Page 1

BITE®3

Battery Impedance Test Equipment

■

Determines health of lead-acid cells up

to 2000 Ah

■

On-line testing with Pass/Warning/Fail

calculations

■

Measures impedance, interconnection

resistance and cell voltage

■

Windows CE operating system with

32 MB of memory

■

Measures float and ripple currents

■

Includes ProActiv™Database Management

Software

BITE

®

3

Battery Impedance Test Equipment

DESCRIPTION

The Megger BITE 3 Battery Impedance Test Equipment

determines the health of lead-acid cells up to 2000 Ah by

taking measurements of the most important battery

parameters. The BITE 3 measures cell impedance, an

internal ohmic test, cell voltage, intercell connection

resistance and ripple current. And, for the first time in a

battery instrument, the BITE 3 measures float current and

the harmonic content of the ripple current. There is even a

built-in spectrum analyzer to show the harmonic content

of the ripple current. It has firmware that can be upgraded

through the Internet and supports multiple languages.

The BITE 3 is one of the easiest instruments to use. Its

measurements, along with temperature, specific gravity and

other battery data, can provide the best basis for

evaluating the overall health of batteries from terminal

plate to terminal plate and to a lesser extent, the charger

(from ripple current and its harmonic content.) Megger

recommends that the BITE 3 be made part of a

comprehensive battery maintenance program with readings

taken and recorded semi-annually for flooded, lead-acid

cells and quarterly for VRLA.

Unlike load-cycle testing which is expensive, nonpredictive and time-consuming (but does provide actual

