Page 1

BESTplus / BESTemc

BESTplus / BESTemc

B

U

R

S

T

E

S

D

S

U

R

G

E

T

R

A

N

S

I

E

N

T

S

B

U

R

S

T

E

S

D

S

U

R

G

E

T

R

A

N

S

I

E

N

T

S

Best

emc

conducted immunity

test system

Page 2

The need to test

The need to test electronic equipment for

electromagnetic compatibility - in the development

lab and on the production floor - is now widely

recognized as essential for quality assurance. Not

only are the financial service and repair

implications of not doing so too great to risk, but

the manufacturer’s reputation is at stake.

By their very nature, electromagnetic interference

phenomena occur sporadically, making faults caused

by insufficient protection difficult to detect.

The European EMC Directive makes the

manufacturer directly responsible. Commercially

available equipment must not only generate no

electromagnetic interference itself, but must also be

largely immune to such influences. Through the

implementation of these laws, EMC testing has

assumed legal aspects pertaining to product liability.

Other

countries are

on the way to

introducing

similar

regulations.

The BEST family

With the right equipment, the EMC tests

most important for product quality can be

carried out in any electronics laboratory.

Self-certification - as required by the law - is

then little more than a matter of logging the

results.

Schaffner has created the BEST family of

instruments to meet this need, costeffectively. Compliance testing with BEST

not only ensures electromagnetic

compatibility to the required standards, but

also guarantees EMC product quality.

BEST is a range of compact bench

instruments that incorporates all six EMC

pulse test procedures in a single housing.

The instruments incorporate all you need to

test and certify your products, in your own

laboratory and with minimal effort.

Test parameters are user-adjustable within

wide limits and offer generous test margins,

so that BEST is also ideal for product

analysis, or for checking compliance with

in-house EMC quality standards.

• Future proof

BEST already meets foreseeable future standards.

Interfaces are designed for future expansion.

• Cost-effective

BEST is designed to suit the needs - and the budget -

of the smaller manufacturer. In larger laboratories,

it helps to relieve pressure on other

high-end installations.

• An all-in-one solution

BEST is an ideal compact, portable test rig for

on-site investigations.

Page 3

BEST checks interference immunity by

injecting standard-calibrated burst pulses on to

power supply and data lines, and provides

functions to identify weak points.

BEST includes an ergonomically styled ÔpistolÕ

for the simulation of electrostatic discharges.

Like the other test pulses generated by BEST,

test parameters are set up and results are

automatically recorded on the bench-top unit.

BEST checks the equipment being tested with

these energy-rich pulses in a safe, controlled

procedure. Safety connectors and well-designed

interlock circuits protect the operator.

BEST needs no ancillary equipment to perform

these tests. Standard test conditions are

pre-programmed, and functional limits are

easily determined by simply entering particular

test values. For more demanding test scenarios,

an external variac can be used with BEST.

