Page 1

4-Channel Power Meter LMG450

Universal Meter for Motors, Power Electronics

and Energy Analysis

Best

Accuracy

0.1%

LMG450 e 01.07

LMG450

Page 2

General

The four-channel LMG450 power

meter is another advanced

product from ZES ZIMMER

LMG series of precision power

meters, tried and tested and

with great acceptance in the

market. It is designed as a universal meter for the entire field

of power electronics and network analysis. It can be used in

practically all power electronics

applications, in development

and test systems, in quality assurance and maintenance.

It is fully frequency inverter

compatible.

Of course, it can also be used

for measurements in motors,

transformers, conventional and

switched power supply units.

It is also suitable for mains

analysis measurements.

Easy operation thanks to

colour graphics display and

hotkeys for important

measured values

Status bar

Various value tables can be

called on the colour graphics

display at the press of a key,

either with six values in large

letters, which can also be read

at a glance from a greater

Channel 1 with 11 measuring values Range setting and scaling

distance, with twelve values

or with up to 40 values e.g. in

range setting or in harmonics

table. The graphics display

allows scope and plot functions

for waveform and timing diagrams, as well as xy diagrams or

bar charts for the harmonics.

The status bar at the top of

each display menu shows the

input level of the four voltage

and the four current inputs – an

important item of information

for the quality of the measurement.

The display also indicates what

groups, A and B, the input

channels are switched to and

which signals the groups are

synchronised to.

Measurement inputs

Scope function for waveform of sampling values Plot function of calculated values

The direct measurement inputs

for voltage and current have a

very wide dynamic range:

Eight voltage ranges from 6V to

600V, and six ranges for current

from 0.6A to 16A.

A further voltage input (six

LMG450 – rear view

ranges from 0.12V to 4V),

designed for isolating current

sensors, extends the current

measuring range almost indefinitely. With the help of the

special current clamps supplied

by ZES ZIMMER and designed

for the LMG450, current can be

measured during running operations, without interrupting the

current path.

