Page 1

USE AND MAINTENANCE

Euro 3

GB

HANDBOOK

Page 2

Page 3

USE AND MAINTENANCE

Euro 3

GB

HANDBOOK

Page 4

The company ASTRA VE I COLI INDUSTRIAL I reserves the righttomakeany modifications to vehicles for technical or commercial reasons at any time; the in f orm a tion , description s and illustrations contained in this publication are therefore correct at the time going to

press.

This Use and Maintenance Handbook deals with optional equipme nt which cannot be present on your vehicle, and alternative equipment

as well (e.g. mechanical and automatic gearbox).

Moreover, the regulations in force in certain countries affect the standard equipment of the vehicle.

This publication could therefore contain information and illustrations not corresponding to the vehicle version provided on a particular market.

ASTRA Veicoli Industriali

Product Logistics

Via Caorsana, 79 --- 29100 PIACENZA (Italy)

Tel. 0523/5431 --- Fax 0523/543459

Print cat. A3502196

First edition - DECEMBER 2011

Second edition - FEBRUARY 2012

Prepared by SIPAL S.p.A. --- Torino (Italy)

Reproduction, whether total or partial, of the text and illustrations is strictly forbidden.

Page 5

HD9 Euro3

I

Introduction VII....................................

After sales service VIII..............................

Warning IX........................................

TECHNICAL DATA 1-1.........................

Position of vehicle identification data plates 1-3.........

Model identification plate 1-3.........................

Imprinting of the vehicle chassis 1-3..................

Vehicle identification plate 1-3........................

Chassis punching 1-4...............................

Vehicle registration number 1-4.......................

Vehicle identification plate 1-5........................

Engine 1-6........................................

Main specifications 1-6..............................

Manual transmission 1-9............................

Clutch 1-9.........................................

Gear shift 1-9......................................

Ratios 1-9.........................................

T ransfer distributor 1-10............................

Axles 1-11.......................................

Front steering axle 1-11............................

Front steering drive axle 9 ton 1-11...................

Front steering drive axle 10 ton 1-11..................

Single rear drive axle 1-12..........................

Tandem rear drive axles 1-12........................

Brakes (simplex without ABS) 1-13...................

Brakes (duplex with ABS) 1-14......................

ABS 1-14........................................

Tyr e s 1 - 1 5........................................

Suspension 1-16..................................

Steering 1-17.....................................

Vehicles without auxiliary cylinder 1-17...............

Vehicles with auxiliary cylinder 1-17..................

Electrical system 1-18..............................

Chassis 1-19.....................................

Standard fuel tank 1-19............................

Oversize fuel tank 1-19.............................

Tightening torques 1-20............................

Vehicle outfitting 1-22..............................

Keys 1-22........................................

INSTRUCTIONS FOR USE 1-23..............

General instructions for correct use of the vehicle 1-25..

Rangeofuseoftheengine 1-28.....................

Left hand drive vehicles 1-29........................

Cab-external 1-29.................................

External lighting 1-30..............................

Front lights 1-30..................................

Rear lights 1-31...................................

Doors 1-32.......................................

Central locking remote control 1-34..................

Replacing remote control battery 1-35................

Driver’s seat 1-36.................................

Internal lighting device 1-38.........................

Upper dashboard 1-38.............................

External rear view mirrors 1-39......................

Mirror selection and handling 1-40...................

Seats 1-42.......................................

Fore and aft adjustment 1-42........................

Cushion angle adjustment 1-42.....................

Seat suspension adjustment 1-42....................

Springing system adjustment 1-43...................

Height adjustment 1-43............................

Backrest angle adjustment 1-43.....................

Seat belts 1-44...................................

Electric window control 1-46........................

Electric window risers control 1-46...................

Hatch 1-47.......................................

Compartments 1-48...............................

Dashboard 1-48..................................

Upper dashboard 1-48.............................

Door 1-49........................................

Page 6

II

HD9 Euro3

Tunnel 1-49......................................

Seat 1-49........................................

Rear wall 1-49....................................

Accessories - devices 1-50.........................

Sun blind tabs 1-50................................

Grip handle 1-50..................................

Coat hook 1-50...................................

Cigar lighter 1-50..................................

Ashtray 1-50......................................

12Volt current socket 1-50..........................

Controls 1-51....................................

Controls on dashboard 1-51........................

Module holder dashboard controls 1-52..............

Steering wheel position control 1-53..................

Accelerator 1-54..................................

Service brake 1-54................................

Clutch 1-54.......................................

Manual transmission control 1-55....................

All vehicles 1-56..................................

Instruments 1-56..................................

Instrument panel 1-56..............................

Functions of instrument panel keys 1-58..............

Warning lights panel A details 1-59...................

Warning lights panel B details 1-60...................

Warning lights panel C details 1-61..................

Warning lights on dashboard 1-62...................

Control operation 1-64.............................

Position and headlight controls 1-64..................

Headlight control 1-64.............................

Direction indicator control 1-65......................

Horn 1-65........................................

Windscreen washer/wiper control 1-66...............

Ignition switch 1-67................................

Engine braking control - Vehicles without

intarder 1-67.....................................

Engine braking control - Vehicles with intarder 1-67.....

Cruise control 1-68................................

Hazard light control 1-69...........................

Exhaust brake pre-selection 1-69....................

Courtesy light switch 1-70..........................

Electro-pneumatic horn pre-selection 1-70............

Swivelling light control 1-71.........................

Work light 1-71...................................

Rear fog light 1-71.................................

Fog light control 1-72..............................

Electric battery isolator control 1-72..................

ASR off command 1-73............................

ABS off command 1-74............................

Distributor-reducer (transfer) 1-75....................

Differential lock control (2 axle vehicles) 1-76..........

Reat longitudinal distributor and transverse

differential lock (4x4 vehicles only) 1-76...............

Rear transverse differential lock

(4x2 vehicles only) 1-76............................

Differential lock control (3-4 axle vehicles) 1-77........

Interaxle longitudinal differential lock and rear

transverse differential lock 1-77......................

Longitudinal distributor differenital lock

(6x6, 8x6 and 8x8 vehicles only) 1-77.................

Power take off control 1-80.........................

Multipower PTO on flywheel 1-81....................

P.T.O. manual transmission 1-82.....................

Tachometric simulator 1-83.........................

Heating and ventilation 1-85........................

Climate control system air vents 1-85.................

Climate controls 1-86..............................

Most common control position 1-88..................

Auxiliary heater (WEBASTO) 1-92....................

Auxiliary heater control panel 1-93...................

Operation of the heater with key-off without

programming 1-95................................

Page 7

HD9 Euro3

III

Operation of the heater with key-on without

programming 1-96................................

Use of the vehicle 1-97.............................

Precautions for the initial period of use 1-97...........

General checks 1-97...............................

Refuelling 1-98...................................

Starting engine 1-99...............................

Checks before starting 1-99.........................

Starting from the driver’s cabin 1-100.................

Starting from engine bay 1-101......................

Tow starting 1-101.................................

Emergency electrical power 1-102...................

Cold start 1-104...................................

Starting with heater 1-105..........................

Stopping engine 1-106.............................

Stopping from drivers cabin 1-106...................

Stopping from engine bay 1-106.....................

Manual transmission vehicles 1-109..................

Starting the vehicle 1-109...........................

Driving the vehicle 1-110...........................

Gearbox 1-112....................................

Gearbox control 1-112.............................

Operating the clutch 1-113..........................

Splitter control 1-114...............................

Stopping the vehicle 1-115.........................

All vehicles 1-117.................................

Speed programmer 1-117..........................

Engine idle speed adjustment / memorising 1-117.....

Vehicle speed (cruise control) adjustment /

memorising 1-119.................................

Enable 1-121.....................................

Changing setting 1-122............................

Tip Function 1-122................................

Ramp Function 1-122..............................

Permanent disable 1-123...........................

Temporary disable 1-123...........................

Engine brake control selection

(vehicles without intarder) 1-124.....................

Engine brake and intarder control selection

(vehicles fitted with intarder) 1-126...................

Vehicle parking 1-129..............................

Parking brake 1-130...............................

Parking brake - vehicles without trailer 1-130..........

Parking brake - vehicle with trailer 1-131..............

Parking brake efficiency check 1-131.................

Additional parking brake 1-132......................

A.B.S. Anti-lock braking system 1-133................

Semi-trailer coupling 1-134.........................

Coupling 1-134...................................

Check closure 1-135...............................

Uncoupling 1-135.................................

ABS coupling (if foreseen) 1-135....................

Pivoting fifth wheel 1-136

Trailer hooking - I type 1-137........................

Trailer hooking - II type 1-138.......................

Norms for towing trailer / semi-trailer 1-139............

T railer coupling 1-140..............................

Semi-trailer coupling 1-140.........................

Ladder 1-140.....................................

Towing the vehicle 1-141...........................

Wheel change 1-146...............................

Diagnostics - Vehicle 1-151.........................

Quick guide to the most common problem 1-151......

Quick guide to most common problems - Vehicles

steering system with steering emergency circuit

without auxiliary cylinder 1-151......................

Quick guide to most common problems - Vehicles

steering system with steering emergency circuit

with auxiliary cylinder 1-152.........................

Diagnostics - Control systems 1-153.................

...........................

Page 8

IV

HD9 Euro3

MAINTENANCE INSTRUCTIONS 1-155......

Introduction 1-157.................................

Opening radiator grill 1-158.........................

Tilting the cab 1-159...............................

Lifting the cab 1-159...............................

Lowering the cab 1-160............................

Main levels check 1-162............................

Check engine oil level 1-162........................

Check engine coolant level 1-163....................

Check windshield washer level 1-163.................

Engine 1-164.....................................

Changing engine oil 1-164..........................

Replacing engine oil filter F2B 1-166.................

Replacing engine oil filter F3B 1-167.................

Engine oil vapour filter change 1-168.................

Accessory drive belts check 1-169...................

Intake-exhaust valve play adjustment 1-170...........

Injector-pump pre-load adjustment 1-170.............

VGT actuator grease application procedure 1-170......

Fuel feed system 1-171............................

Bleed fuel tank condensation water 1-171.............

Fuel tank water drain 1-172.........................

Purging water from fuel decanter 1-172...............

Replacing fuel filters 1-173..........................

Replacing fuel decanter filter 1-174...................

Fuel circuit bleeding 1-175..........................

Intake system 1-176...............................

Intake system seal check 1-176.....................

Turbocompressor lubrication check 1-176.............

Intercooler external cleaning 1-176...................

Main filter element cleaning/change 1-177............

Safety secondary filter element replacement 1-178.....

Replacing the VGT piloting hoses filtering

element 1-179....................................

Cooling system 1-180..............................

Replacing engine coolant 1-181.....................

Checking antifreeze concentration 1-182..............

Clutch 1-183......................................

Check clutch disengagement 1-183..................

Oil level check 1-183...............................

Changing the hydraulic fluid 1-184...................

Air bleeding 1-184.................................

Multipower PTO 1-185.............................

