Installation & Servicing Instructions

3G.51.82.05 / 07.17 Changes reserved. E.& O.

ш

These instructions are to be retained by the user.

Explanation of the Control Panel & Buttons

Contents

| 1 | Introduction4 | ||||||

|---|---|---|---|---|---|---|---|

| 2 | Rules & Regulations (Symbols)5 | ||||||

| 3 | Techn | ical specifications | 7 | ||||

| 4 | Dimensions | ||||||

| 5 | Delivery package | ||||||

| 6 | Boiler | description | 9 | ||||

| 7 | Boiler | photo components list | 10 | ||||

| 8 | Moun | ting boiler frame | .11 | ||||

| • | 8.1 | Wall frame | .12 | ||||

| 9 | Conne | ecting boiler | 13 | ||||

| 9.1 | 13 | ||||||

| 9.2 | 14 | ||||||

| 9.3 | Water quality | 14 | |||||

| 9.4 | Healing systems with plastic pipes | 10 | |||||

| 9.5 | Netural gas connection (NC) | 10 | |||||

| 9.5.1 | Propage das connection (IPC) | 16 | |||||

| 9.5.2 | House pressure regulator | 17 | |||||

| 9.5.5 | Demensioning of the low pressure gas line | 17 | |||||

| 9.5.4 | De-aerating the LPG tank | 17 | |||||

| 9.6.0 | External DHW cylinder | 18 | |||||

| 9.7 | Condensation drain nine | 21 | |||||

| 9.8 | Flue das exhaust system | 25 | |||||

| 981 | Flue terminal locations | 26 | |||||

| 9.8.2 | Dimensioning of the flue gas and air intake duct | 29 | |||||

| 9.9 | Fitting the boiler onto the boiler frame | 31 | |||||

| 10 | Electr | ical connection | 33 | ||||

| 10.1 | One controller, OpenTherm and BUS | 34 | |||||

| 10.2 | Room thermostat volt free connection | 34 | |||||

| 10.3 | ATAG Central Heating volt free timer connection | 34 | |||||

| 10.4 | ATAG Hot Water volt free timer connection | 34 | |||||

| 10.5 | DHW sensor connection | 34 | |||||

| 10.6 | ATAG Outside Sensor | 34 | |||||

| 10.7 | 230V Control block (230V live output) | 34 | |||||

| 10.8 | 230V Control block (SwL Switched live) | 34 | |||||

| 10.9 | Electrical diagram | 35 | |||||

| 11 | Filling | system | 36 | ||||

| 12 | Boller | Controls | 37 | ||||

| 10 | 12.1 | Controls and explanation of the functions | 38 | ||||

| 13 |

39

11 |

||||||

| 10.1 | Deremeter chapter | 41 | |||||

| 11 | IS.Z | ra the boiler | 41 | ||||

| 14 | Comn | ng the bollet | 42 | ||||

| 10 | 15 1 | 40 | |||||

| 15.1 | Checking the OO 2 | 4 7 | |||||

| 15.2 | CO and combustion checks | 48 | |||||

| 16 | Routir | ne servicina | 50 | ||||

| 16.1 | Component replacement | .53 | |||||

| 16.2 | User's instructions | .54 | |||||

| 16.3 | Warranty | 54 | |||||

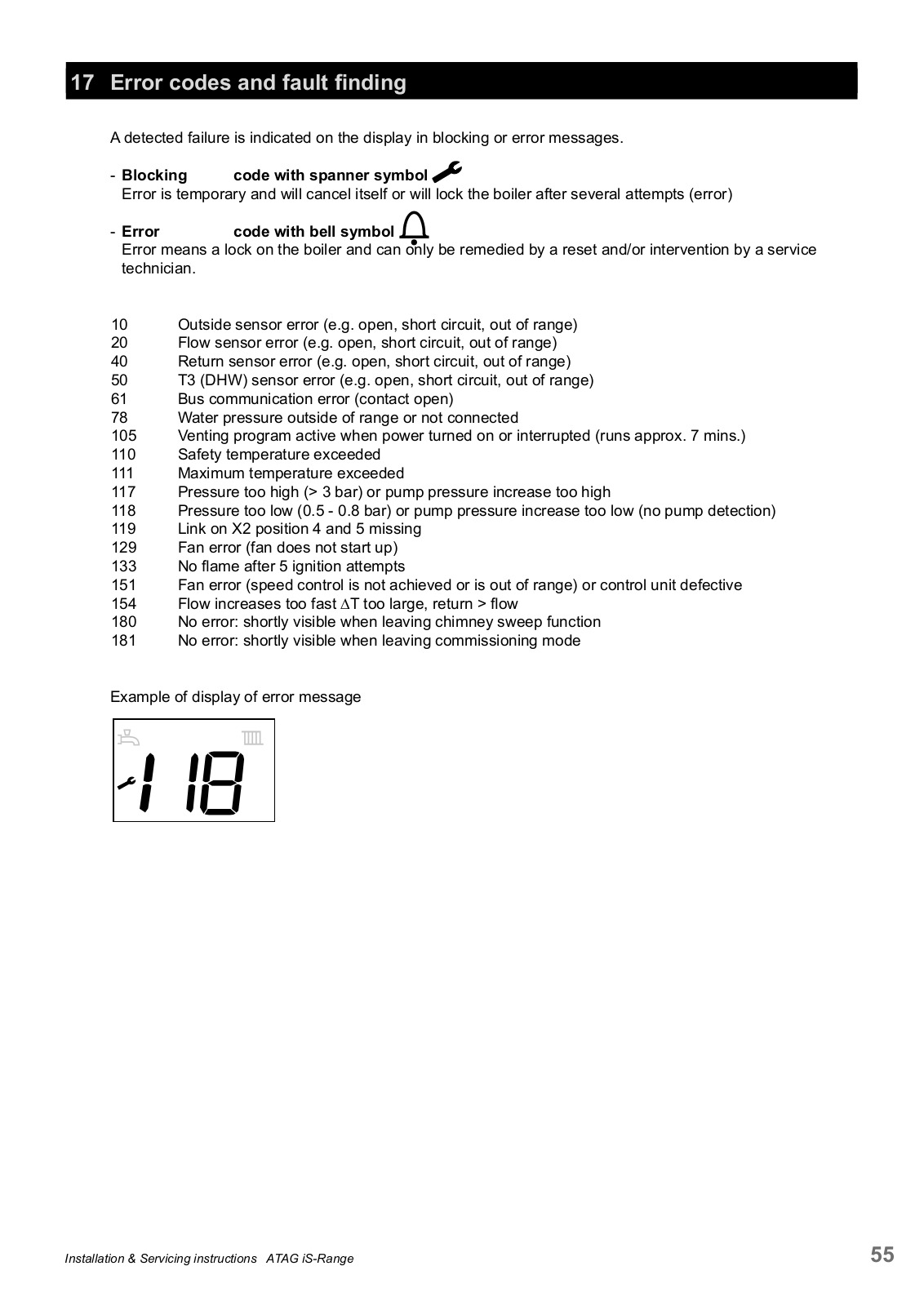

| 17 | Error | codes and fault finding | 55 | ||||

| - • | |||||||

| Ann | ex A | System water additives | 56 | ||||

| Ann | ex B | Declaration of conformity | 57 | ||||

| Ann | ex C | Short parts list | 58 | ||||

Mork on the installation should only be carried out by qualified personnel with calibrated equipment and appropriate tools.

1 Introduction

These instructions describe the functioning, installation, use and primary maintenance of ATAG central heating boilers for the United Kingdom.

These instructions are intended for the use of Gas Safe registed installers in connection with the installation and putting into operation of ATAG boilers. It is advisable to read these instructions thoroughly, well in advance of installation. Separate instructions for use are supplied with the boiler for users of ATAG central heating boilers. ATAG is not liable for the consequences of mistakes or shortcomings which have found their way into the installation instructions or user's manual. Further, ATAG reserves the right to alter its products without prior notification.

When delivering the boiler, give the customer clear instructions concerning its use; present the customer with the user's manual and warranty card.

Each boiler is fitted with an identification plate. Consult the details on this plate to verify whether the boiler is compliant with its intended location, e.g.: gas type, power source and exhaust classification.

On completion of the installation the installer or commissioning engineer must fill out and complete the Benchmark Commissioning Checklist found on page 62 of this manual and hand this to the customer for future record keeping. The Benchmark Service Record must also be completed by the service agent following each service call, and return to the customer.

The following regulations apply to installation of ATAG central heating boilers:

Legislation and Regulations.

Gas Safety (Installation and Use). All gas appliances must by law, be installed by a competent person, eg. Members of Gas Safe Register and in accordance with the current Gas Safety Regulation. Failure to install appliance correctly could lead to prosecution.

All Gas Safe registered installers carry a Gas Safe ID card and have a registration number. You can call Gas Safe Register directly on 0800 408 5577.

In addition to the above regulations this appliance must be installed in compliance with the current IEE Regulations and Building Regulations. Regulations and bye laws of the Local Water Authority and the Current Health and Safety Regulation.

The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance

with the manufacturer's instructions by competent persons and that it meets the

requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

The current Electricity at Work Regulation must be complied with and also be in accordance with the relevant and current editions of the British Standards.

The ATAG iS boiler is a certified appliance and must not be modified or installed in any way contrary to this Installation Manual. Manufacturers instructions must not be taken, in any way, as overriding statutory obligations.

The ATAG iS boiler is a central heating boiler with an integrated hot water function. The boiler must be connected according to these instructions and all installation norms in respect of the part of the boiler to be connected.

The appliance is not to be used by children or persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction.

Children being supervised not to play with the appliance.

Observe the following rules of safety:

- All work on the boiler must take place in a dry environment.

- ATAG boilers may never be in operation without their housing, except in connection with maintenance or adjustments (see Chapter 15 and 16).

- Never allow electrical or electronic components to come into contact with water.

Carry out the following tasks in connection with maintenance, etc. to an already-installed boiler:

- Shut down all programs

- Close the gas isolation valve

- Shut down the 230V power supply

See chapter 15 and 16 for further instructions.

Take note of the following when maintenance or adjustments are needed:

- The boiler must be able to function during these activities; for this reason, the boiler's 230V power supply, gas pressure and water pressure must be maintained. Ensure that there is not a source of potential danger during these activities.

Following maintenance or other activities; always check the installation of all parts through which gas flows (using leak detection spray).

The following (safety) symbols may be encountered in these installation instructions and on the boiler (packaging):

Protect packaging and/or contents from damage as a result of insufficient care taken during

Boiler must be stored away from frost.

transport. Protect the boiler from weather conditions during transport and storage whilst still in its packaging.

If and how to clamp when using transport trucks with clamp equipment.

If and how to transport when using a rolling jack.

The whole packaging is made of recycled materials and can be recycled again.

Transport and place the boiler in its packaging in this position.

Do not to step on or stand on the package.

An assembly or dismantling must be carried out.

Pay extra attention in connection with a particular operation.

Useful tip or advice

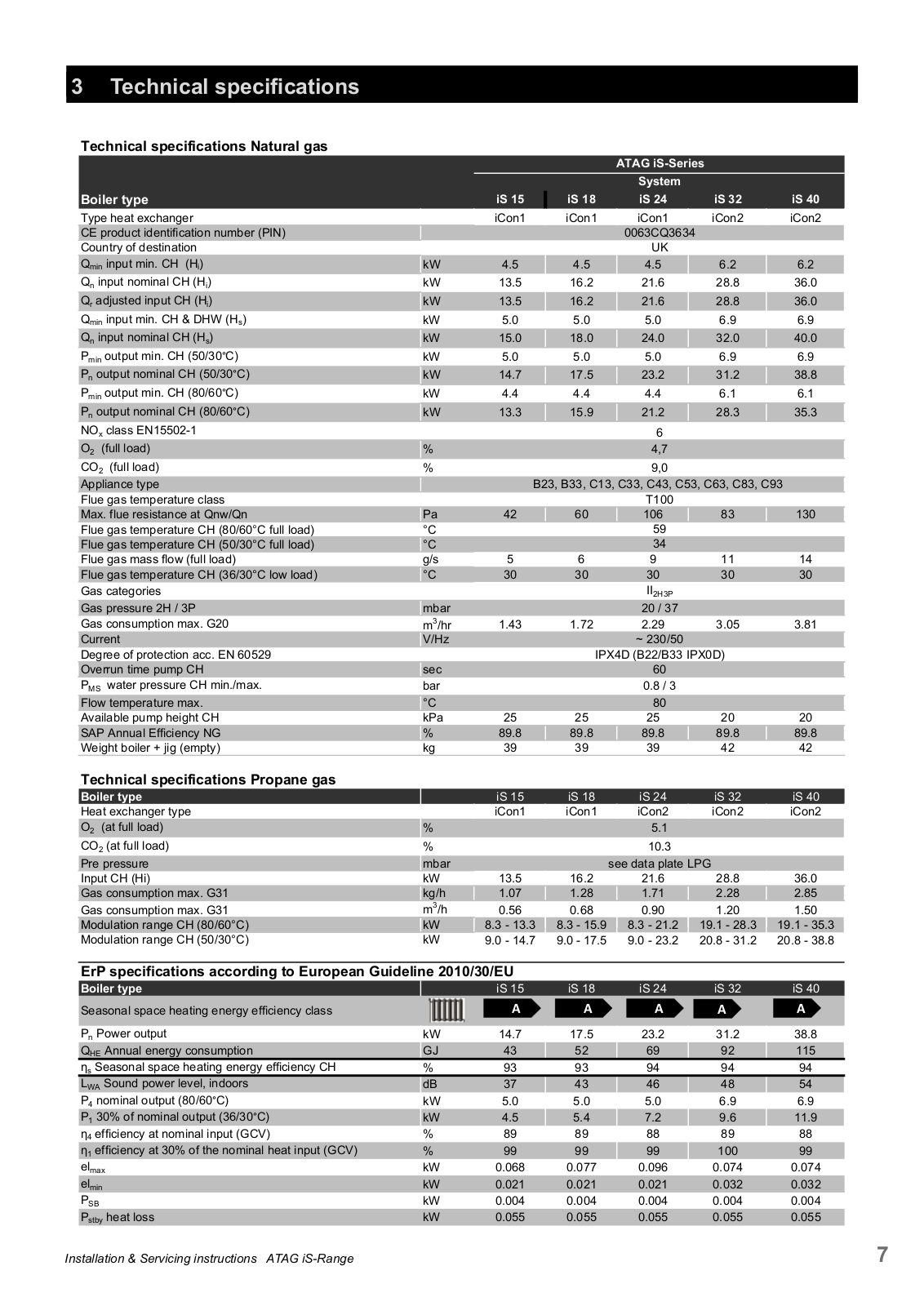

Technical specifications Natural gas

| System Boiler type IS 15 IS 18 IS 24 IS 32 IS 40 Type heat exchanger ICon1 ICon2 < | ATAG iS-Seri | es | |||||