capacity data), the BITE 3 is quick, reliable and easy to

use. With a rapid test time, one person can easily, quickly

and precisely measure cell and string parameters without

taking the system off line. Furthermore, in as little as four

keystrokes, the instrument is ready to take battery

measurements (five, if the power button is included). The

processor of the BITE 3 uses a Windows

®

CE Operating

System and can store more than 1 million cells’ data in any

string configuration. It is menu-driven that is easy to

navigate. Its unique data analysis screens provide

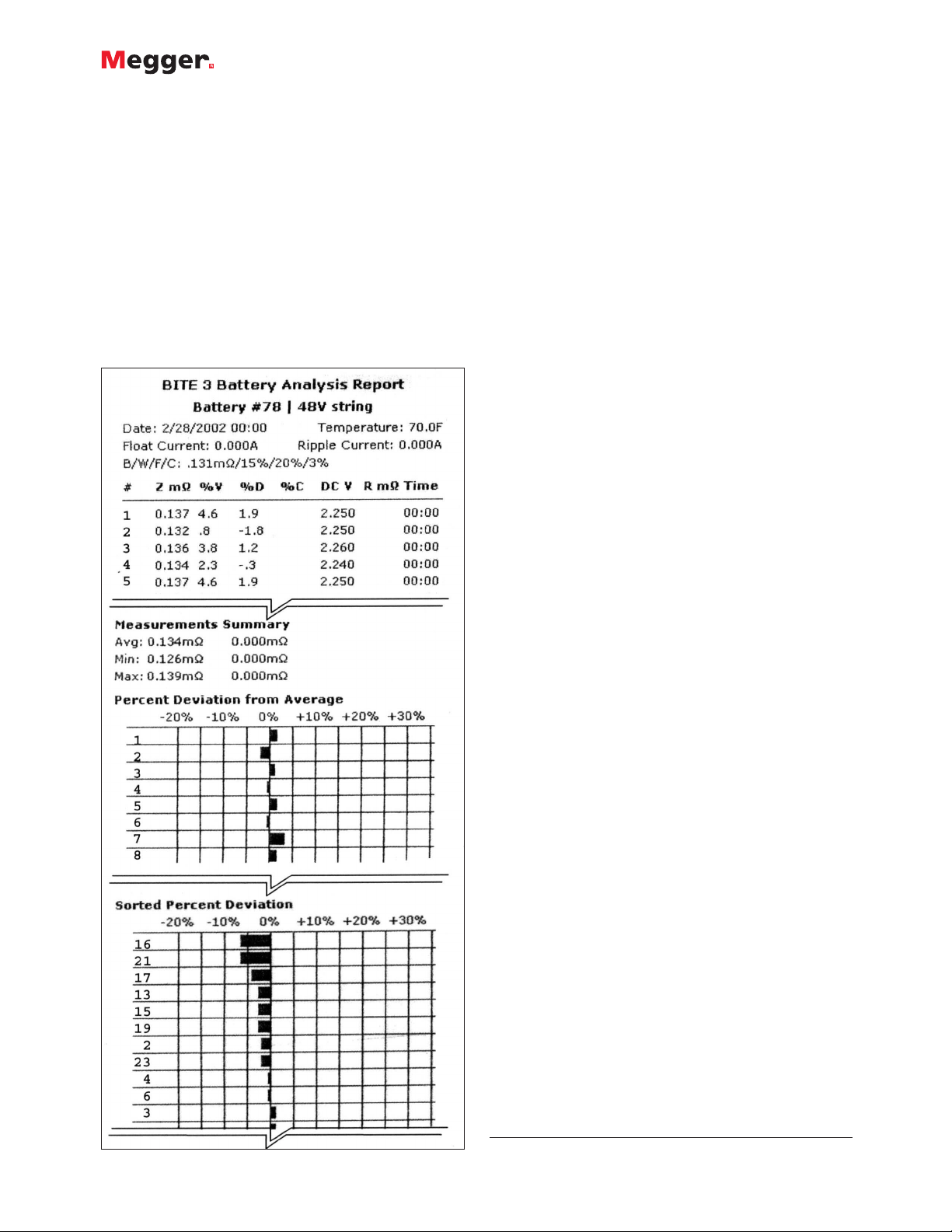

immediate feedback on the status of cell impedance, (see

Figure 1, Battery Analysis Report). The first part of the

report is the numerical data. The second part is the

impedance deviation graph and the third part is the

impedance deviation graph but in ascending impedance

order. The ascending impedance graph groups the weakest

cells together for easier analysis. With the optional printer,

this report can be printed by the user and left at the site as

a record for future reference.

PROACTIV DATABASE MANAGEMENT SOFTWARE

The first of its kind, ProActiv is a powerful software

package that organizes and analyzes battery data in an MS

Access database. Used in conjunction with the BITE 3,

ProActiv manages the transferred test data from the BITE 3

by organizing it according to your needs and displaying it

in an extremely useful manner. Once the database is

configured to your liking and test data are transferred from

the BITE 3, it provides red, yellow and green bands that

coincide with user entered pass, warning and failure limits.

ProActiv allows the user to organize and manage battery

data such as voltages, impedance, intercell connection

resistance, ripple current, and specific gravity. ProActiv

even has a place for IR thermographs, diagrams and

graphics to store with the battery data. It is an allencompassing battery database management tool.

Having such a tool becomes even more important when

you consider the following: battery testing is crucial to

ensure a battery system provides standby and emergency

power to operate devices such as emergency lighting, UPS

Page 2

Figure 1: Battery Analysis Report

BITE®3

Battery Impedance Test Equipment

systems, operating controls, switchgear components,

protective relays and continuous process systems. Failure

of a battery system within environments such as utilities,

hospitals and manufacturing plants can result in

operational failure of the devices connected to it. ProActiv

assists the user to avoid battery failures, budget for future

battery string and cell replacements, and plan battery

changeouts in an orderly manner.

The BITE 3 along with ProActiv software offer the most

comprehensive data analysis system to provide confident

and reliable evaluation of batteries in the dc network.

Together, they combine to make the most powerful battery

health analyzer available on the market today.