Oil level check 1-185...............................

Oil change 1-186..................................

ZF NMV 221 power take off 1-187....................

Oil level check/change 1-187........................

Oil filter change 1-187..............................

Gearbox 1-188....................................

Oil level check 1-188...............................

Oil change 1-189..................................

Distributor-transfer (transfer) - type I 1-190............

Oil level check 1-190...............................

Oil change 1-191..................................

Distributor-transfer (transfer) - type II 1-192............

Checking oil level 1-192............................

Changing oil 1-193................................

Transmission shafts 1-194..........................

Greasing 1-194...................................

Axles 1-195......................................

Front axle 1-195...................................

Check differential oil level 1-195.....................

Differential oil change 1-195........................

Hub oil level check 1-196...........................

Hub oil change 1-197..............................

Front axle - 10 ton version / K version 1-198...........

Checking differential oil level 1-198...................

Changing differential oil 1-198.......................

Checking oil hub level 1-199........................

Changing hub oil 1-200............................

Front intermediate axle 1-201.......................

Check differential oil level 1-201.....................

Page 9

HD9 Euro3

V

Differential oil change 1-201........................

Hub oil level check/change 1-201....................

Rear intermediate axle 1-202........................

Oil level check 1-202...............................

Changing oil 1-203................................

Rear axle 1-204...................................

Oil level check 1-204...............................

Changing oil 1-205................................

Suspensions 1-206................................

Leaf spring pins greasing 1-206.....................

Carriage pin greasing on 3 and 4-axle vehicles 1-207...

Steering system 1-208.............................

Oil level check 1-208...............................

Changing the hydraulic oil - Vehicles without

auxiliary cylinder 1-209.............................

Dumping 1-209...................................

Filling 1-209......................................

Bleeding off air 1-210..............................

Changing the hydraulic oil for - Vehicles with

auxiliary cylinder 1-211.............................

Dumping 1-211...................................

Filling 1-211......................................

Bleeding off air 1-212..............................

Replacing oil filter 1-213............................

Stub axle greasing 1-214...........................

Steering linkage grease application 1-215.............

Front wheel toe-in check 1-216......................

Front wheel toe-in check 1-217......................

Compressed air system 1-218.......................

Tank visual inspection 1-218........................

Air drier functionality check 1-219....................

Air dryer filter change 1-220.........................

Braking system 1-221..............................

Shoe-drum play check 1-221.......................

Check pedal distributors 1-221......................

Tyres and wheels 1-222............................

Checking wheels and tyres 1-222....................

Inflating tyres 1-222................................

Cab tipping system 1-223..........................

Oil level check / fluid change 1-223..................

Greasing 1-224...................................

Towing systems 1-225.............................

Greasing the fifth wheel 1-225.......................

Tow hook greasing - Type I 1-226....................

Tow hook greasing - Type II 1-226...................

Air conditioner 1-227...............................

Air-conditioner system maintenance 1-227............

System charge check 1-228........................

Supplementary heater 1-229........................

Replacing the supplementary heater fuel filter 1-229....

Bodywork 1-230..................................

Replacing front windscreen wiper blade 1-230.........

Windscreen washer reservoir 1-230..................

Bodywork maintenance 1-231.......................

Cleaning plastic parts 1-231........................

Cleaning seat belts 1-231...........................

Lighting system 1-232.............................

Headlight/front sidelight bulb replacement 1-232.......

Headlight alignment 1-233..........................

Front direction indicator light bulb replacement 1-234...

Side direction indicator bulb replacement 1-234........

Rear light bulb replacement 1-235...................

Front clearance light bulb replacement 1-236..........

Rotary warning light bulb replacement 1-236..........

Ceiling light bulb replacement 1-236.................

Replacing cab step light 1-236......................

List of bulbs 1-237.................................

Electrical system 1-238.............................

Precautions 1-238.................................

Battery maintenance (unsealed batteries) 1-239........

Recharge with external devices 1-241................

Changing the battery 1-242.........................

Page 10

VI

Interconnection control unit (fuses and relays) 1-243....

Fuse replacement 1-243............................

Fuse / relays holder plate 1-244.....................

Fuses 1-245......................................

Fuse holder (70005) 1-245..........................

Fuse holder (70601) 1-246..........................

Fuse holder (70602) 1-246..........................

Fuse holder (70401) 1-246..........................

Fuse holder (70402) 1-247..........................

Fuse holder (70403) 1-247..........................

Fuse holder (70403) not used 1-247..................

Relays 1-248.....................................

Supplementary relays 1-249........................

Additional relays board 1-250.......................

Supplementary flying fuse 1-251.....................

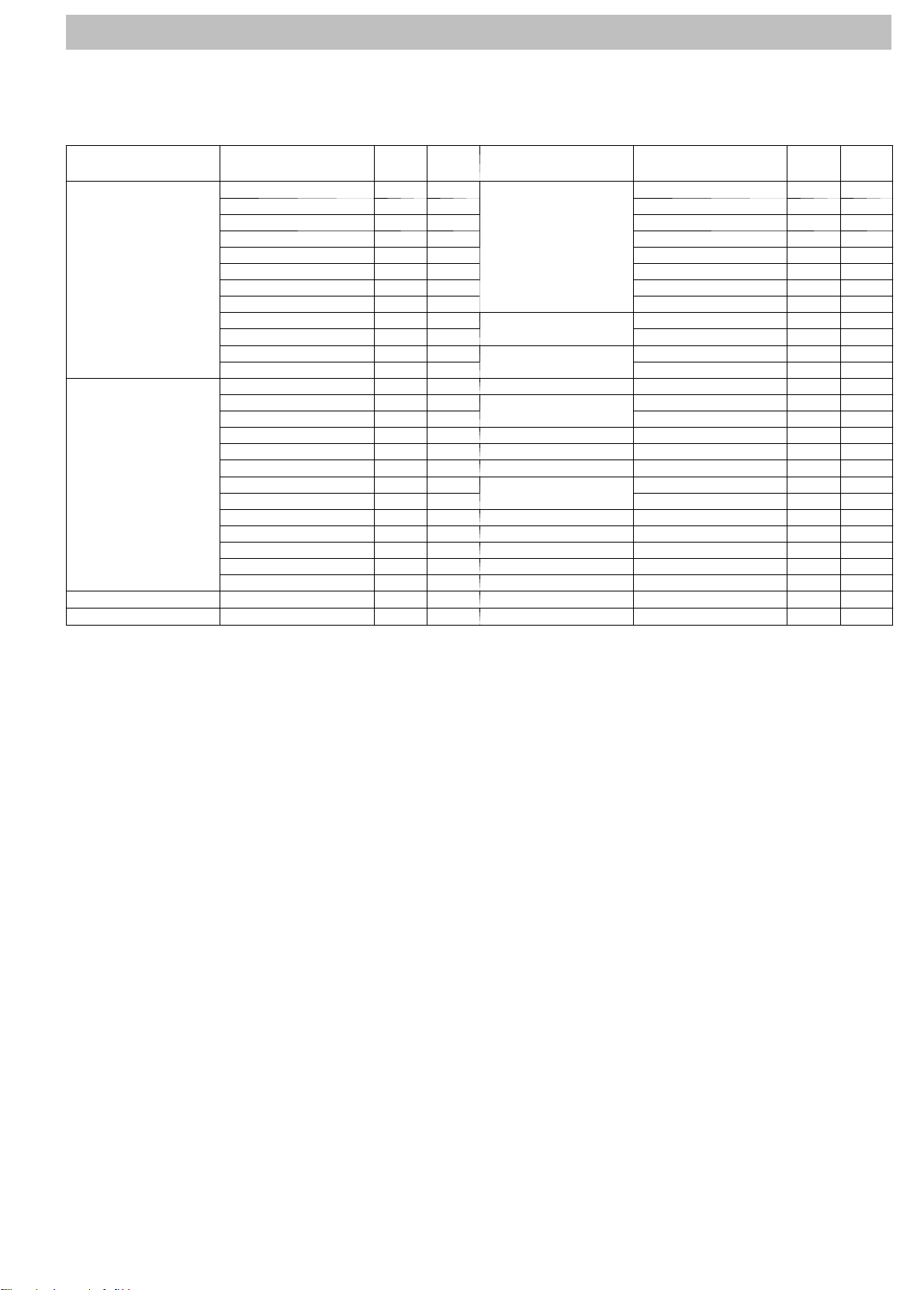

TABLE AND DIAGRAMS 1-253................

Introduction 1-255.................................

Lubricants, oils, hydraulic fluids and filter refilling/

replacement diagram 1-256.........................

2 axle vehicles 1-256...............................

3 axle vehicles 1-258...............................

4 axle vehicles 1-260...............................

Location of components 1-262......................

Engine F3B 1-262.................................

Engine F2B 1-264.................................

Manual transmission 1-266.........................

Multipower/NMV 221 power take off 1-268............

Drive line 1-270...................................

Greasing transmission shaft 1-272...................

Suspension geasing 1-274.........................

Steering linkages, semi-trailer fifth wheel, tow

hook greasing 1-276...............................

Systems 1-278....................................

Service schedule 1-280............................

Lubricant and hydraulic fluid tables 1-284.............

HD9 Euro3

Page 11

HD9 Euro3

INTRODUCTION

This Use and Maintenance Handbook is divided into 4 parts, each of which systematically

subdivided according to subject, for quick and easy consulting.

1) Technical specifications: this contains all the characteristic data which should be read

through at least once to acquire a working knowledge of the vehicle.

2) Use of the vehicle and practical hints: this contains information relevant to the main controls and instruments, and the main rules to be followed especially for new vehicles.

3) Maintenance instructions: this section contains the functional instructions for checking

and maintaining the vehicle which must be implemented to ensure satisfying operation,

cost-effective running and long life of the vehicle.

4) Tables and diagrams: contains vehicle scheduled maintenance tables and diagrams.

In this Use and Maintenance Handbook there are texts that are highlighted in a particular

manner:

VII

Failure to heed and/or correctly carry out

procedures, technical information and

precautions given may cause injury.

Failure to heed and/or correctly carry out

procedures, technical information and

precautions given may cause damage to

the vehicle.

Procedures, technical information and

precautions which must be highlighted.

Failure to heed and/or correctly carry out

procedures, technical information and

precautions given may cause environmental damages.

Page 12

VIII

AFTER SALES SERVICE

Warranty

To comply to the warranty conditions, all the instructions for correct use and maintenance

described in this manual are to be followed.

After-sales service

For any type of servicing the ASTRA V.I. Dealership is at the complete disposal of the Customer. Equipment and skilled staff are available for maintenance or repair jobs. The ASTRA

V.I. Dealership is always willing to offer you hints and advice to ensure you get best performance from your vehicle.

Spare parts

Any spare parts used for replacements are to be “GENUINE ASTRA SPARES” which can be

obtained from the dealer warehouses and authorised workshops. Remember that a correct

order for spare parts must always include the following details:

--- t y p e o f v e h i c l e ;

--- c h a s s i s n u m b e r ;

--- reference and category numbers, to be found in the Spare Parts Catalogue.

