Page 1

BITE® 2 and BITE 2P

Battery Impedance Test Equipment

BITE® 2 and BITE 2P

Battery Impedance Test Equipment

n

Determines condition of lead-acid and

NiCd cells up to 7000 Ah

n

On-board Pass/Warning/Fail indications

n

Robust, repeatable instruments

n

On-line testing

n

Checks charger condition by measuring

ac ripple current

BITE 2P

BITE 2

DESCRIPTION

The BITE 2 and BITE 2P Battery Impedance Test

Equipment determine the condition of lead-acid and

nickel-cadmium cells up to 7000 Ah. An advanced feature

set has been developed that includes Pass/Warning/

Fail calculations based on a user-entered baseline value,

advanced printing functions and more. The case of the

BITE 2P consists of both the transmitter and a carrying

case for all of the standard accessories and some of the

optional accessories, in an all-in-one unit. The BITE 2 and

its accessories fit into a sturdy canvas case with a shoulder

strap.

The instruments work by applying a test signal across the

battery string while on-line, then calculates impedance

based on simultaneous measurements of current and

resulting voltage drop of each cell/jar. They also measure

dc voltage and interconnection (strap) resistance to help

determine the overall condition of the entire battery string’s

electrical path from terminal plate to terminal plate.

In addition, the BITE 2 and BITE 2P measure ac ripple

current which, if too high and over an extended period of

time, can damage the battery by heating it. (An increase of

battery temperature by 18ºF/10ºC will halve the life of leadacid batteries.) Battery manufacturers generally recommend

a limit of 5A of ac ripple current for every 100 Ah of battery

capacity. The first measurement that the instruments take is

ac ripple current which should be trended.

The BITE 2 and BITE 2P receiver stores the readings in

its internal memory. These measurements, along with

other maintenance data such as ambient and pilot cell

temperatures and ac ripple current, assist in determining

the overall condition of battery systems. Megger

recommends that impedance measurements with the

BITE 2 or BITE 2P be made part of a battery maintenance

program with readings taken and recorded semiannually for

flooded batteries and quarterly for VRLA.

Unlike load cycle testing that involves substantial downtime

and repeated discharges, using the instruments require

no battery discharge, nor do they stress the battery in any

way compared to other techniques. With a test time of

less than 15 seconds for each cell and intercell connector,

one person can easily, quickly, and precisely measure

internal cell impedance, dc terminal voltage and intercell

connection resistance without taking the battery system off

line and evaluate charger condition also.

Naturally, everything you need to perform these tests is

included with the basic instruments. There is a full line of

optional accessories to enhance the capabilities of the BITE

2 and BITE 2P. Both have the ability to download to a PC

for data interpretation and to ProActiv™, Megger’s battery

database management software. Additionally, the BITE 2P

has a built-in printer to review the active test and also to

leave a hard copy record at the site.

Receiver

The battery-operated receiver incorporates the potential

leads, clamp-on current sensor, and data storage

capabilities. It stores more than 2000 sets of data (cell

impedance, cell voltage and interconnecting strap

resistance, date and time stamps) in up to 300 tests. It also

allows for printing the active test for easy review and retest.

Selective printing of any test and deleting oldest tests are

now included features to maintain in memory the most

critical tests.

Page 2

BITE® 2 and BITE 2P

Battery Impedance Test Equipment

At any time while performing a test, the operator can

review the current test results by using arrow keys and

scrolling back through the active test screen. The operator

can also print the active test using the BITE 2P transmitter

printer. If needed, the operator can retest any of the cells

and straps in the current test. Stored data can also be

downloaded via the RS-232 connector directly to a personal

computer or the BITE 2P transmitter printer.

One additional feature of the receiver is that if you are

called away while in the middle of the test, simply shut

down the instrument and it will remember where you left

off in the test.

