Page 1

AP3000

Dual Pentium® II Server Platform

Hardware Reference Guide

Page 2

User's Notice

No part of this manual, including the products and software described in it, may be reproduced,

transmitted, transcribed, stored in a retrieval system, or translated into any language in any form or

by any means, except documentation kept by the purchaser for backup purposes, without the express written permission of ASUSTeK COMPUTER INC. (“ASUS”).

ASUS PROVIDES THIS MANUAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL ASUS, ITS DIRECTORS, OFFICERS, EMPLOYEES OR AGENTS

BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING DAMAGES FOR LOSS OF PROFITS, LOSS OF BUSINESS, LOSS OF

USE OR DA T A, INTERRUPTION OF BUSINESS AND THE LIKE), EVEN IF ASUS HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES ARISING FROM ANY DEFECT OR

ERROR IN THIS MANUAL OR PRODUCT.

Product warranty or service will not be extended if: (1) the product is repaired, modified or altered,

unless such repair, modification of alteration is authorized in writing by ASUS; or (2) the serial

number of the product is defaced or missing.

Products and corporate names appearing in this manual may or may not be registered trademarks or

copyrights of their respective companies, and are used only for identification or explanation and to

the owners’ benefit, without intent to infringe.

• Adobe and Acrobat are registered trademarks of Adobe Systems Incorporated.

• Adaptec, AHA, EZ-SCSI, and AIC is a registered trademark of Adaptec, Inc.

• Sound Blaster, SB16, A WE32, A WE64D and SB-LINK are trademarks of Creative T echnology Ltd.

• Intel, LANDesk, and Pentium are registered trademarks of Intel Corporation.

• IBM and OS/2 are registered trademarks of International Business Machines.

• Windows and MS-DOS are registered trademarks of Microsoft Corporation.

• Trend and ChipAwayVirus are trademarks of Trend Micro, Inc.

The product name and revision number are both printed on the product itself. Manual revisions are

released for each product design represented by the digit before and after the period of the manual

revision number. Manual updates are represented by the third digit in the manual revision number.

For previous or updated manuals, BIOS, drivers, or product release information, contact ASUS at

http://www.asus.com.tw or through any of the means indicated on the following page.

SPECIFICA TIONS AND INFORMATION CONT AINED IN THIS MANUAL ARE FURNISHED

FOR INFORMA TIONAL USE ONL Y, AND ARE SUBJECT TO CHANGE AT ANY TIME WITHOUT NOTICE, AND SHOULD NOT BE CONSTRUED AS A COMMITMENT BY ASUS. ASUS

ASSUMES NO RESPONSIBILITY OR LIABILITY FOR ANY ERRORS OR INACCURACIES

THAT MA Y APPEAR IN THIS MANUAL, INCLUDING THE PRODUCTS AND SOFTWARE

DESCRIBED IN IT.

Copyright © 1999 ASUSTeK COMPUTER INC. All Rights Reserved.

Product Name: AP3000

Manual Revision: 1.00 E321

Release Date: February 1999

2

AP 3000 Hardware Reference Guide

Page 3

ASUS Contact Information

ASUSTeK COMPUTER INC. (Asia-Pacific)

Marketing

Address: 150 Li-Te Road, Peitou, Taipei, Taiwan 112

Telephone: +886-2-2894-3447

Fax: +886-2-2894-3449

Email: info@asus.com.tw

Technical Support

Tel (English): +886-2-2894-3447 ext. 706

Tel (Chinese): +886-2-2894-3447 ext. 701

Fax: +886-2-2895-9254

Email: tsd@asus.com.tw

Newsgroup: news2.asus.com.tw

WWW: www.asus.com.tw

FTP: ftp.asus.com.tw/pub/ASUS

ASUS COMPUTER INTERNATIONAL (America)

Marketing

Address: 6737 Mowry Avenue, Mowry Business Center, Building 2

Newark, CA 94560, USA

Fax: +1-510-608-4555

Email: info-usa@asus.com.tw

Technical Support

Fax: +1-510-608-4555

BBS: +1-510-739-3774

Email: tsd-usa@asus.com.tw

WWW: www.asus.com

FTP: ftp.asus.com.tw/pub/ASUS

ASUS COMPUTER GmbH (Europe)

Marketing

Address: Harkort Str . 25, 40880 Ratingen, BRD, Germany

Telephone: 49-2102-445011

Fax: 49-2102-442066

Email: sales@asuscom.de

Technical Support

Hotline: 49-2102-499712

BBS: 49-2102-448690

Email: tsd@asuscom.de

WWW: www.asuscom.de

FTP: ftp.asuscom.de/pub/ASUSCOM

AP 3000 Hardware Reference Guide

3

Page 4

Contents

I. Introduction

1-1. How this Manual is Organized ........................................... 7

Symbols ............................................................................. 7

1-2. Component Checklist......................................................... 8

1-3. Features............................................................................. 9

1-4. Safeguards ...................................................................... 10

1-5. Electrical Safety ................................................................11

II. Components

2-1. Server Front Side............................................................. 13

2-2. Server Back Side ............................................................. 14

2-3. Server Left Side ............................................................... 15

III. Basic Operation

3-1. Starting the Server........................................................... 16

3-2. LEDs ................................................................................ 16

3-3. BIOS Setup...................................................................... 16

IV. Hardware Setup

4-1. Opening the Chassis ....................................................... 17

Panel Screws ................................................................... 17

Removing the Right Panel ............................................... 17

Opening the Left Panel .................................................... 18

Chassis Circulation System ............................................. 18

Fan Modules .................................................................... 18

4-2. Rear Cooling Fan Control Board ..................................... 19

Rear Cooling Fan Control Board Settings........................ 19

4-3. Motherboard .................................................................... 20

Motherboard Spacers ...................................................... 20

Install the Baseboard ....................................................... 20

Motherboard Screws........................................................ 20

Device Cables.................................................................. 21

Cable Connections........................................................... 21

4-4. Central Processing Unit (CPU) ........................................ 22

Install Retention Mechanisms.......................................... 22

Install Retention Mechanism Brace Bars ......................... 22

Install Cartridge Lifters ..................................................... 23

Install Retention Mechanism Cap .................................... 23

Install Retention Mechanism Frame ................................ 23

4-5. Chassis Intrusion Switch.................................................. 24

Chassis Intrusion Connector............................................ 25

4-6. Expansion Cards ............................................................. 25

4-7. Fixed Storage Devices..................................................... 26

4

AP 3000 Hardware Reference Guide

Page 5

Contents

Floppy Drive and CD-ROM.............................................. 26

Fixed Storage Device Tray............................................... 26

Fixed Device Bay Cover Clips ......................................... 27

Fixed Device Bay Cover .................................................. 27

Storage Device Spacers .................................................. 27

4-8. Five-Tray Hot-Swap Bay.................................................. 28

4-9. Three-Tray Hot-Swap Bay ............................................... 28

Hot-Swap Tray ................................................................. 29

Hot-Swap Bay.................................................................. 29

4-10. Front Cooling Fans ........................................................ 30

Front Cooling Fan Control Board..................................... 31

Hard Disk Drive Message Board...................................... 31

4-11. SCSI Backplane............................................................. 32

4-12. SCSI ID Setting.............................................................. 33

SCSI ID Dip Switches ...................................................... 33

4-13. Expansion Card Guide................................................... 34

Securing Expansion Card Guide...................................... 34

4-14. SCSI Termination ........................................................... 35

4-15. Power Supply................................................................. 35

Power Supply Mounting................................................... 35

Power Supply Information................................................ 36

4-16. Power Supply Requirement ........................................... 37

Power Supply Requirement Calculation Table................. 37

V. Appendix

i. Electrical SafetySCSI Cable Limits ...................................... 39

ii. Glossary .............................................................................. 40

AP 3000 Hardware Reference Guide

5

Page 6

FCC & DOC COMPLIANCE

Federal Communications Commission Statement

This device complies with FCC Rules Part 15. Operation is subject to the

following two conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with

manufacturer’s instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

WARNING! The use of shielded cables for connection of the monitor to

the graphics card is required to assure compliance with FCC regulations.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate this

equipment.