If the items are parts of a main group (engine, cab, axles, power steering, gearbox etc.) indicate also the group version and serial number.

HD9 Euro3

Page 13

HD9 Euro3

WARNING

Assembly of accessories, additions and modifications on the vehicle are to be carried out in

conformity with ASTRA directives. The specific document “Directive for conversion and outfittings” can be obtained as a guideline from the After Sales Service workshops.

It is reminded that, especially regarding the electrical system. there are several electrical

sockets available (standard or optionals) to simplify electrical operations carried out by the

outfitters.

For any exemption from the directives for the conversion it is necessary to have authorisation

from ASTRA.

It is strictly forbidden to make modifications or connections to the wiring of electronic control

units. In particular the interconnection lines between control units (CAN lines) are never to

be interfered with.

Diagnostics and maintenance operations are to be carried out by skilled personnel using

approved diagnostics equipment.

Ignoring these afore-mentioned prescriptions will annul the contractual warranty .

IX

The handbook contains use and maintenance instructions for all systems foreseen

on the vehicle by the Manufacturer.

Some systems described in the handbook may not be present on Your vehicle,

according to the chosen version and

market the vehicle is destined for.

Page 14

X

HD9 Euro3

Page left intentionally blank

Page 15

HD9 Euro3

1-1

Technical data

Page 16

1-2

HD9 Euro3

Page left intentionally blank

Page 17

HD9 Euro3

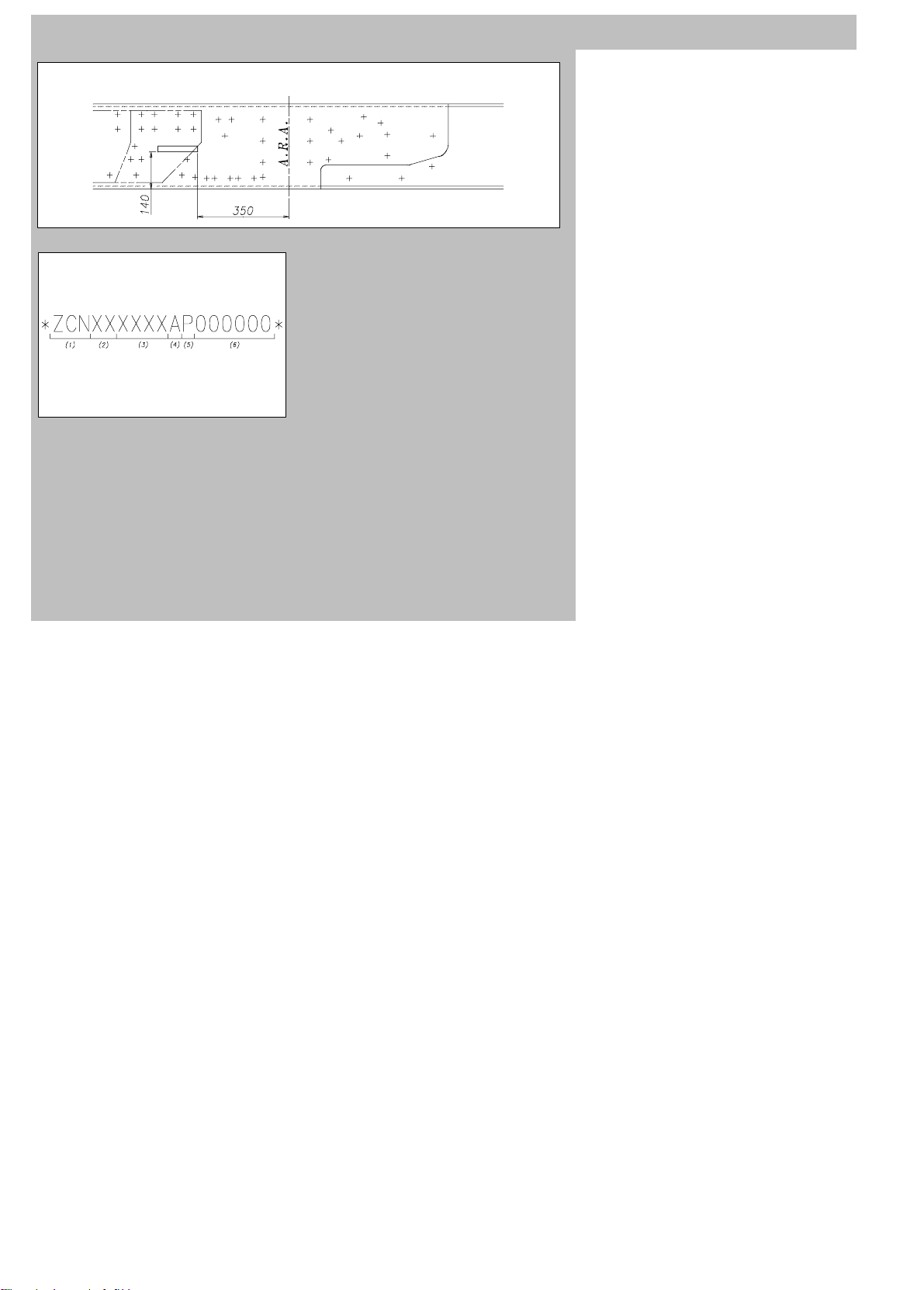

342BNU001L

POSITION OF VEHICLE IDENTIFICATION

1

DATA PLATES

Model identification plate

Located on the side walls of the cab (Fig. 1,

see arrow).

Imprinting of the vehicle chassis

Punch marked at the front end of the righthand side member (Fig. 2, see arrow).

(see following page).

Vehicle identification plate

On bonnet left side in cabin for vehicle identi-

2

fication as per EU standards (Fig. 3, see arrow).

3

1-3

272CDT001

Page 18

1-4

HD9 Euro3

b

1

Chassis punching (Fig. 1)

a. right side member

b. rear axle front leaf spring

a

2

Vehicle registration number (Fig. 2)

1) World–wide identification of manufacturers (Astra Veicoli Industriali S.p.A.)

2) Type of vehicle

3) Vehicle features

4) Year of construction

5) Production facility (P=Piacenza)

6) Chassis number

Page 19

HD9 Euro3

1-5

1

3

Vehicle identification plate (Fig. 3)

1) Type approval number markings

2) Vehicle chassis punch markings

3) Overall vehicle weight

4) Overall tractor + trailer/semitrailer

weight

5) Maximum admissible weight 1st axle

6) Maximum admissible weight 2nd axle

7) Maximum admissible weight 3rd axle

8) Maximum admissible weight 4th axle

9) Maximum admissible weight on fifth

wheel (tractor versions only)

10) Vehicle commercial denomination

11) Axle spacing

12) Engine type

13) Engine power

14) Number of axles

15) Grade of smoke

Page 20

1-6

ENGINE

1

Engine

IVECO F2B (Cursor 8) (Fig. 1)

4-stroke Diesel, liquid cooled, variable geometry exhaust gas turbocharger.

Main specifications

HD9 Euro3

285ADT002L

Number of cylinders

6

Bore mm 115

Stroke mm 125

Total displacement cm

3

7790

Compression ratio 16.5

Injection order 1-4-2-6-3-5

Page 21

HD9 Euro3

ENGINE

1

Engine

IVECO F3B WG (Cursor 13) (Fig. 1)

4-stroke Diesel, liquid cooled, turbocharger

with Wastegate pressure limiter.

Main specifications

1-7

285ADT003L

Number of cylinders

6

Bore mm 135

Stroke mm 150

Total displacement cm

3

12882

Compression ratio 16.5

Injection order 1-4-2-6-3-5

Page 22

1-8

ENGINE

1

Engine

IVECO F3B VGT (Cursor 13) (Fig. 1)

4-stroke Diesel, liquid cooled, variable geometry exhaust gas turbocharger.

Main specifications

HD9 Euro3

285ADT003L

Number of cylinders

6

Bore mm 135

Stroke mm 150

Total displacement cm

3

12882

Compression ratio 16.5

Injection order 1-4-2-6-3-5

Page 23

HD9 Euro3

341BDT001L

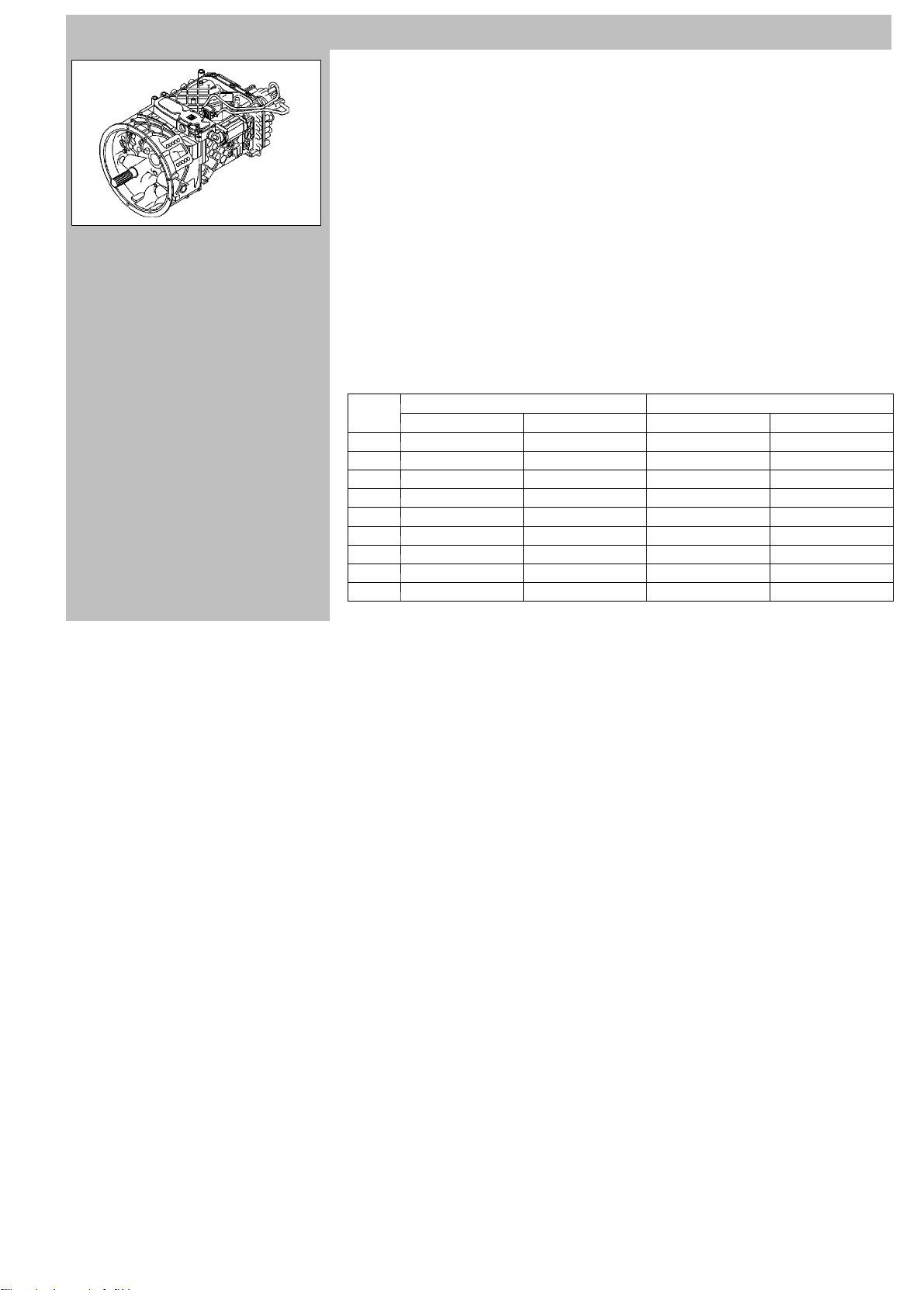

MANUAL TRANSMISSION

1

Clutch

Dry single disk. Diameter 17”.