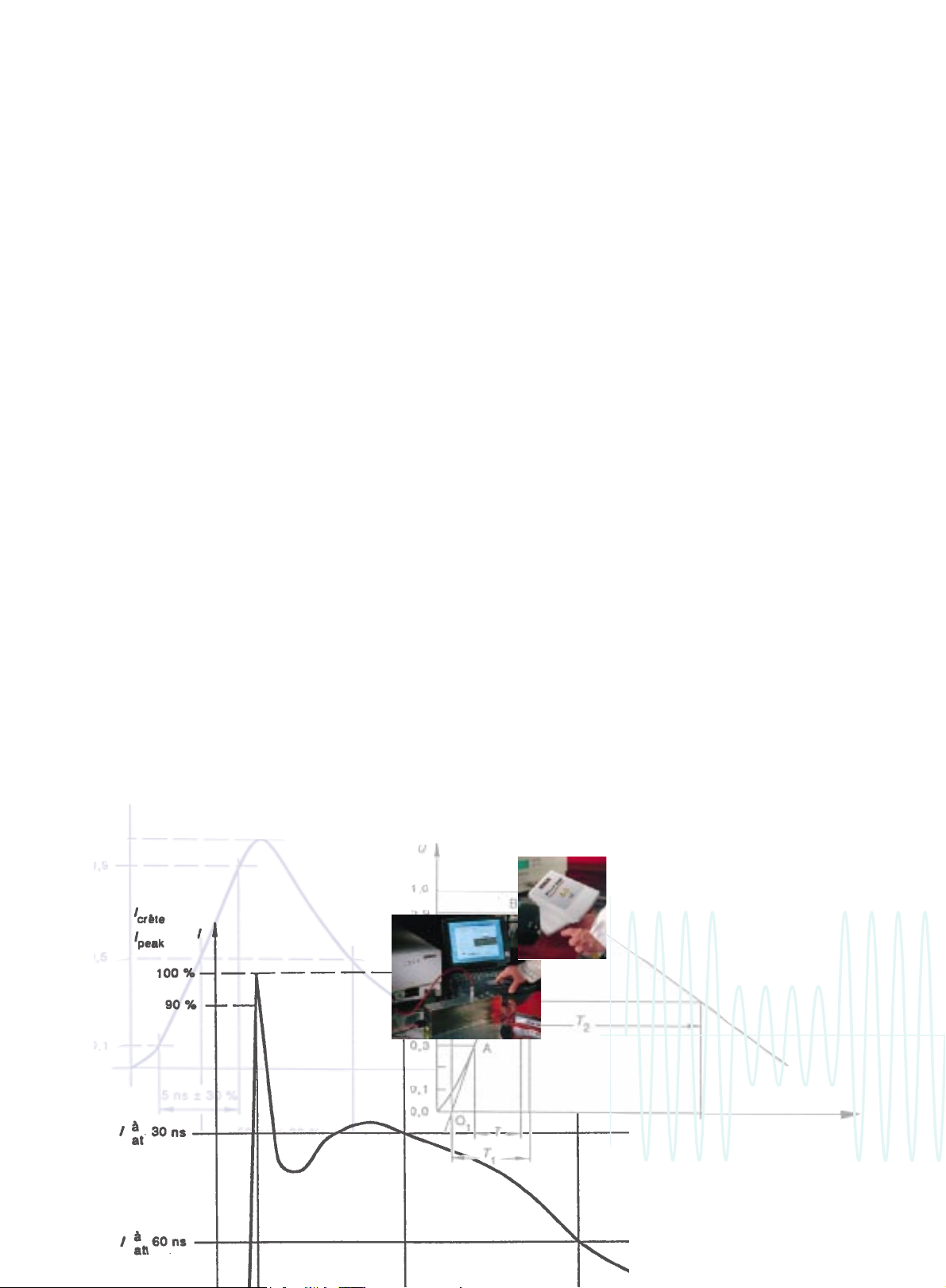

Burst

Burst, or fast transient, pulses are high frequency packets of

spikes that occur during switching operations on power lines

and which spread throughout the supply network. Modern

electronic devices running at ever faster speeds are

vulnerable, particularly if the PCB layout is poor. They tend to

react by functioning incorrectly and/or losing data.

ESD

Electrostatic discharges are familiar as, for example, a small

spark that occurs when a charged person touches a

conductive object. The effect is harmless to the human body,

but can be damaging to microprocessors and logic circuitry.

Surge

Surge pulses take the form of low frequency disturbances

which contain considerable energy. They occur in power

supply networks as a result of a lightning strike or when a

heavy load is switched off, for example. Input circuits and

power supplies for electronic instruments are particularly at

risk from being over-driven or over-loaded.

Transient

Transient power variations occur in the mains supply as,

voltage interruptions or dips, for example. In keeping with

the best engineering practice, and to conform with European

EMC regulations, items of equipment must behave

reasonably in the face of such disruptions.

Page 4

Bestplus

BESTplus meets the test specifications of the

Generic Standard. The system is upgradeable to

meet the higher specification pulse voltage

functions of the Basic Standards, at any time.

Bestemc

BESTemc includes the full range of higher

specification pulse voltage functions according to

the Basic Standards.

Accessories and options

All the models in the BEST range come

complete with a comprehensive set of

accessories as standard, including everything

necessary to set up a standard test rig on

the laboratory bench, or in the field.

Powerful PC control software, also supplied

as standard, features an intuitive multi-lingual

Windows interface, test sequencing and

cataloging capabilities, and an automatic test

report generator.

If the instruments and systems to be

tested contain magnetically sensitive

components then their susceptibility to

disruption caused by mains frequency or

pulsed-magnetic fields must be checked.

Two standard magnetic field antennae each with a

corresponding constant current source suitable for

testing to the generic standards, are offered as

options for BEST. Antennae to other dimensions can

be supplied on request. All these options are

supplied complete with fully integrated firmware and

control software.

