Page 1

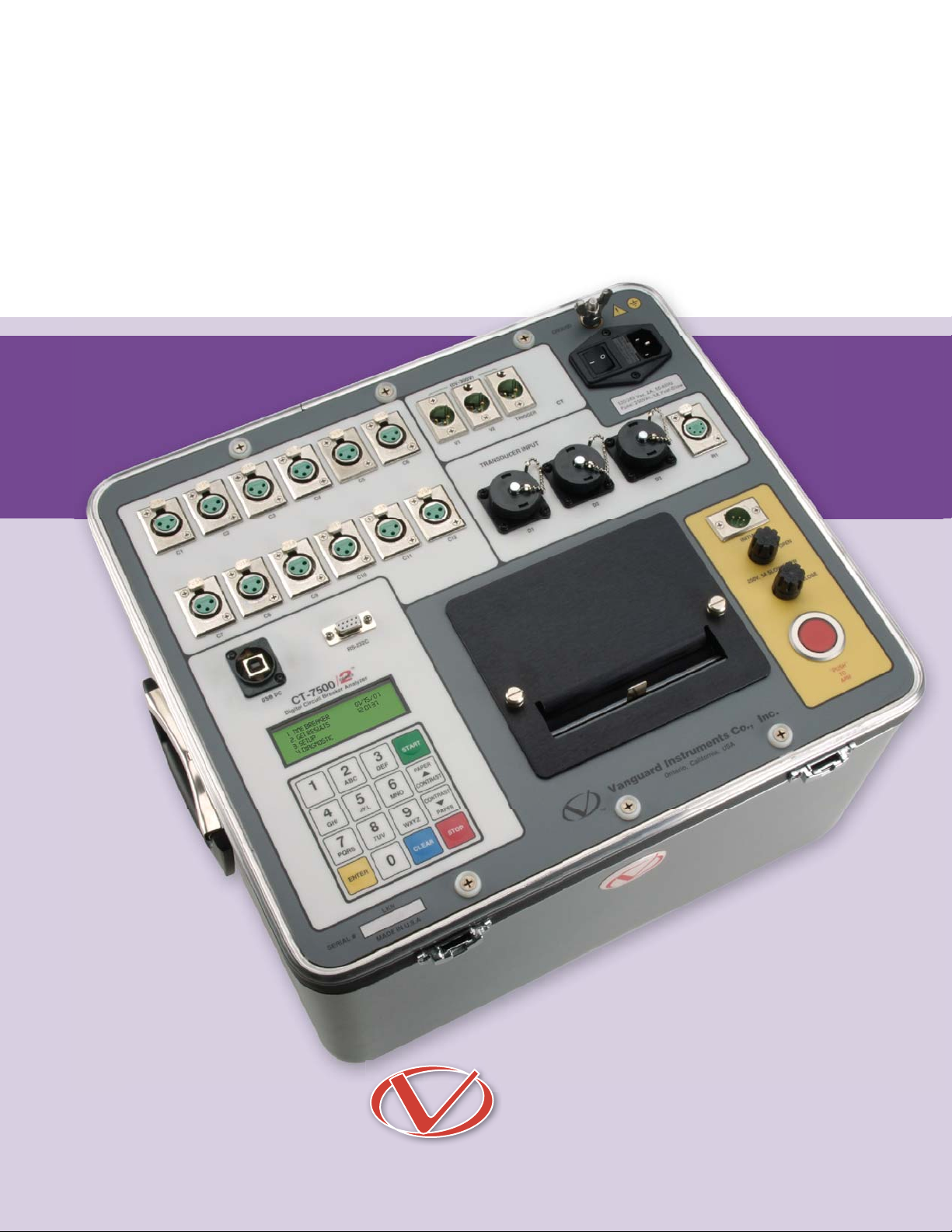

CT-7500 S2

digital circuit breaker analyzer

Vanguard Instruments Company, Inc.

www.vanguard-instruments.com

Page 2

CT-7500 S2

digital circuit breaker analyzer

The CT -7500 S2 is an easy to use, stand alone or computer-controlled, microprocessordriven EHV circuit breaker analyzer. It can operate either in Time Travel analyzer mode or

in “on-line” timing mode. In Time -Travel mode, the CT -7500 S2 can fully analyze a circuit breaker’s performance by testing the contact time, stroke, veloci ty, over travel, and

contact wipe. Contact motion analysis can be performed for all circuit breaker operations (Open, Close, Open – Close, Close – Open, and Open – Close – Open). The CT- 7500

S2’s timing window is selectable between 1 second, 10 second, or 20 second periods.

