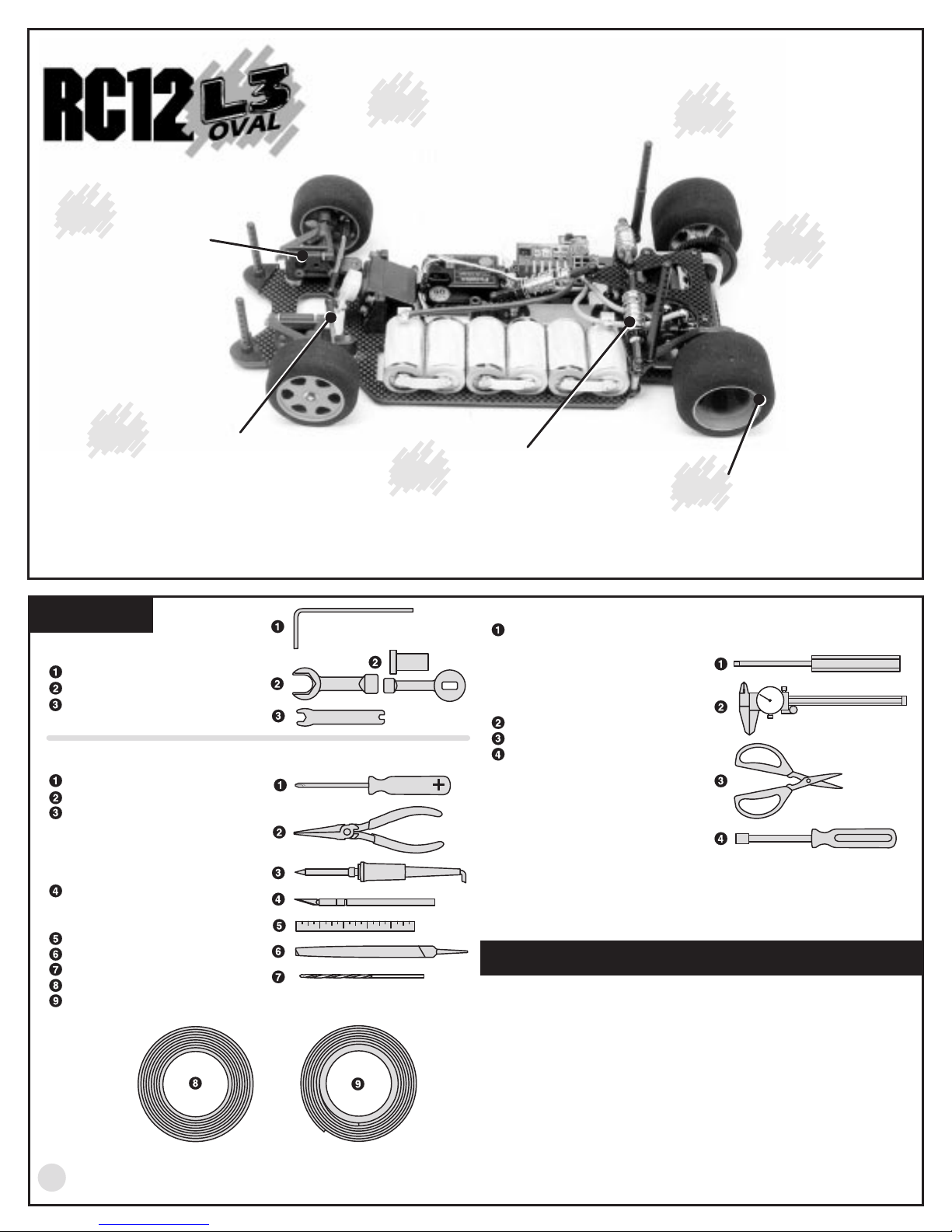

Associated Electrics RC12 L3 Oval Instruction Manual

INSTRUCTION MANUAL FOR THE

#4016 RC12L3 OVAL KIT

©1999 Associated Electrics, Inc.

1:12 SCALE OVAL KIT

SAVE THIS MANUAL!

Use with current catalog for future,

hassle-free re-ordering of parts.

#4016

Race-proven

Facto ry Tea m

blue alum inum screw s

and ball ends

Carbon-fiber

Com posite Chassis

Dynam ic Strut

front suspension

Facto ry Tea m

blue titanium

tu rn b u c k le s

TOOLS

KIT TOOLS SUPPLIED

Allen wrenches, .050", 1/16", 3/32"

shock tools

metal turnbuckle wrench

EXTRA STUFF NEEDED

Phillips screwdriver #2

needlenose pliers

soldering iron (40-50 watts) and a

small amount of Rosin core solder.