Canadian Department of Communications Statement

This digital apparatus does not exceed the Class B limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.

6

AP 3000 Hardware Reference Guide

Page 7

I. Introduction

You are reading the AP3000 Hardware Reference Guide. This hardware reference guide provides information and procedures on the various components

used in this server. Some components shown in this reference guide are optional and may be individually purchased to complete the server. This guide is

intended for experienced users and integrators with hardware knowledge of

personal computers. You should also read all documentation and manuals included with this server and with your separately purchased components.

•

1-1. How this Manual is Organized

There are only a few sections in this reference guide as follows:

I. Introduction

This section gives general and startup information and features for this server .

II. Components

This is the main section which gives descriptions of each server component.

Sections

I. Introduction

I. Introduction

III. Getting Started

This section gives information on getting started with the server.

IV. Hardware Setup

This section gives information on setting up the server.

V . Appendix

This section gives you additional information to help plan your server .

Symbols

T o complete certain tasks safely and completely , you should be aware

of a few symbols used throughout this guide.

WARNING: Information to prevent injury to yourself when trying to

complete a task.

CAUTION: Information to prevent damage to the components when

trying to complete a task.

IMPORTANT: Information that MUST be followed in order to complete a task.

NOTE: Tips and information to aid in completing a task.

PHILIP (CROSS) SCREW DRIVER: Tools required to install or re-

move the components in this server .

STANDARD (FLAT) SCREW DRIVER: Tools required to install or

remove the components in this server .

STEP: Actions to complete a task.

AP 3000 Hardware Reference Guide

7

Page 8

I. Introduction

I. IntroductionI. Introduction

Checklist

• 1-2. Component Checklist

If assembling this server by yourself, it is important to prepare all the

server components before starting. This will save a great deal of time

by not having to hunt down components. The following checklist

provides a guideline as to the necessary components for a server.

Standard components

Motherboard: XG-DLS

Chassis: AS-30

Power Supply: A TX

Processor (CPU): Pentium

Memory Modules: 8, 16, 32, 64, 128, 256, 512MB SDRAM

Hard Drive: Ultra2, Ultra-wide

®

II Xeon

TM

Floppy Drive: 1.44MB

CD-ROM Drive: 40X

Expansion Cards:

SCSI Terminator: Passive terminator for 68pin SCSI

User’s Manuals: CD-ROM, SCSI, Motherboard, Hard

Optional components

Ethernet Card: (optional PCI-L101)

RAID Controller: (optional PCI-DA2100, PCI-DA2200,

Expansion Card Stabilizer

Ethernet, Graphics, Modem

cables

ware Guide

DA-3000 RAID Controller)

AP 3000 Hardware Reference Guide

8

AP 3000 Hardware Reference Guide

Page 9

I. Introduction

• 1-3. Features

AP3000 is a department server configured on the XG-DLS smart

motherboard which uses the 440GX chipset from Intel and supports

two Pentium II processors and 100MHz front side bus in order to

handle even the most complicated server tasks.The following are highlights to this server’s many features. For additional features and details, read the motherboard User’s Manual included with this server

package.

• Processor: Supports dual Intel® Pentium® II Xeon™ processors from

450MHz to 550MHz on each processor for extreme server processing

speeds.

• Memory: Equipped with four DIMM sockets to support up to 2GB

SDRAM with ECC.

• AGP Slot: Supports Accelerated Graphics Port cards for high perfor-

mance, component level interconnect targeted at 3D graphical display

applications. Using AGP will also free up a PCI slot.

Features

I. Introduction

I. Introduction

• Adaptec SCSI Chipset: Features Adaptec AIC-7896 dual-channel Ul-

tra2 SCSI chipset that supports any combination of 50-pin narrow or

68-pin wide/ultra2 devices through the onboard 50-pin and 68-pin SCSI

connectors.

• Device Bays: Support one floppy, one CD-ROM, two additional fixed

devices, and five hot-swap SCA hard disk drives.

• SCSI Backplane: Ultra2 SCSI SCA backplane with remote SCSI ID

dip switches and power to support up to 5 Ultra2 SCSI SCA hard drives.

• Onboard IDE: Up to 33MB/sec IDE transfer with UltraDMA/33.

• Onboard Hardware Monitor: Provides information for system and

processor voltages, fan status, temperature, chassis intrusion, and provides automatic system restart.

• Onboard LAN: Onboard Intel 10/100Base-TX Fast Ethernet.

• ASMA and Intel LDSM: Provides server monitoring, management,

and control.

• RAID Controller: Supports PCI-DA2100A(UW) RAID controller , PCI-

DA2200(U2) or DA-3000(U2) SCSI to SCSI RAID controller, which

provides good fault tolerance.

AP 3000 Hardware Reference Guide

AP 3000 Hardware Reference Guide

9

9

Page 10

I. Introduction

I. Introduction

I. Introduction

Safeguards

• 1-4. Safeguards

Observe the following safety instructions any time you are connecting or disconnecting any devices.

Operation Safety

IMPORT ANT

• Any operation on this server must be conducted by certified or experienced engineers.

• Before operating your server, carefully read all the

manuals included with the server package.

• Before using the server, make sure all cables are correctly connected and the power cables are not damaged. If any damage is detected, contact your dealer as

soon as possible.

• To avoid short circuits, keep paper clips, screws, and

staples away from connectors, slots, sockets and circuitry.

• Before opening the chassis panels, make sure all power

cables are unplugged.

• A void dust, humidity, and temperature extremes. Place

the server on a stable surface.

• If the power supply is broken, do not try to fix it by

yourself. Contact an authorized dealer.

• It is recommanded that you wear gloves when assembling or dissembling the server to protect from cut s and

scrapes.

• Whe n the server is powered on, heat sinks and the sur faces of certain IC devices may be hot. Do not touch

them. Check whether the fans are functioning properly .

Tools Required

A Phillips (cross) screwdriver and a standard (flat) screwdriver are

needed to install or remove the components in this server .

10

AP 3000 Hardware Reference Guide

Page 11

I. Introduction

• 1-5. Electrical Safety

IMPORTANT

• Before installing or removing signal cables, ensure that the

power cables for the system unit and all attached devices are

unplugged.

