Page 1

KEPCO’S

BOP

FAMILY

OF

FOUR

QUADRANT

BIPOLAR

POWER

SUPPLIES

146-1971a

AN ISO 9001 COMPANY

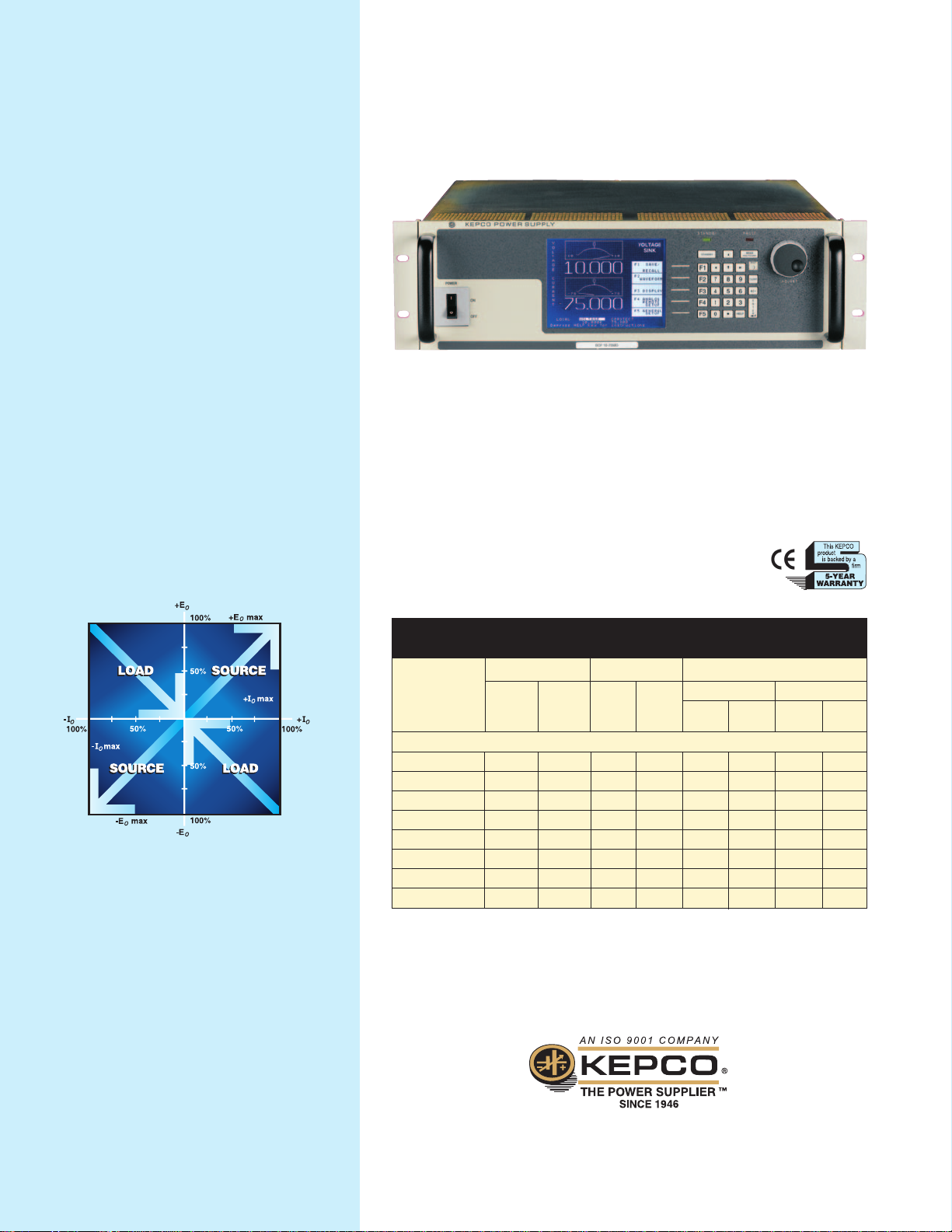

BOP 200W and 400W (Linear)

M MODELS: Standard - Analog Meter

200W Models: 20V, 36V, 50V, 100V, 200V

400W Models: 20V, 36V, 50V, 72V, 100V

D MODELS: Digital Meter

L MODELS: Optimized for Inductive Loads

C MODELS: Optimized for Capacitive Loads

-4886 MODELS: GPIB Control

BOP 40W High Voltage (Linear)

500V, 1000V

BOP 1KW (Switch-Mode)