Pencil-type soldering iron is better

than the gun type.

HOT!

hobby knife

cuts plastic and fingers with equal

ease, so be careful.

precision ruler

file

hand drill with 3/32" (or #43) drill bit

electrician's tape

strapping tape

DANGER! Tip is

WARNING!

This knife

VCS M icro Shocks

3 shock design

fo r b e s t d a m p e n in g

HELPFUL TOOLS (NOT REQUIRED)

Allen drivers (straight Allen wrenches with hex shaped handles)

such as the following made by Associated:

#6957 .050" Allen wrench

#6958 1/16" Allen wrench

#6960 3/32" Allen wrench

#6961 2.5mm Allen wrench

Vernier calipers

Hobby scissors

Nut drivers (screwdriverhandled hex socket tools) such

as the following from Associated:

#SP-86 3/16" nut driver

#SP-85 1/4" nut driver

#SP-82 11/32" nut driver

WARNING!

nylon, plastic, or composite materials. The fast rotation speed

can heat up the screws being installed. They can then break or

strip the threads during installation.

ITEM S N EEDED TO CO M PLETE YO U R KIT

R/C two channel surface frequency radio system.

1

Battery pack (6 cell).

2 *

3

Battery charger (we recommend a peak detection charger).

Electronic speed control.

4 *

5 *

R/C electric motor.

Pinion gear, size to be determined by type and wind of motor you will

6 *

be using.

1:12 scale Lexan body.

7

Wide

battery

slots

Pro-Line/Jaco

wheel/tire com bo

fro n t a n d re a r

Do not use a power screwdriver to install screws into

2

*Available from Team Associated. See your catalogs.

REACHING US

CUSTOMER SUPPORT

(714) 850-9342

Fax (714) 850-1744

web site: http://www.teamassociated.com

©1999 Associated Electrics, Inc.

BEFORE BUILDING

OPEN THE BAGS IN ORDER

The assembly is arranged so that you will open and finish that

bag before you go on to the next bag. Sometimes you w ill

have parts remaining at the end of a bag . T h es e will

become part of the next bag.

amount of small parts. To make it easier to find the parts, we

recommend using a partitioned paper plate for spreading out

the parts so th e y w ill b e e a s ier to find .

MANUAL FORMAT

The following explains the format of these instructions.

The beginning of each section indicates:

1

Which bag to open

("BAG A").

2 Which pa rts y o u w ill u s e fo r th os e s te p s . R e move only the

parts shown. "1:1" indicates an actual size drawing; place

your part on top and compare it so it does not get confused

with a similar part.

3

Which tools you should have handy for that section.

4

In some dra w in gs , th e w o rd

which direction is the rear of the car to help keep you oriented.

Some bags may have a large

"REAR"

with an arrow indicates

ASSOCIATED ELECTRICS, INC.

3585 Cadillac Ave.

Costa Mesa, CA 92626

USA

5 The instructions in each step are ordered in the order you

complete the m, so read the words AND fo llo w th e p ictu re s . T he

numbers in circles are also in the drawing to help you locate

them faster.

6 When we re fe r to le ft and right sides o f th e ca r, w e a re

referring to the dr ive r's p o int o f v iew inside the car.

SUPPLEMENTAL SHEETS

We are constantly developing new parts to improve our kits.

These changes, if any, will be noted in supplementary sheets

located in a parts bag or inside the kit box. Check the kit box

before you start and each bag as it is opened. When a

suppleme n t is fo u n d, attach it to the appropriate se c tio n o f th e

manual.

Now clear off your workbench,

line up some paper plates,

grab your 50-cent soda, 39-cent cheeseburger, $12.99 music

CD, and let's begin!

