Atag iC 24, iC 28, iC Economiser Plus 27, iC 36, iC 40 Installation & Servicing Instructions Manual

...

I n s t a l l a t i o n & S e r v i c i n g

Instructions

iC 24

iC 28

iC 36

iC 40

iC Economiser Plus 27

iC Economiser Plus 35

iC Economiser Plus 39

Natural Gas Boilers

Boiler G.C No

iC 24 47-310-19

iC 28 47-310-21

iC 36 47-310-23

iC 40 47-310-25

iC Economiser Plus 27 47-310-27

iC Economiser Plus 35 47-310-29

iC Economiser Plus 39 47-310-31

CE PIN 0063CQ3634

These instructions are to be retained by the user.

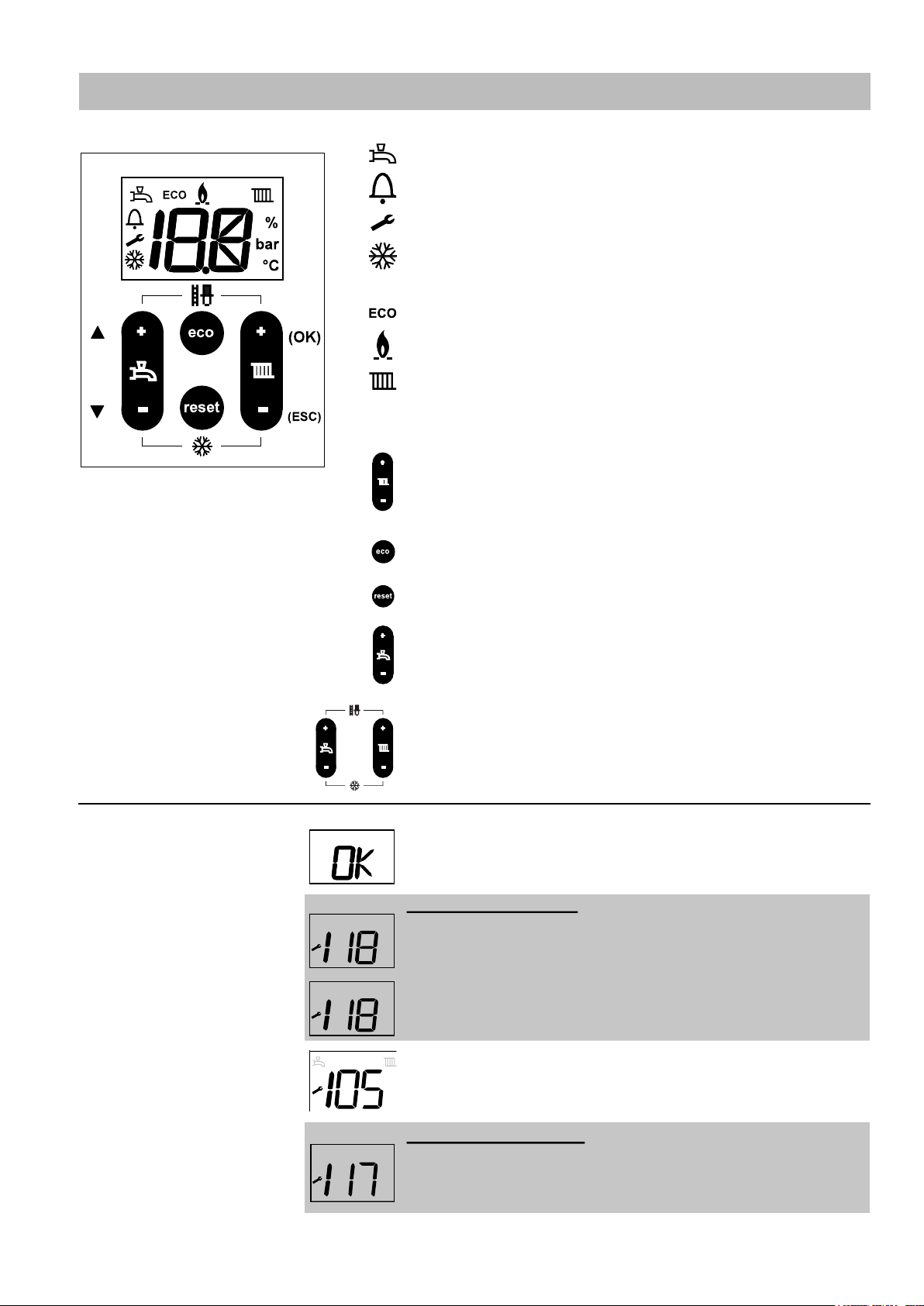

Explanation of the Control Panel & Buttons

DHW Visible when DHW program is active

Flashing when there is a heat demand for DHW

Error Error indication (accompanied with a code).

Alert Service-mode or blocking

Pump Visible when pump is set to continuously

Flashing when frost program is active

Eco Visible when DHW comfort function is not active

Flame Visible when boiler is active for heating or DHW

Heating Visible when heating program is active

Flashing when there is a heat demand for heating

Central heating program (On = +, Off = -)

Setting of boiler temperature (max. fl ow temperature)

+/-function (ancillary function: OK and Escape)

Eco-function DHW on/off . Press 6 seconds for Information

Reset button

DHW program (On = +, Off = -)

Setting of hot water temperature

+/-function (ancillary function: Scroll and +/-function)

Commissioning function (Press both + buttons for 6 seconds)

Pump function (Press both - buttons for 6 seconds)

Information on the water pressure:

The default view of the display shows OK. Press the eco-button for

6 seconds and press the scroll-buttons until A6 is displayed.

The actual water pressure will be shown:

Water pressure too low

Code 118 and spanner symbol visible:

Water pressure is too low (<0.8 bar).

Power is reduced by 20%. The installation should be refi lled.

or

Code 118 and spanner symbol visible:

Water pressure is too low (<0.5 bar).

The boiler is taken out of operation. The installation should be refi lled.

After the installation has been refi lled and if the pressure was below

0.5 bar the de-aeration program will start (Code 105 and spanner

symbol visible). This will last for approx 7 mins.

Water pressure too high

Code 117 and spanner symbol visible:

Water pressure is too high (> 3.0 bar).

The boiler is taken out of operation.

The installation pressure should be reduced by draining water from the heating system.

See chapter 12 for more information about button functions and read-out.

2

Installation & Servicing instructions ATAG iC-Range

Contents

1 Introduction .................................................................................................................................... 4

2 Rules & Regulations (Symbols) .....................................................................................................5

3 Technical specifi cations ..................................................................................................................7

4 Dimensions ................................................................................................................................... 9

5 Delivery package .......................................................................................................................... 10

6 Boiler description .......................................................................................................................... 10

7 Boiler photo components list ........................................................................................................ 11

8 Mounting boiler frame .................................................................................................................. 12

8.1 Wall frame ......................................................................................................................... 13

9 Connecting boiler ......................................................................................................................... 14

9.1 Central heating system ..................................................................................................... 14

9.2 Expansion vessel .............................................................................................................. 15

9.3 Water quality .....................................................................................................................15

9.4 Heating systems with plastic pipes ................................................................................... 17

9.5 Gas connection in general ................................................................................................ 17

9.5.1 Natural gas connection (NG) ............................................................................................17

9.5.2 Propane gas connection (LPG) ......................................................................................... 17

9.5.3 House pressure regulator .................................................................................................18

9.5.4 Dimensioning of the low pressure gas line .......................................................................18

9.5.5 De-aerating the LPG tank ................................................................................................. 18

9.6 Hot water supply ............................................................................................................... 19

9.7 Condensation drain pipe ................................................................................................... 19

9.8 Flue gas exhaust system ..................................................................................................23

9.8.1 Flue terminal locations ...................................................................................................... 24

9.8.2 Dimensioning of the fl ue gas and air intake duct ............................................................27

9.9 Fitting the boiler onto the boiler frame ............................................................................. 29

10 Electrical connection ....................................................................................................................31

10.1 One controller, OpenTherm and BUS connection .............................................................32

10.2 Room thermostat volt free connection ..............................................................................32

10.3 ATAG Central Heating volt free timer connection .............................................................. 32

10.4 ATAG Hot Water volt free timer connection ......................................................................32

10.5 DHW sensor connection ................................................................................................... 32

10.6 ATAG Outside sensor ........................................................................................................ 32

10.7 230V Control Block (230V live output) .............................................................................. 32

10.8 230V Control Block (SwL Switched live) ........................................................................... 32

10.9 Electrical diagram ............................................................................................................. 33

11 Filling system ............................................................................................................................... 34

11.1 Hot water supply ...............................................................................................................34

12 Boiler controls .............................................................................................................................. 35

12.1 Controls and explanation of the functions ......................................................................... 36

13 Commissioning the boiler .............................................................................................................37

13.1 Settings .............................................................................................................................39

13.2 Parameter chapter ............................................................................................................ 39

14 Isolating the boiler .......................................................................................................................40

15 Commissioning ............................................................................................................................. 41

15.1 Checking the CO2 ............................................................................................................. 42

15.2 Checking fl ue integrity .......................................................................................................45

15.3 CO and combustion checks ............................................................................................. 46

16 Routine servicing .......................................................................................................................... 48

16.1 Flow restrictor ................................................................................................................... 52

16.2 Component replacement ................................................................................................... 52

16.3 User's instructions ............................................................................................................. 52

16.4 Warranty ............................................................................................................................ 52

17 Error codes and fault fi nding .......................................................................................................53

Annex A System water additives ..................................................................................................... 54

Annex B Declaration of conformity .................................................................................................. 55

Annex C Short parts list ...................................................................................................................56

Work on the installation should only be carried out by qualifi ed

personnel with calibrated equipment and appropriate tools.

Installation & Servicing instructions ATAG iC-Range

3

1 Introduction

These instructions describe the functioning, installation, use and primary maintenance of ATAG central heating

boilers for the United Kingdom.

These instructions are intended for the use of Gas Safe registered installers in connection with the

installation and putting into operation of ATAG boilers. It is advisable to read these instructions thoroughly,

well in advance of installation. Separate instructions for use are supplied with the boiler for users of ATAG

central heating boilers. ATAG is not liable for the consequences of mistakes or shortcomings which have

found their way into the installation instructions or user’s manual. Further, ATAG reserves the right to alter its

products without prior notifi cation.

When delivering the boiler, give the customer clear instructions concerning its use; present the

customer with the user’s manual and warranty card.

Each boiler is fi tted with an identifi cation plate. Consult the details on this plate to verify whether the boiler is

compliant with its intended location, e.g.: gas type, power source and exhaust classifi cation.

On completion of the installation the installer or commissioning engineer must fi ll out and complete the

Benchmark Commissioning Checklist found on page 59 of this manual and hand this to the customer

for future record keeping. The Benchmark Service Record must also be completed by the service agent

following each service call, and return to the customer.

4

Installation & Servicing instructions ATAG iC-Range

2 Rules & Regulations (Symbols)

The following regulations apply to installation of ATAG central heating boilers:

Legislation and Regulations.

Gas Safety (Installation and Use). All gas appliances must by law, be installed by a competent person, eg.

Members of Gas Safe Register and in accordance with the current Gas Safety Regulation. Failure to install

appliance correctly could lead to prosecution.

All Gas Safe registered installers carry a Gas Safe ID card and have a registration number. You can call Gas

Safe Register directly on 0800 408 5577.

In addition to the above regulations this appliance must be installed in compliance with the current IEE

Regulations and Building Regulations. Regulations and bye laws of the Local Water Authority and the

Current Health and Safety Regulation.

The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and installers. The

purpose is to ensure that customers are provided with the correct equipment

for their needs, that it is installed, commissioned and serviced in accordance

with the manufacturer’s instructions by competent persons and that it meets the

requirements of the appropriate Building Regulations. The Benchmark Checklist can be used to demonstrate

compliance with Building Regulations and should be provided to the customer for future reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the

Benchmark Code of Practice which is available from the Heating and Hotwater Industry Council who manage

and promote the Scheme.

Visit www.centralheating.co.uk for more information.

The current Electricity at Work Regulation must be complied with and also be in accordance with the relevant

and current editions of the British Standards.

The ATAG iC boiler is a certifi ed appliance and must not be modifi ed or installed in any way contrary to

this Installation Manual. Manufacturers instructions must not be taken, in any way, as overriding statutory

obligations.