|---|---|---|---|---|---|---|---|

| Boller type IS 15 IS 16 IS 18 IS 24 IS 32 IS 40 Type heat exchanger iCon1 iCon2< | System | ||||||

| Type heat exchanger iCon1 iCon2 iCon2 GE product identification number (PIN) 0063C03634 0063C0363 0030303 003 003 | Boiler type | iS 15 | iS 18 | iS 24 | iS 32 | iS 40 | |

| CE product identification number (PIN) 0068CO23634 Country of destination UK Comminput min. CH (H) KW 4.5 4.5 6.2 6.2 Qn_input nominal CH (H) KW 13.5 16.2 21.6 28.8 36.0 Q_min put min. CH &DHW (H_s) KW 13.5 16.2 21.6 28.8 36.0 Q_min put min. CH &DHW (H_s) KW 15.0 16.2 21.6 28.8 36.0 Q_ninput nominal CH (H) KW 5.0 5.0 6.9 6.9 Q_ninput nominal CH (50/30°C) KW 15.0 18.0 24.0 32.0 40.0 P_mi output moninal CH (60/60°C) KW 14.7 17.5 23.2 31.2 38.8 P_mi output moninal CH (80/60°C) KW 13.3 15.9 21.2 28.3 35.3 No, class EN15502-1 6 9.0 4.7 CO2 (full load) % 9.0 A Appliance type B23, B33, C13, C33, C43, C53, C63, C93 F10e gas temperature class< | Type heat exchanger | iCon1 | iCon1 | iCon1 | iCon2 | iCon2 | |

| Country of destination UK Qnminput min. CH (H) kW 4.5 4.5 6.2 6.2 Qninput nominal CH (H) kW 13.5 16.2 21.6 28.8 36.0 Qnainput nominal CH (H) kW 13.5 16.2 21.6 28.8 36.0 Qnainput nominal CH (J) kW 5.0 6.9 6.9 Qnin output nominal CH (S0/30°C) kW 15.0 18.0 24.0 32.0 40.0 Pmin output nominal CH (B0/60°C) kW 14.7 17.5 23.2 31.2 38.8 Pnin output nominal CH (B0/60°C) kW 13.3 15.9 21.2 28.3 35.3 NOx class EN15502.1 6 9.0 4.7 7.5 2.2 31.2 38.8 Flue gas temperature Class 7.7 7.5 2.5 5.6 6.9 1.0 Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C93 Flue gas temperature Class 1.30 1.30 Flue gas temperature Class 7.7 7.0 3.0 | CE product identification number (PIN) | 0063CQ3634 | Ļ | ||||

| Qmm input min. CH (H) KW 4.5 6.2 6.2 Qn input nominal CH (H) KW 13.5 16.2 21.6 28.8 36.0 Qn adjusted input CH (H) KW 13.5 16.2 21.6 28.8 36.0 Qnm input min. CH & DHW (Ha) KW 5.0 6.9 6.9 Qn input nominal CH (G0/30°C) KW 5.0 6.9 6.9 Pm output min. CH (80/60°C) KW 4.4 6.1 6.1 Pm output min. CH (80/60°C) KW 4.4 6.1 6.1 Pm output moninal CH (80/60°C) KW 4.3 15.9 21.2 28.3 35.3 NQ, class EN15502-1 6 9.0 6 2.0 10.6 83 130 Flue gas temperature class 7 7.0 82. 833, C13, C33, C43, C53, C63, C6 | Country of destination | UK | |||||

Qn input nominal CH (H)

KW

13.5

16.2

21.6

28.8

36.0

Q, algusted input CH (H)

KW

13.5

16.2

21.6

28.8

36.0

Q, input nominal CH (Hs)

KW

5.0

6.9

6.9

Qn, input nominal CH (Hs)

KW

15.0

18.0

24.0

32.0

40.0

Pmin output nominal CH (50/30°C)

KW

14.7

17.5

23.2

31.2

38.8

Pmin output nominal CH (80/60°C)

KW

4.4

6.1

6.1

Pn, output nominal CH (80/60°C)

KW

13.3

15.9

21.2

28.3

35.3

O

2

(full load)

%

-

4.7

-

|

Q

min

input min. CH (H

i

)

|

kW

|

4.5

|

4.5

|

4.5

|

6.2

|

6.2

|

|

| Q, adjusted input CH (H,) kW 13.5 16.2 21.6 28.8 36.0 Qmin input min. CH & DHW (Ha) kW 5.0 6.9 6.9 Qn input nominal CH (Ka) kW 15.0 18.0 24.0 32.0 40.0 Pmin output min. CH (50/30°C) kW 5.0 6.9 6.9 Pmin output min. CH (80/60°C) kW 14.7 17.5 23.2 31.2 38.8 Pmin output min. CH (80/60°C) kW 4.4 6.1 6.1 P_n output nominal CH (80/60°C) kW 13.3 15.9 21.2 28.3 35.3 NO c (alass EN15502-1 6 9.0 4.7 50 50 6.9 10.6 83 130 Plue gas temperature class 7100 % 9.0 50 | Q n input nominal CH (H i ) | kW | 13.5 | 16.2 | 21.6 | 28.8 | 36.0 |

| Qmmn input min. CH & DHW (H a ) kW 5.0 5.0 6.9 6.9 Qn Input nominal CH (H a ) kW 15.0 18.0 24.0 32.0 40.0 Pmm output min. CH (50/30°C) kW 5.0 6.9 6.9 Pm output min. CH (80/60°C) kW 14.7 17.5 23.2 31.2 38.8 Pmo output min. CH (80/60°C) kW 4.4 6.1 6.1 Pmo output min. CH (80/60°C) kW 13.3 15.9 21.2 28.3 35.3 No, class EN15502-1 6 - O2 (full load) % - 4.7 - Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C83, C93 C9.0 - | Q r adjusted input CH (H i ) | kW | 13.5 | 16.2 | 21.6 | 28.8 | 36.0 |

| Qn input nominal CH (Ha) KW 15.0 18.0 24.0 32.0 40.0 Pmin output min. CH (50/30°C) KW 5.0 5.0 6.9 6.9 Pn output nominal CH (50/30°C) KW 14.7 17.5 23.2 31.2 38.8 Pmin output min. CH (80/60°C) KW 4.4 6.1 6.1 Pn output nominal CH (80/60°C) KW 4.3 15.9 21.2 28.3 35.3 Ox class EN15502.1 6 9.0 4.7 7.5 23.2 31.2 38.8 Plue gas Emperature Class 9.0 4.7 4.7 7.5 23.5 23.53.63.63.63.63.593 5.6 Flue gas temperature class 9.0 106 83 130 6 30 3 | Q min input min. CH & DHW (H s ) | kW | 5.0 | 5.0 | 5.0 | 6.9 | 6.9 |

P

min

output min. CH (50/30°C)

kW

5.0

6.9

6.9

P

n

output nominal CH (50/30°C)

kW

14.7

17.5

23.2

31.2

38.8

P

min

output nominal CH (80/60°C)

kW

4.4

6.1

6.1

P

n

output nominal CH (80/60°C)

kW

13.3

15.9

21.2

28.3

35.3

NO

x

class EN15502-1

6

-

-

6

-

|

Q

n

input nominal CH (H

s

)

|

kW

|

15.0

|

18.0

|

24.0

|

32.0

|

40.0

|

|

| Pn output nominal CH (50/30°C) kW 14.7 17.5 23.2 31.2 38.8 Pmin output min. CH (80/60°C) kW 4.4 6.1 6.1 Pn output nominal CH (80/60°C) kW 13.3 15.9 21.2 28.3 35.3 NOx class EN15502-1 6 0 4.7 7.0 6 0 O2 (full load) % 4.7 7.0 20.2 21.2 28.3 35.3 NOx class EN15502-1 6 9 1.4 7.0 | P min output min. CH (50/30°C) | kW | 5.0 | 5.0 | 5.0 | 6.9 | 6.9 |

| P min output min. CH (80/60°C) kW 4.4 6.1 6.1 P n output nominal CH (80/60°C) kW 13.3 15.9 21.2 28.3 35.3 NO x class EN15502-1 6 7 6 O 2 (full load) % 4.7 5 6 9.0 4 7 | P n output nominal CH (50/30°C) | kW | 14.7 | 17.5 | 23.2 | 31.2 | 38.8 |

| Pn output nominal CH (80/60°C) kW 13.3 15.9 21.2 28.3 35.3 NOx class EN15502-1 6 7 | P min output min. CH (80/60°C) | kW | 4.4 | 4.4 | 4.4 | 6.1 | 6.1 |

NOx class EN15502-1

6

O2 (full load)

%

4,7

CO2 (full load)

%

9,0

Appliance type

B23, B33, C13, C33, C43, C53, C63, C83, C93

Flue gas temperature class

T100

Max. flue resistance at Qnw/Qn

Pa

42

60

106

83

130

Flue gas temperature CH (80/60°C full load)

°C

59

5

6

9

11

14

Flue gas temperature CH (36/30°C low load)

°C

30

Gas actegories

Il2

H3P

Il2

H3P

Il2

H3P

5

6

9

11

14

Gas consumption max. G20

m³/hr

1.43

1.72

2.29

3.05

3.81

Current

V/Hz

~ 230/50

IPX4D (B22/B33 IPX0D)

Verun time pump CH

2.86

60

60

7

Mas atter pressure CH min./max.

bar

0.8 / 3

1.72

2.02

SAP Annual Efficiency NG

%

89.8

|

P

n

output nominal CH (80/60°C)

|

kW

|

13.3

|

15.9

|

21.2

|

28.3

|

35.3

|

|

| O2 (full load) % 4,7 CO2 (full load) % 9,0 Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C93 Flue gas temperature class T100 Max. flue resistance at Qnw/Qn Pa 42 60 106 83 130 Flue gas temperature CH (80/60°C full load) °C 59 5 6 9 11 14 Flue gas temperature CH (36/30°C full load) °C 30 Flue gas temperature CH (36/30°C low load) °C 30 Gas categories Il2H3P 5 6 9 11 14 Gas pressure 2H / 3P mbar 20 / 37 5 3.81 1.72 2.29 3.05 3.81 Current V/Hz ~230/50 IPX4D (B22/B33 IPX0D) 20 20 30 3.81 1.72 2.29 3.05 3.81 3.81 1.72 2.29 3.05 3.81 1.72 2.29 3.05 3.81 | NO x class EN15502-1 | 6 | |||||

| CO2 (full load) % 9,0 Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C93 Flue gas temperature class T100 Max, flue resistance at Qnw/Qn Pa 42 60 106 83 130 Flue gas temperature CH (80/60°C full load) °C 59 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 34 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 30 Gas categories Il2H3P mbar 20 / 37 Gas consumption max. G20 m³/hr 1.43 1.72 2.29 3.05 3.81 Current V/Hz ~ 230/50 20 30 Overrun time pump CH sec 60 60 PMS 40 40 42 | O 2 (full load) | % | 4,7 | ||||

| Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C93 Flue gas temperature class T100 Max. flue resistance at Qnw/Qn Pa 42 60 106 83 130 Flue gas temperature CH (80/60°C full load) °C 59 5 6 9 11 14 Flue gas temperature CH (50/30°C full load) °C 34 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 30 Gas categories Il2 H3P mbar 20 / 37 5 6.8 9 11 14 Current V/Hz ~2.2.9 3.0.5 3.81 2.1 2.1 3.81 2.1 2.2 3.05 3.81 3.1 2.1 2.2 3.05 3.81 3.1 2.1 2.2 3.05 3.81 3.1 | CO 2 (full load) | % | 9,0 | ||||

| Flue gas temperature class T100 Max. flue resistance at Qnw/Qn Pa 42 60 106 83 130 Flue gas temperature CH (80/60°C full load) °C 59 50 | Appliance type | B2 | 23, B33, C13, | C33, C43, C53 | 3, C63, C83, C | 93 | |

Max. flue resistance at Qnw/Qn

Pa

42

60

106

83

130

Flue gas temperature CH (80/60°C full load)

°C

59

50

|

Flue gas temperature class

|

|

|

|

T100

|

|

|

|

| Flue gas temperature CH (80/60°C full load) °C 59 Flue gas temperature CH (50/30°C full load) °C 34 Flue gas mass flow (full load) g/s 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 30 30 Gas categories Il 2H3P Il 1.43 1.72 2.29 3.05 3.81 Current V/Hz ~ 230/50 31 20 31 20 31 31.72 Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D) VHz ~ 230/50 31 31 Overrun time pump CH sec 60 9 1 4 40 41 | Max. flue resistance at Qnw/Qn | Ра | 42 | 60 | 106 | 83 | 130 |

| Flue gas temperature CH (50/30°C full load) °C 34 Flue gas mass flow (full load) g/s 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 30 Gas categories Il2H3P mbar 20 / 37 12 2.29 3.05 3.81 Gas consumption max. G20 m³/hr 1.43 1.72 2.29 3.05 3.81 Current V/Hz ~230/50 12 2.05 3.81 2.21 2.21 3.05 3.81 Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D) 12 2.22 3.05 3.81 Overrun time pump CH sec 60 12 | Flue gas temperature CH (80/60°C full load) | °C | 59 | ||||

| Flue gas mass flow (full load) g/s 5 6 9 11 14 Flue gas temperature CH (36/30°C low load) °C 30 | Flue gas temperature CH (50/30°C full load) | °C | 34 | ||||

| Flue gas temperature CH (36/30°C low load) °C 30 | Flue gas mass flow (full load) | g/s | 5 | 6 | 9 | 11 | 14 |