MG MODELS: Standard

6V, 10V, 20V, 25V, 36V, 50V, 72V, 100V

GL MODELS: Optimized for Very Low Ripple and Noise

20V, 36V, 50V

Page 2

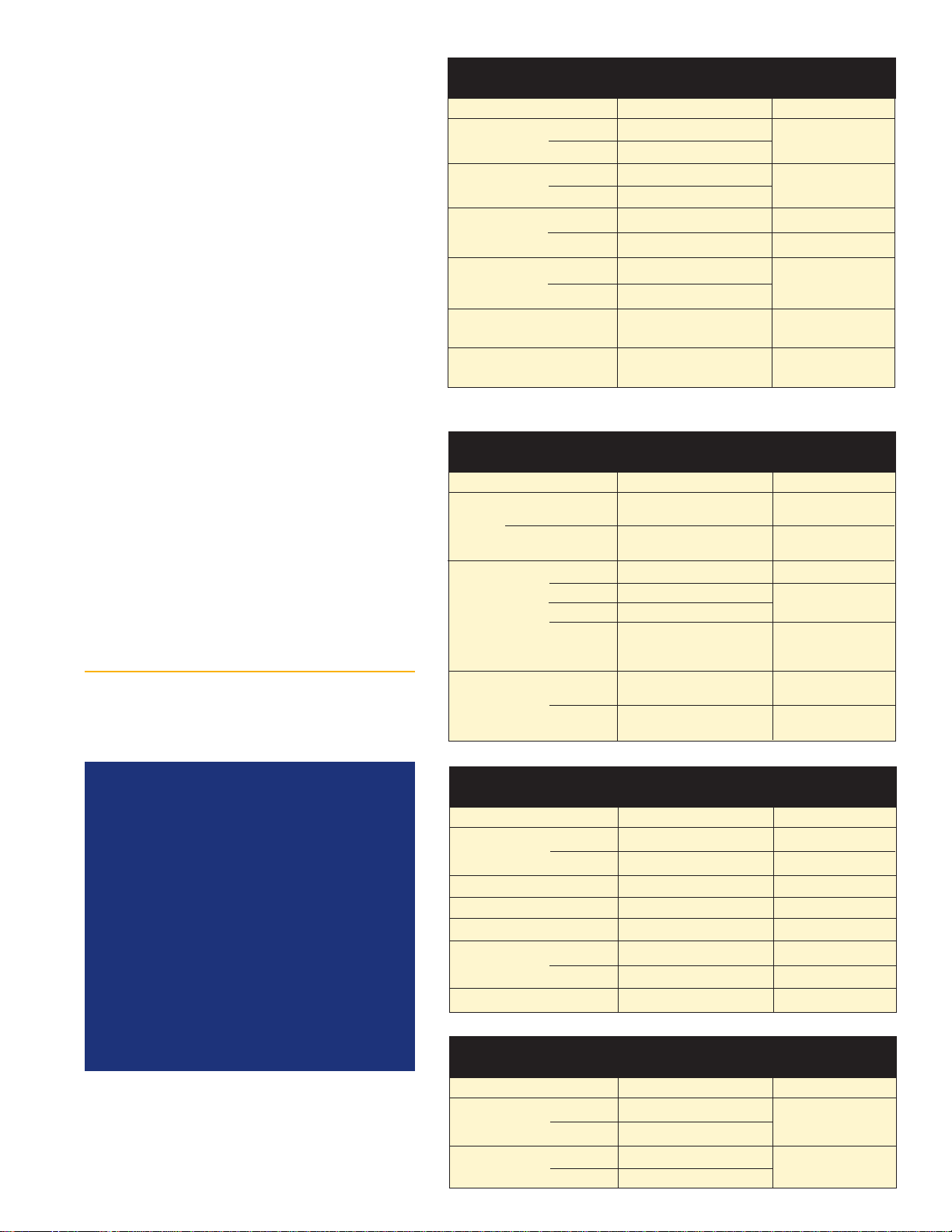

Conventional d-c power supplies operate in

a single quadrant of the voltage-current

axis, delivering stabilized and adjustable

d-c voltage or current to a load. They may

be voltage stabilized, meaning that the

current varies with the load, or they may

be current stabilized, meaning that the

voltage varies with the load.

Kepco's BOP operate in all four quadrants

of the voltage-current axis, therefore their

output may swing seamlessly from negative

to positive voltage and the output current

may also swing from positive to negative

values. The result of this is that BOP will

function as a source or a sink, meaning it

will either deliver power to a load or absorb

power from a load. In order to do that, the

BOP is built as a power amplifier with a

bipolar output, having a frequency bandwidth much larger than a regular power

supply. The frequency bandwidth is model

and option dependent.

In quadrant 1 of the volt-ampere axis, both voltage

and current are positive so the BOP power supply

is able to deliver power to a load. In quadrant 3

both are negative and the BOP is also a source.

In quadrants 2 and 4, however, the voltage and

current are of opposite polarity. In these two

quadrants the BOP will act as a sink, absorbing

power. The sinking may be transient in

nature as BOP absorbs energy stored in

reactive elements or it may be steady

state, when for example, BOP controls

the discharge of a battery or acting as an

electronic load, constant current for an

external voltage source, or a constant

voltage for an external current source.

FOUR-QUADRANT OPERATION

FROM A KEPCO BOP POWER SUPPLY

+ CURRENT

LIMIT

– CURRENT

LIMIT

The BOP 1KW has two primary control channels: voltage or current. Either of these may

be controlled from full plus setting to full minus setting. To assure that they will

intersect in one of the two source quadrants to form a closed boundary as do

conventional unipolar power supplies,four auxiliary limit channels are provided:

plus voltage, minus voltage , plus current and minus current. T hese four are controllable

from a very small value to the nominal values. Their control does not pass through

zero as do the primary voltage and current channels. The intersection of whichever

primary control channel is engaged by the load and the respective limit channel does

form a closed boundary , and a variable load automatically crosses

over from the primary channel to the limit channel.