The ATAG iC boiler is a central heating boiler with an integrated hot water function. The boiler must be

connected according to these instructions and all installation norms in respect of the part of the boiler to be

connected.

The appliance is not to be used by children or persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction.

Children being supervised not to play with the appliance.

Observe the following rules of safety:

- All work on the boiler must take place in a dry environment.

- ATAG boilers may never be in operation without their housing, except in connection with maintenance or

adjustments (see Chapter 15 and 16).

- Never allow electrical or electronic components to come into contact with water.

Carry out the following tasks in connection with maintenance, etc. to an already-installed boiler:

- Shut down all programs

- Close the gas isolation valve

- Shut down the 230V power supply

- Close the shut off valve of the boiler’s cold water supply

See chapter 15 and 16 for further instructions.

Installation & Servicing instructions ATAG iC-Range

5

Take note of the following when maintenance or adjustments are needed:

- The boiler must be able to function during these activities; for this reason, the boiler’s 230V power supply,

gas pressure and water pressure must be maintained. Ensure that there is not a source of potential

danger during these activities.

Following maintenance or other activities; always check the installation of all parts through which

gas fl ows (using leak detection spray).

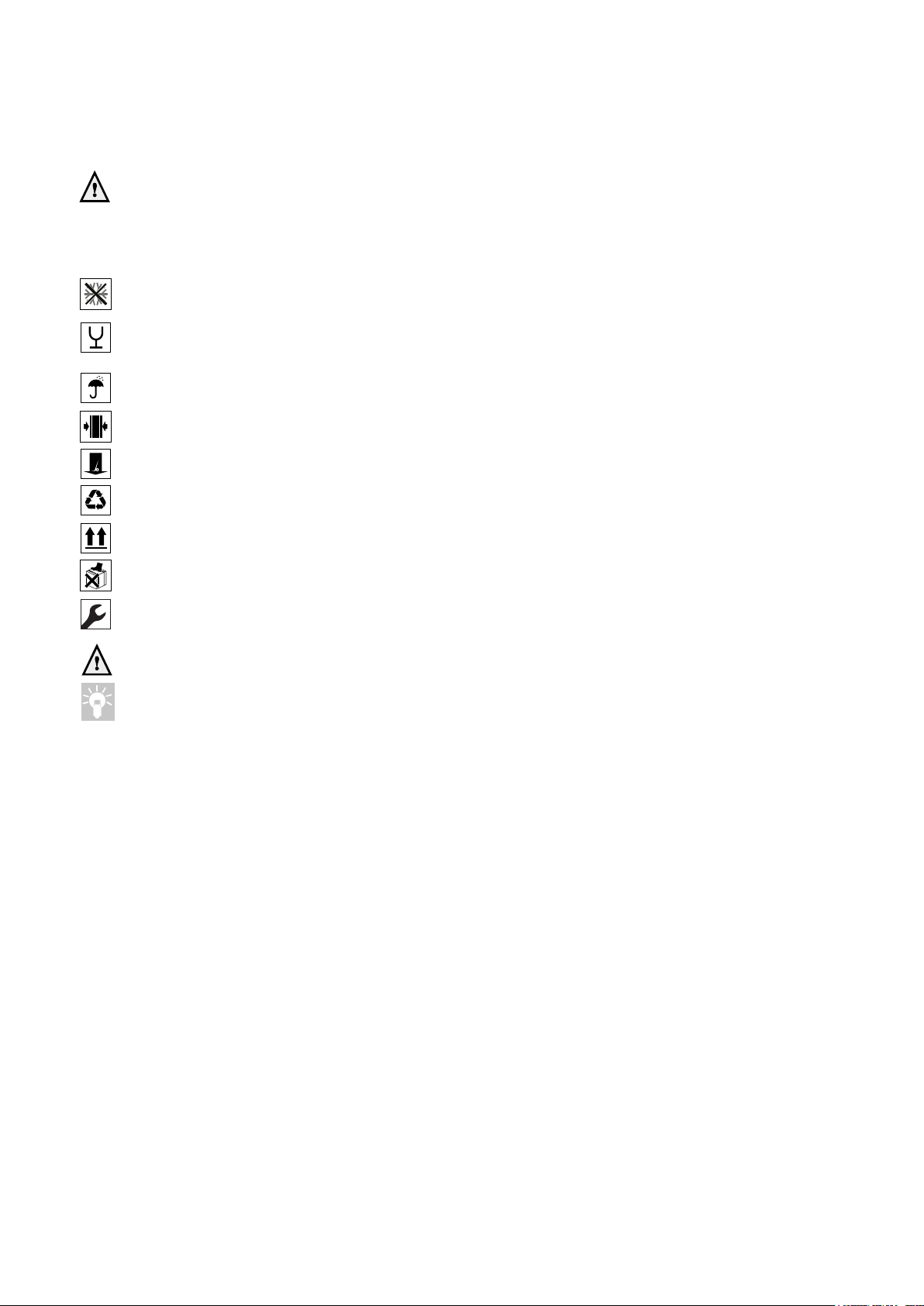

The following (safety) symbols may be encountered in these installation instructions and on the boiler

(packaging):

Boiler must be stored away from frost.

Protect packaging and/or contents from damage as a result of insuffi cient care taken during

transport.

Protect the boiler from weather conditions during transport and storage whilst still in its packaging.

If and how to clamp when using transport trucks with clamp equipment.

If and how to transport when using a rolling jack.

The whole packaging is made of recycled materials and can be recycled again.

Transport and place the boiler in its packaging in this position.

Do not to step on or stand on the package.

An assembly or dismantling must be carried out.

Pay extra attention in connection with a particular operation.

Useful tip or advice

Disposal of the product

This product should be handed in at a designated collection point, e.g. by handing it in at a duly authorized

reseller when purchasing a similar product, or at an authorized collection site for recycling products wich

contains electrical and electronic equipment (EEE) and batteries and accumulators. Because of the

potentially hazardous substances that usually accompany EEE, improper handling of this type of waste could

have a possible impact on the environment and human health.

Your cooperation in the proper disposal of this product will contribute to the eff ective usage of natural

resources.

For more information on recycling this product, please contact your city offi ce, local waste disposal facilities,

offi cial service for chemical waste or landfi ll site.

6

Installation & Servicing instructions ATAG iC-Range

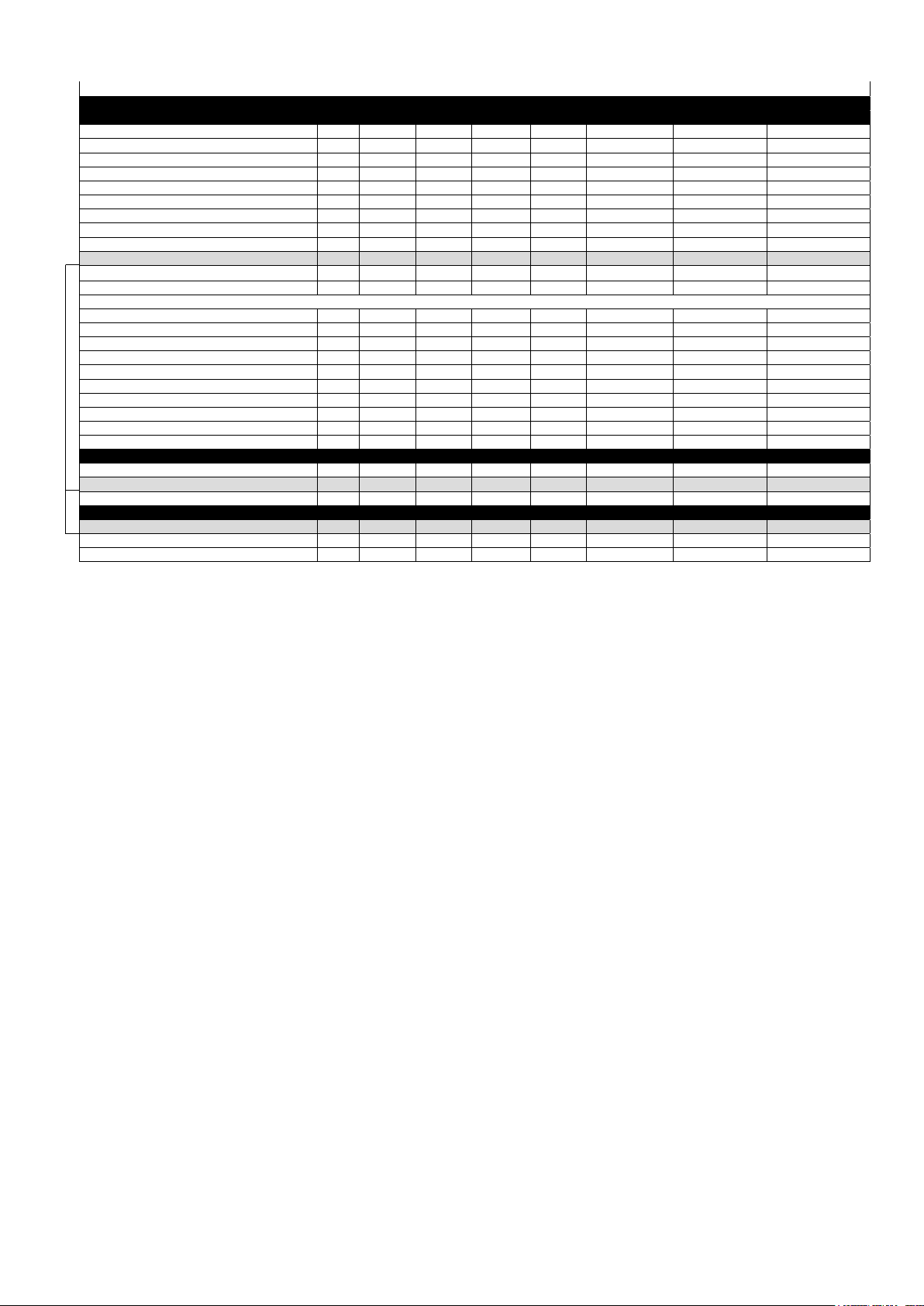

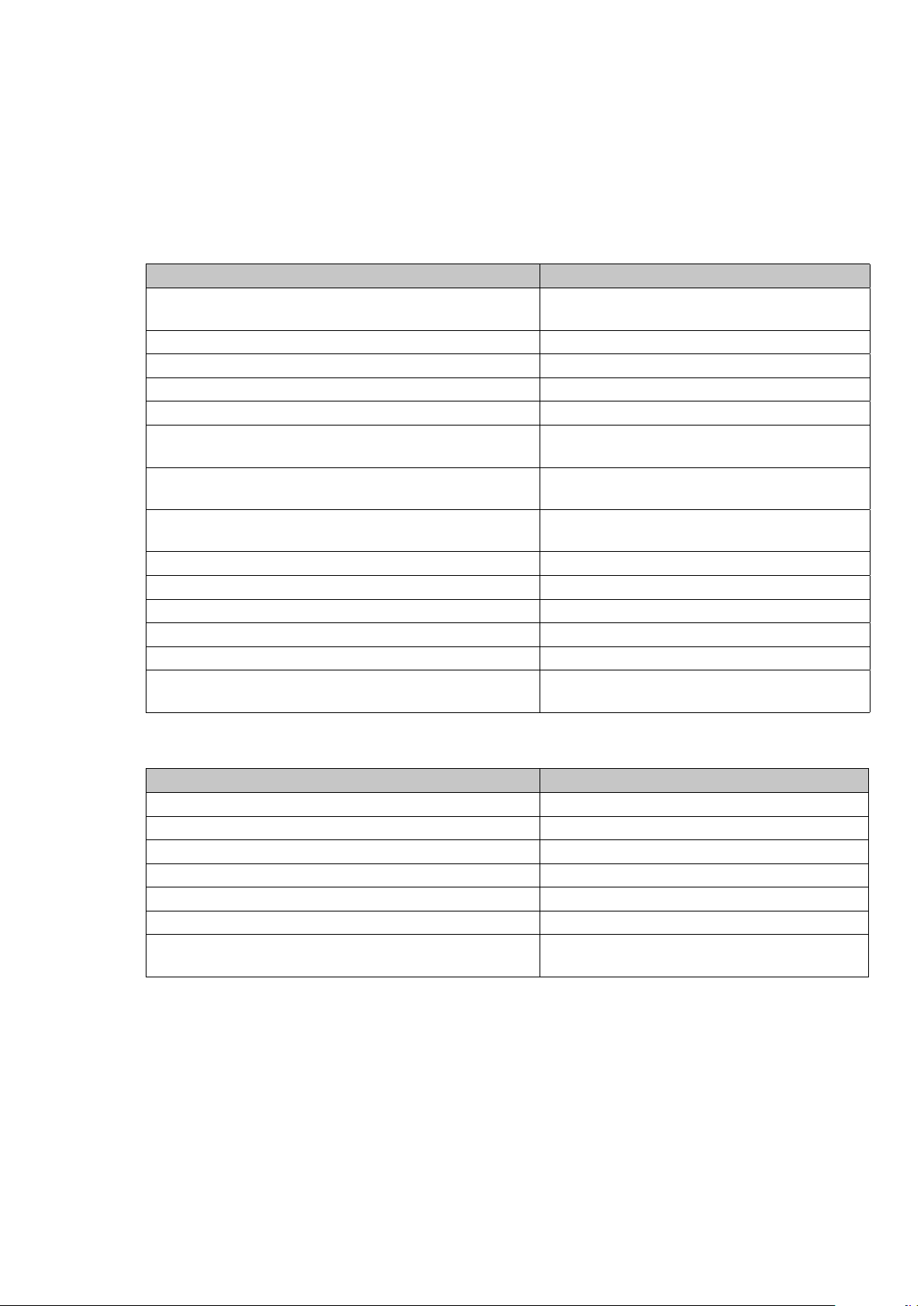

3 Technical specifi cations

Technical specifi cations Natural gas

Boiler type iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Economiser Plus 35 iC Econ omiser Plus 39