The 10 second and 20 second timing windows are ideal for timing long duration events

such as circuit switcher contact testing.

“On-line” Timing Mode

In addition to the conventional off-line timing mode,

the CT-7500 S2 also offers an “on-line” timing mode. In

this mode, the CT-7500 S2 captures the breaker’s trip or

close time, the trip/close coil current “fi ngerprint,” and

the battery supply voltage while the breaker is still in

service. The trip/close time is derived from the time of

trip, or close coil initiation, to the breaker’s bushing current breaker-make as detected by an AC clamp-on current sensing probe.

The “on-line” timing mode can detect a breaker’s operating conditions with little or no down time. In this

mode, the fi rst trip operation time of the breaker is captured. If a breaker has been in service for a long period

of time and sitting in close position, the fi rst trip time of

the breaker may be slow possibly due to a sticky mechanism. The “on-line” mode is very useful in such cases

because traditional breaker timing may not detect this

condition since several operations may have occurred

before the fi rst timing test is conducted.

1

Conventional Time

Travel Analysis Mode

The CT-7500 S2 is available in models with either 3 (CT-7500-3 S2), 6 (CT-7500-6 S2), or 12

(CT-7500-12 S2) dry-contact inputs. Each contact input channel can detect main contact and

insertion-resistor contact times in milli-seconds

and cycles.

2

Breaker Stroke and

Velocity

Three digital travel transducer channels are

available on the CT-7500 S2 for measuring

circuit-breaker velocity, stroke, over-travel, and

bounce-back. Unlike other transducer types, the

digital transducer requires neither calibration

nor setup. A breaker’s contact-velocity is calculated based on the contact’s travel distance over

a period of time. A special feature is also available to “slow-close” test a breaker and obtain a

test result report.

3

Resistor Type Transducer

Input

One resistor type input channel is also available

on the CT-7500 S2. This input channel allows

the unit to measure circuit-breaker motion by

directly interfacing with resistive type transducers. The transducer resistance ranges from 200

ohms to 10K Ohms.

4

Voltage Monitoring

Inputs

One analog voltage input channel, designated as

V1, is dedicated to monitoring a circuit-breaker’s

DC power supply or coil voltage (0 – 255 volts,

DC or peak AC). A second voltage input channel,

designated as V2, is dedicated to detecting the

voltage on/off status (presence or absence) of

an A/B switch.

ordering information

Part number CT-7500-3 S2 CT-7500 S2 with 3 contact channels, cables, and PC software

Part number CT-7500-6 S2 CT-7500 S2 with 6 contact channels, cables, and PC software

Part number CT-7500-12 S2 CT-7500 S2 with 12 contact channels, cables, and PC software

