ATB AQUAmax BASIC, AQUAmax CLASSIC, ATBcontrol 3 Operation And Maintenance Manual

Innovations for clean water

AQUAmax

®

BASIC / CLASSIC

Operation and maintenance manual

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 3 from 40

Contents

General and safety information…………………………… .......................................... 4

Functional description........................................................................................ 6

Control unit ATBcontrol

©

3 ................................................................................... 8

General information on operation.................................................................... 9

Commissioning .............................................................................................. 10

Main level...................................................................................................... 12

Logbook .................................................................................................... 12

Settings..................................................................................................... 13

Service Mode............................................................................................. 15

Manual operation / Info .............................................................................. 16

Date/Time / Language / Error Reset ............................................................ 17

Pre-set Parameters........................................................................................ 18

Current limiting values ................................................................................... 19

Error messages ............................................................................................. 19

UVS

®

............................................................................................................ 19

USB-connection............................................................................................. 20

Control Circuit Board / Fuses.......................................................................... 20

Potential-free Contact .................................................................................... 21

Configuration of the Connection Socket........................................................... 21

Technical Data .............................................................................................. 20

Information on routine maintenance .................................................................... 24

Self-monitoring by the operator .......................................................................... 25

Information on disposal...................................................................................... 26

Rectification of faults ......................................................................................... 27

Important data for fault diagnosis of the electrical units ....................................... 29

Operations diary ................................................................................................ 30

CE documentation / Declaration of performance .................................................. 30

EC Declaration of Conformity ............................................................................. 38

Dear customer,

At this point we would like to thank you for the trust which you have shown with the purchase of

this product.

On the following pages you will find everything necessary about the ioperation and the

maintenance requirements of your AQUAmax

®

small wastewater treatment plant.

Please observe that the maintenance are very important for a good treatment performance.

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 4 from 40

General and Safety Information

With the AQUAmax

®

one is concerned with a technical system which, in combination with a multichamber tank, is employed as small wastewater treatment plant for the aerobic biological treatment

of domestic and comparable wastewater of up to 75 PE from single or several buildings.

Dimensioning, design and operation are to take place up to 50 PE in accordance with EN 12566-3.

With employment in accordance with regulations no hazards whatsoever emanate from the plant. If

the AQUAmax

®

is used for other purposes without the explicit approval of ATB WATER GmbH

and/or the following safety information is ignored, this can lead to the hazarding or injury of

persons and to malfunctions or defects in the plant. In this case any liability is excluded,

Modifications to the plant or unauthorized conversion is not permitted.

The AQUAmax

®

and accessories are not intended to be used by persons (including children) with

limited physical, sensory or mental capabilities or due to a lack of experience and/or knowledge,

unless they are supervised by or receive instruction from a person responsible for their safety, as

to how the AQUAmax

®

and accessories are to be used. Children are to be supervised in order to

ensure that they do not play with them.

Before use the AQUAmax

®

is to be installed correctly and in agreement with the installation

instructions. Installation instructions, operating and maintenance instructions are to be read

thoroughly and the instructions included therein are to be followed implicitly.

With assembly and installation, commissioning and operation as well as, if required,

decommissioning, national standard specifications and regulations are to be complied with. All

tasks may be carried out by trained and qualified specialists with appropriate certificate of technical

qualification. The operator is to be instructed by the fitter.

With the connection of the control system the national applicable regulations and the details on the

type plate are to be complied with (mains voltage, frequency etc.). The equipment is to be operated

on a network which includes a protective earth conductor (PE). Attention is to be paid to correct

phase connection (even with plug-in design)! The connection to the mains must take place by

means of separate fusing and residual current protective circuit breaker. Before commissioning,

the correct function of the electrical protective measures must be checked!

The installation work is to be carried out by qualified electricians only. With work on the equipment

fundamentally the mains plug is to be disconnected. A separation or extension of the cable is not

permitted. The electrical connection data is to be taken from the type plate on the equipment.

Operate no equipment which has a damaged connector/connection cable or plug, which indicates

a malfunction, has been dropped or has been damaged in any way.

With all maintenance and repair work the plant is to be disconnected from the mains. The

AQUAmax

®

can be removed easily from the tank. If the plant is to be climbed into, this may take

place only with the presence of a second person (this is fundamental!). Particular care is to be

taken. The applicable accident prevention regulations and rules of technology are to be complied

with.

