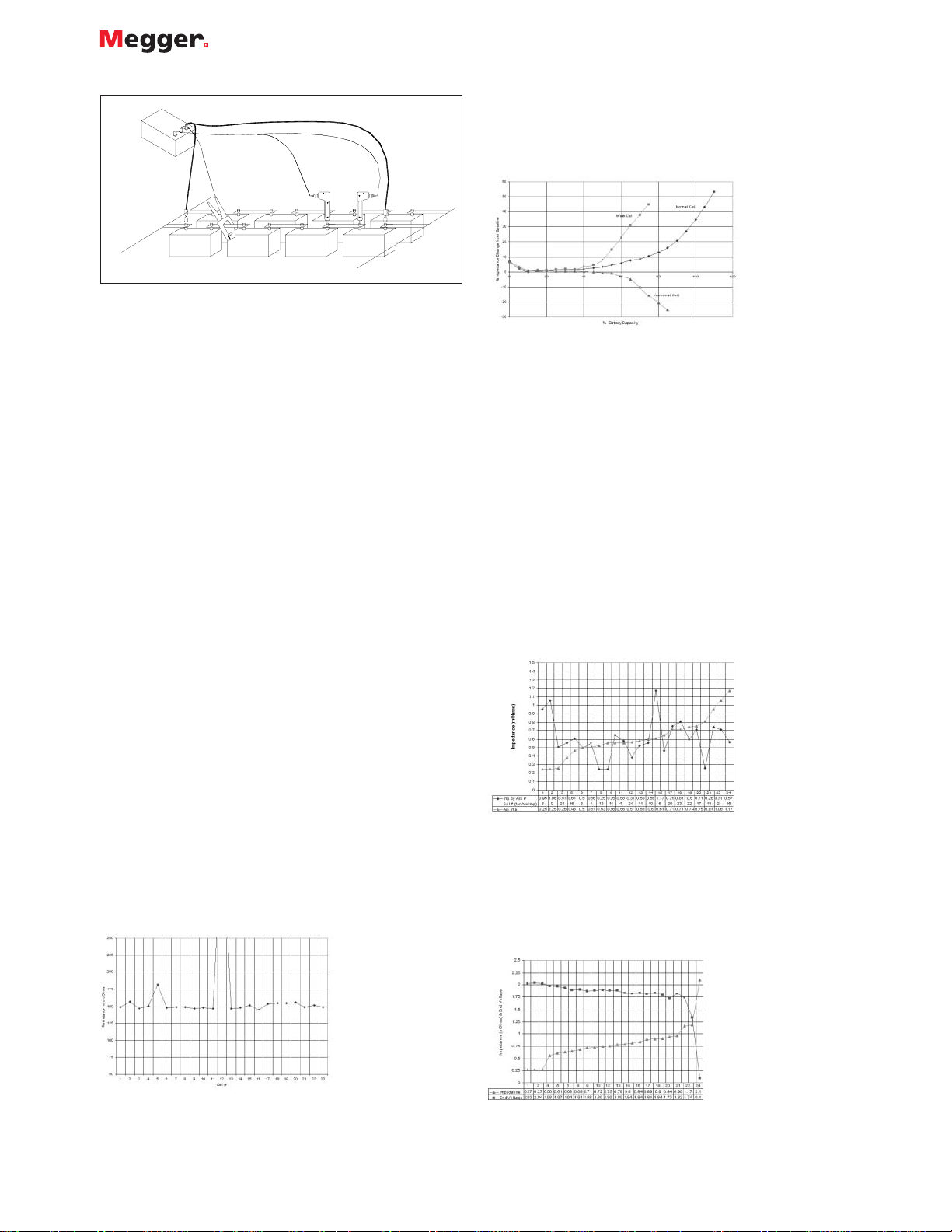

connections. A schematic diagram of a typical test setup is

shown in Figure 2.

Test Procedure

The MBITE base measurement unit applies a capacitively

coupled ac current to the battery under test by way of the

current source leads. Current sensors monitor source

current. The standard CT has a 2-in. (50-mm) internal

dimension while the optional CT is 0.5 in. (13 mm). The

CT is clamped around a convenient battery intercell or

intertier connection within the battery’s current loop. The

potential probes are placed across the cell under test. The

base measurement unit displays cell impedance and dc

float voltage as well as intercell connection resistance.

Figure 3 shows the value of taking direct intercell

connection resistance measurements. The information can

be verified by the operator and then stored by pressing the

data send button on the potential probe before moving

onto the next cell. Intercell resistance measurements also

can be made and

stored using the

cell/strap mode.

Single cell/module

applications

can be

accommodated

using one of the

optional Factory

Probe Lead Sets.

MBITE

Miniature Battery Impedance Test Equipment

Interpretation of Readings

Data produced by the MBITE can be interpreted in both

short- and long-term time frames. It is recommended that

MBITE measurements be made part of a battery

maintenance

program, with

readings taken

and recorded

quarterly or semiannually. Figure

4 shows an

example of how

impedance

changes as cells

weaken over time

and cycle life.

Short Term Interpretation

Impedance readings for individual cells can be used in the

short term to compare with the average impedance

reading for the entire battery. Individual cell values

varying by more than ±40% of the (sealed) battery average

typically indicate a problem with that cell (and ±20% for

flooded). There are two different methods of evaluating

impedance data in Excel

®

: 1) use the bar graph of the

MBITE printout in Cell # order and 2) by rearranging the

data into ascending impedance as shown in Figure 5 using

a spreadsheet. The cells on the right side of the graph are

weaker than the others. The dramatic increase in

impedance is a clear indication of questionable cells.