• T o prevent electrical shock hazard, disconnect the power cable

from the electrical outlet before relocating the system.

• When adding or removing any additional devices to or from

the system, ensure that the power cables for those devices are

unplugged before the signal cables are connected. If possible,

disconnect all power cables from the existing system before

you add a device.

• Use one hand, when possible, to connect or disconnect signal

cables to prevent a possible shock from touching two surfaces with different electrical potentials.

Electrical Safety

I. Introduction

I. Introduction

CAUTION

This product is equipped with a three-wire power cable and plug

for the user’s safety. Use the power cable in conjunction with a

properly grounded electrical outlet to avoid electrical shock.

IMPORTANT

Motherboards, adapters, and disk drives are sensitive to static

electricity discharge. These devices are wrapped in antistatic

bags to prevent this damage. Take the following precautions:

• If you have an antistatic wrist strap available, use it while

handling the device.

• Do not remove the device from the antistatic bag until you

are ready to install the device in the system unit.

• With the device still in its antistatic bag, touch it to a metal

frame of the system.

• Grasp cards and boards by the edges. Hold drives by the

frame. Avoid touching the solder joints or pins.

• If you need to lay the device down while it is out of the

antistatic bag, lay it on the antistatic bag. Before picking it

up again, touch the antistatic bag and the metal frame of the

system unit at the same time.

• Handle the devices carefully in order to prevent permanent

damage.

AP 3000 Hardware Reference Guide

11

Page 12

(This page was intentionally left blank)

12 AP 3000 Hardware Reference Guide

Page 13

II. System Components

• 2-1. Server Front Side

The front side of the server is provided to show the front exterior components of this server. The chassis is made of strong rust-resistant metal and

covered with a protective ivory surfacing.

1

2

3

4

5

6

Front Side

1. Top Panel

2. Power LED

3. ATX Power Button

4. Hard Drive Access LED

7

8

9

10

11

12

13

II. Components

Server Front Side

5. Floppy Disk Drive

6. CD-ROM Drive

7. Drive Expansion Bay

8. Side Panel Handle

9. Side Panel Screw

10. Metal Door Lock

11. Hot Swap Tray

12. Hard Drive Fan Module

13. Chassis Stabilizers

AP 3000 Hardware Reference Guide

13

Page 14

II. System Components

• 2-2. Server Back Side

1

2

3

4

II. Components

Back Side

5

6

7

8

9

10

11

12

13

Server Back Side

1. T op Panel Screw

2. Power Supply

3. Power Supply Fan

4. AC Power In Connector

5. PS/2 Keyboard, PS/2 Mouse

6. USB Ports 1 and 2

7. Serial Port COM1

8. Parallel Port

9. Serial Port COM2

10. RJ45 Port (LAN)

11. Rear Fan Module

12. RAID Controller (Optional)

13. Chassis Stabilizer

14

AP 3000 Hardware Reference Guide

Page 15

II. System Components

• 2-3. Server Left Side

6

Back SideBack Side

1

2

3

II. Components

Left Side

II. Components

Server Left Side

4

5

1. Power Supply

2. Motherboard

3. Chassis Intrusion Switch

4. Chassis Stabilizer (shown recessed)

5. Expansion Card Guide

6. Rear Fans

AP 3000 Hardware Reference Guide

15

Page 16

• 3-1. Starting the Server

Turn ON the server by pushing the power button. The power button will snap

back when released because ATX power systems have an electrical ON /OFF

switch unlike AT systems which require a permanent ON or OFF position. If the

Power O n L ED does not light, make sure the power cord is connected to the

system unit and to a working grounded outlet.

• 3-2. LEDs

There are two LEDs on the top left-hand corner of the front panel. The upper

one is the power LED and the lower one is the hard drive access LED. When

III. Basic Operation

Starting/LEDs

the system is booted, the power LED is green. When the hard drive is being

accessed, the hard drive access LED is green.

LEDs

III. Basic Operation

IMPORTANT

The power switch only turns off DC power (power supply

output). T o turn of f AC power (power supply input), you need

to unplug the electrical cord from the outlet.

Power LED

Power Switch

Hard Drive

Access LED

• 3-3. BIOS Setup

This server does not come with any pre-installed software. When booting

your server for the first time, make BIOS settings by following the motherboard User’s Manual.

NOTE

When installing W indows NT 4.0, use the W indows NT installation disks. Installing from the CD will require you to pre-install

SCSI drivers by pressing F6 before setup begins. You may need

device drivers on a floppy disk in order to install devices during

the Windows NT 4.0 setup. To use the onboard SCSI, you will

need to copy Adaptec’s SCSI driver (from the provided support

CD) onto a floppy disk (“Winnt”, “Disk1”, “Txtsetup.oem”).

16

AP 3000 Reference Guide

Page 17

IV. Hardware Setup

This section gives descriptions of how to install and remove components.

When setting up devices on the server , perform the following steps.

• 4-1. Opening the Chassis

Panel Screws

The top panel on the chassis is

secured by two screws on the

back of the server . T o open the

top panel, remove the screws

with a screw driver.

NOTE: You do not have

to open the top panel before

removing the left panel.

The side panels are secured by

two large thumb screws on the

front of the server, which can

be turned with your fingers.

Removing the

Right Panel

T o remove the right panel, the

front door must be removed by

pushing down on the hinge

spring.

Opening the Chassis

IV. Hardware Setup

AP 3000 Hardware Reference Guide

17

Page 18

IV. Hardware Setup

Pulling the panel forward

Opening the

Left Panel

There are two identical side

panels on the chassis, one on

each side. To open the left

side of the panel (see the left

view), remove the side panel

screw, then pull the handle

outward while pulling the

panel forward. To open the

right panel, the front door

must be removed first.

Chassis

Circulation

IV. Hardware Setup

Chassis Fans

Latches

System

The chassis air circulation

system is comprised of two 3

inch (8 cm) fans. The fan

modules are held by two

screws and four latches on the

inside rear of the chassis. To

take out the fans, remove the

screws.

Fan Modules

There are four screws used to

secure the fan into the individual frames. To replace the

fan, remove the screws.

18

IMPORTANT: Usu-

ally, the rotation of the

fan sends air toward the

manufacturer’s label on the

center of the fan.