APPLICATIONS

It is known that impedance is correlated to battery

capacity and there has been a long-standing question as to

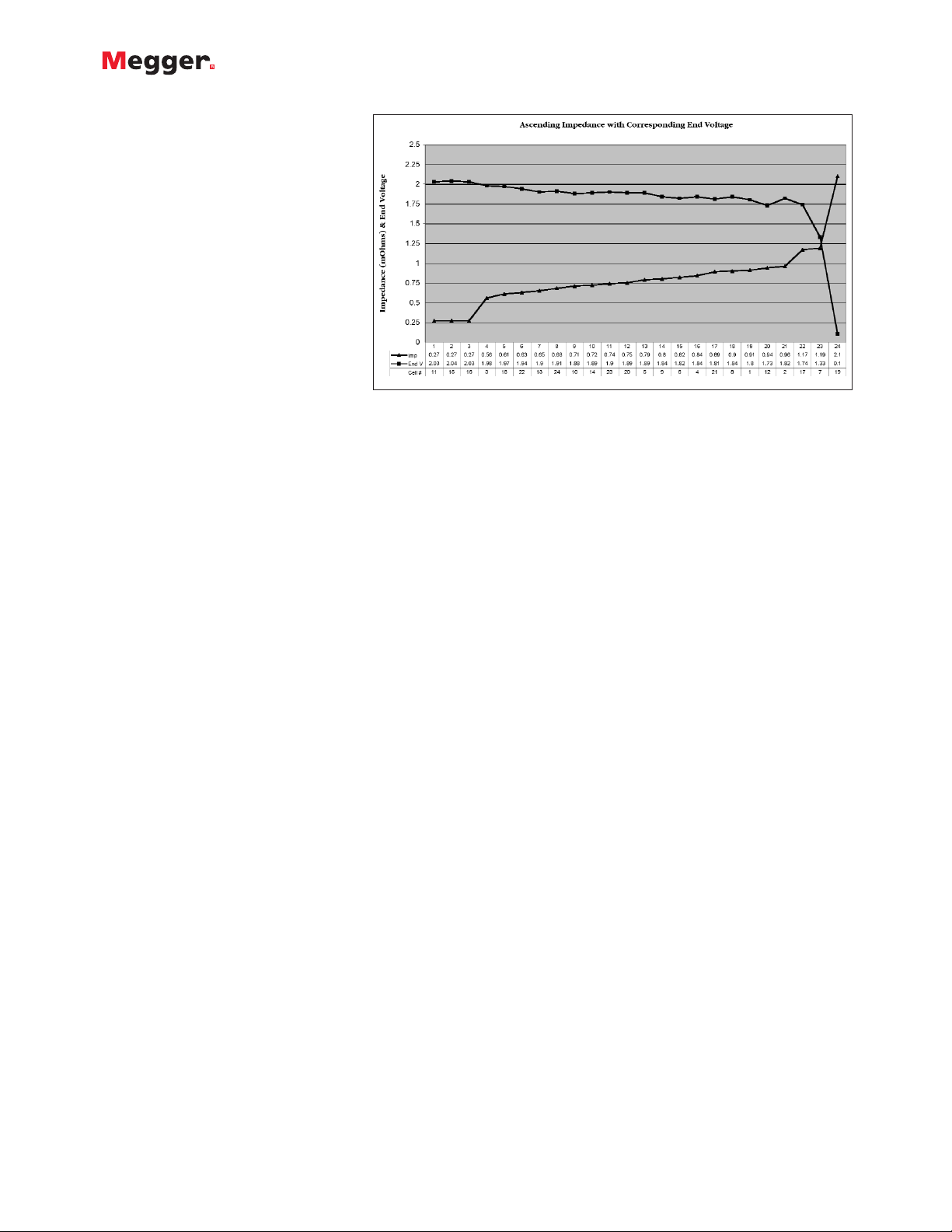

when a user should replace a cell. See Figure 2. Recent

studies by EPRI* and other organizations indicate that

when the impedance of a sealed battery increases by

about 50% from its baseline value, the cell has degraded to

less than about 70% capacity. BITE 3 and ProActiv allow

the user to trend data and to enter baseline values for

comparison purposes and to make decisions whether onsite or in the office. Both the BITE 3’s impedance

deviation graph and the trend graph in ProActiv clearly

show the status of a cell which helps users to decide what

action needs to be taken to ensure battery back up

reliability based on users’ criteria.

A battery’s internal impedance increases as its capacity

decreases due to various factors such as age, ambient

temperature, discharge history, etc. The BITE 3 measures

internal impedance and dc voltage for lead-acid cells up to

2000 Ah in capacity. It also measures intercell connection

resistance, float current and ripple current and the

harmonic content of the ripple current to provide a much

better evaluation than any other single instrument.