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA

Tel: (718) 461-7000 • Fax: (718) 767-1102

Email: hq@kepcopower.com • www.kepcopower.com

1000 WATT

BOP 6-125MG 0 to ±6 0 to ±125 0.6 12.5 0.05 1.5 24 1150

BOP 10-75MG 0 to ±10 0 to ±75 1.0 7.5 0.13 2.0 67 976

BOP 20-50MG 0 to ±20 0 to ±50 2.0 5.0 0.40 8.3 200 371

BOP 25-40MG 0 to ±25 0 to ±40 2.5 4.0 0.63 15.8 313 165

BOP 36-28MG 0 to ±36 0 to ±28 3.6 2.8 1.30 25 640 103

BOP 50-20MG 0 to ±50 0 to ±20 5.0 2.0 2.50 50 1250 55

BOP 72-14MG 0 to ±72 0 to ±14 7.2 1.4 5.14 104 2570 33

BOP 100-10MG 0 to ±100 0 to ±10 10.0 1.0 10.0 163 5000 16

BOP 1KW MODEL TABLE

NOTE: When connecting active loads, the steady-state voltage of the active load must not

exceed the maximum voltage rating of the BOP. Otherwise the overvoltage protection will shut

down the power supply.

d-c OUTPUT RANGE CLOSED LOOP GAIN

VOLTAGE

CHANNEL

GV(V/V)

VOLTAGE

V d-c

CURRENT

A d-c

MODEL CURRENT

CHANNEL

GI(A/V)

VOLTAGE MODE

SERIES RmΩSERIES LµHSHUNT RΩSHUNT C

µF

CURRENT MODE

OUTPUT IMPEDANCE

BOP 1KW (Switch-Mode)

Data subject to change without notice. © 2011 KEPCO, INC. Litho in USA

WHAT IS A 4QUADRANT

POWER SUPPLY?

3

1

2

4

Using switch-mode technology for low dissipation when sinking power from

an active load, the BOP 1KW recuperate the energy for reuse. The key to this

is a bi-directional a-c input power factor correcting (PFC) circuit, which allows

transparent energy interchange without dissipative internal sinking.

2

Page 3

YOU CAN MODEL MANY

REAL-WORLD PHENOMENA IN WHICH

POLARITY OR DIRECTION IS AN ISSUE

RIGHT/LEFT UP/DOWN HOT/COLD

CLOCKWISE/COUNTERCLOCKWISE

CHARGE/DISCHARGE FORWARD/REVERSE

APPLICATIONS FOR KEPCO’S

BOP 1KW

Automotive

Battery and Motor

Simulation and Testing

Wafer Deposition

and Electroplating

Magnet Applications

Particle Beam Correctors and Injectors,

Medical Imaging, etc.

Solar Panel Research and Testing

BOP 1KW FEATURES

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA

Tel: (718) 461-7000 • Fax: (718) 767-1102

Email: hq@kepcopower.com • www.kepcopower.com

BOP 1KW PHYSICAL CHARACTERISTICS

SPECIFICATIONS RATING/DESCRIPTION CONDITION

Dimensions

5.25" x 19" x 21.5"

H x W x D

English

133.3 x 482.6 x 546.1 mm

metric

Weight

53 lbs

English

24.1kg

metric

* BOP 6-125MG and BOP 10-75MG only.

BOP 1KW INPUT CHARACTERISTICS

SPECIFICATIONS RATING/DESCRIPTION CONDITION

a-c Voltage

230V a-c

Single phase

nominal

176-264V a-c

range

Current

9.5A (7.5A)* Maximum

176V a-c

6.4A (4.4A)* Maximum

264V a-c

Frequency

Power

Factor

Efficiency 65% (56%)* Minimum

when sourcing

Active PFC for

source and sink

50/60 Hz

47-63 Hz

0.99

0.97

Nominal output power

Complies with

EN 61000-3-2

nominal

range

source

sink

Switching Frequency 70 KHz ±5%

(50KHz ±5%)*

BOP 1KW PROGRAMMING/DISPLAY CHARACTERISTICS

SPECIFICATIONS RATING/DESCRIPTION CONDITION

Full range output

0.5% to 100%

of nominal range

Direct entry

SCPI

Used for series

and parallel

configurations

Analog

Control

-10V to +10V

voltage or current

main channel

+0.05V to +10V

voltage and current

protection limit channel

Digital

Control

Display

Panel-mounted keypad

IEEE 488-2 (GPIB)

RS 232

RS 485 (BITBUS)

4" backlit LCD displays

all functions

All parameters read back on

RS 232 and GPIB buses

local

remote

remote

remote

front panel

remote

+

–

+

–

BOP 1KW GENERAL (ENVIRONMENTAL) SPECIFICATIONS

SPECIFICATIONS RATING/DESCRIPTION CONDITION

Temperature

0 to +50°C

Full rated load

operating

Vibration

10mm double amplitude 3-axes, non-operating

5 -10 Hz

-20 to +85°C

storage

2g 3-axes, non-operating

10-55 Hz

Cooling

Two internal fans Exhaust to the rear

Humidity

0 to 95% RH Non-condensing

Shock

20g, 11msec ±50% half sine

Non-operating

Altitude

Sea level to 10,000 ft.

For full specs, visit our Web site at

www.kepcopower.com/bophi.htm

• Full 4-quadrant, 1000 watt, source-sink operation.

• Energy recuperation, during sink-mode, through a patented

bi-directional PFC circuit.

• Meets the EN61000-3-2 harmonic limits. A built-in EN55011

Class A input EMI filter is provided.

• High efficiency switch-mode operation.

• Output voltage from ±6V to ±100V.

• Full digital control with built-in standard GPIB. Compatible

with IEEE 488.2. Accepts standard SCPI commands.

VISA driver provided. Also supports RS 232 bus.

• Large graphic LCD, displays settings and output voltage

and current.

• Keypad control from front panel with menu to access functions.

• Calibration adjustments are made via the remote interface

or locally from the keypad and are stored in non-volatile

memory. Calibration is password protected.