The clamp-on current sensor is connected to the receiver

during testing and clamped around a convenient intertier

or intercell connection within the loop created by the

transmitter’s current source leads and the battery string. If

the intercell or intertier connection consists of more cables

than the diameter of the clamp-on current sensor can

encompass, the receiver has a split-strap function.

There are optional RopeCTsTM available for large buss work.

With the optional bar-code wand, additional information

such as location ID, user ID, ambient and pilot cell

temperatures can be recorded and stored. There is space

on the printout to enter specific gravity readings.

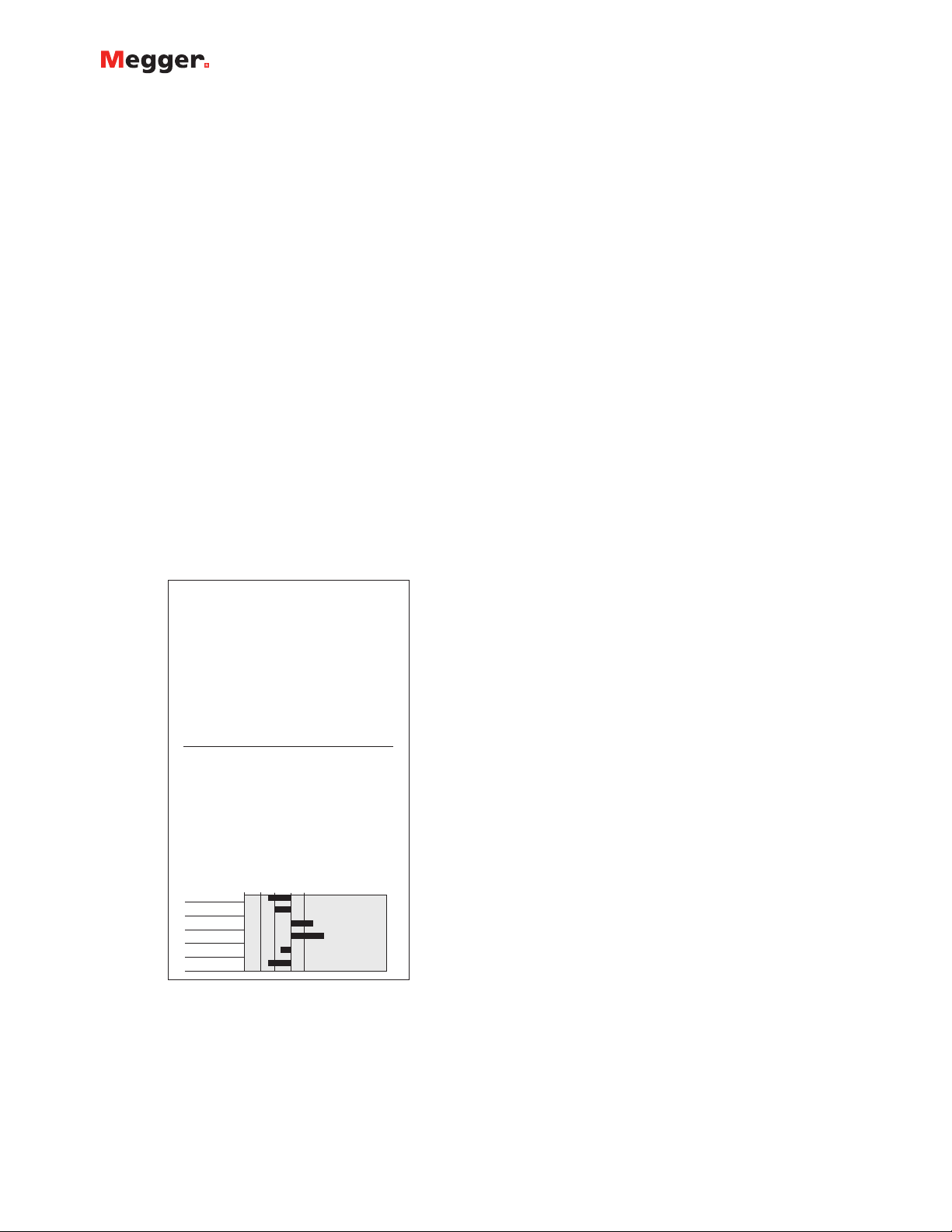

Battery Analysis Report

Location ID:

User ID: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Notes: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Ambient Temp: Pilot Temp:

Ripple Current: .01A Test AC Current: 9.8 A

Multiplier: 1 B/W/F: 11.00 mW/20%/40%

Cell Sp.Gr. Zb mW P/W/F % RS mW Volts DC Time

001 12.09 P 09 0.412 13.52 11:13

002 12.22 P 11 0.407 13.34 11:14

003 14.02 W 27 0.405 13.59 11:14

004 14.54 W 32 0.403 13.48 11:15

005 12.60 P 14 0.042 13.27 11:16

006 12.09 P 09 0.405 13.38 11:17

Minimum Average Maximum

12.09 12.93 14.54

-10 0 10 20 30

001

002

003

004

005

006

Figure 1. Sample battery analysis report

05-SEP-2000

Cell Impedance Summary

Percent Deviation from Average

Transmitter

The transmitter provides the capacitively coupled ac test

signal to avoid transients on the dc buss and applies it to

the cells under test via the source leads. Both the BITE 2

and BITE 2P transmitters have an LCD and built-in receiver

charger, while the BITE 2P transmitter features a built-in

printer.

Data, measured and stored in the receiver can be exported

to a PC. It can also be printed to the BITE 2P transmitter

printer where it can be reviewed. Figure 1 shows a sample

printout of a full battery analysis report.

APPLICATIONS

A battery’s internal impedance increases with decreasing

capacity due to various conditions such as age, ambient

temperature, discharge history, etc. See Figure 2. Both the

BITE 2 and BITE 2P measure impedance values and dc

voltage for lead-acid and nickel-cadmium cells up to 7000

Ah capacity.

Impedance finds electrical path problems due to plate

sulphation, post-seal corrosion, dry-out, and poor intracell

and intercell connections. This information lets the operator

determine maintenance needs such as:

n

Cell replacement criteria based on impedance trends.

n

Jumpering out a cell or two.

n

Clean and/or retorque intercell connectors.

n

Shorten the maintenance interval, etc.

Typical installations that can be tested using the BITE 2

and BITE 2P include:

n

Electrical power generation plants.

n

Substations: utility, railroad, industrial

n

Telecommunications facilities: CO, Wireline, Wireless,

MTSO

n

UPS systems

n

Railroad: Signals and Communications, substation

n

Aircraft power supplies

n

Marine, military

FEATURES AND BENEFITS

n

On-line testing requiring no downtime.

n

Enhanced printing and memory functions.

n

Calculates impedance automatically and stores results

for on-site review.

n

Requires no battery discharge.

n

Receiver has an RS-232 connector for downloading stored

data to a personal computer.

n

Reduced test time: less than 15 seconds for each cell.

n

Measures impedance and dc voltage values for all lead-acid

and nickel-cadmium cells up to 7000 Ah.

n

Stores more than 2000 sets of readings in up to

300 tests.

n

Checks charger condition by measuring ac ripple current.

Page 3

Test Procedure

Circuit

The BITE 2 and BITE 2P work by applying a capacitively

coupled ac test signal across the battery string while online. The receiver and potential probe are placed at the cell

terminals to measure the signal and resulting voltage drop

for each cell/jar. During each measurement, impedance is

calculated following Ohm’s Law, displayed on the LCD and

stored. The instruments also measure, display and record

dc voltage and interconnection (strap) resistance to help

determine the overall condition of the entire battery string’s

electrical path from terminal plate to terminal plate. The

also measure ac ripple current, a charger parameter.