Type heat exchanger iCon1 iCon1 iCon2 iCon2 iCon1 iCon2 iCon2

CE product identifi cation number (PIN) 0063CQ3634

Country of destination UK

Qmin input min. CH & DHW (Hi) kW 4.5 4.5 6.2 6.2 4.5 6.2 6.2

Qn input nominal CH (Hi) kW 21.6 21.6 28.8 28.8 21.6 28.8 28.8

Qr adjusted input CH (Hi) kW 21 .6 21.6 28.8 28.8 21.6 28.8 28.8

Qmin input min. CH & DHW (Hs) kW 5.0 5.0 6.9 6.9 5.0 6.9 6.9

Qn input nominal CH (Hs) kW 24.0 24.0 32.0 32.0 24.0 32.0 32.0

Qnw input nominal DHW (Hi) kW 24.0 27.3 35.4 37.9 28.3 36.3 37.9

Qnw input nominal DHW (Hs) kW 26.7 30.3 39.3 42.1 31.4 40.3 42.1

Pmin output min. CH (50/30°C) kW 5.0 5.0 6.9 6.9 5.0 6.9 6.9

Pn output nominal CH (50/30°C) kW 23.2 23.2 31.2 31.2 23.2 31.2 31.2

Pmin output min. CH (80/60°C) kW 4.4 4.4 6.1 6.1 4.4 6.1 6.1

Pn output nominal CH (80/60°C) kW 21.2 21.2 28.3 28.3 21.2 28.3 28.3

Pww output DHW kW 23.5 26.8 34.7 37.1 30.0 38.4 40.1

NOx class EN15502-1 6

O2 (full load) % 4.7

CO2 (full load) % 9.0

Appliance type B23, B33, C13, C33, C43, C53, C63, C83, C93

Flue gas temperature class T100

Max. fl ue resistance at Qnw/Qn Pa 130 153 191 143 151 140 148

Flue gas temperature CH (80/60°C full load) °C 59

Flue gas temperature CH (50/30°C full load) °C 34

Flue gas mass fl ow (full load DHW) g/s 10 11 14 15 11 14 15

Flue gas temperature CH (36/30°C low load) °C 30 30 30 30 30 30 30

Gas categories II2H3P

Gas pressure 2H / 3P mbar 20 / 37

Gas consumption max. G20 m3/hr 2.54 2.89 3.75 4.01 3.00 3.84 4.01

Current V/Hz ~ 230/50

Degree of protection acc. EN 60529 IPX4D (B22/B33 IPX0D)

Overrun time pump CH sec 60

Overrun time pump DHW sec 20

PMS water pressure CH min./max. bar 0.8 / 2.5

Flow temperature max. °C 85

Available pump height CH kPa 25 25 20 20 25 20 20

PMW water pressure DHW min./max. bar 0.5 / 8

DHW temperature setting (Tin=10°C) °C 60 60 60 60 60 60 60

Threshold DHW l/min 1.5 1.5 1.5 1.5 1.5 1.5 1.5

DHW fl ow (Tin=10°C, DT=35°C) l/min 10.1 11.5 14.9 16.2 12.6 16.1 17.0

DHW fl ow (Tin=10°C, DT=50°C) l/min 6.7 7.7 10.0 10.7 8.6 11.0 11.5

SAP Annual Effi ciency NG % 89.7 89.7 89.7 89.7 89.7 89.7 89.7

Weight boiler + jig (empty) kg 41 41 44 44 43 46 46

Content DHW part l 0.3 0.3 0.3 0.3 0.6 0.6 0.6

ATAG iC-Series

Technical specifi cations Propane (3P)

ATAG iC-Series

Boiler type iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Economiser Plus 35 iC Econ omiser Plus 39

Type heat exchanger iCon1 iCon1 iCon2 iCon2 iCon1 iCon2 iCon2

O2 (full load) % 5.1

CO2 (full load) % 10.3

Restriction diameter/marking mm 4.10/41 4.10/41 4.60/46 4.60/46 4.10/41 4.60/46 4.60/46

Pre pressure mbar see data plate LPG

Input CH (DHW) (Hi) kW 21.6 (23.9) 21.6 (27.3) 28.8 (35.4) 28.8 (37.9) 21.6 (28.4) 28.8 (36.4) 28.8 (38.3)

Gas consumption max. G31 kg/h 1.90 2.16 2.80 3.00 2.24 2.87 3.00

Gas consumption max. G31 m3/h 1.00 1.14 1.48 1.58 1.18 1.51 1.58

Modulation range CH (80/60°C) kW 8.3- 21.2 8.3- 21.2 19.1 - 28.3 19.1 - 28.3 8.3- 21.2 19.1 - 28.3 19.1 - 28.3

Modulation range CH (50/30°C) kW 9.0 - 23.2 9.0 - 23.2 20.8 - 31.2 20.8 - 31.2 9.0 - 23.2 20.8 - 31.2 20.8 - 31.2

Installation & Servicing instructions ATAG iC-Range

7

ErP specifi cations according to European Guideline 2010/30/EU

Brand ATAG

Boiler type iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Economiser Plus 35 iC Econ omiser Plus 39

Condensing boiler yes yes yes yes yes yes yes

Combination heater yes yes yes yes yes yes yes

Declared load profi le DHW XL XL XXL XXL XXL XXL XXL

Seasonal space heating energy effi ciency class CH A A A A A A A

Water heating energy effi ciency class DHW A A A A A A A

Pn Power output kW 21 21 28 28 21 28 28

QHE Annual energy consumption GJ 69 69 104 115 69 104 115

AEC Annual electricity consumption DHW kWh 49 51 52 52 57 52 52

AFC Annual fuel consumption DHW GJ 17 17 21 21 20 20 20

ηs Seasonal space heating energy effi ciency CH % 94 94 94 94 94 94 94

+

ηWH Water heating energy effi ciency DHW % 85 84 90 90 94 96 96

LWA Sound power level, indoors dB 46 46 48 48 46 48 48

P4 nominal output (80/60°C) kW 21.2 21.2 28.3 28.3 21.2 28.3 28.3

P1 30% of nominal output (36/30°C) kW 7.2 7. 2 9.6 9.6 7.2 9.6 9.6

η4 effi ciency at nominal input (GCV) % 88.3 88.3 88.6 88.6 88.3 88.6 88.6

η1 effi ciency at 30% of the nominal input (GCV) % 99.4 99.4 99.5 99.5 99.4 99.5 99.5

elmax kW 0.074 0.074 0.074 0.074 0.074 0.074 0.074

elmin kW 0.021 0.021 0.032 0.032 0.021 0.032 0.032

PSB kW 0.004 0.004 0.004 0.004 0.004 0.004 0.004

Pstby heat loss kW 0.055 0.055 0.055 0.055 0.055 0.055 0.055

Qelec Daily electricity consumption DHW kWh 0.249 0.249 0.240 0.240 0.264 0.238 0.238

Qfuel Daily fuel consumption DHW kWh 22.700 22.961 27.315 27.315 25.649 25.122 25.122

Temperature Control Weathercompensator (outside sensor)

Class of temperature control II II II II II II II

Contribution of temperature control % 2 2 2 2 2 2 2

+

Package

Seasonal space heating energy effi ciency of package % 96 96 96 96 96 96 96

=

CH Package Energy Label A A A A A A A

DHW Package Energy Label A A A A A A A

8

Installation & Servicing instructions ATAG iC-Range

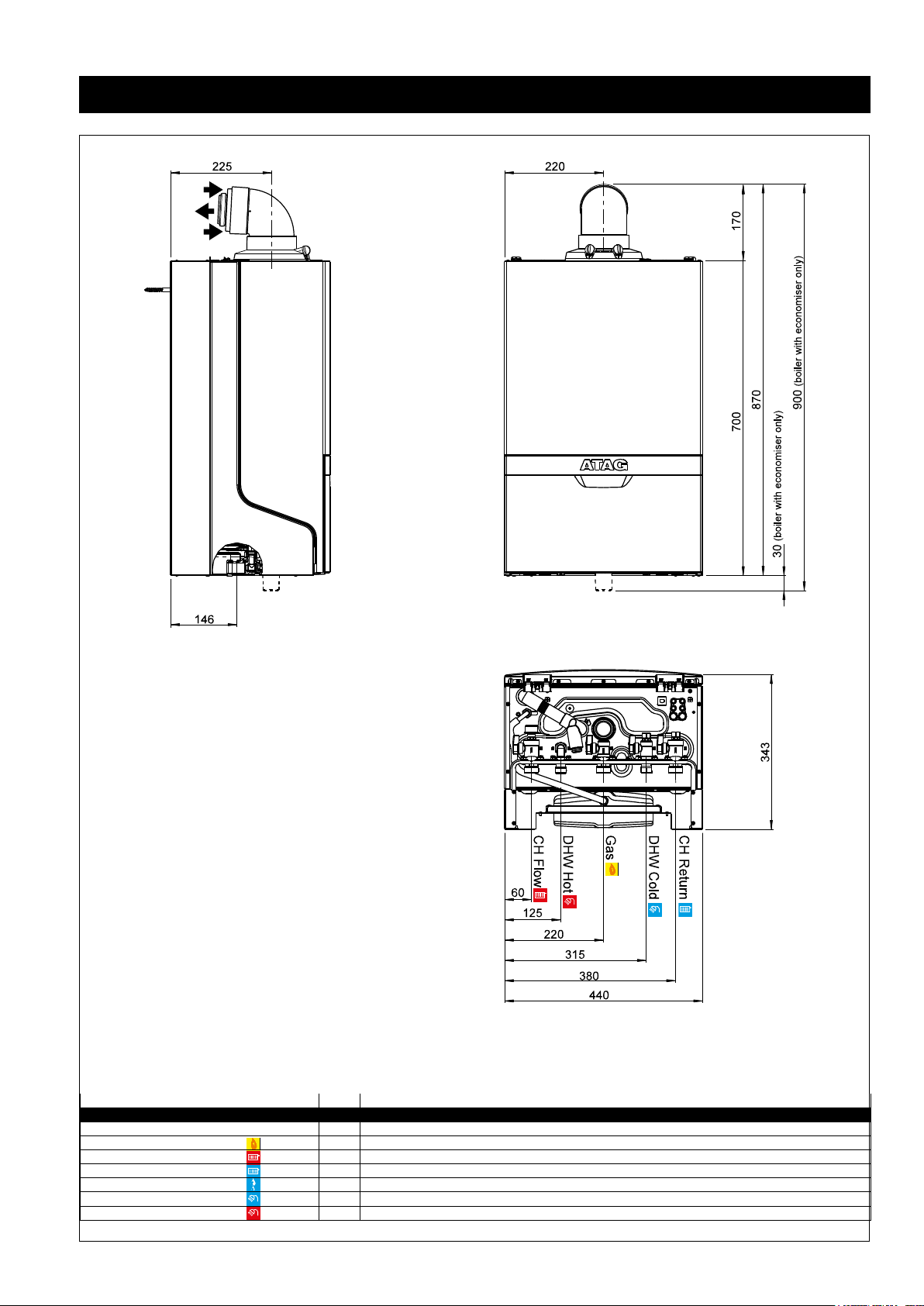

4 Dimensions

B

A

B

iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Econ omiser Plus 35 iC Economiser Plus 39

ATAG iC-Series

Flue gas / Air intake A/B mm 60/100

Gas connection mm 22

CH Flow connection mm 22

CH Return connection mm 22

Condensate drain connection mm 21.5

Cold water connection mm 15

DHW connection mm 15

Installation & Servicing instructions ATAG iC-Range

9

5 Delivery package

The delivery package of the boiler is composed as follows:

- Boiler frame;

- Boiler with cover;

- Automatic air vent (in boiler);

- Safety valve 3 bar (in boiler);

- Three way valve (in boiler);

- Automatic by-pass (in boiler);

- DHW fl ow restrictor (in boiler);

- Economiser (only economiser-versions)

- Expansion vessel 8 litre / 1 bar (in boiler frame);

- Isolation valves with drainpoint (CH 2x, 1x DHW cold)

- Gas isolating valve;

- Filling loop;

- Mains cold water fi lter;

- Fittings consisting of plugs and screws;

- Outside sensor;

- Drawing template;

- Installation instructions;

- User manual;

- Warranty Card.