Hydraulic control.

Gear shift (Fig. 1)

ZF 16 S 1620 TD, ZF 16 S 1820 TO,

ZF 16 S 1920 TD, ZF 16 S 2220 TO,

ZF 16 S 2220 TD, ZF 16 S 2320 TD,

ZF 16 S 2520 TO, ZF 16 S 2720 TO

Syncromesh manual with 8 forward gears,

split into a low range group (1- 4) and a high

range group (5 - 8), and 1 R.G, normal and

low.

Pneumatic servoshift device.

Neutral switch for preventing starting the

motorwithgearengaged.

Hydrodynamic retarder (intarder) mounted

on gearbox output (optional).

Ratios

Direct Drive Over Drive

Normal Low Normal Low

1st 13.80 16.41 11.54 13.80

2nd 9.49 11.28 7.93 9.49

3rd 6.53 7.76 5.46 6.53

4th 4.57 5.43 3.82 4.57

5th 3.02 3.59 2.53 3.02

6th 2.08 2.47 1.74 2.08

7th 1.43 1.70 1.20 1.43

8th 1.00 1.19 0.84 1.00

R.G. 12.92 15.36 10.80 12.92

R.G. = Reverse Gear

1-9

Page 24

1-10

283092101

342ADT001L

TRANSFER DISTRIBUTOR

1

STEYR VG 2700/400 (Fig. 1)

T ransmissio n ratios:

Normal (on road): 0.913

Low (off road): 1.407

Maximum torque at input:

30.000 Nm

IVECO ZF TC 2200 (Fig. 2)

T ransmissio n ratios:

2

Normal (on road): 1.0

Low (off road): 1.6

Maximum torque on input:

22.000 Nm

HD9 Euro3

Page 25

HD9 Euro3

AXLES

1

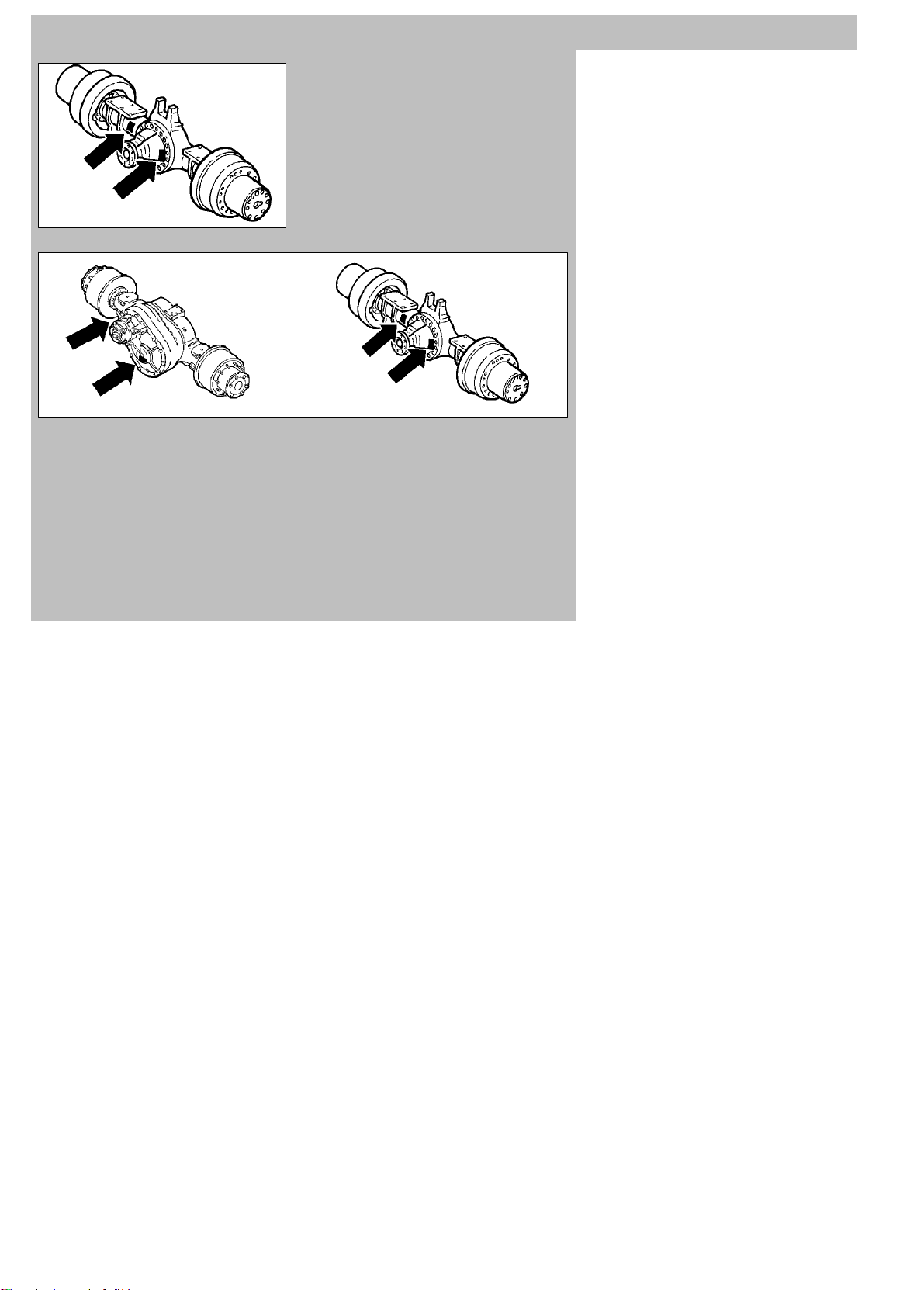

Front steering axle (Fig. 1)

In high strength drop-forged steel, steering

type, not drive.

Front steering drive axle 9 ton (Fig. 2)

With double reduction (central and final) in

wheel hubs by means of epicyclical gear set.

Drive shafts controlling front wheels

equipped with Cardan joints.

Front steering drive axle 10 ton (Fig. 3)

With double reduction (central and final) in

2

wheel hubs by means of epicyclical gear set.

Drive shafts controlling front wheels

equipped with Cardan joints.

3

1-11

Page 26

1-12

HD9 Euro3

1

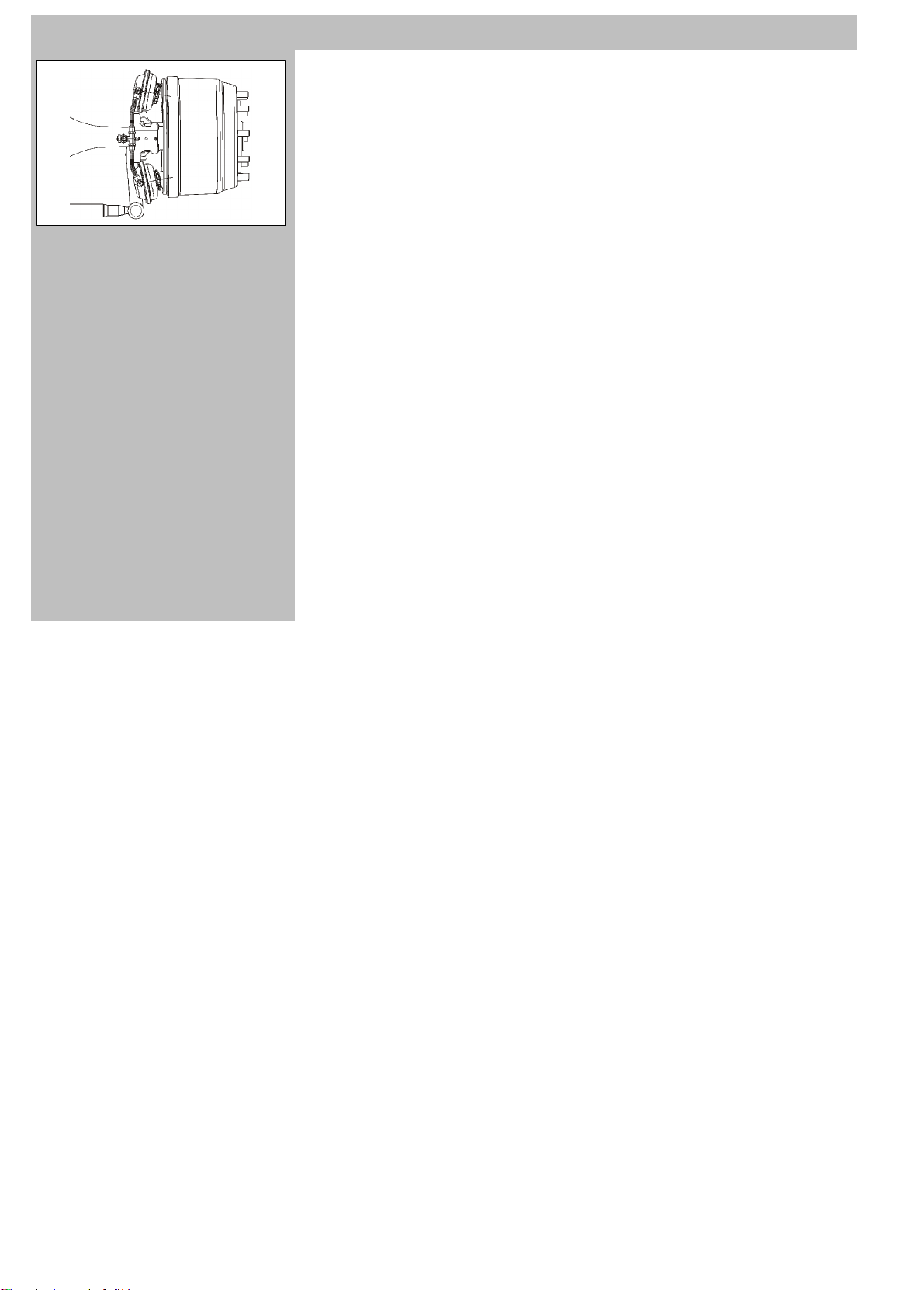

Single rear drive axle (Fig. 1)

With double reduction, central by pinion set

and final in wheel hubs with epycicloid gear.

