Page 1

CSI 2140 Machinery Health Analyzer

V-2140MHA

CSI 2140 Machinery Health Analyzer

n Easy data collection and powerful analysis tools in

a single unit

n Four-channel data collection for faster route

completion and advanced diagnostics

n Embedded intelligence guides test set up and

data analysis

n Ergonomically designed to improve usability in

theeld

n Convenient uploading of data wirelessly to

AMSSuitefromtheeld

The CSI 2140 Machinery Health Analyzer is best in class for speed

and performance in vibration data collection and eld analysis.

Product Data Sheet

June 2013

Overview

In today’s economy, plants are continually looking for ways

to remain competitive in the market place. For maintenance

departments, this often translates into fewer staff and smaller

budgets. In this do-more-with-less environment, maintenance

personnel can’t afford to continuously chase the next

breakdown. They need to quickly and accurately identify

developing faults and determine the root cause of the

machinery problem so it can be fixed.

The CSI 2140 is the next generation in a family of industryleading vibration analyzers and data collectors from Emerson.

As with previous models, the CSI 2140 can provide:

nRoute vibration collection

nAdvanced vibration analysis

nCross-channel analysis

nTransient analysis

nDynamic balancing

nMotor monitoring

nODS modal analysis

In addition to providing fast, actionable information,

an effective solution must take advantage of modern

communication and interface innovations that make tasks

easier and more intuitive. Emerson’s CSI 2140 Machinery

Health Analyzer was designed specifically with these goals

in mind.

Wirelessly upload route data and corrective maintenance jobs

from the field to AMS Suite: Machinery Health Manager for

analysis and reporting. AMS Machinery Manager integrates

data from multiple technologies, including vibration, oil

analysis, thermography, and balancing into a single database.

Alerts generated by AMS Machinery Manager can be exported

automatically to AMS Suite: Asset Performance Management

where they are combined with alerts from other plant assets

to provide a unified view of your plant’s health. Together, the

CSI 2140 and AMS Suite deliver the predictive intelligence

necessary for increasing availability and reliability in the plant.

Page 2

CSI 2140 Machinery Health Analyzer June 2013

scenario

The 4-Channel Advantage

While the CSI 2140 is available in 1- and 2-channel options, it

is the 4-channel option that delivers the most advantages to

a predictive maintenance program. The CSI 2140 is already

30% faster than the CSI 2130 (the fastest data collector in the

industry to date) when collecting a measurement point. With

4-channel capabilities, speed through the data collection

route is increased even more. And unlike other 4-channel units

on the market, the CSI 2140 delivers all four channels when

you need them the most – critical equipment startup and

troubleshooting diagnostics.

Monitor More Machines in Less Time Using True 4-Channel.

Using a triaxial accelerometer, the CSI 2140 simultaneously

collects vertical, horizontal, and axial readings on a bearing.

Place the sensor on the measurement point, press the button,

and when collection is complete move on to the next bearing.

Data collection time is reduced by as much as 30% compared

to the CSI 2130, and even more when compared to other

vibration collectors. Faster data collection translates into

less time in harsh or hazardous environments, more machines

monitored, and more time dedicated to higher value tasks like

analysis and diagnostics.

4-Channel Data Collection Enables Powerful Diagnostic

Options. Perform additional advanced diagnostics and deeper

dive diagnostic tests using 4-channel collection. With 4-channel

monitoring, you will gain additional data and diagnostic tools

to help you identify the root cause of your toughest equipment

problems. For example,

nView dual orbit plots, one on either side of the coupling or

dual orbit/shaft centerline plots of both sleeve bearings on a

turbine, fan, or other production asset to see how the shaft is

moving in relation to the bearing races.

nCollect ODS Modal data 66% faster to animate physical

movement of machinery, an important tool in identifying

the root cause of chronic or complex machinery problems.

Having the information you need for advanced diagnostics

faster allows you to move more quickly towards identifying

machinery faults or determining if it is safe to continue startup

of turbo machinery.

Where is the Vibration Coming From: Coherence

Testing in One Step

TodayisyourrstchancetousethenewCSI2140

Machinery Health Analyzer with four-channel data

collection capabilities to collect route data on the eight

critical motor/pumps that drive 80% of your production.

On pump #3, you notice some unusual vibration readings.

Is this a problem in motor/pump #3, or something else?