Part number CT-7500-CASE CT-7500 S2 shipping case

Part number Paper-TP4 Thermal printer paper

2

Page 3

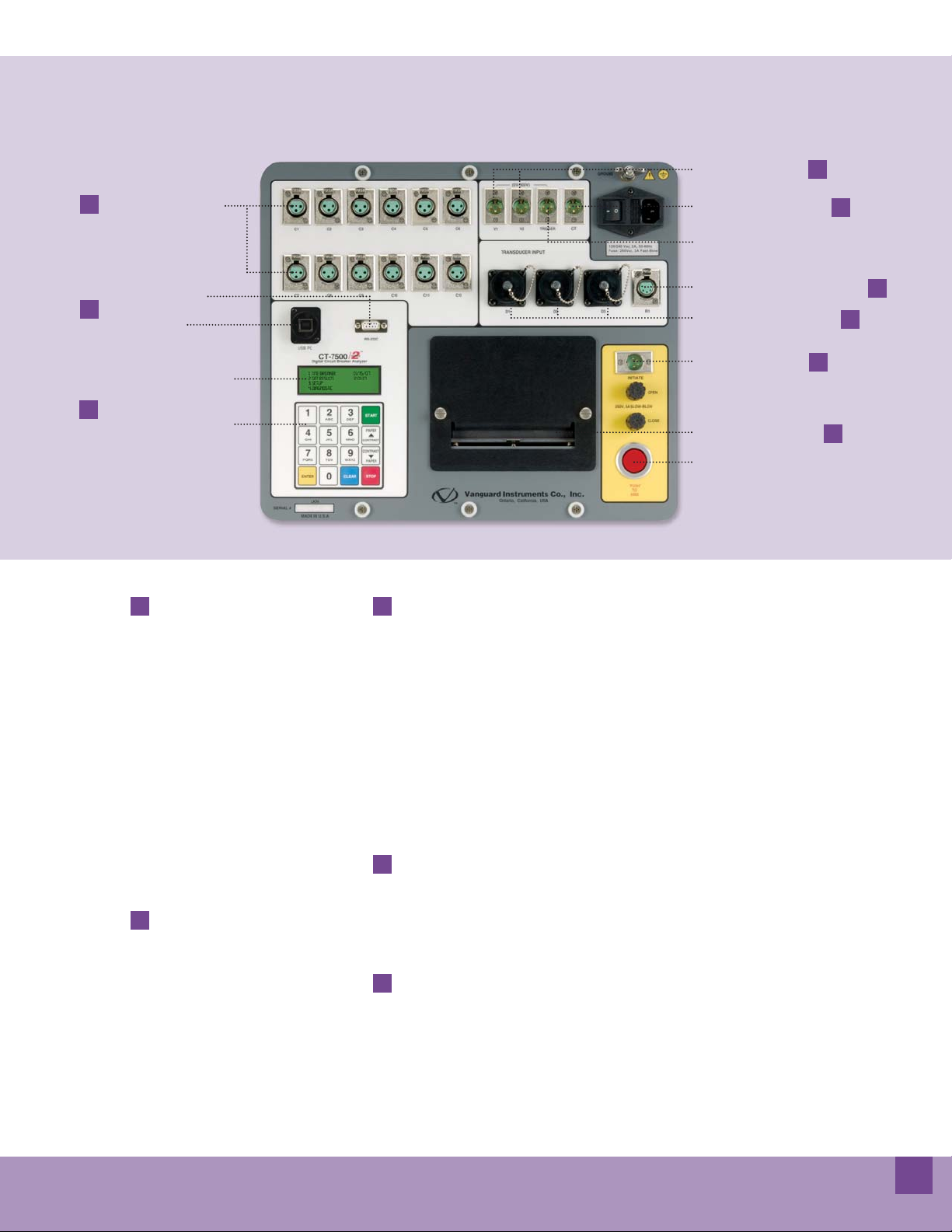

CT-7500 S2 Controls & Indicators

1

Contact Timing Channels

RS-232C PC Interface

7

USB PC Interface

Back-lit LCD Screen

(20 characters by 4 lines)

9

Rugged 16-key membrane

5

keypad

Voltage Input Channels

AC Clamp-on Current Probe

Trigger Input Connector

Resistor Type Transducer Connector

Digital Transducer Connectors

Breaker Initiate Output

4.5" Wide Thermal Printer

Breaker Initiate Arm Switch

7

4

6

3

2

5

8

Breaker Initiate Features

A built-in solid-state initiate device is used to

operate a breaker from the CT-7500 S2. The

operational modes include Open, Close, Open–

Close, Close–Open, and Open–Close–Open.

Multiple operations, such as Open–Close and

Open–Close–Open, can be initiated by using

programmable delay time or by sensing a breaker’s contact condition.

A built-in Hall-effect current sensor records

the Trip/Close current level and duration. The

breaker’s operate-coil current waveform duration (effectively, a performance "fi ngerprint" or

"current profi le") can be used as a diagnostic

tool for analyzing a breaker’s performance.

6

CT Input

One non-contact AC current sensor is used to

monitor circuit breaker on-line current for the

“on-line” timing mode.

Computer Interface

The CT-7500 S2 can be computer-controlled via

its RS232C or USB interface. Windows® based

BreakerAnalysis software is provided with each

unit. Using this software, circuit-breakers can

be timed from the PC. Test records can be retrieved from the CT-7500 S2 and then stored on

the PC for future analysis and report generation.

Circuit-breaker test plans can also be created on

the PC and transferred to the CT-7500 S2. Additionally, test records can be exported in Excel,

PDF, and XML formats for further analysis.

8

Built-in Thermal Printer

The CT-7500 S2’s built-in 4.5-inch wide thermal

printer can print the breaker contact analysis results in both tabular and graphic formats.