The following components are not present in the boiler packaging as a standard and should be included in

the installation according to the requirements:

- Flue system;

- External controls.

6 Boiler description

The ATAG iC is a room sealed, condensing and modulating CH boiler equipped with an integrated hot water

supply.

The boiler is equipped with a compact stainless steel heat exchanger with smooth pipes. It is a well thoughtout principle using sustainable materials.

The boiler burns natural gas to supply heat (LPG conversion kits available). This heat is transferred in

the heat exchanger to the water in the CH installation. The rapid cooling off of the fl ue gases causes

condensation. This results in a very high effi ciency. The condensate that is formed, has no negative impact

on the heat exchanger and it's operation, and is removed through the internal siphon. This feature requires a

condensate drain pipe connected to the drain of the building.

The boiler is equipped with an intelligent control system. The boiler anticipates on the heat demand of the

heating installation or hot water demand. This will cause the boiler to tune its capacity to the installation. This

means that the boiler will function longer and at a low level.

If an outside sensor is connected, the control system is able to function, depending on the weather. This

means that the control system measures the outside temperature and the fl ow water temperature. On the

basis of this information the control system calculates optimum fl ow water temperature required for the

installation.

The boiler has been tested according to valid CE standards and has a CE certifi cate and >88% Effi cient

SEDBUK 2009.

10

Statement: No banned materials including asbestos, mercury, CFC's have or will not be included in

the product.

Installation & Servicing instructions ATAG iC-Range

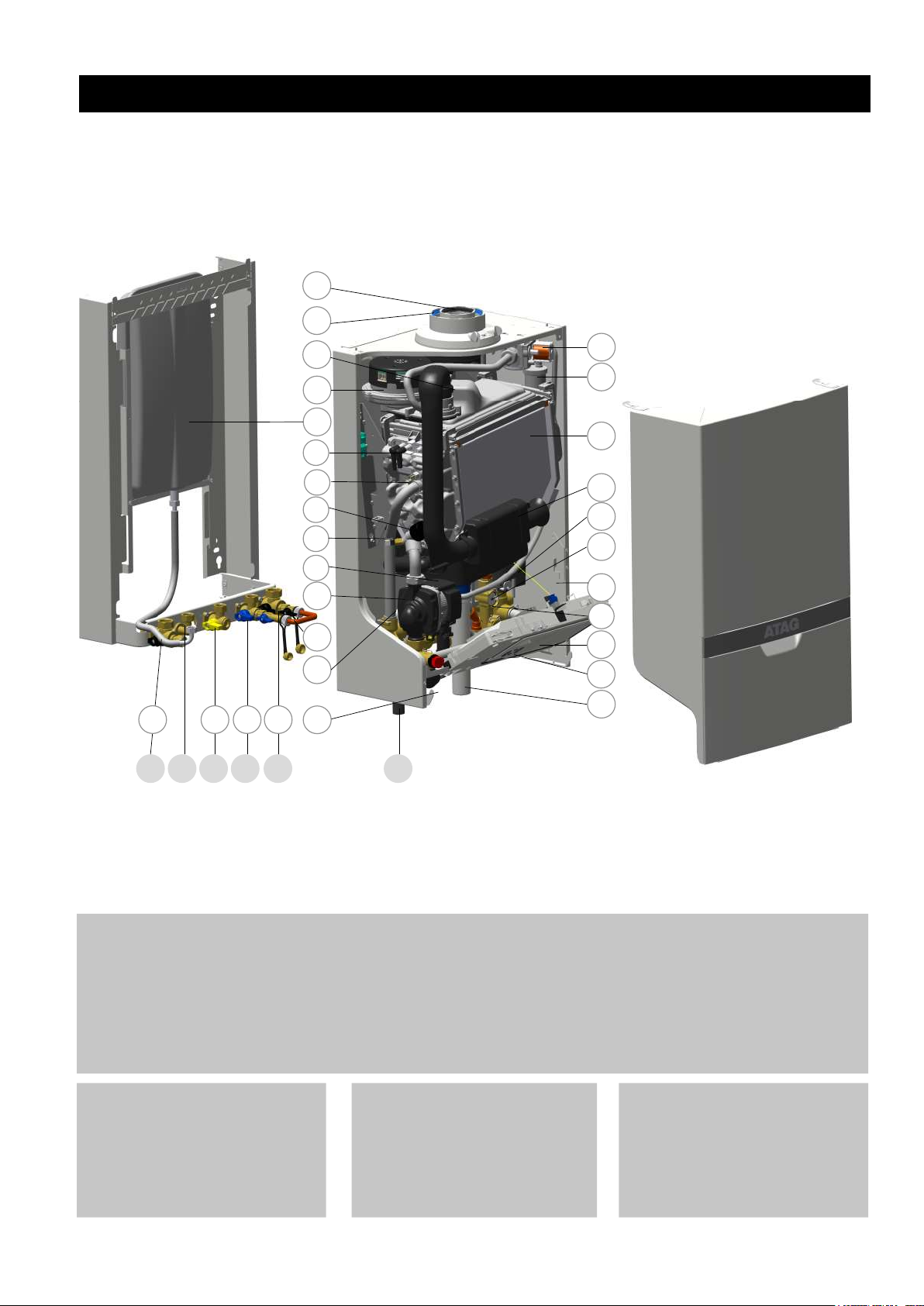

7 Boiler photo components list

13

14

20 21 22 23

W CKG

A

R

24

3

16

2

T1

P1

T2

18

11

12

17

5

6

1

4

10

F1

15

T3

8

7

9

19

ATAG iC Figure 7.a

1 Heat exchanger

2 Ignition unit

3 Fan unit

4 Air supply damper

5 Gas valve

6 Automatic de-aerator

7 DHW plate heat exchanger

8 Control unit

T1 Flow sensor

T2 Return sensor

T3 Hot water sensor

F1 DHW fl ow sensor

P1 Water pressure sensor

Installation & Servicing instructions ATAG iC-Range

9 Control panel

10 Three-way valve

11 Circulation pump

12 Filling loop

13 Flue gas exhaust

14 Combustion air supply

15 Boiler data plate

16 Expansion vessel

G Gas pipe

A Flow pipe CH

R Return pipe CH

C Condensation pipe

K Cold water pipe

W Hot water pipe

17 Safety valve

18 DHW Economiser

19 Siphon

20 Isolation valve fl ow CH

21 Isolation valve gas

22 Isolation valve cold water

23 Isolation valve return CH

24 Flue non return valve

11

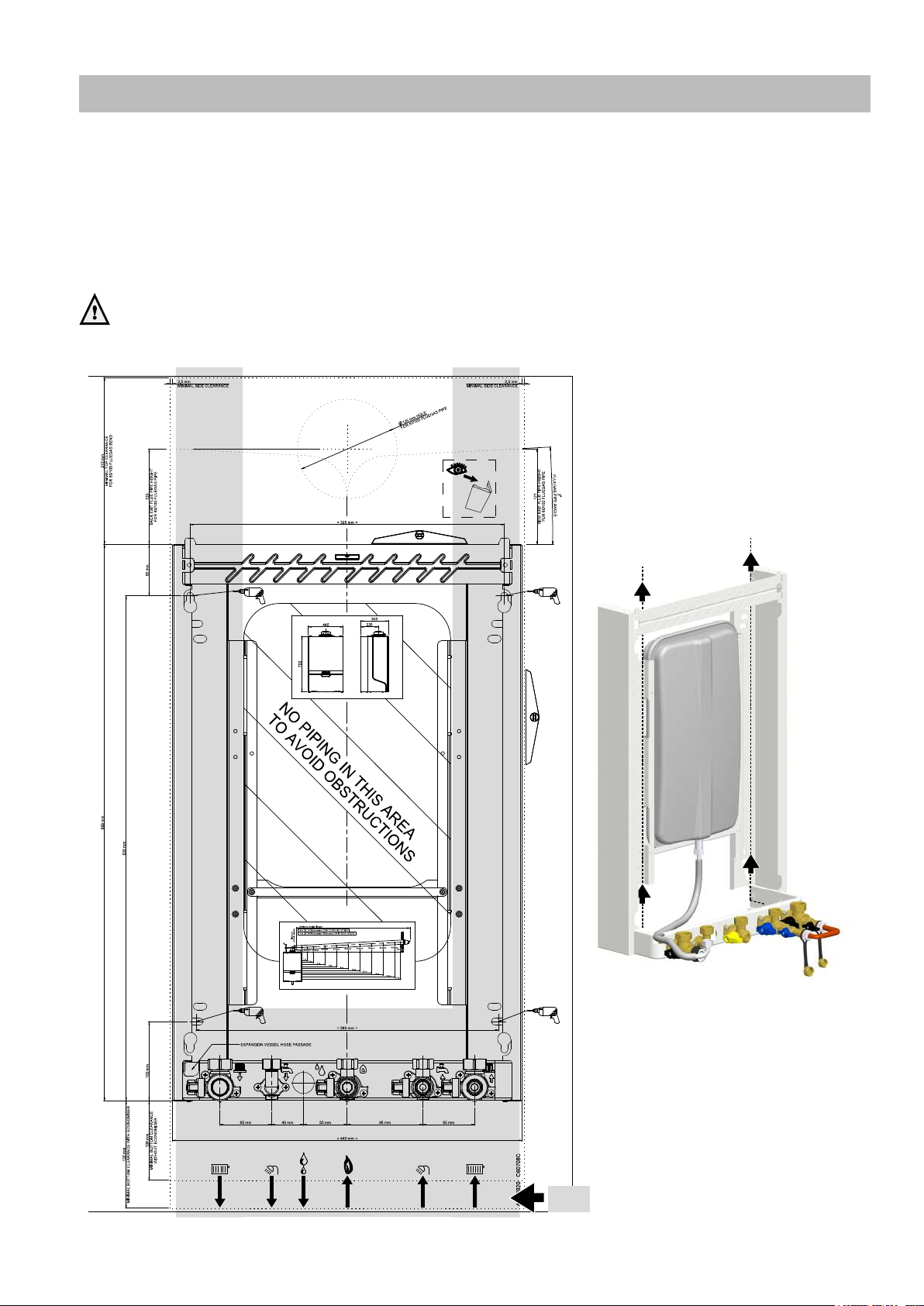

8 Mounting boiler frame

Install the boiler in a boiler room in accordance to the actual local regulations BS5440-2:2009.

The installation location of the boiler has to be, and remain, frost-free. The boiler casing is splash water tight

(IPX4D) and is suitable to be installed in e.g. a bathroom.

It is NOT necessary to have a purpose provided air vent in the room or internal space in which the boiler is

installed. Neither is it necessary to ventilate a cupboard or compartment in which the boiler is installed, due

to the extremely low surface temperature of the boiler casing during operation. Therefore the requirements of

BS5440:2 may be disregarded.