Differential between wheels with pneumatic

lock.

Tandem rear drive axles (Fig. 2)

Two drive axles in tandem with double reduction, central with bevel gear and final in wheel

hubs with epicyclical gear set.

The tandem is provided with splitter between

axles and pneumatic lock.

Differential between wheels with pneumatic

2

lock.

Page 27

HD9 Euro3

BRAKES (simplex without ABS)

1

Simplex w edge drum brakes (Fig. 1) on all

axles. Brake adjustment is automatic and

therefore maintenance free until total brake

lining wear.

Service brake: pneumatic operation with

two independent sections for vehicles without tow bar, three independent sections for

vehicles with tow bar .

Parking and emergency brake: pneumatic

operation acting on rear wheel brake drums

through spring cylinder.

Engine brake: built into engine.

Retarder brake: hydraulic, installed on tran-

smission.

Auxiliary parking brake: pneumatic opera-

tion: must be engaged with engine running.

1-13

Page 28

1-14

BRAKES (duplex with ABS)

1

Duplex wedge drum brakes (Fig. 1) on all

axles. Brake adjustment is automatic and

therefore maintenance free until total brake

lining wear.

Service brake: pneumatic operation with

two independent sections for vehicles without tow bar, three independent sections for

vehicles with tow bar .

Parking and emergency brake: pneumatic

operation acting on rear wheel brake drums

through spring cylinder.

Engine brake: built into engine.

Retarder brake: hydraulic, installed on

transmission.

Auxiliary parking brake: pneumatic oper-

ation: must be engaged with engine running.

ABS

Wheel anti-lock system (ABS) with four

channel electronic system and four solenoid

valves that exercise the ABS function during

the braking phase.

HD9 Euro3

Pulse generators and sensors on 1st and

2nd axles (2-axle vehicles).

Pulse generators and sensors on 1st and 3rd

axles (3-axle vehicles).

Pulse generators and sensors on 2nd and

4th axles (2-axle vehicles).

Page 29

HD9 Euro3

TYRES

Front: single (*)

Rear: double (**) or single (*)

1-15

DIMENSION

13R22.5

315/80R22.5

CONTINENTAL HSR1 - - 525/65R20.5 MICHELIN XS 8 -

495/45R22.5 MICHELIN XDA2 9 - 525/80R25 MICHELIN XL 7 .

445/65R22.5 MICHELIN XZL 8 - 24R21 MICHELIN XZL 6 .

TYPE

MICHELIN XZY2 8 8

MICHELIN XDY3 8 8 MICHELIN XZY2 8.5 8.5

MICHELIN XZH 8 8 MICHELIN XZL 8.5 8.5

PIRELLI AP05 9 - MICHELIN XZY 8.5 8.5

PIRELLI AT75 - 9 PIRELLI AP05 9 PIRELLI AT99 8.5 8.5 PIRELLI AT75 - 8.5

PIRELLI FG85 9 9 PIRELLI FG85 9 9

PIRELLI TG85 9 9 PIRELLI TG85 9 9

PIRELLI FG88 9 9

PIRELLI TG88 9 9 MICHELIN XDE2TL 9 9

CONTINENTAL HSC - CONTINENTAL HDC - - PIRELLI TG88 9 9

MICHELIN XZY2 8.5 8 20.00R20 CONTINENTAL - MICHELIN XDY3 8.5 8

MICHELIN XZE2 8.5 8 MICHELIN XFA1+ 8.5 -

MICHELIN XDE2 8.5 8 365/85R20 MICHELIN XZL 7.5 -

MICHELIN XDE2+ 8.5 8 365/80R20 MICHELIN XZL 6 -

PIRELLI AP05 8 8 16.00R20 MICHELIN XZL 7.6 7.6

PIRELLI AT75 8 8

PIRELLI FG85 8 8 PIRELLI PS22 PISTA 7 7

PIRELLI TG85 8 8 24.00R20.5 MICHELIN XS 6 -

PIRELLI FG88 8.5 8.5 385/95R24 MICHELIN X 9 -

PIRELLI TG88 8.5 8.5 385/55R22.5 MICHELIN XFA2 9 9

CONTINENTAL HDR - - 395/85R20 MICHELIN XZL 8.5 .

(*)

bar

(**)

bar

DIMENSION TYPE

MICHELIN XDY 8.5 8.5

12.00R20

315/70R22.5

325/95R24

385/68R22.5

14.00R20

MICHELIN XZE2TL 9 9

PIRELLI FG88 9 9

MICHELIN XZY3 9 -

MICHELIN XZL 7.6 7.6

(*)

bar

(**)

bar

Page 30

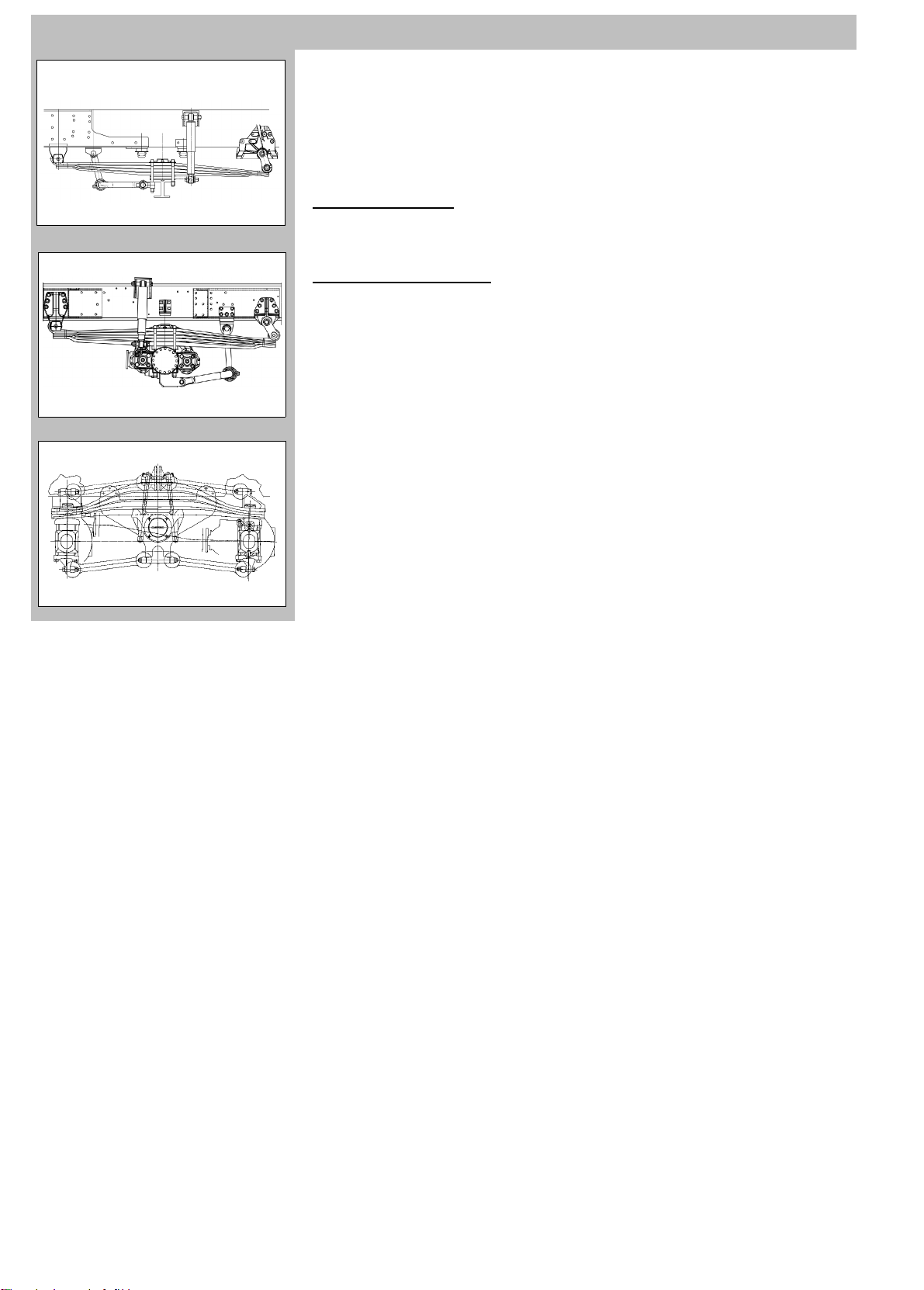

1-16

345CDT001L

SUSPENSION

1

Front (Fig. 1):

Longitudinal single leaf springs. Telescopic

duplex hydraulic shock absorbers and roll

bar.

Rear:

2-axle vehicles (Fig.

Longitudinal double leaf springs.

Telescopic duplex hydraulic shock

absorbers and roll bar.

2

3and4axlevehicles(Fig.

Single leaf springs, individual for the two

rocking axles with rocker system.

The torque bars between axle and central

support counteract the axial thrust on acceleration and braking.

Anti-roll bar on intermediate axle and on rear

axle (upon request).

Leaf spring: parabolic or semi-elliptic (upon

request).

2):

3):

3

HD9 Euro3

345FDT007L

Page 31

HD9 Euro3

STEERING

1

ZF hydraulic ball bearing mounted power

steering.

Vehicles without auxiliary cylinder

Type: 8098 (Fig. 1)

Oil pump driven by engine.

Front wheel steering with quadrilateral kinetic motion assembly.

Vehicles with auxiliary cylinder

2

Type: 8099 (Fig. 2)

Oil pump driven by engine.

Emergency pump driven by transmission.

Front wheel steering with quadrilateral kinematic motion assembly.

Auxiliary cylinder.

1-17

Page 32

1-18

ELECTRICAL SYSTEM

1

Nominal voltage: 24 V

Accumulators (Fig. 1) (n˚ 2):

12 V --- 170 Ah or

12 V --- 220 Ah

A l t e r n a t o r : 28 V --- 9 0 A

HD9 Euro3

274CNU102

Accumulator and alternator features may

change according to the outfitting and

market of destination.

Starter motor

24V - -- 4.5 kW (engine F2B)

24V - -- 5 kW (engine F3B)

Ground reference: negative pole.

Page 33

HD9 Euro3

CHASSIS (Fig. 1)

1

Built with rectilinear side members in high

strength “C” section steel, connected by

riveted or bolted cross-members.

Standard fuel tank

Steel, capacity 300 liters with level and

reserve indicator.

Oversize fuel tank

Steel, capacity 600 liters with level and

reserve indicator.

