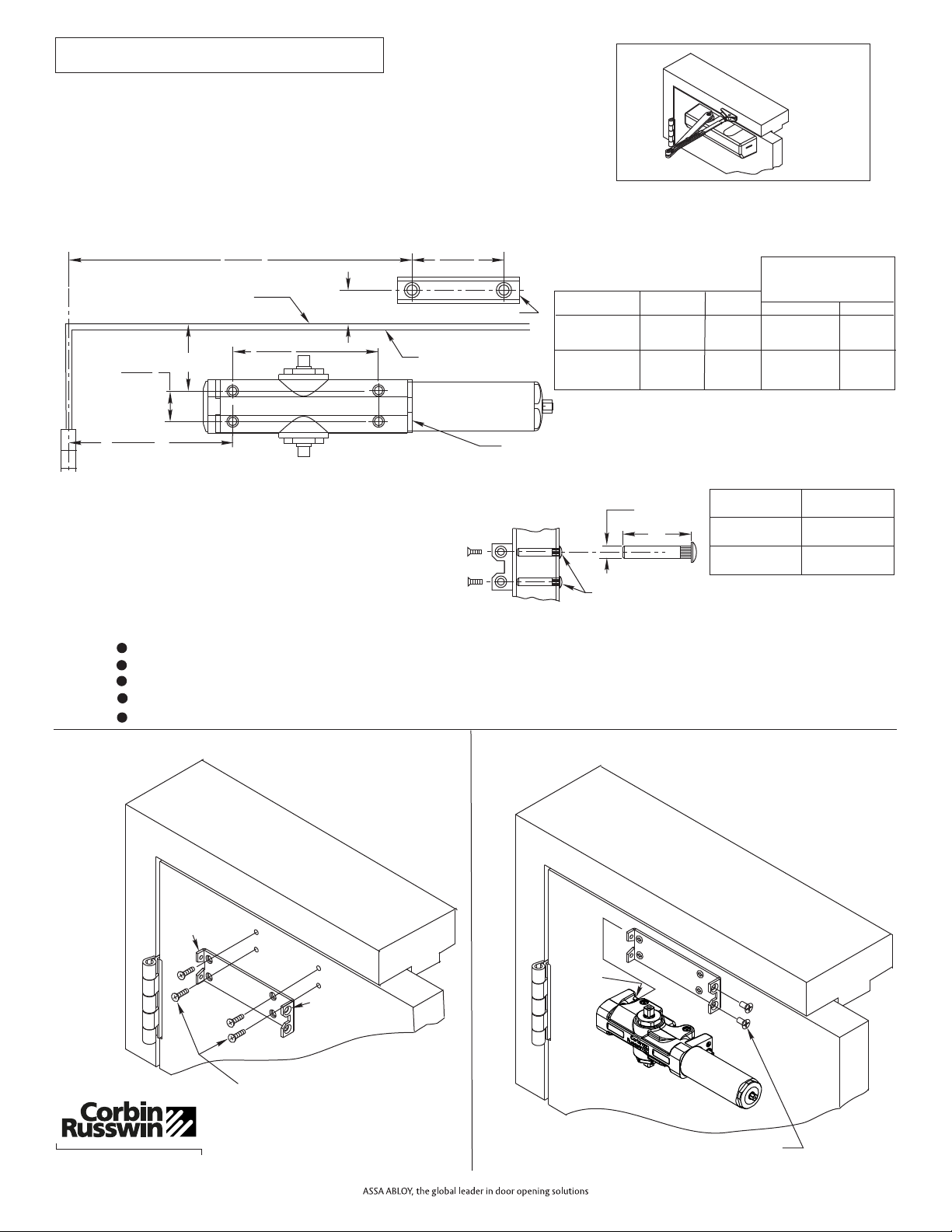

DC3200 Series

Multi-Sized 1 thru 6

Installation Instructions

ASSA ABLOY

Universal Door Closers

For Non-Hold Open or “A1”

Hold Open Arm Options

®

DC3200

IMPORTANT:

BEFORE

INSTALLING:

Regular Arm

See pages

2 & 3

An improperly installed or incorrectly adjusted door closer may cause property

damage or personal injury; and will void product warranty.

