Page 1

ATD-5080

INSTRUCTIONS FOR USE

PLASTIC LEVER PUMP

Congratulations on your purchase of this world class premium construction Pump

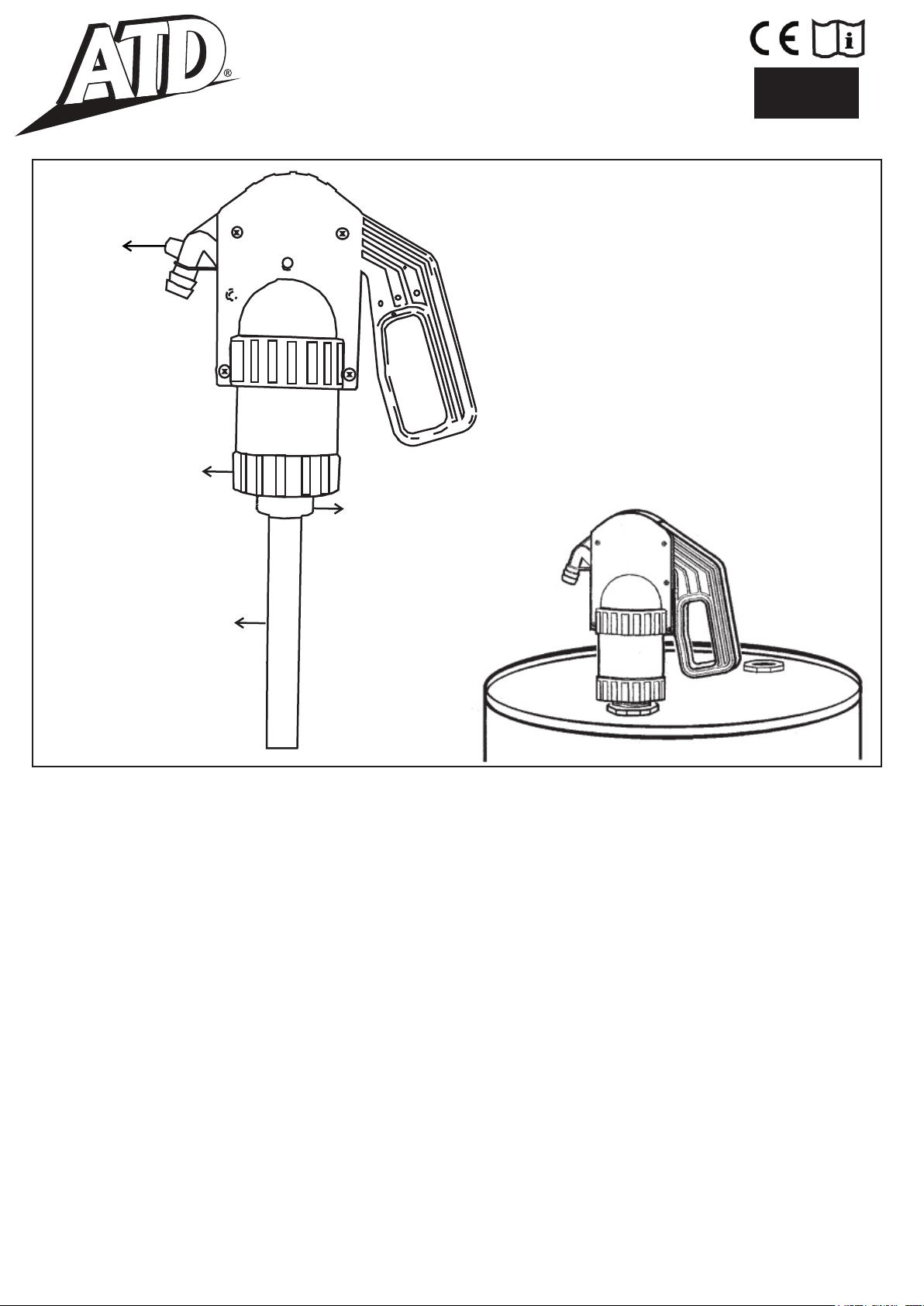

PLP

Air Vent

Cap

Lock Nut

X

X

Suction

Tube

X

X

2” Bung

Adapter

Piece Count

1. Pump Assembly

2. Plastic Suction Tube (in 2 parts)

3. Corrugated Discharge Hose

4. Hose Clip

Features

1. Lever Action Barrel pump, designed specifically for use with high viscosity oils. Pump design makes it

extremely convenient & comfortable to pump thick oils without excessive fatigue

2. Choice of materials used in the pump construction, make it versatile for use with water based media, as well as

select chemicals

3. Built-In 2” Bung Adapter allows the pump to be fixed on Drums with 2” Opening. Pump position can be adjusted

using the Lock Nut incorporated in the pump body

4. Pump outlet is fitted with an Air Vent Cap which when loosened breaks the Siphon action

5. Supplied complete with telescopic suction tube for use with 15- 55 gl ( 50-205 Litre ) drums & 2m x ¾”

Flexible Corrugated discharge hose

6. Delivers 1 Pint (500 ml) per stroke

7. Operating Temperature : -5 to + 45 degree Centigrade

Page 2

Wetted Component

Polyacetal, Polypropylene, Polyethylene, PVC & Viton

Recommended Use

Water-based media, detergents, soaps, antifreeze, windshield washer, Lubricants, Agricultural Chemicals,

Insecticides, Fungicides, Fertilizers & Herbicides, Adblue, Urea, DEF etc.. Pump should only be used with non

Inflammable liquids

Do not use with

Any media not compatible with materials used in the pump construction.

These pumps must never be used for Fuel Transfer or with Thinners, Solvents etc.

Assembly & Pump Operation

1. Pump comes with a 2 part Suction tube. One tube is telescopic in nature & should be used when using the pump

on smaller 5-16 gal. (15-50 litre) drums. When using the pump with 55 gal. (205 litre) drums assemble the other

suction tube also with the telescopic suction tube & extend it fully. Tighten the connections gently so as not to

shear the threads

2. Now screw the Suction tube to the ¾” female threaded opening at the pump inlet.

3. Insert the complete pump assembly (Pump & Suction tube together) into the drum from the 2” threaded opening

on the drum

4. Tighten the 2” Bung Threads on the pump onto the threaded opening on the drum

5. Pump has a Built-in Lock Nut which can be turned & used to position the pump outlet on the drum

6. Connect the Corrugated discharge hose using the Hose Clip onto the Pump Outlet

7. Loosen the Air Vent Cap on the Pump outlet if you wish to manually operate the pump. If Siphon action is desired ,

tighten the cap fully

8. Start operating the pump handle , making sure that the corrugated discharge tube has it's end in the receiving

container

9. Within a few strokes , pump will start dispensing media

10.If Air Vent cap is in the fully closed position, pump will keep dispensing even without operating the pump handle

until the media level in the supply container becomes equal to the media level in the receiving container. Siphon

action can at any time be stopped by opening the air vent cap

11.For best results , pump should be used for pumping only 1 type of media

S1410, Rev B

Loading...

Loading...