The boiler can be mounted practically to any wall with the wall frame and the enclosed fi xing equipment. The

wall must be fl at and of suffi cient strength in order to be able to carry the boiler weight with its water content.

Above the boiler there must be at least 210 mm working space in order to be able to fi t a horizontal

concentric fl ue system to the rear (See chapter 9.8 for more fl ue options). Make sure there is suffi cient

service space around the boiler according fi gure 8.a. The location of the boiler can be determined by using

the template.

The wall frame allows the possibility to pre-fi t the complete heating and DHW system before fi tting the boiler.

Also the fl ue system can be prepared. Finally fi tting of the fl ue system is done after fi tting the boiler. See next

page for all options for connection the heating, DHW, condensate, fl ue and gas installation.

Before hanging the boiler to the boiler frame remove the front panel of the boiler fi rst. The front panel is also

the air cabinet and is attached to the boiler case with 2 fasteners (A and B) (see fi gure 8.a).

Note that there is an earth cable (when present) to disconnect when removing the boiler front panel.

Free space for removing the connector is about 400 mm. Remember to connect this earth cable

(when present) when placing back the boiler front panel and take care the wire does not get stuck

between front panel and boiler. Always replace and turn the 2 screws tight in the fasteners A and B.

Service dimensions (in mm) Figure 8.a

See chapter 9.8 for further procedure to fi t the boiler onto the boiler frame.

12

Installation & Servicing instructions ATAG iC-Range

8.1 Wall frame

- Position the boiler frame against the wall using the template and a level.

- Use the level for horizontal positioning and checking the vertical position.

- Drill 4x ø10mm holes, 60mm deep

- Press the nylon wall plug (ø10x55mm) in the holes

- Mount the boiler frame to wall with the 4 coach screws (ø8x60mm) using a 13mm wrench

The boiler frame allows pipe work to be installed behind the boiler.

Note that there are free spaces on the left and right of the expansion vessel. Do not guide pipe work

in front of the expansion vessel. The pipe work must be installed at least 10mm inside the front of the

frame.

= free space for piping

ATAG i-Serie template and iC-Range boiler frame Figure 8.1.a

Installation & Servicing instructions ATAG iC-Range

13

9 Connecting boiler

The boiler has the following connection pipes;

- The central heating pipes.

The boiler is provided with isolation valves on the fl ow and return pipe to which the installation can be

connected by means of 22mm compression fi ttings;

- The gas pipe.

The boiler is provided with an isolation gas valve to which the gas line can be fi tted with 22mm

compression fi tting;

- The condensation drain pipe.

It consists of a 25mm fl exible plastic pipe. The drain pipe can be connected to this by means of an open

connection;

- The fl ue gas exhaust system and air supply system.

It consists of a concentric connection 60/100 mm.

- Cold and hot water pipes.

The boiler is provided with a isolation valve on the cold water inlet. The DHW installation can be

connected by means of 15mm compression fi ttings.

See following chapters for detailed information regarding each connection.

It is advisable to clean all of the boiler’s connecting pipes and/or to power fl ush the installation

before connecting it to the boiler.

9.1 Central heating system

Connect the central heating system according to the current regulations.

The boiler pipes can be connected to the installation by means of 22mm compression fi ttings. For connecting

to thick-walled pipe (welded or fi tted), adapters should be used.

The boiler has a self-adjusting and self-protecting control system for the load. This involves checking the

temperature diff erence between the fl ow and return water. Table 9.1.a shows the water displacement the

circulation pump can deliver for a particular installation resistance.

If the installation resistance is higher than the value stated, the control system will adjust the load until a

temperature diff erence between fl ow and return water is reached that is acceptable for the control system.

When the temperature diff erence still remains too high the boiler will switch itself off and wait until the high

temperature diff erential between the fl ow and return water has decreased again.

Pump type Grundfos UPM3 15-75

iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Economiser Plus 35 iC Economiser Plus 39

Water fl ow rate l/min 15.2 15.2 20.3 20.3 15.2 20.3 20.3

l/h 912 912 1218 1218 912 1218 1218

Permissible installation resistance kPa 25 25 20 20 25 20 20

mbar 250 250 200 200 250 200 200

Installation resistance table 9.1.a

14

The control system will, if an unacceptable temperature diff erence is detected, repeatedly try to establish a

water fl ow. If this does not succeed, the boiler will block itself (code 154).

The boiler is NOT equipped with a built-in internal fi lter.

Advice: ATAG Heating Technology Ltd recommend the installation of an in-line fi lter installed into the

heating return as close to the boiler as possible. ATAG Heating Technology Ltd recommend the use

of the:

ATAG iGuard Magnetic fi lter 22mm (Plastic) FC000100, (Brass) FC000200, 28mm (Brass) FC000250.

Installation & Servicing instructions ATAG iC-Range

The boiler is not suitable for installations that are equiped with “open” expansion tanks.

Additives in the installation water are only permitted in consultation with the country distributor. See

chapter 9.3 for detailed information.

9.2 Expansion vessel

The iC boilers are featured with a built-in expansion vessel with a capacity of 8 litres and a pre-pressure

charge 1 bar. If the expansion vessel size is insuffi cient for the CH system, an additional expansion must be

installed. The additional expansion vessel should, together with the built-in expansion vessel, be sized to the

water content of the installation. The pre-pressure charge depends on the height of the installation above the

installed expansion vessel. See Table 9.2.a.

The (additional) expansion vessel should be connected as closely as possible in the return pipe near

the boiler.

Installation height above the expansion vessel pre-charge pressure of the expansion vessel

5m 0.5 bar

10m 1.0 bar

15m 1.5 bar

The pressure relief valve outlet is combined with the condensate outlet (see fi gure 9.9.e on page 29).

table 9.2.a

9.3 Water quality

Fill the installation with mains cold water.

In most cases, a heating system can be fi lled with water according to national standards for water and

treatment of this water is not necessary.

In order to avoid problems with the CH-installations, the quality of the fi lling water has to meet the

specifi cations mentioned in table 9.3.a:

If the fi lling water does not meet the required specifi cations, you are advised to treat the water to such an

extent that it does meet the required specifi cations.

The warranty becomes invalid, if the installation is not being fl ushed and/or the quality of the fi lling

water does not meet the specifi cations recommended by ATAG Heating Technology Ltd. Always

contact ATAG Heating Technology Ltd in advance, if things are not clear or you wish to discuss any

deviations. Without approval, the warranty becomes invalid.

Installation:

- The use of groundwater, demi-water and distilled water is prohibited. (on the next page you will fi nd an

explanation of these defi nitions)

- If the mains water quality meets the specifi cations mentioned in table 9.3.a, you can start fl ushing the

installation before installing the device.

- Whilst fl ushing, corrosion products (magnetite), fi tting products, cutting oil and other undesirable products

have to be removed.

- Another possibility is to remove the pollution by installing a fi lter. The fi lter type has to fi t the type and

grain size of the pollution. ATAG Heating Technology Ltd recommends fi lter usage.

- In this case, the whole piping system should be taken into consideration.

- The CH-installation has to be properly vented before using the system. For that purpose, we refer to the

commissioning chapter.

- If a regular water top up is required (>5% on an annual basis), then there is a structural problem and

an installer has to solve the problem. Regularly adding fresh water to the system also adds additional

calcium and oxygen implying that magnetite and calcium residues can continue. The result may be

blockages and/or leakages.

- The use of anti-freeze and other additives requires periodical quality checks of the fi lling water in

accordance with the period laid down by the additives supplier.

Installation & Servicing instructions ATAG iC-Range

15

- Chemical additions are to be avoided and should only be used after ATAG Heating Technology Ltd has

approved their corresponding use.

- Should you wish to achieve the required water quality by using chemical additives, then this is your own

responsibility. The warranty on the product delivered by ATAG Heating Technology Ltd expires, if the

water quality does not meet ATAG Heating Technology's specifi cations or the chemical additives have not

been approved by ATAG Heating Technology Ltd.

- On installation and during additions or changes at a later stage, ATAG Heating Technology Ltd

recommends to keep a record of the type of water used, its quality at the time, and if applicable, which

additives and quantities were added.

Parameter Value

Water type Potable water

Softened water

pH 6.0-8.5

Conductivity (at 20°C in µS/cm) Max. 2500

Iron (ppm) Max. 0.2

Hardness (°dH / ppm):

Installation volume/capacity

<20 l/kW

Installation volume/capacity

>=20 l/kW

Oxygen No oxygen diff usion allowed during operation.

Corrosion inhibitors Refer to Additives Attachment

pH increasing or lowering agents Refer to Additives Attachment

Anti-freeze additives Refer to Additives Attachment

Other chemical additives Refer to Additives Attachment

Solid substances Not allowed

Residues of processing water not forming part of the

drinking water

table 9.3.a

1-12 °dH / 17-214 ppm

1-7 °dH / 17-125 ppm

Max. 5% fi lling water addition annually

Not allowed

Water quality in DHW facility

Parameter Value

Water type Potable water

pH 7.0-9.5

Conductivity (at 20°C in µS/cm) Max. 2500

Chloride (ppm) Max. 150

Iron (ppm) Max. 0.2

Hardness (°dH / ppm): 1-12 °dH / 17-214 ppm

Number of bacterial colonies at 22°C (number/ml). pr

EN ISO 6222

table 9.3.b

- When the amount of chloride is above the required specifi cations mentioned above in table 9.3.b, in case

of the use of a combi boiler will void the warranty for DHW parts of the boiler.

Water type defi nition:

Potable water: Tap water compliant with the European drinking water guideline:

98/83/EG dated 3 November 1998.

Softened water: Water with partly de-ionised calcium and magnesium.

Demi-water: Virtually completely demineralised water (very low conductivity)

Distilled water: Water no longer containing minerals.

Max. 100

16

Installation & Servicing instructions ATAG iC-Range

9.4 Heating systems with plastic pipes

When connecting or using an underfl oor heating system, designed with plastic pipes, or plastic pipes are

used elsewhere in the installation, one should ensure that the plastic pipes used comply with the DIN

4726/4729 standard. It is set out in this standard that the pipes may not have oxygen permeability higher

than 0.1 g/m³.d at 40°C. If the system does not comply with this DIN standard, the underfl oor heating

component will have to be separated from the central heating appliance by means of a plate exchanger.

No recourse can be made to the terms of the warranty in the event of failure to observe the

regulations pertaining to plastic underfl oor heating pipes.

9.5 Gas connection in general

The local gas supplier should be consulted, at the installation planning stage, in order to establish the

availability of an adequate supply of gas. An existing service pipe must NOT be used without prior

consultation with the local gas supplier.

ATAG supplies boilers suitable for natural gas only. Verify the identifi cation plate on the boiler if the

boiler is suitable for the gas kind on site.

For use with propane gas, the LPG conversion kit has to be installed, see separate conversion

instructions.

Make sure that the gas pipe work does not contain dirt, particularly with new pipes.

The complete installation MUST be tested for gas tightness and purged as described in the above

code.

The boiler connection is provided with an isolation valve with 22mm compression fi tting, into which the gas

line can be fi tted.

9.5.1 Natural gas connection (NG)

The gas supply must comply to the current Gas Safety, Installation & Use Regulations, in accordance with

BS.6891.

The nominal inlet working gas pressure measured at the appliance should be 21 mbar +/- 2 mbar for Nat

gas (G20). Allowing for the acceptable pressure loss of 1 mbar across the installation pipework, it can

be assumed that a minimum permitted operating pressure of 18 mbar will be delivered to the inlet of the

appliance. (Reference BS 6400-1 Clause 6.2 Pressure Absorption). When tested at the gas valve, the

pressure drop from the meter to the gas valve must not be more than 4 mbar.

9.5.2 Propane gas connection (LPG)

For use with propane gas, the LPG conversion kit has to be installed, see separate conversion instructions.

The LPG installation must comply to the current Gas Safety, Installation & Use Regulations, in accordance

with BS:6891

Installing of a LPG installation should only be done by a registered LPG installer.

The tank must be provided with a high pressure regulator with a minimum capacity of 24 kg/h to reduce

the tank pressure from 5 to 1.5 bar. The 1.5 bar high pressure gas line should have a minimum diameter of

15mm. In the high pressure gas line a house pressure regulator must be installed. When tested at the gas

valve, the pressure drop from the pressure regulator to the gas valve must not be more than 3.8 mbar.