AP 3000 Hardware Reference Guide

Page 19

IV. Hardware Setup

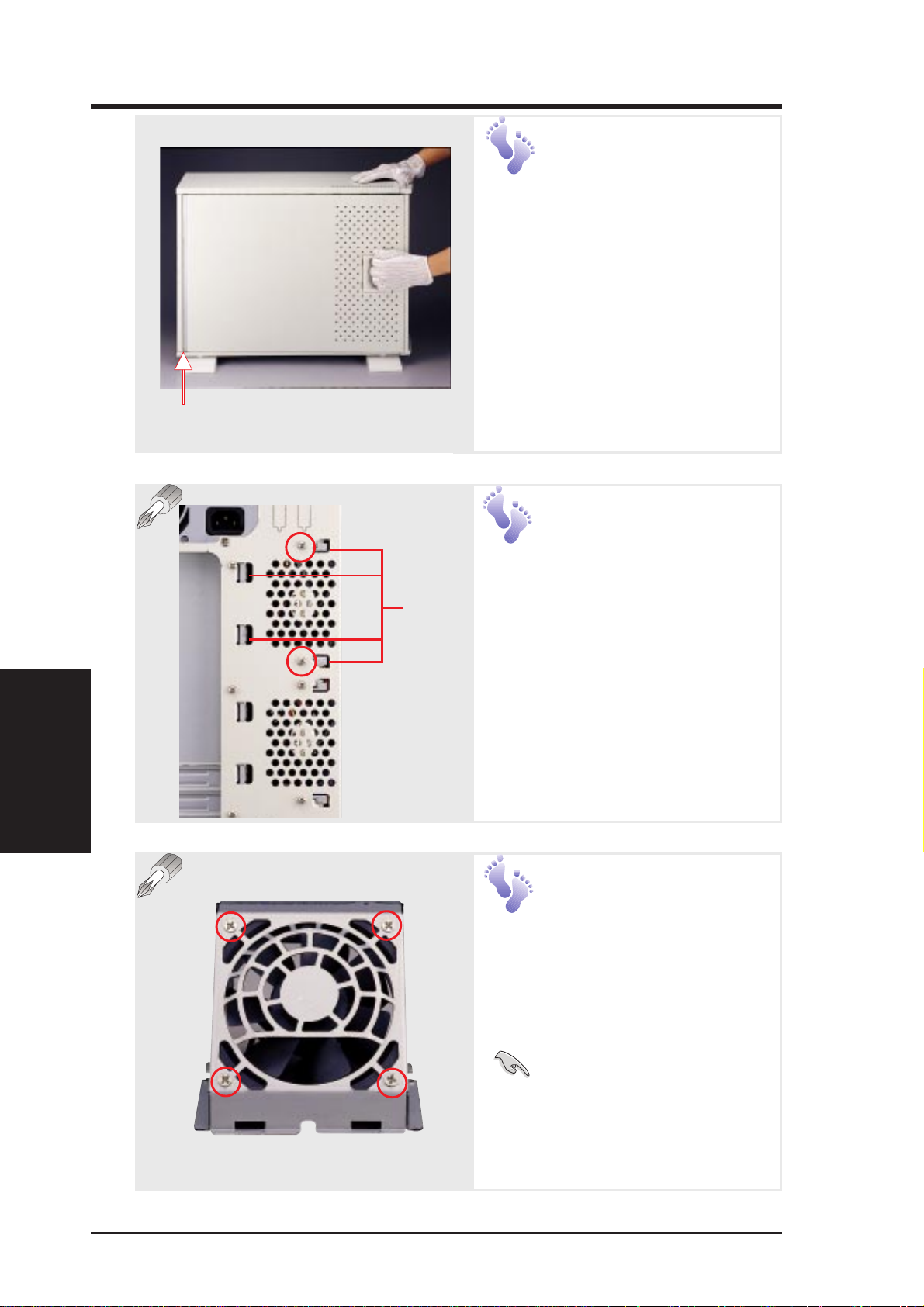

• 4-2. Rear Cooling Fan Control Board

The rear fans are controlled and monitored by a control board. The fan

control board requires power input from the power supply which allows

the individual fans to obtain their power when connected to the control

board. The control board also sends fan status information to the LEDs

located on the front of the server and to the ASMA software. The fan control board’s cable connections are shown below.

Fan

Fan Power

Connectors

Reserved

Connector

Fan Status Signal

Connector

Power Input

Connector

Fan Control

Settings

Reserved

Fan Connectors

Rear Cooling Fan Control Board Settings

The rear fan control board has DIP switches to allow controlling the

control board status and the number of fans.

DIP Switch SET1 Fan Control Board Setting

ON (momentarily) Reset Control Board

OFF Normal (Default)

Rear Fans

IV. Hardware Setup

SET2 SET3 SET4 Number of Fans

ON ON ON 1

ON ON OFF 2 (Default)

ON OFF ON 3

ON OFF OFF 4

OFF ON ON 5

OFF ON OFF 6

OFF OFF ON 7

OFF OFF OFF 8

AP 3000 Hardware Reference Guide

19

Page 20

IV. Hardware Setup

• 4-3. Motherboard

You can remove the extended expansion card guide before installing or removing the motherboard. All screws are necessary to provide the needed

stabilization to support all the motherboard expansion cards used in this chassis.

Motherboard

Spacers

Place four spacers in the areas circled on the chassis.

Extended Expansion Card Guide

Spacer

Install the

IV. Hardware Setup

Motherboard

Place and tighten three captive nuts in

the corner locations circled.

Baseboard

A metal baseboard is required to add

stability to the motherboard. A rubber pad is placed between the metal

board and motherboard to provide

insulation to prevent shorting. Align

the rubber pad over the metal baseboard so that the holes match. Align

the XG-DLS motherboard over the

rubber pad and metal baseboard so

that the screws match up with the

motherboard’s screw holes.

Motherboard

Screws

Place nine screws in the areas

circled on the motherboard. The

four screws used with the

motherboard spacers are longer

than the others. (See page 22 for

samples.) Be careful not to overtighten the screws. Doing so may

damage your motherboard.

20

AP 3000 Hardware Reference Guide

Page 21

IV. Hardware Setup

Floppy Disk Drive Cable

CD-ROM Drive Cable

68-pin SCSI Cable

Power LED

HDD LED

Power Switch

Chassis Intrusion

nector Cable

Con

Device Cables

Several cables are used for connecting devices in this chassis. The following

picture points out the name of each cable and its suggested location. Plastic

keepers protect the cables from contacting with the fans and other devices.

Make sure that all cables are properly secured.

CD-ROM Drive

Cable

68-pin SCSI Cable

68-pin SCSI Cable

Cable Connections

The cables connect to the motherboard as shown. The motherboard includes

onboard SCSI with 68-pin and 50-pin SCSI connectors. RAID connections

require a RAID card.

Motherboard

IV. Hardware Setup

AP 3000 Hardware Reference Guide

21

Page 22

IV. Hardware Setup

• 4-4. Central Processing Unit (CPU)

The motherboard has two connectors for processor retention modules. One

retention module can have one Xeon processor installed. Before installing

the CPU, secure the motherboard on the rubber pad and metal baseboard.

(See p. 20.)

When only one processor is used, the other Slot 2 connector must be terminated with the provided front side bus termination module.

For memory installation, refer to the motherboard User’s Manual.

Captive Nut

Long Screw (aligned with spacers)

Short Screw

Install Retention

IV. Hardware Setup

CPU

Single Dot

Two Dots

Mechanisms

For the retention mechanism,

there is a left and a right side. The

left side has a single dot and the

right side has two dots (when

holding the motherboard with the

A TX connectors to the left). Place

the retention mechanisms’ holes

over the screws and the Slot2.

Screw four captive nuts onto the

screws as circled in the picture on

the right. Do not place the other

captive nuts yet.

Install Retention

Mechanism

Brace Bars

22

Place the retention mechanism brace bar into the groove

on the top of the retention

mechanism as shown.

Retention Mechanism Brace Bar

AP 3000 Hardware Reference Guide

Page 23

IV. Hardware Setup

Install Cartridge

Lifters

Each Xeon processor requires two

lifters in order to allow safe removal

of the processor. The lifters clamp

on to the cartridge on the two holes

at the top of each corner.