Page 3

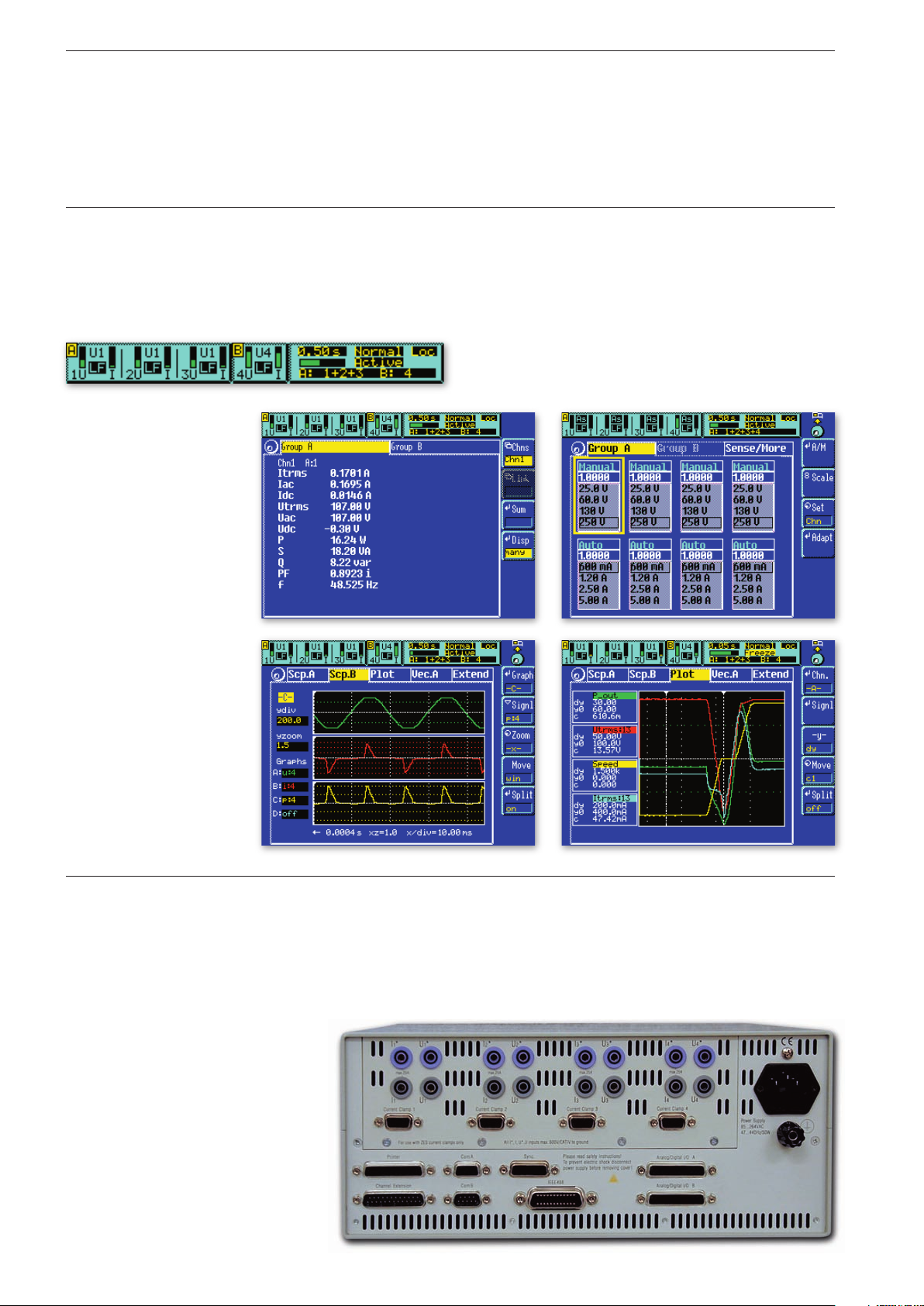

Compensated current clamp

Part No. L45-Z06

A special current measuring device is the

compensated current clamp by ZES ZIMMER.

It features electronic compensation of amplitude

and delay errors. Even at low current levels of

1A to 40A, measurement is exact in the frequency

range from 5Hz to 20kHz. Due to its high dynamic

common-mode rejection, this current clamp is also

very suitable for carrying out measurements at the

frequency inverter output.