Impedance finds electrical path problems due to plate

sulphation, post-seal corrosion, dry-out (loss of

compression), poor intracell welds and intercell

connections and more. These data let the user determine

maintenance needs such as:

■

Cell replacement criteria based on impedance trends

■

Jumper out a cell or two

■

Clean and/or retighten intercell connectors

■

Shorten the maintenance interval, etc.,

■

Evaluate float current and ripple current effects

Typical installations that can be tested using the BITE 3

include:

■

Electrical power generation plants

■

Substations — utility, railroad, industrial

■

Telecommunications facilities — OSP, Wireless, POPs,

MTSOs, Fiber Regens

■

UPS systems — standard and cabinetized batteries

■

Railroad — Signals and Communications, CTC

■

Aircraft power supplies

■

Marine and military

*Stationary Battery Monitoring by Internal Ohmic Measurements

EPRI, Palo Alto, CA: 2002. 1002925

Page 3

drop of the intercell connector to calculate the resistance

of the intercell connector. Then, it measures the strap

again without the instrument current. A mathematical

calculation is performed to determine float and ripple

currents and the intercell connection resistance.

The optional CT can be used with short strings in parallel

configurations to measure “escape current.” Other

techniques do not measure the current and can overstate

the health of batteries in these types of configurations. By

using a CT to measure the actual current in the cell being

tested, better results are obtained.