For the lock bar, there is a left and a

right side. The left side has a single

dot and the right side has

two dots (when holding

the motherboard with the

ATX connectors to the

left).

Single Dot

Install Retention

Mechanism Cap

The cap must go in from the left side

first (with the A TX connectors to the

left). The left side has one dot, while

the right side has two dots. The right

end of the cap enters the retention

mechanism and a click is heard as

it snaps in place.

Two Dots

Single Dot

Install Retention

Mechanism

Frame

A metal frame is used accross both

retention mechanisms. After installing the frame, four captive nuts

should be tightened on the feet of the

frame to the screws protruding from the retention mechanisms.

CPU

IV. Hardware Setup

Sticker (facing

the CPU fan)

AP 3000 Hardware Reference Guide

23

Page 24

IV. Hardware Setup

• 4-5. Chassis Intrusion Switch

The chassis provides a micro toggle switch that must be connected to

the motherboard for the chassis intrusion detection to work. The motherboard will signal the ASMA software when the side panel is opened.

The connection diagram is given here.

Chassis Intrusion Switch

IV. Hardware Setup

Cable

+5VSB

Chasis Signal

IMPORTANT

To prevent misconnection, one pin is removed from the

motherboard’s chassis intrusion connector.

GND

Chassis Intrusion Switches

(one on each side)

from the two Chassis

Intrusion Switches

Motherboard’s

Chassis Intrusion Connector

24

AP 3000 Hardware Reference Guide

Page 25

IV. Hardware Setup

Chassis

Intrusion

Connector

The two chassis intrusion

switches are connected to the

motherboard’s chassis intrusion connector through a

Chassis Intrusion Connector

• 4-6. Expansion Cards

Expansion cards can be easily installed just like on any stan-

dard PC. Up to 5 PCI or 1 ISA cards can be installed. One

AGP slot is also available for an AGP graphics adapter to provide

hardware 3D acceleration and free up an extra PCI slot.

single connector.

Contact

CAUTION

Make sure that the total amperage of your installed expansion

cards does not exceed the system power specification.

AP 3000 Hardware Reference Guide

Expansion Cards

IV. Hardware Setup

25

Page 26

IV. Hardware Setup

• 4-7. Fixed Storage Devices

Internal fixed storage devices are mounted on removable trays. There

are four available, one for a floppy device and another three for fullsize devices.

Floppy Drive

and CD-ROM

The floppy drive fits in the topmost bay along with the power

button. A CD-ROM can fit into

either the second, third, or

fourth bay from the top. A metal

clip on each side of the device

tray secures the tray in place.

Press inward to release the clips.

The tray slides in or out on the

side rails.

IV. Hardware Setup

Fixed Storage Devices

Fixed Storage

Device Tray

There are six screws provided

(as circled) for mounting a 4 inch

device such as a floppy or hard

disk drive. Four screws are provided (as boxed) for mounting a

6 inch device such as a CDROM or tape drive.

26

AP 3000 Hardware Reference Guide

Page 27

IV. Hardware Setup

Fixed Device

Bay Cover

Clips

The device bay panel is held

by two plastic clips on each

side. Press these clips in with

a screwdriver to release.

Fixed Device

Bay Cover

After releasing the device bay

cover clips, pry the cover away

from the chassis using a screw

driver from the front.

Storage Device

Spacers

A floppy drive spacer is used to

cover the floppy drive and power

button. A standard storage device

spacer is used to cover the CDROM, tape drive, or additional

CD-ROMs. You should purchase

an extra spacer for each storage

device.

Floppy Drive Spacer

Fixed Device Spacer

Fixed Storage Devices

IV. Hardware Setup

AP 3000 Hardware Reference Guide

27

Page 28

IV. Hardware Setup

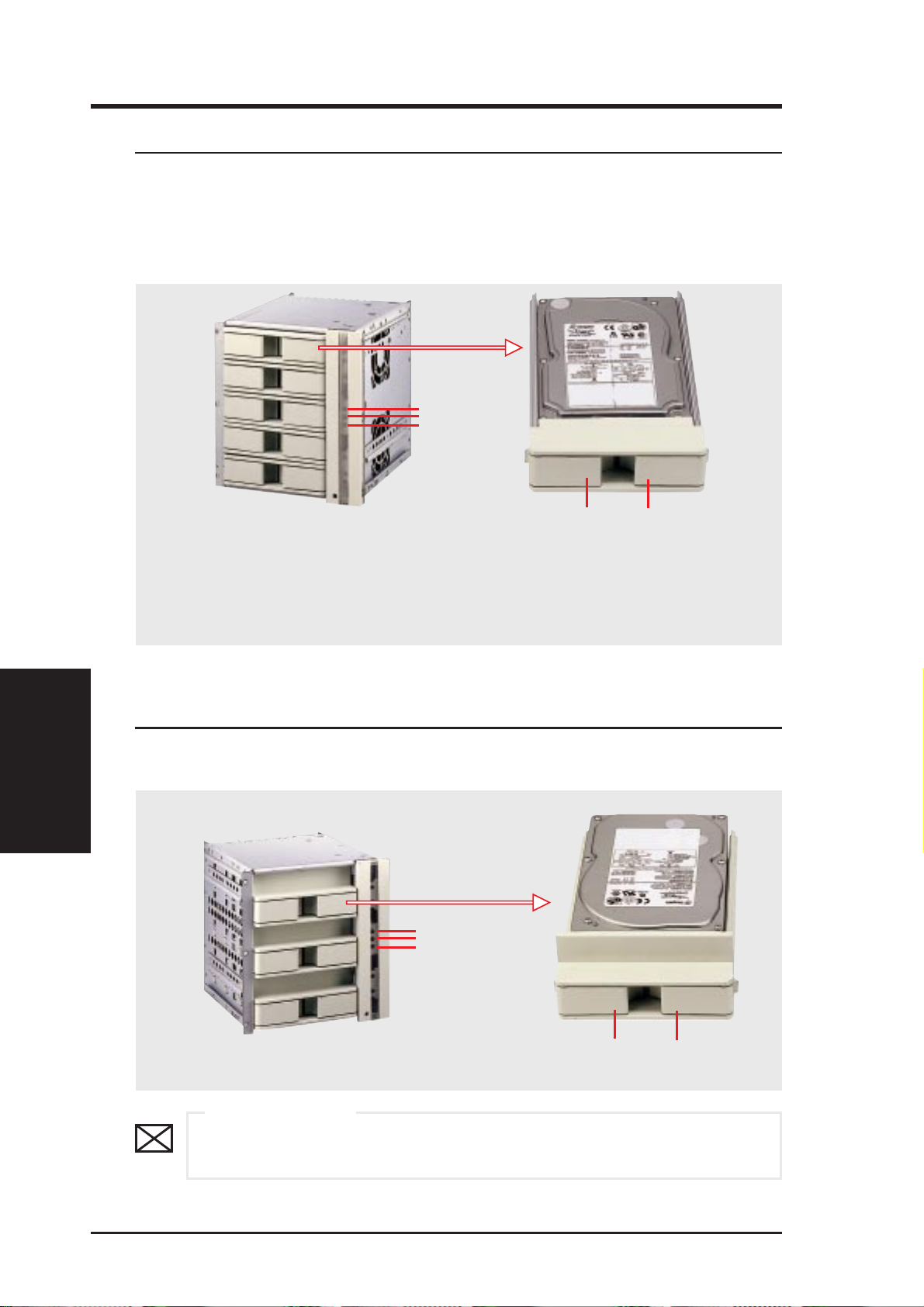

• 4-8. Five-Tray Hot-Swap Bay

Maximum uptime in a server requires devices that can be easily replaced

or “swapped.” The main hard drives are mounted in internal hot-swap trays

for easy replacement. The AP3000 hot-swap bay has two different models:

Five-tray hot-swap bay and three-tray hot-swap bay. The 1.0 inch SCA

hot-swap bay can accommodate five 1.0 inch hard disk drives.