In the versions with submersible aerator the AQUAmax

®

feeds the required air to the wastewater

through a rapidly rotating propeller. Never work in the vicinity of the aerator as long as the

AQUAmax

®

is connected with the mains. Danger of injury!

The correct function can only be guaranteed with the employment of original spare parts or spare

parts approved by ATB. Before commissioning, all points of the operating instructions are to be

checked. Keep these instructions readily to hand at all times!

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 5 from 40

Explanation of the warning notices used:

Attention! Danger due to electrical voltage!

Rotating parts. Danger of crushing and being drawn into the area of the submersible aerator!

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 6 from 40

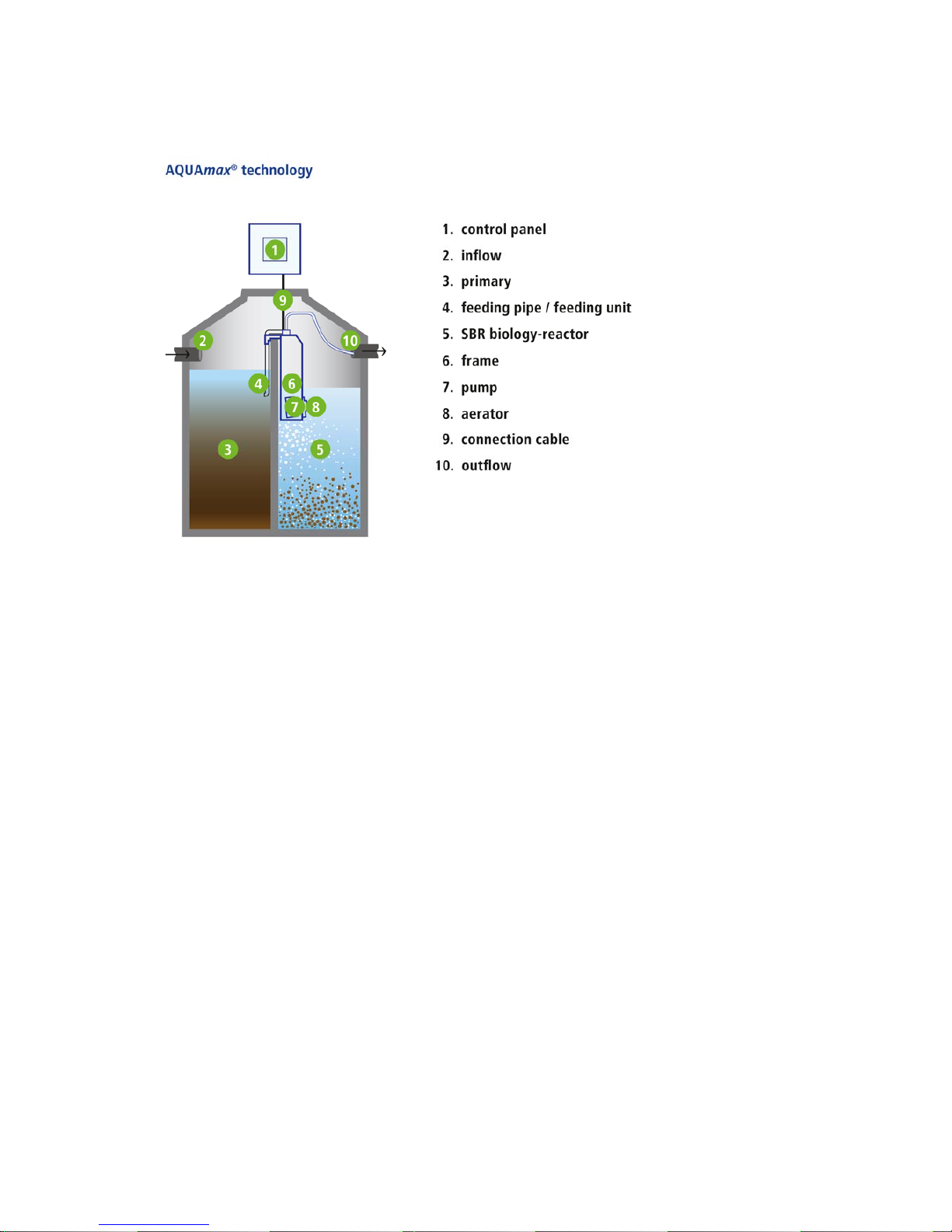

Functional Description

The wastewater treatment plant works according to the activated sludge principle using the

retention process (single tank or SBR plant). With this, the contaminants from the wastewater are

taken up by suspended micro-organisms (activated sludge) and converted into biomass.