Installation & Servicing instructions ATAG iC-Range

17

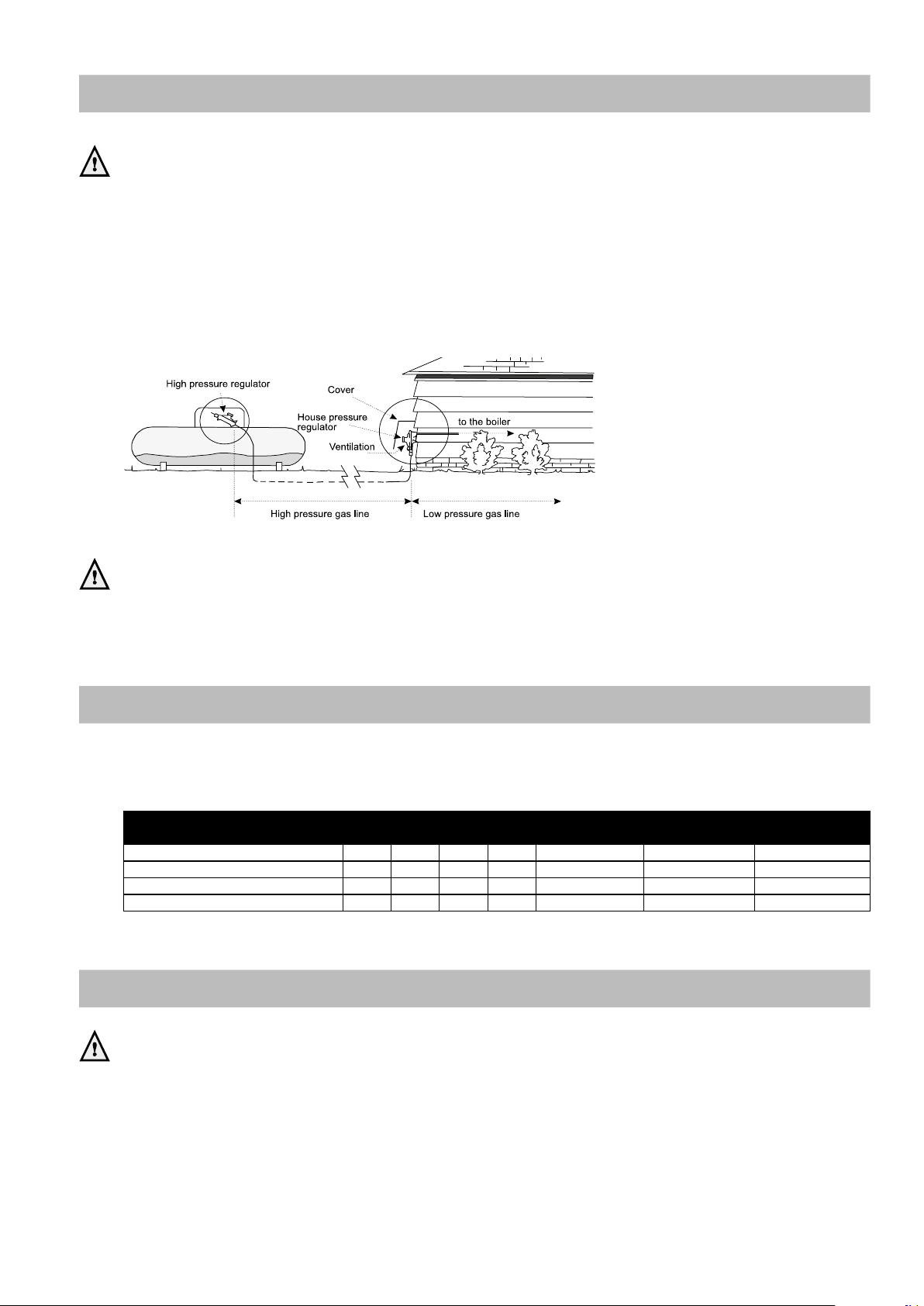

9.5.3 House pressure regulator

Each gas appliance which is connected to the propane installation must be provided with its own

house pressure regulator. The house pressure regulator is a third party delivery.

The house pressure regulator must have a minimum capacity of 10 kg/h / 37 mbar and a CE certifi cation.

ATAG advices to install the house pressure regulator as close as possible to the boiler. When placing the

regulator inside, a discharge drain of ø6mm must be installed. The discharge drain must be directed outdoor.

In case of a discharge the gasses will go outside.

If fi tting the regulator outside the regulator should be protected against infl uences of the weather. The (de-)

aeration must be positioned downwards (see fi gure 9.5.3.a).

ATAG advices to install measure points on all gas line parts to have the possibility to check for pressure loss.

example propane installation fi gure 9.5.3.a

Pre-pressure must be adjusted to 37 mbar by means of the house pressure regulator. The maximum

permitted closing pressure may be 5 mbar higher than the maximum pre-pressure.

A too high closing pressure in the low pressure gas line can be caused by a high resistance or jam in this gas

line. When the closing pressure keeps increasing the valve in the regulator is not closing correctly. In this

case the regulator should be replaced.

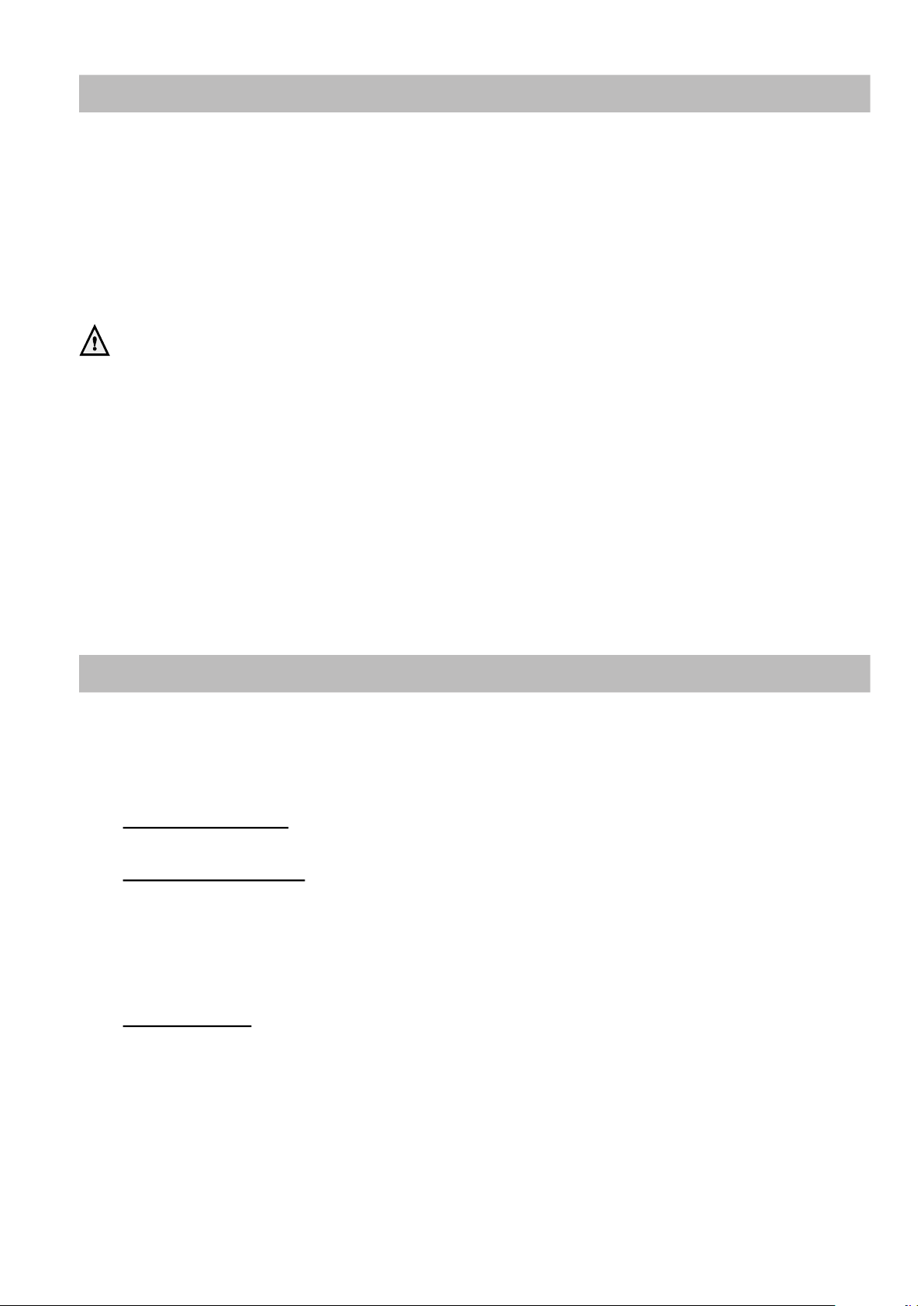

9.5.4 Dimensioning of the low pressure gas line

The gas line from the house pressure regulator to the boiler must have the dimensions according the table

below.

Pump type Grundfos UPM3 15-75

iC 24 iC 28 iC36 iC 40 iC Economiser Plus 27 iC Economiser Plus 35 iC Economiser Plus 39

Diameter gas line m m m m m m m

ø15mm 3 - - - - - -

ø22mm 30 18 18 18 18 18 18

ø28mm - 30 30 30 30 30 30

Dimensioning low pressure gas line table 9.5.4.a

9.5.5 De-aerating the LPG tank

When placing a new or revised LPG tank the tank must always be de-aerated.

ATAG advices to inform the gas supplier that a central heating boiler is connected to the LPG tank. For the

boiler it is absolutely necessary that the tank is free of air. When not the boiler will give ignition problems and

will not function.

ATAG advices to measure the content of O2 . This value should be lower than 1.3%. Contact the gas

supplier in case of doubt.

18

Installation & Servicing instructions ATAG iC-Range

9.6 Hot water supply

Connection of the drinking water installation should be done according to the Water Supply (Water Fittings)

Regulations and Scottish Water Byelaws.

The ATAG iC boiler is fi tted with a stainless steel plate heat exchanger for producing domestic hot water. The

boiler does not have a hot water store and in case of a demand for hot water the boiler will heat the domestic

water fl owing through the plate heat exchanger up to 60°C (adjustable) instantaneous.

The water mains installation must comply with the Water Supply (Water Fittings) Regulations and Scottish

Water Byelaws. See also chapter 9.3.

In regions with a water hardness value higher than 200ppm (2.67 mmol/l), calcium deposits should

be removed from the plate heat exchanger on a regular basis. If problems occur when using sanitary

water with a chlorine content higher than 150 mg/l, no recourse can be made to the terms of the

warranty.

In order to prevent calcifi cation ATAG recommends applying a water softener.

ATAG recommends the use of for instance AlphaPhos for cleaning plates exchangers.

The hardness of the water is variable in the United Kingdom. The water company can provide exact

information about this.

The domestic water installation can be connected to the boiler by means of 15mm compression fi ttings.

If the mains is fi tted with water meter, check valves or loose jumper stop cock, then a DHW expansion device

must be fi tted.

The boiler is provided with a DHW fl ow restrictor. The fl ow restrictor ensures that a quantity of water supplied

has a guaranteed temperature of 60 °C (assuming a cold water temperature of 10°C). The amount of water

is virtually unaff ected by the water pressure.

After installation, check the hot water fl ow rate with a fully opened hot water tap,

If required the fl ow restrictor can be removed. See chapter 16.1.

9.7 Condensation drain pipe

The ATAG condensing boiler has the >88% Effi cient SEDBUK 2009 for high energy effi ciency in heating and

domestic hot water. The ATAG wall hung gas fi red condensing boiler contain a siphonic condensate trap to

collect and realease condensate. The amount of condensate formed is determind by the type of boiler and

the water temperature produced by the boiler.

Condensate pipework.

Use plastic pipework of an internal diameter no less then 19mm ID (typically 22mm OD).

Routing of the pipework,

The condensate pipework must fall at least 45mm per metre away from the boiler, taking the shortest

practicle route to the termination point.

Support the pipe at least every 50 cm for near horizontal sections and 1 metre for vertical sections.