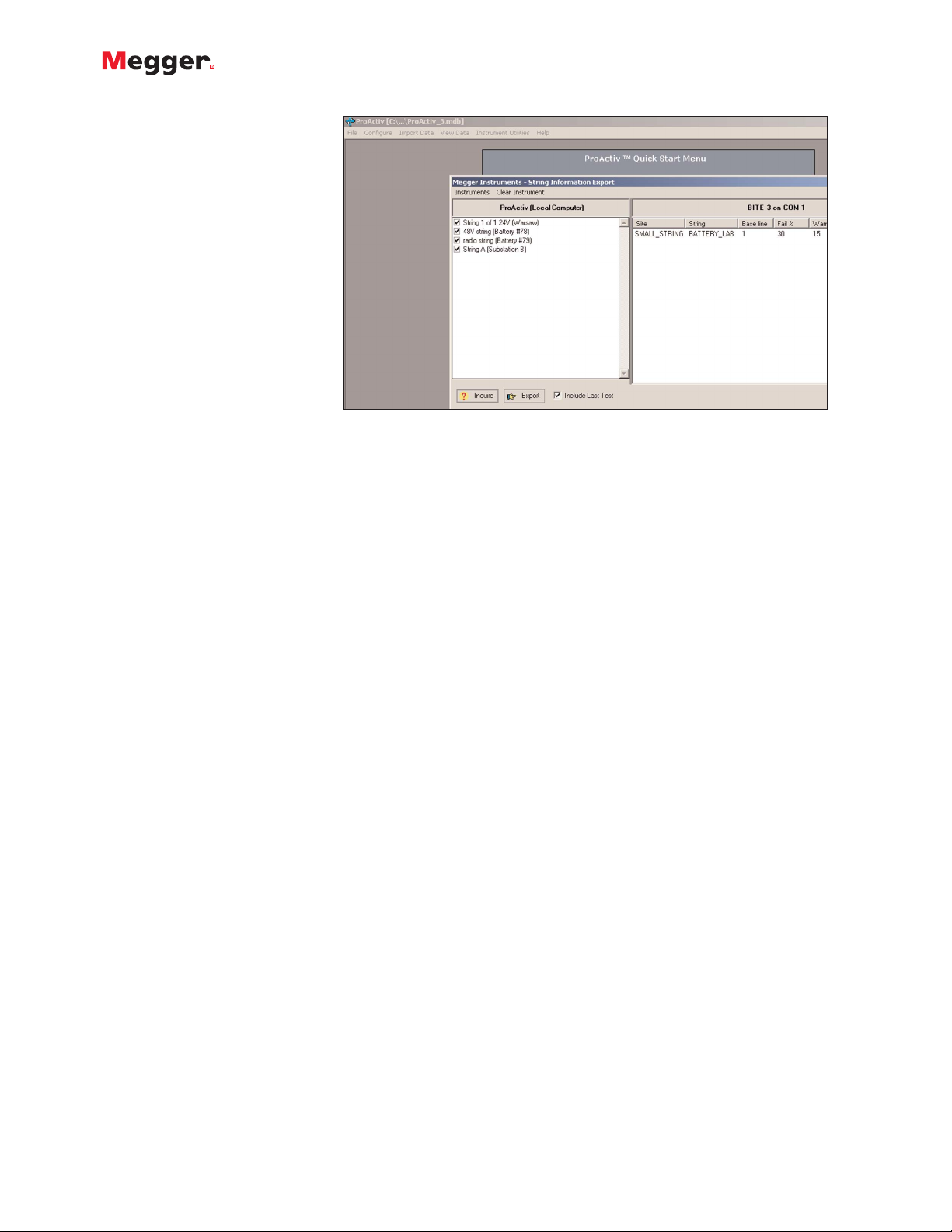

ProActiv can download string header info (with baselines

and limits) into the BITE 3 along with the most recent data

(even if measured by a different BITE). See Figure 3. Then

using the menus, simply scroll to the site and string and

start taking readings. When finished, close the test and

continue to the next string. At the conclusion of the test,

simply download to a PC for further data analysis and

long-term trending. Its versatility allows comments to be

added about the string. These comments will be uploaded

with the battery data. Additional comments about the site,

string and/or cell such as ambient and pilot cell

temperature can be stored by using the keypad to enter

them.

DATA ANALYSIS

The interface between BITE 3 and ProActiv is an

advanced, state-of-the-art feature that ensures that

everyone has access to the latest information and data on

which to base intelligent battery decisions. Not only can

emergency cell replacement criteria be developed but also

budgetary planning for string replacements can now

become part of the fiscal planning process.

ProActiv has the ability to download site and string

information and data as well as firmware updates to the

BITE 3. The data downloaded into the BITE 3 gives access

to the most recent data for the strings being tested during

the upcoming week or month.

BITE®3

Battery Impedance Test Equipment

FEATURES AND BENEFITS

■

Calculates impedance automatically

and stores results for on-site review to

make immediate decisions.

■

Serial connector for uploading stored

data to a personal computer and to

download data from ProActiv.

■

Measures lead-acid cells up to 2000 Ah

to test a wide range of batteries.

■

On-line testing requiring no downtime

and introduces less risk to battery

testing compared to load testing and

other techniques.

■

Stores more than 1 million cells’ data

in any string configuration – no need

to stop, download, delete and continue.

■

Firmware and software updates are fast and easy for

ProActiv and the BITE 3 through the Internet.

■

No programming skills required. ProActiv is an easy to

use, fully functional battery database capable of storing

as much information and data as your hard drive (or

network) has memory to store.

■

ProActiv has the ability to import images such as IR

thermographs, diagrams or photographs. This helps to

document visual inspections, string configurations,

installation techniques, or other aspects of battery

systems. Images and data are stored together, providing

convenient and easy access.

■

The BITE 3 and ProActiv accommodate multiple

languages.

TEST PROCEDURE

The BITE 3 works by placing the lead set at the cell

terminals to measure the voltage drop of the ac current

signal applied by the instrument to the cell while it is

on-line. During each measurement, impedance is

calculated following Ohm’s Law, displayed on the LCD,

and stored. It also measures, displays and records dc

voltage, interconnection (strap) resistance, float and ripple

currents. Float and ripple current measurements are

performed separately at the start of the test. This is

because current is the same everywhere in the series

connection of the string in accordance with Kirchhoff’s

law. All of these data together help determine the overall

health of the entire battery string’s electrical path from

terminal plate to terminal plate and to a lesser extent, the

charger (by measuring ripple current and its harmonic

content).

An innovative, patent-pending measuring technique is

being employed so that a clamp-on current sensor is no

longer necessary. It is well-recognized that the best way to

measure current is with a shunt. Since the battery has

many straps, simply by determining a strap’s resistance, it

can be used as a shunt to determine float and ripple

currents. First, while across an intercell connector, the

instrument applies a current and measures the voltage

Figure 2: Ascending impedance compared to load test

Page 4

BITE®3

Battery Impedance Test Equipment

With previous data loaded, better

analysis can be performed simply by

comparing the last result to the most

recent result. Any cell that changes

by more than a few percent suggests

that further investigation is

warranted.