The wastewater first reaches the coarse interceptor. Every 2 hours – according to the principle of a

communicating pipe and with the aid of an excess sludge pump – the retained wastewater is fed

into the aeration stage. The aeration takes place intermittently via a submersible motor aerator or

with a compressor and membrane tube diffusers on the tank bottom (CLASSIC ZB).

After 6 hours the aeration phase ends and the settling phase begins.

After 2 hours settling time the treated wastewater is pumped out using the clarified water pump.

The switch-off point is determined via a float switch. If, as a result of a pump defect, this minimum

water level is not achieved an alarm is triggered. After ca. 8 hours, with the end of the clarified

water removal, the cycle is ended and a new one begins.

The control unit can be matched to the respective requirement case. With commissioning the plant

is set to the maximum number of persons connected. A modification of this setting is not required

with short-term over or underloading.

The plant achieves its full treatment performance after a run-up period of ca. one month. With more

extreme underloading or temperatures under 12° C it can also take longer until the biology has

developed completely. In this case it is recommended to seed using activated sludge in order to

accelerate matters.

With the AQUAmax

®

BASIC charging, removal of excess sludge and the drawing off of clarified

water take place using only one pump. The water streams with this are fed into the individual areas

using a patented hydraulic system.

*alternatively membrane tube diffuser on the tank bottom

*

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 7 from 40

Holiday / energy-saving operation

If, over a period of more than 4 hours, no wastewater flows into the plant, then the system switches

automatically into the energy-saving holiday operation. The aeration time is reduced to the point

that the micro-organisms just have sufficient oxygen available. With normal loading the plant

switches back into the operating mode set.

Sampling

As the pumping out process is of a short duration only, the treated water is collected into a suitable

container in the filtering tank (accessory: 1.5 l sampling bottle). The container is mounted in the

vicinity of the cover and is thus easily accessible from above.

Alternatively a container can be deployed in a separate sampling shaft.

Installation and dimensioning

Dimensioning and statutory installation conditions are described in more detail in the German

National General Technical Approval.

Operation and maintenance

Small wastewater treatment plants must be checked by the operator at certain intervals as well as

being serviced twice a year by a specialist. Both are important for a correct operation of the plant.

The sludge removal of the primary settling stage takes place, depending on utilisation, once a year

or as required.

Further details on this can be taken from the corresponding chapter.

Application possibilities

The AQUAmax

®

is conceived for the treatment of domestic wastewater. The following may not be

fed to the small wastewater treatment: commercial/trade wastewater (insofar as it is not

comparable with domestic), infiltration water (e.g. drainage water), cooling water, runoff water from

swimming pools, precipitation water.

Technical data

The AQUAmax

®

consists of the following electrical units:

• 1 (BASIC) or 2 submersible pump(s)

• 1 or 2 submersible motor aerator(s)

or compressor(s)

• 1 float switch (BASIC and CLASSIC 1-16

integrated)

• 1 control unit

The units are designed for 230V, 50 Hz.

In addition, the AQUAmax

®

consists of a carrier frame, pipelines and hoses.

The electrical components are subjected to systematic wear. In individual cases these components

must be exchanged after 2 years. The service life of the units, from experience, lies between 5 and

10 years.

Treatment performance

The AQUAmax

®

meets the following limiting values (with standard conditions and correct

operation):

• BOD

5

: 20 mg/l

• COD: 90 mg/l

• NH4N (>12°C): 10 mg/l

• N

tot

: 25 mg/l (>12°C)

Modular system

In combination with the control unit proControl

©

the AQUAmax® BASIC or AQUAmax

®

CLASSIC

forms the basic framework for the phosphate removal and UV disinfection (CLASSIC only).