Last month there was high vibration levels in pump #5 –

yourememberbecauseyouspenthourstryingtondand

xtheproblemandendedupmissingthegameonTVthat

night. Turned out that motor/pump #5 – vibration from

motor/pump #6 was being transferred to #5 If coherence

testinghadbeenanefcientoptionwithyouroldanalyzer,

youwouldhaveknownhowtondthetruesourceofthe

vibration and gotten home on time.

Here you are today with the power of four-channel data

collection in your hands. You can perform coherence

testing of motor/pump #3 and its neighbors in just two

minutes. You already have a sensor attached to motor/

pump #3, so you attach a sensor to each of its neighbors.

Pressing Enter on the analyzer shows you the results.

There is no coherence among the motor vibrations.

Number three is truly the motor you need to address.

Nowyoucancondentlygettoworktosolvetheissue.

www.assetweb.com2

Page 3

CSI 2140 Machinery Health Analyzer June 2013

The CSI 2140 provides four-channels of simultaneous data

collection plus phase, delivering real-time views into the most

complex machinery problems.

More Power That is Easy to Carry into

the Field

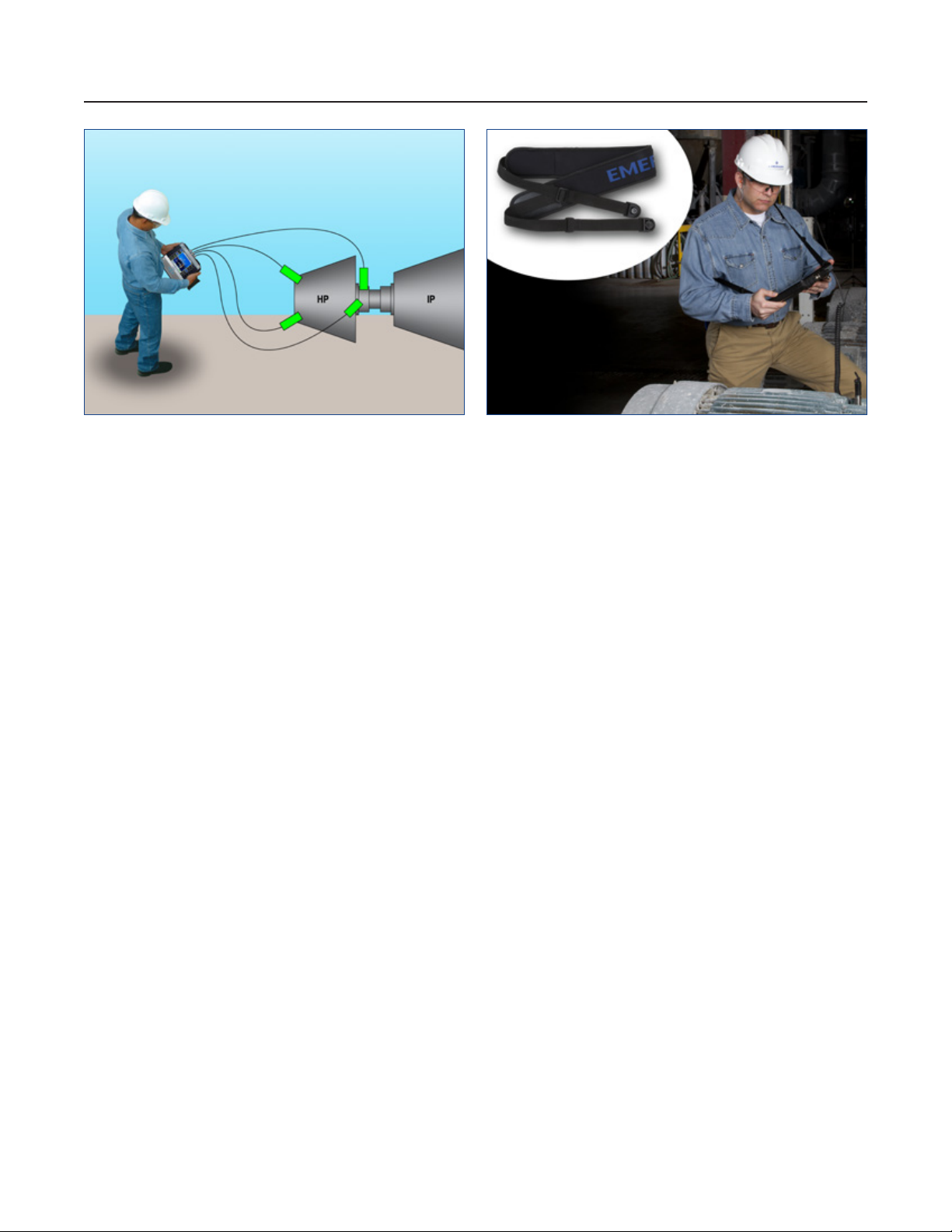

Route data collection can be a long process – and you need an

analyzer that has the battery power to last an entire shift and

comfortable enough to carry around all day. The CSI 2140

takes advantage of ergonomic principles and advanced

engineering to address these needs. This thinner, lighter

analyzer is comfortable to carry on long routes and operate

with one hand. The shoulder strap has a large, slip-proof

padded area to reduce friction on the neck and back.

Connecting the strap is as simple as the push of a button,

making it easy to quickly reconfigure for left- or right-hand

users.

Visibility in Any Environment. Struggling to see the details of

spectrum or waveform data due to sunlight or other lighting

conditions is a thing of the past. The CSI 2140’s glove-friendly

touch screen features an auto light sensor that adjusts the

screen’s backlight to the ambient lighting of the environment

for optimal viewing. Visibility is maintained as you move from

one area of the plant to another – from direct sunlight to darker

interior locations. A backlit keypad allows continued operation

of the unit in the darkest environments. In the office, the built-in

stand sets the unit at the best angle for viewing data. Charger

and communication cables are located at the top of the unit

so they do not interfere with the standing position.

The comfort strap is easy to detach and reattach, and simplies

