Page 1

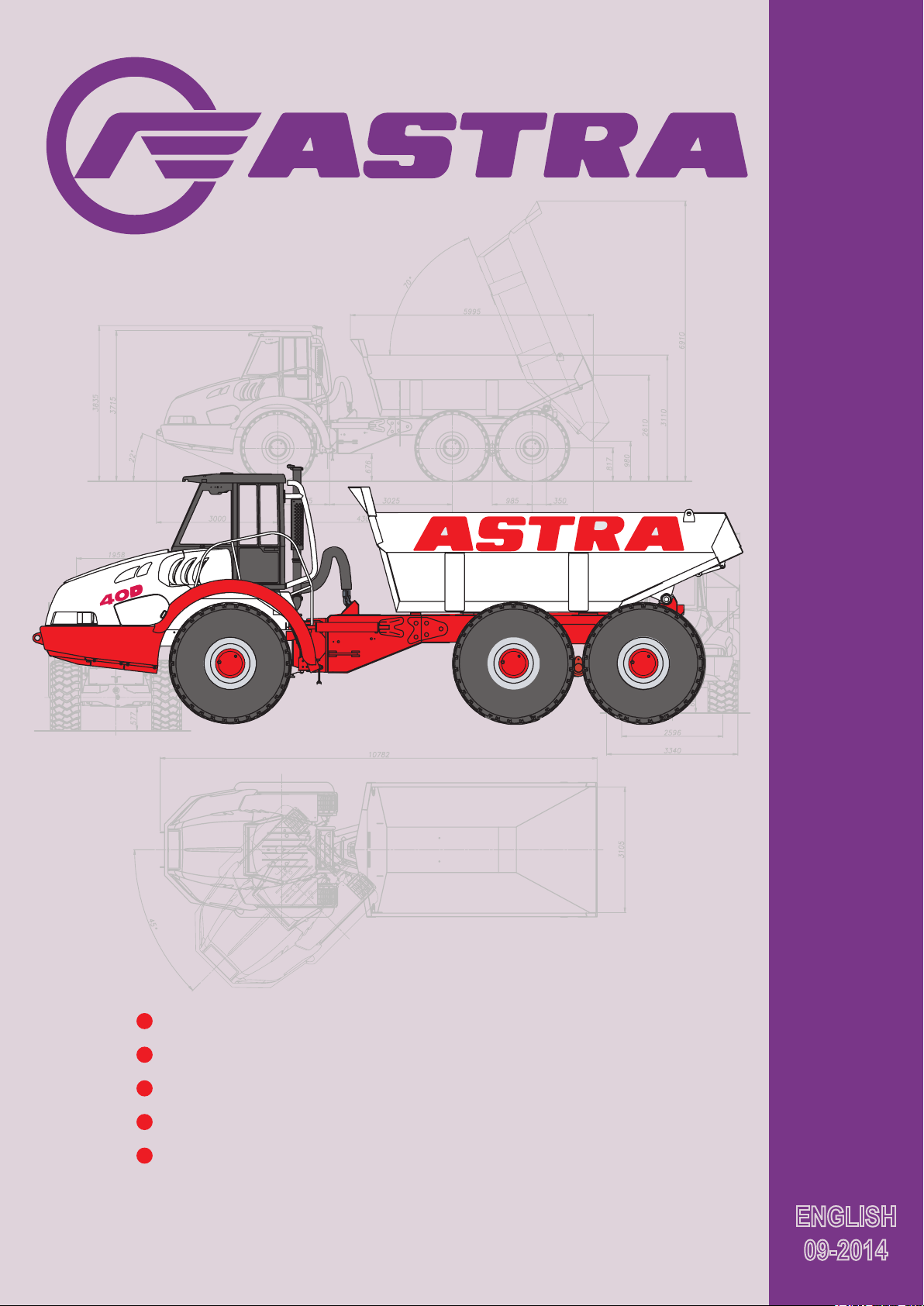

ADT 40D

Engine Iveco Cursor 13

Power 335kW (455 hp)

G.V.W. 65.000 kg

Payload 36.000 kg (40 Sht)

Bodyheaped(SAE2:1) 22 m

3

Articulated Dumper 6x6

ENGLISH

09-2014

Page 2

Articulated Dumper ADT 40D

ENGINE

6 in-line cylinder Diesel cycle, electronically-controlled direct injection,

pump injectors, variable geometry turbocharger with intercooler.