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 8 from 40

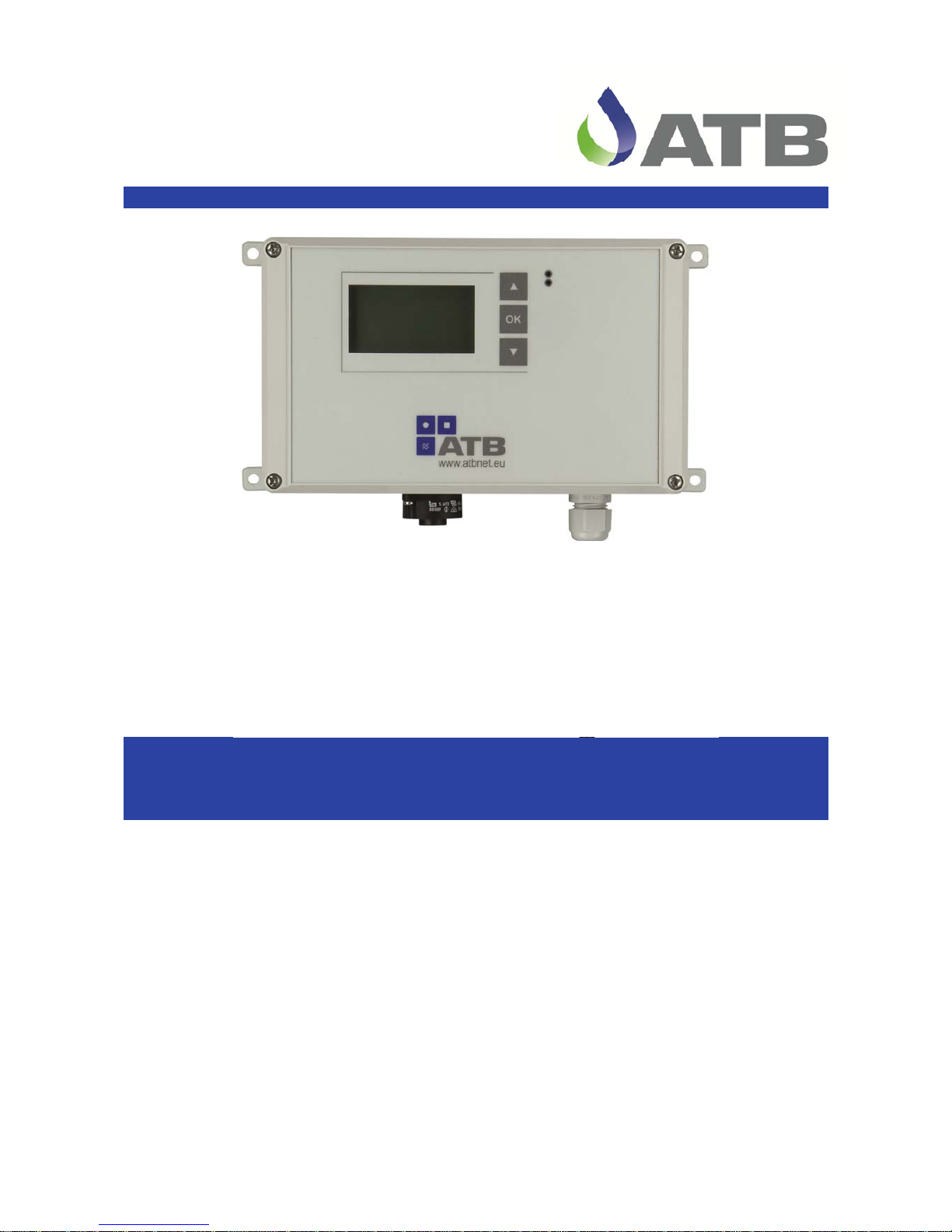

Control unit ATBcontrol© 3

Control unit for the activation of small wastewater treatment plants of the types AQUAmax

®

BASIC

/ CLASSIC and AQUAPRIMO

General and safety information

With intended employment of the equipment no hazards whatsoever emanate from the unit.

National applicable regulations and technical data are to be observed.

Should the ATBcontrol

©

3 be used for other purposes without the express approval of ATB WATER

GmbH and/or if the following safety information is disregarded, this can lead to malfunction of or

defects in the plant. In this case any liability is ruled out.

Modifications to the unit are not permitted and lead to the loss of all claims under warranty.

Do not operate any unit which indicates malfunctions, has been dropped or is damaged in any

way.