To avoid personal injury, DO NOT DISASSEMBLE THIS DOOR CLOSER BODY.

Door closers must be securely fastened to a properly reinforced door and frame

with fasteners provided.

Door closers with the “A1” HOLD OPEN ARM option are not permitted to be

installed in fire door assemblies.

The Americans with Disabilities Act (ADA) requires that doors having door closers

have an opening force not to exceed 5 lbf. for interior doors, 8.5 lbf exterior doors.

Use standard templating for regular arm and parallel arm applications. Jamb

mounted applications use the template for 140° door opening to achieve the

required opening force.

The door closer's power size adjustment feature may require adjustment to its

lowest setting to comply with ADA opening force guidelines.

ADA compliant closers are: DC3200, DC3210, DC3220

DC3210

Parallel Arm

See pages

4 & 5

Jamb Mount

See pages

6 & 7

DC3220

Size of Door & Door Closer

Type

of

Installation

Regular &

Top Jamb

Parallel

Arm

**NOTE: These forces are for standard templating with bearing type hinges and do not account for pressure differentials and draft.

80-9330-3000-152 Rev. 05/12

Interior

' "

2 4

' "

3 0

' "

3 6

' "

4 0

' "

4 6

' "

5 0

' "

2 4

' "

2 6

' "

3 0

' "

3 6

' "

4 0

' "

4 6

Exterior

In-swinging

' "

2 6

' "

3 0

' "

3 6

' "

*4 0

Exterior

Out-swinging

3 0

' "

3 6

' "

4 0

' "

*4 6

' "

' "

2 6

' "

3 0

' "

*3 6

' "

*4 0

Recommended

Closer Size

1

2

3

4

5

6

1

2

3

4

5

6

**Max.

Opening

Force

lbs/f

8

14

16

22

24

26

8

14

16

22

24

26

TO DETERMINE

HAND OF

YOUR DOOR:

RHR

LEFT

HAND

DOOR

RIGHT

HAND

DOOR

LHR

Installation Instructions

Regular Arm Application

DC3200 Series

1. Template

Mark Door and Jamb (for closer bracket and arm bracket)

1

"

"

*10-5/8

(270)

FRAME LINE

A

4-5/16

(109.5)

2-1/4

(57.2)

B

ARM BRACKET

TOP OF DOOR

MOUNTING DIMENSIONS

TOP RAIL

2-1/2 & OVER

"

(64mm)

"

1-3/4 MIN.

(44mm)

If top rail is 2-1/2 (64mm) or greater, use template FM131C provided.

If top rail is 1-3/4 (44mm) to 2-7/16 (62mm), see MOUNTING DIMENSIONS chart.

C

HINGE OR PIVOT

L

(25.4)

A

"

1

(25.4mm)

5/8

"

(16mm)

B

7/8

"

(23mm)

1-1/4

(32mm)

"

Regular Arm

MIN. CLEARANCE

REQUIRED OVER

DOOR

NHO

"

"

1-11/16

(43mm)

2-1/16

(53mm)

1-1/2

(39mm)

1-7/8

(48mm)

HO

"

"

*7-1/2

(191)

To obtain extra closing force add 3 (77mm) to dimensions marked.

*

This will limit degree of door opening to 110°.

MOUNTING SCREW SPECIFICATIONS

ARM AND CLOSER BRACKET

1/4-20 oval head machine screw

or 1/4-14 self-drilling screw.

3/16 (4.8) diameter pilot hole

required for Wood Applications.

NOTES:

}

or

{

Check hand of door, see page 1.

Right Hand Application Shown. Left Hand Opposite.

Dimensions given in inches (mm). Do Not Scale Drawing.

Closer must be installed in a true horizontal plane to ensure proper closer performance.

Door opening (up to 180°) is dependent upon door, frame, wall and hinge/pivot conditions permitting.