LEDs

Levers

LEDs

Green: Power LED

Yellow: Hard Disk Access LED

Red: Hard Disk Status LED (reserved)

(For details about LEDs, see p. 31.)

IV. Hardware Setup

Hot-Swap Bay

• 4-9. Three-Tray Hot-Swap Bay

The 1.6 inch SCA hot-swap bay can accommodate three 1.6 or 1.0

inch hard disk drives.

LEDs

Levers

IMPORTANT

Each SCA hot-swap bay provides an aluminum carrier only for a single

SCSI hard disk drive.

28

AP 3000 Hardware Reference Guide

Page 29

IV. Hardware Setup

Hot-Swap Tray

1

2

3

4

5

There are two levers on the front of the hot-swap tray to help release

or lock the tray. To remove the tray, extend both levers and pull on

both levers. To install the tray, push the tray firmly into the bay with

the levers extended, then close the levers.

Hot-Swap Bay

IV. Hardware Setup

Hot-Swap Bay

To remove the hot-swap bay, release the front cooling fans first by

pressing the eject mechanism with a small screwdriver. Remove the

six retaining screws as circled above and then the entire hot-swap

bay can be slid out of the chassis.

AP 3000 Hardware Reference Guide

29

Page 30

IV. Hardware Setup

• 4-10. Front Cooling Fans

The front cooling fan module consists of a control board, a hard disk

drive LED status board, and two cooling fans. The message LED

board mounted in the front of the cooling fan module consists of five

sets of LEDs to represent the status of up to five hard disk drives.

Each set has three LEDs which can show the power, activity, and

status of each hard disk drive.

The front cooling fans’ main purpose is to cool the hard disk drives.

These fans can be removed by using a small screw driver to push the

eject mechanism in the fan module. The eject mechanism is behind a

small hole as circled below . There are two individual 2 1/4 inch (6cm)

fans secured by four screws on each fan. The ASMA software will

report an error message when any of these two fans malfunctions.

Front Cooling Fan Control Board

(mounted with the component side

facedown)

IV. Hardware Setup

Front Cooling Fans

Lower Fan

ß‚§‚

Upper Fan

Hard Disk Drive Message Board (LEDs)

IMPORTANT

Usually, the rotation of the fan sends air toward the manufacturer’s

label on the center of the fan.

30

AP 3000 Hardware Reference Guide

Page 31

IV. Hardware Setup

Connects to the SCSI

Back plane Board

3-pin

Fan Header

Pin 1

8 1

16 9

3-pin

Fan Header

LED Board Header

(connects to the LED

board through a ribbon

cable)

Front Cooling Fan Control Board

A cable connects the front cooling fan control board and the hard

disk drive message board. Orient the red markings on each end of the

cable to pin 1.

Pin 1

8 1

16 9

of LEDs

Green

RedFirst Set

Yellow

Fifth Set

of LEDs

Hard Disk Drive Message Board

Orient the red markings on the other end of the cable to pin 1. If the fifth set

of LEDs fails, it can be indicating a faulty front cooling fan control board

condition. Remove the control board and send it back to your dealer.

Message LED Description

Green: Power LED

Yellow: Hard Disk Access LED

Red: Hard Disk Status LED

Power LED Status LED Description

off off Power subsystem OK and ready for hard drive insertion

on off Hard disk drive is ready for operation

on on Hard disk drive failure (*)

on fast flash RAID is rebuilding (*)

on slow flash Hot-spare hard disk drive ready (*)

fast flash on Hard disk drive failure/short circuits

fast flash fast flash Fan failure

* Must be provided by RAID controller’s SAF-TE function.

Front Cooling Fans

IV. Hardware Setup

AP 3000 Hardware Reference Guide

31

Page 32

IV. Hardware Setup

• 4-11. SCSI Backplane

The SCSI backplane of this server is comprised of one SCSI board (DABP5) with Ultra2 SCSI connectors, power inputs, and SCSI ID dip switches.

This configuration allows Ultra2 SCSI SCA hard disk drives to be docked

into the server . The SCSI board (DA-BP5) does not have auto termination,

therefore the included terminator block must be used on the end connector .

SCSI Backplane

Front Side

IV. Hardware Setup

SCSI Backplane

PWR3

Connector

PWR2

Connector

PWR1

Connector

SMB Out

SCSI ID Select DIP Switches

Fan Connector

SMB In

Connects to a SCSI

controller through

the Ultra2 cable

The provided terminator must be

placed on this bottom SCSI connector.

SCSI Backplane

Back Side

1.6” Tray

Connector #5B

1.6” Tray

Connector #3B

1.6” Tray

Connector #1

32

1” Tray

Connector #5

1” Tray

Connector #4

Fan Control Board

Connector

1” Tray

Connector #3

1” Tray

Connector #2

1” Tray

Connector #1

AP 3000 Hardware Reference Guide

Page 33

IV. Hardware Setup

• 4-12. SCSI ID Setting

SCSI ID settings are made through DIP switches located on the SCSI board.

The SCSI board has four dip switches to set the hard drive’s power-ON

delay and SCSI ID.

SCSI ID Setting

IDSEL1 IDSEL0 Slot1 Slot2 Slot3A/3B Slot4 Slot5A/5B

off off Reserved

on on 15 12 11 8 3

on off 14 9 6 4 1

(*)

off on 13 10 5 2 0

(*) Default

Hard Disk Drive Power On Delay

RMT_START DLY_START Description

off off Motor (spin) up when powering on

on off Motor (spin) up after START UNIT command

off on Motor (spin) up after 12xSCSI ID ms

(*)

on on Reserved

(*) Default

SCSI ID Dip Switches

DLY_START

RMT_START

IDSEL 1

IDSEL 0

ON

1 2 3 4

IDSEL1 IDSEL0 Slot1 Slot2 Slot3A Slot4 Slot5A

ON

ON

ON

IDSEL 1=off

IDSEL 0=off

IDSEL 1=on

IDSEL 0=on

IDSEL 1=on

IDSEL 1=off

off off Resv.

on on 15 12 11 8 3

on off 14 9 6 4 1

Default setting

ON

1 2 3 4

DLY_START on

RMT_START off

IDSEL 1 off

IDSEL 0 on

SCSI ID Setting

IV. Hardware Setup

ON

ON

IDSEL 1=off

IDSEL 0=on

off on 13 10 5 2 0

AP 3000 Hardware Reference Guide

33

Page 34

IV. Hardware Setup

SCSI ID Dip Switches (Cont’)

IDSEL1 IDSEL0 Slot1 Slot3B Slot5B

ON

ON

ON

ON

ON

All SCSI devices must have a SCSI identification number that is not in

use by any other SCSI device. SCSI devices vary in how they set the ID

number. Refer to the product manual for any additional devices that

you may install for details on how to set its ID number.