9

User Interface

The CT-7500 S2 features a back-lit LCD screen

(20 characters by 4 lines) that is viewable in

both bright sunlight and low-light levels. A rugged, 16-key, membrane keypad is used to control

the unit.

Diagnostic Capabilities

The CT-7500 S2 can perform diagnostics on its internal

electronics. Diagnostics can be performed to verify contact cable connections and to test the travel transducer’s

electronics.

Internal Test Record and Test

Plan Storage

Up to 150 test records can be stored in Flash EEPROM.

Test records can be retrieved and printed on the built-in

thermal printer, or they can be transferred to a PC via the

unit’s RS232C or USB interface.

Up to 99 circuit breaker test plans can be stored in Flash

EEPROM. Test plans are comprised of all circuit-breaker

performance specifi cations (stroke, velocity, and contact time). A test plan can be used to immediately test

a circuit-breaker. A pass/fail report is then generated by

comparing actual performance with the specifi cations in

the stored test plan. Test plans can also be generated

on a PC and transferred to the CT-7500 S2 via the unit’s

RS232C or USB interface.

3

Page 4

CT-7500 S2 connections

CT-7500 S2 desktop printer output

Desktop printout of tabulated test results

Desktop printout of graphic test results

CT-7500 S2 thermal printer output

Thermal printout of tabulated test results

Thermal printout of graphic test results

travel transducer trace

contact 1 trace

velocity curve

coil current trace

4

Page 5

Computer control and analysis with included VCBA S2 Software

The CT-7500 S2 comes with the Vanguard

Circuit Breaker Analysis Series 2 (VCBA S2) PC

software. The VCBA S2 software can be used

to retrieve timing records from the CT-7500 S2,

analyze retrieved records, view test results in

graphic format, generate timing reports, create

breaker test plans, transfer breaker test plans

to the CT-7500 S2, and control the CT-7500

S2 from the PC to perform timing tests. The

software can also be used to print test results

to a desktop printer.

CT-7500 S2 specifi cations

type portable digital circuit-breaker analyzer

physical specifi cations 16”W x 11”H x 14”D (40.6 cm x 29.9 cm x 35.6 cm); Weight: Less than 25 lbs (11.3 kg)

input power 100 ¬ 240 Vac, 50/60 Hz

dry-contact inputs 3, 6, or 12 dry-input channels (depending on model). Each channel detects main and insertion resistor contacts

timing windows 1 second, 10 seconds, or 20 seconds

timing resolutions ±50 micro-seconds @ 1 sec. duration, ±500 micro-seconds @ 10 sec. duration, ±1.0 milli-seconds @ 20 sec. duration

timing accuracy 0.05% of reading ±0.05 ms @ 1 second duration

dry-contact channel protection all contact inputs are grounded until test; input channels are protected against static discharge

dry-contact detection range closed: less than 20 ohms; open: greater than 5,000 ohms

resistor detection range 50 ¬ 5,000 ohms

ct current sensor one, non-contact, 0 ¬ 100 amperes

trigger input voltage open/close: 30 ¬ 300 V, DC or peak AC

voltage sensing input range V1: analog input; 0 ¬ 255 V DC or peak AC; sensitivity ±1 V

V2: voltage presence/absence detector input; 30 ¬ 300 V DC or peak AC

breaker operations Initiate Open, Close, Open-Close, Close-Open, Open-Close-Open

breaker initiate capacity 30A, 250 Vac/dc max

initiate current reading range one, non-contact, Hall-effect sensor, 0 ¬ 20 amp range, dc to 5 Khz

digital travel transducer inputs 3 digital travel transducer channels; linear range: 0.0 ¬ 60.0 in (±0.01 in)

rotary range: 0 ¬ 360 degrees (±0.36 degrees)

resistor type transducer input one channel, resistance range: 200 ohms ¬ 10 K ohms

contact travel point difference measures “slow-close” contact-point distances; results can be printed

display back-lit LCD screen (20 characters by 4 lines); viewable in bright sunlight and low light

printer built-in 4K” wide thermal printer that can print both graphic contact travel waveforms and tabulated test results

internal test record storage stores up to 150 test records and 99 test plans

computer interfaces one RS-232C port, one USB port

pc software Windows® based Breaker Analysis software included with purchase price

safety designed to meet UL 6101A-1 and CAN/CSA C22.2 No 1010.1-92 standards

environment Operating: -10°C to +50°C (+15°F to +122°F); Storage: -30°C to +70°C (-22°F to +158°F)

humidity 90% RH @ 40°C (104°F) non-condensing

altitude 2,000 m (6,562 ft) to full safety specifi cations

cables furnished with full set of test leads (including 20-foot contact leads and 30-foot contact lead extensions)

options transportation case (available for the CT-7500 S2 and travel transducers)

warranty one year on parts and labor

NOTE : the above specifi cations are valid at nominal voltage and ambient temperature of +25°C (+77°F). Specifi cations are subject to change without notice.