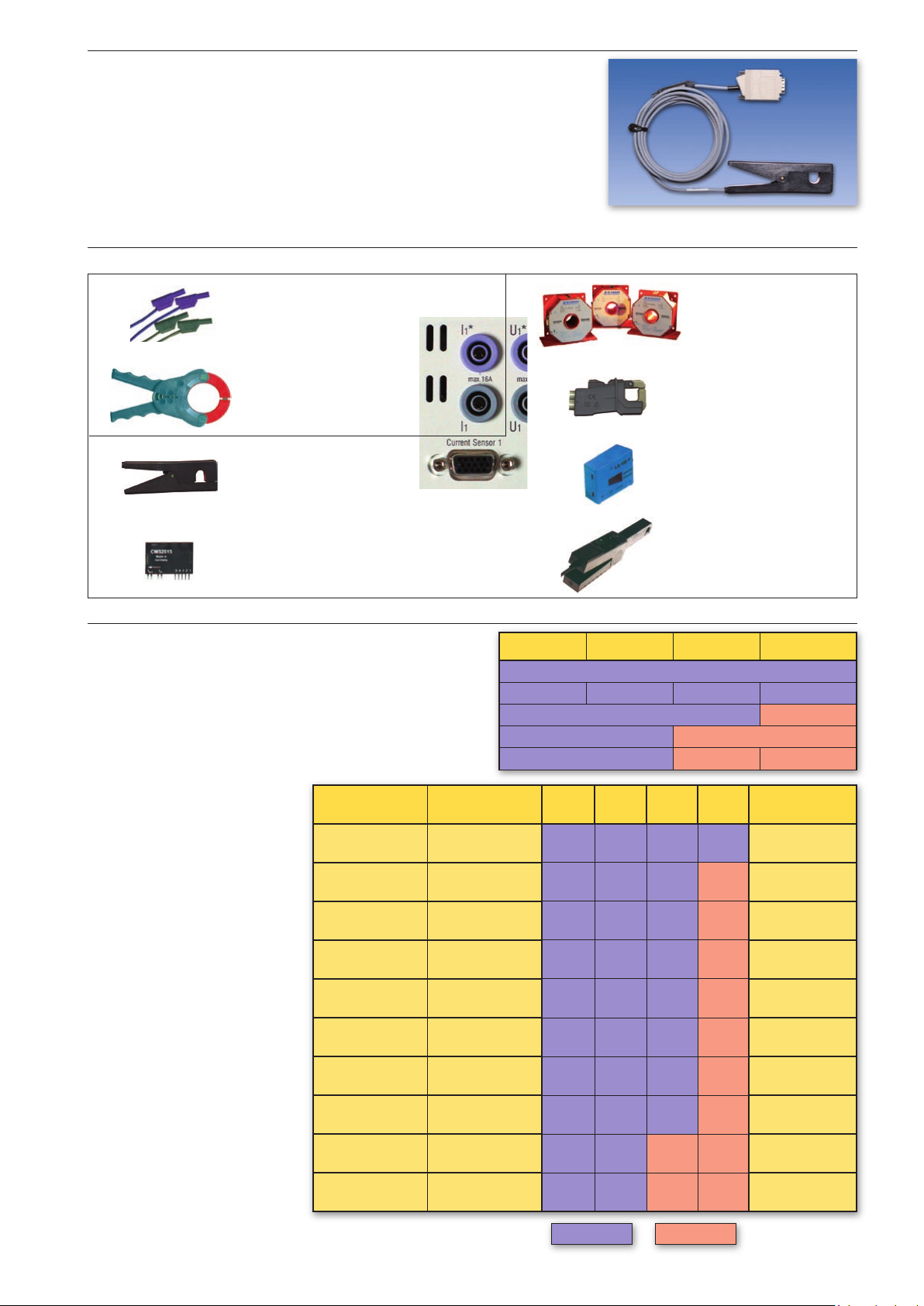

Various methods of applying current to be measured

4mm safety sockets

Direct measurement

0.6 ... 16A (6 Ranges)

DC ... 20 kHz

600V CAT III

Compensated current clamp L45-Z06

PSU200/400/600/700

Precision current transducer

1A ... 700Apeak

DC ... 20kHz

(300kHz, bandwidth of sensor

is limited by LMG450)

Standard current clamps

with current outputs >0.5A

100A ... 3000A

45Hz ... 3kHz

Compensated

ZES current clamps

1.2A ... 40A (6 Ranges)

5Hz ... 20kHz

Magneto-resistive

current transducer modules

5A ... 50A

DC ... 20KHz

4 independent power measuring channels

The current and voltage paths

of the four power measuring

channels are all isolated from

each other and from earth.

This allows a high degree of

measuring freedom in many

different power measurement

applications.

The adjacent table shows vari-

High power batterie

chargers (3Ø -> DC)

ous types of wirings for grouped

and individual measurement

channels. The table also assigns

application examples for the

respective types of wiring.

Rectifier section of

inverters (3Ø -> DC)

inverters (DC -> 3Ø)

Power measurement channels

1 and 4 can each be synchronised to their input signals

(fundamental waves etc.)

independent of each other.

Channels 1 and 4 are then the

Power supplies with

1Ø Transformers with

synchronisation references for

the other channels contained in

groups A and B.

3Ø laods with auxiliary

This is a very useful method for

carrying out efficiency measurements for equipment where the

input and output have different

frequencies, for example a

3-phase frequency inverter with

single-phase mains supply.

Wiring settings in () are featured

by option „Star-Delta Conversion“

Standard current clamps with

voltage/current (<0.5A)

outputs

10A ... 200A

45Hz ... 3kHz

Hall effect transducers

5A ... 200A

DC ... 20kHz

HD15 sockets

for external sensors

DC/AC current clamps with

voltage output

e.g. for oscilloscopes

10A ... 200A

DC ... 20kHz

Ch 1 Ch 2 Ch 3 Ch 4

4Ø 4W / 4Ø 5W

1Ø 2W 1Ø 2W 1Ø 2W 1Ø 2W

3Ø 3W / 3Ø 4W / 4Ø 4W 1Ø 2W

3Ø 3W (Aron) 3Ø 3W (Aron)