single-handed use in the eld.

Uninterrupted Route Collection. The CSI 2140 has the

longest battery life available in the market, which means no

more long trips back to the office to dump data or deal with

a dead battery. New Lithium-Ion batteries extend battery life

and route coverage to a full shift – maybe two – from a single

charge. If you do choose to change out the battery, the unit is

re-engineered to make the task simple enough to accomplish

even in the field. In addition, an external charger allows you to

charge a spare battery while you continue to use your analyzer

in the field. A car charger option enables you to deliver a charge

en route.

The CSI 2140 uses local hotspot availability to wirelessly

transfer data back to the office for quick analysis or from remote

locations to a centralized server. Your team can perform route

collection and analysis in parallel to maximize your efficiency.

Embedded Intelligence

The ability to perform additional diagnostic tests at the

machine site transforms simple data collection into an

effective machinery health program. In today’s demanding

work environment, it is difficult to find the time to acquire

advanced analysis skills. Embedded intelligence, enabled

through Analysis Experts, allow even a novice user to conduct

sophisticated troubleshooting tests with the touch of a button.

Technicians don’t need to remember the complexity of setting

up a test they only perform a few times a year – yet they can

gain the benefit of its diagnostics when needed. The bottom

line impact is that users can quickly do more in the field with

the CSI 2140, avoiding further deterioration of equipment

condition.

www.assetweb.com3

Page 4

CSI 2140 Machinery Health Analyzer June 2013

Building on Field-Proven Technology

Emerson’s next generation vibration analyzer builds on the

field-proven, industry-leading technology of its predecessors.

The same great capabilities you count on in the CSI 2130 are

available in the CSI 2140.

Earliest Detection of Bearing and Gear Wear - Detecting

imbalance or misalignment is simple with most data collectors,

but these issues are the least impactful of the faults you will

find on your equipment. Over 50% of mechanical faults are

due to bearing and gearbox issues. And most data collectors

do not have the technology to detect these faults as they are

developing – and can only find them when the machinery is

already damaged and near failure.

The backlit keypad and ambient lighting of the larger, brighter

screens makes the CSI 2140 visible in any environment.