Emissions: ...................................... EPA - CARB - OFF ROAD TIER 3

Make and type: .................................................... IVECO CURSOR 13

Bore x stroke: .................................................................. 135x150 mm

Total displacement: ............................................................. 12800 cm

Max power: ......................................... 335 KW ( 455 HP) @ 2100 rpm

Max torque: ........................................................ 2000 Nm @ 1185 rpm

Integrated engine brake: ......................................... Iveco Turbo Brake

Air lter: ........................................................ dry, with double cartridge

Cold start - 25° C

PERFORMANCE

With standard 29,5R25 tyres

gear gear ratio speed (km/h)

1° 5,350 5,9

2° 3,455 9,1

3° 2,206 14,3

4° 1,421 22,2

5° 0,969 32,6

6° 0,624 50,6

st

1

RG 5,350 5,9

nd

2

RG 2,206 14,3

rd

3

RG 0,969 32,6

TYRES

Rim: ......................................................................................... 25x22x3”

Tyres: ............................................................. 29,5 R25 Triangle TB 516

Optional: 29,5 R25 Michelin

3

STEERING

Complies with ISO 5010, SAE J1511

Hydraulic steering (ORBITROL) with ow amplier integrated by two

double-acting cylinders operating on the articulating hitch.

Variable displacement pump.

Pump ow: ........................................................ 331 l /min. @ 2300 rpm

Max. operating pressure: ......................................... 250 bars (25 Mpa)

Radial piston emergency pump anged to gearbox and ground driven

Adjustable steering column/steering wheel.

Steering angle: .............................................................................. ± 45°

BRAKES

Independent circuit complyng with ISO 3450/SAE J 1473

Oil-cooled wet multiple disc brakes, with engine powered gear pump

and with two pressure accumulators.

Overall braking surface: ...................................................... 5900 cm

Parking brake: .............. pneumatically controlled disc on rear tandem.

Electronic integrated Engine Brake and hydraulic retarder engagement

when the accelerator pedal is released (exclusive Astra system).

Max braking force 396 kW @ 2100 rpm.

2

TRANSMISSION

Automatic ERGOPOWER ZF 6WG 310 transmission with 6 gears

forward and 3 reverse.

ECO (energy saving) and POWER (performance boosting) selectable

modes.

Hydraulic torque converter, multiplication ratio(stall torque): ....... 1: 1,84

Lock-up in all gears.

Torque to front axle: ................................................................... 33,3%

Torque to rear axles: ................................................................... 66,7%

Hydraulic retarder max. braking power 242 kW @ 2100 rpm.

Integrated and lockable transfer box.

Integrated front differential with limited slip.

AXLES

Permanent 6x6 drive conguration, 2nd and 3rd axle ZF MT-D3105.

Double reduction: central by bevel gear and nal by planetary gears

in wheel hubs. Lockable rear interaxle..

Central reduction ratio: .............................................................. 1 : 3,5

Final reduction ratio: .............................................................. 1 : 6,353

Total reduction ratio: .............................................................. 1 : 22,24

Floating front axle with outboard planetary reduction gearing (1:6) and

gearbox integrated differential.

SUSPENSIONS

Front: semi-independent, with “A” frame and PANHARD crossbar

Hydro-pneumatic suspension cylinders (oil-nitrogen).

Rear: semi-independent rocker type, connected to axles by exible

joints and integrated with central reaction bars on axles.

Optional: front suspension ination kit.

ELECTRICAL SYSTEM

Two batteries: .................................................................. 12 V / 170 Ah

Voltage: .......................................................................................... 24 V

Alternator: ...................................................................................... 90 A

Starter: .......................................................................................... 5 kW

All wires are coded, covered and fastened to the chassis.