3Ø 3W (Aron) 1Ø 2W 1Ø 2W

Device Measured Value Ch 1 Ch 2 Ch 3 Ch 4

4Ø motors Power of all windings Phase 1 Phase 2 Phase 3 Phase 4 4+0

Output section of

1Ø -> 3Ø inverter

Low power motor

drives

multiple outputs

multiple output

windings

supplies

3Ø -> 3Ø inverter

High power motor

drives

3Ø -> 1Ø

AC power source

Input and output

power, efficiency

Input power,

rectifier efficiency

Output power,

chopper efficiency

Input and output

power, efficiency

Input and output

power, efficiency

Input and output

power, efficiency

Complete input power Phase 1 Phase 2 Phase 3

Input and output

power, efficiency

Input-, output- and

DC-Bus power,

efficiency

Phase 1 Phase 2 Phase 3 DC-Out

Phase 1 Phase 2 Phase 3 DC-Bus

AC-Out 1 AC-Out 2 AC-Out 3 DC-Bus

AC-Out 1 AC-Out 2 AC-Out 3 Phase 1

DC-Out 1 DC-Out 2 DC-Out 3 Phase 1 3 +1

AC-Out 1 AC-Out 2 AC-Out 3 AC-In 3+1

Aux. AC

or DC

AC-In 1 AC-In 2 AC-Out 1 AC-Out 2

AC-In 1 AC-In 2 DC-Bus AC-Out

Appropriate setting

Group A Group B

of wiring

3+1

(UD I* -> U* I*)

3+1

(UD I* -> U* I*)

3+1

(UD I* -> UD ID)

3+1

(UD I* -> U* I*)

3+1

(UD I* -> UD ID)

2+2

(UD I* -> UD ID)

2+2

(UD I* -> U* I*)

Page 4

V

U

4

A

A

I

3

I

4

U

2

A

A

I

1

I

2

V

U

1

V

Aircraft

electrical

system

V

U

3

3Ø

f=400Hz

3Ø

f=60Hz

˜

˜

˜

3

f=var

1

f=50Hz

L

N

V

U

4

A

I

4

A

V

U

1

V

U

2

V

U

3

A

I

1

A

I

2

I

3

Motor

Measurement on two systems

with different frequencies

In wiring A:1+2 B:3+4, the

ARON circuit is two times used.

The block diagram shows that

60Hz -> 400Hz

only one LMG450 is needed for

complete measurement.

Generally frequency converters

for speed variable drives or

frequency conversion have no

neutral on input or output.

1

Setting of global parameters,

e.g. wiring (see table at

previous page)

2

Configuration of measuring

inputs and sychronisation

source for group A

The following block diagram

applies wiring A:1+2+3 B:4 and

is typical for a low power speed

50Hz -> f=variable

variable drive. This example is

used to explain the settings

and displays of the LMG450.

1

The screenshots were made with

the free software BMP2PC from

ZES ZIMMER.

2

3

Configuration of measuring

inputs and synchronisation

source (same as picture ,

2

but for group B)

4

Measuring ranges, autorange

or manual, setting of scaling

factors for external CT’s or

VT’s (group A)

4

5

Measuring ranges, autorange

3

or manual, setting of scaling

factors for external CT’s or

VT’s (group B)

6

Display of different plugged

external current sensor

devices from ZES ZIMMER,

here the bottom one is in use

(enabled)

5 6

Page 5

Scope of power (yellow),

7

current (red) and voltage

(green) of the frequency

converter single phase input

8

Scope display of the low

pass filtered 3Ø output, the

chopper frequency is no more

contained because of being

outside the filtered range

Large display with

9

six important values of the

frequency converter input,

measured in group B

10

Phase values and summing

values of the frequency

converter 3Ø output gives a

quick overview (group A)

11

Efficiency, slip, speed and

other interesting values

calculated by user defined

formulas

12

The formula editor provides

the individual calculations

shown in picture

11

7

9 10

8

13

Vector display of 3Ø systems

immediately checks the phase

sequence and shows phase

interchanges

14

Plot display works like a strip

chart recorder and can plot

all measured or formula

calculated values

15

Harmonic analysis conform to

CE standards

(precompliance tests)

16

Frequency spectrum for

current, voltage (as bar chart),

with CE-limits, linear or

logarithmic

11

13

12

14

15

16

Page 6

3

f=var

1

f=50Hz

L

N

V

U

4

A

I

4

A

V

U

1

I

3

Motor

A

I

1

V

U

3

V

U

2

A

I

2

All necessary functions

in the basic device:

- Printer interface

- RS232 interface

- Formula editor

- Harmonics analysis for

CE pre-compliance

All necessary functions are

included in the basic device at

reasonable price.