2. Install Closer Bracket

"

Option M54:

Sex nuts, furnished

when ordered

CLOSER BRACKET

3/8

(10)

L

1/4-20 THREAD

Drill thru 9/32 (7.1) Enlarge to

3/8 (9.5) Dia. This Side Only

(4 Places)

THICKNESS

1-3/8 (35mm)"

1-3/4 (44mm)

DOOR

"

& OVER

SEX NUT

LENGTH “L”

1-9/32 (33mm)"

1-21/32 (42mm)"

3. Mount Closer Body to Closer Bracket

Pin Hole

End

®

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

Countersunk

Hole End

1/4-14 x 1-1/2 OH Self-Drilling (4)

or

1/4-20 x 3/4 OHMS w/ Sex Nuts (4)

(M54 Option)

Pins

(2)

1/4-20 x 1/2 OHMS (2)

Page 2

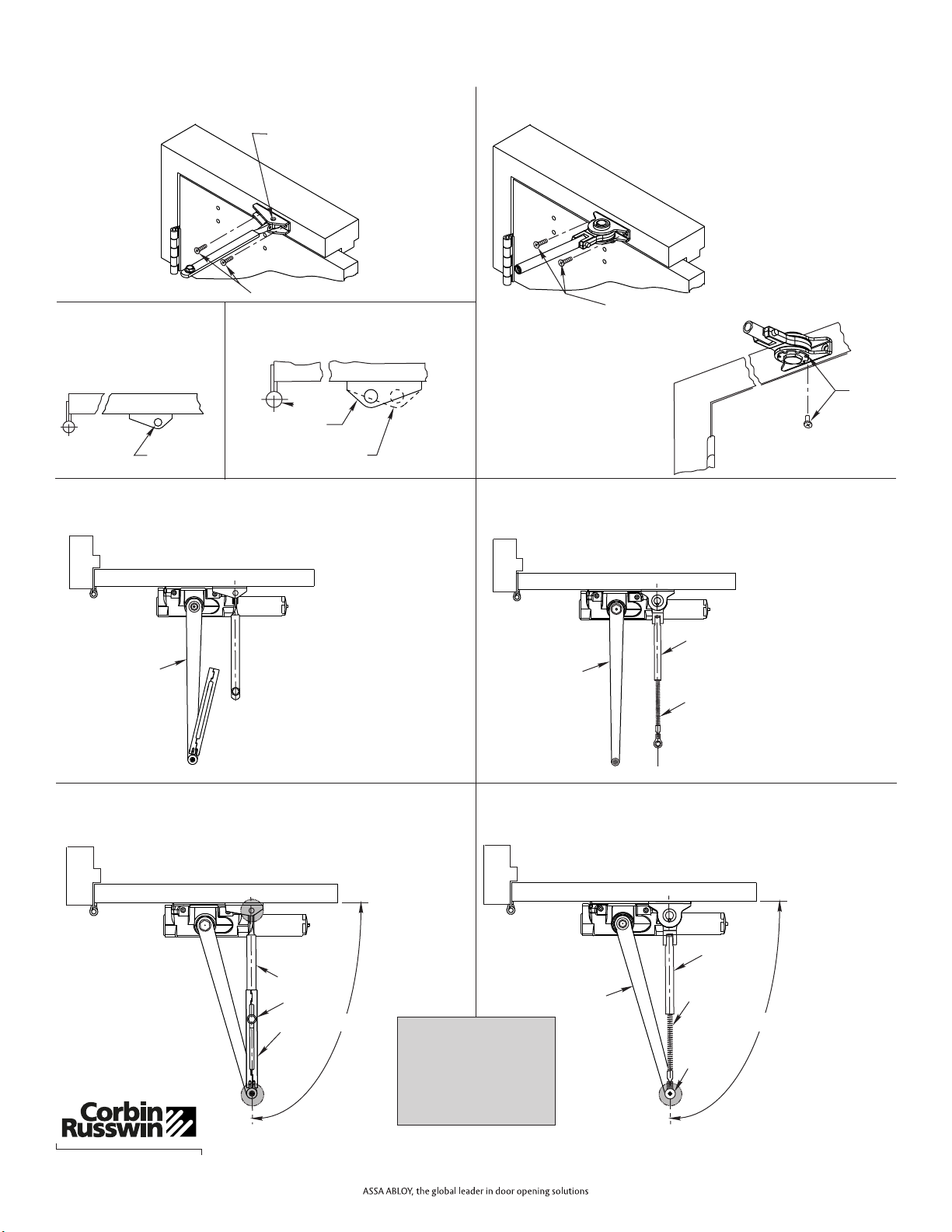

Regular Arm Application (Continued)