CAN bus Simple-Mux system allowing the communication between

engine control unit (ECU), gearbox and Body Computer.

New cluster with high denition multifunctional color display.

New Black Box able to manage 140 records for each memory area.

Optional: Rear view camera with cluster integrated display.

Articulated Dumper ADT 40D

Page 3

60

65

70

75

60

70

80

90

100

30

3

4

5

6

7

8

9

1

40

50

60

130

120

110

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

60

65

70

75

60

65

70

75

60

70

80

90

100

30

3

4

5

6

7

8

9

1

40

50

60

130

120

110

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

60

65

70

75

600

500

400

300

200

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

100

80

60

40

20

10

9

8

7

6

5

4

3

2

1 st

1 st

2 nd

2 nd

3 rd

3 rd

4 th

4 th

5 th

5 th

6 th

6 th

Articulated Dumper ADT 40D

HYDRAULIC SYSTEM

4 pumps, circuit: “load sensing” system with variable displacement

pump anged to gearbox for steering and tipping. One engine-driven

pump for brake actuation, connected in series with 2 pumps for brake

cooling with displacement electronic control. (Exclusive Astra System)

BODY

Walls and bottom in high abrasion strength steel (Hardox 400).

Bottom thickness: ........................................................ 15 mm 0.590 in

Side wall thickness: ..................................................... 12 mm 0.472 in

Front wall thickness: ..................................................... 10 mm 0.934 in

Multistage dumping cylinders: two, double acting on the last stage

and installed inside the chassis members.

Elastic pads between body and chassis.

Tipping angle: ................................................................................. 70°

Tipping time: ............................................................................. 11 sec

Lowering time: .......................................................................... 13 sec

Automatic body tipping control system.

Capacity:

struck: ............................................................................ 17 m3 22.2 yd

heaped (SAE 2:1): ....................................................... 22 m3 28.7 yd

Optional:

Reinforced “semi-rock” body; “Extra Heavy Duty” body for extreme

applications; body extensions; body heating kit; rear tailgate; body front

spillguard.

CAB

Complies with ROPS ISO 3471 / FOPS ISO 3449 Level II

Stainless steel, soundproof and centrally installed, suspended through

oil-rubber pads;

Reverse gear buzzer;

Automatic climate control with anti-pollen lter;

Hydraulic engine hood and cab tipping system;

Athermic glasses;

Side mudguards with gullwing opening for maintenance;

Door with glazing in the lower part to give maximum visibility;

Tilting cab on the LEFT-side to facilitate extraordinary maintenance

activities;

Fully adjustable air suspension central operator seat with safety belts;

Instructor seat with belts;

Windscreen sunvisor.

Optional:

RDS radio;

Electrical engine hood tipping system;

Fire-Extinguisher;Yellow rotating beacon;

3

3

Work lights on top of the cab;

Refrigerator;

Remote-controlled heated rear view mirrors;

Side window wipers;

Rear view camera.

INSTRUMENTS PANEL

On-board computer with digital/analogic instrumentation and

performance/fault messages to manage all vehicle operating information

(levels, warning lights, etc.). Advanced vehicle diagnostic system:

management and storage of engine, transmission, steering system,

brakes, body tipping and pneumatic system data.

Trip Computer to analyse vehicle productivity.

External level gauges on fuel, hydraulic oil and brake cooling oil tanks.

Optional:

Electronically controlled transmission and brake oil warm-up system for

quick start-up in cold weather (exclusive ASTRA system).

e

G

r

s

e

a

GREASING SYSTEM

Automatic programmable and central greasing system with grease gauge

on dashboard.

WEIGHT Kg

CHASSIS

Front and rear chassis made of high strength steel (ST 52.3) with

extruded (non-welded) rectangular side members linked by bracing

crossmembers.

Oscillating hitch: two rows ball bearing with double lip sealing.

FLUID CAPACITIES

Refer to the use and maintenance manual for uids specications.

