Page 1

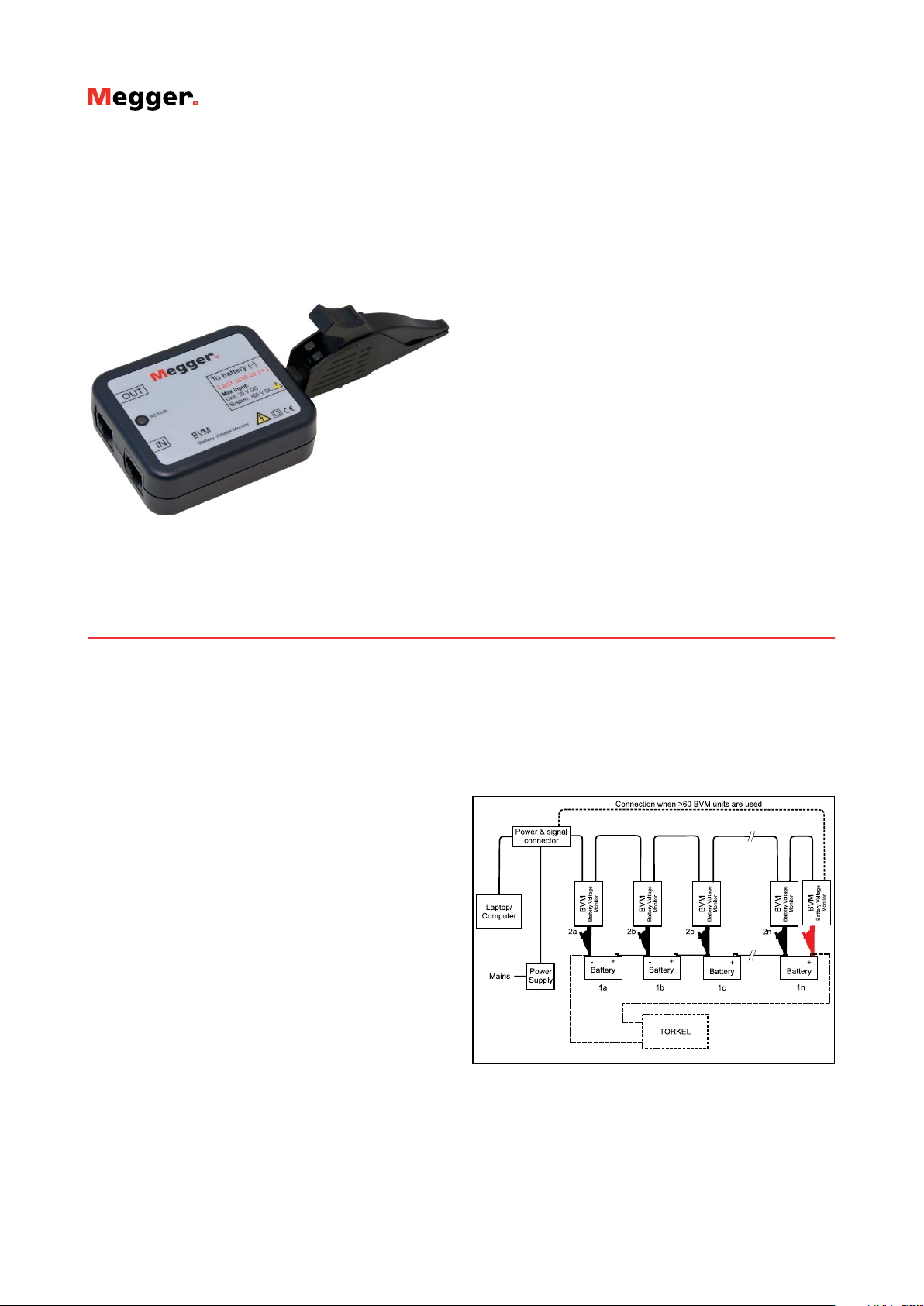

BVM

Battery Voltage Monitor

▪▪

Automates battery voltage measurement

during capacity tests

▪▪

“Daisy-chain” design allows expandability

up to 120 units

▪▪

High accuracy and stability for precise data

collection

▪▪

Integrates with TORKEL Win and PowerDB

Test Data Management software

▪▪

Wide voltage range

▪▪

Easy set-up

BVM

Battery Voltage Monitor

Description

The Megger BVM is a battery voltage measurement device that

is used for the capacity testing of large, industrial battery banks

commonly found in electrical power sub-stations, telecom facilities

and computer data center UPS systems. When used in conjunction

with a load device, such as the TORKEL unit, and test data

management software, such as PowerDB and TORKEL Win, the

BVM enables to perform a completely automated battery bank

capacity test, according to IEC test method. The test also meet

NERC/FERC requirements. The BVM is designed in modular

form where one BVM device is used for each battery or “jar” in

the string to be tested. One BVM for each battery connects to

the next in a “daisy-chain” fashion, thereby providing easy and

economical expandability to meet the testing requirements for

small-to-large battery bank systems.