Further investigation of such cells is recommended,

including a

verification of

intercell

connections,

specific gravity,

if appropriate,

ambient

temperature, and

perhaps, a single

cell load-cycle

test.

Long-Term Interpretation

Impedance readings can be used in the long term to

determine replacement criteria. Battery cell impedance

values should be recorded and compared to previous

readings to determine

the cell’s position on

the curve of

impedance versus cell

life. Individual cell

values varying by

more than ±40% from

the initial baseline of

the battery average

typically indicate a

problem with that cell

(and ±20% for

Figure 2. A typical test set-up.

(-)

(+)

Figure 3. Intercell Connection

Resistance.

Figure 4. Impedance increases with

battery age (and weakness.)

Figure 5. Ascending Impedance.

Figure 6. Ascending Impedance

compared to Load Test,

Page 3

MBITE

Miniature Battery Impedance Test Equipment

flooded). A sample curve is shown in Figure 4. In order

to facilitate the long-term interpretation of impedance

values, Megger maintains a database of impedance values

of many battery types. For comparison purposes, this

information is available upon request.

An additional data evaluation method that can be used in

either a short-term or a long-term mode is in conjunction

with load test data. By taking impedance measurements

just prior to a load test and comparing them with end

voltage, a correlation between impedance and that string’s

capacity can be derived. See Figure 6.

FEATURES AND BENEFITS

■

Provides excellent data to evaluate critical systems’

back-up time

■

On-line testing requires no downtime

■

Graphical printout aids to quickly determine cell/jar

condition to make immediate decisions

■

Data is stored for on-site review

■

Requires no battery discharge to save cycle life

■

Built-in printer to leave a record at the site

■

RS-232 connector for downloading stored data to PC

■

Reduced testing time; less than 30 seconds per cell

■

Measures impedance and dc cell voltage for lead-acid

and nickel-cadmium cells

■

Directly measures intercell connection resistance to

eliminate routine retorquing

■

Up to 1000 sets of readings can be stored in an

unlimited number of tests

■

Custom Lead Sets available to meet specific needs

SPECIFICATIONS

Maximum Total Voltage at MBITE Leads

250 V dc. Larger battery systems can be sectioned

Power Requirements

120 V ac 60 Hz (240 V ac 50 Hz on –47 and –47-CE models)

Display

Backlit LCD panel with 5-in. (125 mm) viewing area

Voltage Range

0 to 2.500 V dc, 1 mV resolution

2.5 to 25.00 V dc, 10 mV resolution

Impedance Range

0 to 1.000 mΩ 1 µΩ resolution

1 to 10.00 mΩ 10 µΩ resolution

Measurement Accuracy

AC impedance: ±(5% rdng + 1 lsd)

DC voltage: ±(1% rdng + 1 lsd)

Settling Time per Reading

3 seconds maximum

Temperature

Operating: 32° F to 104° F (0° C to 40° C)

Storage: -5° F to 130° F (-20° C to 55° C)

Humidity: 20% to 90% RH, non-condensing

Clamp Range

Standard Opening: 2.0 in. (50 mm) maximum

Optional Opening: 0.5 in. (12 mm) maximum

Safety

Designed to meet IEC 1010-1 specifications

Dimensions: 7H x 11D x 17W in. (18 H x 29 D x 45 W cm)

Weight: 19.5 lbs. (8.8 kg)

Item (Qty) Cat. No.

MBITE, 110/60 246005B

MBITE, 240/50 246005B-47

MBITE, 240/50, CE-marked 246005B-47-CE

Included Accessories

Potential Probe set 33530

Potential Probe cable (8 ft.) 33806

Fused Current Source Leads (8 ft.) 33805

Clamp-on current sensor, CT, with 1⁄2 in. opening (5 ft.) 33863

Extension cable, CT (6 ft.) 33864-1

AVOLink, downloading software Instruction manual AVTM246005B

Optional Accessories

Potential Probe extension cable (8 ft.) 33806

Extension cable, CT (20 ft.) 246033

Clamp-on current sensor, CT, with 1⁄2 in. opening 246034

Factory Probes, dual-point helical hand spikes 33532

Factory Probes, AMP/Burndy Lead Set 33531

Bar Code wand with preprinted, laminated code sheet 246036

Bar Code Label printing software 246039

ORDERING INFORMATION

Page 4

UK

Archcliffe Road, Dover

CT17 9EN England

T (0) 1 304 502101

F (0) 1 304 207342

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1018 USA

T 1 800 723 2861

T 1 214 333 3201

F 1 214 331 7399

OTHER TECHNICAL SALES OFFICES

Norristown USA, Toronto CANADA,

Mumbai INDIA,

Le Raincy FRANCE, Cherrybrook

AUSTRALIA, Guadalajara SPAIN

and The Kingdom of BAHRAIN.

ISO STATEMENT

Registered to ISO 9001:1994 Reg no. Q 09250

Registered to ISO 14001 Reg no. EMS 61597

MBITE_DS_en_V01

www.megger.com

Megger is a registered trademark

MBITE

Miniature Battery Impedance Test Equipment

Loading...

Loading...