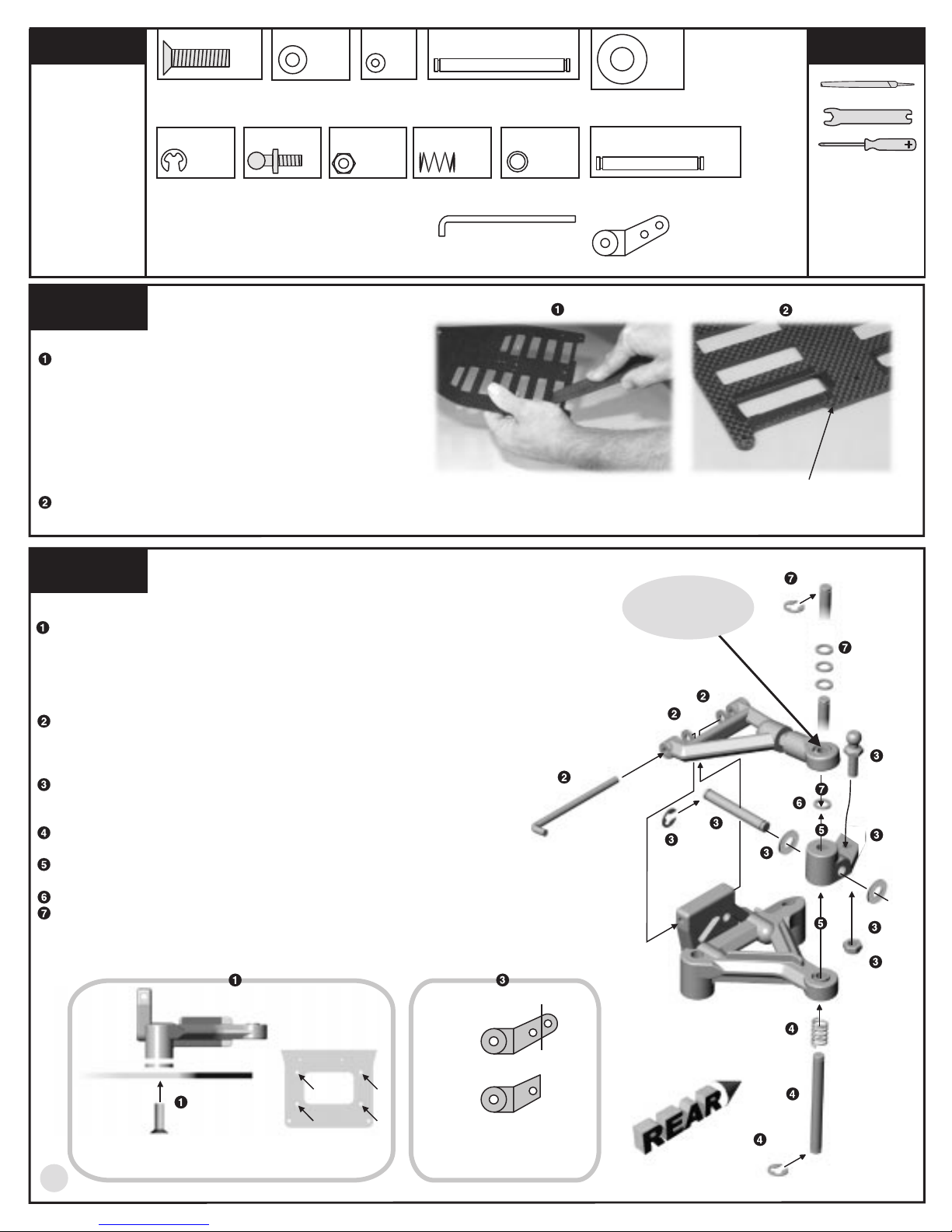

BAG A

REMOVE THESE

PARTS FOR:

TEAM: step 1

8405, qty 2

upper suspension

arm

step 1

ASSEMBLE UPPER

SUSPENSION ARM

LEFT S ID E

Assemble parts #8405, 8415,

and 8411.

ATTACH UPPER ARM MOUNT TO LOWER ARM

Attach #8407 0° mount to the #8419 lower suspension

arm using two #8409 screws.

difficult to screw in. Turn carefully so y ou do n ot s trip

out the head.

INSTALLING UPPER AND LOWER PIVOT BALLS

Before popping in the #8417 pivot balls, make sure

3

there are no burrs inside the pivot ball holes.

Pop the #8417 pivot balls into the suspension arms as

shown. Make sure that the shoulders of the pivot balls

in the lower suspension arms are facing upward and

the pivot balls in the upper arm are facing downward

as shown. Orient ball to the rounded side of the upper

arm as shown.

5

Now assemble the right side.

8407, qty 2

0° upper suspension arm

mount

WARNING!