Engine oil and lter: ......................... 35 l ........................... 9.2 US Gals

Transmission oil and lter: ............35,5 l ...........................9.4 US Gals

Cooling system: ............................... 47 l ......................... 12.4 US Gals

Fuel tank: ......................................400 l .......................105.7 US Gals

Front differential: ..............................14 l ........................... 3.7 US Gals

Intermediate axle: ............................ 34 l ........................... 9.0 US Gals

Rear axle: ........................................33 l ...........................8.7 US Gals

Hydraulic tank: ...............................240 l .........................63.4 US Gals

Hub oil (per hub): ...............................9 l ...........................2.4 US Gals

Brakes cooling oil: ...........................90 l ......................... 23.7 US Gals

TARE (*) PAYLOAD TOTAL WEIGHT (G.V.W.)

Kg lb Kg lb Kg lb

Front axle 14.340 31.614 4.660 10.273 19.000 41.887

Rear axles (tandem) 14.660 32.320 31.340 69.093 46.000 101.413

Total 29.000 69.934 36.000 79.366 65.000 143.300

* Tare includes fuel, lubricants and driver (75 kg)

Articulated Dumper ADT 40D

Page 4

Articulated Dumper ADT 40D

Cross the G.V.W. of the vehicle and the sloped line corresponding to the total resistance %, to determine on the left the corresponding

gear and, coming down,the max.speed of the vehicle.

65

60

70

75

60

50

40

30

RIMPULL (kN)

Speed (kph)

130

120

110

100

90

80

70

60

50

40

30

20

10

9

8

7

6

5

4

3

2

TOTAL RESISTANCE %

600

500

400

300

200

100

90

80

100

70

80

60

60

50

40

40

30

20

20

10

10

9

9

8

8

7

7

6

6

5

5

4

Iveco turbo brake plus Retarder

RETARDATION PERFORMANCE (kN)

4

3

3

2

2

1 st

1 st

2 nd

2 nd

3 rd

3 rd

4 th

4 th

5 th

5 th

1

9

8

7

6

5

4

3

60

60

70

65

70

80

75

90

100

Speed (kph)

grade % plus rolling resistance %

G.V.W. (kg x 1000)

65

6 th

6 th

70

75

130

120

60

Speed (kph)

110

100

50

90

40

80

70

30

60

50

40

30

20

10

9

8

7

6

5

4

3

2

60

TOTAL RESISTANCE %

1

9

8

7

6

5

4

3

grade % minus rolling resistance %

ROLLING RESISTANCE

Road surface for each t %

features G.V.W.

Black top-concrete 15kg 1,5%

Hard packed soil 20kg 2,0%

Mud on packed soil 40kg 4,0%

Packed snow 25kg 2,5%

Soft snow 45kg 4,5%

Sand-gravel 100kg 10,0%

60

60

70

65

70

80

75

90

100

Speed (kph)

G.V.W. (kg x 1000)

Articulated Dumper ADT 40D

Page 5

Articulated Dumper ADT 40D

Dimensions in mm

Vehicle with Tubeless 29,5R25 tyres

laden: front 19.000 Kg, rear 46.000 Kg

°07

5995 - 9'11"

"21'21 - 5173

"7'21 - 5383

"7'8 - 0162

°22

"3'2

676

3000 - 9'10"

1275 - 4'2"

3025 - 9'11"

4300- 14'1"

10782 - 35'4"

985 - 3'3"

1970 - 6'6"

350 - 1'2"

1512 - 4'12"

"3'3-089

"8'2

718

"2'01 - 5013

"8'22 - 0196

"2'01 - 0113

°54

"6'82-5868R

3465 - 11'4"

1690 - 5'7"

2596 - 8'6"

3340 - 10'11"

"8'31 - 4614R

1958 - 6'5"

"21'1

406

"11'1

775

Articulated Dumper ADT 40D

Page 6

Articulated Dumper

ADT 40D

ASTRA Veicoli Industriali S.p.A.

Via Caorsana, 79

29122 Piacenza (Italy)

Tel. ++39-523.5431

Fax ++39 523.591773

www.astraspa.com

M.K.T.- 09.14- A3501761Features and equipment subject to change without notice

DEALER

Loading...

Loading...