Gas categories

II

2H3P

Gas pressure 2H / 3P

mbar

20 / 37

Gas consumption max. G20

m

3

/hr

1.43

1.72

2.29

3.05

3.81

Current

V/Hz

~ 230/50

|

Flue gas temperature CH (36/30°C low load)

|

°C

|

30

|

30

|

30

|

30

|

30

|

|

| Gas pressure 2H / 3P mbar 20 / 37 Gas consumption max. G20 m 3 /hr 1.43 1.72 2.29 3.05 3.81 Current V/Hz ~ 230/50 | Gas categories | II 2H3P | |||||

| Gas consumption max. G20 m³/hr 1.43 1.72 2.29 3.05 3.81 Current V/Hz ~ 230/50 PX4D (B22/B33 IPX0D) Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D) 60 Overrun time pump CH sec 60 90 P MS water pressure CH min./max. bar 0.8 / 3 90 90 20 Flow temperature max. °C 80 25 25 20 Available pump height CH kPa 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | Gas pressure 2H / 3P | mbar | 20 / 37 | ||||

| Current V/Hz ~ 230/50 Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D) Overrun time pump CH sec 60 P MS water pressure CH min./max. bar 0.8 / 3 Flow temperature max. °C 80 Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | Gas consumption max. G20 | m 3 /hr | 1.43 | 1.72 | 2.29 | 3.05 | 3.81 |

| Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D) Overrun time pump CH sec 60 P MS water pressure CH min./max. bar 0.8 / 3 Flow temperature max. °C 80 Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | Current | V/Hz | ~ 230/50 | ||||

| Overrun time pump CH sec 60 P MS water pressure CH min./max. bar 0.8 / 3 Flow temperature max. °C 80 Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 39 42 42 | Degree of protection acc. EN 60529 | IPX | 4D (B22/B33 IF | PX0D) | |||

| P MS water pressure CH min./max. bar 0.8 / 3 Flow temperature max. °C 80 Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | Overrun time pump CH | sec | 60 | ||||

| C 80 Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | P MS water pressure CH min./max. | bar | 0.8 / 3 | ||||

| Available pump height CH kPa 25 25 20 20 SAP Annual Efficiency NG % 89.8 | Flow temperature max. | °C | 80 | ||||

| SAP Annual Efficiency NG % 89.8 Weight boiler + jig (empty) kg 39 42 42 | Available pump height CH | kPa | 25 | 25 | 25 | 20 | 20 |

| Weight boiler + jig (empty) kg 39 39 42 42 | SAP Annual Efficiency NG | % | 89.8 | 89.8 | 89.8 | 89.8 | 89.8 |

| Weight boiler + jig (empty) | kg | 39 | 39 | 39 | 42 | 42 |

Technical specifications Propane gas

| Boiler type | iS 15 | iS 18 | iS 24 | iS 32 | iS 40 | |

|---|---|---|---|---|---|---|

| Heat exchanger type | iCon1 | iCon1 | iCon2 | iCon2 | iCon2 | |

| O 2 (at full load) | % | 5.1 | ||||

| CO 2 (at full load) | % | 10.3 | ||||

| Pre pressure | mbar | S | ee data plate | LPG | ||

| Input CH (Hi) | kW | 13.5 | 16.2 | 21.6 | 28.8 | 36.0 |

| Gas consumption max. G31 | kg/h | 1.07 | 1.28 | 1.71 | 2.28 | 2.85 |

| Gas consumption max. G31 | m³/h | 0.56 | 0.68 | 0.90 | 1.20 | 1.50 |

| Modulation range CH (80/60°C) | kW | 8.3 - 13.3 | 8.3 - 15.9 | 8.3 - 21.2 | 19.1 - 28.3 | 19.1 - 35.3 |

| Modulation range CH (50/30°C) | kW | 9.0 - 14.7 | 9.0 - 17.5 | 9.0 - 23.2 | 20.8 - 31.2 | 20.8 - 38.8 |

| ErP specifications according to European Guideline 2010/30/EU | ||||||||

|---|---|---|---|---|---|---|---|---|

| Boiler type | iS 15 | iS 18 | iS 24 | iS 32 | iS 40 | |||

| Seasonal space heating energy efficiency class | Α | А | А | А | Α | |||

| P n Power output | kW | 14.7 | 17.5 | 23.2 | 31.2 | 38.8 | ||

| Q HE Annual energy consumption | GJ | 43 | 52 | 69 | 92 | 115 | ||

| η s Seasonal space heating energy efficiency CH | % | 93 | 93 | 94 | 94 | 94 | ||

| L WA Sound power level, indoors | dB | 37 | 43 | 46 | 48 | 54 | ||

| P 4 nominal output (80/60°C) | kW | 5.0 | 5.0 | 5.0 | 6.9 | 6.9 | ||

| P 1 30% of nominal output (36/30°C) | kW | 4.5 | 5.4 | 7.2 | 9.6 | 11.9 | ||

| η 4 efficiency at nominal input (GCV) | % | 89 | 89 | 88 | 89 | 88 | ||

| η 1 efficiency at 30% of the nominal heat input (GCV) | % | 99 | 99 | 99 | 100 | 99 | ||

| el max | kW | 0.068 | 0.077 | 0.096 | 0.074 | 0.074 | ||

| el min | kW | 0.021 | 0.021 | 0.021 | 0.032 | 0.032 | ||

| P SB | kW | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | ||

| Pethy heat loss | kW | 0.055 | 0.055 | 0.055 | 0 055 | 0.055 | ||

Dimensions Δ

The delivery package of the boiler is composed as follows:

- Boiler frame;

- Boiler with cover;

- Automatic air vent (in boiler);

- Safety valve 3 bar (in boiler);

- Automatic by-pass (in boiler);

- Expansion vessel 8 litre / 1 bar (in boiler frame);

- Isolation valves with drainpoint (CH 2x,)

- Gas isolating valve;

- Fittings consisting of plugs and screws;

- Drawing template;

- Installation instructions;

- User manual;

- Warranty Card.

The following components are not present in the boiler packaging as a standard and should be included in the installation according to the requirements:

- Flue system;

- External controls.

6 Boiler description

The ATAG iS is a room sealed, condensing and modulating CH boiler.

The boiler is equipped with a compact stainless steel heat exchanger with smooth pipes. It is a well thoughtout principle using sustainable materials.

The boiler burns gas to supply heat (natural gas and LPG versions available). This heat is transferred in the heat exchanger to the water in the CH installation. The rapid cooling off of the flue gases causes condensation. This results in a very high efficiency. The condensate that is formed, has no negative impact on the heat exchanger and it's operation, and is removed through the internal siphon. This feature requires a condensate drain pipe connected to the drain of the building.

The boiler is equipped with an intelligent control system. The boiler anticipates on the heat demand of the heating installation or hot water demand. This will cause the boiler to tune its capacity to the installation. This means that the boiler will function longer and at a low level.

The boiler has been tested according to valid CE standards and has a CE certificate and >88% Efficient SEDBUK 2009.

7 Boiler photo components list

- 3 Fan unit

- 4 Air supply damper

- 5 Gas valve

- 6 Automatic de-aerator

- Control unit

- 8 Control panel

- T1 Flow sensor

- T2 Return sensor

- P1 Water pressure sensor

- 11 Combustion air supply

- Boiler data plate 12

- 13 Expansion vessel

- Safety valve 14

- 15 Siphon

-

Isolation valve flow CH 16

- Gas pipe

- Flow pipe CH

- Return pipe CH

- Condensation pipe

- Installation & Servicing instructions ATAG iS-Range

Install the boiler in a boiler room in accordance to the actual local regulations BS5440-2:2009.

The installation location of the boiler has to be, and remain, frost-free. The boiler casing is splash water tight (IPX4D) and is suitable to be installed in e.g. a bathroom.

It is NOT necessary to have a purpose provided air vent in the room or internal space in which the boiler is installed. Neither is it necessary to ventilate a cupboard or compartment in which the boiler is installed, due to the extremely low surface temperature of the boiler casing during operation. Therefore the requirements of BS5440:2 may be disregarded.

The boiler can be mounted practically to any wall with the wall frame and the enclosed fixing equipment. The wall must be flat and of sufficient strength in order to be able to carry the boiler weight with its water content. Above the boiler there must be at least 210 mm working space in order to be able to fit a horizontal concentric flue system to the rear (See chapter 9.8 for more flue options). Make sure there is sufficient service space arround the boiler according figure 8.a. The location of the boiler can be determined by using the template.

The wall frame allows the possibity to pre-fit the complete heating system before fitting the boiler. Also the flue system can be prepared. Finally fitting of the flue system is done after fitting the boiler. See next page for all options for connection the heating, condensate, flue and gas installation.

Before hanging the boiler to the boiler frame remove the front panel of the boiler first. The front panel is also the air cabinet and is attached to the boiler case with 2 fasteners (A and B) (see figure 8.a).

Note that there is an earth cable (when present) to disconnect when removing the boiler front panel. Free space for removing the connector is about 400 mm. Remember to connect this earth cable (when present) when placing back the boiler front panel and take care the wire does not get stuck between front panel and boiler. Always replace and turn the 2 screws tight in the fasteners A and B.

Service dimensions (in mm)

See chapter 9.8 for further procedure to fit the boiler onto the boiler frame.

8 1 Wall frame

- Position the boiler frame against the wall using the template and a level.

- Use the level for horizontal positioning and checking the vertical position

- Drill 4x ø10mm holes, 60mm deep

- Press the nylon wall plug (ø10x55mm) in the holes

- Mount the boiler frame to wall with the 4 coach screws (ø8x60mm) using a 13mm wrench

The boiler frame allows pipe work to be installed behind the boiler.

Note that there are free spaces on the left and right of the expansion vessel. Do not guide pipe work in front of the expansion vessel. The pipe work must be installed at least 10mm inside the front of the frame.

The boiler has the following connection pipes:

- The central heating pipes. The boiler is provided with isolation valves on the flow and return pipe to which the installation can be connected by means of 22mm compression fittings;

- The gas pipe. The boiler is provided with an isolation gas valve to which the gas line can be fitted with 22mm compression fitting;

- The condensation drain pipe. It consists of a 25mm flexible plastic pipe. The drain pipe can be connected to this by means of an open connection;

- The flue gas exhaust system and air supply system. It consists of a concentric connection 60/100 mm.

See following chapters for detailed information regarding each connection.

It is advisable to clean all of the boiler's connecting pipes and/or to power flush the installation before connecting it to the boiler.

9.1 Central heating system

Connect the central heating system according to the current regulations.

The boiler pipes can be connected to the installation by means of 22mm compression fittings. For connecting to thick-walled pipe (welded or fitted), adapters should be used.

The boiler has a self-adjusting and self-protecting control system for the load. This involves checking the temperature difference between the flow and return water. Table 9.1.a shows the water displacement the circulation pump can deliver for a particular installation resistance.

If the installation resistance is higher than the value stated, the control system will adjust the load until a temperature difference between flow and return water is reached that is acceptable for the control system. When the temperature difference still remains too high the boiler will switch itself off and wait until the high temperature differential between the flow and return water has decreased again.

| Pump type | ||||||

|---|---|---|---|---|---|---|

| Boiler | Water flow rate at ∆ | ۲ 20°C آ | Permissible installation resistar | |||

| type | l/min | l/h | kPa | mbar | ||

| Grundfos | ||||||

| iS 15 | UPM3 15-75 | 9.5 | 570 | 25 | 250 | |

| iS 18 | UPM3 15-75 | 11.4 | 680 | 25 | 250 | |

| iS 24 | UPM3 15-75 | 15.2 | 910 | 25 | 250 | |

| iS 32 | UPM3 15-75 | 20.3 | 1220 | 20 | 200 | |

| iS 40 | UPM3 15-75 | 25.3 | 1520 | 20 | 200 | |

Installation resistance

table 9.1.a

The control system will, if an unacceptable temperature difference is detected, repeatedly try to establish a water flow. If this does not succeed, the boiler will block itself (code 154).

The boiler is NOT equipped with a built-in internal filter.

Advice: ATAG Heating Technology Ltd recommend the installation of an in-line filter installed into the heating return as close to the boiler as possible. ATAG Heating Technology Ltd recommend the use of the:

ATAG iGuard Magnetic filter 22mm (Plastic) FC000100, (Brass) FC000200, 28mm (Brass) FC000250.

The boiler is not suitable for installations that are equiped with "open" expansion tanks.

Additives in the installation water are only permitted in consultation with the country distributor. See chapter 9.3 for detailed information.

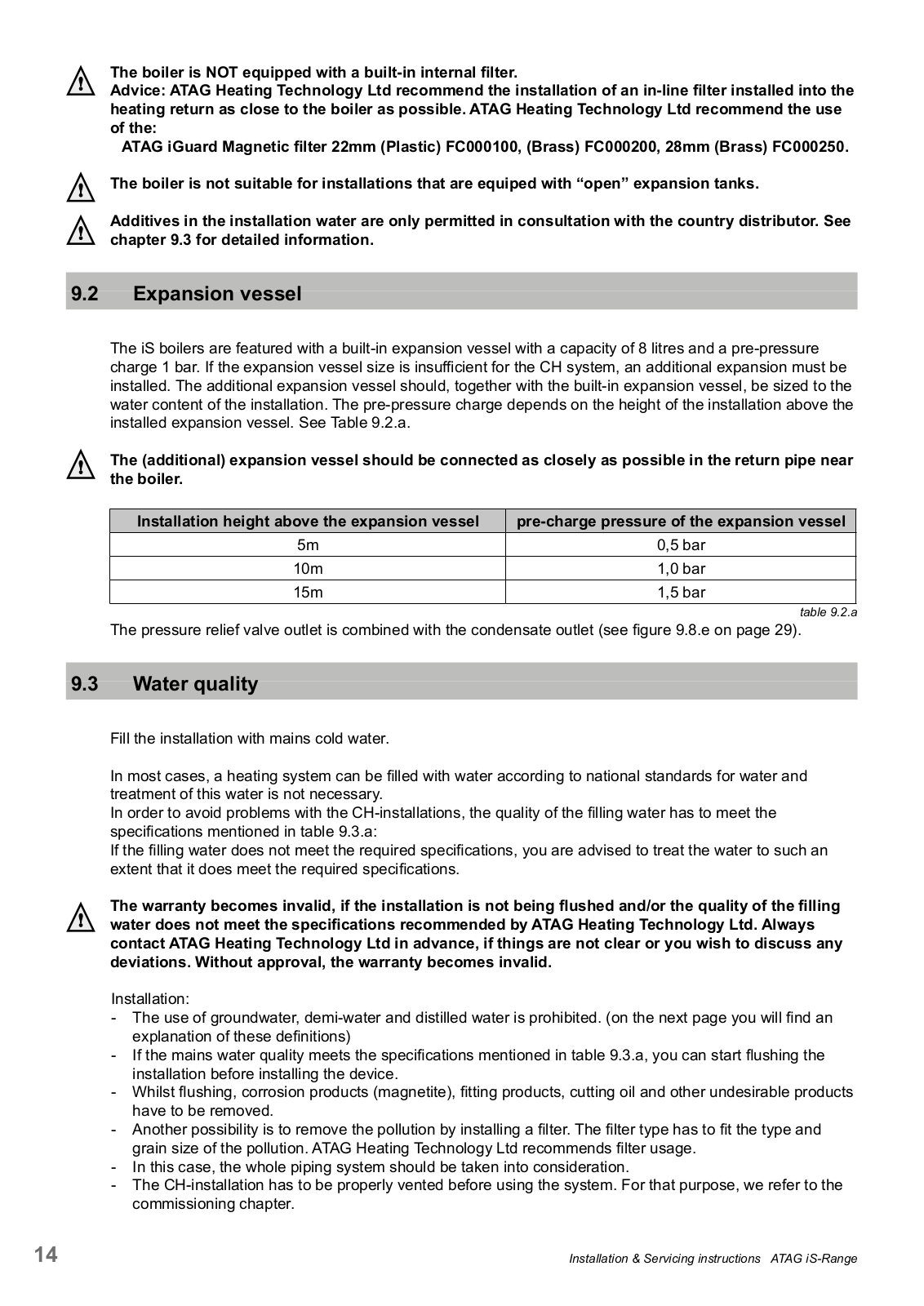

9.2 Expansion vessel

The iS boilers are featured with a built-in expansion vessel with a capacity of 8 litres and a pre-pressure charge 1 bar. If the expansion vessel size is insufficient for the CH system, an additional expansion must be installed. The additional expansion vessel should, together with the built-in expansion vessel, be sized to the water content of the installation. The pre-pressure charge depends on the height of the installation above the installed expansion vessel. See Table 9.2.a.

