Page 1

OWNER’S MANUAL

DUAL HEAT SOLDERING GUN

MODEL NUMBER

ATD - 3740

SAFETY INSTRUCTIONS TO OPERATOR

!

WARNING : Read and understand this owner’s

ma nual before using soldering gun. Unsafe

operation and improper maintenance can cause

burns to bod y or eyes , electric shock, health

issues, damage to the tool , e, or explosion.

!

WARNING : Solder containing lead must n ever be

used for plumbing applications. This soldering gun

is not intended for plumbing connections and, if

used for this application , will likely result in poor

quality plumbing joints.

!

WARNING : Some ATD Soldering Guns are

provided with solder. This solder may contain

metals or chemicals that may be toxic if inhaled.

Do not inhale dust , smoke , or fumes when

operating.

!

WARNING : To avoid injury, do not use tips

containing copper. Use only ATD tips speci

SAFETY INSTRUCTIONS AND MAINTENANCE

1. This appliance has a polarized plug (one blade is wider

than the other). To reduce the risk of electric shock, this

plug is intended to

If the plug does not

If it still does not

modify the plug in any way.

2. Arrange a secure resting place on your worktable where

the tip will never contact a

or the power cord. With a peak temperature of about

1000° F, the tip may remain hot for several minutes after

you release the trigger switch.

3. To reduce the risk of burns, remove excess hot molten

solder from the tip by wiping with a damp cloth, damp

sponge, or solder brush made for that purpose. Never

swing the gun.

in a polarized outlet only one way.

fully in the outlet, reverse the plug.

contact a electrician. Do not

surface, your body,

4. To protect eyes from splatte r, wear safety goggles

meeting requirements of ANSI Z87.1 (shown on safety

goggle package).

5. To reduce the risk of destroying the tool, observe the

20% “On” time duty cycle rating of a soldering gun. This

rating means a maximum of 1 minute of “On” time over

5 minutes total time. Never tie down the trigger switch.

6. To reduce the risk of respirator y, eye, or skin irritation,

keep your head out of the soldering fumes.

7. To reduce the risk of electrical shock,

explosion, work only in surroundings that are dry, and are

free from

8. After use, unplug the power cord and let tip cool down.

Store soldering gun in a dry secure place, out of the

reach of children.

ed.

re, injury, or

ammable materials including vapors and liquids.

Page 2

Assembly

1. Soldering Gun comes complete with solder tip(s).

Operation

Maintenance

Operation

Troubleshooting

2. Loosen screws located on the front of the soldering tool

using a #2 Phillips screwdriver.

3. Insert solder tip into openings and tighten down the screws.

Using Soldering Gun

1. Screws holding tip must always be snug for soldering gun

to function properly. Use a #2 Phillips screwdriver to tighten

screws when necessary. To avoid stripping screws, be

careful not to over-tighten.

2. Clean the surfaces to be soldered together to insure a good

bond. Use a wire brush or sandpaper to remove paint,

varnish, or rust. To remove oil or grease, use alcohol.

!

WARNING : To reduce the risk of re , burns , or

toxic vapors , do not use solvents other than

alcohol for oil or grease removal.

3. Select the proper solder type. Rosin core solder is

recommended for work on electrical items such as PC

boards, radio and TV kits, model railroads, etc. The rosin, or

ux, as it is sometimes called, helps clean the soldering

joint as the solder is being melted and helps in the bonding

process.

Another type of solder is ACID core solde r. Do not use acid

core solder when soldering electrical connections. Damage

to electrical components may result. Acid core solder is

recommended when soldering some types of steel plates

together, but not for electrical connections.

4. For best results, tin the tip of the soldering gun with a

coating of rosin core solder. This is done by cleaning the tip

with steel wool, then pulling the trigger to heat the tip and

then applying a light coating of new solder to the tip. Excess

solder may be removed with a

or damp cloth.

5. When soldering, hold soldering gun tip to the two surfaces

(the “joint”) to be soldered at the same time. Pull trigger to

apply heat to the joint. It takes approximately 12 seconds for

the tip to reach soldering temperature. Apply solder to the

joint, NO T to the TIP , but close to the tip. When the surfaces

are su fciently heated, the solder will ow into the joint. Do

not apply too much solder to the joint. Use just enough to

give strength and a good appearance.

6. Release trigger of gun and set soldering gun in a safe

position to cool.

IMPOR TANT : Remember to use your soldering gun with a

20% duty cycle. Never use it continuously for more than

one minute without letting it cool for 4 minutes. Never tie

down the trigger expecting the tip to remain at peak

temperature for soldering. This will damage the tip and the

remainder of the soldering gun.

solder brush, damp sponge

Taking Care of Your Soldering Gun

!

WARNING : To avoid burns or electrical shock,

alwa ys unplug the soldering gun and all ow to cool

before servicing.

Keep tip screws snug. Periodically inspect the tip screws for

looseness and tighten when necessar y. However , to avoid

stripping screws, do not over-tighten.