On-Site Interpretation

Impedance readings for individual

cells can be used to compare to the

string average. Individual cells with

deviations of more than ±15% for

flooded and ±35% for VRLA typically

indicate a problem with that cell.

The Battery Analysis Report clearly

shows the cells that are weakest

when compared to the string average

and the other cells in the string. It is

typically the one or two weak cells

that can take the string off line. By

comparing each cell to the string average, it is possible to

determine which cell is the weakest in the string and by

how much.

If previous data were downloaded through ProActiv, then

a comparison of each cell to its previous reading (%C) can

provide additional information about each cell. The

Battery Analysis Report is designed to provide as much

information as possible on which to make decisions while

on site; decisions to ensure that the string will properly

support the load.

Trending Analysis

Impedance readings can be used for trending to determine

replacement criteria. Battery cell impedance values should

be recorded and compared to previous readings to

determine the position of the cell on the curve of

impedance versus cell life. Based on experience, a

variation of ±20% from baseline of a flooded lead-acid and

±50% for VRLA cells indicate significant change in the

electrical path to warrant serious evaluation of the health

of the battery system. Megger maintains a database of

impedance values by some manufacturers and battery

size/type. The BITE 3 with baseline values entered can be

used as a trending tool while on site. Trending is the best

method available to know the most about the health of

batteries.

Configuring the ProActiv Database

There are three basic steps to setting up ProActiv:

■

Configuring battery manufacturers, models, sites, and

strings including baselines and limits

■

Entering data from previous BITE downloads, manually

or directly from the BITE 3

■

Performing data analysis

ProActiv is configured by entering and setting up each

battery manufacturer and battery model type used in a dc

network. Optionally, other information such as sales

contact names, purchase order numbers or technical

support contact names may be added. Extensive model

information may be entered including model type,

plate count, rating, charger type, baseline impedance

value as well as warning and fail percentages. Limits

on other parameters can also be set such as upper and

lower float voltage limits and specific gravity limits.

All of the individual battery cell information can then

be configured under a specific site name, string ID,

battery model, installation date, and charger

information. If a cell needs to be replaced, but the

same model is not available, ProActiv will allow it to

be replaced with another manufacturer or model.

ProActiv keeps track of cell-level information and data

and this is reflected when viewing information and

data for that string. In instances where there is such a

large installed battery base and a string is replaced,

some of the better cells may be used in other strings to

replace weak cells. ProActiv allows the user to keep

track of these movements.

Entering Data

Data entry is easy with the Data Entry Wizard: direct

import of test data from a BITE, manual entry, via

browsing for a file. When uploading from a BITE 3,

ProActiv can automatically create a site and string for a

new site that hasn’t been prevoulsy configured in

ProActiv. Digital photographs and IR thermographs can

be imported also into ProActiv to document the health

and condition of the battery.