Expansion Card Stabilizer

IV. Hardware Setup

• 4-13. Expansion Card Guide

IDSEL 1=off

IDSEL 0=off

IDSEL 1=on

IDSEL 0=on

IDSEL 1=on

IDSEL 1=off

IDSEL 1=off

IDSEL 0=on

NOTE

off off Resv.

on on 15 11 3

on off 14 6 1

off on 13 5 0

The chassis provides an adjustable expansion card guide to help hold

expansion cards in their slots.

Securing

Expansion Card

Guide

The expansion card guide is

mounted by four screws on the

top and bottom edge of the chassis. There are 18 knobs on the

stabilizer . Turn the knob over the

appropriate expansion card

counterclockwise to extend the

Knob

Metal Arm

metal arm under each knob.

Keep turning until the arm is

firmly pressed against the expansion card. Turn the knob clockwise to retract the metal arm.

34

AP 3000 Hardware Reference Guide

Page 35

IV. Hardware Setup

• 4-14. SCSI Termination

Terminating the SCSI bus “chain” is necessary for SCSI devices to work

properly. Ultra2 devices do not have termination jumpers and must be terminated using a terminator on the SCSI cable which means you cannot

connect a device on the last connector.

Female Terminator for SCSI cable Male Terminator for SCSI Board

• 4-15. Power Supply

SCSI/Power

IV. Hardware Setup

Power Supply Mounting

Mounting and unmounting the power supply must be done from the

inside. Four screws are used to secure the power supply to the chassis

back side.

AP 3000 Hardware Reference Guide

35

Page 36

IV. Hardware Setup

Power Supply Information

Output Voltage Regulation, Ripple, and Noise

Output Voltage Limits (Vdc) Ripple/Noise

Output Min Nom Max Maximum

1 3.17V 3.30V 3.46V 50mV

2 4.80V 5.00V 5.25V 50mV

3 11.40V 12.00V 12.60V 120mV

4 -4.50V -5.00V -5.50V 120mV

5 -10.92V -12.00V -13.20V 120mV

6 4.75V 5.00V 5.25V 50mV

Output Current Capacity

Output Nom (Vdc) Max (A) Min (A)

1 3.3V *20.0 1.0

2 5.0V *45.0 2.0

3 12.0V 12.0 0.5

IV. Hardware Setup

Power Supply Info

4 -5.0V 0.5 0.0

p-p

p-p

p-p

p-p

p-p

p-p

5 -12.0V 0.5 0.0

* Total output power for 3.3V and 5V combined shall be 210W

Input V oltage

Range Min (V) Nom (V) Max (V)

Range 1 90 120 137

Range 2 180 230 265

Safety

The power system meets all applicable clauses for UL 1950 2nd edition without D3 deviations. The power system passes all tests for CUL and TUV

safety.

EMI

The power system, operating with resistive load, meets FCC class B and

CISPR 22 class B conducted limits.

36

AP 3000 Hardware Reference Guide

Page 37

IV. Hardware Setup

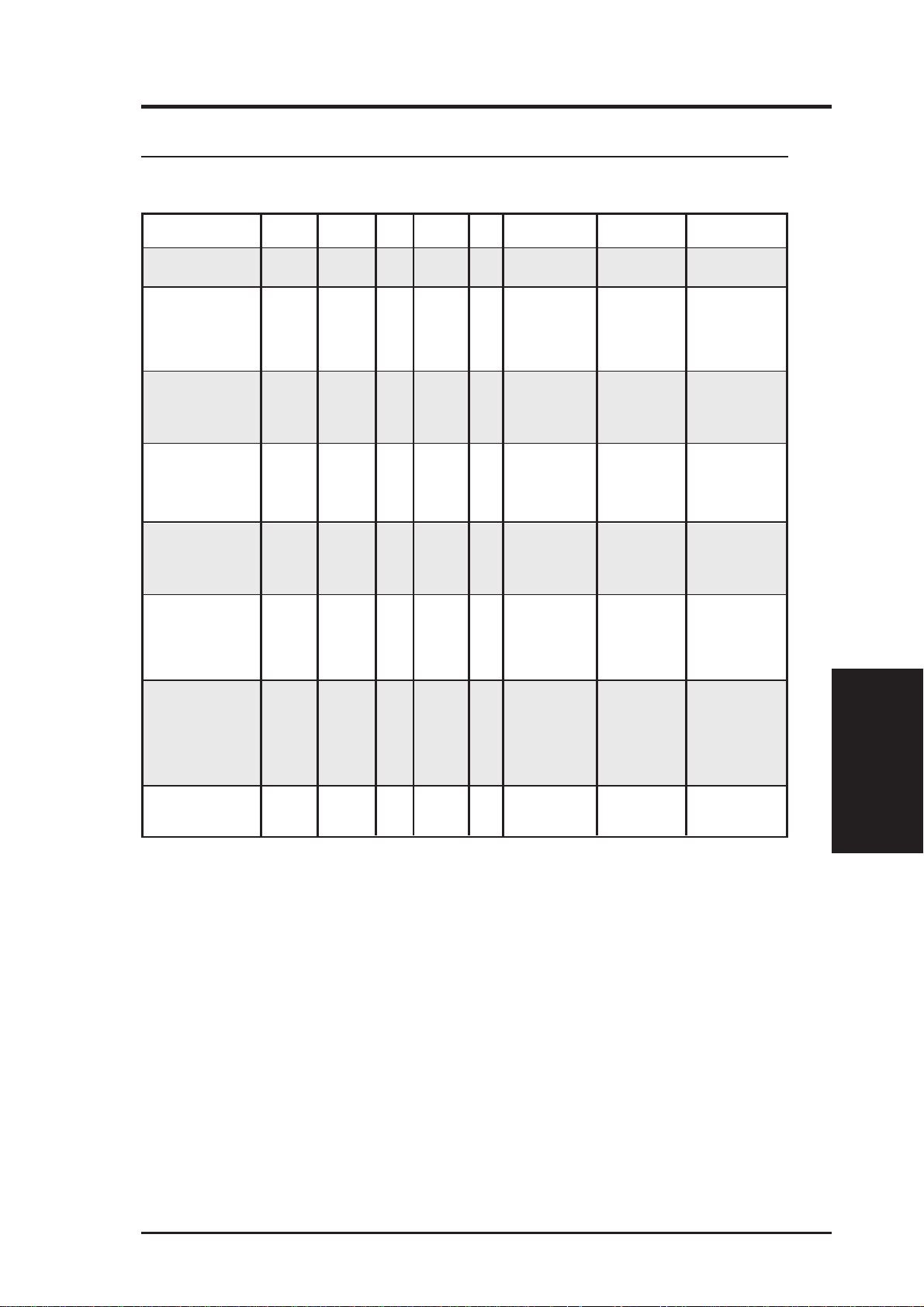

• 4-16. Power Supply Requirement

Power Supply Requirement Calculation Table

Item Volts Amp x Qty. = Total Amp Watts (5V) Watts (12V)

T otal

Motherboard Power

Hard Drive 5.0V 1.3 x =

12V 1.5 x =

CD-ROM 5.0V x =

12V x =

Tape Drive 5.0V x =

12V x =

209.55 3.6

Floppy Drive 5.0V x =

12V x =

System Fans 5.0V x =

12V 0.3 x = 0.6 7.2

Other 3.3V x =

5.0V x =

12V x =

Total Power

Power Supply

IV. Hardware Setup

AP 3000 Hardware Reference Guide

37

Page 38

(This page was intentionally left blank)

38

AP 3000 Hardware Reference Guide

Page 39

V. Appendix

i. SCSI Cable Limits

SCSI cables have a limit to the length that it may have. Exceeding the length

may cause problems mounting or using any one of the SCSI devices.