Features

• Microprocessor controlled

• USB connection for data readout and input

• Splash water protected. Conditionally suitable for outside areas (IP54)

• Wall mounting

• Voltage failure detection system (UVS

®

)

• Potential-free contact for an additional alarm facility

• Simple and rapid operation

• Times for all parameters completely pre-programmed

• Automatic run-in phase with suppression of excess sludge removal

• Parameter settings freely selectable

• Alarm interval

• Alarm volume adjustable

• Deployable for AQUAmax

®

BASIC / CLASSIC and AQUAPRIMO

• Plug-in

• Winter operation and sludge removal mode for the reduction of the aeration times

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 9 from 40

General information on operation

The operation of the control unit takes place via three short-stroke keys. By pressing a key the

display illumination is switched on (lapses if no key is operated within 5 minutes).

Key functions:

↑↓ Scroll upwards or downwards / menu selection

OK Transition of cursor to the character, which is to be changed / value input is saved /

selection of menu point / menu setback.

With temperatures below 0°C a severely limited function of the LC display is to be anticipated.

The ATBcontrol

©

3 is supplied as plug-in variant. Cabling on site is dispensed with.

All tasks, which nevertheless require an opening of the control unit, are to be carried out by

a qualified electrician!

ATTENTION! Before opening the ATBcontrol© 3 and/or the connection box it/they

must be disconnected from the mains supply. Work on opened units may be

carried out exclusively by qualified electricians! Pay attention to phase-correct

connection (even with plug-in design)!

As you are concerned with an electrical plant with submerged motor units, a

separate B16 fuse and a (separate) upstream 30 mA ELCB (earth leakage circuit

breaker) is absolutely essential!

Attention is to be paid to correct laying of the protective earth conductor up to the

earthing of the building.