Printer and RS232 interfaces,

formula editor, harmonics

analysis of current and voltage

for pre-compliance tests in

accordance with EN61000-3-2.

Options

- Star-Delta Conversion

Part No. L45-O6

Formula editor: the window shows the available mathematical

formulae, functions and logical conditions

50Hz -> f=variable, instrument for motor measurement in I∗ U∆ wiring

For detailed test and evaluation of 3Ø motors the electrical

quantities for each winding

phase is needed. In some cases

you have access to the motor

terminal block with start and

end of all three windings. Then

you can measure all what you

need. But in most cases the

motor has only three terminals

and the internal star point or

the delta winding as to measure

its current is not accessible.

Also far away from the motor

you have only the three wires.

With the option star-delta conversion you have the capability

to calculate the not accessible

values (e.g. voltages, currents,

power, harmonics). This intelli-

Program example for the monitoring of overvoltage and

undervoltage

gent solution with an additional

DSP works well at all waveforms

and every unbalance of mains

and load. Simply connect the

voltage paths in delta and click

the current clamps around the

wires. Select the internal connection of your load and press

the „Link“ softkey.

Calculation of the real values in the star connected winding

phases (wiring: 3+1, U∆ I∗ -> U∗ I∗)

Further options:

Flicker meter

(Part No. L45-O4)

IEEE488 interface

(Part No. L45-O1)

Interpretation of the complete

SCPI, as well as the LMG450

specific command set. The data

transfer yields up to 1Mbyte/sec.

Disk or memory card

(Part No. L45-O2F or L45-O2)

The two memory media, disk or

memory card, can be used as

required. They serve to record

measured and sampled values

and to save and recall device

settings (setups).

Compliant to EN61000-4-15.

The evaluation of the voltage

fluctuations by currents up to

16A compliant to EN61000-3-3,

by currents up to 75A compliant

to EN61000-3-11.

Process signal interfaces,

digital and analog inputs

and outputs

(Part No. L45-O3)

To monitor further process

magnitudes like revolution,

torque etc. With assistance of

the formula editor efficiency

and other magnitudes can be

deduced and be applied as control parameters.

Harmonics up to 99th

from U, I and P

(Part No. L45-O8)

The harmonics up to 99th

option can be used to analyse

current, voltage and power

related to the fundamental

ranging from 1Hz to 1.2kHz.

It is possible to detect

interharmonics by a selectable

division factor giving a new

fundamental as reference.

Calculation of the real values in the delta connected

winding phases (wiring: 3+1, U∆ I∗ -> U∆ I∆)

Transients

(Part No. L45-O5)

The transients option detects

peaks and dips up to a resolution of 20µsec, scanning

taking place at 50kHz.

Torque determination

(Part No. L45-O16)

Precision Power Meter Series

LMG calculates torque and

speed of three-phase asynchronous motors from motor current

and voltage without torque

measuring shaft.

Page 7

Dimensioning of insulation

for all standard low voltages

The measurement inputs are

dimensioned for 600V/CAT III,

with option L45-O15 up to

1000V. This makes it possible to

measure in all standard 3-phase

low voltage networks.

The adjacent table shows that

the voltage “Line to Neutral/

Earth” is always less than 600V.

3 Phase/

4 Wire

66/115V 115V 66V

120/208V 208V 120V

230/400V 400V 230V

277/480V 480V 277V

400/690V 690V 400V

3 Phase/

3 Wire

120V 120V 69V

240V 240V 139V

500V 500V 289V

1000V 1000V 578V

Line to Line

Voltage

Line to

Neutral/Earth

Technical Data

Voltage measuring ranges

Nominal value /V 6 12.5 25 60 130 250 400 600

Maximum trms value /V 7.2 14.4 30 60 130 270 560 720

Maximum peak value for full scale /V 12.5 25 50 100 200 400 800 1600

Overload capability 1500V for 1s

Input impedance 1M

Current measuring ranges

Nominal value /A 0.6 1.2 2.5 5 10 16

Maximum trms value /A 1.3 2.6 5.2 10 18 18

Maximum peak value for full scale /A 1.875 3.75 7.5 15 30 60

Overload capability 18A permanent, 50A for 1s, 150A for 20ms

Input impedance 2mΩ

Isolation All direct current and voltage inputs of power measuring channels against each other and against earth isolated, max. 600V/CAT III