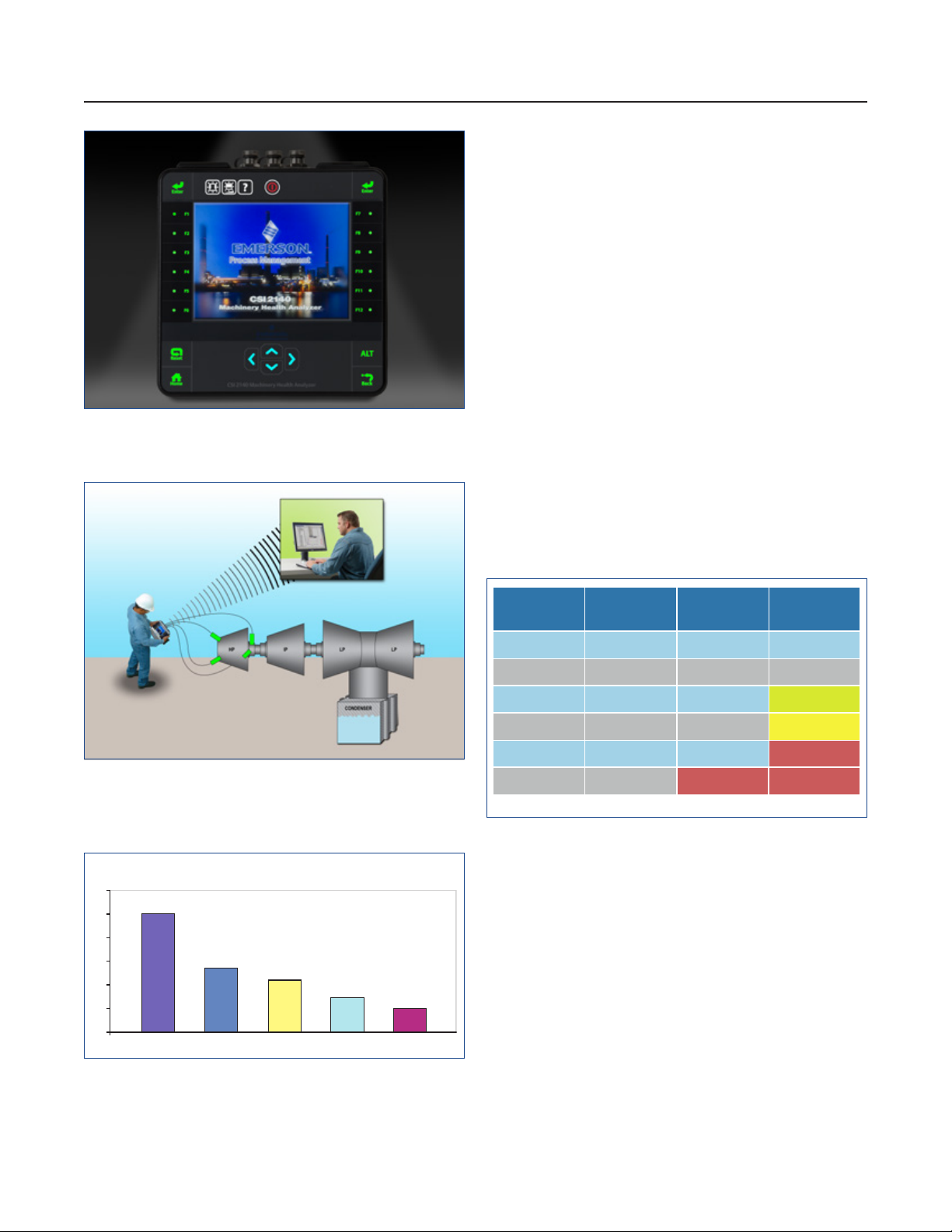

Wireless transmission of route data from the eld to the analyst

back at the ofce allows collection and analysis to be performed in

parallel

300

250

200

150

100

Tempo de Correção de Dados Relativos em Segundos

CSI 2120

Analyzer

CSI 2130

1 Ch.

213

50

0

Analyzer

133

CSI 2130

2 Ch.

Analyzer

108

CSI 2130

2 Ch.

Analyzer

with Triax

73

CSI 2140

4 Ch.

Analyzer

with Triax

55

The CSI 2140 uses Emerson’s patented PeakVue™ processing

and applies digital technology to determine bearing and gear

wear earlier than any other technology. By measuring stress

waves emitted from impacting – the earliest sign of bearing

and gear wear – the CSI 2140 gives you time to plan for

maintenance on your machine – while avoiding significant,

and costly, damage.