Screws are

8419, qty 2

lower suspension

arm

8409

(blue)

right side

8415, qty 2

upper suspension

arm turnbuckle

8417, qty 4

pivot ball

8405

8409 (blue)

8407

F

R

O

N

T

1:1

left side

1:1

8411, qty 2

upper suspension

arm eyelet

8415

8417

8417

1:1

Match this number

to the text to find

your way faster

8411

the rounded corner

8419

should face up

1:1

8409, qty 4

4-40 x 1/2"

shoulder screw,

blue aluminum

shoulder down

the side with

TOOLS USED

1/16"

shoulder up

3

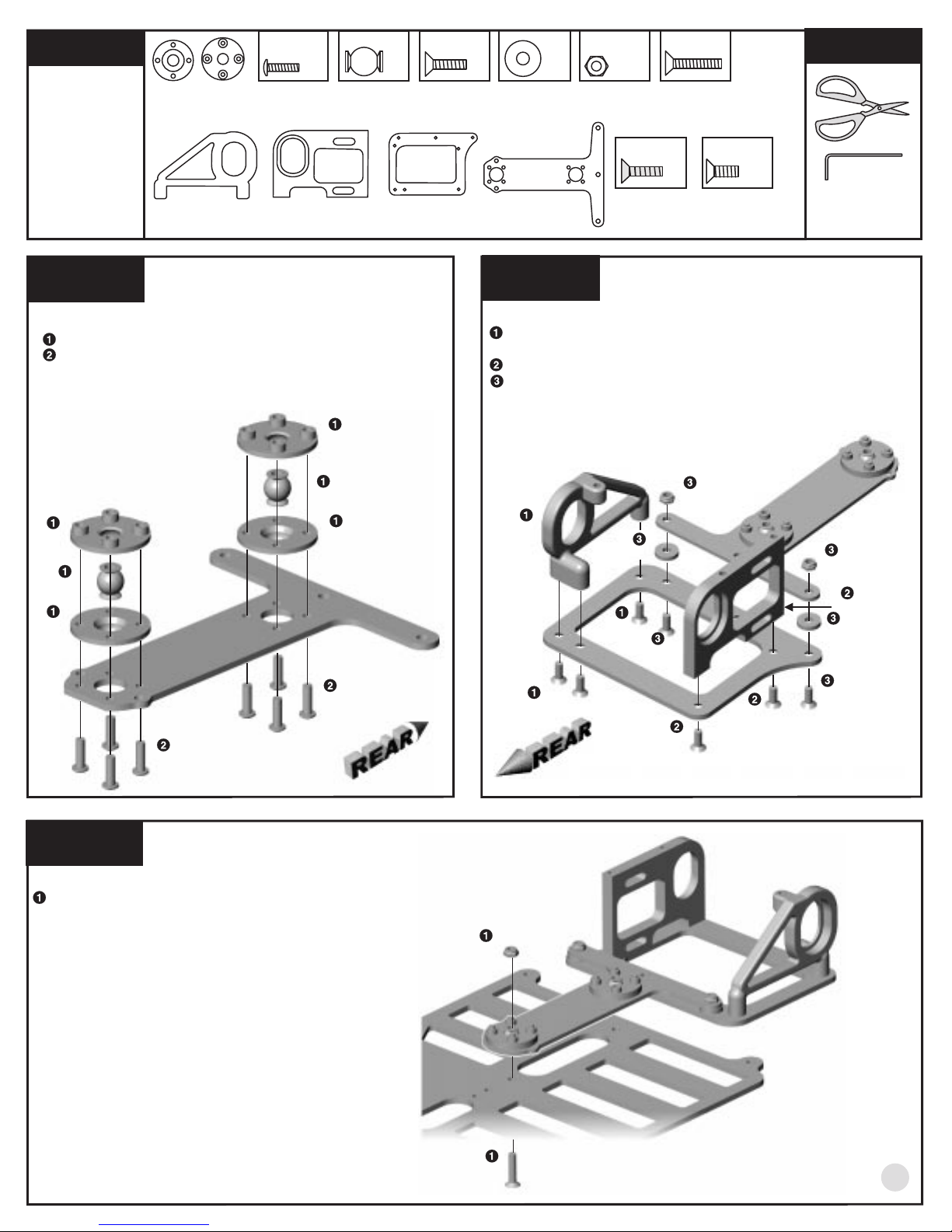

BAG A

REMOVE THESE

PARTS FOR:

TEAM: steps 2-3

8439, qty 4

8-32 x 5/8

blue aluminum

1:1

4187, qty 4

spacer

1:1

1:1

8413, qty 4

caster shim

4403, qty 2

kingpin

1:1

1:1

3323, qty 4

#8 thick washer

TOOLS U SED

1:1

6299, qty 6

E-clip

1:1

4448, qty 2

ball end

blue aluminum

4449, qty 2

4-40 locknut

step 2

FILE THE CHASSIS

Use your file to bevel the slots on the top of the chassis so

the edges won't cut through the battery cell wrap.