The (additional) expansion vessel should be connected as closely as possible in the return pipe near the boiler.

| Installation height above the expansion vessel | pre-charge pressure of the expansion vessel |

|---|---|

| 5m | 0,5 bar |

| 10m | 1,0 bar |

| 15m | 1,5 bar |

The pressure relief valve outlet is combined with the condensate outlet (see figure 9.8.e on page 29).

9.3 Water quality

Fill the installation with mains cold water.

In most cases, a heating system can be filled with water according to national standards for water and treatment of this water is not necessary.

In order to avoid problems with the CH-installations, the quality of the filling water has to meet the specifications mentioned in table 9.3.a:

If the filling water does not meet the required specifications, you are advised to treat the water to such an extent that it does meet the required specifications.

The warranty becomes invalid, if the installation is not being flushed and/or the quality of the filling water does not meet the specifications recommended by ATAG Heating Technology Ltd. Always contact ATAG Heating Technology Ltd in advance, if things are not clear or you wish to discuss any deviations. Without approval, the warranty becomes invalid.

Installation:

- The use of groundwater, demi-water and distilled water is prohibited. (on the next page you will find an explanation of these definitions)

- If the mains water quality meets the specifications mentioned in table 9.3.a, you can start flushing the installation before installing the device.

- Whilst flushing, corrosion products (magnetite), fitting products, cutting oil and other undesirable products have to be removed.

- Another possibility is to remove the pollution by installing a filter. The filter type has to fit the type and grain size of the pollution. ATAG Heating Technology Ltd recommends filter usage.

- In this case, the whole piping system should be taken into consideration.

- The CH-installation has to be properly vented before using the system. For that purpose, we refer to the commissioning chapter.

- If a regular water top up is required (>5% on an annual basis), then there is a structural problem and an installer has to solve the problem. Regularly adding fresh water to the system also adds additional calcium and oxygen implying that magnetite and calcium residues can continue. The result may be blockages and/or leakages.

- The use of anti-freeze and other additives requires periodical quality checks of the filling water in accordance with the period laid down by the additives supplier.

- Chemical additions are to be avoided and should only be used after ATAG Heating Technology Ltd has approved their corresponding use.

- Should you wish to achieve the required water quality by using chemical additives, then this is your own responsibility. The warranty on the product delivered by ATAG Heating Technology Ltd expires, if the water quality does not meet ATAG Heating Technology's specifications or the chemical additives have not been approved by ATAG Heating Technology Ltd.

- On installation and during additions or changes at a later stage, ATAG Heating Technology Ltd recommends to keep a record of the type of water used, its quality at the time, and if applicable, which additives and quantities were added.

| Parameter | Value |

|---|---|

| Water type |

Potable water

Softened water |

| рН | 6.0-8.5 |

| Conductivity (at 20°C in µS/cm) | Max. 2500 |

| Iron (ppm) | Max. 0.2 |

| Hardness (°dH / ppm): | |

|

Installation volume/capacity

<20 l/kW |

1-12 °dH / 17-214 ppm |

|

Installation volume/capacity

>=20 l/kW |

1-7 °dH / 17-125 ppm |

| Oxygen |

No oxygen diffusion allowed during operation.

Max. 5% filling water addition annually |

| Corrosion inhibitors | Refer to Additives Attachment |

| pH increasing or lowering agents | Refer to Additives Attachment |

| Anti-freeze additives | Refer to Additives Attachment |

| Other chemical additives | Refer to Additives Attachment |

| Solid substances | Not allowed |

| Residues of processing water not forming part of the drinking water | Not allowed |

table 9.3.a

Water type definition:

| Potable water: | Tap water compliant with the European drinking water guideline: |

|---|---|

| 98/83/EG dated 3 November 1998. | |

| Softened water: | Water with partly de-ionised calcium and magnesium. |

| Demi-water: | Virtually completely demineralised water (very low conductivity) |

| Distilled water: | Water no longer containing minerals |

9.4 Heating systems with plastic pipes

When connecting or using an underfloor heating system, designed with plastic pipes, or plastic pipes are used elsewhere in the installation, one should ensure that the plastic pipes used comply with the DIN 4726/4729 standard. It is set out in this standard that the pipes may not have oxygen permeability higher than 0.1 g/m3.d at 40°C. If the system does not comply with this DIN standard, the underfloor heating component will have to be separated from the central heating appliance by means of a plate exchanger.

No recourse can be made to the terms of the warranty in the event of failure to observe the regulations pertaining to plastic underfloor heating pipes.

9.5 Gas connection in general

The local gas supplier should be consulted, at the installation planning stage, in order to establish the availability of an adequate supply of gas. An existing service pipe must NOT be used without prior consultation with the local gas supplier.

ATAG supplies boilers suitable for natural gas only and boilers for LPG only. Verify the identification plate on the boiler if the boiler is suitable for the gas kind on site. The boilers cannot be converted to another kind of gas.

Make sure that the gas pipe work does not contain dirt, particularly with new pipes.

The complete installation MUST be tested for gas tightness and purged as described in the above code.

The boiler connection is provided with an isolation valve with 22mm compression fitting, into which the gas line can be fitted.

9.5.1 Natural gas connection (NG)

The gas supply must comply to the current Gas Safety, Installation & Use Regulations, in accordance with BS.6891.

The nominal inlet working gas pressure measured at the appliance should be 21 mbar +/- 2 mbar for Nat gas (G20). Allowing for the acceptable pressure loss of 1 mbar across the installation pipework, it can be assumed that a minimum permitted operating pressure of 18 mbar will be delivered to the inlet of the appliance. (Reference BS 6400-1 Clause 6.2 Pressure Absorption). When tested at the gas valve, the pressure drop from the meter to the gas valve must not be more than 3.8 mbar.

9.5.2 Propane gas connection (LPG)

The LPG installation must comply to the current Gas Safety, Installation & Use Regulations, in accordance with BS:6891

Installing of a LPG installation should only be done by a registered LPG installer.

The tank must be provided with a high pressure regulator with a minimum capacity of 24 kg/h to reduce the tank pressure from 5 to 1,5 bar. The 1,5 bar high pressure gas line should have a minimum diameter of 15mm. In the high pressure gas line a house pressure regulator must be installed. When tested at the gas valve, the pressure drop from the pressure regulator to the gas valve must not be more than 3.7 mbar.

9.5.3 House pressure regulator

Each gas appliance which is connected to the propane installation must be provided with its own house pressure regulator. The house pressure regulator is a third party delivery.

The house pressure regulator must have a minimum capacity of 10 kg/h / 37 mbar and a CE certification.

ATAG advices to install the house pressure regulator as close as possible to the boiler. When placing the regulator inside, a discharge drain of ø6mm must be installed. The discharge drain must be directed outdoor. In case of a discharge the gasses will go outside.

If fitting the regulator outside the regulator should be protected against influences of the weather. The (de-) aeration must be positioned downwards (see figure 9.5.3.a)

ATAG advices to install measure points on all gas line parts to have the possibility to check for pressure loss.

Pre-pressure must be adjusted to 37 mbar by means of the house pressure regulator. The maximum permitted closing pressure may be 5 mbar higher than the maximum pre-pressure.

A too high closing pressure in the low pressure gas line can be caused by a high resistance or jam in this gas line. When the closing pressure keeps increasing the valve in the regulator is not closing correctly. In this case the regulator should be replaced

9.5.4 Dimensioning of the low pressure gas line

The gas line from the house pressure regulator to the boiler must have the dimensions according the table helow

| Boiler type | iS 15 | iS 18 | iS 24 | iS 32 | iS 40 |

|---|---|---|---|---|---|

| Diameter gas line | m | m | m | m | m |

| ø15mm | - | - | - | - | - |

| ø22mm | 18 | 18 | 18 | 18 | 18 |

| ø28mm | 30 | 30 | 30 | 30 | 30 |

9.5.5 De-aerating the LPG tank

When placing a new or revised LPG tank the tank must alway be de-aerated.

ATAG advices to inform the gas supplier that a central heating boiler is connected to the LPG tank. For the boiler it is absolutly necessary that the tank is free of air. When not the boiler will give ignition problems and will not function

ATAG advices to measure the content of O2. This value should be lower than 1.3%. Contact the gas supplier in case of doubt.

ATAG 3-port external diverter valve kit including the ONE controller (CT500111) used with a vented hot water cylinder.

The ATAG 3-port diverter valve is to be fitted external to the boiler on the system pipework with the electrical wiring routed back to the wiring loom diverter valve connection within the iS boiler with a connection plug and wire included with in the 3-port diverter valve kit.

The installation will use the cylinder sensor supplied within the 3-port diverter valve kit to control the hot water temperature. Therefore no other cylinder thermostat is required.

The ONE controller will control the heating and hot water time and temperature requirements.

The weather compensation for heating will be controlled by the boiler and ONE controller via the internet connection and postal code weather data. An optional outside sensor (ARZ0055U) can be added to the 3-port diverter valve kit to sense the outside temperature specifically for the individual property.

Fitting the cylinder temperature sensor

The cylinder sensor may be fitted into a sensor pocket if available, please refer to the cylinder manufactures instructions. If there is no sensor pocket, as found with foam covered cylinders then the following steps should be followed.

1. Mark a rectangular section of approximately 50mm (w) x 100mm (h) about one third of the cylinder height up from the bottom of the cylinder.

Caution: Cut carefully. Do not pierce the wall of the cylinder or cut away any metal insulation outer casing.

- 2. Using a sharp knife, carefully cut through the insulation, remove and retain the piece of insulation.

- 3. Clear off any excess material from the surface of the cylinder to ensure the best contact.

- 4. Place the sensor in position on the cylinder body and hold in place with aluminium tape and where available apply heat conductive paste.

- 5. Replace the previously removed insulation material

- 6. Secure the insulation in place with suitable tape or strapping.

Wiring of components

Connect the 3-port diverter valve to the spare 3-port valve connector on the wiring loom

Connect the cylinder sensor with the yellow connector to the yellow DHW volt free position and the ONE control wires with the blue connector to the blue BUS volt free position on the back of the control panel.

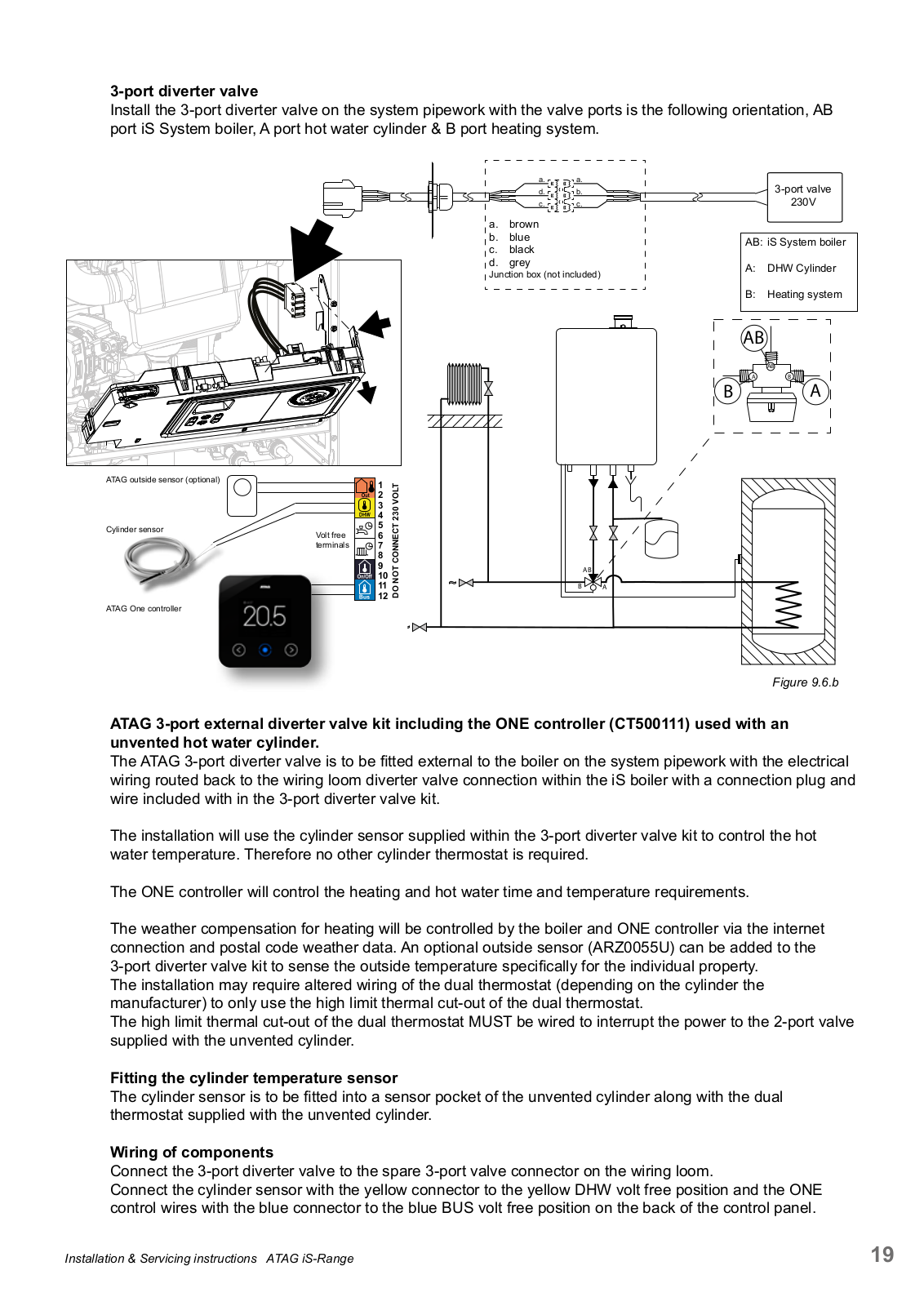

3-port diverter valve

Install the 3-port diverter valve on the system pipework with the valve ports is the following orientation, AB port iS System boiler, A port hot water cylinder & B port heating system.