• CE; Complies with the requirements of the Low Voltage

Directive 73/23/EEC, the Marking and Declaration

Directive 93/28/EEC, and the EMC Directive 89/336/EEC.

• Built-in complex waveform generator.

• Parallel (max. 5 units) or Serial (max. 3 units) connection of

identical units. Parallel and Series connecting cables are

required; contact factory for pricing.

3

Page 4

BOP 1KW ALLOW FOR AUTOMATIC

CREATION AND DISPLAY OF VARIOUS

WAVEFORMS AND COMPLEX PATTERNS

The 1000-watt models have an internal w aveform generator

that allows a user to combine segments of a sinusoidal

waveform, triangular waveform, a ramp, a saw tooth

waveform and a square 50% duty cycle pulse, plus d-c to

create a variety of arbitrary waveforms . 3,933 of points per

basic waveform can be programmed with arbitrary phase

relationships. The resulting waveshape can be repeated

from 1 to 255 times. The waveshape can also be executed

indefinitely until a stop command is received. The waveshape graphics are displayed on the front panel-mounted

LCD display , which also shows both settings and actual d-c

output values. The programmed waveshapes can be used

to control either voltage or current with both positive and

negative values. It is possible to reproduce an a-c sinusoid

with differing degrees of distortion or dropouts for test

purposes. Alternatively, varying amounts of “noise” can be

added to a d-c output to gauge the effect on a test subject.

Sine Waveform

Triangle W aveform

Complex Sine Waveform

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718)767-1102

Email: hq@kepcopower.com • www.kepcopower.com

For full specs, visit our Web site at www.kepcopower.com/bophi.htm

BOP 1KW OUTPUT CHARACTERISTICS

SPECIFICATIONS RATING/DESCRIPTION CONDITION

Type of Stabilizer

Voltage/Current 4-quadrant Switch mode

Output stage

Switching Frequency

Voltage Stabilization

in

Voltage

Mode

Source

Adjustment

Range

100KHz ±5%

-100% to +100% of rating

-100% to +100% of rating

0-50°C

voltage

current

Sink

Adjustment

Range

-100% to +100% of rating

-100% to +100% of rating

0-50°C,

recuperated energy is

sent back into line for

general reuse

voltage

current

0.05% of rating

0.1% of rating

0.02% of rating

0.02%/°C of rating

2% Eomax p-p

0.2% Eomax rms

min-max

input voltage

0-100% load current

0.5 - 8 hours

0-50°C

Includes switching

noise

source effect

load effect

time effect (drift)

temperature effect

ripple

noise

Current Stabilization

in

Current

Mode

0.05% of rating

0.2% of rating

0.02% of rating

0.02%/°C of rating

2% Iomax p-p

0.2% Iomax rms

min-max

input voltage

0-100% load current

0.5 - 8 hours

0-50°C

Includes switching

noise

source effect

load effect

time effect (drift)

temperature effect

ripple

noise

Error Sensing

0.25 volts per wire

Above rated output

Output Common

Mode Voltage

Series Operation

Output Protection Limiting

Output Stage

Protection

300V

Master/slave

Voltage and current

limited in four quadrants

Output overvoltage/

overcurrent,

heat sink overtemperature,

switchers overcurrent

Input Stage

Protection

(PFC)

Internal overvoltage,

undervoltage, overcurrent,

heat sink overtemperature,

fan inoperative

Triggers latched

shutdown protection

of the output module

and PFC stage.

Recover by cycling

power off, then on or

by pressing RESET

at the front panel

Maximum of

3 identical units,

up to 300V max.

Parallel Operation

Master/slave

Output to chassis

ground

Transient

Recovery in

Voltage Mode

5% of nominal output nominal voltage,

50% load step

maximum

excursion

200 μsec Return within 0.1%

of set voltage

recovery

time

Maximum of

5 identical units

Input circuit breaker

overcurrent

Trips circuit breaker to

shut off unit

Small

Signal

Bandwidth

2 KHz maximum

voltage channel

800 Hz maximum

(600 Hz Maximum)

(1)

current channel

Rise/Fall

Time

250/200 μsec

voltage channel

0.7/1.2 mSec

current channel

Into short circuit

Into nominal

resistive load

Into short circuit

Into nominal

resistive load

4

(1) BOP 6-125MG only.