1-19

Page 34

1-20

TIGHTENING TORQUES

HD9 Euro3

Assembly

Engine

Multipower power take-off

ZF manual transmission

ZF iIntarder

ZF As-T ronic automated transmission

Allison automatic transmission

IVECO splitter

ZF splitter

Wheels

Front axle (Iveco)

Element Type

To r q u e

(Nm)

F2B engine oil magnetic drain plug

F3B engine oil magnetic drain plug

Magnetic oil drain plug

Oil filler cap 25 ÷ 30

Oil drainage, level and filler caps 80

Oil magnetic drain plug on clutch bell M38x1.5 140

Oil filter cover fastening screw

Oil drain plug M25x1.5 60

Side oil drain plugs

Bottom oil drain plug

Filler and level cap

Oil filter cover fastening screw 20 ÷ 25

Oil drain plug 25 ÷ 32

Filler and level cap

Oil drain plug M14x1.5 54 ÷ 66

Magnetic oil drain plug M27x2 90 ÷ 110

Oil filler and level cap M22x1.5 63 ÷ 77

Oil drain plug M22x1.5 60

Oil filler and level cap M22x1.5 60

Fasteners (nut and washer) 580 ÷ 650

Fasteners (countersunk nut) 380 ÷ 450

Magnetic oil drain plug

Oil filler and level plug

Oil drain plug on transfer case

Oil level plug on transfer case

Page 35

HD9 Euro3

1-21

Assembly

Frontintermediateaxle(Iveco)

Rear intermediate axle (Iveco)

Rear axle (Iveco)

Front axle (Kessler)

Intermediate axle (Kessler)

Rear axle (Kessler)

Element Ty p e

To r q u e

(Nm)

Magnetic oil drain plug

Oil filler and level plug 72 ÷ 88

Oil drain plug on transfer case

Oil level plug on transfer case

Magnetic oil drain plug

Oil filler and level plug 100 ÷ 120

Oil drain plug on transfer case

Oil level plug on transfer case

Magnetic oil drain plug

Oil filler and level plug 36 ÷ 44

Oil drain plug on transfer case

Oil level plug on transfer case

Magnetic oil drain plug M16x1.5 60

Oil filler and level plug M30x1.5 160

Oil drain plug on transfer case M16x1.5 60

Oil level plug on transfer case M24x1.5 120

Magnetic oil drain plug M16x1.5 60

Oil filler and level plug M30x1.5 160

Transfer case oil drainage cap M24x1.5 120

T ransfer case oil filler and level plug M24x1.5 120

Oil drain plug on transfer case M16x1.5 60

Oil level plug on transfer case M24x1.5 120

Magnetic oil drain plug M16x1.5 60

Oil filler and level plug M30x1.5 160

Oil drain plug on transfer case M16x1.5 60

Oil level plug on transfer case M24x1.5 120

Page 36

1-22

VEHICLE OUTFITTING

Each vehicle is equipped with a set of toolsand

wrenches so that the Customer can carry out

the normal maintenance operations.

D Lifting j ack.

D Cab tilting jack/rod and wheel wrench.

D n˚ 2chocks.

D Instructionsfor USE AND MAINTENANCE

HANDBOOK.

D Log-book holder.

Keys

Each vehicle is supplied with:

D Ignition/door/fuel filler cap keys (3).

D Door lock remote control (optional).

HD9 Euro3

Page 37

HD9 Euro3

1-23

Instructions for use

Page 38

1-24

HD9 Euro3

Page left intentionally blank

Page 39

HD9 Euro3

1-25

GENERAL INSTRUCTIONS FOR CORRECT USE OF THE VEHICLE

Before driving

Adjust the seat, steering wheel and rear-view mirrors to obtain a correct driving position.

Check that there are no obstructions to pedal excursion, in particular the brake pedal.

Check that the horn works correctly.

Check that all external lights function correctly, and if necessary clean the lighting groups.

Check, especially when travelling by night, that headlights are correctly aligned.

Check that no oil or fluids are leaking from under the vehicle.

Check that any cargo is correctly stowed.

Check that the handbrake is on and that no dashboard warning light indicates a fault.

To prevent accidental vehicle movements, disengage the handbrake with the brake pedal pressed.

Do not apply transfers or stickers to the windscreen: these could distract or impair vision.

When driving

Long journeys should only be undertaken in ideal physical conditions.

Light, easily digestible meals help in keeping reflexes ready as well as maintaining the concentration required for safe driving.

Never drive for too many consecutive hours, but make frequent stops, taking the opportunity to stretch and generally refresh.

Make use of the wide range of adjustments offered by the heating, ventilation or air-conditioning system to maintain constant cabin air

change.

The abuse of alcohol, drugs and or certain medicines is extremely dangerous. Never undertake a journey under the influence of alcohol,

pharmaceuticals or drugs.

Careful driving also means being in a condition to foresee the mistakes or carelessness of other drivers.

Always observe speed limits and always drive in the slow lane on motorways.

Always use indicators when changing direction or lane.

Keep a safe distance from the vehicle in front. This distance varies according to speed, weather, traffic and road conditions.

Never drive with the gearbox in neutral.

Never freewheel downhill: With the engine off there is no engine braking, requiring greater force on the brake pedal.

Use engine braking by engaging a low gear to avoid overheating the brakes.

In case of breakdown, park the vehicle off the carriageway, switch on the hazard warning lights and set up the red reflecting triangle sign

to warn other drivers. Always follow the Highway Code.

Page 40

1-26

HD9 Euro3

Night driving

Take special care, reducing speed if necessary, especially on unlit roads.

Keep a greater safety distance than when driving by day: in effect it is more difficult to estimate the speed of an approaching vehicle when

only its lights are visible.

Stop and rest as soon as you feel tired. To continue would only be a hazard to yourself and others.

Use high beams only outside built-up areas an only when you are sure they do not other drivers.

Always dip headlights with oncoming traffic.

Driving in rain, fog and snow

If the road is wet the grip between the tyres and the road surface is significantly reduced, so braking distance is greater and grip when turning

is reduced. Reduce speed and keep a greater distance from the vehicles in front.

Heavy rain and fog reduce visibility. In compliance with the Highway Code, switch on dipped headlights even by day to render your vehicle

more visible.

Do not drive through puddles or flooded sections of road at high speed. Aquaplaning may cause loss of control. Use engine braking and

in all cases avoid braking sharply .

Set ventilation controls to ensure efficient windscreen demisting.

Before starting out, check the condition of windscreen wipers. If temperature is below 0˚, or if it is snowing, check that the wiper blades and

not frozen against the windscreenProceed with extreme caution in case of fog. Moderate speed and avoid overtaking if possible.

Check that windscreen/headlight washer fluid contains antifreeze and anti-scale products.

In winter, even apparently dry roads may have icy patches, especially sections in the shade or lined by trees or rocks.

Parking

Switch off the engine.

Engage the parking brake.

Engage 1st gear if the vehicle is parked on a slope or reverse gear if the vehicle is facing downwards (manual gearshift vehicles only).

Never leave the key turned to MAR with the engine off to avoid flattening the batteries.

Tyr e s

Always reduce speed before taking on a tight bend, even if vehicle performance permits.

Avoid sharp acceleration of heavy braking.

Do not drive at constant high speeds for long periods, especially on uneven road surfaces.

Make certain that wheels are correctly balanced and adjusted.

Avoid violent impacts to tyre walls (for example when parking).

Nevertamperwithtyreinflationvalves.

Page 41

HD9 Euro3

1-27

Do not insert any kind of tool between tyre and wheel rim.

If the rim is damaged, replace it.

If a tyre loses pressure for no apparent reason, replace the wheel and check the faulty tyre.

Tyre pressures, including the spare, must always be as specified.

Tyres that are old (over 6 years) or used should only be used in case of emergency and with due caution.

Do not leave the vehicle parked for long periods on the edge of the kerb or similar irregularities on the road surface.

Regularly check tyre tread depth, changing tyres when depth is less than the legal minimum.

The vehicle mounts ’tubeless’ tyres, meaning without inner tube. Inner tubes must not be fitted to tubeless tyres.

Certain types of tyres are fitted with wear indicators. They must be changed as soon as the indicators become visible on the tread.

Aquaplaning is more likely with worn tyre treads.

Snow chains

The use of snow chains is governed by local law in each country.

Chains should only be fitted to drive wheels.

To prevent tyre damage, do not drive on clear roads with chains fitted. In extreme cases (tunnels, etc....) proceed at low speed and in any

case remove the chains as soon as conditions permit.

Maintain moderate speed with chains mounted, avoiding potholes and driving onto the kerb.

Certain tyres of snow chain require tension adjustment after travelling a short distance.

Economic, ecological driving

Road conditions and driving style have a direct influence on fuel consumption and environmental impact.

Carry out the maintenance operations described below at regular intervals and with care.

Do not demand maximum power from the vehicle with the engine cold.

Do not rev the engine when parked.

Always avoid sharp acceleration and repeated braking/acceleration. Engage a higher gear as soon as conditions permit.

If possible, avoid driving with side windows lowered. Use the air-conditioner/ventilation system to obtain the desired conditions in the cab.

Engage a high gear whenever traffic and road conditions permit.

Limit the use of high power absorption utilities (air-conditioner on full, for example) when driving in city traffic or behind slow moving vehicles.

Revving the engine between gears or before stopping the engine serves absolutely no purpose.

Avoid accelerating on full throttle. Fuel consumption will be significantly lower with gradual acceleration.

Page 42

1-28

Rangeofuseoftheengine

1

The following table shows indications for

correct engine use.

a white sector: minimum, low use

b green sector: economic running

c yellow sector: maximum engine speed

range

d red sector: runaway rate

HD9 Euro3

The best performance/consumption ratio

is obtained when the engine rate is in the

green sector.

NEVER USE RED SECTOR.

Engine

F2B/F3B 0 - 1200 1200 - 1900 2400 - 3000 3000 - 3200

White Green Yellow Red

Tachometer sector (RPM)

Page 43

HD9 Euro3

342BNU001L

2

LEFT HAND DRIVE VEHICLES

1

CAB-EXTERNAL

Thecab(Fig.1)ishingedatthefrontand

suspended both to front and rear on the

chassis:

D to the front by two longitudinal arms with

springs, shock absorbers and buffers.

D to the rear by two control arms with

springs, shock absorbers and buffers.

The cabin can be tipped forward by means

of a manually controlled hydraulic cylinder.

Always use the grips and steps (Fig. 2, see

arrow) specifically designed to permit easy

accessibility to get on and off the vehicle.

1-29

Always keep handles and foot-boards

clean to avoid slipping.

342BNU001L

Page 44

1-30

HD9 Euro3

1

1

EXTERNAL LIGHTING

Front lights (Fig. 1)

1. High beam

2. Parking light and headlight

3. Front direction indicator

4. Side direction indicator

5. Front clearance light

6. Rotary warning lights (if fitted)

342BNU009L

Page 45

HD9 Euro3

1-31

1

1

Rear lights (Fig. 1)

1. Direction indicator

2. Stop light

3. Side light

4. Fog warning light

5. Reversing light

6. Licenseplatelight(onesideonly)

7. Side clearance

228NU205

Page 46

1-32

342BNU004L

DOORS

1

The vehicle has two doors symetrically

placed at each side.