ATAG 3-port external diverter valve kit including the ONE controller (CT500111) used with an unvented hot water cylinder.

The ATAG 3-port diverter valve is to be fitted external to the boiler on the system pipework with the electrical wiring routed back to the wiring loom diverter valve connection within the iS boiler with a connection plug and wire included with in the 3-port diverter valve kit.

The installation will use the cylinder sensor supplied within the 3-port diverter valve kit to control the hot water temperature. Therefore no other cylinder thermostat is required.

The ONE controller will control the heating and hot water time and temperature requirements.

The weather compensation for heating will be controlled by the boiler and ONE controller via the internet connection and postal code weather data. An optional outside sensor (ARZ0055U) can be added to the 3-port diverter valve kit to sense the outside temperature specifically for the individual property. The installation may require altered wiring of the dual thermostat (depending on the cylinder the manufacturer) to only use the high limit thermal cut-out of the dual thermostat. The high limit thermal cut-out of the dual thermostat MUST be wired to interrupt the power to the 2-port valve supplied with the unvented cylinder.

Fitting the cylinder temperature sensor

The cylinder sensor is to be fitted into a sensor pocket of the unvented cylinder along with the dual thermostat supplied with the unvented cylinder.

Wiring of components

Connect the 3-port diverter value to the spare 3-port value connector on the wiring loom. Connect the cylinder sensor with the yellow connector to the yellow DHW volt free position and the ONE control wires with the blue connector to the blue BUS volt free position on the back of the control panel.

2 port zone valve & dual thermostat (supplied with unvented cylinder)

The 2-port zone valve must be installed in the primary flow pipework between the 3-port valve and the cylinder connection as per the following diagram and G3 unvented hot water requirements. The 230v mains power supply MUST be wired only to the high limit thermal cut-out of the dual thermostat and be wired to interrupt the power to the motor of the 2-port valve as per electrical diagram below.

3-port diverter valve

Install the 3-port diverter valve on the system pipework with the valve ports is the following orientation, AB port iS System boiler, A port hot water cylinder & B port heating system.

9.7 Condensation drain pipe

The ATAG condensing boiler has the >88% Efficient SEDBUK 2009 for high energy efficiency in heating and domestic hot water. The ATAG wall hung gas fired condensing boiler contain a siphonic condensate trap to collect and realease condensate. The amount of condensate formed is determind by the type of boiler and the water temperature produced by the boiler.

Condensate pipework.

Use plastic pipework of an internal diameter no less then 19mm ID (typically 22mm OD).

Routing of the pipework,

The condensate pipework must fall at least 45mm per metre away from the boiler, taking the shortest practicle route to the termination point.

Support the pipe at least every 50 cm for near horizontal sections and 1 metre for vertical sections. Wherever possible, the condensate pipework should be routed internally to prevent freezing. In order to minimise the risk of freezing during prolonged very cold spells, one of the following methods of terminating condensate drainage pipe should be adopted.

Internal pipework

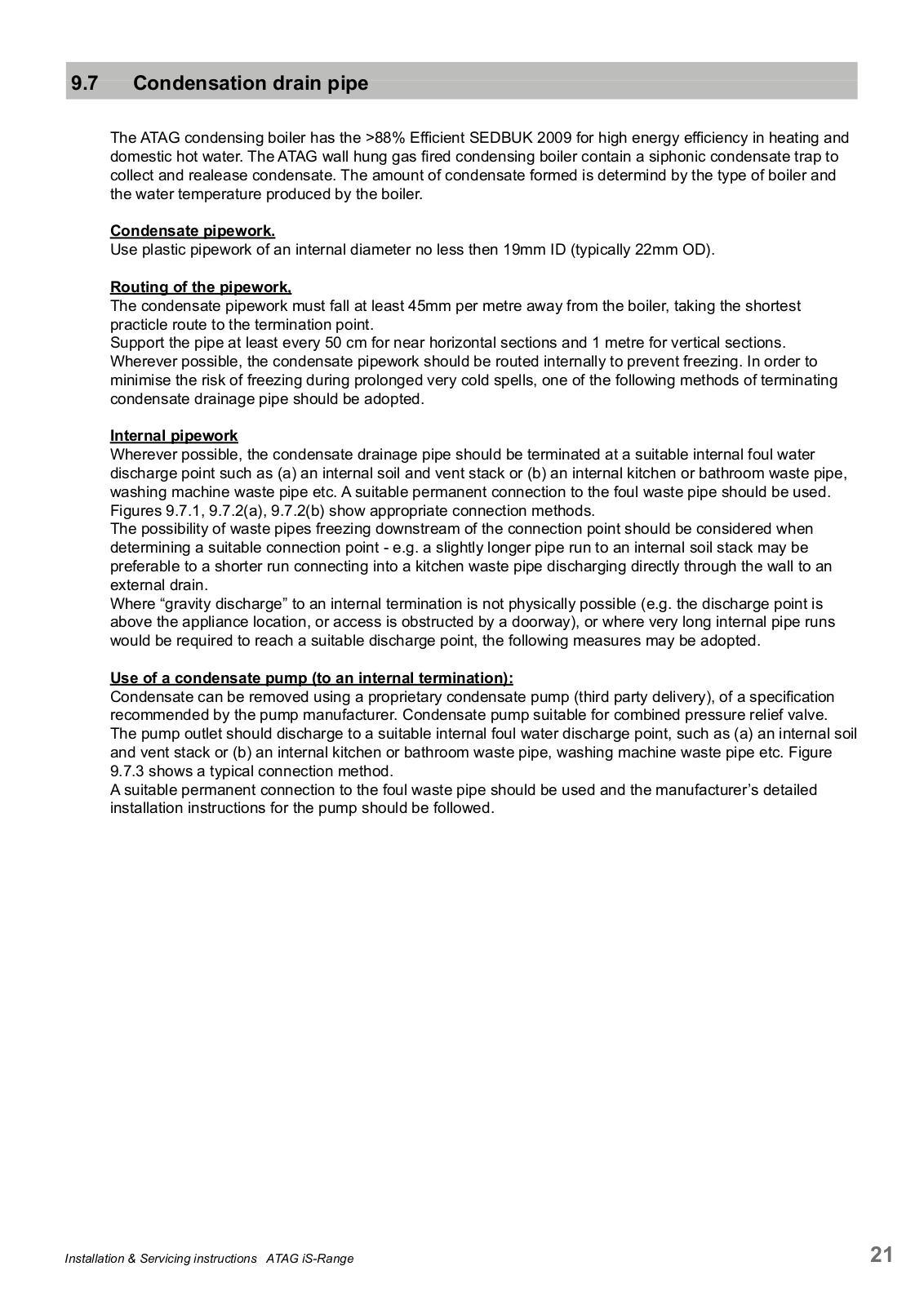

Wherever possible, the condensate drainage pipe should be terminated at a suitable internal foul water discharge point such as (a) an internal soil and vent stack or (b) an internal kitchen or bathroom waste pipe, washing machine waste pipe etc. A suitable permanent connection to the foul waste pipe should be used. Figures 9.7.1, 9.7.2(a), 9.7.2(b) show appropriate connection methods.

The possibility of waste pipes freezing downstream of the connection point should be considered when determining a suitable connection point - e.g. a slightly longer pipe run to an internal soil stack may be preferable to a shorter run connecting into a kitchen waste pipe discharging directly through the wall to an external drain.

Where "gravity discharge" to an internal termination is not physically possible (e.g. the discharge point is above the appliance location, or access is obstructed by a doorway), or where very long internal pipe runs would be required to reach a suitable discharge point, the following measures may be adopted.

Use of a condensate pump (to an internal termination):

Condensate can be removed using a proprietary condensate pump (third party delivery), of a specification recommended by the pump manufacturer. Condensate pump suitable for combined pressure relief valve. The pump outlet should discharge to a suitable internal foul water discharge point, such as (a) an internal soil and vent stack or (b) an internal kitchen or bathroom waste pipe, washing machine waste pipe etc. Figure 9.7.3 shows a typical connection method.

A suitable permanent connection to the foul waste pipe should be used and the manufacturer's detailed installation instructions for the pump should be followed.

ain requirements

Drain requirer

External pipework

The use of an externally-run condensate drainage pipe, terminating at a suitable foul water discharge point or purpose-designed soakaway, may be also be considered; however if this termination method is chosen then the following measures should be adopted

- The pipe should be run internally as far as possible before going externally and the pipe diameter should be increased to a minimum of 30mm ID (typically 32mm OD) before it passes through the wall.

- The external run should be kept as short as possible, taking the most direct and "most vertical" route possible to the discharge point, with no horizontal sections in which condensate might collect. Do not exceed 3 metres outside the dwelling.

- The external pipe should be insulated using suitable waterproof and weatherproof insulation ("Class O" pipe insulation is suitable for this purpose).

- The use of fittings, elbows etc should be kept to a minimum and any internal "burrs" on cut pipework should be removed so that the internal pipe section is as smooth as possible.

The customer/householder should be advised that even with the above measures this type of installation could freeze, and that if this were to occur then boiler shutdown could result, requiring remedial action - possibly involving a chargeable engineer call-out.

Where there are likely to be extremes of temperature or wind-chill, the use of a proprietary trace-heating system for external condensate drainage pipework, incorporating an external frost thermostat, should therefore be considered. If such a system is used then the installation instructions of the trace heating manufacturer and any specific recommendations regarding pipe diameter, insulation, etc. should be followed. All other relevant guidance on condensate drainage pipe installation should also be followed.

Other cold weather protection methods approved or endorsed by boiler manufacturers and/or service organisations may be adopted if these are considered suitable by the parties involved.

If an external soil/vent stack is used as the external termination then the connection method shown in Figure 9.6.4 should be used, together with the measures on insulation etc. as described above and shown in the diagram.

When a rain water downpipe is used as the termination (NB only permissible if this downpipe passes to a combined foul and rainwater drainage system) an air break must be installed between the condensate drainage pipe and the downpipe to avoid reverse flow of rainwater into the boiler should the downpipe itself become flooded or frozen. Figure 9.7.5 shows a suitable connection method.

Where the condensate drainage pipe is terminated over an open foul drain or gully, the pipe should terminate below the grating level, but above water level, in order to minimise "wind chill" at the open end. Pipe drainage will be improved if the end is cut at 45° as opposed to a straight cut. The use of a drain cover (such as those used to prevent blockage by leaves) may offer further protection from wind chill. Figure 9.7.6 shows a suitable connection method.

Where the condensate drain pipe terminates in a purpose-designed soakaway (see BS 6798:2014 or boiler installation manual for soakaway design requirements) any above-ground section of condensate drainage pipe should be run and insulated as described above. Figure 9.7.7 shows a suitable connection method.

Unheated internal areas:

Internal condensate drainage pipes run in unheated areas such as lofts, basements and garages should be treated as external pipe.

Before putting the boiler into operation fill the siphon with 150 ml of water.

9.8 Flue gas exhaust system

The flue gas exhaust system and air supply system consists of:

- Flue gas pipe;

A

- Air supply pipe:

- Roof or wall terminal.

The flue gas exhaust system and air supply system must comply with:

The flue gas outlet and air supply installation must comply with the current regulation requirements in accordance with BS:5440 Part 1 and 2.

The ATAG iS boiler as described in this manual is NOT suitable for a combined flue system.

The appliance concentric connection diameter is 60/100 mm, to which the flue gas outlet and air supply system can be fitted, with or without elbow pieces. The maximum permissible pipe length is set out in Table 9.8.2.a.

For further information about the available components of the flue gas and air supply system we recommend you consult the Flue system literature. Combinations with other brands or systems are, without written permission from ATAG Heating, not permitted.

The ATAG flue gas system is meant, and designed, solely for the use on ATAG central heating boilers adjusted to Nat gas or LPG. For this purpose the CE Certificate has been supplemented under the Gastec nr: 0063CQ3634 The maximum flue gas temperatures are below 70°C (full load 80/60°C).

The proper operation may be adversely influenced by changes of or adjustments to the correct set up. Possible warranty claims will not be honoured if incorrect changes result in non compliance with the installation manual or local rules and regulations.

I

Room sealed syste

igure 9.8.a

9.8.1 Flue terminal locations

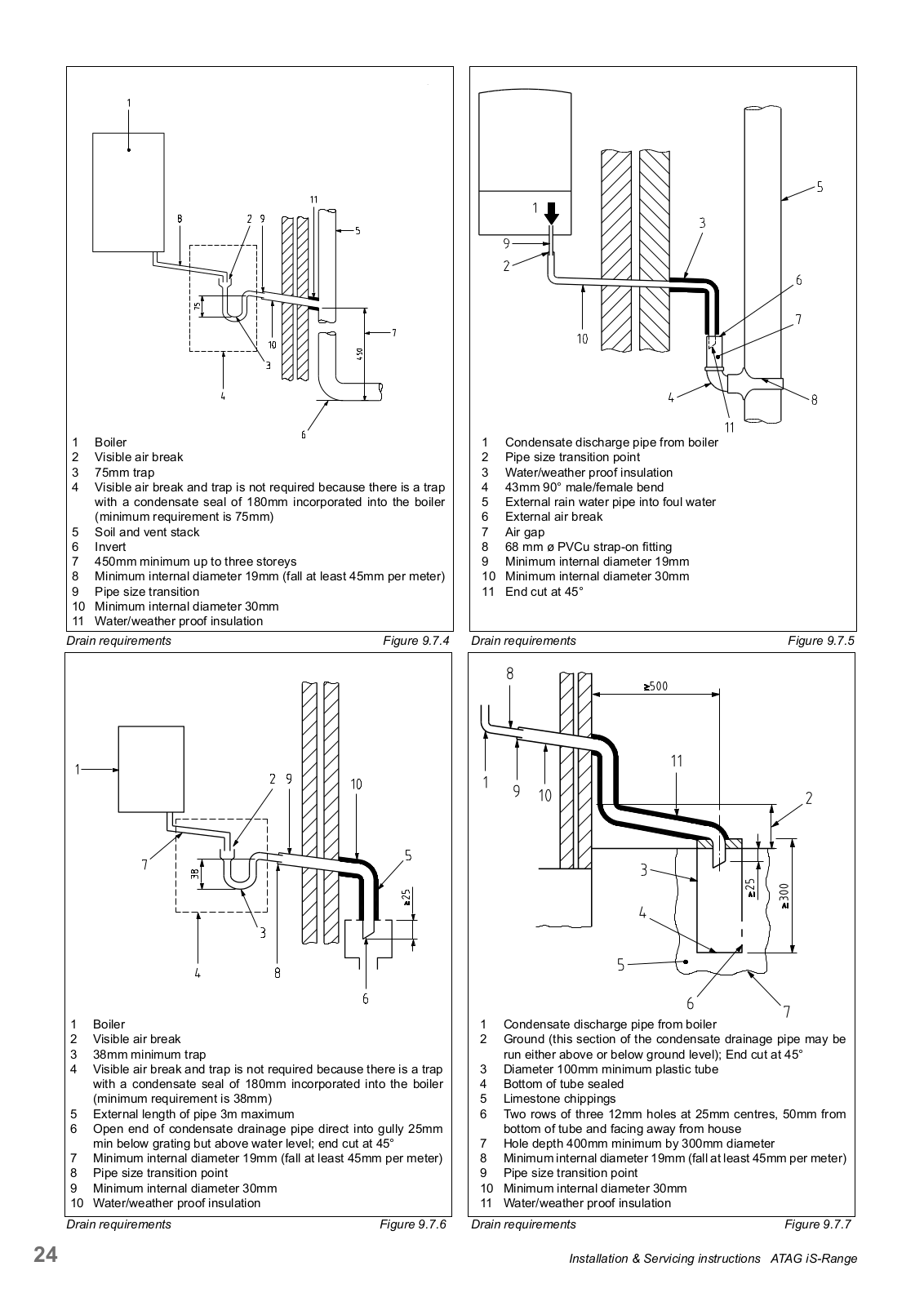

The terminal should be located where dispersal of combustion products is not unimpeded and with due regard for the damage or discolouration that might occur to parts of the building in the vicinity (see fig 9.8.1.a).