Page 5

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718)767-1102

Email: hq@kepcopower.com • www.kepcopower.com

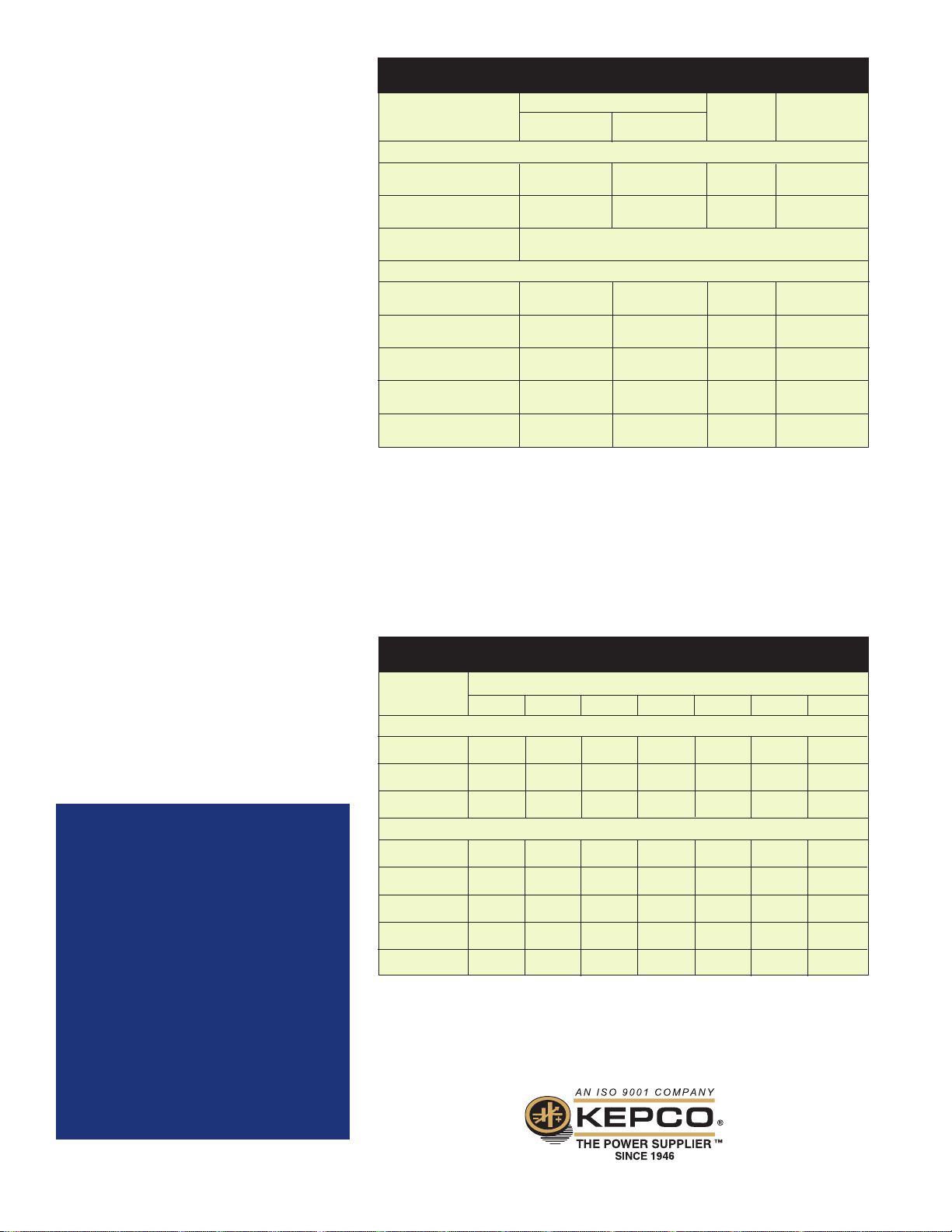

USING KEPCO BOP 1KW FOR SOLAR DEVICE TESTING

Demonstration Application Interface Showing User Inputs

and Rendered I-V Curve Output

The K epco BOP 1KW provides a one-step solution for test and characterization

of solar cells and solar panels. A free LabView subvi allows rapid

characterization of the solar device using only the BOP 1KW, eliminating the

need for separate DVMs to measure voltage and current. T he subvi is designed

for both I-V Trace and Dark I-V testing, and can be plugged in or easily adapted

to existing LabView test applications, even those previously using two DVMs.

This solution offers lower cost, greater throughput and increased ROI when

testing solar devices.

BOP 1KW SOLAR DEVICE TESTING FEATURES AND BENEFITS

• SOLAR DEVICE TESTING - Both I-V Trace and Dark I-V Tests supported.

• FLEXIBILITY - KEPCO BOP 1KW LabView Driver allows Solar Device testing while

maintaining full functionality of the BOP 1KW Instrument Power Supply features.

• FASTER THROUGHPUT- 20mS per point.

• ROI - Test setups are quick and easy, require no special programming for

synchronization, require no dedicated engineering resources to design and/or

maintain components comprising a custom solution.

• LOWER COST AND SIMPLICITY - No need to purchase, maintain and calibrate

two DVMs - Simplifies calibration, test setup and operation; no trigger

connections needed.

• RELIABILITY - With all triggering and measurements done within BOP 1KW

there are no synchronization or noise issues.

• PROVEN TECHNOLOGY - Enhancement of proven BOP 1KW technology.

• ENERGY CONSERVATION- Employs energy recuperation as well as active

Power Factor Correction (PFC).

NOTE: When connecting active loads, the steady-state voltage of the active load must not exceed

the maximum voltage rating of the BOP. Otherwise the overvoltage protection will shut down the

power supply.

For other volt-ampere combinations, consult factory.

1000 WATT

BOP 20-50GL 0 to ±20 0 to ±50 2.0 5.0 0.02% 0.01%

BOP 36-28GL 0 to ±36 0 to ±28 3.6 2.8 0.02% 0.01%

BOP 50-20GL 0 to ±50 0 to ±20 5.0 2.0 0.02% 0.01%

BOP-GL 1000 WATT MODEL TABLE

d-c OUTPUT RANGE CLOSED LOOP GAIN

VOLTAGE

CHANNEL

E

o MAX

V d-c

I

o MAX

A d-c

MODEL CURRENT

CHANNEL

RIPPLE AND NOISE

VOLTAGE

rms

CURRENT

rms

The BOP-GL series models are a standard modification

of the 1KW that have been optimized for exceptionally

low current ripple and noise and improved stability

(drift and temperature), making them ideal for driving

inductive loads such as large magnets or motors.

These bipolar power supplies pass smoothly through

zero without switching to provide true ± voltage and

± current.