4a. Attach Arm Bracket to Frame

NON-HOLD OPEN ARM ONLY:

Pivot (away from hinge)

1/4-14 x 1-1/2 OH Self-Drilling (4)

Standard Position

Normal mounting position.

Position with pivot point

away from hinge.

Away from

hinge

For Additional 15% Closing Force

Reposition arm mounting bracket so that

pivot point is toward hinge.

Hinge

FOR MAXIMUM

POWER

FOR REGULAR

POWER

5a. Position Arm on Closer

NON-HOLD OPEN ARM ONLY:

Main arm projects straight out at 90° angle to door.

4b. Attach Arm Bracket to Frame

HOLD OPEN ARM (A1 OPTION ONLY):

1/4-14 x 1-1/2 OH Self-Drilling (4)

HOLD OPEN ARM:

Position so that dial

screw is on

UNDERSIDE of bracket

5b. Position Arm on Closer

HOLD OPEN ARM ONLY:

Main arm projects straight out at 90° angle to door. Remove main

arm screw from elbow joint and disassemble arm. Thread the rod

into the Arm Bracket as shown below.

DIAL

SCREW

MAIN ARM

6a. Preload and Adjust Arm

NON-HOLD OPEN ARM ONLY:

Open door and slide arm rod into arm loop. Close door, swing arms

so adjusting arm is 90° to frame. With 7/16 wrench INSTALL and

TIGHTEN SCREW SECURELY.

ARM ROD

SCREW

ARM

LOOP

®

"

90°

MAIN ARM

6b. Preload and Adjust Arm

HOLD OPEN ARM ONLY:

While door is closed, adjust the Threaded Arm in the Arm Bracket

until the bearing fits back onto the elbow joint on the Main Arm at 90°

as shown below. RE-INSTALL AND TIGHTEN SCREW SECURELY.

MAIN ARM

Extended Maintenance

Lubricate Arm periodically

shaded points with a drop or

two of appropriate lubricant.

NOTE: When lubricating a

Hold Open Arm, DO NOT

use any lubricant on the

Holding Surface components.

at

ARM

BRACKET

THREADED

ROD

ARM

BRACKET

THREADED

ARM

SCREW

90°

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

For Adjustments See Page 8

Page 3

Installation Instructions

Parallel Arm Application

DC3210 Series

1. Template

Mark Door and Jamb (for closer bracket and adapter plate)

Use template FM131C provided or use dimensions in this template.

6-1/8

5/8

(16)

*

(156)

2-3/4

(70)

SPACER BLOCK

(When required)

Parallel Arm

FRAME

DOOR

FRAME STOP

TOP OF DOOR

1

(25.4)

To obtain extra closing force add 3 (77mm) to dimensions marked.

*

FRAME STOP

4-5/16

(109.5)

CLOSER

BRACKET

1/4

(6.35)

"

1-1/2

(38.1)

2-3/4

(70)

*

5/8

(16)

7-1/2

(191)

This will limit degree of door opening to 110°.

MOUNTING SCREW SPECIFICATIONS

ARM AND CLOSER BRACKET

1/4-20 oval head machine

screw or 1/4-14 self-drilling

screw. 3/16 (4.8) diameter

pilot hole required for Wood

Applications.

}

2. Install Closer Bracket

Option M54:

Sex nuts, furnished

or

{

when ordered

3. Mount Closer Body to Closer Bracket

HINGE

C

OR

L

PIVOT

NOTES:

Check hand of door, see page 1.

Right Hand Application Shown. Left Hand

Opposite.

Dimensions given in inches (mm). Do Not

Scale Drawing.

Closer must be installed in a true horizontal

plane to ensure proper closer performance.