Voltage measuring ranges for external

isolated current transduceers

Nominal value /V 0.12 0.25 0.5 1 2 4

Maximum trms value /V 0.15 0.3 0.6 1.2 2.5 5

Maximum peak value for full scale /V 0.25 0.5 1 2 4 8

Overload capability 250V for 1s

Input impedance 100kΩ, 10pF

Measuring range selection Automatic, manual or remotely controlled

Measuring accuracy

Accuracies based on:

1. sinusoidal voltage and current 4. definition of power range as the product of

2. ambient temperature 23 °C current and voltage range, 0 ≤ IλI ≤ 1, (λ=Power factor=P/S)

3. warm up time 1h 5. calibration interval 12 month

Other values All other values are derived from the current, voltage and active power values. Accuracies for derived values depend on the

functional relationship (e.g. S = I * U, DS/S = DI/I + DU/U)

Synchronization The measurement is synchronized on the signals period. There is a choice to determine the period from u(t), i(t), p(t), further

u

frequency inverter and amplitude modulated electronic ballast, synchronization also with external signal or „Line“

Scope function Graphical representation of sampled values over the time

Plot function Time diagram of max. four readings, minimal resolution 50ms

Harmonic analysis prCE Harm

Harmonic analysis Harm100

Fundamental in the range from 1Hz to 1.2kHz. By selectable integer divider (1...50) a new reference fundamental can be created

as to detect interharmonics.

Flicker measuring

Transients – monitoring and storing

selectable recording duration from 0.05 to 60 seconds. Adjustable pre-trigger, different possibilities of triggering

Computer interfaces

Remote control All functions can be remote controlled, keyboard lock for measuring parameters available

Output data Output of all readable data, data formats equal for all interface types, SCPI command set

Transfer rate RS232: max.115200 Baud, IEEE488.2: max. 1MByte/sec

Printer interface

Processing signal interface

• four analog inputs for registration of process magnitudes (16Bit, ±10V, 1kHz)

• four analog outputs for output of readings or measured magnitudes (16Bit, ±10V, 100kHz)

• four digital inputs for registration of states (1kHz, ULOW<1V, UHIGH=4...60V/2.5mA)

• four digital outputs to signal states and alarms (open collector, output high max. 30V@100µA, output low max. 1.5V@100mA)

• one input for registration of frequency (0.1Hz...500kHz) and rotation direction of motors (ULOW<1V, UHIGH=4...10V, 1MΩ)

In- and outputs are isolated groupwise against each other and against the other electronics (testing voltage 500V)

Ω, 20pF

Measuring accuracy

Voltage 0.2+0.2 0.1+0.1 0.05+0.05 0.2+0.2 0.3+0.4

Current (direct) 0.4+0.4 0.15+0.1 0.05+0.05 0.2+0.2 0.5+0.5

Active power (direct) 0.5+0.5 0.2+0.1 0.07+0.08 0.3+0.2 0.6+0.5

Current (via ext. current transducer) 0.2+0.2 0.1+0.1 0.05+0.05 0.2+0.2 0.3+0.4

Active power (via ext. current transducer) 0.3+0.3 0.15+0.1 0.07+0.08 0.3+0.2 0.6+0.5

2

(t), i2(t) by using a settable filter . By this very stable readings are achieved, even at signals of pulse width modulated

Measuring of current and voltage according to EN61000-4-7 with evaluation according to EN61000-3-2 (Pre-compliance)

Analysis of current, voltage and power up to 99th harmonics (max. 10kHz), in total 100 harmonics, when including DC part.