BOP 1KW GL SERIES

OPTIMIZED FOR VERY

LOW RIPPLE AND NOISE

5

Page 6

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718)767-1102

Email: hq@kepcopower.com • www.kepcopower.com

The Kepco Model BOP 500M and BOP 1000M

are high voltage power sources, up to ±500V or

±1000V, respectively.

For full specs, visit our Web site at

www.kepcopower.com/bophv.htm.

BOP 200W AND 400W (Linear)

BOP 200W AND 400W FEATURES

• Source 100% and sink 50% of the output power rating.

• Separate control circuits for voltage and current

with automatic crossover between main channel

and limit channel.

• Controls and flag signals accessible through a

50-terminal port at the rear.

• Zeroable preamplifier available for scaling and

summing external signals.

• Optional digital control via GPIB or RS 232. Add suffix -4886.

• Parallel and Series connection of identical models.

• Mounting in standard 19" racks

RA 37: 3/4 rack size

Mounting "ears" supplied: full rack size

APPLICATIONS FOR KEPCO’S BOP 200W AND 400W

Automotive

Battery and Motor Simulation and Testing

Wafer Deposition and Electroplating

Magnet Applications

Beam Steering, Medical Imaging, etc.

Solar Panel Research and Testing

For full specs, visit our Web site at www.kepcopower.com/bop.htm.

Their output is capable of both sustained d-c and the

replication of arbitrary a-c waveforms. Voltage and

current outputs can be controlled smoothly and

linearly through the entire rated plus and minus

ranges, passing smoothly through

zero with no polarity switching.

The BOP 200W and 400W are high-speed operational

amplifiers with full 4-quadrant, bipolar operation.

BOP 40W HIGH VOLTAGE (Linear)

These combine the capabilities of fast programmable power supplies with a Class A

output stage, which can respond bi-directionally from zero. They can be operated in

either a “voltage stabilizing” or “current stabilizing” mode. To realize the full high

speed potential of the BOP HV, the load characteristics should be mainly resistive.

Load capacitance and inductance up to 0.01µF and 0.5mH can

be tolerated without performance deterioration.

CLOSE LOOP GAIN

VOLTAGE CURRENT

MODEL

(3)

CHANNEL CHANNEL OUTPUT IMPEDANCE

d-c OUTPUT RANGE G

V

G

I

VOLTAGE MODE CURRENT MODE

Eomax. Iomax. (V/V) (mA/V)

SERIES R

SERIES L

(1)

SHUNT R

SHUNT C

(2)

BOP 500M ±500V ±80mA 50 8.0 0.05Ω 5mH 100MΩ 0.3μF

BOP 1000M ±1000V ±40mA 100 4.0 0.2Ω 50mH 400MΩ 0.4μF

BOP HIGH VOLTAGE MODEL TABLE

(1) For determining dynamic impedance in voltage mode.

(2) For determining dynamic impedance in current mode.

(3) To specify digital display, substitute the suffix “DM” for “M.”

(1) Optional digital control va GPIB or RS232. Add suffix -4886.

(2) For determining dynamic impedance in voltage mode.

(3) For determining dynamic impedance in current mode. (4) Same size as 400W models.

(5) To specify digital display, substitute the suffix letter “D” for the suffix letter “M.”

200 WATT

BOP 20-10M 0 to ±20 0 to ±10 2.0 1.0 0.04 40 20 0.05

BOP 36-6M 0 to ±36 0 to ±6 3.6 0.6 0.12 20 36 0.03

BOP 50-4M 0 to ±50 0 to ±4 5.0 0.4 0.25 50 50 0.02

BOP 100-2M 0 to ±100 0 to ±2 10.0 0.2 1.0 60 100 0.03

BOP 200-1M

(4)

0 to ±200 0 to ±1 20.0 0.1 4.0 1200 200 0.03

400 WATT

BOP 20-20M 0 to ±20 0 to ±20 2.0 2.0 0.02 10 20 0.5

BOP 36-12M 0 to ±36 0 to ±12 3.6 1.2 0.06 50 36 0.4

BOP 50-8M 0 to ±50 0 to ±8 5.0 0.8 0.125 100 50 0.15

BOP 72-6M 0 to ±72 0 to ±6 7.2 0.6 0.24 200 72 0.1

BOP 100-4M 0 to ±100 0 to ±4 10.0 0.4 0.5 200 100 0.1

BOP 200W AND 400W MODEL TABLE

d-c OUTPUT RANGE CLOSED LOOP GAIN

VOLTAGE

CHANNEL

GV(V/V)

VOLTAGE

V d-c

CURRENT

A d-c

MODEL

(1) (5)

CURRENT

CHANNEL

GI(A/V)

VOLTAGE MODE

SERIES RmΩSERIES L

µH

(2)

SHUNT RKΩSHUNT C

µF

(3)

CURRENT MODE

OUTPUT IMPEDANCE

6

Page 7

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718)767-1102

Email: hq@kepcopower.com • www.kepcopower.com

OPTIMIZE BOP 200W AND 400W

FOR DRIVING INDUCTIVE LOADS

TO 1HENRY

BOP INDUCTIVE LOAD SPECIFICATIONS

BANDWIDTH (DC TO F-3dB)

INDUCTIVE

LOAD, 2mH

RESISTIVE

LOAD, NOMINAL

RISE/FALL

TIME

(2)

BOP 20-20ML

0 to ±20V, 0 to ±20A

MODEL /

SPECIFICATION

(1)