Door opening (up to 180°) is dependent

upon door, frame, wall and hinge/pivot

conditions permitting.

3/8

(10)

1/4-20 THREAD

Drill thru 9/32 (7.1) Enlarge to

3/8 (9.5) Dia. This Side Only

(4 Places)

ADAPTER

PLATE

L

5/8

(16)

DOOR

THICKNESS

1-3/8 (35mm)"

"

1-3/4 (44mm)

& OVER

REF.

DOOR

1-9/32 (33mm)"

1-21/32 (42mm)"

SEX NUT

LENGTH “L”

1/4-14 x 1-1/2 OH Self-Drilling (4)

1/4-20 x 3/4 OHMS w/ Sex Nuts (4)

Pin Hole End

®

Countersunk Holes

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

or

(M54 Option)

Holding Pins

1/4-20 x 1/2 OHMS (2)

Page 4

Parallel Arm Application (Continued)

4. Mount Adapter Plate

5. Mount Arm Bracket

Bracket on Jamb

Using holes spotted on

soffit or stop in Step 1

mount adapter plate

bracket.

6. Position Arm onto Closer

Using hex wrench provided, turn closing speed and latching speed

valves clockwise until completely closed. DO NOT OVER TIGHTEN.

Using wrench, turn under side of spindle 45° toward the closer

tube until it reaches the diamond position (fig. 2). Immediately

place arm on spindle so that it is parallel to the closer body.

Install and tighten arm screw and washer assembly.

Reopen valves.

NON-HOLD OPEN ARM:

1/4-20 x 1-1/2 OHMS (2)

Pivot point must

be AWAY from hinge

edge of door.

R

F

Y

A

W

A

HOLD OPEN ARM ONLY (A1 Option)

1/4-20 x 1-1/2 OHMS (2)

DIAL SCREW

Install with dial

screw facing down.

5/16 Hex Head

R

O

O

D

F

O

E

G

D

E

E

G

N

I

H

M

O

Screw & Washer Assembly

CLOSER TUBE

CLOSING

SPEED

VALVE

Fig. 1

Square position

At rest

Fig. 2

Diamond position

Rotated 45°

7. Connect and Position Arms

Open door and slide arm rod into arm loop.

door, swing arms so that they form a “V” position,

as in Step 8. With 7/16 wrench, INSTALL AND

"

TIGHTEN SCREW SECURELY.

Close

LATCHING

SPEED VALVE

HOLD OPEN ONLY

Remove main arm screw from elbow joint and disassemble

arm. Thread the rod into the Arm Bracket as shown below.

While door is closed, adjust the Threaded Arm in the Arm

Bracket until the bearing fits back onto the elbow joint on

the Main Arm and forms a "V" as shown below.

RE-INSTALL AND TIGHTEN SCREW SECURELY.

ARM LOOP

ARM ROD

SCREW

THREADED

ARM

8. Power Adjustment

To increase the power of the closer, re-adjust the arm so it is nearer the door.

To decrease power, re-adjust the arm so it is farther away from the door and

then secure screw in arm loop (non-hold open) or elbow joint (hold open).

Rotate 45°

MAIN ARM

ARM

BRACKET

Extended Maintenance

Lubricate Arm periodically with a drop

or two of appropriate lubricant.

NOTE: When lubricating a Hold Open Arm, DO NOT use

any lubricant on the Holding Surface components.

at shaded points

3-0

MAX.

(76)

®

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

MINIMUM POWER

For Adjustments See Page 8

1-1/2

(38)

MIN.

MAXIMUM POWER

Page 5

Installation Instructions

Jamb Mount Application

DC3220 Series

1. Template

Mark Door and Jamb (for closer bracket and arm bracket)

use dimensions in template below.

Jamb Mount

CEILING LINE

1

2-1/4

(57.2)

(25.4)

}

4-5/16

(109.5)

or

{

CLOSER

BRACKET

FRAME

STOP

TOP OF

DOOR

ARM BRACKET

MOUNTING SCREW SPECIFICATIONS

ARM AND CLOSER BRACKET

1/4-20 oval head machine

screw or 1/4-14 self-drilling

screw. 3/16 (4.8) diameter

pilot hole required for Wood

Applications.