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 10 from 40

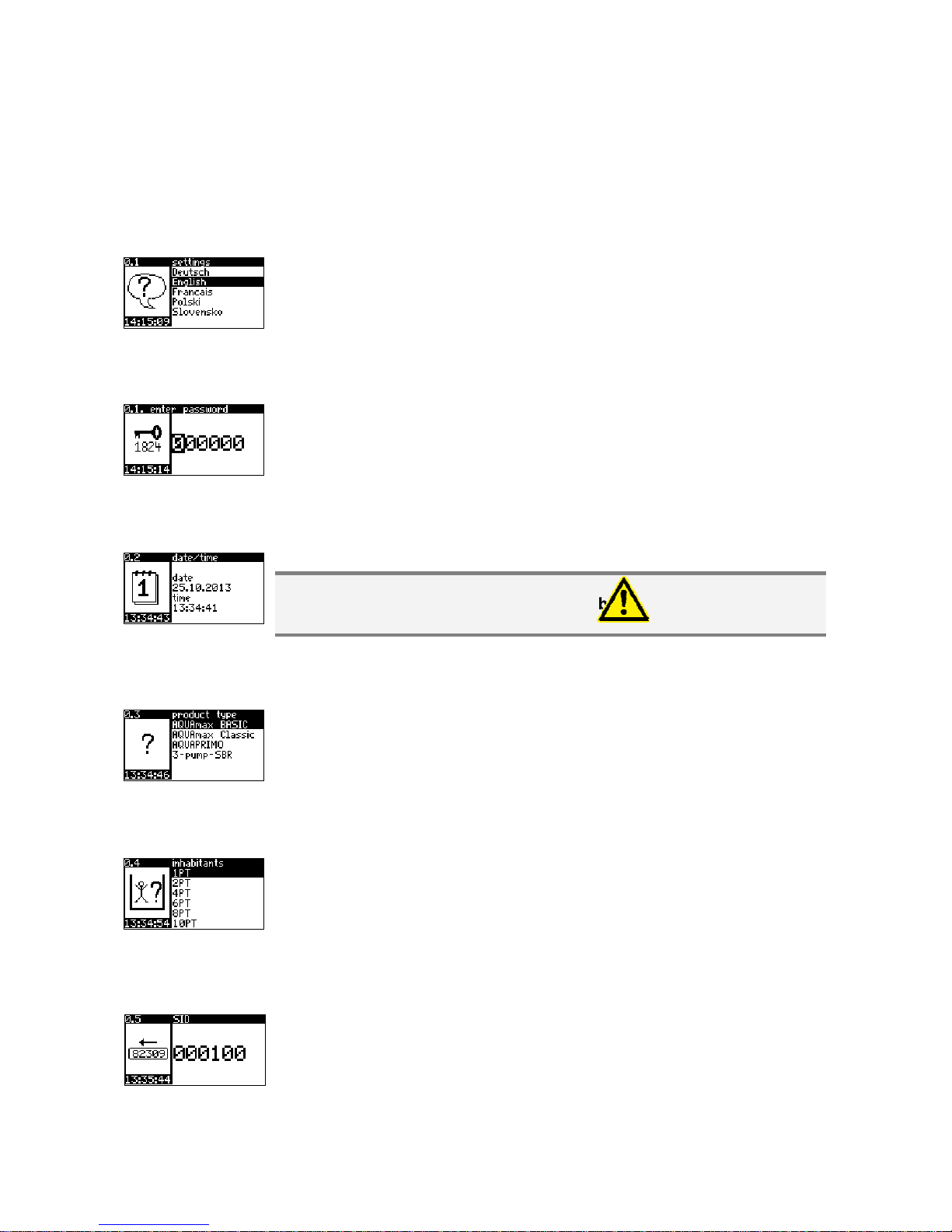

Commissioning

With first commissioning basic settings and tests are carried out. Please ensure that all information

for this is available. With input of the plant values all important parameters are pre-set. However,

we recommend that, following commissioning, the parameters are again checked under

Settings, as false values can, inter alia, lead to an increased power consumption.

In the Service Mode you have the possibility later of undertaking modifications.

Language selection

Enter language you need.

Password input

Please enter the six-figure code number.

Date and time

Enter the date and time.

Important for the correct entries in the logbook

Selection of the plant type

Select between BASIC, CLASSIC or AQUAPRIMO.

Number of inhabitants

Select the connected PT.

The settings belonging to the number of inhabitants are carried out

automatically.

Serial number

Enter the serial number, which is located on the frame of the AQUAmax

®

(not the serial number of the control unit), here. Please ensure that the serial

number is entered right-aligned, in order that leading zeros result.