BOP 36-6ML

0 to ±36V, 0 to ±6A

BOP 36-12ML

0 to ±36V, 0 to ±12A

BOP 50-4ML

0 to ±50V, 0 to ±4A

BOP 50-8ML

0 to ±50V, 0 to ±8A

12 KHz

LOAD EFFECT

RESISTIVE LOAD,

NOMINAL

(4)

3 ppm/Hz2.5 KHz 33μS

BOP 72-6ML

0 to ±72V, 0 to ±6A

BOP 100-2ML

0 to ±100V, 0 to ±2A

BOP 100-4ML

0 to ±100V, 0 to ±4A

RECOVERY TIME

CONSTANT AT

STEP LOAD

(3)

180μS

BOP 20-10ML

0 to ±20V, 0 to ±10A

11.2 KHz 12 ppm/Hz4.1 KHz 35μS 220μS

12 KHz 4 ppm/Hz5 KHz 30μS 210μS

12.7 KHz 3 ppm/Hz6.8 KHz 28μS 100μS

1.43 KHz 20 ppm/Hz1.8 KHz 245μS 280μS

10.6 KHz 7 ppm/Hz4.9 KHz 31μS 200μS

2.6 KHz 50 ppm/Hz2.7 KHz 125μS 200μS

3.5 KHz 47 ppm/Hz5.0 KHz 84μS 250μS

1.2 KHz 70 ppm/Hz1.7 KHz 220μS 280μS

For digital meters, substitute the letter D for M when ordering - example: BOP 20-10DL.

For GPIB control of the BOP, add the suffix 4886 after the letter L in the model name example: BOP 20-10ML4886.

(1) All specifications listed are for inductive load models in Current Mode.

All other specifications are identical to the standard BOP.

(2) 10% - 90%, nominal resistive load.

(3) Short-circuit, nominal resistive load.

(4) Load effect increases nonlinearly with frequency from the typical 0.5 mA in DC full scale

(same as the standard unit) at the average rate listed.

As an option (L suffix), Kepco’s 200W (except BOP

200-1M) and 400W BOP models may be optimized

for driving inductive loads. These BOP units are

designed to operate in a stable manner in Current or

Current Limit Mode for loads up to 1 Henry . T h ey are

also stable with any R-L series load combination.

To prevent voltage limit operation, the equivalent

impedance of the R-L series load at the working

frequency, must be lower than the nominal resistive

load value (nominal output voltage/nominal output

current).

All specifications of the unit in voltage mode are

unchanged from the standard model. T he specifications

listed in the table to the right are for inductive load

models in Current Mode. All other specifications are

identical to the standard BOP.

In current mode the bandwidth of the BOP is reduced

when operating with a resistive load. Correspondingly,

the rise and fall time of the unit is increased (model

dependent). Further, it is possible to reduce the

bandwidth in current mode in a predictable way,

using one customer installed component on the rear

programming connector of the BOP (see Bandwidth

Correction Chart).

BOP INDUCTIVE LOAD - BANDWIDTH CORRECTION

BOP 20-20ML

EXTERNAL CAPACITOR

(ACROSS PINS 16 AND 18 OF PC 12 PROGRAMMING CONNECTOR)

MODEL

0.01 μF 0.02 μF 0.05 μF 0.1 μF 0.2 μF 0.5 μF 1 μF

4.0 KHz 2.4 KHz 1.0 KHz 0.57 KHz 0.30 KHz 0.12 KHz 0.07 KHz

BOP 20-10ML 4.1 KHz 2.3 KHz 1.0 KHz 0.57 KHz 0.27 KHz 0.11 KHz 0.06 KHz

BOP 36-6ML 4.0 KHz 2.5 KHz 1.0 KHz 0.55 KHz 0.25 KHz 0.12 KHz 0.06 KHz

BOP 36-12ML 4 KHz 2.4 KHz 1 KHz 0.57 KHz 0.27 KHz 0.11 KHz 0.06 KHz

BOP 50-4ML 1.4 KHz 1.2 KHz 0.7 KHz 0.47 KHz 0.25 KHz 0.11 KHz 0.06 KHz

BOP 50-8ML 3.6 KHz 2.1 KHz 0.93 KHz 0.54 KHz 0.29 KHz 0.12 KHz 0.06 KHz

BOP 72-6ML 1.75 KHz 1.3 KHz 0.75 KHz 0.47 KHz 0.26 KHz 0.11 KHz 0.06 KHz

BOP 100-2ML 1.8 KHz 1.4 KHz 0.8 KHz 0.51 KHz 0.27 KHz 0.11 KHz 0.06 KHz

BOP 100-4ML 1.0 KHz 0.8 KHz 0.6 KHz 0.4 KHz 0.23 KHz 0.11 KHz 0.06 KHz

For more information on the

BOP Inductive Load Models visit

www.kepcopower.com/bop-ind.htm

APPLICATIONS FOR KEPCO’S

BOP INDUCTIVE LOAD MODELS

Motor Testing

Testing of Magnetic Components

Coils, Speakers, etc.

Industrial Applications with

Inductive Loads

Driving CRT Coils

Cryogenic Applications

Correcting Magnets for

Medical Imaging or

Particle Accelerators

200 WATT

400 WATT

200 WATT

400 WATT

7

Page 8

OPTIMIZE BOP 200W AND 400W

FOR DRIVING CAPACITIVE LOADS

TO 10 MILLI-FARADS

8

For digital meters, substitute the letter D for M when ordering - example: BOP 20-20DC.

For GPIB control of the BOP, add the suffix 4886 after the letter C in the model name example: BOP 20-20MC4886.

(1) All specifications listed are for capacitive load models in Voltage Mode.