NOTES:

FRAME

1-9/16

B

Sex nuts, Option

M54, furnished

when ordered

TOP OF FRAME

A

FRAME

LINE

(40)

1/2

(12.7)

1-3/4

(44)

MIN.

3/8”

(10)

1/4-20 THREAD

Drill thru 9/32 (7.1) Enlarge to

3/8 (9.5) Dia. This Side Only

OPENING

MAXIMUM

3

(76)

MIN.

110°

140°

180°

140°

Dimensions “A” and “B” are taken from

centerline of hinge as shown and apply to

pivot point of swing clear hinges. Offset

and centerhung pivots.

*Must be single acting door.

L

(4 Places)

A

8-7/8

(225)

7-3/8

(187)

5-7/8

(149)

7-3/8

(187)

THICKNESS

1-3/8 (35mm)"

1-3/4 (44mm)

Check hand of door, see page 1.

Right Hand Application Shown. Left Hand Opposite.

Dimensions given in inches (mm). Do Not Scale Drawing.

Closer must be installed in a true horizontal plane to ensure proper closer performance.

All degrees of door opening are dependent upon door, frame, wall and hinge/pivot conditions permitting.

13-3/8

(340)

11-7/8

(302)

10-3/8

(264)

11-7/8

(302)

DOOR

"

& OVER

B

HINGE

CONDITION

Butts, Offset

Pivots, and

Swing Clear

Hinges

CENTER

*

HUNG

SEX NUT

LENGTH “L”

1-9/32 (33mm)"

1-21/32 (42mm)"

2. Install Closer Bracket to Jamb

1/4-14 x 1-1/2 OH Self-Drilling (4)

Countersunk

Hole End

Pin Hole End

®

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

3. Mount Closer Body to Closer Bracket

Holding Pins

1/4-20 x 1/2 OHMS (2)

Page 6

Jamb Mount Application (continued)

4a. Attach Arm Bracket to Door

NON-HOLD OPEN ARM ONLY:

Pivot

(away from Hinge)

Standard Position

Normal mounting position.

Position with pivot point

away from hinge.

Away from hinge

For Additional 15% Closing Force

1/4-14 x 1-1/2 OH Self-Drilling (2)

1/4-20 x 3/4 OHMS w/ Sex Nuts (2)

Reposition arm mounting bracket so that

pivot point is toward hinge.

(M54 Option)

FOR REGULAR

POWER

5a. Position Arm on Closer

NON-HOLD OPEN ARM ONLY:

Main arm projects

straight out at 90°

angle to door.

or

Hinge

FOR MAXIMUM

POWER

MAIN ARM

4b. Attach Arm Bracket to Door

HOLD OPEN ARM (A1 Option):

1/4-14 x 1-1/2 OH Self-Drilling (2)

1/4-20 x 3/4 OHMS w/ Sex Nuts (2)

Install with dial screw

facing down

or

(M54 Option)

FRAME STOP

DIAL

SCREW

5b. Position Arm on Closer

HOLD OPEN ARM ONLY (A1 Option):

Main arm projects straight

out at 90° angle to door.

Remove main arm screw

from elbow joint and

disassemble arm. Thread

the rod into the Arm Bracket

as shown below.

ARM

BRACKET

THREADED

ROD

MAIN ARM

6a. Preload and Adjust Arm

NON-HOLD OPEN ARM ONLY:

Open door and slide arm rod into arm loop. Close door,

swing arms so adjusting arm is 90° to frame. With 7/16

wrench, INSTALL and TIGHTEN SCREW SECURELY.

ARM ROD

SCREW

90°

ARM

LOOP

®

For Adjustments See Page 8

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

6b. Preload and Adjust Arm

HOLD OPEN ARM ONLY (A1 Option):

While door is closed, adjust the Threaded Arm in

"

Extended Maintenance

Lubricate Arm periodically

shaded points with a drop or

two of appropriate lubricant.

NOTE: When lubricating a

Hold Open Arm, DO NOT

use any lubricant on the

Holding Surface components.

the Arm Bracket until the bearing fits back onto the

elbow joint on the Main Arm at 90° as shown below.