The BITE 2 and BITE 2P receiver stores the readings in

its internal memory. These measurements, along with

other maintenance data such as ambient and pilot cell

temperatures and ac ripple current, assist in determining

the overall condition of battery systems. Figure 3 shows a

typical test setup.

BITE® 2 and BITE 2P

Battery Impedance Test Equipment

Figure 2. Impedance increases with battery age (and weakness)

Interpretation of Readings

Data produced by the BITE 2 and BITE 2P can be

interpreted in several modes: instantaneous, short-term and

long-term time frames. An impedance distribution plot, as

shown in Figure 4, assists in the analysis.

Instantaneous Interpretation

The operator can enter a baseline value from either the

impedance measurements obtained at commissioning

or from the Megger website. The percent changes from

baseline for warning and fail levels are entered, but 20

percent and 40 percent are the default settings. The LCD

on the receiver will display the status of the cell for a few

seconds before proceeding to the next cell. The status of

each cell/jar will be printed on the Battery Analysis Report.

Short-Term Interpretation

Impedance readings for individual cells can be used in

the short term to compare with the average impedance

readings for the entire battery string. Individual cell values

with deviations of more than ±15% for flooded lead-acid,

±35% for VRLA, and 50% for NiCd cells from the battery

string average typically indicate a problem with that cell.

Megger recommends additional investigation of such cells

including a verification of intercell connections and a single

cell load-cycle test.

Long-Term Interpretation

Impedance readings for the entire battery can be used in

the long term to determine replacement criteria. Battery

cell impedance values should be recorded and compared

to previous readings to determine the position of the cell

on the curve of impedance versus cell life as shown in

Figure 2. Based on experience, a variation of ±20% from

baseline for flooded lead-acid, ±40% for VRLA and 50%

for NiCd cells indicate significant change in the electrical

path to warrant serious evaluation of the condition of the

battery system. Megger maintains a database of impedance

values by some manufacturers and battery size/type. For

comparison purposes, this information is available upon

request.

STRAP

CURRENT SOURCE

LEAD

CELL

RED

TRANSMITTER

LINE

VOLTAGE

CURRENT SOURCE

LEAD

BLACK

“CT”

Located

in Battery

Figure 3. A typical test setup

Figure 4. Ascending impedance compared to load test

SPECIFICATIONS

Application

The BITE 2 and BITE 2P test lead-acid and nickel-cadmium cells

up to 7000 Ah.

Maximum Total Voltage at Current Source Leads

275 V dc (larger battery systems can be sectioned to accommodate

this specification)

Transmitter

Supply Voltage

100 to 130 V, 50/60 Hz, 200 VA max

210 to 250 V, 50/60 Hz, 200 VA max

Source Output Current

10 A nominal, 50/60 Hz operation

Page 4

BITE® 2 and BITE 2P

Battery Impedance Test Equipment

Maximum Battery String Test Voltage

275 V dc at source lead terminals (section the battery if >275 Vdc)

Display

Digital LCD meter, 0 to 15 A

BITE 2P Printer

Built-in thermal, with 4.25 in. (110 mm) printing width

Charger

Supply Voltage

100 to 130 V, 50/60 Hz, 14 VA

210 to 250 V, 50/60 Hz, 14 VA

Output

6.50 V dc @ 1.10 A dc charging (max)

9.60 V dc open circuit

Receiver

Accuracy

ac impedance 5% +1 LSD

dc voltage ±(0.5% of rdg +1 LSD)

Precision

Better than 0.5% one sigma

Voltage Range and Resolution

1 to 2.500 V dc, 1 mV resolution

2.5 to 25.00 V dc, 10 mV resolution

Impedance Range and Resolution

0 to 1.000 mΩ, 1µΩ resolution

1 to 10.00 mΩ, 10µΩ resolution

10 to 100.0 mΩ, 0.1mΩ resolution

Setting Time per Reading

3 seconds maximum

Display

LCD, 2 x 16 characters

ORDERING INFORMATION

Supply

4.8 V dc, 800 mAh, quick charge nickel-cadmium battery pack

Battery Pack Life, Full Charge

5 hours continuous

Maximum Cell/Jar Test Voltage

25 V dc between receiver and potential probe

Temperature

Operating: 32 to 105° F (0 to 40° C)