CAUTION

Exceeding the SCSI cable limits may cause unreliable data transfers even if all the devices are mounted properly.

Cable Limits Max Data Transfer Rates Max Devices

1) 12m (29.4ft) Ultra2-SCSI (68 pin 80MB/Sec) 15

2) 3m - 1.5m Wide Ultra-SCSI (68 pin 40MB/Sec) 4 - 8

3) 3m (9.8ft) Wide-SCSI (68 pin 20MB/Sec) 15

4) 3m - 1.5m Narrow Ultra-SCSI (50 pin 20MB/Sec) 4 - 7

5) 3m (9.8ft) Narrow Fast-SCSI (50 pin 10MB/Sec) 7

IMPORTANT

• Narrow refers to 50 pin and Wide refers to 68 pin. Don’t get

confused by the width of the connector or cable.

• The SCSI ID for devices on one connector cannot be the same

as the SCSI ID for devices on the other connectors. None of the

devices on any connector can use ID7, which is reserved for

the SCSI controller.

• A maximum of 15 devices may be connected to the motherboard

(three connectors) at one time.

NOTE

• A total of 15 “Ultra2-SCSI” devices (ID0-ID15) may be connected

to the 68-pin Ultra2 connector on the motherboard.

• If connecting Fast/Ultra devices with Ultra2 devices on the Ul-

tra2 connector, the entire SCSI bus will be limited to the Ultra

SCSI conditions listed above. Mixing SCSI devices is highly

not recommended.

• A total of 8 “Wide Ultra-SCSI” devices (ID0-ID15) may be con-

nected to the 68-pin Wide connector if using a 1.5m (4.9ft) cable,

but only 4 “W ide Ultra-SCSI” devices if using a 3m (9.89ft) cable.

Ultra-SCSI technology is unstable over long lenghts, therefore stability will depend on they quality of your cable and devices.

• A total of 15 “Wide-SCSI” devices (ID0-ID15) may be connected

to the 68-pin Wide connector.

• A total of 7 “Narrow Ultra-SCSI” devices (ID0-ID6) may be

connected to the 50-pin Narrow connector when using 1.5m

(4.9ft) cable but only 4 devices when using 3m (9.8ft) cable.

Ultra-SCSI technology is unstable over long lengths, therefore

stability will depend on the quality of your cable and devices.

• A total of 7 “Narrow Fast SCSI” devices (ID0-ID7) may be con-

nected to the 50-pin Narrow connector.

V. Appendix

SCSI Cable Limits

AP3000 Hardware Reference Guide 39

Page 40

V. Appendix

ii. Glossary

Byte (Binary Term)

One byte is a group of eight contiguous bits. A byte is used to represent a

single alphanumeric character, punctuation mark, or other symbol.

CHKDSK (Check Disk)

An MS-DOS command that gives you information such as disk space, files,

and directories on your hard disk drive.

COM Port

COM is a logical device name used to designate the computer serial ports.

Pointing devices, modems, and infrared modules can be connected to COM

ports. Each COM port is configured to use a different IRQ and address

assignment.

CPU (Central Processing Unit)

The CPU, sometimes called “Processor,” actually functions as the “brain”

of the computer. It interprets and executes program commands and processes all the data stored in memory. Currently, there are socket 7, slot 1,

and slot 2 CPUs. Intel Pentium Processors fit on socket 7, Intel Pentium II

fit on slot 1, and Intel Xeon fit on slot 2.

V. Appendix

Glossary

FDISK (Fixed Disk Setup Program)

An MS-DOS program used to partition the hard disk drive. FDISK is required to setup a new non-RAID hard disk drive before formatting and installing an operating system.

IDE (Integrated Drive Electronics)

IDE devices integrate the drive control circuitry directly on the drive itself,

eliminating the need for a separate adapter card (in the case for SCSI devices). UltraDMA/33 IDE devices can achieve up to 33MB/Sec transfer.

LPT Port (Line Printer Port)

Logical device name reserved by DOS for computer parallel ports. Each

LPT port is configured to use a different IRQ and address assignment.

PCI Bus (Peripheral Component Interconnect Local Bus)

PCI bus is a specification that defines a 32-bit data bus interface. PCI is a

standard widely used by expansion card manufacturers.

40 AP3000 Hardware Reference Guide

Page 41

V. Appendix

Peripherals

Peripherals are components on the outside of the computer such as a monitor, printer, keyboard, or mouse. Peripherals are attached to the computer

via I/O ports. Peripheral devices allow your computer to perform an almost

limitless variety of specialized tasks.

POST (Power On Self Test)

When you turn on the computer, it will first run through the POST, a series

of software-controlled diagnostic tests. The POST checks system memory,

the motherboard circuitry , the display , the keyboard, the diskette drive, CPU,

and other I/O devices.

PS/2 Port

PS/2 ports are based on IBM’s Micro Channel Architecture. This type of

architecture transfers data through a 16-bit or 32-bit bus. A PS/2 mouse and/

or keyboard may be used on ATX motherboards.

RAID (Redundant Array of Inexpensive Disks)

RAID can be set up to provide mirroring (for fault tolerance), parity (for

data guarding), or striping (for data distribution over several drives for increased performance). A RAID card is required to setup a RAID system.

RAM (Random Access Memory)

There are several different types of RAM such as DRAM (Dynamic RAM),

EDO DRAM (Extended Data Out DRAM), SDRAM (Synchronous DRAM).

ROM (Read Only Memory)

ROM is nonvolatile memory used to store permanent programs (called firmware) used in certain computer components. Flash ROM (or EEPROM) can

be reprogrammed with new programs (or BIOS).

SCSI (Small Computer System Interface)

High speed parallel interface defined by the X3T9.2 committee of the American National Standards Institute (ANSI) for connecting many peripheral

devices.

UPS (Uninterruptible Power Supply)

A battery system that can provide power to an electronic device or computer when power fails in the building. A passive UPS only provides power .

An active UPS provides power conditioning that offers protection against

transient power conditions and short-term power outages.

Glossary

V. Appendix

AP3000 Hardware Reference Guide 41

Page 42

(This page was intentionally left blank.)

42

AP3000 Hardware Reference Guide

Loading...

Loading...