State

Bearing Life

Remaining

Vibration

(in/sec)

PeakVue

(g’s)

0 20-100% 0.15 0

1 <20% 0.15 4

2 <10% 0.20 8

3 <5% 0.25 12

4 <1% 0.45 25

Failure

Typical values for a Horizontal Pump, direct coupled, with machine speed of 600-60000 RPM.

0% >0.30 >40

PeakVue data provides the earlier indication of developing faults in

bearings and gearboxes

PeakVue technology not only offers the earliest warning of

developing faults, it also provides an indication of severity.

Measurements can be translated into reliable trends to

determine the optimal timing for maintenance. Machinery

faults are clearly visible in the waveform, opening up new

options for fault detection and diagnosis.

www.assetweb.com4

Page 5

CSI 2140 Machinery Health Analyzer June 2013

Full Range of Measurement - The CSI 2140 sets the industry

bar with its exceptional frequency range. The CSI 2140 can

accurately measure signals on critical low speed equipment

that would be out of range for other vibration analyzers/

collectors. The CSI 2140 also boasts the highest frequency

range in the market. It can measure signals up to 80,000 Hz,

critical for accurate diagnosis of centrifugal compressors and

other high speed machinery.

In-Field Analysis - When your reliability goals require more

advanced care of your equipment and the diagnosis of complex

machine faults than standard route spectrum and waveform

data can provide, you need a vibration analyzer with advanced

analysis tools. The CSI 2140 delivers advanced in-field analysis

tools, including:

nWaveform autocorrelation for distinguishing between

periodic impacting from bearings and gears versus random

impacting associated with lubrication issues.

nFault frequency overlays to match and identify the specific

source of energy peaks in the vibration spectrum

nTrending of up to 12 narrow band parameters for as long

as two years, allowing you to see where on the trend your

immediate measurement acquisition appears as compared

to previous data

nFourteen predefined analysis experts (such as coast down,

bump tests, time synchronous averaging, order tracking,

MCSA, high resolution, high frequency, etc.) for

troubleshooting difficult machine problems

nView up to 8 plots for comparisons of multiple measurements

Variable Speed Analysis - Variable speed analysis is essential

to any effective machinery health program because many

critical pieces of equipment are operated at varying speeds

to accommodate the changing production demands. While

most vibration systems do not take variable speed into account

during data collection, the CSI 2140 automatically adapts its

diagnostic tools to variable turning speeds during routine data

collection. This helps eliminate data blur/smear and provides

an accurate trend for evaluation of developing problems in the

field.

Predict Catastrophic Failure of Sleeve Bearings - Many online

monitoring systems installed in plants today serve as nothing

more than a shutdown switch in the case of a catastrophic

condition. By collecting the signals from these systems with

the CSI 2140, you can add predictive capabilities by identifying

faults before a major issue occurs. Four-channel data collection

allows for the simultaneous monitoring of orbit plots from both

of the bearings on sleeve bearing equipment. These orbit plots

can identify problems such as oil whirl/oil whip, misalignment

and shaft rubs. Trending data can uncover developing cracks

and other types of structural faults.

Monitoring Problem Machines - The CSI 2140 can also

serve as a temporary online monitor. With line power, you can

continuously monitor machine health for up to a month. The

CSI 2140 can automatically acquire and store data, including

overall vibration, fault frequency bands associated with specific

fault types, or even the complete spectrum over an extended

period of time. Capture the break-in period for new equipment

or ensure that a machine with a known fault can make it to the

next outage.

Capture Machine Startups/Shutdowns - For analysis of

transient events, the CSI 2140 collects a continuous waveform

that can have specific data extractions during startup, coastdown, or process changes. Spectra extracted from the transient

waveform can be viewed individually or in a Cascade plot to

show changes with speed and time. This analysis can be very

useful for identifying critical and resonant frequencies for turbo

machinery.

Correlate Vibration and Process Variables – The CSI 2140

has the ability to measure, store, and trend process variables

associated with equipment in addition to the equipment

vibration signals. The process variables such as pressure,

temperature, speed, flow, etc. can either be measured through

the voltage inputs or manually entered via the touch screen

user interface. These process variables can be correlated with

vibration to provide information about the health of the

machine or help determine root cause operational conditions

for the machinery health.

www.assetweb.com5

Page 6

CSI 2140 Machinery Health Analyzer June 2013

Modular Design to Match Your Needs

The CSI 2140 can be configured to specifically address your

current needs – and is modular to expand as your needs change

in the future. Easily and affordably expand your capabilities

while protecting your initial investment. This versatile unit can

be purchased as a single-, dual-, or 4-channel analyzer – with or

without route measurement capability or as a dedicated field

balancer. Put together any combination of capabilities to match

your requirements. Additional modules are also available for

transient and structural analysis.