The included dolphin clip can be easily removed and exchanged

with different styles of standard banana plug clamps and / or

extension cables to accommodate any battery connection

requirement.

Setup is fast and easy using the BVM. Each BVM is identical

and can be connected in any battery test position, thus providing

maximum flexibility and interchangeability of the BVMs. Up to

120 BVMs can be daisychained in a single battery bank under test.

The BVM “Auto Discovery” feature enables the host device to

automatically determine the number of batteries under test and

provide sequential identification of each BVM in the test string.

Application

Each BVM is identical and can be connected in any battery test

position. Up to 120 BVMs can be daisy-chained in a single battery

bank under test.

A single cable connects the first BVM in the string to a Power &

signal connector. The laptop or other data acquisition device is

connected via an Ethernet cable to the Power & signal connector.

The last dolphin clip (red) in the chain should be connected to the

positive battery pole of the last battery in the bank.

When used together with TORKEL the voltage will be logged

through the complete discharge test.

Page 2

BVM

Battery Voltage Monitor

Specifications

Specifications are valid at an ambient temperature of +25°C,

(77°F). Specifications are subject to change without notice.

Environment

Application field The instrument is intended for use

Temperature

Operating 5°C to +50°C (41°F to +122°F)

Storage & transport 0°C to +60°C (32°F to +140°F)

Humidity 5% – 95% RH, non-condensing

CE-marking

LVD 2006/95/EC

EMC 2004/108/EC

General

Mains voltage 100 / 240 V AC, 50 / 60 Hz

Power consumption (max) 50 VA

Protection Over voltage, reverse voltage, voltage

Dimensions

BVM unit 75 x 64 x 25 mm

Carrying case 575 x 470 x 205 mm

Weight

BVM unit 0.07 kg (0.15 lbs)

With accessories and

carrying case

Measurement section

Maximum number of

channels

Voltage ranges 0-5 V DC and 0-20 V DC

Resolution 1.00 mV both ranges

Inaccuracy < 0.1% of full scale ±0.002 V DC

Battery string voltage 300 V DC (max)

Measurement input

impedance

BVM600

in medium-voltage substations and

industrial environments.

Altitude <2000 m (6500 ft) above sea

level.

transients, ESD

(3” x 2.5” x 1”)

(22.6” x 18.5” x 8.1”)

BVM system of 31 units 8.8 kg (19 lbs)

BVM system of 61 units 12.5 kg (27 lbs)

120

1 MΩ

Additional equipment

For complete information on additional products see appropriate

data sheets.

TORKEL 820/840/860

Testing can be carried out without disconnecting the battery from

the equipment it serves.

TORKEL Win

TORKEL Win PC software

Shows the complete voltage curve

Last recorded time, voltage, current and discharged capacity

Remote control of TORKEL

PowerDB

Windows-based PC software available in four versions

Interfaces to instruments via either Serial RS232, Ethernet, or USB

flash drive (depending on instrument)

Allows user to set up test routines in advance of testing

Allows analysis, comparison and trending of data

Merge test results between field and office databases

Ordering information

Item Art. No.

BVM

Including:

Dolphin clips, Power & signal connector,

Power supply, Connection cables and Carrying case

BVM300

With TORKEL Win software

System of 31 BVM units

BVM600

With TORKEL Win software

System of 61 BVM units

BVM300

With PowerDB software

System of 31 BVM units

BVM600

With PowerDB software

System of 61 BVM units

BVM

Single unit

CJ-59093

CJ-59096

CJ -59193

CJ -59196

CJ-59090

SWEDEN

Megger Sweden AB

Eldarvägen 4, Box 2970

SE-187 29 TÄBY

T +46 8 510 195 00

F +46 8 510 195 95

E seinfo@megger.com

UK

Archcliffe Road Dover

CT17 9EN England

T +44 (0) 1304 502101

F +44 (0) 1304 207342

Other Technical Sales Offices

Dallas USA, Norristown USA,

Toronto CANADA, Trappes FRANCE,

Oberursel GERMANY, Johannesburg

SOUTH AFRICA, Kingdom of BAHRAIN

Mumbai INDIA, Chonburi THAILAND

Sydney AUSTRALIA

Registered to ISO 9001 and 14001

Subject to change without notice.

Art.No. ZI-CJ01E • Doc. CJ0062BE • 2011

BVM_DS_en_V02

www.megger.com

Megger is a registered trademark

Loading...

Loading...