The external door handle (Fig. 1, see arrow)

can be locked from the outside with a key.

To open the door pull down the external

handle.

D to block the lock, turn the key anticlock-

wise(Fig.1,ref.1);

D to block the lock, turn the key clockwise

(Fig.1,ref.2);

D to open the door, pull handle downward.

When the door is opened the cabin interior

light comes on automatically, along with the

cabin step lights.

HD9 Euro3

Page 47

HD9 Euro3

342BNU005L

The inner side of the door has the following

1

controls (Fig. 1):

1. Door opening handle

2. Electric window control

3. Door closing handle

4. Knob for locking doors from the inside

5. Electric mirrors adjustment control (only

driver’s door)

1-33

Page 48

1-34

272CNU001

Central locking remote control

1

Briefly press the button (Fig. 1, ref. 1) on the

remote control, while pointing the control in

the direction of the vehicle, the direction indicators will flash simultaneously indicating

that all doors are unlocked.

To lock the doors press the button (Fig. 1 ref.

2) still while pointing the control in the direction of the vehicle, the direction indicators will

flash simultaneously indicating that all doors

are locked.

HD9 Euro3

Page 49

HD9 Euro3

272CNU002

Replacing remote control battery

1

D Insert a small coin or screwdriver into the

slot on the side of the remote control and

open it (Fig. 2).

D Replace the battery, paying attention to

the polarity.

D The remote control has a lithium battery.

CR 2032 3V

D Close the two halves of the remote control

checking that they are correctly coupled.

1-35

A reduction in range of the remote control

is an indicator that the battery is almost

exhausted.

Exhausted batteries are harmful to the

environment. Exhausted batteries must

be disposed of as required by law. Or it

canbehandedovertotheServiceNetwork that will provide for correct disposal.

Page 50

1-36

DRIVERS SEAT

HD9 Euro3

1

342BNU006L

Page 51

HD9 Euro3

DRIVER’S SEAT (Fig. 1 previous page)

1. Driver’s seat adjustment controls

2. Steering wheel position control

3. Ashtray

4. Cigarlighter-12Vpowersocket-Diagnosticsocket

5. Gear lever

6. Differential lock / splitter / supplementary parking brake

7. Climate control system controls

8. Parking brake

9. Document holder

10. Controls lever Cruise control / retarder

11. Ignition switch

12. Dashboard

13. Steering wheel

14. Instrument panel

15. Controls lever lights / headlights / direction indicators / windscreen wiper controls

16. Pedal controls

1-37

Page 52

1-38

HD9 Euro3

1

1

1

342BNU007L

2

INTERNAL LIGHTING DEVICE

Upper dashboard (Fig. 1)

1. Ceiling light

Press button (Fig. 2) to switch on the ceiling

light.

Press again to switch off the ceiling light.

2. Access step lighting

The light switches on when the door is

opened.

342BNU008L

Page 53

HD9 Euro3

1-39

1

341DNU020L

EXTERNAL REAR VIEW MIRRORS

The vehicle is fitted with the following external rear view mirrors (Fig. 1, 2 and Fig. 3):

1 Left side wide-angle mirror

2 Main left side mirror

3 Right side wide-angle mirror

4 Main right side mirror

5 Right pull-in mirror

Page 54

1-40

342BNU050L

2

Mirror selection and handling

1

Using the mirror selection control (Fig. 1, ref.

1) brings up a specific page on the techometerLCD(Fig.2,ref.1).

Use the mirror adjustment control (Fig. 1, ref.

2) to adjust the selected mirror.

HD9 Euro3

This adjustment must be made with vehicle stationary.

Without remote control the driver has to

adjust the mirrors manually.

285ANU002L

Page 55

HD9 Euro3

285ANU003L

284CNU004L

The selected mirror is identified by the num-

1

ber on the LCD (Fig. 1, ref. 1)

The selected mirror is graphically highlighted on the LCD (Fig. 1, ref. 2).

The mirrors controlled by the system are

(Fig. 2):

1. Main driver’s mirror

2. Driver’s wide-angle mirror

3. Main passenger side mirror

4. Passenger side wide-angle mirror

2

Press the mirror heater button (Fig. 1, ref. 3)

to rapidly demist the mirrors. Press the button to turn the mirror heating system on.

Press the button again to turn the mirror

heating system off.

3

1-41

342BNU051L

Page 56

1-42

HD9 Euro3

1

342BNU010L

SEATS

Fore and aft adjustment

Lift lever (Fig. 1, ref. 1) to have the seat free

to move backwards or forward.

Release the lever and ensure the mechanism is fully.

Cushion angle adjustment

The cushion angle may be adjusted by lifting

lever (Fig. 1, ref. 2) and pulling and pushing

the backrest (12˚ max.). Release the lever

after adjustment.

Seat suspension adjustment

Lift lever (Fig. 1, ref. 3) to lower and lock the

seat; lower the lever to raise the seat (set

beforehand with lever 5).

Page 57

HD9 Euro3

1-43

1

342BNU010L

Springing system adjustment

Springing system adjustment is obtained by

lifting or lowering lever (Fig. 1, ref. 4):

D Lever up = Maximum suspension effect.

D Lever down = Minimum suspensions

effect.

With this device seat suspension is

according to road surface and weight of

the driver. The shock absorber has to be

adjusted rigidly, to avoid that on rough

surfaces the seat hits the end of stroke,

jeopardising the spring system.

Height adjustment

Lift lever (Fig. 1, ref. 4) to raise the seat; release the lever after adjustment. Seat height

is memorised automatically.

Lower lever to lower the seat (100 mm max.)

Backrest angle adjustment

Lift lever (Fig.1, ref. 5) and set the backrest to

the desired angle with your back. Release

the lever to block the backrest.

Page 58

1-44

SEAT BELTS

1

The vehicle is equipped with three-point seat

belts and automatic reel (Fig. 1).

D To fasten the belt grip the tab and insert it

into the buckle until it clicks (Fig. 2).

D To release the belt, press the button on the

top of the buckle (Fig. 3).

HD9 Euro3

178NU08

2

178NU09

178NU10

Do not adjust the mirrors while driving.

3

Page 59

HD9 Euro3

178NU08

The belt does not need to be adjusted by

1

hand: the webbing adjusts itself automatically to the length most suited to the driver

allowing him freedom of movement provided that his movements are not abrupt.

The belt mechanism is affected by changes

in vehicle attitude and as a consequence the

belt may lock in the following cases:

D sudden braking or acceleration;

D vehicle driving on a slope;

D when cornering.

1-45

Thebeltmustnottwistandmustadhere

to the hips, not the abdomen, to prevent

the risk of slipping forwards.

Occasionally check that the anchor bolts

are fully tightened and that the belt itself

is not cut or frayed.

In case of accident of a certain gravity,

replace the belt involved, even if it does

not appear damaged.

Do not make alterations likely to reduce

seat belt efficiency

Page 60

1-46

ELECTRIC WINDOW CONTROL

1

Electric window risers control

Left side (Fig.

1. Left side window control

2. Right side window control

1)

HD9 Euro3

342BNU011L

342BNU012L

342BNU013L

Right side (Fig.

1. Right side window control.

Press (Fig. 3, ref a) the switch to lower the

2

glass.

Pull the switch upward (Fig. 3, ref b) to raise

the glass.

The glass stops when the switch is released.

2)

3

Page 61

HD9 Euro3

178NU02

2

272NU102X

HATCH

1

To open the hatch turn the handle (Fig. 1, ref.

1) anti-clockwise.

To close the hatch proceed as follows:

D Turn the handle clockwise until closing the

hatch.

D Return the handle to its original position

(Fig. 2).

D Turnthehandleatmostbyaquarterturn

until reaching the stop (Fig. 3, arrow).

D Return the handle to closed position and

lock it by tipping the knob.

3

1-47

Toescape from the cabin in an emergency

turn the full release handles downward

(Fig.1,ref.2)andpushthehatchoutwards.

272NU103X

Page 62

1-48

HD9 Euro3

1

342BNU014L

2

COMPARTMENTS

Dashboard (Fig. 1)

1. Bottle/can holder

2. Mobile phone holder

3. Items tray (according to outfitting)

4. Gloves compartment

5. Compartment in front of passenger

Upper dashboard (Fig. 2)

1. Compartment in front of passenger

(closed with lid).

Act on button and raise lid to open.

Lower lid and press until it clicks into

place.

2. Loose items tray (according to outfitting)

342BNU015L

Page 63

HD9 Euro3

1-49

342BNU016L

1

2

Door (Fig. 1)

1. bottle holder

2. pocket

3. pocket

Tunnel (Fig. 2)

1. coin holder

2. loose items tray

Seat (Fig. 3)

1. Compartment (closed with lid)

Act on button and lower lid to open.

Raise lid and press until it clicks to close.

2. items holder

Rear wall (Fig. 4)

1. bottle holder

2. items compartment

3

4

342BNU017L

342BNU018L

342BNU019L

Page 64

1-50

HD9 Euro3

1

342BNU020L

2

ACCESSORIES - DEVICES

Sunblindtabs(Fig.1,ref.1)

Grip the front edge of the tab and turn downward.

Bring to position by hand.

Griphandle(Fig.1,ref.2)

On passenger side.

Coathook(Fig.1,ref.2)

On both sides of cab.

Cigarlighter(Fig.2,ref.1)

Press to activate cigar lighter: a click indicatesitisreadyforuse.

After use return to its seat without pressing.

Ashtray (Fig. 2, ref. 2)

On both sides of cab.

Raise lid to open.

Lower lid to close.

12Voltcurrentsocket(Fig.2,ref.3)

Open cap and insert facility .

After use close cap.

342BNU021L

Page 65

HD9 Euro3

1-51

1

342BNU022L

CONTROLS

Controls on dashboard (Fig. 1)

1. Headlamps geometry adjustment

2. External lights switch

3. Hazard lights

4. Parking brake control

Page 66

1-52

HD9 Euro3

1

1

Module holder dashboard controls

(Fig. 1)

1. Engine brake switch

2. Fog light switch

3. Rear fog light

4. Mirrors heating switch

5. Horn selector switch

6. Pivoting headlamps switch

7. Ceiling light switch

8. Not used

9. Not used

10. PTO activation switch

11. PTO 1 activation switch

12. PTO 2 activation switch

13. ABS switch (OFF-ROAD)

14. ASR switch

15. Additional parking brake switch

16. Work light switch

17. Electric battery master switch

18. Not used

19. Climate controls

20. Not used

21. 12 V current socket

342BNU023L

Page 67

HD9 Euro3

Controls on roof (Fig. 1)

1

1. Radio CD equipment housing

2. CB housing

3. Tachograph housing

1-53

342BNU024L

272NU061X

Controls on

Steering wheel position control

Steering wheel position adjustment is pneumatic, and can be regulated by means of the

button on the floor at the base of the steering

column, driver’s side.

1

Proceed as follows:

D With the button pressed (Fig. 2, ref. 1) take

the wheel in your hands and bring it to the

required position.