Advanced Cross-Channel Analysis - Standard data

collection serves as an excellent base for identifying

developing machinery faults, but cross-channel analysis is

often required to identify the root cause of the fault. In

addition to regular data collection, the advanced cross-channel

application also measures coherence and transfer functions

between the measured channels. Cross-channel analysis

enhances the vibration data by helping to determine the

actual movement of the shaft during operation and identifying

structural faults such as cracks and resonance. Cross-Channel

data is typically collected between a reference sensor and up

to three other sensors, and full transfer function, phase and

coherence data is available with every channel.

Transient Analysis - The Advanced Transient Analysis

application allows you to record the raw vibration signal over

a prolonged period of time for post-processing and analysis.

This is essential for diagnostics of turbomachinery startup and

coastdown or machines with short, repetitive duty cycles.

Unlike other offerings the CSI 2140 captures transient

waveform data as a single continuous block of data and not

multiple shorter data blocks that are then pieced together in

the software. This continuous waveform data ensures that

nothing is missed in the collection or diagnosis. This data can

be examined directly on the CSI 2140 or even replayed live in

AMS Machinery Manager.

Operating Deflection Shape (ODS) Modal Analysis – ODS

data allows for a structural modeling of a machine that is then

animated using actual operating vibration data. Analysts can

observe visually how the machine is moving during operation,

and could identify the need for a structural correction. Data is

collected while the machine is running and shows motion due

to a combination of structural resonances (typically seen in

modal analysis) and operational forces such as misalignment or

imbalance. Using four-channel data collection is a non-intrusive

means for easily capturing all the necessary data without

interrupting production. The pairing of a triaxial and regular

single axis accelerometer combined with simultaneous

4-channel collection can make the ODS data acquisition

simple and efficient.

The triaxial accelerometer collects data at the measurement

location from a vertical, horizontal, and axial directions

simultaneously.

Field Balancing - The Advanced Balancing application

allows you to use the CSI 2140 as a field balancer. This

application combines advanced technology with simple,

straightforward operation for a fast, effective solution to your

balancing problems. The graphical user interface automatically

guides you through the balance checklist so only minimal

training is required for effective operation. The application

offers a basic mode for simpler machine trains and an advanced

balancing mode with up to 4-planes for longer more complex

machine trains. Full job documentation can be printed or

stored in AMS Machinery Manager.

www.assetweb.com6

Page 7

CSI 2140 Machinery Health Analyzer June 2013

The Advanced Balancing application offers two solutions to the

typical challenges of field balancing:

nVector Averaging – This technique systematically removes

background vibration that would otherwise contaminate the

calculated solution.

nBalancing Watchdog – This patented technology

automatically checks the vibration data on the machine

while you perform the balance job. The Watchdog is able to

identify and alert you of structural faults (such as looseness

or resonance) that would otherwise make the job difficult

or impossible to complete. You can take corrective action

to correct the structural fault, balance the rotor, and leave

the machine in reliable operating condition.

Motor Current Analysis – The CSI 2140 comes standard with

an MSCA Analysis Expert for detecting broken or cracked

rotors bars in AC induction motors using a current clamp

around the motor electrical leads. If used together with the

Motor Diagnostics module in AMS Machinery Manager, the

CSI 2140 performs non-intrusive analysis of the rotor and stator

condition in AC induction motors. This can be accomplished

with a standard current clamp or Emerson’s patented fluxcoil

monitoring. Flux, temperature, and current data can be used

to identify motor-related electrical faults such as broken rotor

bars, high-resistance joints, voids in aluminum cast rotors,

stator winding shorts, and voltage unbalance in AC induction

motors without turning the motor off.

Industrial Ratings

Designed for use in industrial environments, the CSI 2140 has

received an IP 65 rating certifying that it is dust- and splash

water-tight. It also complies with international safety standards

for FM and CSA Class 1 Division 2 Groups (A,B,C,D) and ATEX

and IECeX Zone 2 hazardous areas in the United States, Canada,

and Europe.

