Page 1

User manual

8G.52.80.00/03.15 Changes reserved.

iC-Range

iS-Range

iR-Range

Page 2

User manual ATAG iC, iS and iR-Range

2

Contents

1. Introduction ....................................................................................3

2. Safety .............................................................................................5

3. Boiler description ............................................................................6

4. Display and functions .....................................................................7

4.1 DHW and Heating program ....................................................8

4.2 Eco function DHW (iC-Range only) .......................................9

4.3 Requesting current boiler data (info mode) ............................9

4.4 The Reset button .................................................................10

4.5 Frost protection ....................................................................10

5. Filling the heating system .............................................................11

6. Decommissioning the boiler .........................................................13

7. Error codes ...................................................................................14

8. Maintenance .................................................................................14

9. Warranty .......................................................................................14

Important!

It is in your own interest that we should know that you have an ATAG

boiler. Please ll out the warranty card completely and send it back to us.

Then we can be fully at your service.

Page 3

User manual ATAG iC, iS and iR-Range

3

1 Introduction

These operating instructions describe the functioning and the operating of the

ATAG i-Range boilers. This manual is for the end user. For installation and

servicing there is an installation & servicing instructions manual for the installer.

Read this manual fully before operating the boiler. In case of doubt or errors

contact your installer.

ATAG Heating Technology Ltd reserves the right to change the specications and

dimensions without prior notice.

Work on the boiler must be carried out by a competent person, (Ref: Gas Safe

Register) using correctly calibrated instruments with current test certication.

When replacing parts use only ATAG Service parts.

Contact details for ATAG Heating Technology Ltd can be found on the back page

of this manual.

Page 4

User manual ATAG iC, iS and iR-Range

4

The Benchmark Scheme

ATAG Heating Technology Ltd is a licensed member of the Benchmark Scheme

which aims to improve the standards of installation and commissioning of

domestic heating and hot water systems in the UK and to encourage regular

servicing to optimise safety, efciency and performance.

Benchmark is managed and promoted by the Heating and Hotwater Industry

Council. For more information visit www.centralheating.co.uk

Please ensure that the installer has fully completed the Benchmark Checklist on

the inside back pages of the installation instructions supplied with the product and

that you have signed it to say that you have received a full and clear explanation

of its operation. The installer is legally required to complete a commissioning

checklist as a means of complying with the appropriate Building Regulations

(England and Wales).

All installations must be notied to Local Area Building Control either directly

or through a Competent Persons Scheme. A Building Regulations Compliance

Certicate will then be issued to the customer who should, on receipt, write the

Notication Number on the Benchmark Checklist.

This product should be serviced regularly to optimise its safety, efciency and

performance. The service engineer should complete the relevant Service Record

on the Benchmark Checklist after each service.

The Benchmark Checklist may be required in the event of any warranty work

and as supporting documentation relating to home improvements in the optional

documents section of the Home Information Pack.

Page 5

User manual ATAG iC, iS and iR-Range

5

2 Safety

Work on the installation should only be carried out by qualied personnel with

calibrated equipment. When replacing parts, only ATAG Service components may

be used.

If you smell gas:

- No naked ames! No smoking!

- Do not switch lights on or off or use other electrical switches.

- Do not use the phone

- Close the gas mains

- Open windows and doors

- Warn the occupants and leave the building

- Only call the gas company or installer once you are outside the building.

Corrosion protection

Do not use sprays, chlorine-containing cleaning products, solvents, paints etc.

in the vicinity of the device or its air supply. These substances have an adverse

impact on the device and can lead to corrosion that may result in failures.

Checking the heating water

Always use potable water for lling the installation.

Adding chemical agents such as frost and corrosion inhibitors are only to be

added by your installer.

If in doubt, check with your installer or ATAG Heating Technology Ltd.

Page 6

User manual ATAG iC, iS and iR-Range

6

3 Boiler description

The ATAG i-Range boiler is a closed, condensing and modulating heating boiler

which meets the European standard (CE).

A declaration of conformity can be obtained from the manufacturer.

The efficiency of the boiler is very high and the radiation convection and

standby losses very low. The emission of noxious substances is far below

the fixed standards so the boiler is >88% Efcient SEDBUK 2009 rated.

Page 7

User manual ATAG iC, iS and iR-Range

7

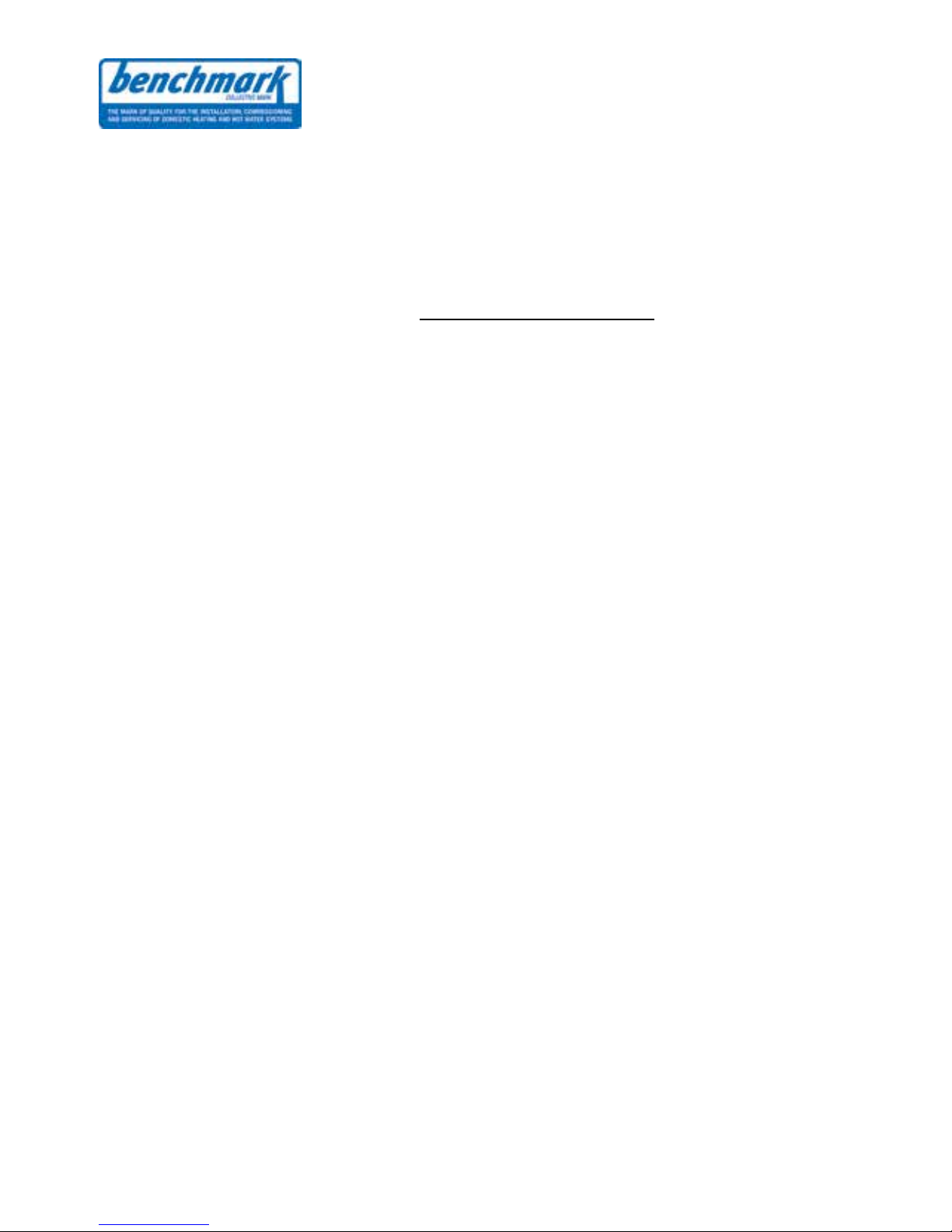

4 Display and functions

The boiler is equipped with a door at the front. For opening the door just pull at

the door handle.

After opening the door you will nd next to the display and buttons a brief

overview of the meaning of all the buttons and icons. These are described below.

DHW program

(iC-Range only); On = + ( symbol visible in display), Off = -

Setting of hot water temperature

+/-function (ancillary function: Scroll and +/-function)

Central heating program; On = +( symbol visible in display), Off = -)

Setting of boiler temperature (max. ow temperature)

+/-function (ancillary function: OK and Escape)

Eco-function DHW on/off. (iC-Range only: see also chapter 4.2)

Press 6 seconds for boiler information (see also chapter 4.3)

Reset button (see also chapter 4.4)

Commissioning function (Do not use. For service purposes only)

Pump function (Press both - buttons for 6 seconds). See chapter 4.x

%

bar

°C

+

-

-

+

reset

eco

(OK)

(ESC)

-

+

+

-

eco

reset

+

-

-

+

Page 8

User manual ATAG iC, iS and iR-Range

8

Meaning of the icons in the display

DHW Visible when DHW program is active (iC-Range only)

Flashing when there is a heat demand for DHW (iC-Range only)

Error Error indication (accompanied with a code).

Alert Service-mode or blocking

Pump Visible when pump is set to continuously (iC and iS-Range only)

Flashing when frost program is active (only when

outside sensor is connected

Eco Visible when DHW comfort function is not active (iC-Range only)

Flame Visible when boiler is active for heating or DHW

Heating Visible when heating program is active

Flashing when there is a heat demand for heating

4.1 DHW and Heating program

Hot water (iC-Range only)

Setting the hot water (DHW) temperature:

Briey press + or – ; the display will show the ashing

preset value;

Briey press + or – to change the set value. Each change

becomes active directly.

Hot water program OFF: Press – until the lowest value is

reached and then press – again. The display shows - - .

Switching on works in reverse order.

Central heating

Setting the water temperature for central heating:

Briey press + or – ; the display will show the ashing

preset value;

Briey press + or – to change the set value. Each change

becomes active directly.

CH program OFF: Press – until the lowest value is

reached and then press – again. The display shows - - .

Switching on works in reverse order.

+

-

-

+

reset

eco

+

-

-

+

reset

eco

Page 9

User manual ATAG iC, iS and iR-Range

9

4.2 Eco function DHW (iC-Range only)

With the ECO button you can select DHW ECO mode or

DHW Comfort mode.

(DHW program must be on;

visible on display)

Press ECO-button briey:

- ECO mode is on when symbol is visible on display.

- Comfort mode is on when ECO symbol is not visible on display.

From factory the boiler is set to Comfort mode. This mode keeps the DHW

facility on 50°C. The advantage is that the boiler produces hot water almost

instantaneously when hot water is tapped.

When ECO mode is selected it will take a few seconds longer before the hot

water runs from the opened xture.

4.3 Requesting current boiler data (info mode)

Press the eco-button for 6 seconds in order to obtain the

following current boiler data using the scroll buttons:

A0 Flow water temperature in °C

A1 Return water temperature in °C

A2 DHW temperature in °C (only iC-Range)

A3 Calculated ow temperature (T-set) in °C

A4 Flue gas temperature (only if a ue gas sensor is connected) in °C

A5 Outside temperature (only if an outside sensor is connected) in °C

A6 Water pressure in °C (only iC and iS-Range)

A7 DHW ow in l/min. (only iC-Range)

A8

Ionisation current in mA

A9 Revolutions of the fan in rpm

To return to the standard view press ESC.

+

-

-

+

reset

eco

OK

ESC

scroll

+

-

-

+

reset

eco

Page 10

User manual ATAG iC, iS and iR-Range

10

4.4 Reset-button

The reset button allows the boiler to restart if an error has

occurred.

In case of an error the

symbol is displayed with a

XXX code.

In other cases the reset button does not function and will

not respond to operation.

See chapter XX for a brief overview of error codes.

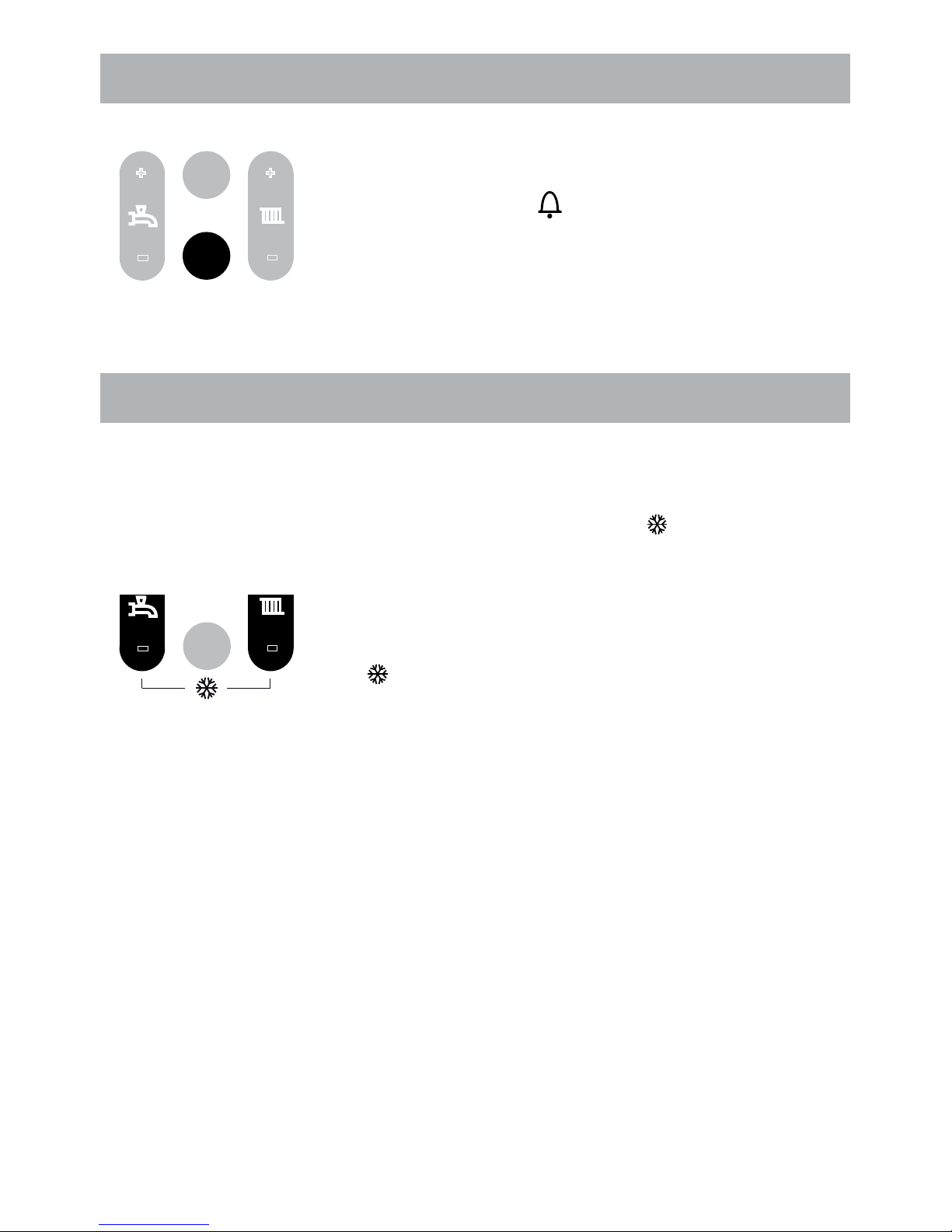

4.5 Frost protection

The iC and iS-Range boiler control is from standard provided with a boiler frost

protection.

The frost protection is switched on automatically when the

symbol in the

display is ashing and the pump is running.

In case there is danger of frost of the rest of the heating

system the frost protection can be switched on manually

by pressing the two - buttons for 6 seconds.

The

symbol is constant in the display and the pump is

running constantly.

Press both - buttons again for 6 seconds to switch back to

automatic.

+

-

-

+

reset

eco

+

-

-

+

reset

eco

Page 11

User manual ATAG iC, iS and iR-Range

11

5 Filling the heating system

Information on the water pressure:

The default view of the display shows OK. Press the eco-button for

6 seconds and press the eco-button a few times more until A6 is

displayed. The actual water pressure will be shown:

Water pressure too low

Code 118 and spanner symbol visible:

Water pressure is too low (<1.0 bar)*.

Power is reduced by 20%. The installation should be relled.

or

Code 118 and spanner symbol visible:

Water pressure is too low (<0.7 bar)*.

The boiler is taken out of operation. The installation should be relled.

After the installation has been relled and if the pressure was below

0.7 bar the de-aeration program will start (Code 105 and spanner

symbol visible). This will last for approximately 7 minutes.

Water pressure too high

Code 117 and spanner symbol visible:

Water pressure is too high (> 3.0 bar)*.

The boiler is taken out of operation.

The installation pressure should be reduced by draining water from the heating system.

Page 12

User manual ATAG iC, iS and iR-Range

12

Filling procedure

Combi boiler (iC-Range):

The iC-Range boiler is provided with a lling

loop.

Connect the lling loop between cold water

connection (1) and CH connection (2)

- Open slowly the valves (A and B) of the

lling loop;

- Read the water pressure from the pressure

gauge under the boiler or from the display

according to the procedure described

above and wait until the pressure reaches

between 1.7 and 2 bar;

- Close both valves (A and B) of the lling

loop.

Always disconnect the lling loop and close

the valves with the cap nut (3).

System boiler (iS-Range)

The heating system connected to the iS-Range boiler is provided with a lling

loop.

Connect the lling loop between cold water tap and the connection on the heating

system

- Open slowly the valves of the lling loop

- Read the water pressure from the pressure gauge under the boiler or from

the display according to the procedure described above and wait until the

pressure reaches 1.7 bar.

- Close both valves of the lling loop

Always disconnect the lling loop.

Regular boiler (iR-Range)

This boiler is part of an 'Open Vent' heating system. The system is not

pressurized, but is lled automatically by a lling system in the loft.

If there is a problem with this system, please contact your installer.

When the heating system is lled and after a power

interruption the boiler will be reset and starts with a

venting program. After the venting program (display

shows 1 05) of approx. 7 minutes has ended, the boiler

will be operational again.

OPEN CLOSED

1

2

A

B

3

Page 13

User manual ATAG iC, iS and iR-Range

13

6 Decommissioning the boiler

In case of, for instance, a holiday:

Make sure no heat request occurs: set the room thermostat to low.

Hot water (iC-Range only)

Hot water program OFF: Press – until the lowest value is

reached and then press – again. The display shows - - .

Switching on works in reverse order.

Central heating

CH program OFF: Press – until the lowest value is

reached and then press – again. The display shows - - .

Switching on works in reverse order.

In case of work on the heating installation:

Make sure no heat request occurs: set the room thermostat to low. Pull the plug

from the wall socket. If the installation is being drained, you have to take into

account that part of the heating water will remain in the boiler. Make sure that the

remaining heating water in the boiler cannot freeze in case of frost.

+

-

-

+

reset

eco

+

-

-

+

reset

eco

Page 14

User manual ATAG iC, iS and iR-Range

14

7 Error codes

In the event of a failure (this is indicated by a number code on the display) you

can try to eliminate the failure by pressing the Reset button. If the failure persists,

please contact your installer as soon as possible and tell him the number code.

There are also messages with a number code that

constitute no failures. These messages will cancel

themselves over time (*) or they need intervention.

Operating the reset button has no effect then.

10 Outside sensor error 111 Maximum temperature exceeded

20 Flow sensor error 117 Pressure too high (> 3 bar) or pump pressure increase too high

(iC & iS-Range only)

40 Return sensor error 118 Pressure too low (< 1 bar) or pump pressure increase too low

(no pump detection) (iC & iS-Range only)

50 DHW sensor error (iC-Range only) 119 Link on X2 position 4 and 5 missing

61 Bus communication error 129 Fan error (fan does not start up)

78 Water pressure out of range 133 No ame after 5 ignition attempts

105* Venting program active when power turned on or

interrupted (runs approx. 7 mins.)

151 Fan error (speed control is not achieved or is out of range) or

control unit defective

110 Safety temperature exceeded 154 Flow temperature increases to fast, return > ow

If leaks occur in the installation, please contact your installer.

8 Maintenance

Conclude a maintenance agreement with your installer in order to have the

installation periodically checked and adjusted.

The cover of the boiler consists of metal and plastic parts, which can be cleaned

with a normal (non-aggressive) cleansing agent.

9 Warranty

For the warranty conditions, see the Warranty Card that has been supplied with

the boiler.

Page 15

User manual ATAG iC, iS and iR-Range

15

Page 16

This renewed publication cancels all previous installation instructions. The company reserves the right to change the specications and dimensions without prior notice.

E. & O. E.

ATAG Heating Technology Ltd. • 47 Castle Street • Reading • Berkshire RG1 7SR

Phone: 0800 254 5061 • E-mail: info@atag-heating.co.uk • Internet: www.atagheating.co.uk

Loading...

Loading...