RE-INSTALL and TIGHTEN SCREW SECURELY.

at

ARM

BRACKET

THREADED

ARM

90°

MAIN ARM

SCREW

Page 7

Spring Power Adjustment

Locate spring power adjuster from Illustration below

DC3200 Size 1 thru 6 Adjustment See Chart

DC6200 SPRING POWER ADJUSTMENT CHART

All DC6200 closers are factory set at an approximate Size 3.

Adjust closer as necessary for door size using this chart.

Readjustment may be required to suit prevailing conditions.

Interior

' "

2 4 (712)

' "

2 6 (764)

' "

3 0 (915)

' "

3 6 (1067)

Size of Door

Exterior

In

Swing

' "

2 6 (764)

' "

3 0 (915)

' "

3 6 (1067)

' "

4 0 (1219)

Exterior

Out

Swing

2 6 (764)

' "

3 0 (915)

' "

No. of Full

(360°) Turns

Clockwise

of Power

Adjuster

4

8

12

16

Equivalent

Closer Size

(Approx.)

2

3

4

5

CLOSING

SPEED VALVE

OPTION M71

DELAYED

ACTION VALVE

BACKCHECK

LOCATION VALVE

BACKCHECK

INTENSITY VALVE

(FLAT TIP SCREWDRIVER

W/ 5 (127mm) Min. Shaft Length)"

SPRING POWER ADJUSTER

(5/16 WRENCH or SOCKET)"

a

l

y

e

e

d

D

t

i

o

c

n

d

e

e

p

S

g

n

i

s

o

l

C

hc

t

a

L

Closing Speed Valve

A

Option

M-71

(3/32 Allen Wrench Provided)

To adjust speed of door closing from fully open to a position

2 to 5 from closed, turn Closing Speed Valve CLOCKWISE

" "

to SLOW closing, COUNTER-CLOCKWISE to SPEED

closing.

Latching Speed Valve

(3/32 Allen Wrench Provided)

After closing speed has been obtained, turn latching speed valve

CLOCKWISE to SLOW latching or COUNTER-CLOCKWISE to

SPEED latching for last 2 to 5 of door travel.

" "

NOTE: Set combination of CLOSING and LATCHING speeds to

h

e

c

k

c

c

k

a

B

Installing Cover

To Adjust Hold Open (A1 Option)

Open the door to desired position and tighten the hold open

screw firmly (For RH application, turn screw on underside

CLOCKWISE. For LH application, turn screw COUNTERCLOCKWISE.) Place the hold open dial over the hex head

of the bracket screw so that one of the slots in the dial is

directly over small screw hole tapped in bracket. Seat the

dial tightly over the bracket. INSERT DIAL SCREW AND

TIGHTEN SECURELY.

between 3 and 7 seconds Use of door by handicapped,

elderly or small children may require even greater

closing time.

Delayed Action Valve

(3/32 Allen Wrench Provided)

Turn valve CLOCKWISE to SLOW closing, COUNTERCLOCKWISE to SPEED closing. Delayed action may be

adjusted from 20 seconds to 90 seconds, depending on

degree of door swing. Delay occurs at the beginning of the

door closing cycle from fully open down to 70°, where the

closing speed valve then begins its control.

Backcheck Intensity Valve

Turn valve COUNTER-CLOCKWISE to reduce backcheck

or CLOCKWISE to increase backcheck. (Backcheck should

be set to give a soft cushioning action, not a sudden stop.)

®

Full Cover

(Standard)

DIAL

LATCHING

SPEED

VALVE

Power

Size

Date Stamp

Stamp

Slip cover over closer. Hold tightly

against closer mounting surface.

Secure on each side with 6-32 x

1/4 PBHMS screws."

HOLD OPEN

SCREW

DIAL

SCREW

ASSA ABLOY

80-9330-3000-152 Rev. 05/12

Copyright© 2005, 2012 Corbin Russwin, Inc., an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Corbin Russwin, Inc. is prohibited.

Page 8

Loading...

Loading...