5

Page 6

VCBA S2

Vanguard circuit breaker analyzer software

The Vanguard Circuit Breaker Analyzer Series 2 (VCBA S2) Windows®-based software is included with all compatible Vanguard

Circuit Breaker Analyzers (CT-6500 S2, CT-7000 S2, CT-7500 S2, CT-8000, DigiTMR S2, DigiTMR S2 PC) at no additional cost.

This robust application can be used to control the circuit breaker analyzer from a PC to perform CB timing tests. It can also be

used to retrieve test records from the circuit breaker analyzer, analyze timing records, and view test results in tabulated and

graphical format. Circuit breaker test plans can also be created and transferred to the circuit breaker analyzer.

Retrieving and Analyzing Test Records

The VCBA S2 software can be used to quickly retrieve test records from a compatible Vanguard circuit breaker analyzer. Test

results can be viewed in tabular and graphical format and can be saved on the PC hard drive. Test record header information,

such as the company name, station, circuit, operator name, manufacturer, model, and serial number can also be edited.

Sample Test Results (OPEN Test)

Getting a Closer View with Graph Expansions

The VCBA S2 software can be used to expand a portion of the graphical test results for more accurate analysis.

Expansion Area

Velocity Trace

Graphical Test Results Graphical Test Results Expansion (from 0 to 200ms)

6

Page 7

Timing a Circuit Breaker with the VCBA S2 Software

The VCBA-S2 software can be used to control a CB analyzer and run circuit breaker

timing tests. The following tests are supported: OPEN, CLOSE, OPEN-CLOSE,

CLOSE-OPEN, OPEN-CLOSE-OPEN, and

STATIC RESISTANCE. Also, a test plan for a

specifi c breaker can be used with the test.

If a test plan is used, the Pass/Fail indicator

will be displayed based on the settings in

the test plan.

Breaker Testing Parameters

Creating Test Plans for Faster Testing

A circuit breaker test plan is comprised of all

circuit-breaker performance specifi cations

(stroke, velocity, and contact time). A test

plan can be used to test a circuit breaker.

When used with a test record, a Pass/Fail

report is generated by comparing the actual performance of the breaker with the

specifi cations in the stored test plan. Test

plans can be easily created with the VCBAS2 software and can be stored on the hard

drive or transferred to a CB analyzer.

Creating a Test Plan

7

Page 8

Instruments designed and developed

by the hearts and minds of utility

electricians around the world

Vanguard Instruments Company, (VIC), was founded in 1991.

Currently, our 28,000 square-foot facility houses Administration,

Design & Engineering, and Manufacturing operations. From its

inception, VIC’s vision was, and is to develop and manufacture

innovative test equipment for use in testing substation EHV circuit

breakers and other electrical apparatus.

The fi rst VIC product was a computerized circuitbreaker analyzer,

which was a resounding success. It became the forerunner of an entire

series of circuitbreaker test equipment. Since its beginning, VIC’s

product line has expanded to include microcomputer-based, precision

micro-ohmmeters, single and three phase transformer winding turnsratio testers, transformer winding-resistance meters, mega-ohm

resistance meters, and a variety of other electrical utility maintenance

support products.

VIC’s performance-oriented products are well suited for the utility

industry. They are rugged, reliable, accurate, user friendly, and

most are computer controlled. Computer control, with innovative

programming, provides many automated testing functions. VIC’s

instruments eliminate tedious and time-consuming operations, while

providing fast, complex, test-result calculations. Errors are reduced

and the need to memorize long sequences of procedural steps is

eliminated. Every VIC instrument is competitively priced and is

covered by a liberal warranty.

Vanguard Instruments Company, Inc.

1520 S. Hellman Avenue • Ontario, California 91761, USA

Phone 909-923-9390 • Fax 909-923-9391

www.vanguard-instruments.com

August, 2012

Loading...

Loading...