Wherever possible, the condensate pipework should be routed internally to prevent freezing. In order to

minimise the risk of freezing during prolonged very cold spells, one of the following methods of terminating

condensate drainage pipe should be adopted.

Internal pipework

Wherever possible, the condensate drainage pipe should be terminated at a suitable internal foul water

discharge point such as (a) an internal soil and vent stack or (b) an internal kitchen or bathroom waste pipe,

washing machine waste pipe etc. A suitable permanent connection to the foul waste pipe should be used.

Figures 9.7.1, 9.7.2(a), 9.7.2(b) show appropriate connection methods.

The possibility of waste pipes freezing downstream of the connection point should be considered when

determining a suitable connection point - e.g. a slightly longer pipe run to an internal soil stack may be

preferable to a shorter run connecting into a kitchen waste pipe discharging directly through the wall to an

external drain.

Where “gravity discharge” to an internal termination is not physically possible (e.g. the discharge point is

above the appliance location, or access is obstructed by a doorway), or where very long internal pipe runs

would be required to reach a suitable discharge point, the following measures may be adopted.

Installation & Servicing instructions ATAG iC-Range

19

1 Boiler

2 Visible air break

3 75mm trap

4 Soil and vent stack

5 Invert

6 450mm minimum up to three storeys

7 Minimum internal diameter 19mm (fall at least 45mm per meter)

Drain requirements Figure 9.7.1 Drain requirements Figure 9.7.2 (a)

1 Boiler

2 Visible air break

3 75mm trap

4 Sink, basin, bath or shower

5 Open end of condensate drainage pipe direct into gully 25mm

min below grating but above water level; end cut at 45°

6 Sink lip

7 Minimum internal diameter 19mm (fall at least 45mm per meter)

8 Pipe size transition

9 Minimum internal diameter 30mm

10 Water/weather proof insulation

1 Boiler

2 Visible air break

3 Visible air break at plug-hole

4 75 mm sink, basin, bath or shower waste trap

5 Sink, basin, bath or shower with integral overfl ow

6 Open end of condensate drainage pipe direct into gully 25mm

min below grating but above water level; end cut at 45°

7 Minimum internal diameter 19mm (fall at least 45mm per meter)

8 Pipe size transition

9 Minimum internal diameter 30mm

10 Water/weather proof insulation

Drain requirements Figure 9.7.2 (b)

20

1 Condensate discharge from boiler

2 Visible air break

3 Condensate pump

4 Visible air break at plug hole

5 Sink or basin with integrated overfl ow

6 75mm sink waste trap

Drain requirements Figure 9.7.3

Installation & Servicing instructions ATAG iC-Range

Use of a condensate pump (to an internal termination):

Condensate can be removed using a proprietary condensate pump (third party delivery), of a specifi cation

recommended by the pump manufacturer. Condensate pump suitable for combined pressure relief valve.

The pump outlet should discharge to a suitable internal foul water discharge point, such as (a) an internal soil

and vent stack or (b) an internal kitchen or bathroom waste pipe, washing machine waste pipe etc. Figure

9.7.3 shows a typical connection method.

A suitable permanent connection to the foul waste pipe should be used and the manufacturer’s detailed

installation instructions for the pump should be followed.

External pipework

The use of an externally-run condensate drainage pipe, terminating at a suitable foul water discharge point

or purpose-designed soakaway, may be also be considered; however if this termination method is chosen

then the following measures should be adopted

- The pipe should be run internally as far as possible before going externally and the pipe diameter should

be increased to a minimum of 30mm ID (typically 32mm OD) before it passes through the wall.

- The external run should be kept as short as possible, taking the most direct and “most vertical” route

possible to the discharge point, with no horizontal sections in which condensate might collect. Do not

exceed 3 metres outside the dwelling.

- The external pipe should be insulated using suitable waterproof and weatherproof insulation (“Class O”

pipe insulation is suitable for this purpose) .

- The use of fi ttings, elbows etc should be kept to a minimum and any internal “burrs” on cut pipework

should be removed so that the internal pipe section is as smooth as possible.

The customer/householder should be advised that even with the above measures this type of installation

could freeze, and that if this were to occur then boiler shutdown could result, requiring remedial action possibly involving a chargeable engineer call-out.

Where there are likely to be extremes of temperature or wind-chill, the use of a proprietary trace-heating

system for external condensate drainage pipework, incorporating an external frost thermostat, should

therefore be considered. If such a system is used then the installation instructions of the trace heating

manufacturer and any specifi c recommendations regarding pipe diameter, insulation, etc. should be followed.

All other relevant guidance on condensate drainage pipe installation should also be followed.

Other cold weather protection methods approved or endorsed by boiler manufacturers and/or service

organisations may be adopted if these are considered suitable by the parties involved.

If an external soil/vent stack is used as the external termination then the connection method shown in Figure

9.7.4 should be used, together with the measures on insulation etc. as described above and shown in the

diagram.

When a rain water downpipe is used as the termination (NB only permissible if this downpipe passes to

a combined foul and rainwater drainage system) an air break must be installed between the condensate

drainage pipe and the downpipe to avoid reverse fl ow of rainwater into the boiler should the downpipe itself

become fl ooded or frozen. Figure 9.7.5 shows a suitable connection method.

Where the condensate drainage pipe is terminated over an open foul drain or gully, the pipe should terminate

below the grating level, but above water level, in order to minimise “wind chill” at the open end. Pipe drainage

will be improved if the end is cut at 45° as opposed to a straight cut. The use of a drain cover (such as

those used to prevent blockage by leaves) may off er further protection from wind chill. Figure 9.7.6 shows a

suitable connection method.

Where the condensate drain pipe terminates in a purpose-designed soakaway (see BS 6798:2014 or boiler

installation manual for soakaway design requirements) any above-ground section of condensate drainage

pipe should be run and insulated as described above. Figure 9.7.7 shows a suitable connection method.

Unheated internal areas:

Internal condensate drainage pipes run in unheated areas such as lofts, basements and garages should be

treated as external pipe.

Draining of the condensation water to the external rain guttering is not permitted in view of the

danger of freezing.

Before putting the boiler into operation fi ll the siphon with 150 ml of water.

Installation & Servicing instructions ATAG iC-Range

21

1 Boiler

2 Visible air break

3 75mm trap

4 Soil and vent stack

5 Invert

6 450mm minimum up to three storeys

7 Minimum internal diameter 19mm (fall at least 45mm per meter)

8 Pipe size transition

9 Minimum internal diameter 30mm

10 Water/weather proof insulation

Drain requirements Figure 9.7.4 Drain requirements Figure 9.7.5

1 Condensate discharge pipe from boiler

2 Pipe size transition point

3 Water/weather proof insulation

4 43mm 90° male/female bend

5 External rain water pipe into foul water

6 External air break

7 Air gap

8 68 mm ø PVCu strap-on fi tting

9 Minimum internal diameter 19mm

10 Minimum internal diameter 30mm

11 End cut at 45°

1 Boiler

2 Visible air break

3 38mm minimum trap

4 External length of pipe 3m maximum

5 Open end of condensate drainage pipe direct into gully 25mm

min below grating but above water level; end cut at 45°

6 Minimum internal diameter 19mm (fall at least 45mm per meter)

7 Pipe size transition point

8 Minimum internal diameter 30mm

9 Water/weather proof insulation

Drain requirements Figure 9.7.6

22

1 Condensate discharge pipe from boiler

2 Ground (this section of the condensate drainage pipe may be

run either above or below ground level); End cut at 45°

3 Diameter 100mm minimum plastic tube

4 Bottom of tube sealed

5 Limestone chippings

6 Two rows of three 12mm holes at 25mm centres, 50mm from

bottom of tube and facing away from house

7 Hole depth 400mm minimum by 300mm diameter

8 Minimum internal diameter 19mm (fall at least 45mm per meter)

9 Pipe size transition point

10 Minimum internal diameter 30mm

11 Water/weather proof insulation

Drain requirements Figure 9.7.7

Installation & Servicing instructions ATAG iC-Range

9.8 Flue gas exhaust system

The fl ue gas exhaust system and air supply system consists of:

- Flue gas pipe;

- Air supply pipe;

- Roof or wall terminal.

The fl ue gas exhaust system and air supply system must comply with:

The fl ue gas outlet and air supply installation must comply with the current regulation requirements in

accordance with BS:5440 Part 1 and 2.

The ATAG iC boiler as described in this manual is NOT suitable for a combined fl ue system.

The appliance concentric connection diameter is 60/100 mm, to which the fl ue gas outlet and air supply

system can be fi tted, with or without elbow pieces. The maximum permissible pipe length is set out in Table

9.8.2.a.

For further information about the available components of the fl ue gas and air supply system we recommend

you consult the Flue system literature. Combinations with other brands or systems are, without written

permission from ATAG Heating, not permitted.

The ATAG fl ue gas system is meant, and designed, solely for the use on ATAG central heating boilers

adjusted to Nat gas or LPG. For this purpose the CE Certifi cate has been supplemented under the Gastec

nr: 0063CQ3634 The maximum fl ue gas temperatures are below 70°C (full load 80/60°C).

The proper operation may be adversely infl uenced by changes of or adjustments to the correct set up.

Possible warranty claims will not be honoured if incorrect changes result in non compliance with the

installation manual or local rules and regulations.

Room sealed system

Boiler Class C

Permitted only

when the air

P/A

LEGEND:

P/A Polypropylen / Aluminium

intake and the fl ue gas

outlet are in the same

pressure area.

P/A P/A P/A

Room sealed system Figure 9.8.a

Installation & Servicing instructions ATAG iC-Range

23

9.8.1 Flue terminal locations

The terminal should be located where dispersal of combustion products is not unimpeded and with due

regard for the damage or discolouration that might occur to parts of the building in the vicinity (see fi g

9.8.1.c).

In certain weather conditions condensation may also accumulate on the outside of the air inlet pipe. Such

conditions must be considered and where necessary insulation of the inlet pipe may be required.

In cold and/or humid weather water vapour may condense on leaving the fl ue terminal. The eff ect of such

‘plumeing’ must be considered.

The terminal must not be located in a place where it is likely to cause a nuisance, where the terminal is less

than 2m (6.6ft) above a pavement or platform to which people have access (including) any balcony or fl at

roof. The terminal must be protected by a guard of durable material.

Where a terminal is fi tted below a window which is hinged at the top, and where the hinge axis is

horizontal, and the window opens outwards, the terminal shall be 1m below the bottom of the window

opening.

The fl ue must be terminated in a place not likely to cause a nuisance.

For horizontal fl ue terminal direct to the rear or side through the wall (only 1 bend

and 1 wall terminal) the terminal should be placed horizontal. The fl ue pipe inside

the terminal is fi tted in a 3 degrees angle to ensure the condensation water can run

back to the boiler. See fi gure 9.8.1.a.

For longer horizontal sections, the outlet system should always be fi tted on an

incline (52 mm/m = 3°) sloping down towards the boiler so that no condensation

water is able to accumulate in the outlet system. The chances of icicles forming on

the outlet is minimised by causing the condensation water to run back towards the

boiler. See fi gure 9.8.1.b.

Figure 9.8.1.a

24

Figure 9.8.1.b

Installation & Servicing instructions ATAG iC-Range

Terminal position Min. distance (mm)

A Directly below an opening, air brick, windows, etc. 300 (See Note 1)

B Below gutters, soil pipes or drain pipes 75 (See Note 3)

C Below eaves 200 (See Note 3)

D Below balconies 200 (See Note 3)

E From a vertical drain pipe or soil pipe 150 (See Note 3)

F From an internal or external corner 300 (See Note 2)

G Above ground, roof or balcony level 300

H From a surface or boundary facing the terminal 600 (See Note 4)

I F rom a terminal facing the terminal 1200

J Above an opening, air brick, window etc. 300 (See Note 1)

K Vertically from a terminal on the same wall 1500

L Horizontally from a terminal on the same wall 300

M Horizontally from an opening, air brick, window etc. 300 (See Note 1)

N Minimum protrusion through a roof 300

O From a vertical obstruction 300

P From an openable window 600

Q From an adjacent vertical terminal 600

R From an opening in the car port (e.g. door, window) into the dwelling 1200

S Below a roof window 2000

T Terminal parallel to a boundary 300

Figure 9.8.1.c

Notes:

1. In addition, the terminal should not be nearer than 150mm to the framework of an opening into the building, i.e. a window surround or door surround.