WARNING!

health. File in a well ventilated area. Then wash the

chassis with running water and dry with paper towels.

Wash your hands afterward with cold water and soap.

Deposit graphite filings in trash.

TAPE THE CHASSIS

Insulate the battery slots by wrapping the slots with

electrical tape.

step 3

LEFT SID E

SUSPENSION ARMS TO CHASSIS

Place two #3323 washers where shown and bolt the

suspension arm on the #4509 chassis with two #8439 blue

aluminum screws from underneath the chassis as shown

below. Do the other side.

Graphite dust can be harmful to your

1:1

1:1

4114, qty 2

spring, .018

8413, qty 2

hinge pin

1:1

8425, qty 8

kingpin shim

1599, qty 2

axle

NOTE: The bottom of the chassis

has the screw holes countersunk.

1:1

8421, qty 2

offset steering

block

the side with

the rounded corner

should face up

chassis 4509

6299

8425

UPPER ARM TO THE SUSPENSION MOUNT

Assemble the upper arm assembly to the suspension mount

as shown, using the #8413 hinge pin and #8413 shims.

FINAL FRONT SUSPENSION ASSEMBLY

Cut the #8421 steering blocks as shown below. Assemble

the steering block as shown using parts #1599, 6299, 4448,

4187, and 4449.

Place one #6299 E-clip on the bottom of the #4403 kingpin

then slide the #4114 spring over.

Slide the #4403 kingpin completely through the bottom of

the suspension arm and up through the steering block.

Place one #8425 shim on top of the #8421 steering block.

Now push the upper arm over the kingpin. Place three

#8425 shims over the kingpin and secure with a #6299 Eclip.

8

Do the other side.

3323

chassis

8439

chassis (top view)

FRONT VIEW SHOWN

4

8413

8421

before

after

CUT STEERING BLOCK

AS SHOWN

8413

6299

8413

1599

4448

8425

8421

4187

4187

4449

4114

4403

6299

BAG B

REMOVE THESE

PARTS FOR:

TEAM: steps 1-3

4335, qty 2 ea

pivot socket,

upper and lower

1:1

4334, qty 8

2-56 x 5/16

1:1

4336, qty 2

pivot ball

1:1

6292, qty 2

4-40 x 3/8

1:1

4526, qty 2

T-bar spacer

1:1

4449, qty 3

4-40 locknut

1:1

6922, qty 1

4-40 x 1/2

TOOLS USED

4536, qty 1

left rear bulkhead

4537, qty 1

motor bulkhead

step 1

LEFT S ID E

T-BAR ASSEMBLY

Assemble the #4335 T-bar sockets and #4336 pivot balls.

Secure the T-bar pivot assembly to the #4522 T-bar using

eight #4334 screws as shown, installing both on the same

side of the T-bar. The side with the screw head showing will

be the bottom.

4335

4336

4335

4336

4335

4335

4334

4532, qty 1

lower pod plate

4522

4522, qty 1

T-bar, .063"

1:1

6934, qty 3

4-40 x 3/8

blue aluminum

1:1

.050", 1/16"

7673, qty 2

4-40 x 5/16

step 2

RIGHT SIDE

REAR POD ASSEMBLY

Bolt the #4532 lower pod plate to the black #4536 left bulkhead

with three #6934 blue aluminum screws.

Bolt the aluminum #4537 motor bulkhead with two #7673 screws.

Attach the #4532 lower pod plate to the T-bar with two #4526

spacers, two #6292 screws, and two #4449 locknuts. The spacer

goes between the T-bar and the pod plate. The T-bar is on top.

4449

4536

4532

6934

4526

6934

6292

6934

7673

4449

4537

4526

6292

4334

step 3

LEFT S ID E

T-BAR TO CHASSIS

Insert the #6922 sccrew through the chassis hole shown

and into the T-bar and secure with a #4449 locknut.

4449

6922

7673

5

Loading...

Loading...