Accessory Options

Speed Detection - Accurate detection of the shaft turning

speed is critical to effective machinery health analysis. The

CSI 430 Laser Speed Sensor allows you to determine shaft

speed without requiring machine shutdown to apply reflective

tape or specific markings on the machine.

Triaxial Accelerometer - The Model A0643TX is a revolutionary

new triaxial sensor. This sensor can be magnetically mounted to

the machine and provides high-quality readings in all three

directions. All three measurement orientations on a bearing

can be collected simultaneously with a 4-channel CSI 2140.

The CSI 430 Laser Speed Sensor determines shaft speed without

shutting down the machine - even in extremely tight locations.

Proximity Probe Connections – Use BNC-type cables to

measure orbits from a protection system. The phase reference

can be read using the tachometer cable.

Structural Analysis - For advanced structural analysis, use the

modally-tuned hammer.

Wireless Headphones – To incorporate another dimension to

your monitoring program, use wireless headphones to listen to

your vibration signals.

Four-Channel Accessories Kit – The four-channel accessories

kit includes everything you need to unlock the power of the

CSI 2140 four-channel analyzer. The easy-to-install input

adapter collects acceleration data from one side, volts data

from the other. The kit includes the adapter plus the cables,

accelerometers, and magnets necessary to perform most any

kind of four-channel analysis.

Battery Charger for Car – The car charger allows charging

of the CSI 2140 in route between remote locations. If used in

conjunction with the External battery charger a spare battery

can be left charging in the car while the CSI 2140 is being used

to collect data in the field.

External Battery Charger – Take the CSI 2140 for data

collection while a spare battery is charging in the office and

switch them when needed.

www.assetweb.com7

Page 8

CSI 2140 Machinery Health Analyzer June 2013

Hardware specifications

Physical dimensions

Dimensions 8.8” (248 mm) high, 1.57” (40 mm) deep, 8.9” (226 mm) wide

Weight 3.95 lbs (1.79 kg)

LCD display 6” x 4.5” (151 x 115 mm) color TFT w/ LED backlight.

Resolution 640 x 480 pixels. Touchscreen - XY resistive.

Keypad Tactile Dome buttons, 12 tactile dome buttons with backlit keys,

Electroluminescent panel illumination

Built-in stand

Environmental

Operating Temperature -4° to 122° F (-20° to 50° C)

Long-term Storage Temperature -4° to 95° F (-20C to 35 C) with battery

Long-term Storage Temperature -40° to 150° F (-40C to 65 C) without battery

Environmental Rating Sealed enclosure, IP-65 rated

1

Storageatelevatedtemperatureswillsignicantlyreducebatterylife.

1

Hazardous Area Approvals

FM and CSA Class 1 Division 2 Groups (A, B, C, D)

ATEX and IECEx Zone 2, CE EXII 3G, nA nC IIC T4

Battery and Charging

Battery type Rechargeable Lithium-Ion battery pack

7.2 Volts (Nominal) Protected Output

On pack LED readout

10+ hours of continuous use

4 hours recharge time (Nominal)

Charging temperature 32° to 95° F (0° to 35° C)

www.assetweb.com8

Page 9

CSI 2140 Machinery Health Analyzer June 2013

Measurement specifications

Frequency analysis

A/D converter 24 bits of precision.

Automatic Integrator Correction Allows precise measurement of low frequency vibrations down to 0.2 Hz.

Averaging modes Normal, exponential, peak hold, order tracking, negative averaging, synchronous time

Cursors Spectrum Single, Harmonic, Moving Harmonic, Sideband, and Time/Frequency for waveform.

Dynamic range Converter has 120 dB dynamic range.

Frequency range DC to 10 Hz minimum, DC to 80 kHz maximum

Frequency Units Hz, CPM, Orders.

Full-scale range Accelerometer input: 0-20V, Volts input -20V + 20V

Noiseoor Typically less than 20 μV for a 400-line spectrum at 1000 Hz maximum frequency.

Number of averages 5,000 in Route mode, 10,000 in Job mode.

Resolution 100, 200, 400, 800, 1600, 3200, 6400, or 12800 lines of resolution. True Zoom provides

effective resolution of up to 300,000 lines.

Response Flat to DC for non-integrated and DC-coupled signals; optional AC coupling -3 dB at 1 Hz

Scaling Linear or Log, both X and Y.