Page 5

A complete test system

All the functions of the BEST system including real-time test functions and safety

features - are microprocessor controlled.

Self-test routines check that the generators

are operating properly, and that calibration

values are correct.

The BEST front panel gives a continuous

LC-display of the current parameter settings,

system status and test-in-progress status.

Language is user selectable.

Test parameters for the

Generic Standards are

pre-programmed, and

can be simply called up

at the touch of a button. Custom

test parameters can be keyed in,

and stored to be used again at

any time.

Tests can also be controlled via a PC, using

the standard multi-lingual software supplied,

to give access to a wide range of additional

test management functions. Standard test

parameters are pre-programmed, custom

test specifications can be created, and tests

can be combined into complete test

sequences, which can be saved and re-used

at any time. Test reports suitable for the

Technical File and / or quality assurance

purposes are generated automatically.

A new test concept

The BEST concept is designed to make inhouse testing - for product optimization,

quality assurance, and compliance testing and the process of CE certification, as simple

as possible. That is why every BEST test

system comes complete with a

comprehensive set of accessories, including

ground reference mat, capacitive coupling

clamp, insulating spacers, resistors, earth

cable and much more. You

can be sure you have all you

need to complete the test

process, without any of the

bother of sourcing

components separately.

Interfaces are incorporated so

that the system can be

expanded at a later date, for

three-phase testing, for

example. Combined threephase coupling networks for

burst and surge, and coupling devices for

data lines are available.

The BEST multi-lingual report generator

allows test reports to be printed in English,

French, German or Spanish.

In addition to the comprehensive hardware

and software manual, there is also an easyto-follow guide to EMC standards and

achieving CE certification.

Page 6

A reliable test partner

Schaffner’s manufacturing operations are certified

to the ISO 9000 quality standard, with tight control

over all procedures from material procurement to

final test.

A world-renowned certificated calibration service,

and world-wide network of EMC test and

measurement laboratories demonstrate the

company’s technical competence in the field of test

and measurement. An consultancy service offering

free advice to customers on all aspects of EMC

standards and testing, including help with confirming

which standards apply to a particular product, is

available from your local Schaffner office, or via the

Schaffner web site at

www.schaffner.com

Generic standards:

EN 50082-1 Generic immunity standard -

part 1: residential,

commercial and light

industry

EN 50082-2 Generic immunity standard -

part 2: industrial

environment

Product standards:

EN 50090 Home and building

electronic systems (HBES)

EN 50130 Alarm systems including fire,

intruder and personal alarms

EN 55011 Industrial scientific and

medical (ISM) equipment

(CISPR 11)

EN 55103 Professional audio, video,

audio-visual and

entertainment lighting

control apparatus

EN 55104 Household appliances, tools

and similar apparatus

EN 60601 Medical electrical equipment

EN 60945 Maritime navigation and

radio communication

equipment and systems

EN 60947 Low voltage switchgear and

control gear

EN 61131 Programmable controllers

EN 61800 Adjustable speed electrical

power drive systems

Page 7

TECHNICAL DATA

Burst Pulse form Pulse amplitude Pulse frequency Polarity Pulses/burst Burst period Coupling

BESTplus 5/50ns 200 - 2200V 1 - 100kHz pos/neg 1 - 75 100ms - 99s L➔Ref.GND

N➔Ref.GND

PE➔Ref.GND

L+N➔Ref.GND

Coupling clamp

BESTemc 200 - 4400V

EUT supply: 250V/16Aac, 65V/10Adc.

Surge Pulse form Pulse amplitude Impedance Polarity Pulse repetition Coupling

BESTplus 1.2/50µs 200 - 2200V 2/12W pos/neg 10s min. L➔N

(open-circuit) 600s max. L➔PE / N➔PE

8/20µs L+N➔PE

(short-circuit)

BESTemc 200 - 4400V

EUT supply: 250V/16Aac, 65V/10Adc.

ESD Discharge voltage Pulse rise-time Network Polarity Pulse repetition

BESTplus 8.8kV (air) 0.7 - 1ns 150pF/330W pos/neg Single pulse Pre-settable

6.6kV (contact) repetitive up counter

to 25Hz Remote triggering

BESTemc 16.5kV (air)

9kV (contact)

Power Mains drop-out Voltage dip Phase angle Power up current

quality

BESTplus 10ms - 5s 70%Vn for 10ms - 5s 0 - 359º 500A

BESTemc 40%Vn for 10ms - 5s

EUT supply: 250V/16Aac, 65V/10Adc. Interface for optional external variac.