Keep the soldering tip clean. Use steel wool or very ne

sandpaper to clean.

Tin tip before using. Refer to Step 4 of

Changing T ip

1. Remove tip after loosening both screws holding tip.

2. Insert new tip and tighten screws. To avoid stripping screws,

do not over tighten.

NOTE: Soldering gun is not serviceable except to replace tips.

Some models are provided with a light. If the light burns out,

replace it with a 2.25V bulb.

The use of non-recommended tips may result in improper tip

temperatures and damage to the gun.

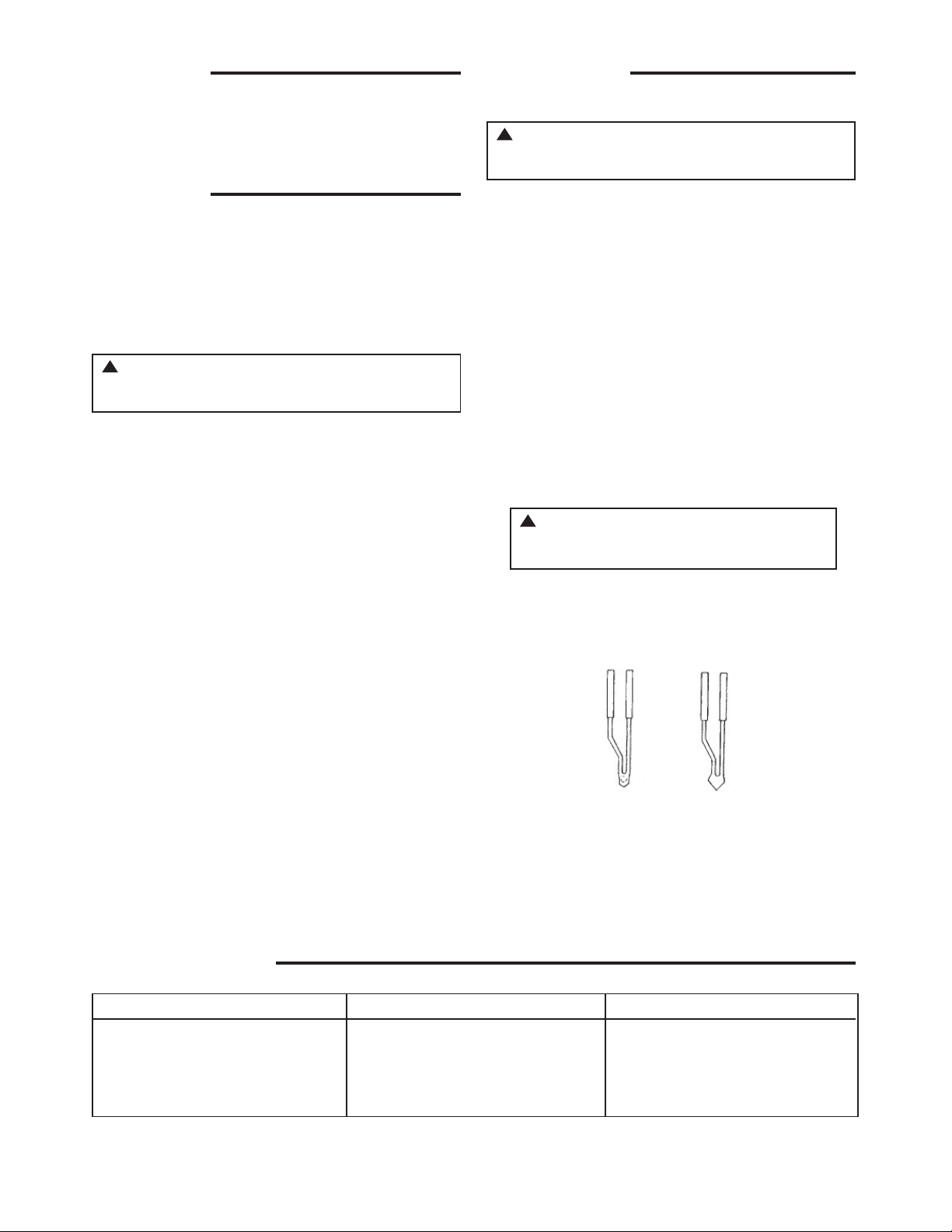

Replacement Tips Available Through Your ATD Tools Supplier

!

WARNING : To reduce the risk of injury or

damage to soldering gun , do not use tips

containing copper. Use only the specied ATD tips.

Your ATD-3740 Soldering Gun

one each of the tips below.

General

Purpose T ip

PRT3740-1

PRT3740-10

Contains

Cutting

Tip

.

Trouble

Tip does not heat although unit is

plugged in and trigger is depressed.

Probable Cause

1. Tip screws are loose.

2. Tip cracked or broken.

3. Tip is dirty.

Action

Unplug gun from power receptacle

1. Tighten tip screws.

2. Replace with new tip.

3. Clean tip with steel wool or ne

sandpaper .

Loading...

Loading...