D Once in position, release the button.

floor

This operation can only be done with:

D sufficient air pressure;

D parking brake engaged.

Page 68

1-54

272NU062X

Accelerator

1

The accelerator is controlled by means of a

pedal on the floor to be operated by the

driver’srightfoot(Fig.1,ref.1).

Press the pedal to increase the torque output

by the engine proportionally to the position

of the pedal.

Service brake

The service brake is controlled by means of

a pedal on the floor to be operated by the

driver’srightfoot(Fig.1,ref.2).

Press the pedal to obtain a braking effect in

proportion to the exerted pressure.

Clutch

The clutch is controlled by a pedal to be

operated with the driver’s left foot (Fig. 1, ref.

3).

Press the pedal to release the clutch. Only for

manual trasmission vehicles.

HD9 Euro3

Page 69

HD9 Euro3

1

342BNU025L

1-55

Manual transmission control

Transmission is controlled by a manually

operated lever. (Fig. 1, see arrow).

By shifting the lever, the different gears are

engaged.

The lever also has a splitter pre-selection

lever. Acting on this lever pre-selects the

engagement of reduced gears range, actuated through the clutch pedal.

Page 70

1-56

ALL VEHICLES

INSTRUMENTS

Instrument panel (Fig. 1)

HD9 Euro3

1

1

341DNU001L

341DNU001L

Page 71

HD9 Euro3

Instrument panel (Fig. 1)

1) Front axles brake wear warning light

Red light indicates front brakes have reached the wear limit

2) Rear axles brake wear warning light

Red light indicates rear brakes have reached the wear limit

3) Rear axle brakes air pressure indicator.

4) Front axle brakes air pressure indicator.

5) ABS failure warning light

Yellow light indicates ABS system is not functioning

6) Braking system failure warning light

Red light indicates there is a failure in the braking system

7) Rev counter

8) Digital speedometer

9) LCD screen with hour-counter and partial trip display

10) Partial trip reset button

11) Fuel level indicator

12) Fuel reserve warning light

Red light indicates fuel tank level is in reserve

13) Engine water overheating

Red light indicates the engine water is overheated

14) Engine water temperature indicator

15) Instruments illumination adjustment button

A) Warning lights panel A

B) Warning lights panel B

C) Warning lights panel C

1-57

See the below for further information

regarding instrument panel.

Page 72

1-58

Functions of instrument panel keys

1

Key1(Fig.1,ref.

Instrument illumination adjustment.

or

Error memory display.

285ANU009L12

Key2(Fig.1,ref.

Press key 2 for less than three seconds to

2

display trip km or total km

Trip odometer reset

With trip odometer displayed on LCD (Fig. 2,

ref. 1), press key 2 for more than three seconds to zero the indicated distance.

Units of measure conversion (Km To convert the units of measure displayed on

the LCD, proceed as follows:

D With ignition key out, press both buttons

(Fig.1,ref1and2).

D Holding the buttons down, turn the key to

MAR and wait 10 seconds.

1):

2):

1

HD9 Euro3

Refer to the DIAGNOSTIC chapter for more information

miles)

285ANU010L

Page 73

HD9 Euro3

341DNU002L

Warning lights panel A details

1

1 Automatic gear converter functioning warning light.

Yellow light indicates lock-up clutch is not engaged.

2 Retarder on warning light.

Y ello w. Indicates that hydraulic retarder is active.

3 Engine brake engaged warning light.

Yellow. Indicates that the engine brake is engaged.

4 Rear traverse differential locked warning light.

Yellow. Indicates that the rear differential clamp is engaged.

5 Transfer box longitudinal differential locked warning light.

Yellow. Indicates that the transfer box differential clamp is engaged.

6 Tandem longitudinal differential locked warning light.

Yellow. Indicates that the tandem longitudinal differential is engaged.

7 External lights on warning light.

Green. Indicates that the side lights (and dip headlights) are on.

8 Mainbeamonwarninglight.

Blue. Indicates that main beam headlights are on.

9 Parking brake engaged warning light.

Red. Indicates that the parking brake is engaged.

10 Left direction indicator warning light.

Green. Indicates that the left direction indicator has been activated.

11 Power steering main circuit failure warning light.

Red. Indicates there is a failure on the power steering main circuit.

12 Power steering emergency circuit failure warning light.

Red. Indicates there is a failure on the power steering emergency circuit.

1-59

Page 74

1-60

1

2

43

285ANU012L

Warning lights panel B details

1

1. Seat belt not fastened warning light

Red. Indicates that the driver’s seat belt is not fastened.

2. Warning light

Y ellow. Indicates a general vehicle fault.

3. Preheating on warning light

Yellow. Indicates that the engine preheating system is active.

4. ECM warning light

Y ellow. Indicates an ECM malfunction.

HD9 Euro3

Page 75

HD9 Euro3

341DNU003L

Warning lights panel C details

1

1. Second speed limit engaged warning light.

Yellow. This indicates that the second speed limiter is engaged.

2. ABS off warning light.

Y ellow. Indicates ABS off.

3. ASR off warning light

Y ellow. Indicates ASR off.

4. Engine oil temperature high warning light.

Red. Indicates that the engine oil temperature is high.

5. Low trailer brake air pressure warning light.

Red. Indicates trailer air brake malfunction.

6. Power steering oil level low warning light.

Red. Indicates that the power steering oil level is insufficient.

7. Alternator warning light.

Red. Indicates that the current delivered to the alternator is insufficient.

8. Water in fuel pre-filter warning light.

Yellow. Indicates the presence of water in the fuel pre-filter.

9. Hazard lights on warning light.

Red. Indicates that the hazard warning lights are on.

10. Right direction indicator warning light.

Green. Indicates that the right direction indicator has been activated.

11. Cab unhooked warning light

Red. Indicates that the cab has not been secured correctly.

12. Air filter clogged warning light

Yellow. Indicates that the engine air filter is clogged.

1-61

Page 76

1-62

341DNU004L

1

Warning lights on dashboard

1. PTO 1 on gearbox engaged warning

light.

Yellow light indicates that PTO 1 on

gearbox is engaged.

2 PTO 2 on gearbox engaged warning

ligh.

Yellow light indicates that PTO 2 on

gearbox is engaged.

3 PTO on flywheel engaged warning light.

Yellow light indicates that PTO on flywheel is engaged.

4 Splitter unit reduced gear ratio engaged

warning light.

Green light indicates that splitter unit

reduced gear ratio is engaged.

5 Low range engaged warning light.

Green light indicates that the gear low

range is engaged.

6 Reduced gears engaged warning light.

Green light indicates that the gearbox

reduced gears are engaged.

7 T railer ABS failure warning light.

Yellow light indicates that the trailer ABS

system is not functioning.

8 Windshield washer liquid level warning

light.

Red light indicates that windshield

washer liquid level is low.

9 Front transverse differential locked war-

ning light.

Yellow light indicates that front differential lock is engaged.

HD9 Euro3

Page 77

HD9 Euro3

1-63

Page left intentionally blank

Page 78

1-64

CONTROL OPERATION

1

Position and headlight controls (Fig. 1)

The control has three positions:

D position 0: off;

D position 1: first click: position lights on;

D position 2: second click: headlights on.

HD9 Euro3

272NU043X

1

Headlight control (Fig. 2)

The control has three positions.

D position 0: normal headlights;

2

D position 1 (light push forward): high

beams;

D position 2 (pull lever back): Beam flasher.

0

2

272NU044X

Page 79

HD9 Euro3

1-65

1

0

2

272NU045X

Direction indicator control (Fig. 1)

1

The control has three positions:

D position 0 off;

D position 1 (up) right direction indicators;

D position 2 (down) left direction indicators.

Horn (Fig. 2)

The horn can be sounded by pressing the

indicated points (Fig. 2, ref. 1, 2).

2

1

2

272NU046X

Page 80

1-66

HD9 Euro3

3

2

1

0

272NU047X

272NU048X

Windscreen washer/wiper control

1

The control (Fig. 1) has four positions:

D position 0 = disengaged;

D position 1 = intermittent;

D position 2 = slow;

D position 3 = fast.

Pushing the end of the ring (Fig. 2, see

arrow), the windscreen wiper makes one

sweep.

The windscreen washer is the button (Fig. 3,

see arrow) on the control stick.

2

Pressing the windscreen washer button also

activates slow windscreen wiper operation.

Releasing the washer button, the wiper

makes three more cleaning strokes before

stopping.

3

272NU049X

Page 81

HD9 Euro3

1-67

1

272NU056X

2

272NU057X

3

Ignition switch (Fig. 1)

The ignition switch has three positions:

D position 0 (STOP): all off, key may be

removed;

D position 1 (MAR): ready to start, electrical

power on, key locked in;

D position 2 (AVV): starting engine.

Engine braking control - Vehicles without

intarder

The device is controlled by turning the end

part of the lever (Fig. 2) and which has three

positions (from 0 to 2), corresponding to one

only braking level.

Positions 1 and 2 are equivalent.

Engine braking control - Vehicles with

intarder

The device is controlled by turning the end

part of the lever (Fig. 3) and which has seven

position lever (from 0 to 6), corresponding to

progressively higher levels of braking.

272NU058X

Page 82

1-68

HD9 Euro3

1

341DNU007L

1

2

272NU060X

Cruise control

The vehicle is fitted with an engine speed /

vehicle speed control.

Memory control (Fig. 1, ref.

RESUME: Pulling the lever memorises the

current regulator setting / recalls memorised

setting.

OFF: Operate the lever to deactivate the

clutch.

1).

2

Speed setting

ON button (+): pressing the button (Fig. 2,

ref. 1) increases the rpm / vehicle speed

value.

ON button (-): pressing the button (Fig. 2, ref.

2) decreases the rpm / vehicle speed value.

control

Page 83

HD9 Euro3

1

272NU055X

285ANU039L

1

Hazard light control

Press the control (Fig. 1, ref. 1) to turn the

hazard lights on.

Press again to switch the hazard lights off.

Exhaust brake pre-selection

The control (Fig. 2) has three positions:

D position 0: the exhaust brake is applied

when the command is actuated;

D position 1: the exhaust brake is applied

when the accelerator pedal is released;

D position 2: exhaust brake applied each

2

time the brake pedal is pressed;

1-69

All Cruise Control operations are deactivated when the exhaust brake is applied.

Page 84

1-70

285ANU021L

285ANU022L

Courtesy light switch

1

Press the button (Fig. 1) to turn the courtesy

light on.

Press the button again to turn the courtesy

light off.

Electro-pneumatic horn pre-selection

Press the control (Fig. 2) to operate the electro-pneumatic horn by means of the horn

control on the left steering stalk.

Press the control again to operate the electric

horn by means of the horn control on the left

2

steering stalk.

HD9 Euro3

Page 85

HD9 Euro3

342ANU001L

342ANU002L

Swivelling light control

1

Press the button (Fig. 1) to turn the swivelling

light on.

The warning light (Fig. 1, ref. 1) indicates that

the swivelling light is on.