Windows Hanning or uniform

Data storage capacity

Internal memory 1 GB

External memory SD (Secure Digital). Virtually unlimited memory with off the shelf SDHC SD cards up to

32 GB.

Data analysis speed

400 line, 1000 HZ spectrum 67% overlap 6 avg/sec

1600 line, 1000 Hz spectrum 67% overlap 3 avg/sec

www.assetweb.com9

Page 10

CSI 2140 Machinery Health Analyzer June 2013

Input specifications

Input signals

A 2-milliampere, 20-volt (nominal), constant-current power supply inside the analyzer

powers sensors such as accelerometers connected to the accelerometer channel inputs.

Full scale input level

Accel Channels A, B, C, D; Volts A, B, C, D

Accelerometer Input 0-20V

Full scale vibration level is +/- 90 g’s when using a 100-mV/g accelerometer

Volts Input -20V to +20V

Input Impedance Greater than 125K ohms

Input signal types

Dynamic signals Single channel/Dual channel/Four channel

DC signals Single channel/Dual channel/Four channel

RPM/tach signal TTL pulse

Keypad entry Full alphanumeric capability

Four-Channel Data Collection

Simultaneous 4-channels Dynamic Input + Phase

Simultaneous 4-channels DC Input

Simultaneous 4-channel Route collection + Phase

Simultaneous 4-channel Display - Spectrum and Waveform

Simultaneous 4-channel Transient + Phase

Simultaneous 4-channel ODS/Modal + Phase

Simultaneous 4-channel Volt/Displacement + Phase (for sleeve bearing monitoring)

Simultaneous Dual Orbits Display [accelerometer/displacement] (for rolling element/

sleeve bearing monitoring)

Simultaneous 4-channel Cross Channel + Phase

In-field Route Analysis Tools

Fault frequency overlays on plot Identiessourceofvibrationpeaks

Parameter trends Up to 12 parameters trended over 2+ years

Colored alarms Showsspecicparameterinalarmandpercentageofalarmvalue

Waveform autocorrelation Identieswhetherimpactingisperiodicorrandom

Input sensor types

Portable sensors Accelerometers,velocityprobes,RPM/tachometerprobes,temperaturesensors,uxcoil,

current clamp, pressure sensors, triaxial accelerometer, impact hammer

Installed sensors Any vibration or dynamic sensor with a voltage output; any DC-type signal.

www.assetweb.com10

Page 11

CSI 2140 Machinery Health Analyzer June 2013

Input unit types

Vibration Signals Units Acceleration g’s

Velocity In/sec or mm/sec

Displacement Mils or microns

Other dynamic signals Anyuser-speciedunit

DC Signals Anyuser-speciedunit

Tachometer input

RPM range 1 to 100,000 RPM

Tach input level TTL input, built in conditioning for non-TTL signals, adjustable trigger level. The tachometer

input measures a once-per-rev pulse to measure RPM.

Advanced Acquisitions

PeakVue Selectablelters

Pseudo tach Generates tach pulses for hidden shafts.

Demodulation Selectablelters

Wireless

Bluetooth 2.0 Class 2 (optional)

Range up to 10 meters

Wi-Fi 802.11 b/g

Range up to 33 meters

Warranty

12 months warranty against manufacturing defects

Connecting to a PC

Requirements

Connections/Output USB 2.0, 100M Ethernet.

Compatible software AMS Suite: Machinery Manager v5.6 or greater. Refer to www.assetweb.com/mhm under

AMS Machinery Manager software for most currently operating requirements.

www.assetweb.com11

Page 12

CSI 2140 Machinery Health Analyzer

V-2140MHA

Product Data Sheet

June 2013

Emerson Process Management

Asset Optimization

835 Innovation Drive

Knoxville, TN 37932 USA

T (865) 675-2400

F (865) 218-1401

www.assetweb.com/mhm

©2013, Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every

effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their

use or applicability. All sales are governed by our terms and conditions, which are available on

request.Wereservetherighttomodifyorimprovethedesignsorspecicationsofourproducts

at any time without notice.

All rights reserved. AMS, PeakVue, and Machinery Health are marks of one of the Emerson

Process Management group of companies. The Emerson logo is a trademark and service mark

of Emerson Electric Co. All other marks are the property of their respective owners.

Loading...

Loading...