2. This clearance may be reduced to 25mm without eff ecting the performance of the boiler. However, to ensure the condensate plume does not aff ect adjacent

surfaces a clearance of 300mm is preferable.

3. These clearances may be reduced to 25mm without eff ecting the performance of the boiler. However, to ensure the condensate plume does not aff ect adjacent

surfaces the terminal can be extended beyond gutters, pipes, eaves, balconies etc.

4. To reduce the possibility of nuisance to neighbouring buildings etc. it is recommended the terminal should not be less than 2500mm from car parking spaces,

building boundary walls, fences etc.

5. A terminal must not be sited under a car port roof.

6. In certain weather conditions the terminal will emit a plume of steam. If possible avoid positioning the terminal where this may cause a nuisance, i.e. positions A,

D, G, H, J or M.

7. The fl ue terminal must be exposed to the external air and the position must allow the free passage of air across it at all times.

8. A terminal must not be sited below 2m where people have access to, such as public footpaths, access routes, patios etc. However, If the terminal is fi tted less

than 2m above a surface where there is no public access, the terminal must be protected by a terminal guard.

Installation & Servicing instructions ATAG iC-Range

25

The appliance produces a white wisp of condensate (plumeing). This wisp of condensation is harmless, but

can be unattractive, particularly in the case of outlets in outside walls.

For wall terminals a plume management kit is available as an option (see fi g. 9.8.1.d).

Plume management kit Figure 9.8.1.d

Figure 9.8.1.e

Terminal position Plume Management Kit (mm)

1 Clearance no less than 200 mm from the lowest point of the balcony or overhang.

2 1.200 mm from an opening in a car port on the same wall i.e. door or window leading into dwelling.

3 The fl ue cannot be lower than 1.000 mm from the top of the light well due to the build up of combustion products.

4 1.200 mm between air intake and facing terminal.

5 Internal/external corners. The air intake clearance can be reduced to 150 mm providing the fl ue exhaust outlet has a 300 mm clearance.

6 600 mm distance to a boundary or surface facing a boundary, unless it will cause a nuisance.

BS 5440: Part 1 recommends that care is taken when siting terminals in relation to boundaries.

Notes:

1. See also Notes on previous page.

2. Plume kits running horizontally must have a 10° fall back to the boiler for proper disposal of condensate.

3. For details on specifi c lengths see relevant chapter Dimensioning of the fl ue gas and air intake duct.

4. A terminal must not be sited under a car port roof.

26

Installation & Servicing instructions ATAG iC-Range

9.8.2 Dimensioning of the fl ue gas and air intake duct

The total length of the run of the fl ue is determined by the fl ue diameter, including for the connection pipe,

elbows fi ttings and terminal covers etc..

An incorrect dimensioned fl ue system can lead to disorders. Look at table 9.8.2.a for the choice of the boiler

and the corresponding maximum equivalent fl ue length.

Explanation table 9.8.2.a:

Concentric fl ue gas system:

maximum noted length L = distance between boiler (from elbow or vertical adapter) and the end of terminal

When using bends the noted value behind every bend should be deducted from the maximum straight

length. See example.

Dimensions fl ue gas system and air supply system

Concentric fl ue system ø60/100 (Horizontal & Vertical)

Type iC 24 iC 28 iC Economiser Plus 27 iC 36 iC 40 iC Economiser Plus 35 iC Economiser Plus 39

Maximum equivalent length (L) m 13 6

45° bend resistance length m -1.0 -1.0

87° bend resistance length m -1.6 -1.6

Concentric fl ue system ø80/125 (Horizontal & Vertical)

Type iC 24 iC 28 iC Economiser Plus 27 iC 36 iC 40 iC Economiser Plus 35 iC Economiser Plus 39

Maximum equivalent length (L) m 50 45

45° bend resistance length m -1.9 -1.9

87° bend resistance length m -3.0 -3.0

Tabel 9.8.2.a

Example:

An iC28 with a

concentric fl ue gas system

ø60/100mm has according

to the table a maximum fl ue

straight length of 18m In the

system that is going to be put

in there are 2 x 45° bends, so

the maximum fl ue gas length

is 18 – ( 2 x -1.0 ) = 16m.

Flue dimensions

Rear Flue B (mm)

Min Max

Telescopic fl ue (FA100105) 280 430

Side Flue B + C (mm)

Telescopic fl ue (FA100105) 285 435

Installation & Servicing instructions ATAG iC-Range

Min Max

27

Rear Flue

L = wall thickness (B) + 150mm

Side Flue

L = wall thickness (B) + distance between boiler and wall (C) + 150mm

If the length L is more than 580mm rear fl ue or 585mm side fl ue, then a

Horizontal fl ue fi xed length 1000mm (60/100mm) with elbow (FA100205)

will need to be used instead, up to 810mm.

Figure 9.8.2.a

Fitting the fl ue

Note: If it is required to cut an extension, DO NOT cut the end of the inner duct that incorporates the seal

joint.

Ensure the inner duct end without the seal joint is cut so that it is fl ush with the outer duct.

Ensure that all cuts are square and free from burrs.

Once assembled with the components pushed home, the fl ue is fully sealed.

1. Adjust the telescopic fl ue and secure with sealing tape supplied or cut the fi xed length terminal fl ue to the

required length.

2. Fit the fl ue to the extensions (if required) by locating the inner duct into the seal joint and push fully home

the inner and outer duct.

3. When connecting the horizontal fl ue terminal length ensure the terminal end outlet is at the uppermost

part of the fl ue.

4. Pass the terminal fl ue assembly through the wall.

5. Fit the bend to the boiler turret.

6. If the inside sealing collar (white) is being used, then it will need to be fi tted before assembling the fl ue

and making good the inside wall.

7. Pull the fl ue assembly towards the bend, locating the inner duct into the seal joint on the bend and secure

the fl ue assembly to the bend by pushing fully home (Outer fl ue duct must be seen through the small

inspection hole to confi rm fully home).

8. Make good the outside wall and fi t the outside sealing collar onto the location provided immediately

behind the fl ue terminal grille.

When mounting the fl ue gas system, pay attention to the fl ow direction (See

fi gure 9.8.2.b). It is not permitted to mount a system upside down and will lead to

complaints.

Use a soap solvent or special grease (supplied in the accessory bag with the

boiler) to simplify the fi tting.

The ATAG fl ue system used is a push fi t fl ue system, which does not require

screws to be fi tted at each fl ue joint.

The fl ue system must be adequately supported at regular intervals between

brackets of no more than 1.0 metres for horizontal sections and no more than

2.0 metres for vertical sections.

Flow direction Figure 9.8.2.b

28

Installation & Servicing instructions ATAG iC-Range

9.9 Fitting the boiler onto the boiler frame

After the pipe work of gas, heating installation and DHW installation has been fi tted to the boiler frame, the

boiler can be placed on the boilerframe.

Before hanging the boiler to the boiler frame remove fi rst the cover of the boiler fi rst. The cover is also the air

cabinet and is attached to the boiler case with 2 fasteners (A and B) (see fi gure 8.a).

Note that there is an earth cable (when present) to disconnect when removing the cover from the

boiler. Free space for removing the connector is 400mm. Remember to connect this earth cable

(when present) when replacing the cover.

Always replace and turn the 2 screws tight in the fasteners A and B after replacing the cover.

Remove furthermore the 6 plastic caps from the boiler connections.

When removing the plastic sealing caps from the pipes, contaminated testing water may be released.

Lift the boiler only by the boilers case.

Lifting and carrying precautions:

- Lift only a manageable weight, or ask for help.

- When lifting the boiler, bend the knees, and keep the back straight and feet apart.

- Do not lift and twist at the same time.

- Lift and carry the boiler close to the body.

- Wear protective clothing and gloves to protect from any sharp edges.

Place mains

water fi lter in

cold water inlet

1 2

Figure 9.9.a

1. Press all connection underneath the boiler upwards

2. Put on each valve and the elbow fi tting a fi bre washer (supplied)

2

3 and 4. Take the boiler and hang it from approx. 50mm higher than the boiler frame vertical downwards on

the boiler frame so the fi ttings will be axial approached.

3

4

Figure 9.9.b

Installation & Servicing instructions ATAG iC-Range

29

Figure 9.9.c

Fitting the nuts:

Turn each nut of the fi ttings on the boiler connections by hand and tighten each nut with a wrench.

Figure 9.9.d

Fitting expansion vessel hose:

Take the end of the fl exible expansion vessel hose and fi t it to the 3/8" boilers expansion vessel connection

using a fi bre washer.

2

1

7

10

9

iR-Range

only*

3

6

8

10

Note:

Pressure relief valve outlet is

combined with condensate outlet.

5

4

Figure 9.9.e

Fitting siphon:

- Press and turn the assembly (3), with the elbow fi rst, in the corresponding holes in the bottom plate of the

boiler.

- Press the black fl exible pipe (1) from inside the boiler in the rubber T-piece (3).

- Press the black rubber elbow with fl exible drain pipe (1) on the condensate tray (2)

- Lead the long black fl exible pipe (4) through the free hole of the boiler frame and press it in the T-piece (3)

- Lead the other end of the fl exible pipe outside the boiler to the drain as installed according to the

installation and service manual.

- Fill the siphon cup (5) with 150 ml water, insert the siphon pipe (6) in the siphon cup (do not press)

and insert this through the hole in the bottom plate of the boiler into the condensate tray (2) of the heat

exchanger. Secure the siphon cup with the securing clip (7) by turning it clockwise (click!).

- Press the sealing ring (8) around the siphon cup and press/turn it in the bottom plate of the boiler.

* iR-Range only: Press the black rubber plug (9) from inside the boiler in the rubber elbow of assembly (3).

- Open the plug of the elbow of assembly (1) and push the fl exible transparent tube from the automatic

deaerator in the opening (10). NOTE: The plug remains closed when the fl exible transparent tube

from the automatic deaerator is not connected.

30

Before putting the boiler into operation fi ll the siphon with 150 ml of water.

Installation & Servicing instructions ATAG iC-Range

10 Electrical connection

The appliance complies with the actual directives. The installation must continue to comply with:

- A 230V -50Hz mains electrical supply is required fused externally at 3A.

- A deviation on the grid of 230V (+10% or -15%) and 50Hz

- the national rules for electrical installations.

The appliance must be connected to an earthed socket. This must be visible and within reach.

The following general stipulations also apply:

- No changes may be made to the wiring of the appliance;

- All connections should be designed in accordance with the enclosed regulations;

- Should it be necessary to change it, the mains power supply cable may only be replaced with an ATAG

mains power supply cable.

The connection terminals are positioned at the back of the control unit:

- Press handle A slightly to the left (see fi g. 10.a)

- Turn the control unit downwards.

A

Terminal block iC-Range

230V control terminal block iC-Range

SwL: Switched live

L: Live

N: Neutral

E: Earth

230V live input only!

230V live output

ATAG Outside sensor 1kOhm*

n.a. = not applicable

ATAG programmer for DHW timer

ATAG programmer for CH timer

On/off room thermostat Volt free

Bus = OpenTherm controller / room thermostat

terminal block Figure 10.a

Installation & Servicing instructions ATAG iC-Range

* Mounting on north – north/east facade of the house.

Prevent outside infl uences such as snow, ventilation

air or chimney heat.

DO NOT CONNECT 230VOLT

31

10.1 One controller, OpenTherm and BUS connection (blue)

The blue BUS connection can only be used for the ATAG ONE controller (CT000111), an OpenTherm

controller or the ATAG 7 Day Two Channel Plug-In Digital Programmer (CT200002).

10.2 Room thermostat volt free connection (black)

A volt free on / off room thermostat or a programmable room thermostat with volt free connections can be

wired to the black volt free room thermostat connector position.

The ATAG 7 day, Single Channel Digital Wireless Programmer and Room Thermostat (CT200001) or ATAG

24 hour, Single Channel Mechanical Wireless Programmer and Room Thermostat (CT100002) both come

with the receiver fi tted within a replacement facia panel for the front of the boiler and their volt free plug

connects into this Room thermostat volt free connections (black).

10.3 ATAG Central Heating volt free timer connection (white)

The ATAG 24 hour, Single Channel Plug-in Mechanical Timer (CT100001) comes fi tted within a replacement