(2) For BOP 20-20MC, DC: nonuniformities of the frequency response creates a larger 3-dB bandwidth

for the resistive load than for the standard BOP.

(3) Nonuniformities of the frequency response for the standard 10μF load create a larger 3-dB bandwidth

than for the resistive load.

(4) 10% - 90%, with nominal resistive load.

(5) Load between infinity and nominal resistive values.

As an option (C suffix), Kepco's 200 Watt (except

BOP 200-1M) and 400 Watt BOP models may be

optimized for driving capacitive loads.

These BOP units are designed to operate in a stable

manner in voltage or voltage limit mode for capacitive

loads up to 10mF. They are also stable when driving

any R-C parallel combination where load R is ≥

nominal value and C is ≤10mF. Load R (nominal value)

= nominal output Voltage/nominal output Current

(e.g., BOP 36-6MC, R = 36/6 = 6 Ohms). To prevent

current limit operation, the equivalent impedance of

the R-C parallel load circuit at the working frequency

must be greater than the nominal R value.

Static specifications representing accuracy for various

influence parameters are identical to the standard

BOP models. Ripple and noise specifications are better

(approximately 50% lower) for the C option units

compared to the standard BOP.

In voltage mode, with a resistive load, the

bandwidth of the BOP Capacitive Load is reduced

versus the standard model, while the response time is

increased (except the 20V model: see Specifications

Chart). The frequency response variations can be

practically eliminated by reducing the bandwidth in

voltage mode in a predictable manner using an

internal user-installed component to increase the

internal compensation capacitance (see Bandwidth

Correction Chart).

In Current Mode the dynamic specifications are

almost identical for all BOP C option models: 3-dB

bandwidth of 4.9kHz and rise/ fall time of 72µsec

(lower bandwidth and higher rise/fall time than the

standard BOP models).

For more information on the BOP Capacitive Load Models visit

www.kepcopower.com/bop-cap.htm

APPLICATIONS FOR KEPCO’S

BOP CAPACITIVE LOAD MODELS

Solar Cell/Panel

Research and Testing

Driving and Testing

Piezo-Electric Devices

Capacitor Testing

Driving and Testing

Capacitive Transducers

Industrial or Lab Applications

with Capacitive or

Capacitive-Resistive Loads

BOP CAPACITIVE LOAD SPECIFICATIONS

BANDWIDTH (DC TO F-3dB)

CAPACITIVE

LOAD, 10uF

(3)

RESISTIVE

LOAD, NOMINAL

(2)

RISE/FALL

TIME

(4)

BOP 20-10MC

0 to ±20V, 0 to ±10A

MODEL /

SPECIFICATION

(1)

BOP 36-12MC

0 to ±36V, 0 to ±12A

BOP 50-4MC

0 to ±50V, 0 to ±4A

BOP 72-6MC

0 to ±72V, 0 to ±6A

BOP 100-4MC

0 to ±100V, 0 to ±4A

12 KHz 14 KHz 32μS

RECOVERY TIME

AT STEP LOAD

(5)

100μS

BOP 36-6MC

0 to ±36V, 0 to ±6A

13.5 KHz 16.3 KHz 32μS 95μS

BOP 20-20MC

0 to ±20V, 0 to ±20A

4.8 KHz 5.3 KHz 75μS 225μS

13.5 KHz 16 KHz 30μS 95μS

BOP 50-8MC

0 to ±50V, 0 to ±8A

9 KHz 11 KHz 38μS 160μS

11.5 KHz 15 KHz 35μS 100μS

6.5 KHz 8.3 KHz 60μS 184μS

6.0 KHz 8.0 KHz 66μS 190μS

200 WATT

400 WATT

KEPCO, INC. • 131-38 SanfordAvenue• Flushing, NY 11355 USA • Tel: (718) 461-7000 • Fax: (718)767-1102

Email: hq@kepcopower.com • www.kepcopower.com

BOP CAPACITIVE LOAD - BANDWIDTH CORRECTION

BOP 36-6MC

INTERNAL USER-INSTALLED CAPACITOR

MODEL

1 nF 2.2 nF 4.7 nF 15 nF 33 nF 47 nF 100 nF

12.1 KHz 10 KHz 7.8 KHz 3.5 KHz 2.2 KHz 1.4 KHz 0.5 KHz

BOP 20-20MC 4.6 KHz 4.4 KHz 3.2 KHz 1.3 KHz 0.7 KHz 0.6 KHz 0.5 KHz

BOP 20-10MC 11.5 KHz 9 KHz 7.5 KHz 3.5 KHz 2.2 KHz 0.5 KHz

BOP 36-12MC 12 KHz 10 KHz 7.6 KHz 3.5 KHz 2.2 KHz 1.4 KHz 0.5 KHz

BOP 50-4MC 11 KHz 9 KHz 7 KHz 3 KHz 1.5 KHz 1 KHz 0.5 KHz

BOP 50-8MC 8.5 KHz 8 KHz 6.5 KHz 4.5 KHz 3 KHz 1.5 KHz 0.5 KHz

BOP 72-6MC 6.5 KHz 6.0 KHz 5.3 KHz 2.7 KHz 1.4 KHz 0.9 KHz 0.5 KHz

BOP 100-4MC 6.0 KHz 5.4 KHz 4.2 KHz 2.5 KHz 1.5 KHz 1.1 KHz 0.5 KHz

The listed bandwidth values are for C option units in Voltage Mode, nominal resistive load.

1.3 KHz

200 WATT

400 WATT

Loading...

Loading...