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 11 from 40

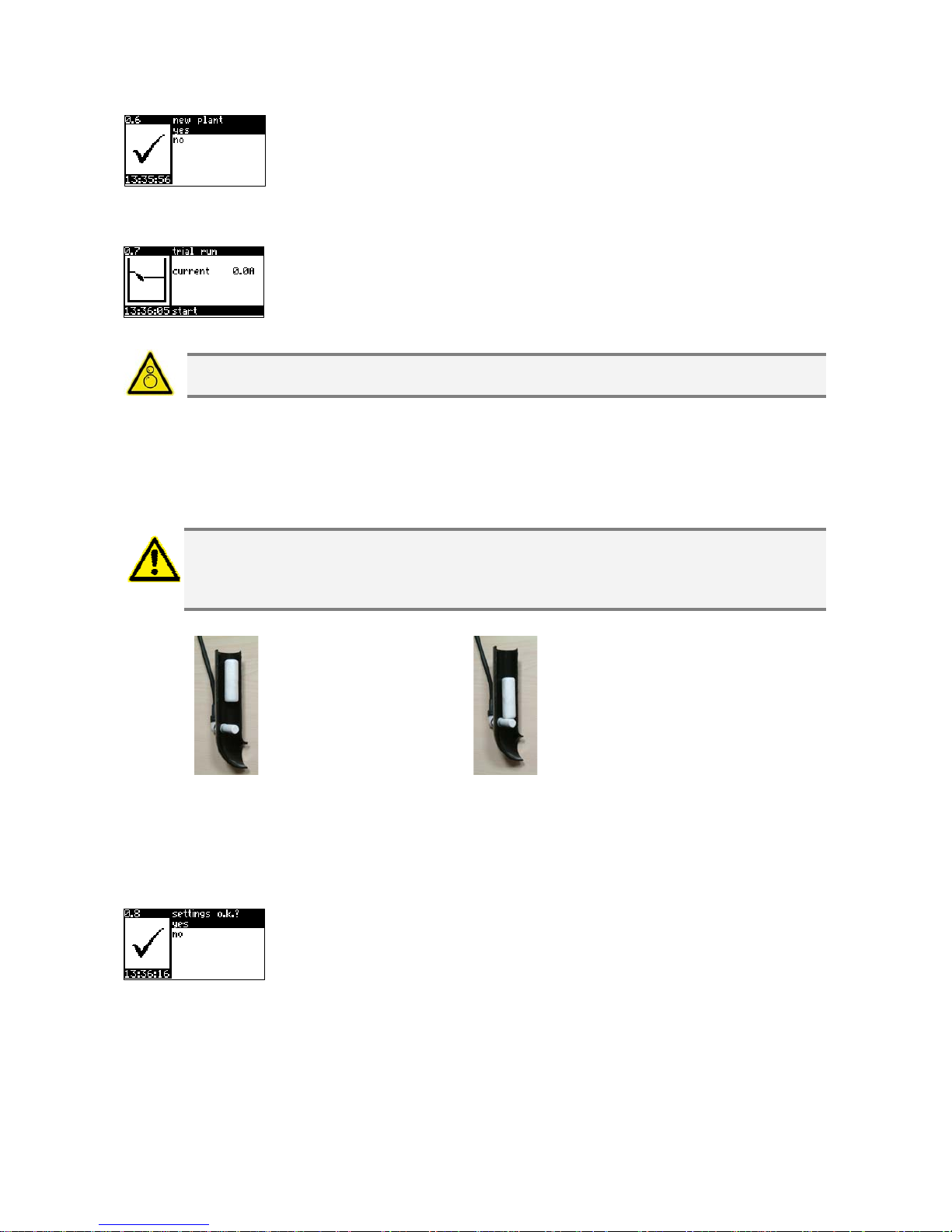

New plant?

With yes the sludge return feed is suppressed for half a year (run-in phase).

Test run

In test run operation the current float level and the current power input are

indicated. Pressing OK carries out the test run.

With this make absolutely sure that no one is working in the danger area of the

running submerged aerator!

The individual units are taken into operation for 4 seconds and are checked for overload and/or

underload. If the minimum permitted value is undercut or the maximum permitted value is

exceeded a warning signal results.

By manual switching of the float switch (BASIC / CLASSIC: submerging in or removing from the

water) the test run can be repeated and concluded.

AQUAmax® BASIC and CLASSIC are equipped with the AQUAswitch

©

. With this you are

concerned with a reed contact switch, which is integrated in the air intake line. The actual

float body cannot be seen from outside. For switching, the AQUAmax

®

has to be

submerged or removed or tilted.

The test run can be interrupted through OK.

Saving of the parameters

Have you made an incorrect input? By selecting no and OK the

commissioning can be repeated.

If the inputs are correct, confirm with yes and OK.

Float at the top =

Contact closed

Float at the bottom =

contact open

Operation and maintenance manual AQUAmax® BASIC/CLASSIC

ATB WATER GmbH, Südstraße 2, D-32457 Porta Westfalica, www.atbwater.com /

Art.-No.: 9060 0210 / Status: 30.01.2019 / Page 12 from 40

Info indication / Current phase

A switchover to info indication now takes place. Indicated is the plant type,

the selected PT number, the software version and serial number of the

wastewater treatment plant type.

With this commissioning is completed. Should in the course of time a

necessity for an amendment to the settings arise, then the specialists have

the possibility of undertaking this in the Service Mode.

The current phase is indicated after ca. 5 minutes. By pressing ↑↓ you,

however, have the possibility of changing over again to info indication or to

the main level.

The indication of the current phase informs you about the current status of

the wastewater treatment plant. Indicated are the operating hours of the individual units, the

current cycle phase and its duration as well as the time. In the case of malfunction, in addition, the

fault which has occurred is indicated. By a single pressing of any key the background lighting is

activated lapses 5 minutes after the last operation of a key).

Main Level

In the main level you have the possibility, using OK, ↑↓ and OK again, of

accessing various sub-menus, which enables the acquisition of further

information, amendment of settings or moving into manual operation.

You leave the main level through ↑↓ until the point Return and OK.

Logbook

All relevant errors, run times, events and messages are lodged in the

logbook.

You access the individual points using ↑↓ and OK.

Errors

Recording of the error messages which have

arisen (max. 1000). An explanation of the

indicated messages can be found in the appendix.

Return using OK.

Run times

You can have the run times

shown in a weekly summary

and over the complete

operating time.

Loading...

Loading...