In certain weather conditions condensation may also accumulate on the outside of the air inlet pipe. Such conditions must be considered and where necessary insulation of the inlet pipe may be required. In cold and/or humid weather water vapour may condense on leaving the flue terminal. The effect of such 'plumeing' must be considered.

The terminal must not be located in a place where it is likely to cause a nuisance, where the terminal is less than 2m (6.6ft) above a pavement or platform to which people have access (including) any balcony or flat roof. The terminal must be protected by a guard of durable material.

A The flue must be terminated in a place not likely to cause a nuisance.

For horizontal flue terminal direct to the rear or side through the wall (only 1 bend ar terminal should be placed horizontal. The flue pipe inside the terminal is fitted in a 3 degrees angle to ensure the condensation water can run back to the boiler. See figure 9.8.1.a.

For longer horizontal sections, the outlet system should always be fitted on an incline (52 mm/m = 3°) sloping down towards the boiler so that no condensation water is able to accumulate in the outlet system. The chances of icicles forming on the outlet is minimised by causing the condensation water to run back towards the boiler. See figure 9.8.1.b.

Figure 9.8.1.a

Figure 9.8.1.b

| Below eaves | 200 (See Note 3) |

|---|---|

| Below balconies | 200 (See Note 3) |

| From a vertical drain pipe or soil pipe | 150 (See Note 3) |

| From an internal or external corner | 300 (See Note 2) |

| Above ground, roof or balcony level | 300 |

| From a surface or boundary facing the terminal | 600 (See Note 4) |

| From a terminal facing the terminal | 1200 |

| Above an opening, air brick, window etc. | 300 (See Note 1) |

| Vertically from a terminal on the same wall | 1500 |

| Horizontally from a terminal on the same wall | 300 |

| Horizontally from an opening, air brick, window etc. | 300 (See Note 1) |

| Minimum protrusion through a roof | 300 |

| From a vertical obstruction | 300 |

| From an openable window | 600 |

| From an adjacent vertical terminal | 600 |

| From an opening in the car port (e.g. door, window) into the dwelling | 1200 |

| Below a roof window | 2000 |

| Terminal parallel to a boundary | 300 |

- In addition, the terminal should not be nearer than 150mm to the framework of an opening into the building, i.e. a window surround or door surround. This clearance may be reduced to 25mm without effecting the performance of the boiler. However, to ensure the condensate plume does not affect adjacent

- surfaces a clearance of 300mm is preferable. These clearances may be reduced to 25mm without effecting the performance of the boiler. However, to ensure the condensate plume does not affect adjacent

- surfaces the terminal can be extended beyond gutters, pipes, eaves, balconies etc. by up to 500mm. If the flue is extended more than 500mm outside, it should

- To reduce the possibility of nuisance to neighbouring buildings etc. it is recommended the terminal should not be less than 2500mm from car parking spaces. building boundary walls, fences etc.

- A terminal must not be sited under a car port roof

- In certain weather conditions the terminal will emit a plume of steam. If possible avoid positioning the terminal where this may cause a nuisance, i.e. positions A D. G. H. J or M.

- The flue terminal must be exposed to the external air and the position must allow the free passage of air across it at all times.

- A terminal must not be sited below 2m where people have access to, such as public footpaths, access routes, patios etc. However, If the terminal is fitted less than 2m above a surface where there is no public access, the terminal must be protected by a terminal guard

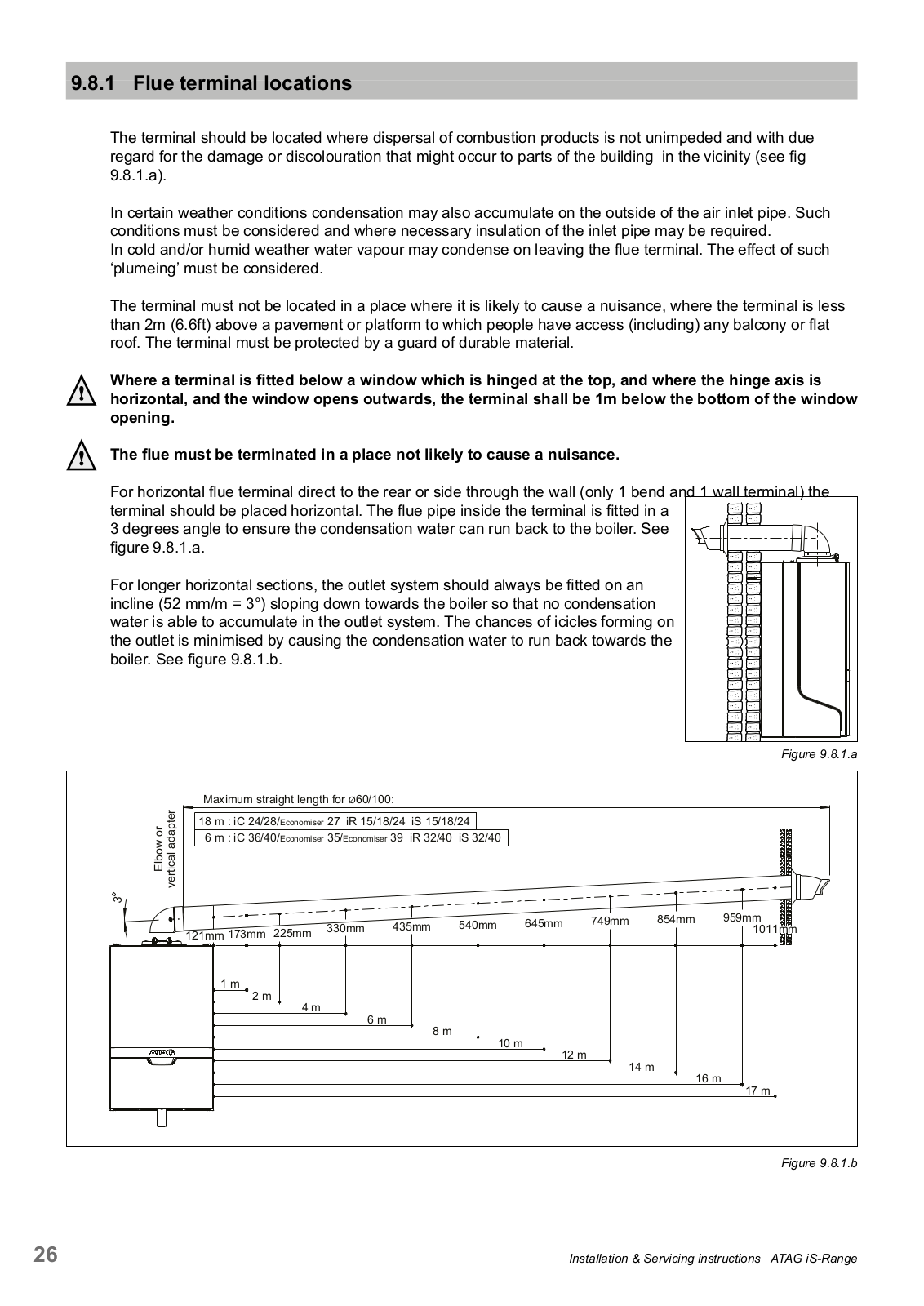

The appliance produces a white wisp of condensate (plumeing). This wisp of condensation is harmless, but can be unattractive, particularly in the case of outlets in outside walls.

For wall terminals a plume management kit is available as an option (see fig. 9.6.1.d)

Plume management kit

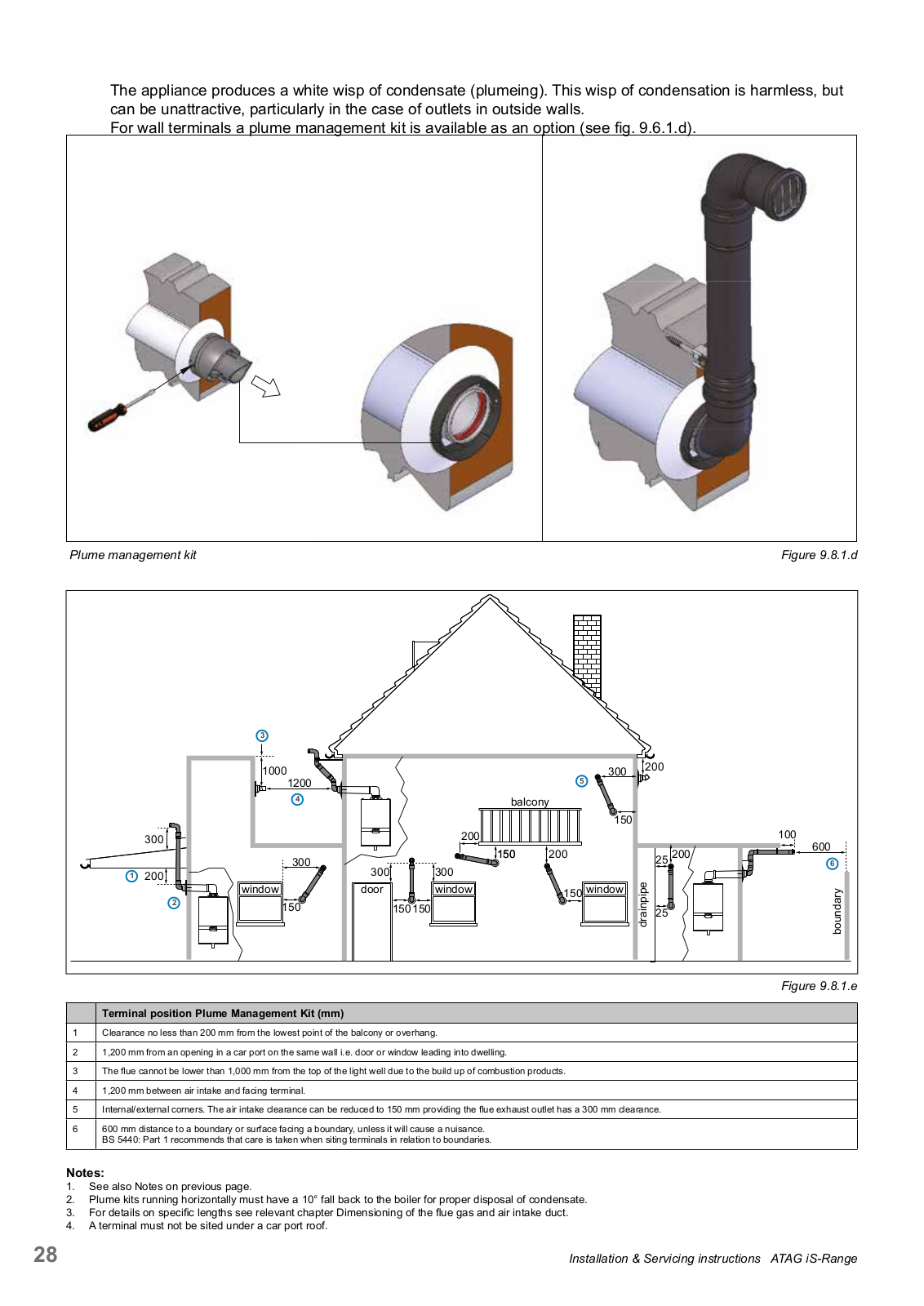

| Terminal position Plume Management Kit (mm) | |

|---|---|

| 1 | Clearance no less than 200 mm from the lowest point of the balcony or overhang. |

| 2 | 1,200 mm from an opening in a car port on the same wall i.e. door or window leading into dwelling. |

| 3 | The flue cannot be lower than 1,000 mm from the top of the light well due to the build up of combustion products. |

| 4 | 1,200 mm between air intake and facing terminal. |

| 5 | Internal/external corners. The air intake clearance can be reduced to 150 mm providing the flue exhaust outlet has a 300 mm clearance. |

| 6 |

600 mm distance to a boundary or surface facing a boundary, unless it will cause a nuisance.

BS 5440: Part 1 recommends that care is taken when siting terminals in relation to boundaries. |

- See also Notes on previous page. Plume kits running horizontally must have a 10° fall back to the boiler for proper disposal of condensate. For details on specific lengths see relevant chapter Dimensioning of the flue gas and air intake duct.

- 4. A terminal must not be sited under a car port roof.

9.8.2 Dimensioning of the flue gas and air intake duct

The total length of the run of the flue is determined by the flue diameter, including for the connection pipe, elbows fittings and terminal covers etc..

An incorrect dimensioned flue system can lead to disorders. Look at table 9.8.2.a for the choice of the boiler and the corresponding maximum equivalent flue length.

Explanation table 9.8.2.a:

Concentric flue gas system:

maximum noted length L = distance between boiler (from elbow or vertical adapter) and the end of terminal

When using bends the noted value behind every bend should be deducted from the maximum straight length.