Storage: -5 to 130° F (-20 to 55° C)

Humidity: 20 to 90% RH, noncondensing

Clamp Range

Standard CT

2.0 in. (50 mm) maximum opening

Optional Miniature CT

0.5 in. (12 mm) maximum opening

Optional RopeCT

TM

12 in. (300 mm) opening, approx.

Standards

Conforms to the EMC Directive 2004/108/EC and the

LVD Directive 2006/95/EC

Dimensions

Transmitter

BITE 2: 6.5 H x 14 W x 10.6 D in. (16.5 H x 35.6 W x 27 D cm)

BITE 2P: 7.5 H x 18.5 W x 14.6 D in. (19 H x 47 W x 37 D cm)

Receiver (irregular shape)

7.25 H x 11.25 W x 2 D in. (18 H x 29 W x 5 D cm)

Weight

Transmitter

BITE 2: 17 lb (7.7 kg)

BITE 2P: 18 lb (8.2 kg) alone, 32 lb (14.5 kg) packed

Receiver

1.6 lb (0.7 kg)

Item (Qty) Cat. No.

BITE 2, 110/230 V ac, 50/60 Hz, CE-Marked 246002B

BITE 2P, 110/230 V ac, 50/60 Hz, CE-Marked 246004

Included Accessories

Transmitter for BITE2 P30044-300

Transmitter for BITE2P P30044-100

Receiver P30620-3

Source Leads, 20 ft (6 m), fused 29386-2

Current sensor, 2 in. (50 mm) opening

with 5 ft (1.5 m) lead 33863

CT extension cable, 20 ft (6 m) 33864-2

Communication cable, 6 ft (1.8 m) 35340

Charger cable 35341

Thermal paper 26999

ProActiv™ Battery Database Mgt Software BI-90001

ac line cord, 8 ft (2.5 m) 17032-7

UK

Archcliffe Road, Dover

CT17 9EN England

T +44 (0) 1 304 502101

F +44 (0) 1 304 207342

UKsales@megger.com

UNITED STATES

4271 Bronze Way

Dallas, TX 75237-1019 USA

T 1 800 723 2861 (USA only)

T +1 214 333 3201

F +1 214 331 7399

USsales@megger.com

Item (Qty) Cat. No.

Canvas carrying case for BITE2 218746

Manual for BITE2 and BITE2P AVTM246004

Accessory bag for BITE2 29996

Optional Accessories

Current sensor 0.5 in. (12 mm) opening

with 2.5 ft (0.8 m) lead 246034

Current sensor, RopeCTTM 24 in. (60 cm) length 246050

Current sensor, RopeCTTM 36 in. (90 cm) length 246051

CT extension cable, 20 ft (6 m) 246033

Current source leads, 10 ft (3 m), fused 246147

Current source leads, 30 ft (9.1 m), fused 246347

Current source leads, 40 ft (12.2 m), fused 246447

Bar code wand with preprinted code sheet 246201

Transit case for BITE2 35491

OTHER TECHNICAL SALES OFFICES

Valley Forge USA, College Station

USA, Sydney AUSTRALIA, Täby

SWEDEN, Ontario CANADA, Trappes

FRANCE, Oberursel GERMANY, Aargau

SWITZERLAND, Kingdom of BAHRAIN,

Mumbai INDIA, Johannesburg SOUTH

AFRICA, and Chonburi THAILAND

ISO STATEMENT

Registered to ISO 9001:2000 Cert. no. 10006.01

BITE2_2P_DS_en_V17

www.megger.com

Megger is a registered trademark

Loading...

Loading...