Flicker Meter according to EN61000-4-15 with evaluation according to EN61000-3-3

Storing and graphical displaying of transients with a resolution of 20µs. Storing depth is 1.4 Millions sample values/channel,

Interfaces: RS232 and IEEE488.2, only one interface can be used at the same time

Parallel PC-Printer interface with 25-pin SUB-D socket for printing measuring values, tables, graphics to matrix, inkjet or laser printers

25 pin SUB-D socket with (The option processing signal interface can be built in twice):

DC 1Hz..1kHz 45...65Hz, AC-Coupling 1kHz..5kHz 5kHz...20kHz

± (% of measuring value + % of measuring range)

Page 8

Other data

Display STN colour display, 320 x 240 pixel, 5,7’’

Dimensions - Bench case, W 320mm x H 147mm x D 307mm

- 19‘‘-chassis, 84PU, 3HU, D 307mm

Weight about 6,5kg

Protection class EN61010 (IEC1010, VDE0411), protection class I, overvoltage category III

Electromagnetic compatibility EN50081, EN50082

Protection system IP20 in accordance to DIN40050

Operating/storage temperature 0...40°C, -20...50°C

Climatic class KYG in accordance to DIN40040

Power supply 85...264V, 47...440Hz, about 45W

LMG450 accessories

ZES ZIMMER compensated current clamps

Nominal value /A 1.25 2.5 5 10 20 40

Permissible trms value /A 2.5 5.0 10 20 40 80

Permissible peak value for full scale /A 3.75 7.5 15 30 60 120

Overload capability 500A for 1s

Max. cord diameter 12mm

Isolation 300V/CATIII, 600V/CATII

Part No.

L45-Z06 (1 pc.)

L45-Z07 (Set of 4 pc.)

Hall current sensors for range extension

Part No. Current Supply

nominal trms peak

L45-Z28-Hall50 35A 50A 70A Internally

L45-Z28-Hall100 60A 100A 120A by LMG450

L45-Z28-Hall200 120A 200A 240A via HD15

L45-Z29-Hall300 250A 300A 500A Externally e.g. with

L45-Z29-Hall500 400A 500A 800A ZES power supply for

L45-Z29-Hall1000 600A 1000A 1200A up to four sensors

L45-Z29-Hall2000 1000A 2000A 2100A Part No. SSU-4

Measuring accuracy of clamp

Current 1.5+0.25 0.4+0.15 0.15+0.05 0.3+0.15 1.0+0.25 4.0+0.5

Phase 6 3 0.5 2 6 20

Current: ± (% of measuring value + % of measuring range) / Phase: degrees

1Hz...10Hz 10Hz...45Hz 45Hz...1kHz 1kHz...5kHz 5kHz...20kHz 20kHz...50kHz

Current transducers with Hall effect

sensors for range extension of LMG450,

DC...20kHz, accuracy class 0,5

connected to LMG450 via HD15 sensor

input, incorporated EEPROM for scaling

and adjustment data as well as data for

automatically setting of appropriate

current range

Power supply unit for up to 4 Sensors

Part No. SSU-4

Adapter for 3-phase measurements

Part No. LMG-MAK3

Longtime Data Logging NDL5

Part No. NDL5

LMG450 application software

Product name (Part No.)

LVDRV-L45 Driver for LMG450 under LAB-View 5.1.1 for RS232 as well as IEEE488 interface, with programming samples

LWINDRV-L45 Driver for LMG450 under LAB Widows/CVI for RS232 as well as IEEE488 interface, with programming samples

TERM-L5 Data transfer from LMG450/LMG95 to PC via RS232- and IEEE488-interface, recording as ASCII in Microsoft Excel- (CSV) or

ZES-format, or in tables with any separator, visualisation in real time of some selectable measurement values

BMP2PC Bitmap transfer from LMG450/LMG95 to PC via RS232, downloaded screens can be processed and scaled in Windows.

Free download from the website www.zes.com

Power supply unit for up to 4 Sensors for L45-Z29 and PSU-600 series, device fitting under LMG450/95,

design equal to NDL5 (see below)

• CEE-Plug, 5 pins, 16A, 2m supply cord

• CEE-Socket, 5 pins, 16A, for EUT

• Socket for supplying the meter LMG450

• 4mm safety sockets, measuring access to current and voltage

• Safety acc. IEC61010: 300V/CAT III

Longtime-data logging to harddisk for LMG450/LMG95

Communication via Internet/Ethernet, even when recording

Subject to technical changes, especially to improve the product, at any time without prior notification.

ZES ZIMMER Electronic Systems GmbH

Tabaksmühlenweg 30, D-61440 Oberursel/Ts.

Tel. ++49 6171 628750 Fax ++49 6171 52086

http://www.zes.com e-mail: sales@zes.com

Loading...

Loading...