Dimensions flue gas system and air supply system

Concentric flue system ø80/125 (Horizontal & Vertical)

| Concentric flue system ø60/100 (Horizontal & Vertical) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Туре | iS 15 | iS 18 | iS 24 | iS 32 | iS 40 | |||

| Maximum equivalent length (L) | m | 18 | 6 | 3 | ||||

| 45° bend resistance length | m | -1.0 | -1 | .0 | ||||

| 87° bend resistance length | m | -1.6 | -1 | .6 | ||||

iS 15

50

-1.9

Example:

An iS24 with a concentric flue gas system ø60/100mm has according to the table a maximum flue straight length of 18m In the system that is going to be put in there are 2 x 45° bends, so the maximum flue gas length is 18 – (2 x -1.0) = 16 m.

Flue dimensions

laximum equivalent length (L)

Tabel 982a

iS 18 iS 24 iS 32 iS 40

Rear Flue L = wall thickness (B) + 150mm

Side Flue

L = wall thickness (B) + distance between boiler and wall (C) + 150mm

If the length L is more than 580mm rear flue or 585mm side flue, then a Horizontal flue fixed length 1000mm (60/100mm) with elbow (FA100205) will need to be used instead, up to 810mm.

Figure 9.8.2.a

Fitting the flue

Note : If it is required to cut an extension, DO NOT cut the end of the inner duct that incorporates the seal joint.

Ensure the inner duct end without the seal joint is cut so that it is flush with the outer duct. Ensure that all cuts are square and free from burrs.

Once assembled with the components pushed home, the flue is fully sealed.

- 1. Adjust the telescopic flue and secure with sealing tape supplied or cut the fixed length terminal flue to the required length.

- 2. Fit the flue to the extensions (if required) by locating the inner duct into the seal joint and push fully home the inner and outer duct.

- 3. When connecting the horizontal flue terminal length ensure the terminal end outlet is at the uppermost part of the flue.

- 4. Pass the terminal flue assembly through the wall.

- 5. Fit the bend to the boiler turret.

- 6. If the inside sealing collar (white) is being used, then it will need to be fitted before assembling the flue and making good the inside wall.

- Pull the flue assembly towards the bend, locating the inner duct into the seal joint on the bend and secure the flue assembly to the bend by pushing fully home (Outer flue duct must be seen through the small inspection hole to confirm fully home).

- 8. Make good the outside wall and fit the outside sealing collar onto the location provided immediately behind the flue terminal grille.

When mounting the flue gas system, pay attention to the flow direction (See figure 9.8.2.b). It is not permitted to mount a system upside down and will lead to complaints.

Use a soap solvent or special grease (supplied in the accessory bag with the boiler) to simplify the fitting.

The ATAG flue system used is a push fit flue system, which does not require screws to be fitted at each flue joint.

The flue system must be adequately supported at regular intervals between brackets of no more than 1.0 metres for horizontal sections and no more than 2.0 metres for vertical sections.

low direction Figure 9.8.2.b

99 Fitting the boiler onto the boiler frame

After the pipe work of gas, heating installation has been fitted to the boiler frame, the boiler can be placed on the boilerframe

Before hanging the boiler to the boiler frame remove first the cover of the boiler first. The cover is also the air cabinet and is attached to the boiler case with 2 fasteners (A and B) (see figure 9.9.a).

Note that there is an earth cable (when present) to disconnect when removing the cover from the boiler. Free space for removing the connector is 400mm. Remember to connect this earth cable (when present) when replacing the cover.

Always replace and turn the 2 screws tight in the fasteners A and B after replacing the cover.

Remove furthermore the 4 plastic caps from the boiler connections.

When removing the plastic sealing caps from the pipes, contaminated testing water may be released.

A Lift the boiler only by the boilers case.

Lifting and carrying precautions:

- Lift only a manageable weight or ask for help

- When lifting the boiler, bend the knees, and keep the back straight and feet apart.

- Do not lift and twist at the same time.

- Lift and carry the boiler close to the body

- Wear protective clothing and gloves to protect from any sharp edges.

- 1. Press all connection underneath the boiler upwards

- 2. Put on each valve and the elbow fitting a fibre washer (supplied)

3 and 4. Take the boiler and hang it from approx. 50mm higher than the boiler frame vertical downwards on the boiler frame so the fittings will be axial approached.

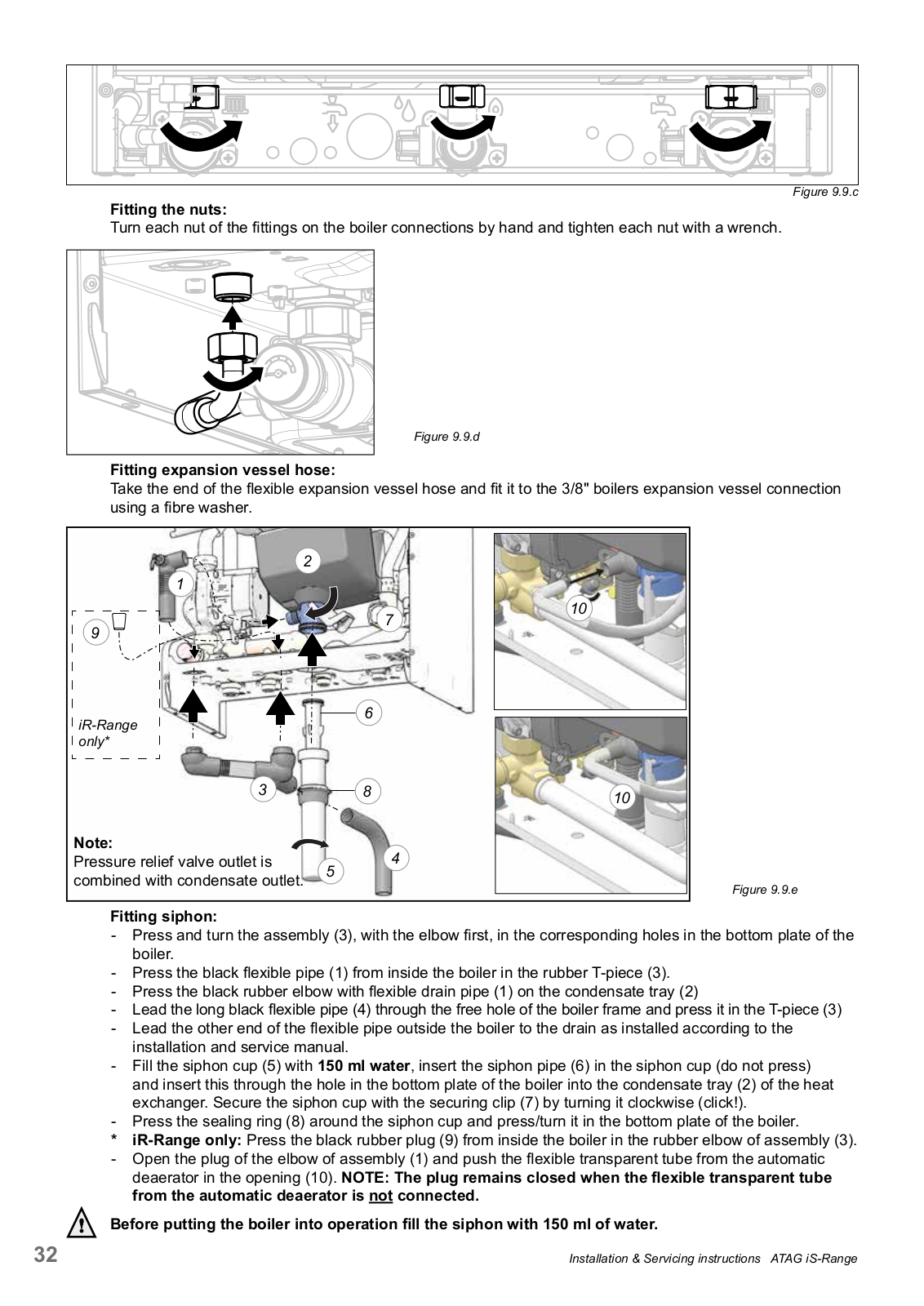

Fitting the nuts:

Turn each nut of the fittings on the boiler connections by hand and tighten each nut with a wrench.

Figure 9.9.d

Fitting expansion vessel hose:

Take the end of the flexible expansion vessel hose and fit it to the 3/8" boilers expansion vessel connection using a fibre washer.

Fitting siphon:

- Press and turn the assembly (3), with the elbow first, in the corresponding holes in the bottom plate of the boiler.

- Press the black flexible pipe (1) from inside the boiler in the rubber T-piece (3).

- Press the black rubber elbow with flexible drain pipe (1) on the condensate tray (2)

- Lead the long black flexible pipe (4) through the free hole of the boiler frame and press it in the T-piece (3)

- Lead the other end of the flexible pipe outside the boiler to the drain as installed according to the installation and service manual.

- Fill the siphon cup (5) with 150 ml water , insert the siphon pipe (6) in the siphon cup (do not press) and insert this through the hole in the bottom plate of the boiler into the condensate tray (2) of the heat exchanger. Secure the siphon cup with the securing clip (7) by turning it clockwise (click!).

- Press the sealing ring (8) around the siphon cup and press/turn it in the bottom plate of the boiler.

- iR-Range only: Press the black rubber plug (9) from inside the boiler in the rubber elbow of assembly (3). Open the plug of the elbow of assembly (1) and push the flexible transparent tube from the automatic

- Open the plug of the elbow of assembly (1) and push the flexible transparent tube from the automatic deaerator in the opening (10). NOTE: The plug remains closed when the flexible transparent tube from the automatic deaerator is not connected.

Before putting the boiler into operation fill the siphon with 150 ml of water.

Figure 9.9.e

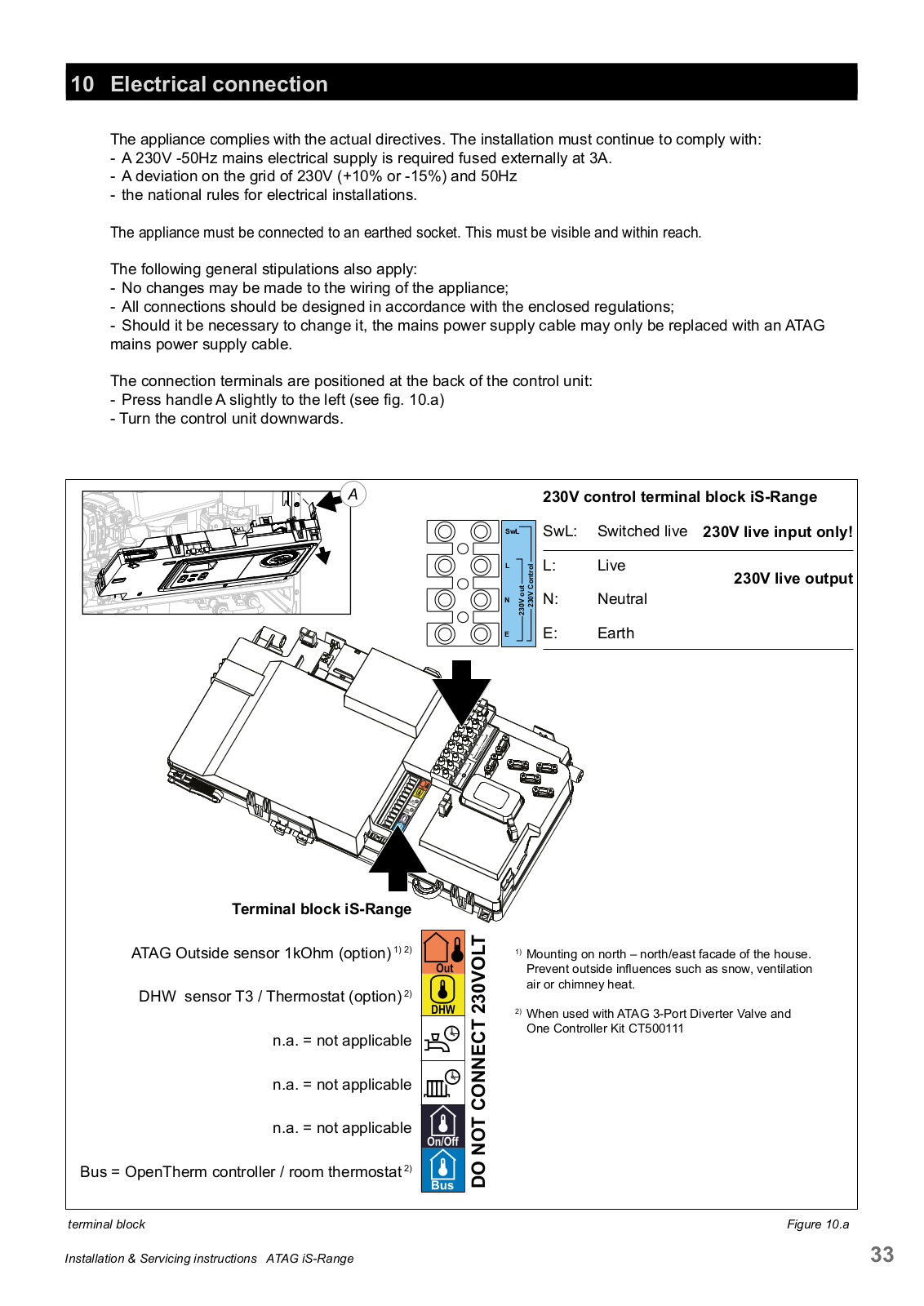

10 Electrical connection

The appliance complies with the actual directives. The installation must continue to comply with:

- A 230V -50Hz mains electrical supply is required fused externally at 3A.

- A deviation on the grid of 230V (+10% or -15%) and 50Hz

- the national rules for electrical installations.

The appliance must be connected to an earthed socket. This must be visible and within reach.

The following general stipulations also apply:

- No changes may be made to the wiring of the appliance;

- All connections should be designed in accordance with the enclosed regulations;

- Should it be necessary to change it, the mains power supply cable may only be replaced with an ATAG mains power supply cable.

The connection terminals are positioned at the back of the control unit:

- Press handle A slightly to the left (see fig. 10.a)

- Turn the control unit downwards.

terminal block

10.1 ONE controller, OpenTherm and BUS connection (blue)

The blue BUS connection can only be used for the following ATAG products:

- ATAG ONE controller in conjunction with the ATAG 3 Port Valve (22mm) with Cylinder Sensor Kit CT500111;

- ATAG ONE controller in conjunction with the ATAG 3 Port Valve (28mm) with Cylinder Sensor Kit CT500112;

- ATAG 3-Port diverter valve kit (22mm) with cylinder sensor, & 7 Day Two Channel Plug-In Digital Programmer. (iS boilers only) CT500222;

- ATAG 3-Port diverter valve kit (28mm) with cylinder sensor, & 7 Day Two Channel Plug-In Digital Programmer. (iS boilers only) CT500228.

10.2 Room thermostat volt free connection (black)

When an ATAG 3-Port diverter valve kit & 7 Day Two Channel Plug-In Digital Programmer is fitted then a volt free on / off room thermostat with volt free connections can be wired to the black volt free room thermostat connector position.