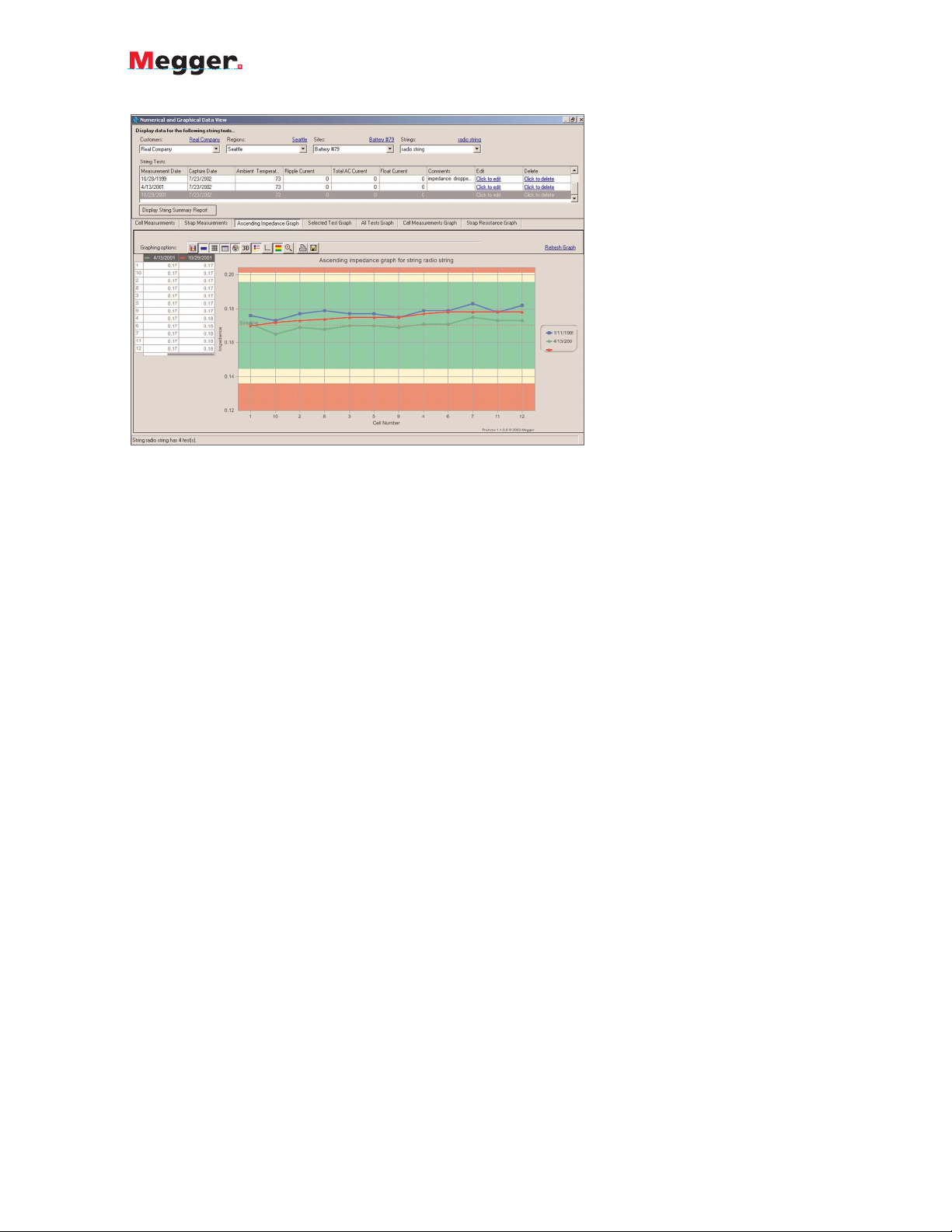

Performing Data Analysis

The last step is “analyze.” Using both numerical data

displays and graphs, the user can see how the batteries

in the dc network are performing based on the userentered limits for each parameter. Graphs can be

printed and saved as bitmaps to export to other

programs for written reports. A summary report may be

printed which lists all cells' data and each cell's status.

The graph shown in Figure 4 clearly shows which cells

are in the pass (green), warning (yellow) and fail (red)

bands. It is possible to select and graph one cell and

verify its entire history.

Figure 3: ProActiv to BITE 3 download screen

Page 5

BITE®3

Battery Impedance Test Equipment

ACCESSORIES

The BITE 3 has many accessories that enhance its

versatility. There are several lead sets, a printer,

lighted probe extensions and a CT.

The lead set family contains:

■

AMP/Burndy lead set for small telco batteries

■

Quick Disconnect lead set for ELU systems, security

systems, etc.

■

Kelvin Clip lead set for other types of batteries

The CT is for measuring escape current in short

strings in parallel configurations. The lighted probe

extensions are ideal for measuring batteries in (dark)

cabinets. The extensions eliminate the need to take

the battery off line and can be tested during normal

working hours, saving time and money. As with

previous BITEs, it is a one person job since the

batteries need not be removed from the cabinet.

SPECIFICATIONS

BITE 3 Instrument

Impedance Range and Resolution

0.05 to 1.000 mΩ 1 µΩ resolution

1 to 10.00 mΩ 10 µΩ resolution

10 to 100.0 mΩ 0.1 mΩ resolution

Voltage Range and Resolution

1 to 30 V dc across probes

1 to 8.0 V dc 1 mV resolution

8.0 to 30.00 V dc 10 mV resolution

Current Range and Resolution

0.5 — 9.99 A ac/dc 0.01 A resolution

10.0 — 99.9 A ac/dc 0.1 A resolution

Accuracy

dc voltage: ±(1% rdg +1 lsd)

ac impedance: ±(5% of rdg +1 lsd)

ac/dc current: ±(5% rdg +0.5 A)

Precision

Better than 0.5% one sigma

Source Output Current

1/2 A rms

Display

1/4 VGA LCD

Settling Time per Reading

3 seconds maximum

Battery Pack

2 to 4 hours continuous

4.8 V dc, 7000 mAh, quick charge NiMH battery pack

Temperature

Operating: 32° to 105° F (0° to +40° C)

Storage: -5° to 130° F (-20° to +55° C)

Humidity: 20 to 90% RH, noncondensing

Safety

Designed to meet IEC 61010-1 specifications

Dimensions

8.6 x 4 x 9.5 in.

220 x 100 x 237 mm

Weight

5.7 lbs (2.6 kg)

Charger

Supply Voltage

100 to 130 V, 50/60 Hz, 14 VA

210 to 250 V, 50/60 Hz, 14 VA

Output

6.50 V dc at 1.10 A dc charging (max.)

Optional Printer

Thermal, with 4-1/4 in. (110 mm) printing width

Figure 4: ProActiv ascending impedance graph with Pass/Warning/Fail bands

Page 6

BITE 3, 110/230 V ac, 50/60 Hz, CE-marked BITE 3

Included Accessories

ProActiv™ software BI-90001

Canvas carrying case 35788

RS-232 null modem cable 33533-1

Line charger EV6280-333

Battery EV6121-492

Dual-point lead set BI-10002

Tip kit BI-10017

Operating manual AVTMBITE3

ORDERING INFORMATION

ISO STATEMENT

Registered to ISO 9001:1994 Reg no. Q 09250

Registered to ISO 14001 Reg no. EMS 61597

BITE3_DS_en_V12

www.megger.com

Megger is a registered trademark

BITE®3

Battery Impedance Test Equipment

ProActiv System Requirements

Processor

300 MHz Pentium II or better

Operating System

Windows 98

Windows Me

Windows NT 4.0 (SP6a required)

Windows 2000 (SP2 recommended)

Windows XP

Note:Windows 95 is not supported

Software

Microsoft®Internet Explorer 5 or later

Microsoft .Net Framework

Will be automatically installed by ProActiv if it is not already

installed on your computer. For additional information about

Microsoft .Net Framework please visit: www.microsoft.com/net

Hard Drive Space

100 MB

System Memory (RAM)

64 MB (128 MB recommended)

Other Drives

CD-ROM (used only for installation)

Communications Port

COM (used only for importing data from test equipment or to

download information to the BITE 3)

Monitor/Display

True color, 800 x 600 resolution

Additional Information

For improved usage, an internet connection will make it easy to

get automatic ProActiv software updates.

The user should have Microsoft Excel 9.0, or later, to import

AVOLink or COMLink files into ProActiv.

Optional Accessories

Printer, battery-operated, 110 V ac 35755-3

Printer, battery-operated, 220 V ac 35755-4

Printer paper, 1 roll 26999

AMP/Burndy lead set BI-10004

Kelvin clip lead set BI-10005

Quick Disconnect lead set BI-10006

Cigarette lighter charger EV6280-332

Current transformer kit 35873

USB-serial adapter 35871

Probe extensions, lighted 35865

Hard-sided carrying case 35890

Standard transit case 35915

Field test shunt, 0.01 Ω, current rating 10 A 249003

Field test shunt, 0.001 Ω, current rating 100 A 249004

Field test shunt, 0.0001 Ω, current rating 500 A 249005

Item Cat. No.Item Cat. No.

Item Cat. No.Item Cat. No.

UK

Archcliffe Road, Dover

CT17 9EN England

T (0) 1 304 502101

F (0) 1 304 207342

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1019 USA

T 1 800 723 2861

T 1 214 333 3201

F 1 214 331 7399

OTHER TECHNICAL SALES OFFICES

Norristown USA, Toronto CANADA,

Mumbai INDIA,

Le Raincy FRANCE, Cherrybrook

AUSTRALIA, Guadalajara SPAIN

and The Kingdom of BAHRAIN.

Loading...

Loading...