Magnetic field coil options for:

BESTplus

BESTemc

Power line magnetic fields Pulsed magnetic fields Dimensions

INA 711 Field strength 0.1 to 4A/m Field strength: 100 to 1100A/m with BESTplus 1m x 1m, adjustable in all planes

Frequency 40 to 70Hz 100 to 2200A/m with BESTemc

INA 712 Field strength 0.1 to 40A/m Field strength: 100 to 1100A/m with BESTplus 1m x 1m, adjustable in all planes

Frequency 40 to 70Hz 100 to 2200 A/m with BESTemc

Three-phase extension for

BESTplus

BESTemc

CDN 135 Three phase coupling unit for burst and surge with automatic control from the BEST unit

Power rating: 3 x 440Vac, 50/60Hz, 25A continuous, 30A for 0.5 hour

Page 8

Schaffner EMV AG

CH-4542 Luterbach Switzerland

Tel: +41 32 6816 626 Fax: +41 32 6816 641

www.schaffner.com

Schaffner Beijing Liaison Office

Room 911 Bright China Chang An Building

No. 7 Jianguomennei Dajie

Beijing 100005

China

Tel: [+86] 10 6510 1761

Fax: [+86] 10 6510 1763

Schaffner SA

43 rue Michel Carré

95103 Argenteuil

France

Tel: [+33] 1 34 34 30 60

Fax: [+33] 1 39 47 02 28

Schaffner EMV GmbH

Schoemperlenstrasse 12B

76185 Karlsruhe

Germany

Tel: [+49] 721 56910

Fax: [+49] 721 569110

Schaffner Limited

National Technological Park

Castletroy

Limerick

Ireland

Tel: [+353] 61 332233

Fax: [+353] 61 332584

Schaffner EMC KK

2-31-6 Kamiuma

Setagaya-Ku

Tokyo 154-0011

Japan

Tel: [+81] 3 3418 5822

Fax: [+81] 3 3418 3013

Schaffner EMC Pte Ltd

1200 Depot Road 06–01

Singapore 109675

Tel: [+65] 377 3283

Fax: [+65] 377 3281

Schaffner EMC AB

Turebergstorg 1,6

19186 Sollentuna

Sweden

Tel: [+46] 8 92 11 21

Fax: [+46] 8 92 96 90

Schaffner Altrac AG

Mühlehaldenstrasse 6

8953 Dietikon

Switzerland

Tel: [+41] 1 744 6111

Fax: [+41] 1 744 6161

Schaffner EMC Ltd

Ashville Way

Molly Millar’s Lane

Wokingham RG41 2PL

UK

Tel: [+44] 118 9770070

Fax: [+44] 118 9792969

Schaffner EMC Inc

9B Fadem Road

Springfield NJ 07081

USA

Tel: [+1] 973 379 7778

Fax: [+1] 973 379 1151

Ordering information

BESTplus - 1 Complete package with burst and surge generators up to 2.2kV, power transient

generator, ESD gun for 6.6 / 8.8kV, WINDOWS software, ground plane, data-line

coupling clamp, interface for external variac, test literature, instruction manual and

accessories

BESTplus - 2 As above but without ESD gun

BESTemc - 1 Complete package with burst and surge generators up to 4.4kV, power transient

generator, ESD gun for 9 / 16.5kV, WINDOWS software, ground plane, data-line

coupling clamp, interface for external variac, test literature, instruction manual and

accessories

BESTemc - 2 As above but without ESD gun

INA 711 Magnetic field coil option for power magnetic fields to 4A/m and pulsed magnetic

fields to 1100A/m with BESTplus or 2200A/m with BESTemc

INA 712 Magnetic field coil option for power magnetic fields to 40A/m and pulsed magnetic

fields to 1100 A/m with BESTplus or 2200A/m with BESTemc

INA 715 Upgrade option for BESTplus, burst and surge to 4.4kV, ESD to 9 / 16.5kV

CDN 135 Three-phase extension unit for burst and surge

690 - 499C Urs Uebelhart / February 1999

© 1998 Schaffner EMV. Specifications subject to change

without notice.

All trademarks recognised.

Certified

ISO 9001

supplier

Schaffner is an ISO-registered company.

Its products are designed and manufactured

under the strict quality requirements of

the ISO 9001 standard

Loading...

Loading...