10.3 ATAG Central Heating volt free timer connection (white)

N/A not applicable.

10.4 ATAG Hot Water volt free timer connection (white)

N/A not applicable.

10.5 DHW sensor connection (yellow)

When an ATAG 3-Port diverter valve kit is fitted it will come with a cylinder sensor and yellow plug. The cylinder sensor wires and plug connect to the yellow volt free DHW connector position.

10.6 ATAG Outside Sensor (orange)

When a weather compensation sensor (optional) is used in conjunction with an ATAG 3-Port diverter valve kit, the two wires from the outside sensor get wired into the plug supplied with the sensor and connect onto the orange connector position.

10.7 230V Control Block (230V live output)

If a live, neutral or earth wire is required for external controls these can be taken from the (L) live, (N) Neutral or (E) earth 230V live output connections on the 230v control terminal block.

If external 230V controls are used, then a switched live is required from the control(s) to connect to the 230V control terminal block in position (SwL) Switched live to fire up the boiler.

10.8 230V Control Block (SwL Switched live)

If external 230V controls are used, then a switched live is required from the control(s) to connect to the 230V control terminal block in position (SwL) Switched live to fire up the boiler. This could be in series after programmers, room stats, cylinder stats and motorised valves, then to SwL on the 230V control terminal block.

35

Filling system

The central heating installation needs to be filled with potable water according to the requirements in chapter 9.3 'Water guality'. For filling or topping up the heating system the installation must be provided with a filling loop or a fill and drain valve to connect a garden hose i.e.. Use the filling loop according to the following procedure.

| 1 | Attach the filling loop pipe to the filling loop assembly; |

|---|---|

| 2 | Open the filling loop valves; |

| 3 | Slowly fill the central heating system up to 1.0 – 1.2 bar; (at the bottom left a pressure gauge indicates the water pressure in the central heating system) |

| 4 | Close the filling loop valves; |

| 5 | Vent the entire heating installation starting at the lowest point; |

| 6 | Check the water pressure and top up if necessary to 1.0 – 1.2 bar; |

| 7 | Check the filling loop valve is closed; |

When powering up the boiler (described in chapter 13) an automatic de-aeration program will run to vent the boiler. During this program the pressure in the central heating needs to be checked, and when necessary. topped up again

It may take some time before all the air has disappeared from a filled installation. Certainly during the first week sounds may be audible that indicate air. The automatic air vent in the boiler will let this air escape, causing the water pressure to drop during this period and water will need to be refilled again.

Always remove the filling loop pipe or garden hose after filling or topping up the heating system and Always remove the many roop part of the close the connections with a cap nut.

12 Boiler controls

Before the electrical power is switched on, it helps to know the operation of the boiler in advance. On this page the controls are described in short. The next page describes the button functions and the symbols on the display.

The boiler is equipped with self-managing control system. This control system takes over a large part of the manual settings, which simplifies the start-up of the installation considerably.

After filling the installation and switching on the electrical power supply a short start-up program is activated. This shows all digits, boiler type and software version and the automatic de-aeration program is activated. The automatic de-aeration program lasts for approx. 7 minutes and stops automatically. Then the boiler will switch on for the enabled program (See chapter 11 'Filling and bleeding boiler and installation').

CH controls

With a demand from the heating controls, the boiler activates its 1 minute delay period. This is to prevent the heat exchanger from losing its heat too quickly in the event of a hot water demand. Then the pump starts and after 30 seconds the gradient control becomes active. The starting point of the gradient control is the currently existing flow temperature. A Delta-T control (25K) ensures a stable control according to heat request.

If the flow temperature is below the T-set value of 20°C the boiler will immediately start.

If during a demand from the heating the burner switches off, because the desired flow temperature is exceeded, there will be an anti-cycle time in operation for 5 minutes.

| Resistance ta | ble sensors | ATAG iC-, iS- an | d iR-series | |||

|---|---|---|---|---|---|---|

| Outside senso | r T4 | Flow sensor T1 | ||||

| Return sensor T | 2 | |||||

| DHW sensor T3 | ||||||

| Flue sensor T5 | ||||||

| NTC1k (25°C) | NTC10k (25°C) | |||||

| Temperature | Resistance | Temperature | Resistance | |||

| [°C] | [Ohm] | [°C] | [Ohm] | |||

| -10 | 4.574 | -10 | 55.047 | |||

| -9 | 4.358 | 0 | 32.555 | |||

| -8 | 4.152 | 10 | 19.873 | |||

| -7 | 3.958 | 12 | 18.069 | |||

| -6 | 3.774 | 14 | 16.447 | |||

| -5 | 3.600 | 16 | 14.988 | |||

| -4 | 3.435 | 18 | 13.674 | |||

| -3 | 3.279 | 20 | 12.488 | |||

| -2 | 3.131 | 22 | 11.417 | |||

| -1 | 2.990 | 24 | 10.449 | |||

| 0 | 2.857 | 26 | 9.573 | |||

| 1 | 2.730 | 28 | 8.779 | |||

| 2 | 2.610 | 30 | 8.059 | |||

| 3 | 2.496 | 32 | 7.406 | |||

| 4 | 2.387 | 34 | 6.811 | |||

| 5 | 2.284 | 36 | 6.271 | |||

| 6 | 2.186 | 38 | 5.779 | |||

| 7 | 2.093 | 40 | 5.330 | |||

| 2.004 | 42 | 4.921 | ||||

| 9 | 1.920 | 44 | 4.547 | |||

| 10 | 1.840 | 46 | 4.205 | |||

| 11 | 1.763 | 48 | 3.892 | |||

| 12 | 1.690 | 50 | 3.605 | |||

| 13 | 1.621 | 52 | 3.343 | |||

| 14 | 1.555 | 54 | 3.102 | |||

| 15 | 1.492 | 56 | 2.880 | |||

| 16 | 1.433 | 58 | 2.677 | |||

| 17 | 1.375 | 60 | 2.490 | |||

| 18 | 1.320 | 62 | 2.318 | |||

| 19 | 1.208 | 64 | 2.159 | |||

| 20 | 1.218 | 60 | 2.013 | |||

| 21 | 1.170 |

68

70 |

1.8/8 | |||

| 22 | 1.125 | 70 | 1.753 | |||

| 23 | 1.001 | 74 | 1.030 | |||

| 24 | 1.040 | 74 | 1.001 | |||

| 20 | 1.000 | 70 | 1 244 | |||

| 20 | 902 | /8 | 1.341 | |||

| 27 | 920 | 80 | 1.200 | |||

| 20 | 092 | 02 | 1.170 | |||

| 29 |

000

827 |

06 | 1.105 | |||

| 30 | 687 | 00 | 974 | |||

| 30 | 575 | 00 | 914 | |||

| 40 | 575 | 90 | 515 | |||

This means that the burner switches on again after 5 minutes if there is still a demand from the heating.

The ATAG iS is equipped with boiler sensors of 10kOhm. The resistance value and corresponding temperature are shown in the accompanying table.

table 12.a

12.1 Controls and explanation of the functions

Central heating

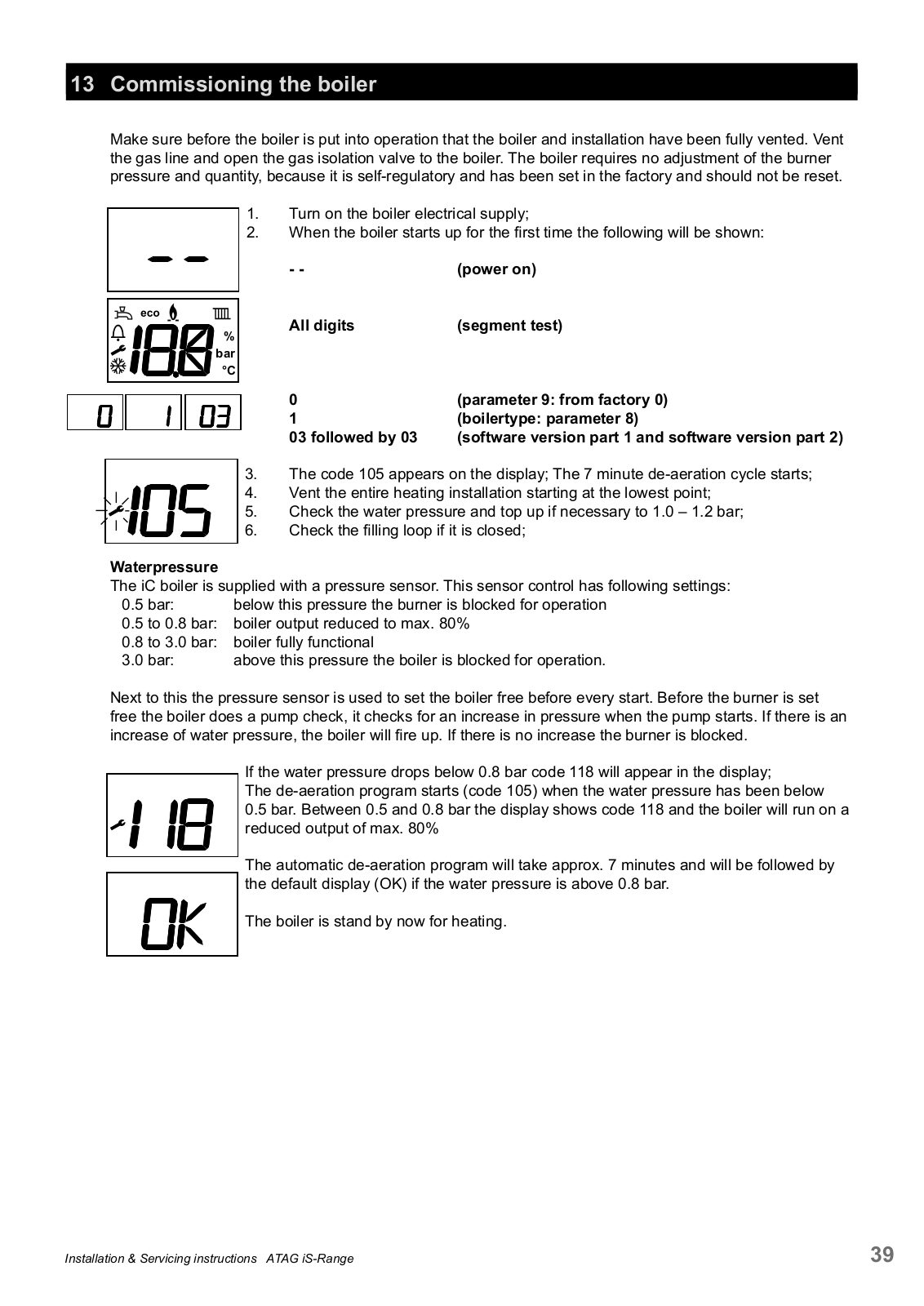

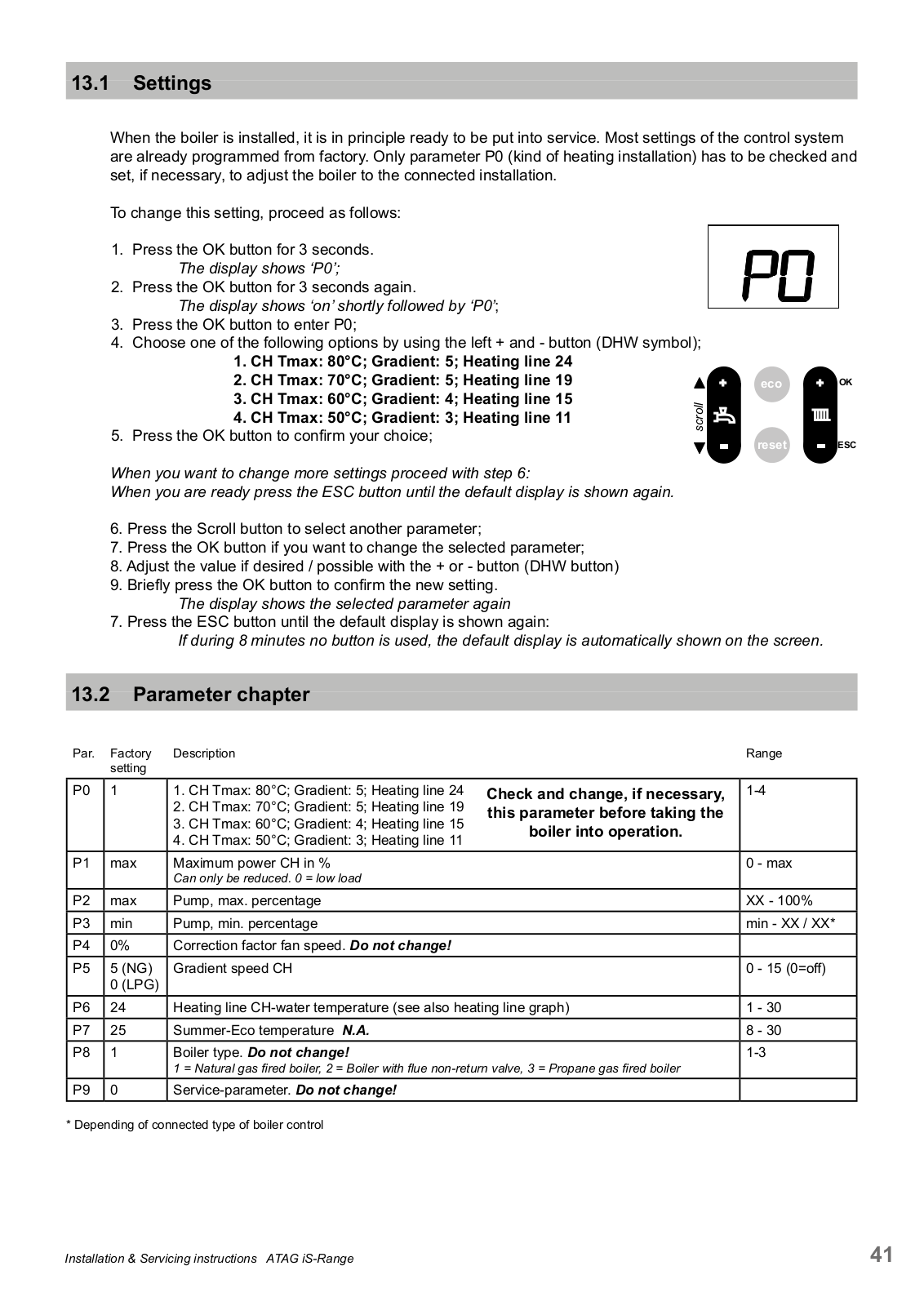

Setting the CH water temperature: