Page 1

華華碩碩電電腦

腦

GTC ■ Service Manual

ASUS P550 Level 3 4

Trouble shooting Guide

Page 2

華華碩碩電電腦

腦

GTC ■ Service Manual

Context

1. Feature Introduction ........................................................................................................................................... 3

ID Overview ................................................................................................................................................... 3

Main key function Description....................................................................................................................... 4

2. Block Diagram ................................................................................................................................................... 5

3.1 Solaris TOP View..................................................................................................................................... 6

3.2 Solaris Bottom View ................................................................................................................................ 7

4. Base Band Repair Tooling.................................................................................................................................. 8

4.1 HW ........................................................................................................................................................... 8

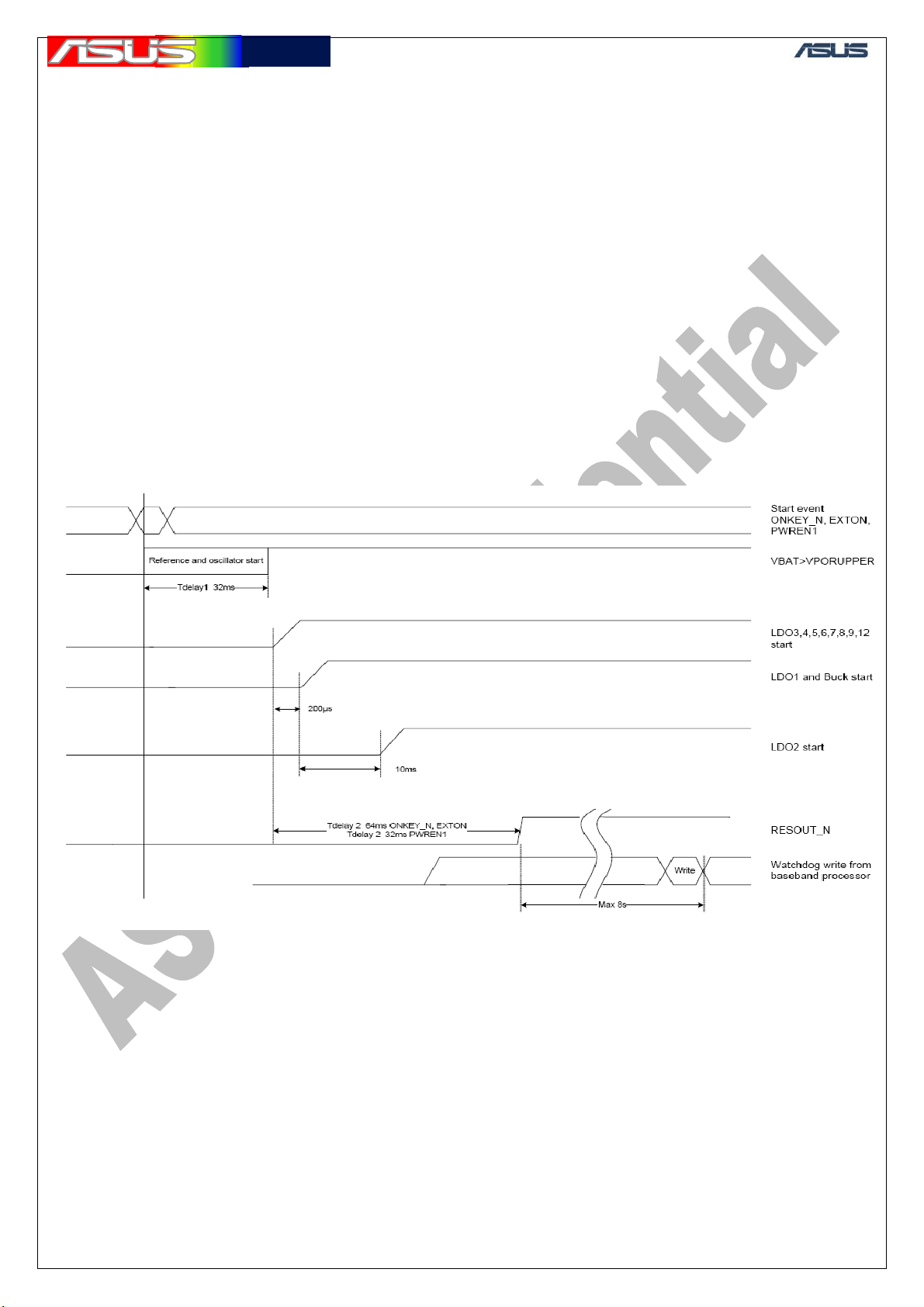

5. Chip Timing Sequence ..................................................................................................................................... 10

5.1 PMU Timing Sequence .......................................................................................................................... 10

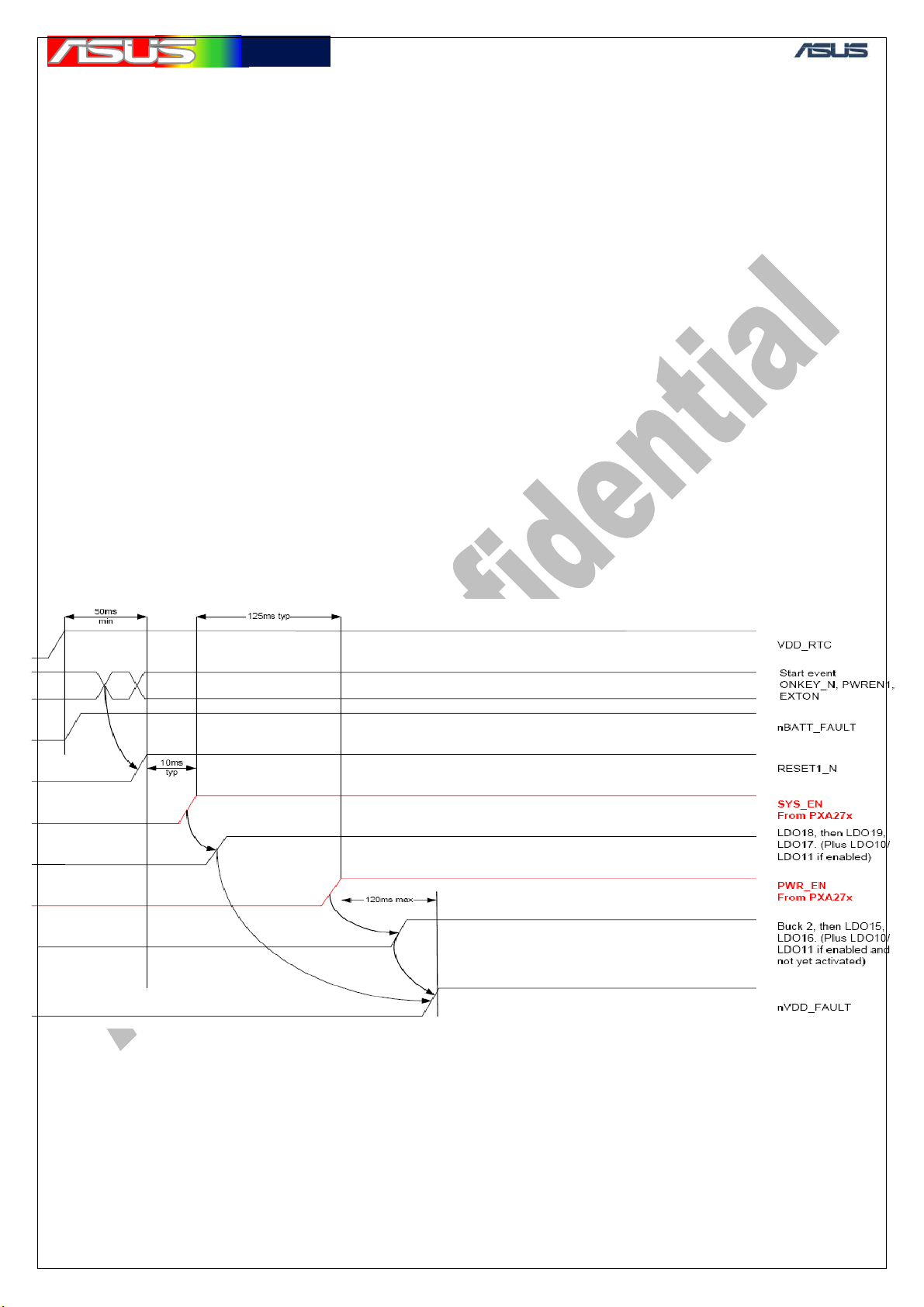

5.2 CPU Timing sequence ............................................................................................................................ 11

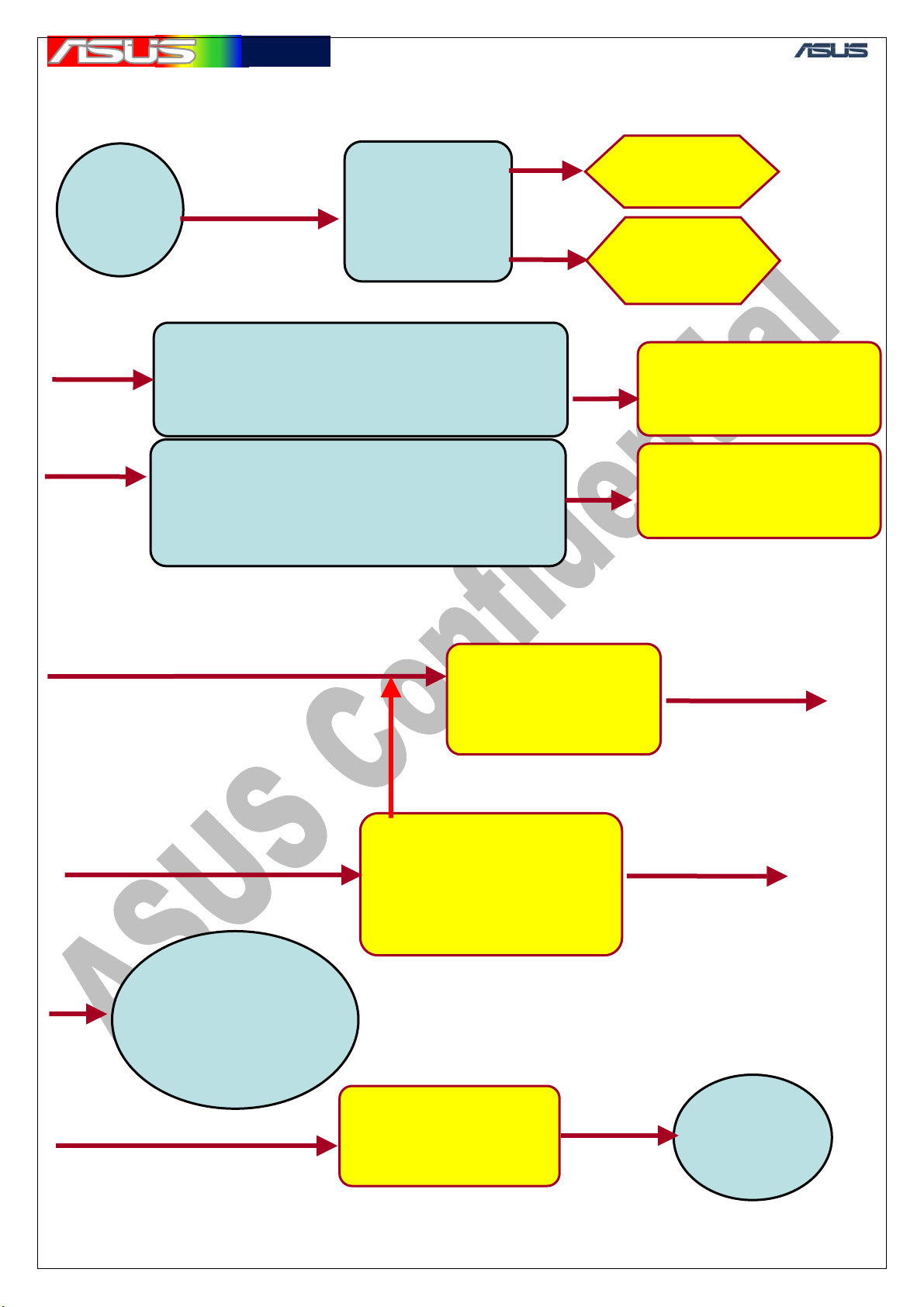

5.3 System Flowchart ................................................................................................................................... 12

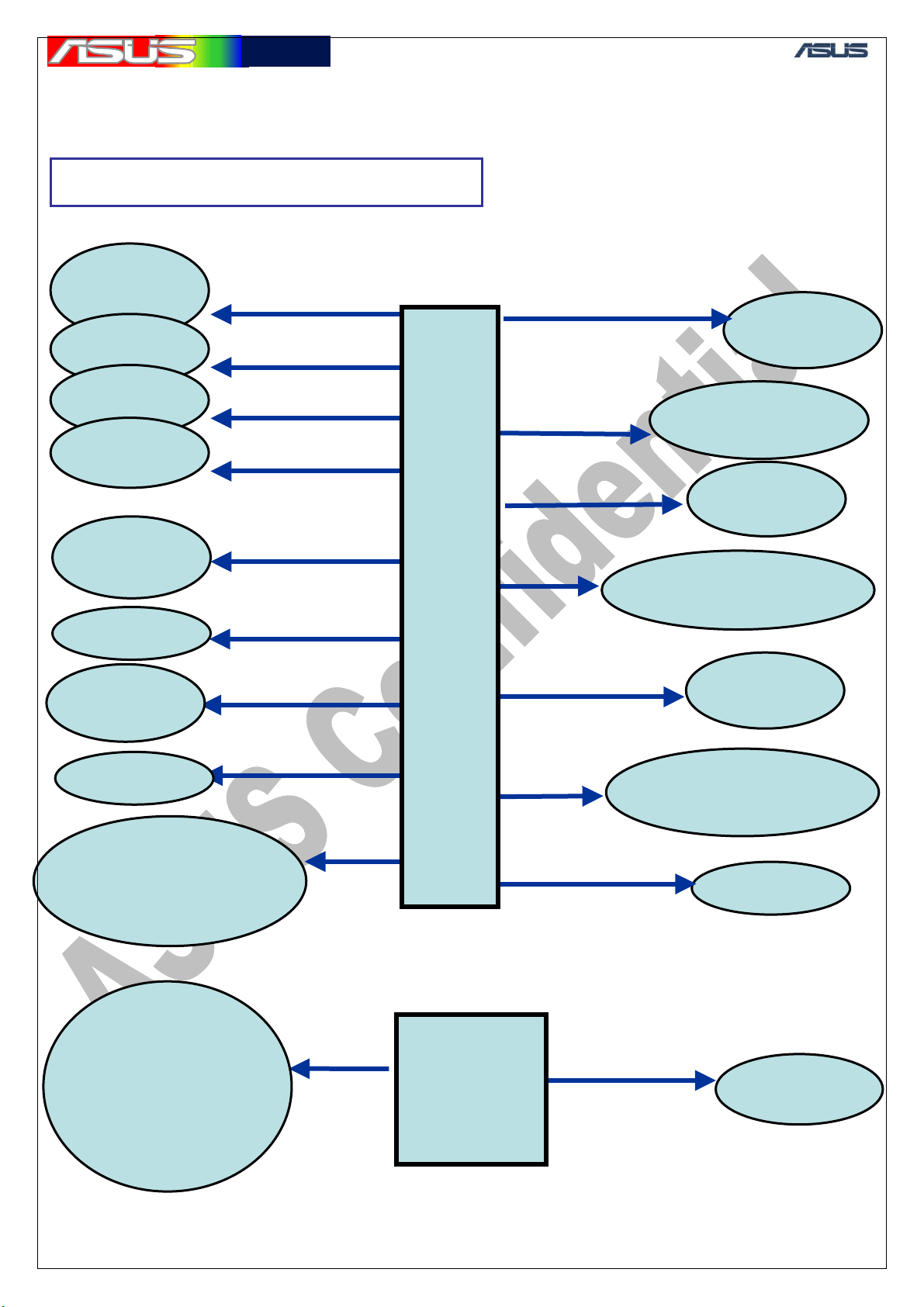

5.4 Power supply Block................................................................................................................................ 13

5.5 Power system Supplied Block................................................................................................................ 14

5.6 Power System Charging block ............................................................................................................... 14

6. Trouble shooting............................................................................................................................................... 15

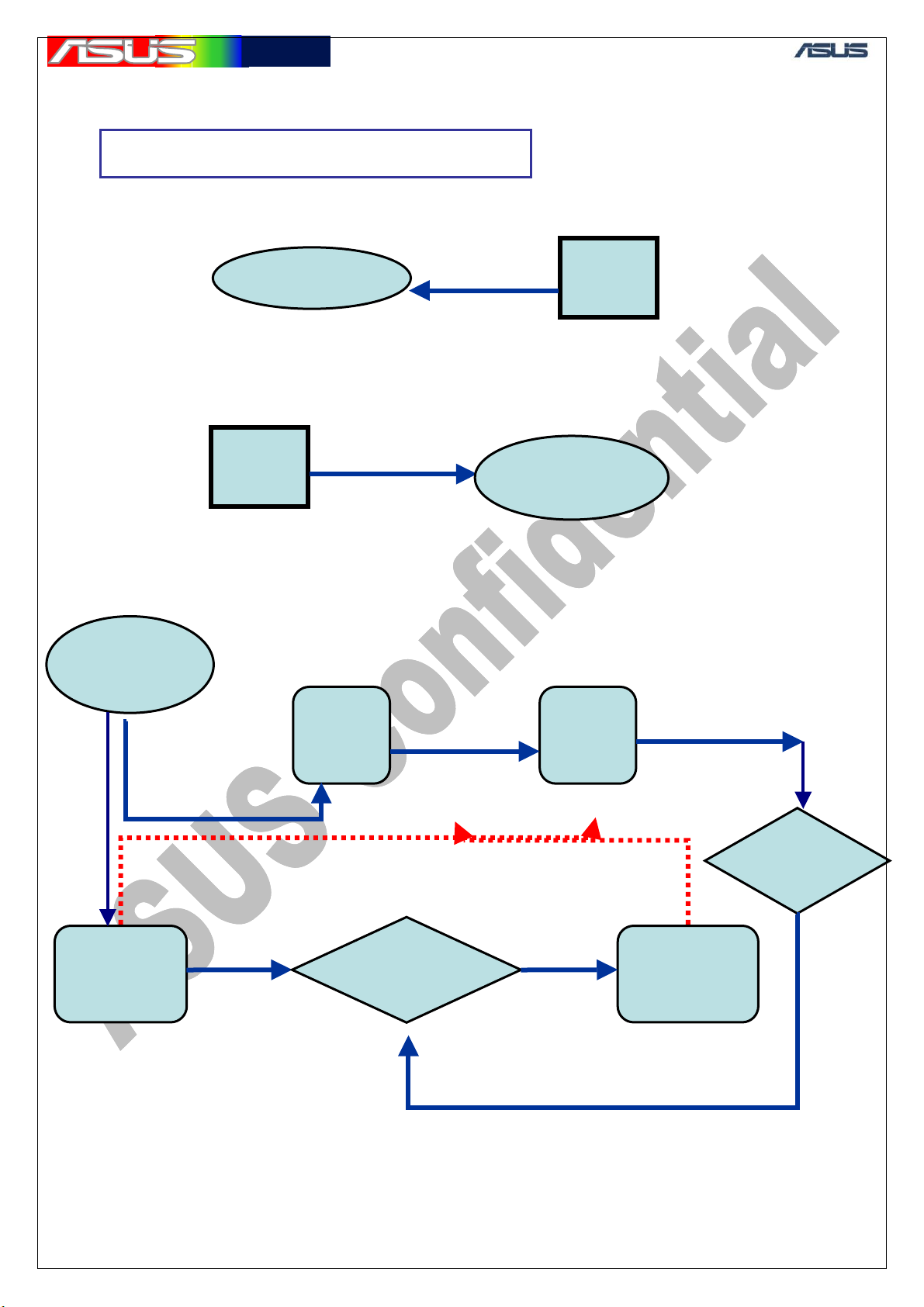

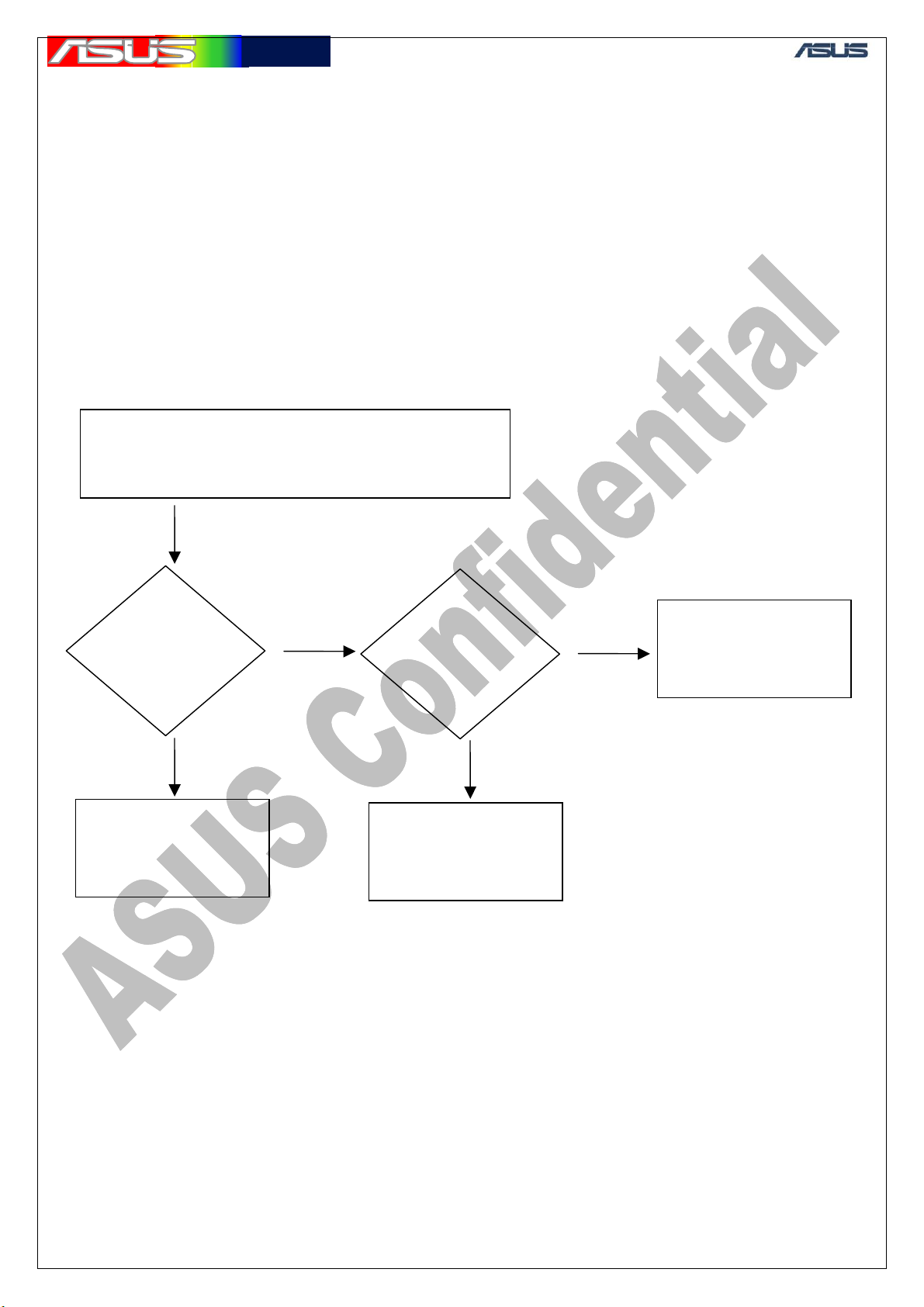

6.1 General Process ...................................................................................................................................... 15

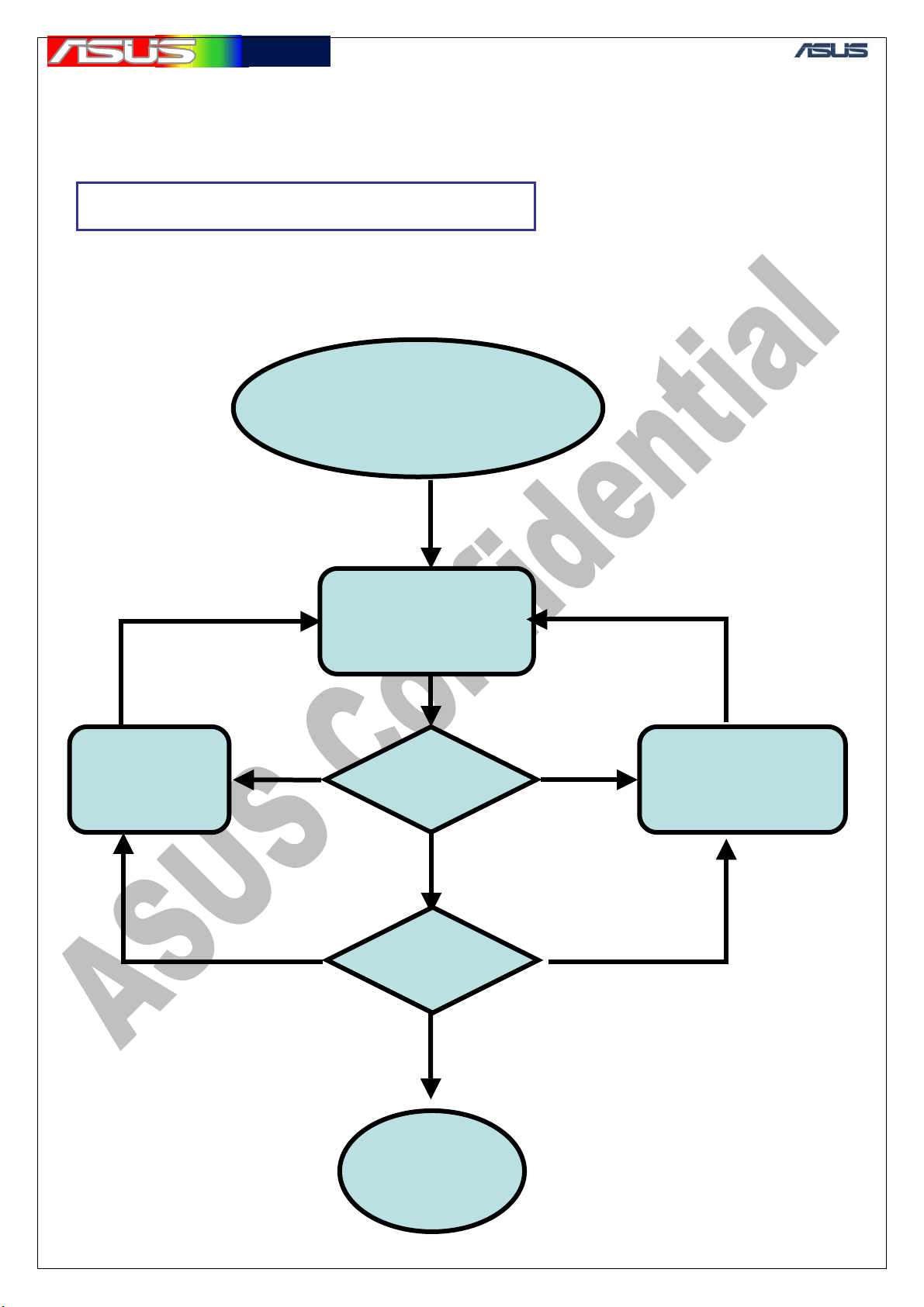

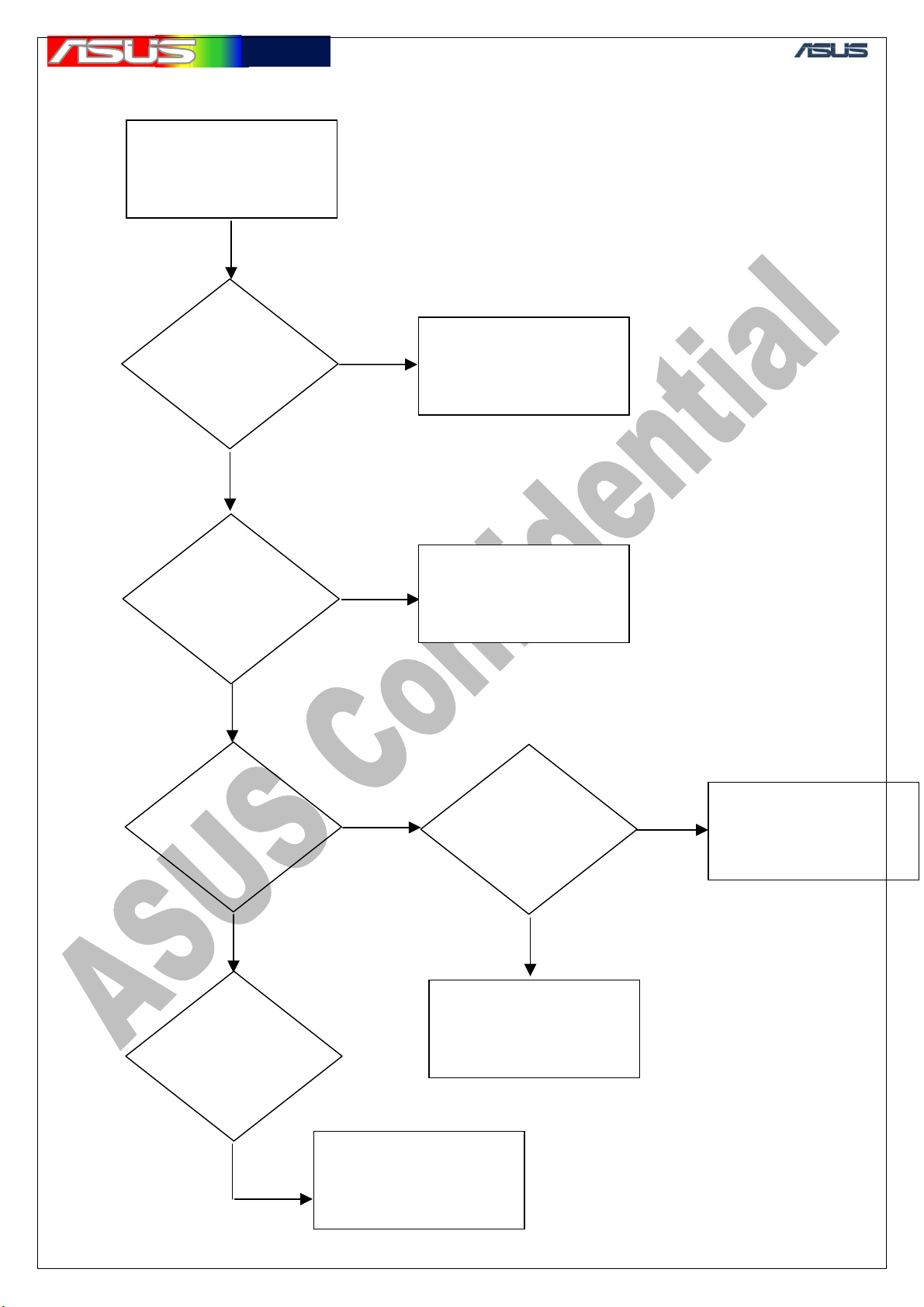

6.2 Can’t Power ON process ........................................................................................................................ 16

7. Trouble shooting............................................................................................................................................... 18

7.1 Touch panel failed .................................................................................................................................. 18

7.2 SDRAM.................................................................................................................................................. 19

7.3 Flash failed ............................................................................................................................................. 20

7.4 SDCARD................................................................................................................................................ 20

7.5 WiFi failed.............................................................................................................................................. 22

7.6 Modem-BUS failed ................................................................................................................................ 23

7.7 SIM failed............................................................................................................................................... 24

7.8 LED ........................................................................................................................................................ 24

7.9 Display failed.......................................................................................................................................... 25

7.10 Battery failed ........................................................................................................................................ 26

7.11 Vibrator failed....................................................................................................................................... 27

7.12 Camera.................................................................................................................................................. 27

7.13 Button failed ......................................................................................................................................... 28

7.14 BT failed............................................................................................................................................... 29

7.15 Audio failed .......................................................................................................................................... 29

Speaker no sound.................................................................................................................................. 29

Receiver no sound ................................................................................................................................ 30

Headphone no sound ............................................................................................................................ 31

Headphone MIC no record ................................................................................................................... 32

7.16 Standby current failed........................................................................................................................... 33

8. RF Repair Requirement............................................................................................................................ 34

8.1 SW: ...................................................................................................................................................... 34

8.2 HW: ..................................................................................................................................................... 34

8.3 Equipment: .......................................................................................................................................... 34

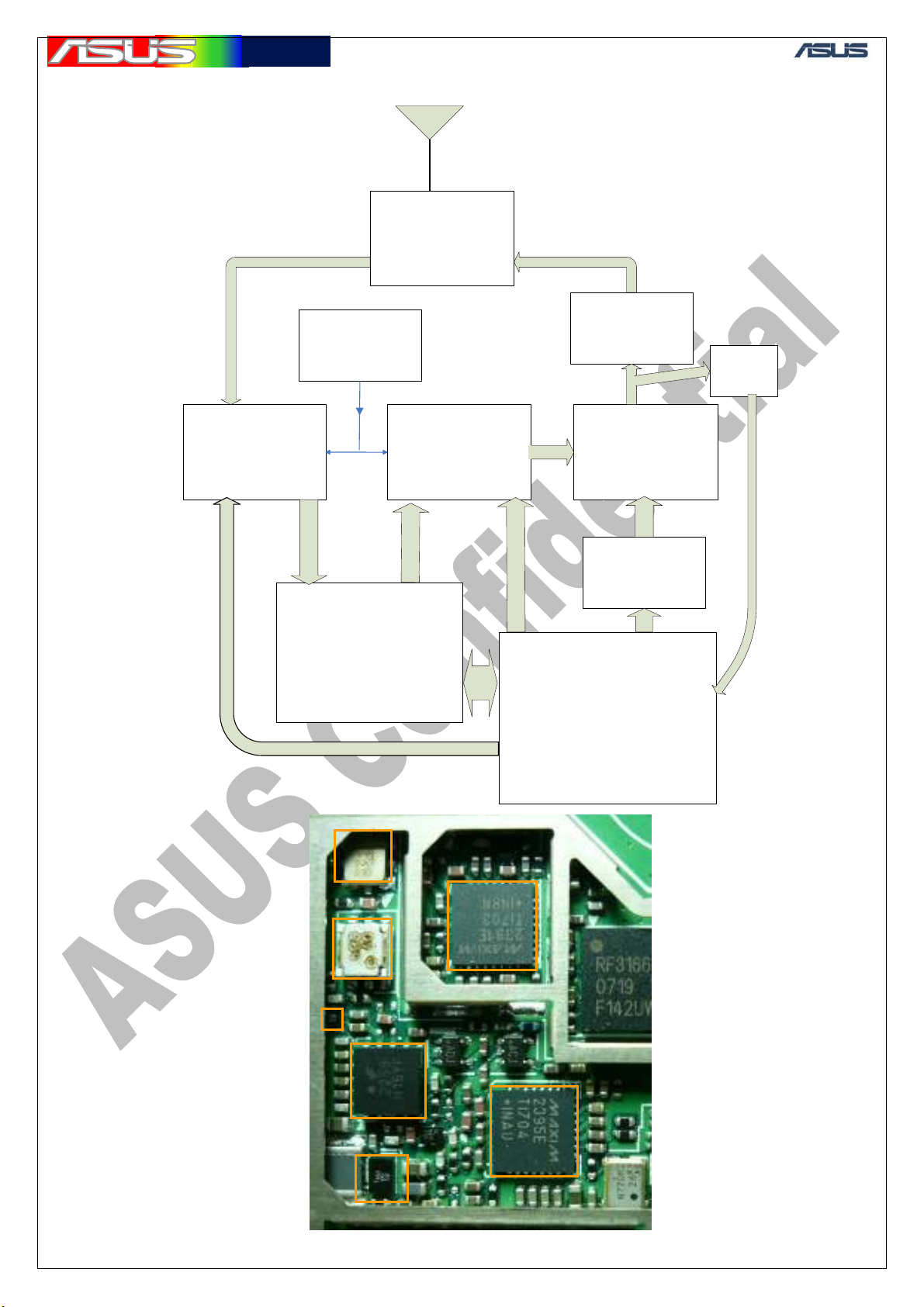

9. Block Diagram ................................................................................................................................................. 35

9.1 System Block Diagram........................................................................................................................... 35

9.2 GSM/GPRS – GSM RFMD solaris I Block Diagram............................................................................ 36

9.3 WCDMA – Maxim 3G Block Diagram.................................................................................................. 37

9.4 Blue tooth – CSR BC04 ......................................................................................................................... 38

9.5 WIFI– UGGZ3X10BA ........................................................................................................................... 39

9.6 GPS– GSC3F/LP-7................................................................................................................................. 40

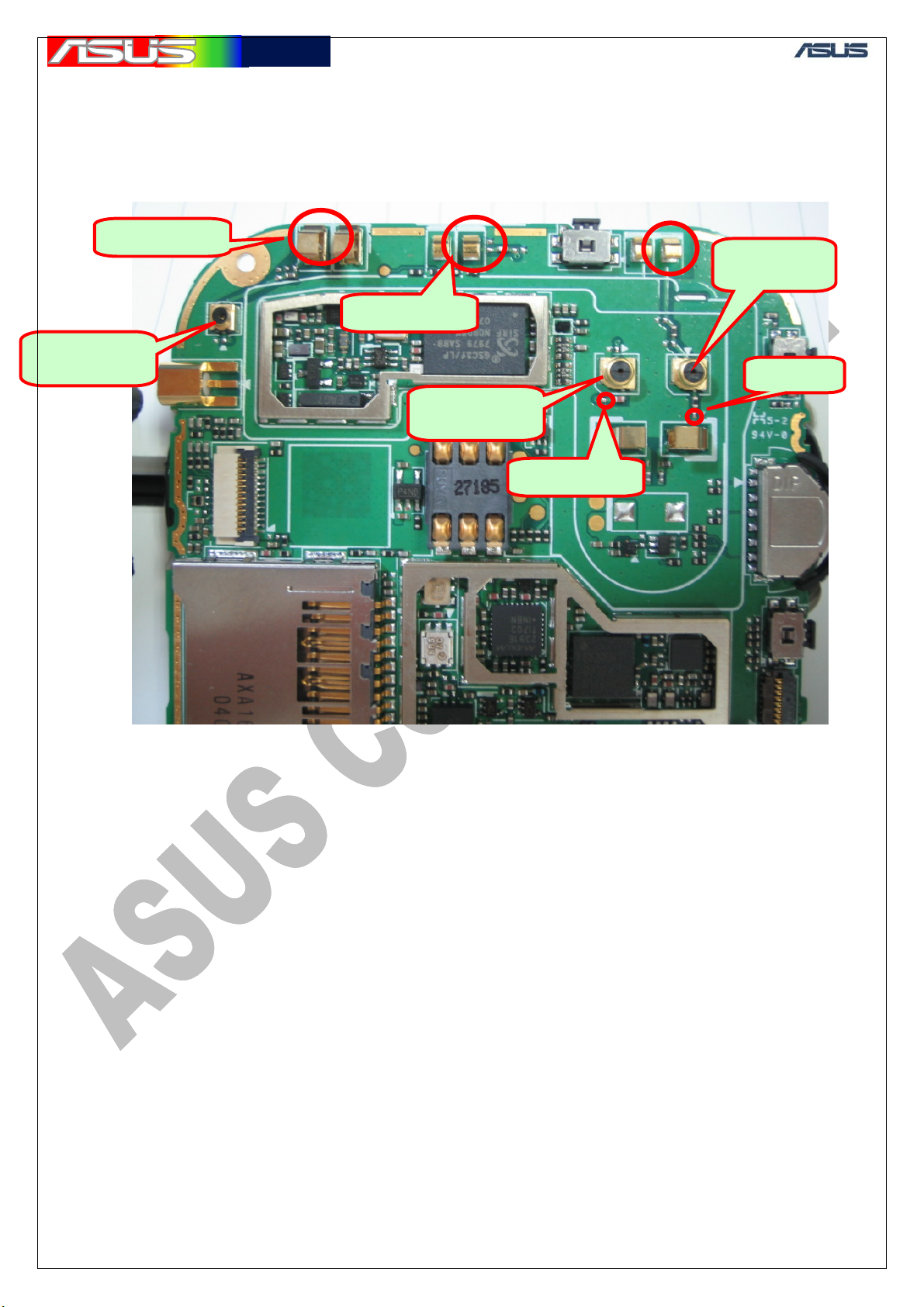

10.1 Backside Antenna Area Test Points...................................................................................................... 41

10.2 GSM/GPRS Test Points........................................................................................................................ 42

10.3 WCDMA Test Points............................................................................................................................ 43

1

Page 3

華華碩碩電電腦

腦

11. GSM & WCDMA RF Tx/Rx Path.................................................................................................................. 44

11.1 GSM Tx path ........................................................................................................................................ 44

11.2 GSM Rx path........................................................................................................................................ 44

11.3 WCDMA Tx path ................................................................................................................................. 45

11.4 WCDMA Rx path ................................................................................................................................. 45

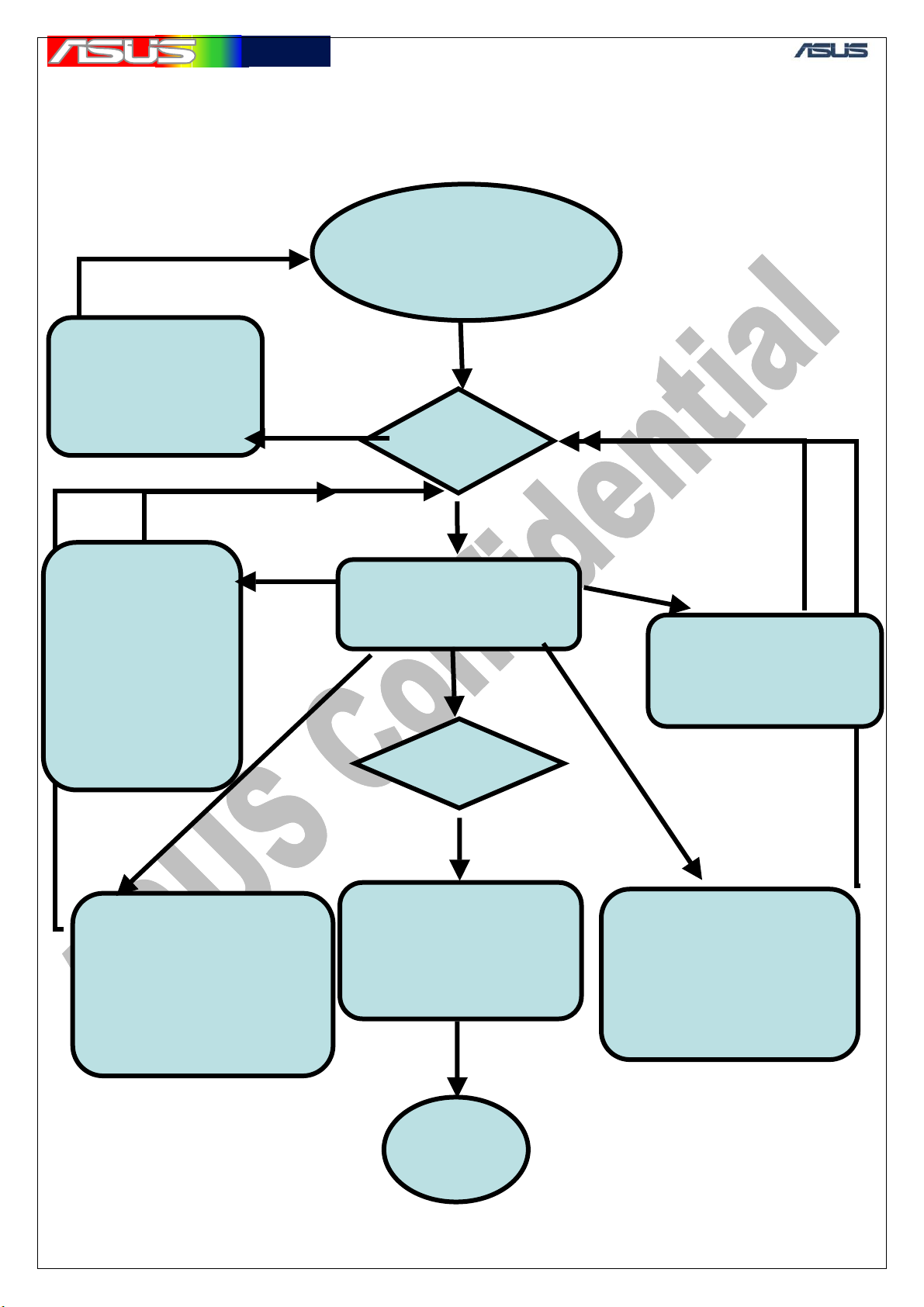

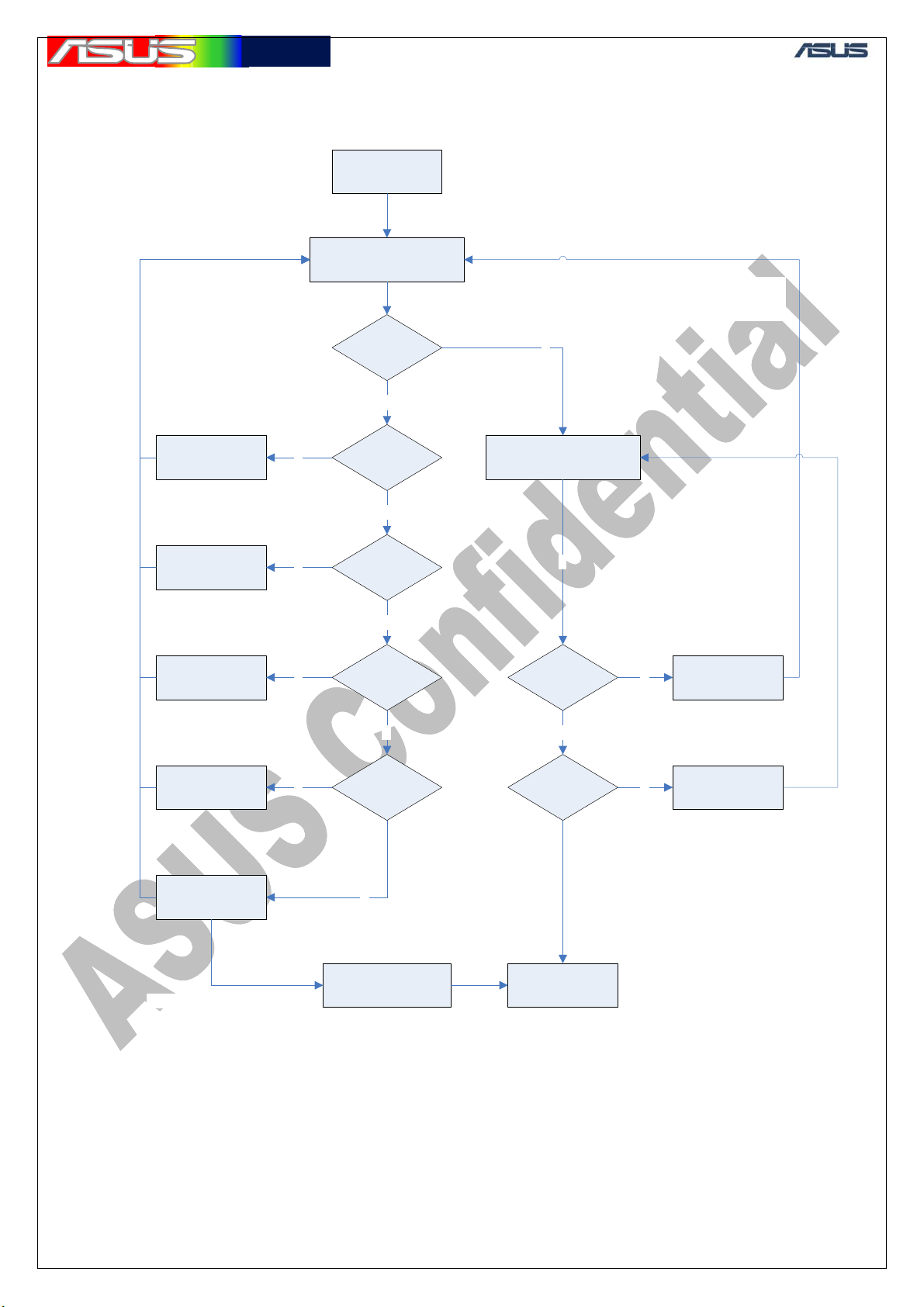

12. Test & Repair Flow Chart............................................................................................................................... 47

12.1 Conductive & Antenna Test Procedure ................................................................................................ 47

12.3 WCDMA Test & Repair Procedure ...................................................................................................... 49

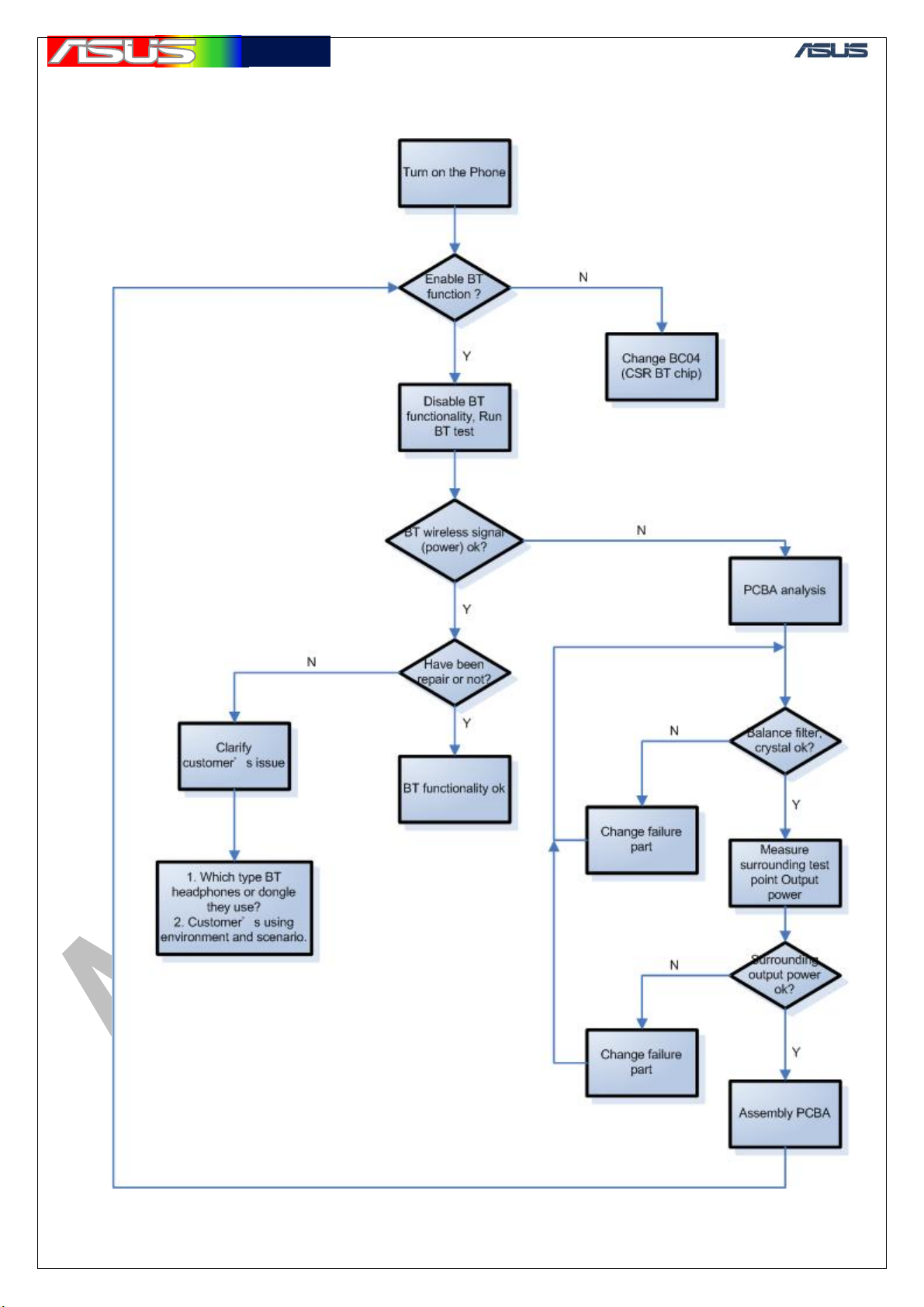

12.4 Blue tooth Test & Repair Procedure..................................................................................................... 50

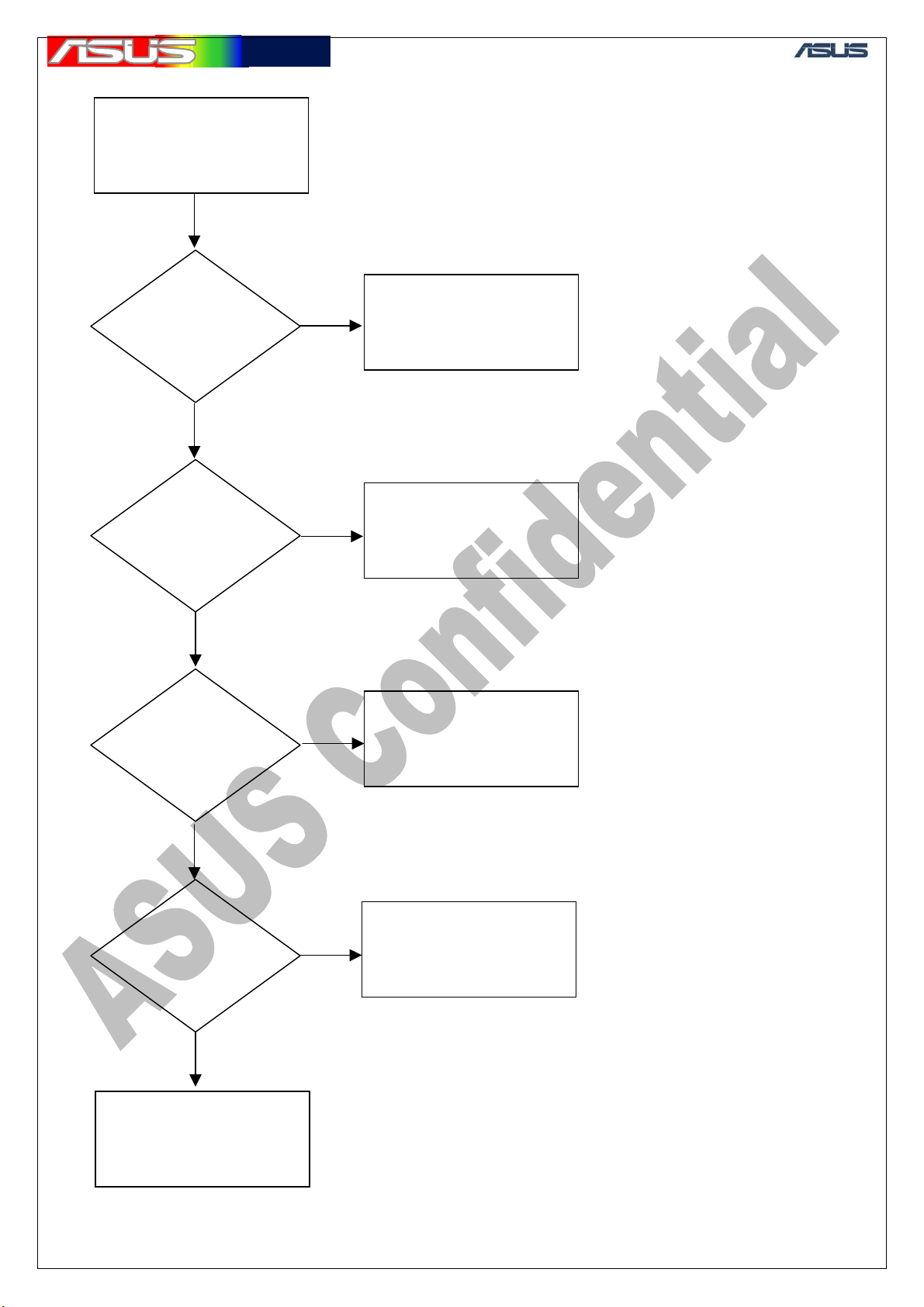

12.5 WIFI Test & Repair Procedure............................................................................................................. 51

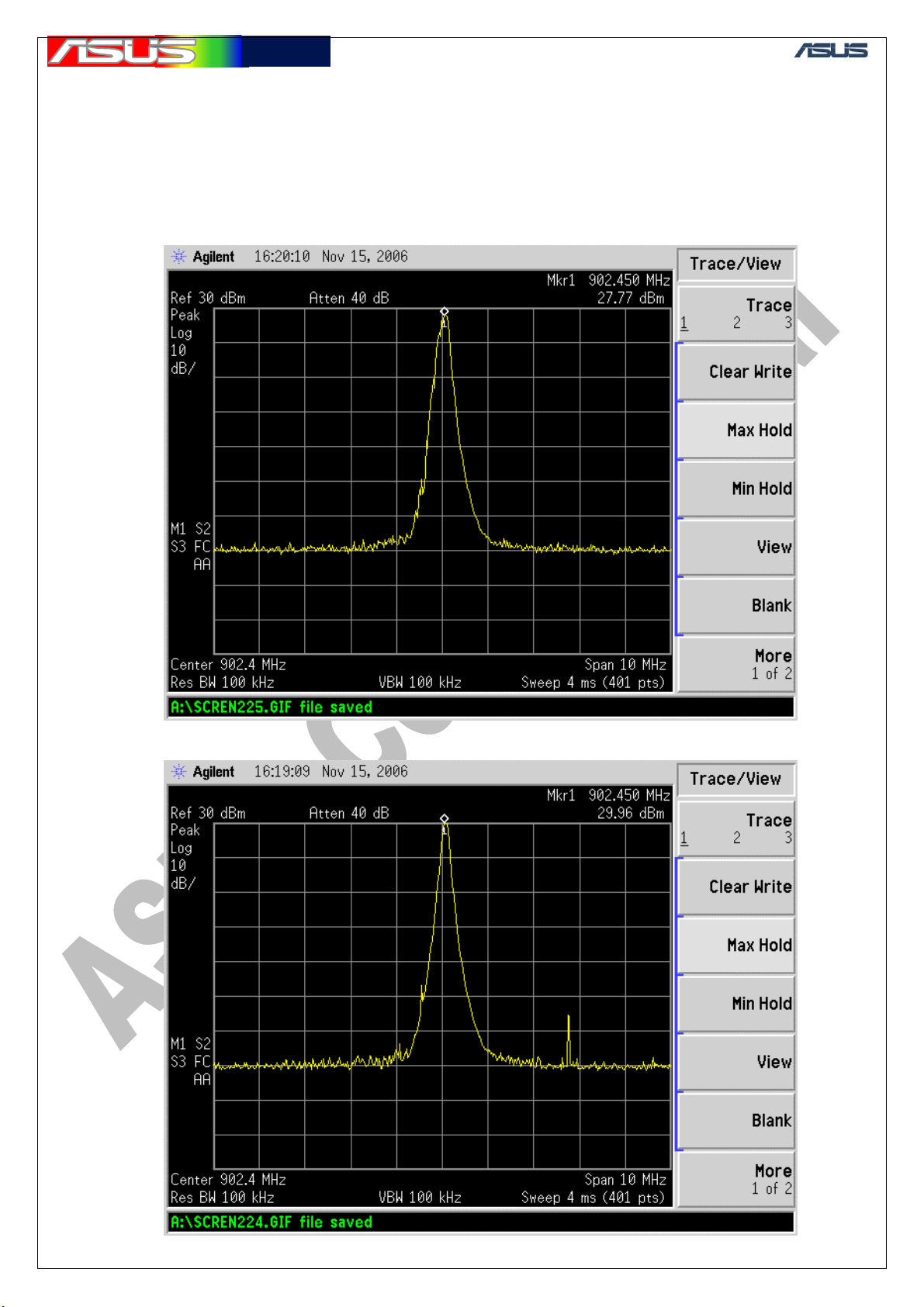

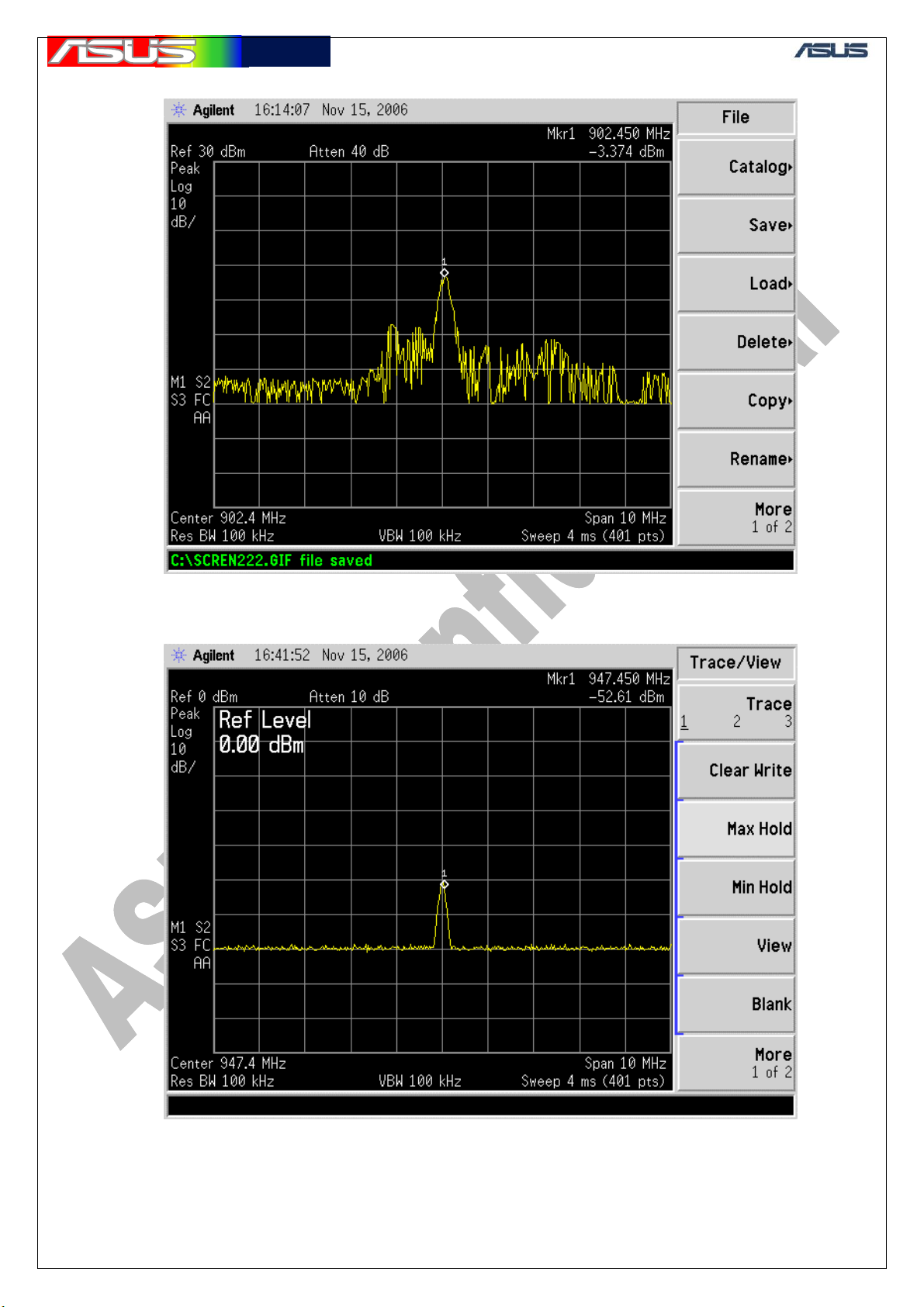

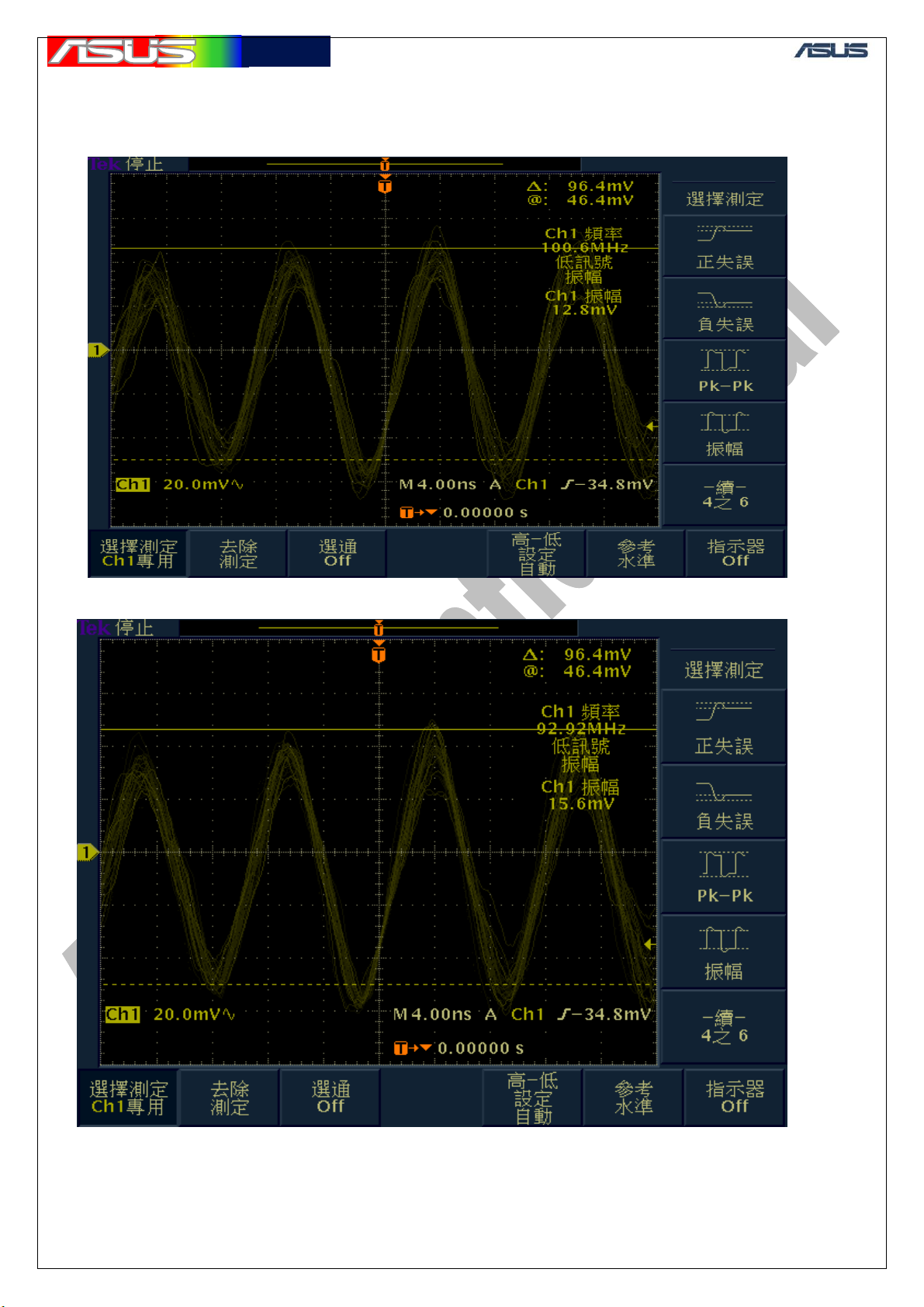

13. Test Points Signal Examples .......................................................................................................................... 52

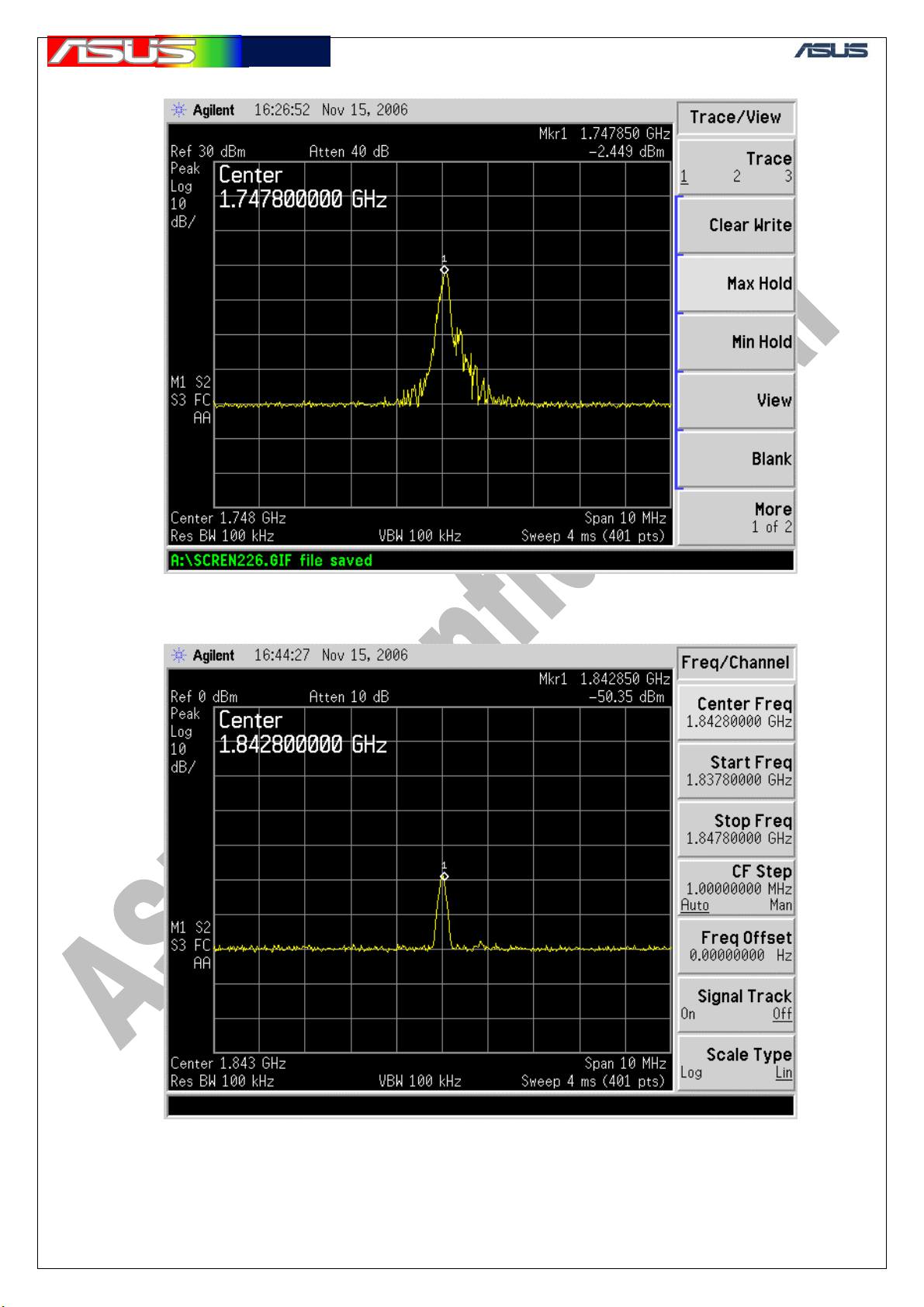

13.1 GSM900 ............................................................................................................................................... 52

13.2 DCS1800 .............................................................................................................................................. 55

13.3 PCS1900............................................................................................................................................... 58

13.4 WCDMA .............................................................................................................................................. 61

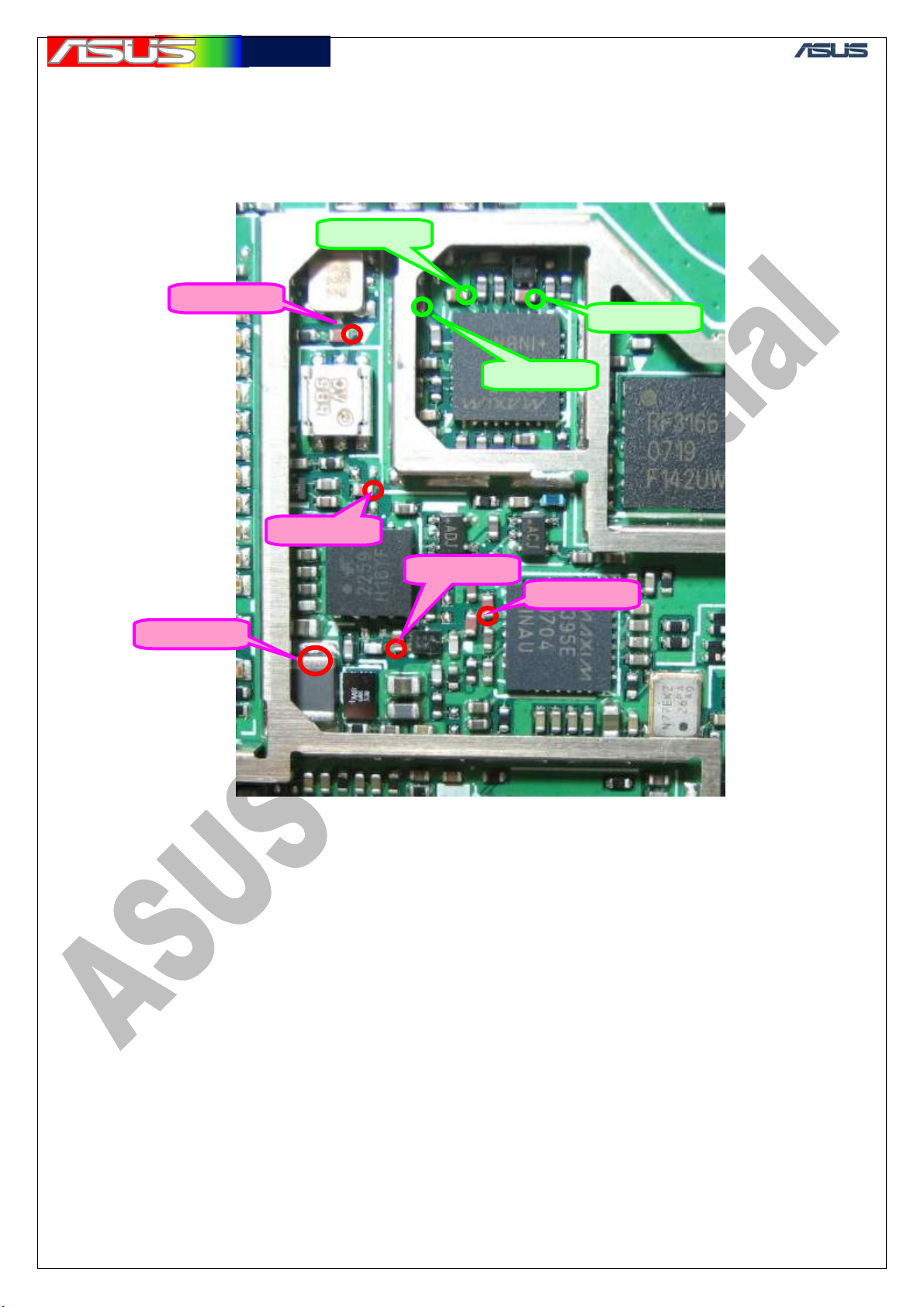

14. Blue tooth ....................................................................................................................................................... 67

15. WIFI ............................................................................................................................................................... 71

16. Appendix ........................................................................................................................................................ 75

16.1 Typical Value of GSM/GPRS Conductive Tx/Rx Test......................................................................... 75

16.2 Typical Value of WCDMA Conductive Tx/Rx Test ............................................................................. 75

16.3 Tx Test Environment Setup .................................................................................................................. 76

16.4 Rx Test Environment Setup.................................................................................................................. 77

17. GPS Introduce Purpose: ................................................................................................................................. 78

17.1 Equipment requires............................................................................................................................... 78

17.2 Software: .............................................................................................................................................. 78

17.3 Hardware: ............................................................................................................................................. 78

18. GPS Test points & Schematic......................................................................................................................... 79

18.1 GPS Active Path................................................................................................................................... 79

18.2 Passive Path.......................................................................................................................................... 80

18.3 GPS Chip.............................................................................................................................................. 80

18.4 Power part test points ........................................................................................................................... 81

18.5 Testing signal from base band .............................................................................................................. 81

19. Test points placement point ............................................................................................................................ 82

19.1 GPS Antenna ........................................................................................................................................ 82

20. GPS Hardware Examination Procedure ................................................................................................. 83

21. Measurement results of all test points ............................................................................................................ 87

22. Software procedure......................................................................................................................................... 89

22.1 GPS firmware download ...................................................................................................................... 94

GTC ■ Service Manual

2

Page 4

華華碩碩電電腦

腦

GTC ■ Service Manual

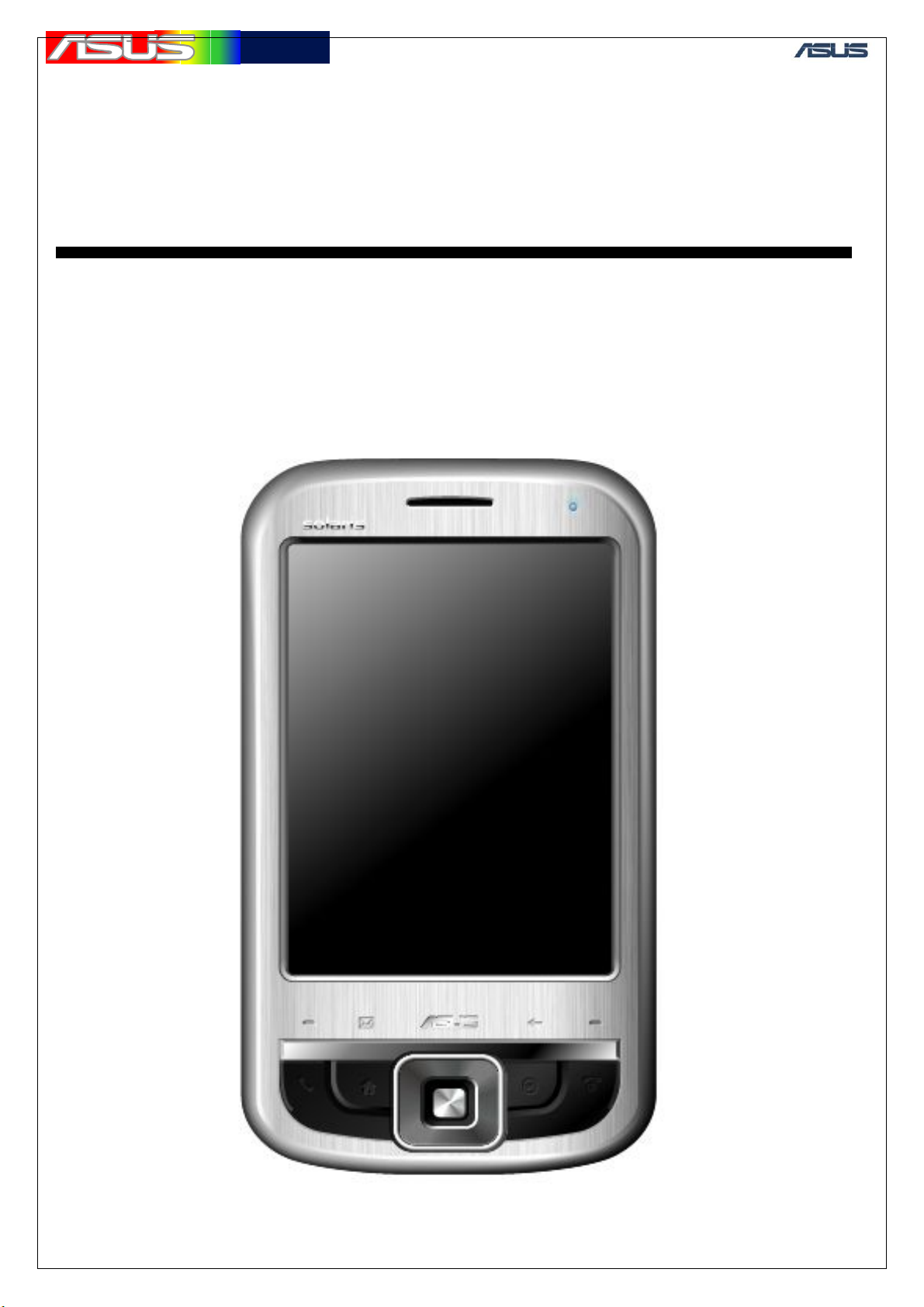

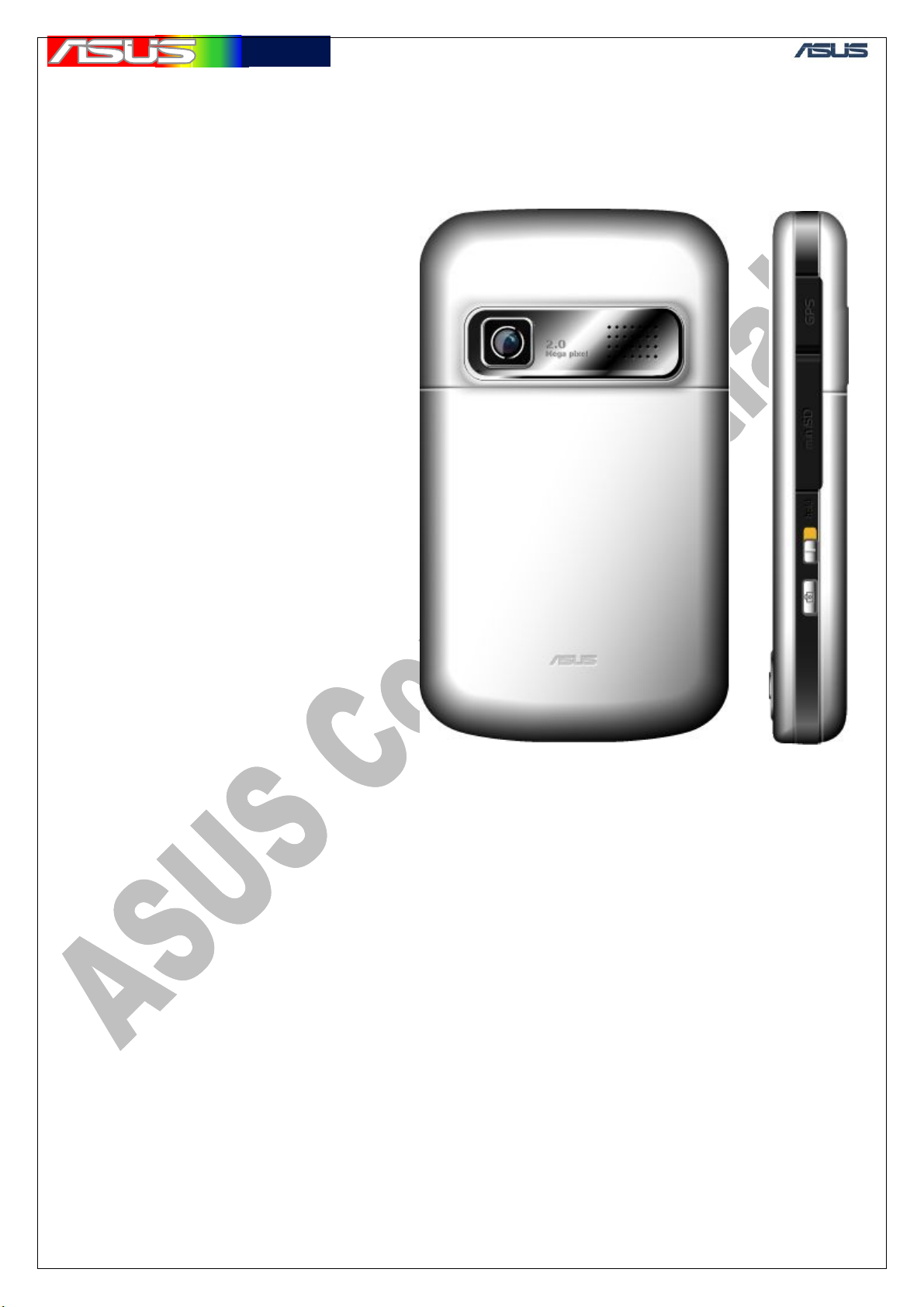

1. Feature Introduction

Solaris: WCDMA/GSM/GPS PDA Phone ( Mars-series)

1.1 Specification

Operation system : Windows Mobile 6.0

CPU : Marvell PXA270 520MHz

Main Memory : 256MB Flash (M-System H3) + 64MB SDRAM

(INFINEON HYB18L512320BF-7.5)

Modem : Intel PCPXA900 312MHz

Modem Memory : 32MB Stacking Flash + 16Mb PSRAM (Micron

MT45W1M16PDGA)

LCD : 3.5 inch, QVGA, Transflective, Touch-panel

(TPO TD035STED8)

Camera : 2M pixel, Fixed Focus (Walton COB20MZ1-solaris)

WiFi : IEEE 802.11b/g (ALPS UGGZ3X10BA)

Bluetooth : Bluetooth V2.0 (CSR BC41B143A05-IXB-E4)

GPS : SiRF StarIII GSC3F/LP-7979

Extended memory : Mini-SD Socket

Battery : 1530mAh (Welldone SBP-14)

ID Overview

3

Page 5

華華碩碩電電腦

腦

GTC ■ Service Manual

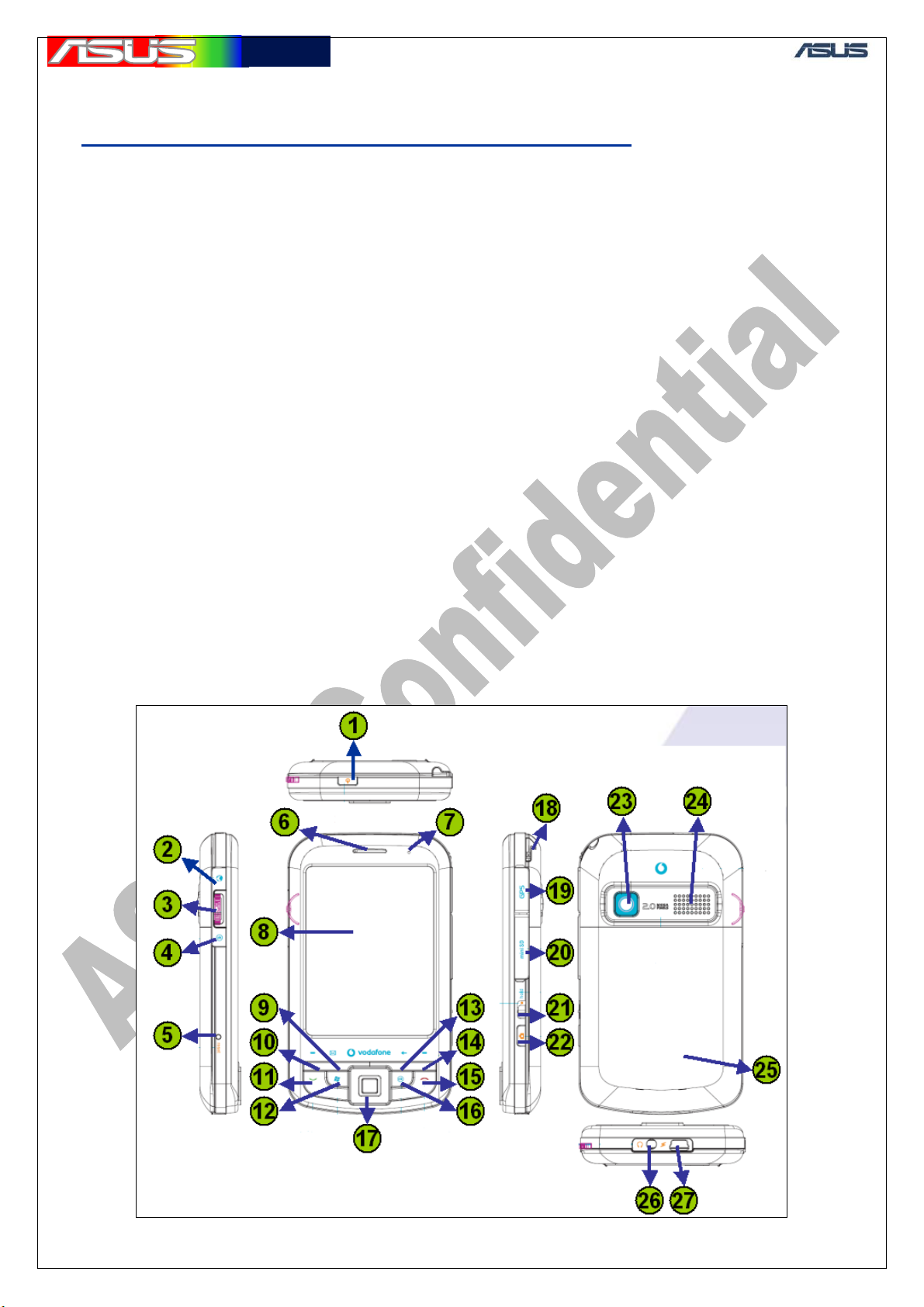

Main key function Description

1.Power Key

2.Explorer Key

3.3-way Navigation-Key

4.OK Key

5.Reset Key

6.Receiver

7.Notification LED

8.LCD (Touch)

9.Message center

10.Function Key1

11.Send Key

12.Start Key

13.Back Key

14.Function Key2

15.End Key

16.OK Key

17.5-way Navi-Key

18.Stylus

19.Active GPS antenna socket

20.Mini-SD socket

21.Hold Key

22.Camera Key

23.Camera

24.Speaker

25.Battery Cover

26.Phone Jack

27.Mini USB socket

4

Page 6

華華碩碩電電腦

腦

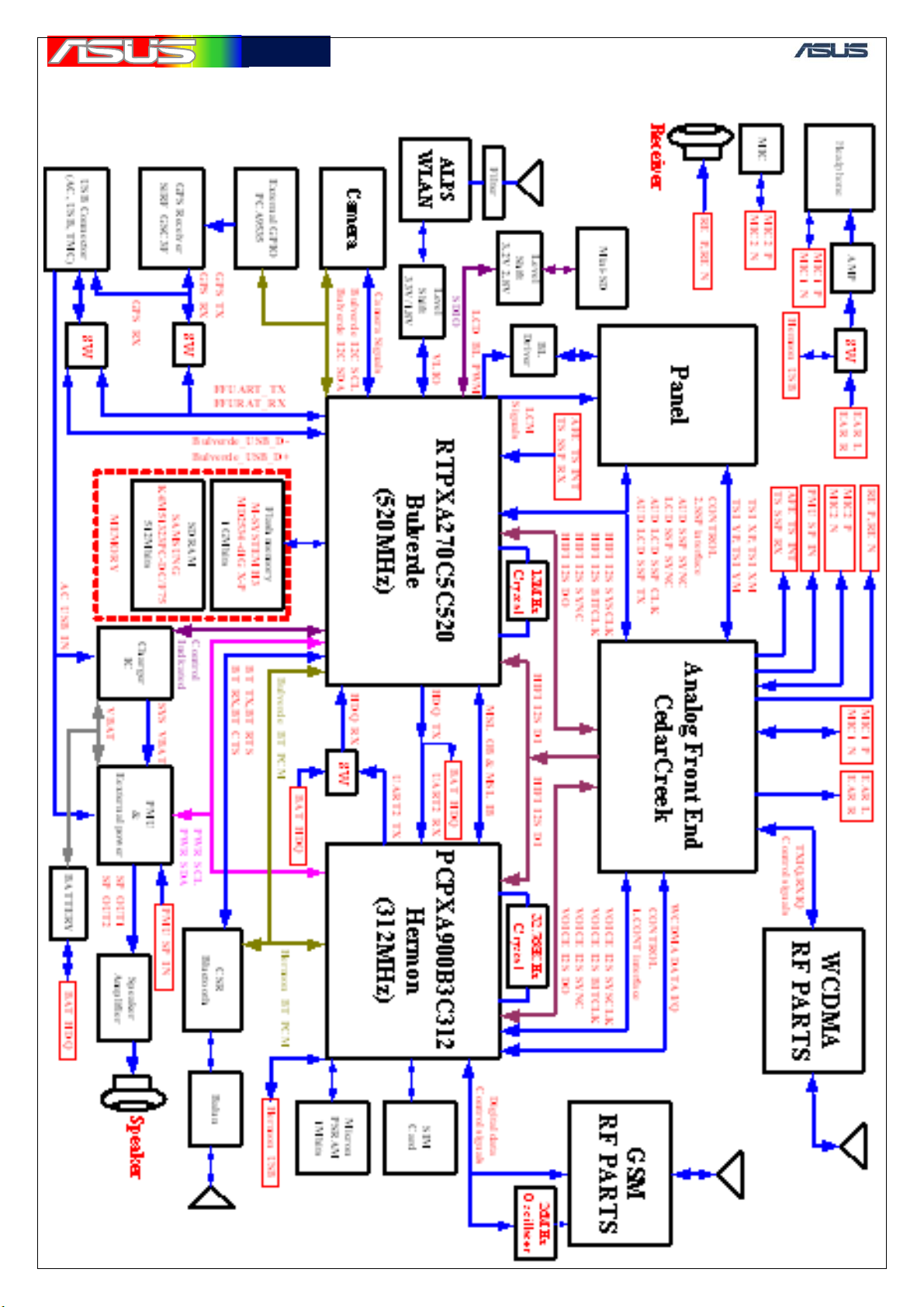

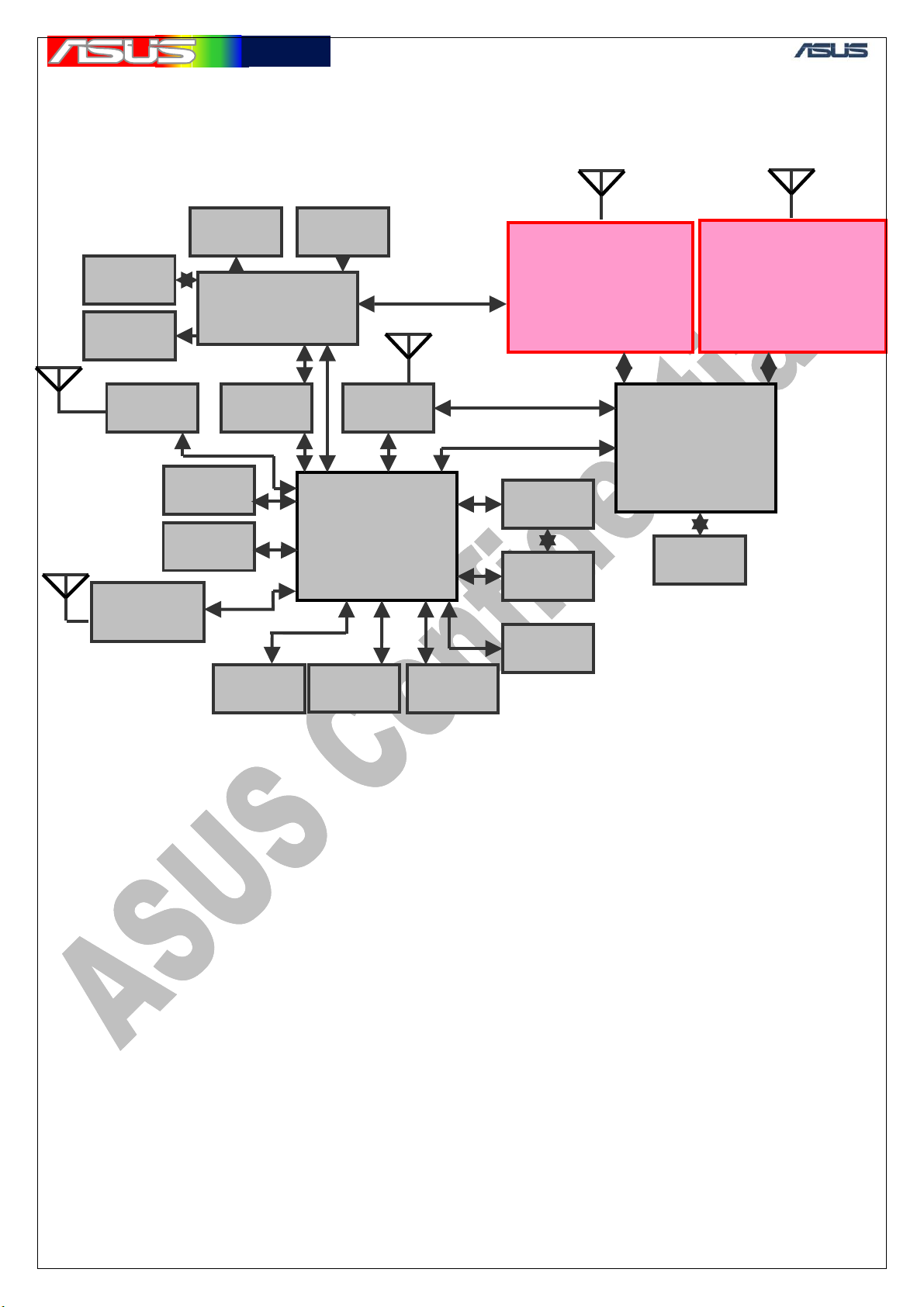

2. Block Diagram

GTC ■ Service Manual

5

Page 7

華華碩碩電電腦

腦

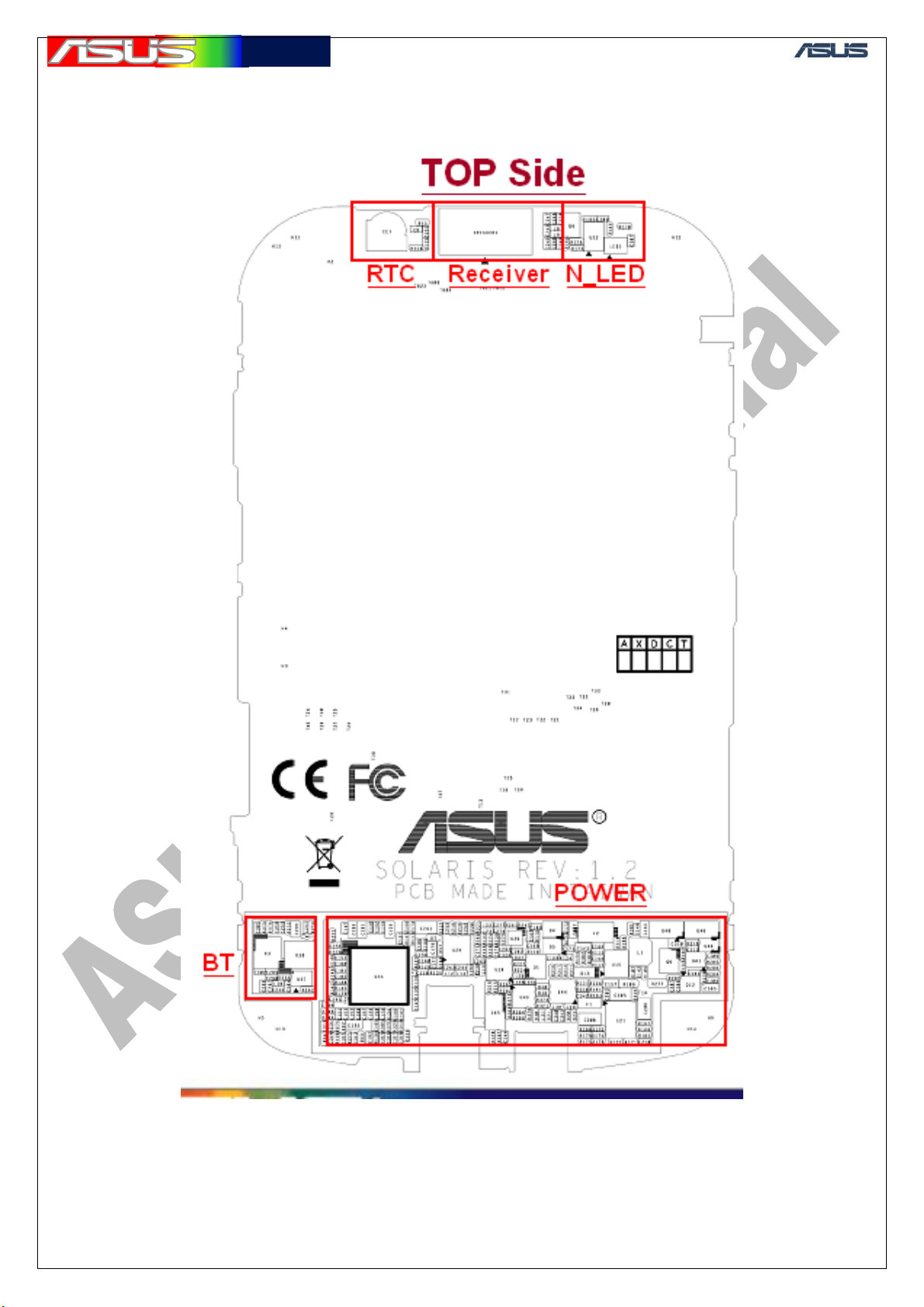

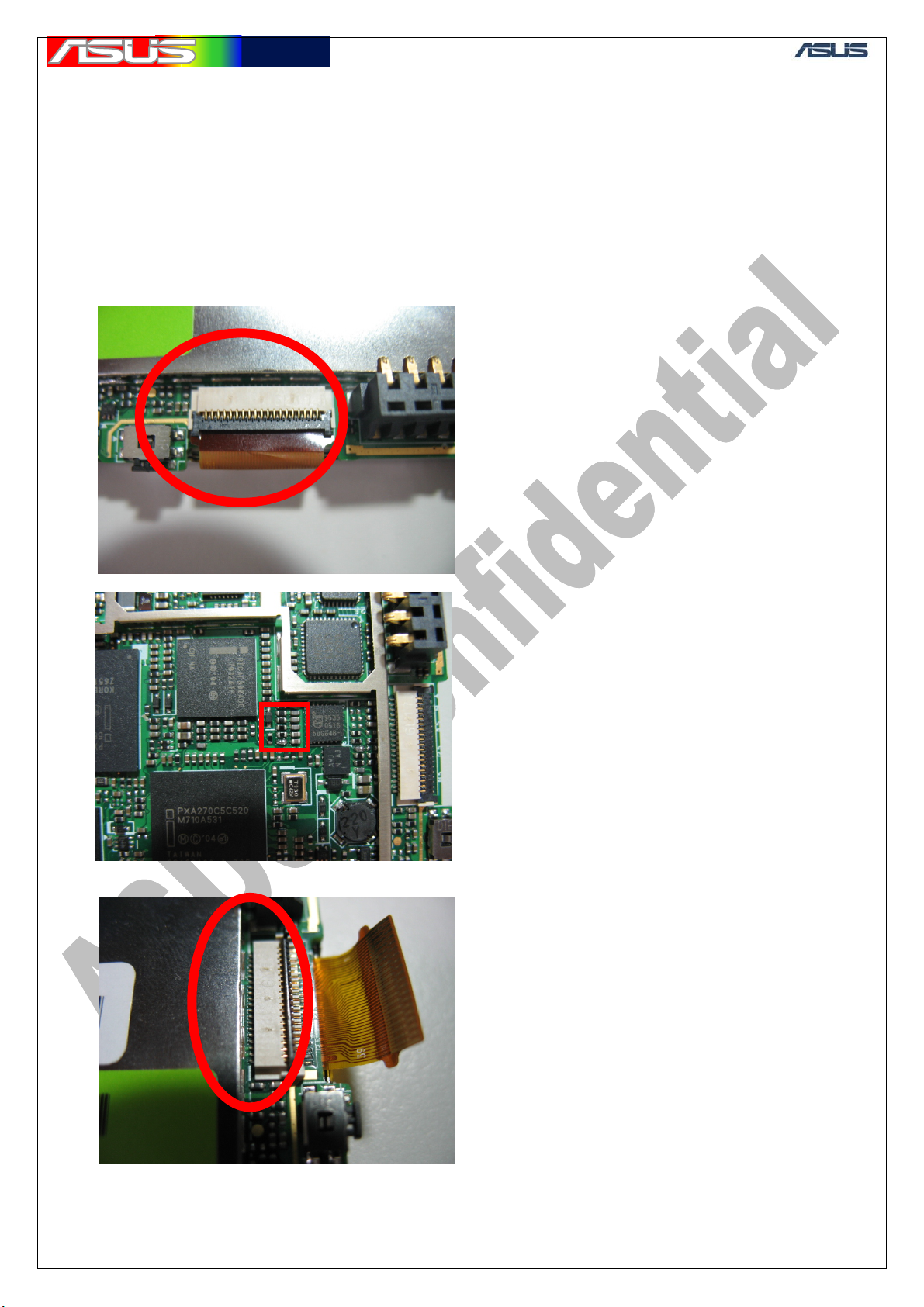

3. BASE Band Placement

3.1 Solaris TOP View

GTC ■ Service Manual

6

Page 8

華華碩碩電電腦

腦

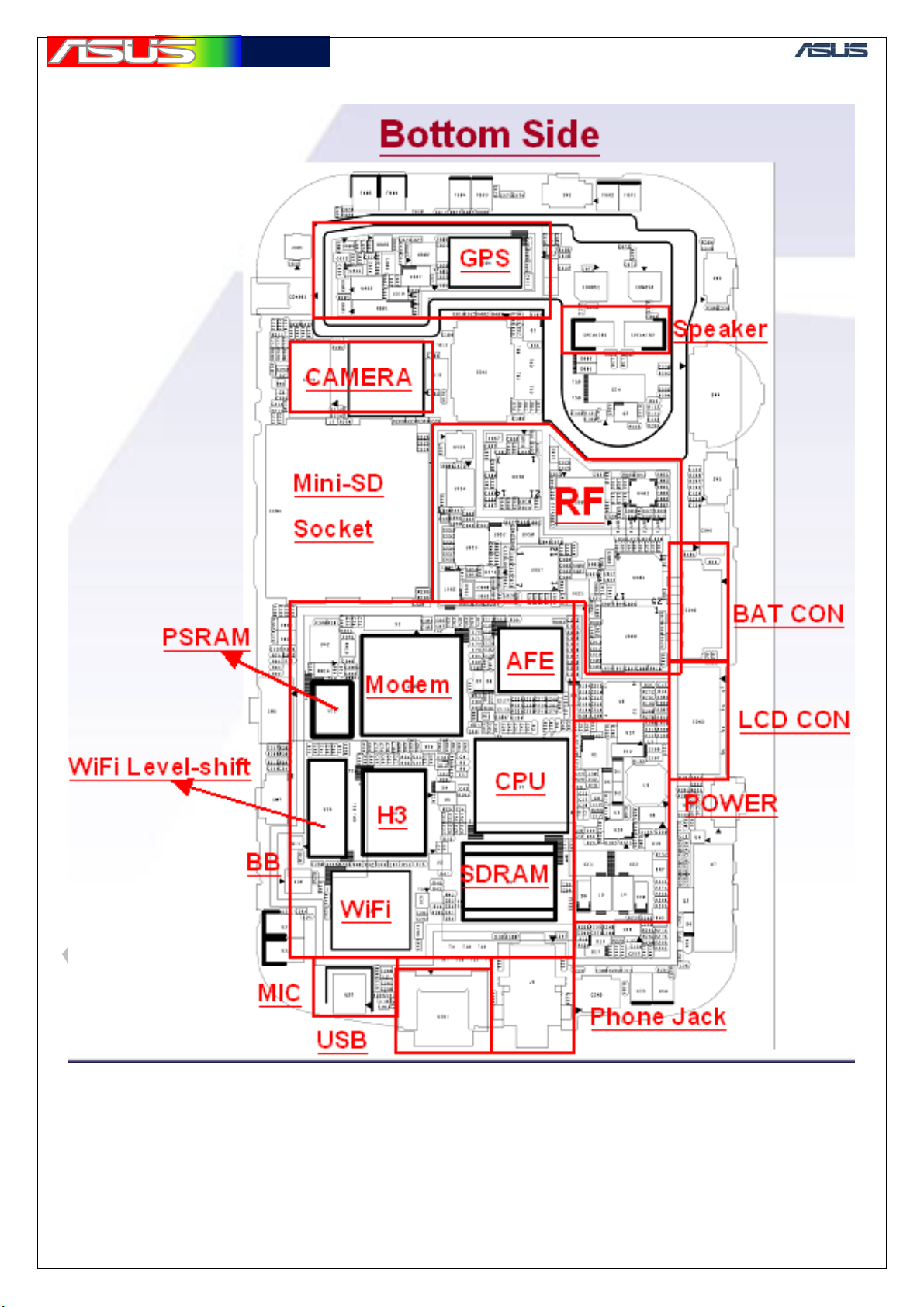

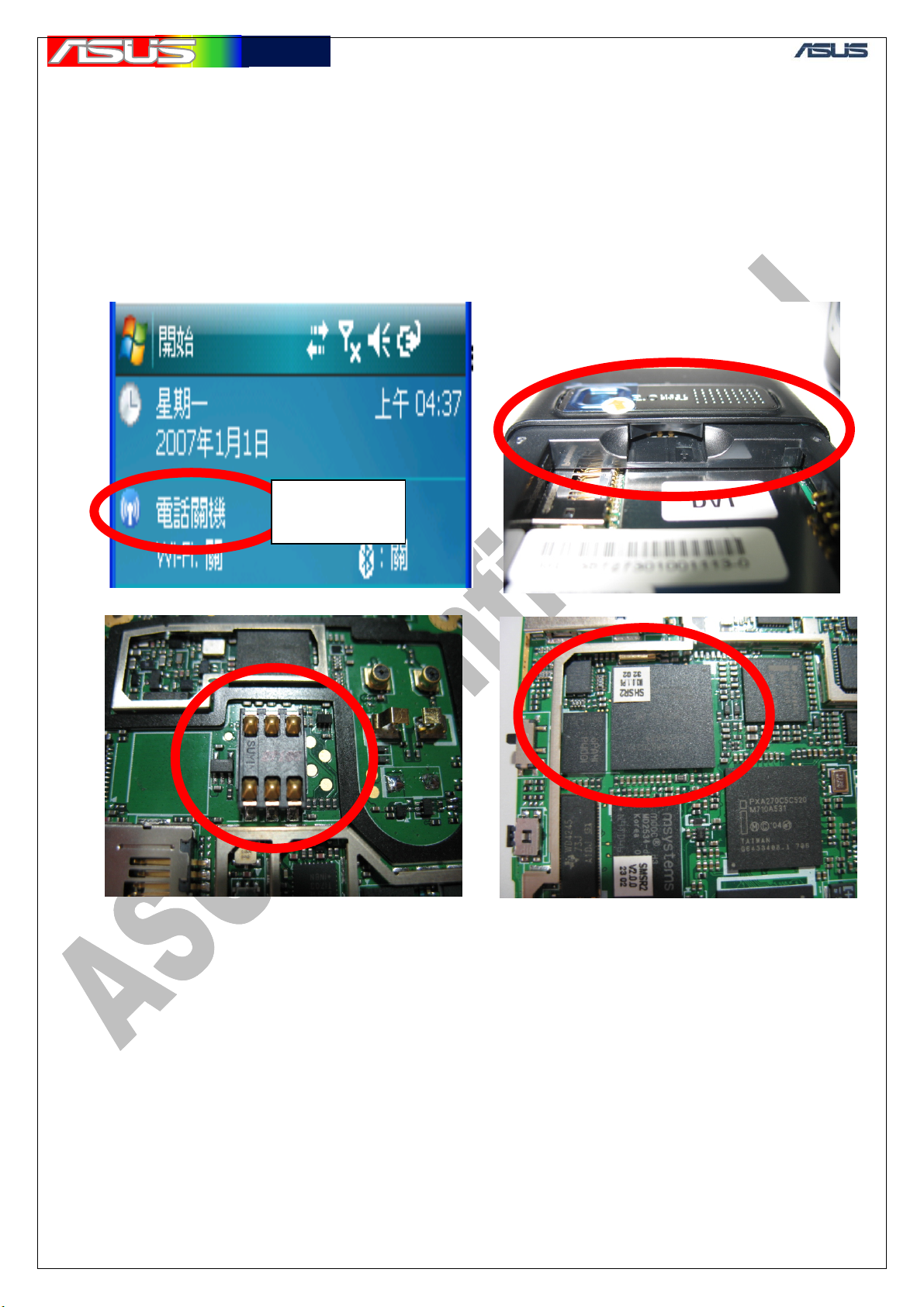

3.2 Solaris Bottom View

GTC ■ Service Manual

7

Page 9

華華碩碩電電腦

腦

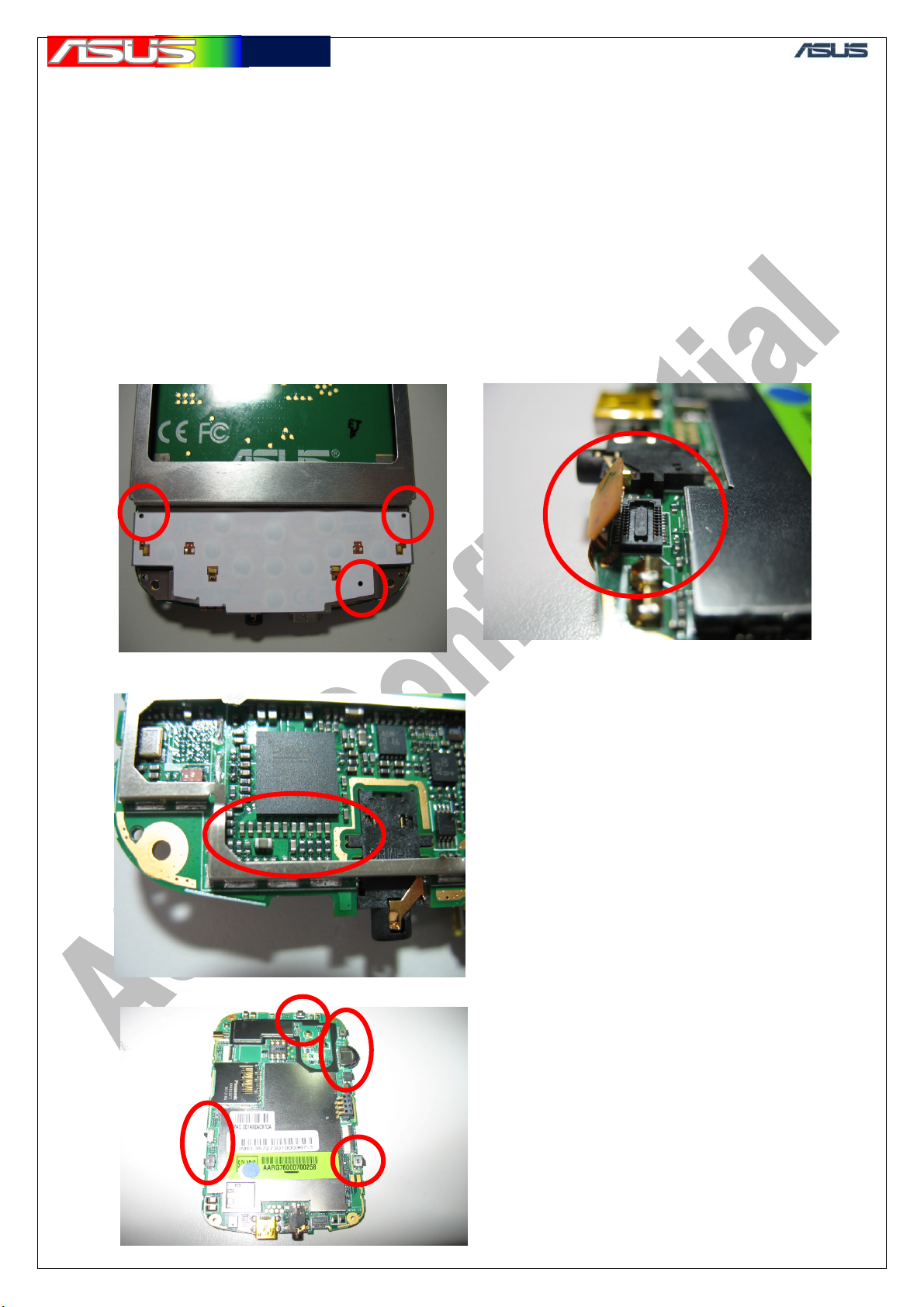

4. Base Band Repair Tooling

4.1 HW

Power source: power supply (Monitor current)

Digital Phosphor Oscilloscope

GTC ■ Service Manual

Digital Meter

8

Page 10

華華碩碩電電腦

腦

GTC ■ Service Manual

Adapter: JSP050090UU

Mini SD with test-program

ME tool

9

Page 11

華華碩碩電電腦

腦

5. Chip Timing Sequence

5.1 PMU Timing Sequence

Base band start-up sequence:

1. The DA9030 powers up the following LDO for the Baseband: LDO3, LDO4,

LDO5, LDO 6, LDO8, LDO7, LDO9,LDO12, LDO14 (I/O LDOs, RF l LDOs

and VCTXO LDO).

2. After delay of 200μs from end of stage 1 the DA9030 powers up LDO1 and

DC/DC1 (Base band core and PLL).

3. After delay of 10ms from end of stage 2 the DA9030 will power up LDO2

(internal Flash LDO).

4. After delay of Tdelay2 (32ms) from the start of the start-up sequences (stage 1)

the DA9030 will raise RESOUT_N

signal to the base-band chip

GTC ■ Service Manual

.

10

Page 12

華華碩碩電電腦

腦

GTC ■ Service Manual

5.2 CPU Timing sequence

PXA27x Start-up sequence:

1. Once the VBAT has risen above the VBATUNDER threshold, the DA9030

de-asserts (High) BATT_FAULT signal to

the PXA27x chip (indicating that VBAT is ok).

2. On receiving a start event the DA9030 de-asserts RESOUT1_N (high) (a

minimum 50ms from power up of the RTC

LDO is required to reset the PMU unit in the PXA27x and before RESOUT1_N

can be de-asserted).

3. The DA9030 waits for the PXA27x to assert (High) SYS_EN and powers up

the LDOs associated with this signal

(described below).

4. The DA9030 waits for the PXA27x to assert PWR_EN (typically 125ms after

asserting SYS_EN) and powers up the

sources associated with this signal (described below).

5. After all sources are stable for the PXA27x, the DA9030 will de-assert (High)

VCC_FAULT (so the PXA27x can

continue with its power up sequence).

11

Page 13

華華碩碩電電腦

腦

5.3 System Flowchart

GTC ■ Service Manual

Plug-in

Battery

(VBAT)

PWR_ON#

=VBAT

VLDO_RTC =

2.65V

Hermon_XTAL_IN(OUT) = 32KHz

VCXO_CLK(BB_CLK = 13MHz

Hermon_RESET_IN# = 2.65V

PMU_RESOUT_HERMON_OD#= 2.8V

32K_OUT_SLP = 32KHz

Bulverde_PXTAL_IN(OUT) = 13MHz

Bulverde_HW_RST# = 2.8V

Bulverde_SW_RST# = 2.8V

Push

Power-Key

PMIC with

Hermon

Power On

PMIC with

Bulverde

Hermon

Execute Boot-code

from Stack-Flash

Bulverde

Execute Boot-code

from Flash (U9)

Read

ON-mode

Check power-on

mode

Normal, download,

charging

Hermon

Execute OS in

RAM (U11)

from Stack-Flash

Re-boot

Write mode to

PMIC

Reset Hermon

Bulverde

Execute OS in RAM (U8)

from Flash (U9)

Read

ON-mode

Bulverde_SD_CS

0#

Bulverde_NF_

CS#

Bulverde

Init pheripherals

(Phone, LCD...)

12

Windows

START

Page 14

華華碩碩電電腦

腦

5.4 Power supply Block

¾ Power system ~ Supplied

CPU

VCORE

CPU RTC

Mini-SD

LCD

Mic,

Headphon

CPU PLL

CPU

SRAM

CPU USB

CPU IO(2.8V), Flash

CORE

PCA9535,

Modem IO(1.8V)

Modem memory,

Codec VCCP

CPU IO(1.8V),

Flash IO

SDRAM, Camera

VLDO15, 1.3V

VLDO16, 1.1V

VLDO17, 3.2V

VLDO18, 2.8V

VCORE_2, 1V~1.5V

VLDO3, 2.8V

VLDO10, 3.2V

VLDO11, 2.8V

VLDO13, 2.1V

AUX_1V8, 1.8V

PMU

U14

DC/DC

(U15)

GTC ■ Service Manual

VCORE_1, 1.25V

VLDO_RTC, 2.65V

VLDO1, 1.2V

VLDO3, 2.8V

VLDO5, 2.8V

VLDO6, 1.8V ~ 3V

VLDO19, 1.8V

Modem

VCORE

Modem RTC,

GPS RTC

Modem

PLL

Modem IO(2.8V),

Codec VCC

Codec

VCCA

Modem SIM, SIM

card

BT CORE

13

Page 15

華華碩碩電電腦

腦

(

GTC ■ Service Manual

5.5 Power system Supplied Block

¾ Power system ~ Supplied

Camera 2.8V

DC/D

LCD LED,

20V(Max)

CAM_2V8, 2.8V

C

LDO

U18

LCD

Backlight

5.6 Power System Charging block

Charger IC

(U21)

Cable

insert

AC_USB_IN, 5V

CHG_ST1, CHG_ST2

Charging

USB,

100mA

PMIC

(U14)

PMU_IRQ#, 0V

Change

charging

CPU

(U1)

Charging

CHG_P_SEL, CHG_USB_ISET, CHG_DIS

USB_C_D+, 3.2V

Detect

type

Battery

(CON2)

14

Page 16

華華碩碩電電腦

腦

r

6. Trouble shooting

6.1 General Process

¾ Trouble shooting ~ Procedure

Check orientation, position

Check SMT

components

PCBA

Abnormal

Set Power supply to 4V,

and

limit current to 1A

Press Power Key

(>5sec)

Monitor

current

RUN

Test-prog

GTC ■ Service Manual

Connect +,- to VBAT, GND

Check connector, components

System

Abnormal

Failed item in System level Failed item in Board level

Disassemble

assembly parts

15

Page 17

華華碩碩電電腦

腦

6.2 Can’t Power ON process

VBAT & GND short

U14, U15, U17, U18,

1. CPU failed to

load image

2. Flash failed to

provide image

3. SDRAM failed

to execute image

see note_1

Complete rework

Check supplied

components

LED1, U21

Complete rework

PMIC provide

abnormal power

(U14)

Check power supplied

domain

see note_2

Abnormal

Limit current

Abnormal

200mA -> 0mA

(8sec)

Abnormal

Suddenly

0mA

Check LCD connector

Set Power supply to

4V, and

limit current to 1A

Connect +,- to VBAT, GND

Monitor

current

Current ~ 0mA

Press Power Key

(>5sec)

Abnormal display

Monitor

Complete rework

Normal

200~400mA

and components

between

LCD and CPU

END

GTC ■ Service Manual

Complete rework

Abnormal

> 400mA

Check components

Abnormal

Sustain

U14 is the most case.

orientation and

touch BGA chip, feel

temperature.

0mA

Check Battery

connector and

VBAT-related

components

16

Page 18

華華碩碩電電腦

腦

GTC ■ Service Manual

Note 1

Measure reset signal (Bulverde_HW_RST#, Bulverde_SW_RST#), High =>

Inspect related components.

2. Measure clock signal (Bulverde_PXTAL_IN, Bulverde_PXTAL_OUT),

13MHz. (Bulverde_32K_IN), 32KHz.

Inspect U1, X1. And U10.

3. Measure chip-select signal (Bulverde_NF_CS#), H-L...

(Bulverde_SD_CS0#), H-L... => Inspect U1

4. Measure data-signal (D0), H-L... => Inspect U8, U95. Un-mount Flash(U9)

and re-download image. And then re-mount.

Note 2

1. Don’t supply VBAT to PCB, and measure impedance of all power supplier

(VCORE_1, VCORE_2.....)

Note3

Re-download image

2. If re-download image remain failed, please un-mount Hermon (U10) and

re-download by DATA-IO.

17

Page 19

華華碩碩電電腦

腦

7. Trouble shooting

7.1 Touch panel failed

1. Check LCD connector (CON3) => Assembly, Soldering issue

2. Replace LCD to golden sample => Component issue

3. Check communicated components between LCD (CON3) and Codec (U13)

=> Soldering issue

GTC ■ Service Manual

18

Page 20

華華碩碩電電腦

腦

GTC ■ Service Manual

7.2 SDRAM

1. Check SDRAM (U8) and peripherals => Soldering issue

2. Measure power supplied, AUX_1V8_2 (R43) => Power supplied issue, check

U15, Q5 peripherals

3. Measure clock signal, Bulverde_SDCLK1 (R1) => Check U1 and peripherals

4. Measure chip-select signal, Bulverde_SD_CS0# (T51) => Check U1 and

peripherals

Note: If normal display and hang-up,

Modem failed to load image.

see note_3

END

BAT_HDQ

19

Page 21

華華碩碩電電腦

腦

GTC ■ Service Manual

7.3 Flash failed

1. Check Flash (U9) and peripherals => Soldering issue

2. Measure power supplied, AUX_1V8_2 (R43), VLDO18 (R49) => Power

supplied issue, check U15, Q5 peripherals

3. Measure chip-select signal, Bulverde_NF_CS# (T49) => Check U1 and

peripherals

4. Measure chip-select signal, M-SYSTEM_BUSY# (R47) => Components

issue, replace U9

7.4 SDCARD

1. Check mini-SD socket (CON6) => Soldering issue

2. Check communicated components between mini-SD (CON6) and CPU (U1),

U42 and peripherals => Soldering

3. Measure power supplied, VLDO10 (R290) => Power supplied issue, Check

PMIC (U14)

4. Measure clock signal, SDMMC_CLK (R5) => Check U1 and peripherals

1. Check SDRAM (U8) and peripherals => Soldering issue

2. Measure power supplied, AUX_1V8_2 (R43) => Power supplied issue, check

U15, Q5 peripherals

3. Measure clock signal, Bulverde_SDCLK1 (R1) => Check U1 and peripherals

4. Measure chip-select signal, Bulverde_SD_CS0# (T51) => Check U1 and

peripherals

Note: If normal display and hang-up,

Modem failed to load image.

see note_3

END

BAT_HDQ

20

Page 22

華華碩碩電電腦

腦

21

GTC ■ Service Manual

Page 23

華華碩碩電電腦

腦

GTC ■ Service Manual

7.5 WiFi failed

1. If performance failed, check assembly WiFi antenna, Spring (U31,U32)

contact => Assembly, Soldering issue

2. Check WiFi (U35), Level-shift (U36) and peripherals => Soldering issue

3. Measure power supplied, WLAN_3V3 (R277), WLAN_1V5 (R278) => Q12,

U41 and peripherals, soldering issue

4. Measure chip-select, Bulverde_WLAN_CS# (R255) => Components issue,

U35, U36, U1 and peripherals

22

Page 24

華華碩碩電電腦

腦

GTC ■ Service Manual

7.6 Modem-BUS failed

1. Check Modem (U10), PSRAM (U11) and peripherals => Soldering issue

2. Clean-boot or Re-download image => Image crash

3. Measure power supplied, VCORE_1 (R79) and etc. => Check PMIC (U14)

and peripherals

4. Measure clock signal, VCXO_CLK ( OSC1), 13MHz. X’TAL (X2), 32KHz.

=> Check PMIC (U14) and peripherals

23

Page 25

華華碩碩電電腦

腦

GTC ■ Service Manual

7.7 SIM failed

1. Check Wireless-manager, Phone must be ON => Operation issue

2. Check antenna cover => Assembly issue

3. Check SIM socket (CON1) and peripherals => Soldering issue

4. Check Modem (U10) and peripherals => Soldering issue

Phone OFF

7.8 LED

1-1. If Keypad LED failed, please check Keypad FPC assembly => Assembly

issue

1-2. If assembly is fine, please check connector (CON5) and peripherals =>

Soldering issue

2-1. If notification LED (LED1) failed, check LED1 and peripherals =>

Soldering issue

24

Page 26

華華碩碩電電腦

腦

GTC ■ Service Manual

7.9 Display failed

1. Check LCD connector (CON3) => Assembly, Soldering issue

2. Replace LCD to golden sample => Component issue

3. Check power supplied (R216), reset# (R198), SD (R270) => Soldering issue

4. Check communicated components between LCD (CON3) and CPU (U1) =>

Soldering issue

25

Page 27

華華碩碩電電腦

腦

GTC ■ Service Manual

7.10 Battery failed

1. Double check Battery on fine device => Component issue

2. Check Battery connect (CON2) => Soldering issue

3. Check signal, BAT HDQ(CON2, pin4), Q8, U20 => Soldering issue

26

Page 28

華華碩碩電電腦

腦

GTC ■ Service Manual

7.11 Vibrator failed

1. Check Vibrator => Assembly issue

2. Replace Vibrator to golden sample => Component issue

3. Check power supplied (R36), Driving signal (Q2) => Soldering issue

7.12 Camera

1. Check Assembly => Assembly issue

2. Replace Camera module to golden sample => Component issue

3. Check Camera connector => Soldering issue

4. Check power supplied (U18), CAM_RESET# (R187), CAM_STBY (R185),

Bulverde_I2C (RN1), CAM_MCLK (R8)

26MHz => Soldering issue

5. Check signal from Camera, CAM_XXX => Component issue

27

Page 29

華華碩碩電電腦

腦

GTC ■ Service Manual

7.13 Button failed

1. Check stick position of keypad board => Assembly issue

2. Check assembly between keypad and connector (CON5) => Assembly issue

3. Replace to golden sample => Component issue

4. Check signal KP_XXX => Soldering issue

5. Check assembly of side-Key => Assembly issue

6. Check SMT switch (SW1 ~ SW7) => Soldering issue

28

Page 30

華華碩碩電電腦

腦

GTC ■ Service Manual

7.14 BT failed

1. If performance failed, check assembly BT antenna, Spring (U33,U34) contact

=> Assembly, Soldering issue

2. Check BT (U38), Filter (U37) and peripherals => Soldering issue

3. Measure power supplied (R251, R252), BT_RESET# (R280), X’TAL (X3) =>

Soldering issue

7.15 Audio failed

Speaker no sound

1. Check Speaker and Spring (Speaker2, Speaker3) => Assembly, SMT issue

2. Replace to golden sample => Component issue

3. Check amplifier (U24), PMIC(U14) and peripherals => SMT issue

29

Page 31

華華碩碩電電腦

腦

GTC ■ Service Manual

Receiver no sound

1. Check Receiver and Contact-pad (Speaker1) => Assembly issue

2. Replace to golden sample => Component issue

3. Check Signal RE_N, RE_P, and Codec (U13) => SMT issue

30

Page 32

華華碩碩電電腦

腦

GTC ■ Service Manual

Headphone no sound

1. Check Phone-jack (J1) => SMT issue

2. Check switch (U26), amplifier (U29), Codec (U13) and peripherals => SMT

issue

31

Page 33

華華碩碩電電腦

腦

GTC ■ Service Manual

Headphone MIC no record

1. If headphone no sound, please repair headphone first

2. Check power supplied (R224), amplifier (U28), Codec (U13) and peripherals

=> SMT issue

Board mic no record

1. Check assembly rubber => Assembly issue

2. Check SMT mic (U27), Codec (U13) and peripherals => SMT issue

32

Page 34

華華碩碩電電腦

腦

GTC ■ Service Manual

7.16 Standby current failed

1. Manual phone-off and press power-key to entry suspend-mode => Test

program issue

2. Remove camera module => Component issue

3. Measure signal PWR_EN (T64), Low. VCXO_CLK (C86), Low => SMT

issue

33

Page 35

華華碩碩電電腦

腦

8. RF Repair Requirement

8.1 SW:

IFL software

GSM and WCDMA debug tool

Hermon image database files

8.2 HW:

Specific fixture for repair and test, following must be included

i. Hermon USB Contact and USB Cable

ii. Power Supply Contact

iii. RF Connector and RF cable (30cm)

iv. High Frequency Probe with DC Block

GTC ■ Service Manual

8.3 Equipment:

1. PC

2. Spectrum Analyzer (up to 3.0 GHz)

3. Signal Generator (up to 3.0GHz)

4. Communication tester: Agilent 8960, CMU200 or Anritsu 8820

5. Digital Multi-meter

6. Power Supply

34

Page 36

華華碩碩電電腦

腦

9. Block Diagram

9.1 System Block Diagram

GTC ■ Service Manual

Phone

Jack

Speaker

WLAN

GPS

SD RAM

FLASH

AFE/Codec

Cedar Creek

LCD

Mini SD

MIC Receiver

BT

Bulverde

(App. CPU)

Gas

Gauge

Camera

WCDMA

Maxim 3G

PMIC

Mini USB

Keypad

GSM

RFMD

Polaris I

Hermon

(Comm. CPU)

USIM

35

Page 37

華華碩碩電電腦

腦

GTC ■ Service Manual

9.2 GSM/GPRS – GSM RFMD solaris I Block Diagram

ANT

EPCOS

A030

T/R switch

U902

Tx out

Rx in

RFMD

RF3166

GSM PA

U904

RFMD

RF2722

GSM receiver

buffer

U901

GSM 3 -wi re bu s

Tx

Tx out

26MHz VC-TCXO

Tx out

GSM t ransceiver

Rx IQ

Digital IQ

Hermon

OSC1

Reference clock

RFMD

RF6001

U900

Digital IQ

GSM 3-wire bus

U904

OSC1

U902

SAW filters

U901

U900

36

Page 38

華華碩碩電電腦

腦

9.3 WCDMA – Maxim 3G Block Diagram

ANT

Murata

Duplexer

Rx

U959

GTC ■ Service Manual

Tx

MAXIM

MAX2391

WCDM A receiv e r

U958

26MHz VC-TCXO

OSC1

k

c

o

l

c

e

c

n

e

r

e

f

e

R

WCDMA transm itter

WCDMA Rx IQ

Q

I

x

T

A

M

D

C

W

Codec- Cedar Creek

WCDMA 3-wire bus

MAXIM

MAX2395

U957

Isol at or

U954

Power

dector

Tx

U95 5

Fair child

Tx out

RAMP2259

WCDM A PA

U953

s

u

b

e

r

i

w

3

A

M

D

C

W

Vcc PA

MAXIM

1820

U951

Hermon

U959

U954

U955

U953

U958

U957

U951

37

Page 39

華華碩碩電電腦

腦

9.4 Blue tooth – CSR BC04

(1) BT Introduction

Frequency: 2402(ch0) ~ 2480(ch78) MHz

Maximum Transmitter power: -6 ~ +4 dBm

(2) Bluetooth circuitry

GTC ■ Service Manual

Antenna

BT Module

CSR BC04

Balance

Filte r

BT module

Balance

filter

38

Page 40

華華碩碩電電腦

腦

9.5 WIFI– UGGZ3X10BA

(1) WIFI introduction

Frequency: 2412~ 2472 MHz

Maximum output power: 15 dBm

(2) WIFI circuitry

GTC ■ Service Manual

ANT

WIFI m odule

U36

U30

RF in/out

2.4 G HZ BAND PASS FILTER

U30

U36

39

Page 41

華華碩碩電電腦

腦

9.6 GPS– GSC3F/LP-7

(1) GPS Introduction

Frequency: 1575.42 MHz

(2) GPS circuitry

GTC ■ Service Manual

ANT

GPS SAW

U809

x

R

T

N

A

NEC

UPC8215TU-E2

i

n

U806

LNA

ANT Rx in

MMCX

CON801

Active Rx in

UPG2179TB

RF Switch

U807

TCXO

16.369MHz

R

GPS SAW

n

x

i

U808

R

n

x

i

GPS RECEI VER

GSC3F/LP-7979

Crystal

32KHz

SIRF3

U804

SAW

U806

TCXO

U804

CRYSTAL

U807

SAW

40

Page 42

華華碩碩電電腦

腦

10. RF Circuit Test Points Location

10.1 Backside Antenna Area Test Points

GPS.ANT1

WCDMA.ANT1

GPS RF

Connector.

WCDMA RF

Connector.

GTC ■ Service Manual

GSM RF

Connector.

GSM ANT2

WCDMA.ANT2

41

Page 43

華華碩碩電電腦

腦

10.2 GSM/GPRS Test Points

1. Definition of test point’s suffix:

2. TH:Tx High band, DCS1800 & PCS 1900

3. TL:Tx Lowland, GSM900

4. RG:Rx GSM900

5. RP:Rx PCS1900

6. RD:Rx DCS1800

GSM.TH1

GSM.TL1

GTC ■ Service Manual

GSM.RP1

GSM.TL2

GSM.TH2

GSM.RD1

GSM.RD2

GSM.RG1

GSM.RG2

GSM.RP2

GSM.TL3

GSM.TH3

42

Page 44

華華碩碩電電腦

腦

GTC ■ Service Manual

10.3 WCDMA Test Points

43

Page 45

華華碩碩電電腦

腦

11. GSM & WCDMA RF Tx/Rx Path

How RF signal is transmitted and received between components on Solaris PCB

is explained in this section. It is important to realize RF transmission path (Tx)

and receiving path (Rx) before starting out to repair NG PCB, because engineers

need to choose proper test points, which assist us to distinguish where the

problem is. The following paragraphs describe both Tx and Rx path in GSM and

WCDMA bands. The related test points are listed in previous section.

11.1 GSM Tx path

Transceiver, RF6001 (U900), receives IQ signals coming from base band, and

output signals of RF6001 Pin22 and Pin23 are transmitted into the buffer of

receiver, RF2722. Then RF2722 Pin12 and Pin13 emit the low band signal

(GSM900) and high band signals (DCS1800 or PCS1900) separately.

In the low band, output signal from RF2722 Pin12 passes through C917,

attenuator (U903) and RF3166 (U904) Pin7, power amplifier, sequentially.

Transmission and receiving switch (U902), also named T/R switch, gets the

amplified signal from RF3166 Pin23 via matching circuits. RF signal coming

from T/R switch Pin12 is transmitted to connector (Con850) and radiated via the

GSM antenna of Solaris.

In the high band, output signal from RF2722 Pin13 passes through C934,

attenuator (U905) and RF3166 (U904) Pin1, power amplifier, sequentially.

Transmission and receiving switch (U902), also named T/R switch, gets the

amplified signal from RF3166 Pin30 via matching circuits. RF signal coming

from T/R switch Pin10 is transmitted to connector (Con850) and radiated via the

GSM antenna of Solaris.

GTC ■ Service Manual

11.2 GSM Rx path

RF signals, receiving from base station via the GSM antenna, pass through

connector (Con850) and T/R switch Pin6 (U902) sequentially. There are three

output pins of T/R switch, including Pin1, Pin14, and Pin15. The output path

which RF signal is transmitted depends on band selection of T/R switch.

In GSM900 band, the receiving signal, which is transmitted from T/R switch

Pin1, passes through SAW filter (BPF1) and matching circuits sequentially.

Upon RF2722 (U901) receiving the signal, it is amplified in the Low Noise

Amplifier (LNA) of the receiver, down converted the signal’s frequency and

transformed into IQ signals. The IQ signals from RF2722 Pin20, Pin21, Pin22,

and Pin23 travel to the transceiver RF6001 (U900). The transceiver RF6001

transfers the signals to the base band signals.

In DCS1800 band, the receiving signal, which is transmitted from T/R switch

Pin14, passes through SAW filter (BPF4) and matching circuits sequentially.

Upon RF2722 (U901) receiving the signal, it is amplified in the Low Noise

Amplifier (LNA) of the receiver, down converted the signal’s frequency and

transformed into IQ signals. The IQ signals from RF2722 Pin20, Pin21, Pin22,

and Pin23 travel to the transceiver RF6001 (U900). The transceiver RF6001

transfers the signals to the base band signals.

44

Page 46

華華碩碩電電腦

腦

GTC ■ Service Manual

In PCS1900 band, the receiving signal, which is transmitted from T/R switch

Pin15, passes through SAW filter (BPF3) and matching circuits sequentially.

Upon RF2722 (U901) receiving the signal, it is amplified in the Low Noise

Amplifier (LNA) of the receiver, down converted the signal’s frequency and

transformed into IQ signals. The IQ signals from RF2722 Pin20, Pin21, Pin22,

and Pin23 travel to the transceiver RF6001 (U900). The transceiver RF6001

transfers the signals to the base band signals.

11.3 WCDMA Tx path

The output signal from transmitter MAX2395 Pin2 travels to SAW filter (BPF5), and

RMPA2259 Pin2 sequentially. The output power coming from RMPA2259 Pin8 passes

through isolator (U954), duplexer Pin1 (U959), and connector (Con851). At last, the RF

signal is radiated via WCDMA antenna of Solaris.

11.4 WCDMA Rx path

RF signal in WCDMA, receiving from base station via the WCDMA antenna,

passes through connector (Con851) and duplexer Pin3 sequentially. MAX2391

Pin9 (U958), built-in LNA, receives the signal from duplexer. Then the signal is

transmitted to SAW filter (BPF6) and returns to receiver MAX2391 again. After

down converting the signal’s frequency and transforming into IQ signals, the IQ

signals from MAX2391 Pin20, Pin21, Pin22, and Pin23 travel to base band.

45

Page 47

華華碩碩電電腦

腦

GTC ■ Service Manual

46

Page 48

華華碩碩電電腦

腦

12. Test & Repair Flow Chart

12.1 Conductive & Antenna Test Procedure

Conductiv e & Antenna

Test Procedure

Insert test 3G USIM

Connect to

8960/CMU200/8820

2G

Registration

OK? Tx/Rx

Signal

Normal?

Registration

*1* 2

Y

3G

OK? Tx/Rx

Signal

Normal?

*3

N

N

Proceed to “2G

Board Level Test &

Repair Procedure"

Proceed to “3G

Board Level Test &

Repair Procedure"

GTC ■ Service Manual

Y

Check the

antenna

appearance

and contact

OK?

Y

Insert real 3G

USIM, check if

both 2G/3G

signal OK?

Y

Update the latest

firmware

Test c omplet e

N

N

Change new

antenna

*1:Refer to appendix A1 for GSM/GPRS typical values of conductive test

*2:Refer to appendix A2 for WCDMA typical values of conductive test

47

Page 49

華華碩碩電電腦

腦

GTC ■ Service Manual

12.2 GSM/GPRS Test & Repair Procedure

2G Board Level

Test & Repair

Procedure

Change GSM RF

Connector

Setup Tx test

environment*

Run Tx Debug Tool

GSM.ANT1

Y

GSM.ANT2

signal OK?

signal OK?

1

N

Run Rx Debug Tool

N

U902, U901 are Tx/Rx common devices

Tx must be tested after changing them

Y

Setup Rx test

environment*

GSM RF Connector &

2

Change U902

(T/R Switch)

Change U904

(RF3166 )

Change

U903 or U905

(Attenuator)

Change U901

(RF2722 )

Still failed by changing U901

Y

Y

Y

Reheat or change

GSM.TH1

GSM.TL1

signal OK?

N

GSM.TH2

GSM.TL2

signal OK?

N

GSM.TH3

GSM.TL3

signal OK?

N

Hermon

Y

GSM.RG1

GSM.RD1

GSM.RP1

signal OK?

Y

GSM.RG2

GSM.RD2

GSM.RP2

signal OK?

Run CMU go

production tests

N

N

Change U902

(T/R Switch)

Change BPF1,

BPF3 or BPF4

(Rx SAW)

*1:Refer to appendix B1 for Tx test environment setup

*2:Refer to appendix B2 for Rx test environment setup

48

Page 50

華華碩碩電電腦

腦

12.3 WCDMA Test & Repair Procedure

3G Board Level

Test & Repair

Procedure

GTC ■ Service Manual

Change WCDMA

RF Connector

Change U959

(Duplexer)

Change U951

(MAX1820)

Setup Tx test

environment*

Run Tx Debug Tool

WCDMA.ANT1

Y

Y

WCDMA.ANT2

N

signal OK?

N

signal OK?

N

WCDMA.T1

signal OK?

N

WCDMA.T2

signal OK?

1

WCDMA RF Connector &

U956 ar e Tx/Rx common devices

Tx must be tested after changing them

Y

Setup Rx test

environment*

Run Rx Debug Tool

WCDMA.R1

signal OK?

2

Y

N

Y

Change U956

(Duplexer)

Change U954

(Isolator)

Change U953

(RMPA2259)

Change BPF5

(Tx SAW)

Change U957

(MAX2395)

WCDMA.R2

Y

Y

Y

Y

WCDMA.T3

signal OK?

N

WCDMA.T4

signal OK?

N

WCDMA.T5

signal OK?

N

Still failed by changing U957

signal OK?

Y

WCDMA.R3

signal OK?

Y

Run CMU go

production tests

N

N

Change U958

(MAX2391)

Change BPF6

(Rx SAW filter )

Still failed by change U958

Reheat or change

Hermon

*1:Refer to appendix B1 for Tx test environment setup

*2:Refer to appendix B2 for Rx test environment setup

49

Page 51

華華碩碩電電腦

腦

12.4 Blue tooth Test & Repair Procedure

GTC ■ Service Manual

50

Page 52

華華碩碩電電腦

腦

12.5 WIFI Test & Repair Procedure

Turn on PDA

Change WIFI

module

N

Turn on WIFI

ok?

Y

GTC ■ Service Manual

Search any

APs?

Y

NO

TROUBLE

FOUND

N

Disassemble

PDA

Check antenna

contact well

Y

PCB analysis

power supply

to WIFI

module

normal?

Y

N

N

Make sure

antenna

contact well

Change

components

Measure

signals

Output signal

normal?

Y

Assemble

PDA

51

N

Change WIFI

module

Page 53

華華碩碩電電腦

腦

13. Test Points Signal Examples

13.1 GSM900

Due to the spec of probe is not exactly the same please use the “working

sample” for signal reference.

GSM.ANT1:

GTC ■ Service Manual

GSM.ANT2 & GSM.TL1

52

Page 54

華華碩碩電電腦

腦

GSM.TL2 & GSM.TL3

GTC ■ Service Manual

GSM.RG1

53

Page 55

華華碩碩電電腦

腦

GSM.RG2

GTC ■ Service Manual

54

Page 56

華華碩碩電電腦

腦

GTC ■ Service Manual

13.2 DCS1800

Due to the spec of probe is not exactly the same please use the “working

sample” for signal reference.

GSM.ANT1

GSM.ANT2 & GSM.TH1

55

Page 57

華華碩碩電電腦

腦

GSM.TH2 & GSM.TH3

GTC ■ Service Manual

GSM.RD1

56

Page 58

華華碩碩電電腦

腦

GSM.RD2

GTC ■ Service Manual

57

Page 59

華華碩碩電電腦

腦

GTC ■ Service Manual

13.3 PCS1900

Due to the spec of probe is not exactly the same please use the “working

sample” for signal reference.

GSM.ANT1

GSM.ANT2 & GSM.TH1

58

Page 60

華華碩碩電電腦

腦

GSM.TH2 & GSM.TH3

GTC ■ Service Manual

GSM.RP1

59

Page 61

華華碩碩電電腦

腦

GSM.RP2

GTC ■ Service Manual

60

Page 62

華華碩碩電電腦

腦

GTC ■ Service Manual

13.4 WCDMA

Due to the spec of probe is not exactly the same please use the “working sample”

for signal reference.

WCDMA.ANT1

WCDMA.ANT2 (Tx)

61

Page 63

華華碩碩電電腦

腦

WCDMA.T1

GTC ■ Service Manual

WCDMA.T2

62

Page 64

華華碩碩電電腦

腦

WCDMA.T3

GTC ■ Service Manual

WCDMA.T4

63

Page 65

華華碩碩電電腦

腦

WCDMA.T5

GTC ■ Service Manual

WCDMA.ANT2 (Rx)

64

Page 66

華華碩碩電電腦

腦

WCDMA.R1

GTC ■ Service Manual

WCDMA.R2

65

Page 67

華華碩碩電電腦

腦

WCDMA.R3

GTC ■ Service Manual

66

Page 68

華華碩碩電電腦

腦

14. Blue tooth

Turn on the phone, make sure if BT can be enable.

(1) Confirm if BT is enabled or not

Touch here

GTC ■ Service Manual

BT Disable BT Enable and blue led flashed

(2)Turn off Blue tooth functionality:

Tap here

(3) BT test tool

TestCSR.exe

test.TXT

Put these two files above into PDA’s main directory (my device\)

67

Page 69

華華碩碩電電腦

腦

(4) Start BT test mode

Tap here

GTC ■ Service Manual

(5) Showing as the following menu. *

(i)

(iii)

(ii)

frequency

(i) First, turn on BT。

(ii) Enter test mode:

(iii) Choose a frequency

This option is used only for Anritsu885X series equipment

,press SETto start TX power

E.X. Frequency 2402:BT generate TX Power at2402MHz。

Frequency 2441:BT generate TX Power at2441MHz。

Frequency 2480:BT generate TX Power at2480MHz

68

。

Page 70

華華碩碩電電腦

腦

GTC ■ Service Manual

(6)Choose one frequency and measure power

(7) Measuring wireless performance via BT test program first. You may need to put the phone on shielding

box or TEM cell to insure no other interference. By comparing the golden sample’s normal output

value, you can judge the functionality of BT. Apparently, the wireless performance will differ within ±

2dBm. If the deviation of DUT is beyond the normal value, go straight for next step.

* The testing position should be the same with golden sample to reduce testing uncertainty.

8

BT Antenna in Bottom side

69

Page 71

華華碩碩電電腦

腦

(8) BT position and testing point.

i. Make sure the RF probe is contact the resistor, BT output testing point1, (green circle) properly, the

output power will between -5 ~ +3 dBm normally.

ii. Next, measuring the BT output testing point2 (yellow circle) via RF probe, the output power will

between -5 ~ +3 dBm normally.

iii. If the output power still be abnormal, change the balance filter and go back to step ii.(You should

notice that the balance filter has its own orientation, so change it carefully.)

iv. Afterwards, the BT output power still be abnormal, change the BT chip.

.

GTC ■ Service Manual

BT Chip

BT Output

tesing point 1

Antenna

feed pin

Balance Filter

BT Output testing point 2

70

Page 72

華華碩碩電電腦

腦

15. WIFI

(1)

Turn on the phone, make sure if WIFI can be enable。

GTC ■ Service Manual

WIFI Disable WIFI Enable

(2)Searching AP:

SrartÆSettingsÆConnectionsÆWi-Fi manager

71

Page 73

華華碩碩電電腦

腦

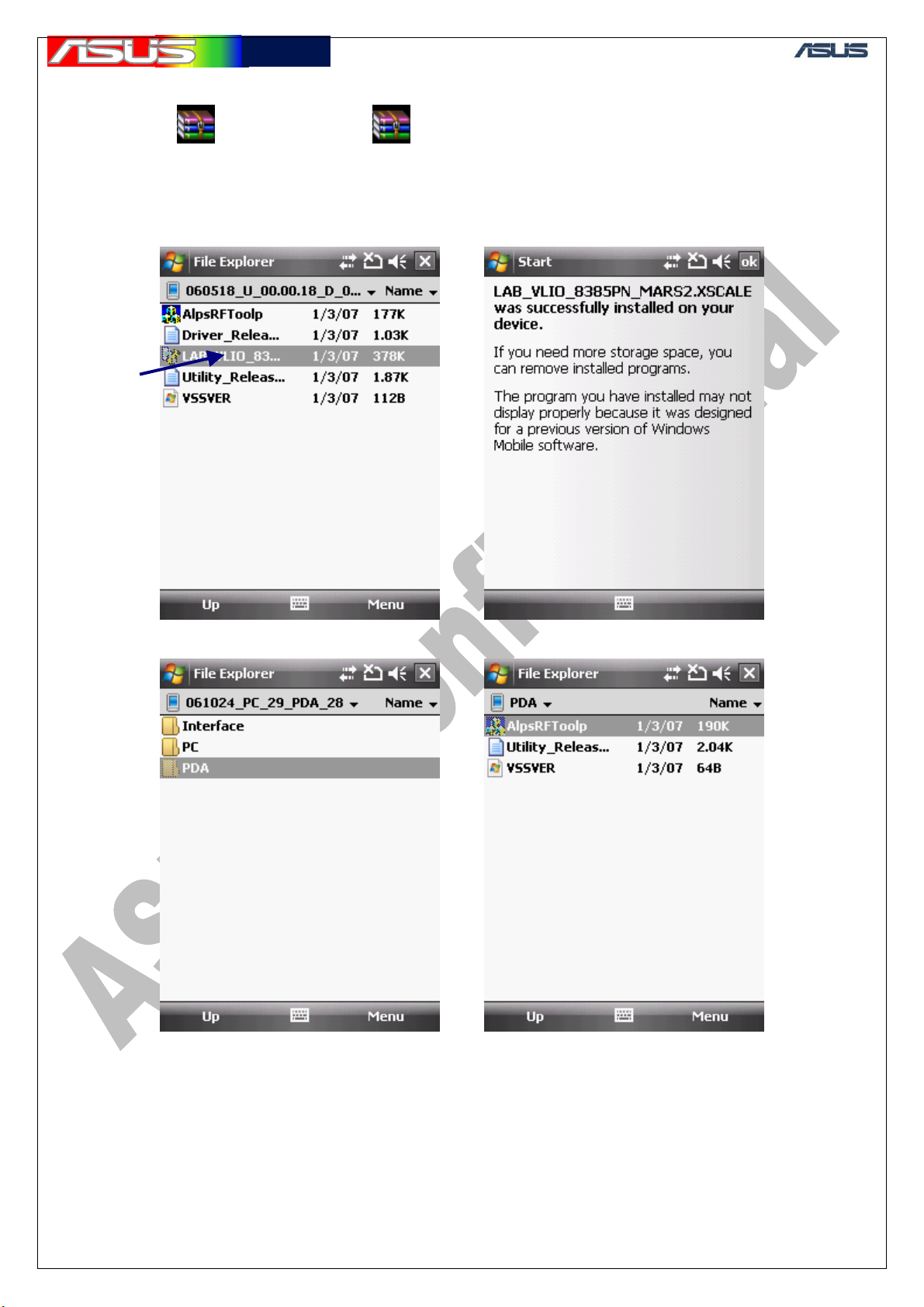

(3)WIFI test mode

GTC ■ Service Manual

060518_u_00.00.18_d_0.05.01.05.zip 061024_pc_29_pda_28.zip

Unzip the above two files and put into PDA

execute

Go to another folder

Restart after installation

Tap AlpsRFtoolp

72

Page 74

華華碩碩電電腦

腦

.

The main menu is as above.

Settings are as above, you can choose

different channels then press start to

transmit power.

GTC ■ Service Manual

(4)Measure output power at test points

WIFI test point 1

WIFI test point 2

73

Page 75

華華碩碩電電腦

腦

GTC ■ Service Manual

Measure at test point1 typical power is about 13-15dBm.

If the power value is abnormal, change U35.

Measure at test point1 typical power is about 11-13dBm

If the power value is abnormal, change U30.

74

Page 76

華華碩碩電電腦

腦

GTC ■ Service Manual

16. Appendix

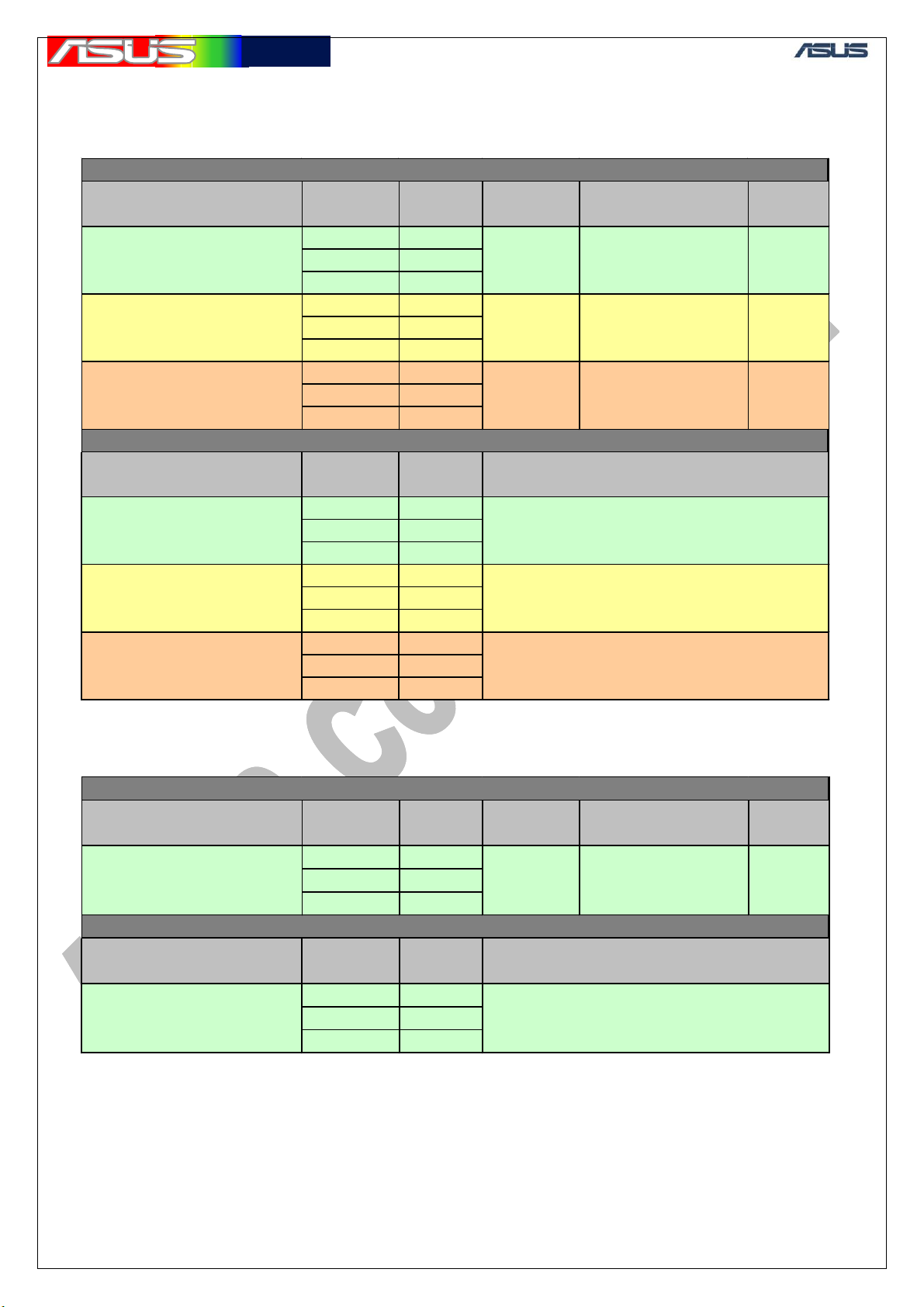

16.1 Typical Value of GSM/GPRS Conductive Tx/Rx Test

GSM/GPRS Tx Typical Value

Band Channel No.

975 880.2

EGSM 900

DCS1800

PCS1900

Band Channel No.

EGSM 900

DCS1800

PCS1900

62 902.4

124 914.8

512 1710.2

700 1747.8

885 1784.8

512 1850.2

661 1880

810 1909.8

975 925.2

62 947.4

124 959.8

512 1805.2

700 1842.8

885 1879.8

512 1930.2

661 1960

810 1989.8

Frequency.

(MHz)

GSM/GPRS Rx Typical Value

Frequency.

(MHz)

Power Level

5 32.5 +/- 1

0 29.5

0

Sensitivity Level - BER < 2% (dBm)

Typical Output Power

(dBm)

29.5 +/- 1

Maximum

-104

-103

-103

Tolerence

(dB)

+/- 1

16.2 Typical Value of WCDMA Conductive Tx/Rx Test

WCDMA Tx Typical Value

Band Channel No.

9612 1922.4

WCDMA Tx

Band Channel No.

WCDMA Rx

9750 1950

9888 1977.6

10562 2112.4

10700 2140

10838 2167.6

Frequency.

(MHz)

WCDMA Rx Typical Value

Frequency.

(MHz)

Power L evel

Maximum

(all up bit)

Sensitivity Level - BER < 0.1% (dBm)

Typical Output Power

(dBm)

23.5 +/- 1.5

Maximum

-111

Tolerence

(dB)

75

Page 77

華華碩碩電電腦

腦

16.3 Tx Test Environment Setup

Equipments Required:

1. PC

2. Specific Fixture for repair and test, including

A. Hermon USB contact

B. Power Supply contact

3. RF Probe with DC block and RF cable (30cm)

4. Spectrum Analyzer

5. Digital Multi-meter

Example of Tx Test Environment Setup:

GTC ■ Service Manual

76

Page 78

華華碩碩電電腦

腦

16.4 Rx Test Environment Setup

Equipments Required:

1. PC

2. Specific Fixture for repair and test, including

A. Hermon USB contact

B. Power Supply contact

C. RF connector and RF cable

3. RF Probe with DC block and RF cable (30cm)

4. Signal Generator

Example of Rx Test Environment Setup:

GTC ■ Service Manual

77

Page 79

華華碩碩電電腦

腦

GTC ■ Service Manual

17. GPS Introduce Purpose:

The Service Colleagues would be able to identify the GPS hardware trouble

issues of Solaris and then repair the hardware trouble issues soon.

17.1 Equipment requires

For identifying and repairing the GPS hardware trouble issues

of Solaris

17.2 Software:

SiRFDemoPPC, GPS Firmware: GSW3.2.4 or GSW Instant fix 3.2.4

17.3 Hardware:

GPS active antenna, Oscilloscope, GPS signal generator, Digital

Multimeter

78

Page 80

華華碩碩電電腦

腦

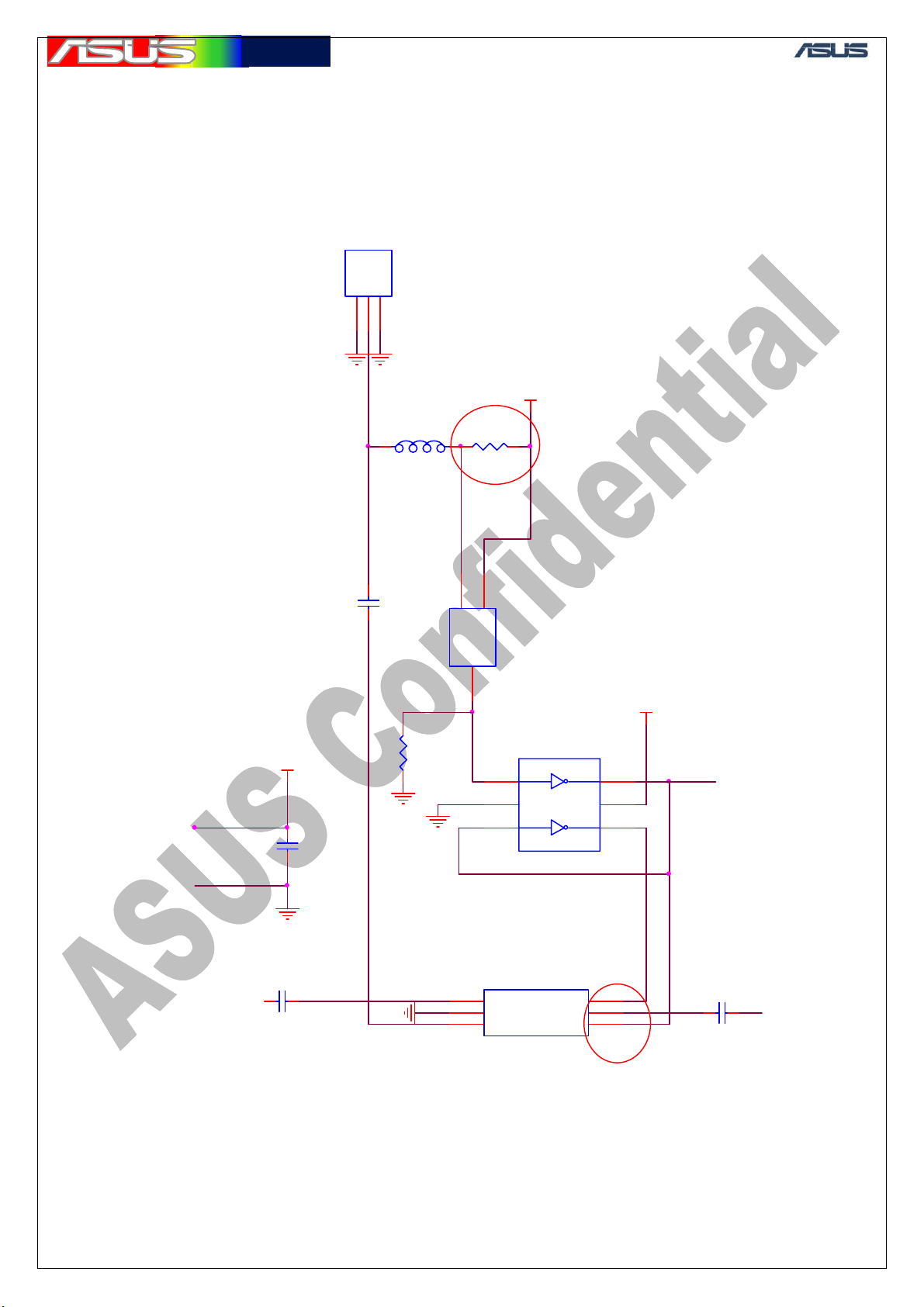

18. GPS Test points & Schematic

18.1 GPS Active Path

CON801

MMCX_JACK_1P

11GND1

GND2

2

3

L802

33NH

12

C802

100PF/50V

R803

+2.85V_GPS_LNA

12

C806

0.1UF/10V

C814

1 2

100PF/50V

10KOhm

1 2

1 2

21

10Ohm

3

Load

1

1

2

3

+2.85V_GPS_RF

R802

2

U802

Vin

ZXCT1009FTA

Iout

U803

1

A1

2

GND

3

A2

NC7WZ04L6X

U807

OUTPUT1

GND

OUTPUT2

UPG2179TB

R802

VCC

Vcont1

INPUT

Vcont2

GTC ■ Service Manual

+2.85V_GPS_RF_1

Y1

Y2

6

5

4

ACT_ANT_OFF

U807 pin 6

6

5

4

C817

1 2

100PF/50V

U807 pin 5

79

Page 81

華華碩碩電電腦

腦

18.2 Passive Path

GTC ■ Service Manual

4

OUTPUT

3

1575.42MHz

C823

L801

2.7NH

C803

1.2NH

21

1

IN

3

4

OUT

2

U809

1

C831

1 2

NC

RF_CON_4P

5

GND3

INPUT

GND12GND2

J801

21

100PF/50V

C822

1 2

12

C823

NC

C801

1 2

21

100PF/50V

L870

12NH

12

NC

C824

U806

GND34VCC

3

GND2

2

INPUT

1

GND1

UPC8215TU-E2

F805

1

1

SQ_37

F806

1

SQ_37

1

GND4

OUTPUT

GND5

5

6

7

8

+2.85V_GPS_BB

C807 C803

R889

0Ohm

1 2

12

C820

NC

C807

100PF/50V

12

+2.85V_GPS_LNA

12

C806

0.1UF/10V

C814

1 2

100PF/50V

18.3 GPS Chip

+2.85V_GPS_RF_1

12

C808

0.01UF/16V

C816

33PF/50V

L805

4.7nH

2 1

TCXO_OUT

C821

80

12

+1.5V_GPS_RTC

12

12

C821

1000PF/50V

GPS_RTC

C825

GPS_BOOTSEL{13}

C809

1000PF/16V

+2.85V_GPS_RF_1

1000PF/16V

GPS_XTAL_O

GPS_XTAL_I

R811

VDDK1

VDDK2

RXA

RXB

ECLK

SCLK

MOE#

MWE#

SS#[0]

SS#[1]

GPIO[0]

ODO

EIT[0]

CS_F#

CS[0]#

TMODE

JTDO

JTDI

JTCK

JTRST#

JTMS

TXA

TXB

SO

SK

RIN

SI

B4

A10

C5

B3

C4

F7

B10

C10

A5

A6

C7

B7

A7

A8

B8

C8

J10

G10

B1

P1

D1

B2

J9

H1

A4

A2

J6

J8

J7

C6

B5

A3

D3

F1

C1

E1

E7

D10

M1

J1

N1

K1

L1

E10

F10

+1.5V_GPS_RTC

GPS_SPI_CS#

GPS_LNAPWR_EN

GPS_SPI_DO

GPS_SPI_DI

GPS_SPI_CLK

GPS_CS#

JTRST#

JTMS

N3

N10

N9

GND_RF10N4GND_RF11N5GND_RF12N6GND_RF13N7GND_RF14N8GND_RF15

P7

GND_RF7

GND_RF16P5GND_RF17

J3

F6

U804

GND_RF1L4GND_RF2L5GND_RF3L6GND_RF4L7GND_RF5L8GND_RF6L9GND_RF8N2GND_RF9

12

C810

100PF/50V

1 2C818 1000PF/16V

GPS_RST_RF#

SIGN_MAG

CLKACQ

C825

12

100KOhm

M10

VCC_RF1

M9

VCC_RF9

M8

VCC_RF8

M7

VCC_RF7

M6

VCC_RF6

M5

VCC_RF5

M4

VCC_RF4

M3

VCC_RF3

M2

VCC_RF2

P4

TP_IF

P8

NC

P9

VCC_RTC

P6

RFIN

P3

XTAL_OUT

P2

XTAL_IN

H6

PLL_FILTER

H10

1 2

RESET#

K6

SPI_DO

K8

SPI_DI

K7

SPI_CLK

K9

SPI_CEB

K3

AGCPWM

K5

SIGN_MAG_O

J5

SIGN_MAG_I

K4

CLKACQ_O

J4

CLKACQ_I

K10

RTC_OUT

L10

RTC_XO

P10

RTC_XI

A9

*EA[0]

B9

*EA[1]

D7

*EA[2]

C9

*EA[3]

B6

*EA[4]

D8

*EA[5]

D9

*EA[6]

E8

*EA[7]

E9

*EA[8]

G9

*EA[9]

H9

*EA[10]

G8

*EA[11]

H8

*EA[12]

G7

*EA[13]

H7

*EA[14]

G6

*EA[15]

G5

*EA[16]

H5

*EA[17]

F8

*EA[18]

F9

*EA[19]

ED[0]G1ED[1]C2ED[2]F3ED[3]F2*ED[4]D2*ED[5]H2*ED[6]H4ED[7]J2*ED[8]E3*ED[9]E2*ED[10]C3*ED[11]G3*ED[12]G2*ED[13]H3*ED[14]G4*ED[15]

GSC3F

GPS_ED0

GPS_ED1

GPS_ED2

GPS_ED3

GPS_ED7

GPS_SPI_DO

GPS_SPI_DI GPS_RST_RF#

GPS_SPI_CLK

GPS_SPI_CS#

R811

L3

VDD_BB1D4VDD_BB2E4VDD_BB3F4VDD_BB4K2VDD_BB5L2VDD_BB6

GND_BB1A1GND_BB2D5GND_BB3D6GND_BB4E5GND_BB5E6GND_BB6F5GND_BB7

VDD_RTC

VDDPLL_O

VDD_PLL

VDD_FLASH

VDD_REG1

VDD_REG2

Reserved1

Reserved2

SRESET#

ON_OFF

RFPWRUP

GRFRST#

TIMEMARK

GPIO[13]

GPIO[14]

GPIO[15]

WAKEUP#

Reserved3

C805 0.01UF/16V

1 2

C811 10UF/6.3V

1 2

GPS_TX {13}

GPS_RX {13}

GPS_RST# {13}

GPS_ON_OFF

GPS_RFPWR_EN

GPS_EIT

1 2R812 100KOhm

1 2R808 100KOhm

1 2R809 100KOhm

GPS_RTC

+2.85V_GPS_BB

+2.85V_GPS_BB

Page 82

華華碩碩電電腦

腦

GTC ■ Service Manual

18.4 Power part test points

GPS_PWR_EN{13}

R813

RF_VBAT{13}

GPS_RFPWR_EN

12

R813

100KOhm

12

C832

10UF/6.3V

GPS_LNAPWR_EN_OUT

12

C819

0.1UF/10V

U811

A1

INA

A4

INB

A2

SHDNA#

A3

SHDNB#

MAX8559EBAJJ

OUTA

OUTB

BP

GND

B1

B4

B2

B3

12

C833

0.01UF/16V

C830

10UF/6.3V

10UF/6.3V

12

C830

+2.85V_GPS_LNA

12

C834

C819

L806

1

1

22MHZ

C834

GND

3

+1.5V_GPS_RTC

BACKUP_BAT

C838

2.2UF/6.3V

1 2

U319

5

GND

4

3

VOUT

VIN

CE

XC6215B152GR

VSS

1

2

C839

1UF/10V

1 2

C839 C838

+2.85V_GPS_BB

RF_VBAT{13}

GPS_PWR_EN{13}

2

C836

2.2UF/10V

1

U318

C3

IN

A3

EN

TPS79328YZQR

OUT

NR

GND

C1

B2

A1

C837

1

2

C837

1000PF/50V

+2.85V_GPS_RF+2.85V_GPS_RF_1

2

2

18.5 Testing signal from base band

81

Page 83

華華碩碩電電腦

腦

19. Test points placement point

19.1 GPS Antenna

C823

C803

R813

C819

Test point displacement plot 1

C807

U807 pin6

R802

C838

GTC ■ Service Manual

R811

C821

C825

U807 pin4

Testing signal from baseband

T809T808

82

Page 84

華華碩碩電電腦

腦

N

GTC ■ Service Manual

20. GPS Hardware Examination Procedure

The GPS examination procedure includes six parts. In the six parts, SiRFDemo

PPC program must be used. (Appendix A)

1. Start the SiRFDemoPPC program. Then, make sure that the GPS comport

setting is [Port:COM3][Baud Rate:4800 ]. After this step, check whether the

GPS function works or not.

Re-download the GPS firmware (as Appendix B) and then check if the GPS

function or works or not.

2. Active Path Fault Finding Chart

Put GSP active antenna into CON801 and then make

the active antenna near the window or open sky.(To

get the fine GPS signal)

YES

The C/N0 value

(got by the

SiRFDemo) > 35

YES

Do 4. Passive Path

Fault Finding Chart

O

Make sureU807

Pin6:Low(<0.2V)

Pin4:High(>2.5V)

OK?

YES

Do as SiRF StarIII

Fault Finding Chart

NO

Replace U807

with a new one

83

Page 85

華華碩碩電電腦

腦

g

d

n

4.Passive Path Fault Finding Chart

GTC ■ Service Manual

Remove the GPS

active antenna

See if the GPS

antenna contacts

with the antenna

contact spring well?

Check if C803.Pin1 an

C823 Pin 1 get connectio

directly?

Make sure that the GPS

antenna contact well with

the sprin

YES

Change J801 with a

new one

YES

Check if the voltage of

C819 is 3±10% (V)?

Check if the voltage of

C807.Pin1 is 2.85±5%

(V)?

Do the Power Part

Fault Finding Chart

YES

YES

Check if the voltage

of C807.Pin1 is

2.85±5% (V) ?

Replace U801 with a

new one

YES

Replace U806 or do

SIRF StarIII Fault

Finding Chart

84

Page 86

華華碩碩電電腦

腦

N

t

N

N

N

t

5.Power Part Fault Finding Chart

Make sure the V_BAT

is 4V

GTC ■ Service Manual

C830 and C834

are 2.85±5%

YES

Check if

the voltage of

R813 >1.6V?

YES

Check if

(V) ?

O

O

Do SiRF StarIII Faul

Finding Chart or change

U318

Replace U811

with a new one

Check if the voltage of

C838 >1.5V?

Check if the

voltage of C839 is

1.5±5% (V)?

YES

YES

O

O

YES

V_bat is not on

Replace U319 with a

new one

Do SiRF StarIII Faul

Finding Chart

85

Page 87

華華碩碩電電腦

腦

NO N

N

N

6.SiRF StarIII Fault Finding Chart

GTC ■ Service Manual

Put the GPS active

antenna into CON301

YES

Checnk

C837(2.85V±5%)

C810(1.5V±5%)

OK?

YES

Measure

C821.Pin1

OK?

O

Do Power Part Fault

Finding Chart

Replace X802 with a

new one

YES

Measure

C406.Pin2

OK?

YES

Measure

T305

T306

OK?

YES

O

O

Replace

X3801 with new

ones

Replace U804

with a new one

Re-Download GPS

Firmware

86

Page 88

華華碩碩電電腦

腦

21. Measurement results of all test points

Test point : T808

GTC ■ Service Manual

Test point :T809

87

Page 89

華華碩碩電電腦

腦

Test point :C821

GTC ■ Service Manual

Test point :C825

88

Page 90

華華碩碩電電腦

腦

22. Software procedure

GTC ■ Service Manual

Put SIRFDemoPPC at Micro SD

Card

1. choose [SiRFDemoPPC]

2. choose [OK]

89

Page 91

華華碩碩電電腦

腦

GTC ■ Service Manual

1. choose [OK]

1. choose [Connect]

4800 or 57600

1. choose [Done]

90

Page 92

華華碩碩電電腦

腦

GTC ■ Service Manual

SiRFDemoPPC plantface

1.choose [Signal]

GPS signal receiving

91

Page 93

華華碩碩電電腦

腦

GTC ■ Service Manual

The green signal means the

signal has been demodulated.

When all tests are finished

1. choose [setup]

1. choose [Exit]

92

Page 94

華華碩碩電電腦

腦

GTC ■ Service Manual

93

Page 95

華華碩碩電電腦

腦

22.1 GPS firmware download

1.choose [Pegasus_DGPS.exe]

GTC ■ Service Manual

Re-download automatically

begins

The re-download is finished

94

Page 96

華華碩碩電電腦

腦

Mobile re-boot

GTC ■ Service Manual

95

Loading...

Loading...