Page 1

PN# 500-16900

Rev. A.2, 10/03

SECURITRON MODEL DK-26 DIGITAL KEYPAD

TABLE OF CONTENTS AND GUIDE TO THIS MANUAL

The DK-26 is a powerful and versatile product with many features and modes of operation. In

most applications you will use only some of these features so this table of contents includes a

description of the type of application that applies to each different section. By studying it first,

you can save considerable time by skipping over those parts of the manual that don't apply to

your application.

SECTION 1. DESCRIPTION --------------------------------------------------------------------Page 1

SECTION 2. PHYSICAL INSTALLATION---------------------------------------------------Page 1

SECTION 3. WIRING------------------------------------------------------------------------------Page 3

SECTION 3.1 POWER SELECTION----------------------------------------------------------Page 3

This section explains the power that must be used and gives you power consumption

figures.

SECTION 3.2 CONNECTING THE KEYPAD CABLE TO THE CPU BOARD -----Page 3

SECTION 3.3 POWER AND ELECTRIC LOCK WIRING--------------------------------Page 3

This section introduces the different basic wiring schemes generally required for electric

strike control (no exit switch needed). The three sections below provide separate drawings

and descriptions depending on your power source and on the power required by the lock.

SECTION 3.3.1 AC LOCK WITH AC POWER ---------------------------------------------Page 3

SECTION 3.3.2 DC LOCK WITH AC POWER ---------------------------------------------Page 5

SECTION 3.3.3 DC LOCK WITH DC POWER ---------------------------------------------Page 6

SECTION 3.4 USE OF THE “F” TERMINAL -----------------------------------------------Page 7

The “F” terminal is mainly used for convenient connection of fire alarm contacts which will

release a fail safe lock in the event of activation of the fire alarm.

SECTION 3.5 ADDING OTHER LOCK CONTROL SWITCHES-----------------------Page 7

This section and drawing show proper connection for an external switch such as from

Securitron’s Lock Control Panel.

SECTION 3.6 THE REX FUNCTION----------------------------------------------------------Page 8

When you are using a magnetic lock or solenoid bolt, you often require a separate switch to

allow egress. This switch can be connected to the CPU board to provide timed egress in

different ways. This section fully covers this requirement.

SECTION 4. PROGRAMMING -----------------------------------------------------------------Page 10

SECTION 4.1 FIXED PROGRAMMING------------------------------------------------------Page 10

Fixed programming is for lower security applications when the code is not expected to need

regular changing by the user. The “Hard” code is used for this requirement.

© Copyright, 2003, all rights reserved • Securitron Magnalock Corp., 550 Vista Blvd., Sparks NV 89434, USA

Tel: (775) 355-5625 • (800) MAGLOCK • Fax: (775) 355-5636 • Website: www.securitron.com

An ASSA ABLOY Group company

Page 2

Rev. A.2. 10/03

SECTION 4.2 KEYPAD CHANGEABLE PROGRAMMING-----------------------------Page 12

This section explains how to set up easy code change from the keypad by employing a

Program code which is relatively constant and a User code which is often changed for better

security.

SECTION 4.2.1 CHANGING THE USER AND PROG. CODE FROM KEYPAD --Page 13

This details the code changing procedure that should be taught to the end user.

SECTION 4.2.2. ADDING MULTIPLE USER CODES------------------------------------Page 14

The previous two sections explain how to set up keypad changeable programming for the

common requirement of a single User code. Up to 59 separate User codes can be added to

memory so that individuals or groups can have their own code. This section explains the

procedure.

SECTION 4.3 “MASTERKEY” USE OF THE HARD CODE----------------------------Page 14

The Hard code is normally used for “fixed” programming but in a multiple door installation, it

can be used as a “masterkey” code which will open all doors.

SECTION 4.4 SUBSET CODES----------------------------------------------------------------Page 15

This section must be read for all multiple code installations.

SECTION 4.5 DELETING CODES-------------------------------------------------------------Page 15

This section is most important for multiple code installations but should at least be scanned

for all installations as it explains all code deletion procedures.

SECTION 4.6 SETTING THE TIME RANGE AND TOGGLE MODE -----------------Page 16

As factory set, the DK-26 will release the lock for five seconds. This section explains how to

change that setting and enable “toggle” mode where successive code entries will energize

and then deenergize the lock control relay.

SECTION 5. CHANGING LED AND BEEPER OPERATION---------------------------Page 16

Special commands can be sent to the CPU board from the keypad to change the way the

beeper and LED’s function.

SECTION 6 USE OF THE PROGRAMMABLE RELAY----------------------------------Page 17

The CPU board has a second relay that can be assigned to any of several functions which

are explained in the following sections. These are enhancements to a standard installation

and are therefore not always used.

SECTION 6.1 DOORBELL FUNCTION------------------------------------------------------Page 17

Pressing the “Bell” key will energize the programmable relay which can be used to summon

someone to the door.

SECTION 6.2 DURESS FUNCTION ----------------------------------------------------------Page 17

This section applies only in high security applications where you require the user to be able

to activate a silent alarm if someone is forcing him to open the door via the Keypad. The

programmable relay is used to send this signal.

Page 3

Rev. A.2. 10/03

SECTION 6.3 ANTI-TAMPER ALARM FUNCTION ---------------------------------Page 18

Someone entering 16 wrong digits while attempting to guess the code will activate the

programmable relay.

SECTION 6.4 DOOR PROP ALARM FUNCTION-----------------------------------------Page 18

The programmable relay will activate if the door is left open too long.

SECTION 6.5 NIGHTLIGHT FUNCTION-----------------------------------------------------Page 19

The programmable relay will activate for five seconds when any key is pressed. This can be

used to turn on a lamp (not supplied) for operation in the dark.

SECTION 7 ADDITIONAL HARD WIRED OPTIONS -------------------------------------Page 19

The sections that follow discuss additional ways to use the DK-26.

SECTION 7.1 DUAL PAD OPERATION-----------------------------------------------------Page 19

This section applies if you want to use two Keypads reporting to one CPU Board for digital

control of entry and exit.

SECTION 7.2. HARD WIRED CODE DISABLING ----------------------------------------Page 19

Through the use of jumpers or external switches you can disable the Hard code and/or all

User codes. This is generally used with a time clock for day/night operations.

SECTION 7.3 ALARM SYSTEM SHUNTING-----------------------------------------------Page 20

The DK-26 can shunt an active alarm point for authorized entry.

SECTION 7.4 ANTI-TAILGATING-------------------------------------------------------------Page 20

With this feature, you can abort the DK-26’s timer once the door is opened to make sure

only one person enters.

SECTION 7.5 WIRING WITH TOUCH SENSE BAR AND MAGNALOCK----------Page 20

This section provides a drawing for a popular combination of Securitron products.

APPENDIX A COMMAND SUMMARY -------------------------------------------------------Page i

This section lists all possible command sequences that can be sent to the unit when it is in

program mode. These commands are referenced throughout the manual as they apply to

different requirements.

APPENDIX B TROUBLE SHOOTING --------------------------------------------------------Page ii

Page 4

Rev. A.2, 10/03 Page-1

SECURITRON MODEL DK-26 DIGITAL KEYPAD

INSTALLATION & OPERATING INSTRUCTIONS

1. DESCRIPTION

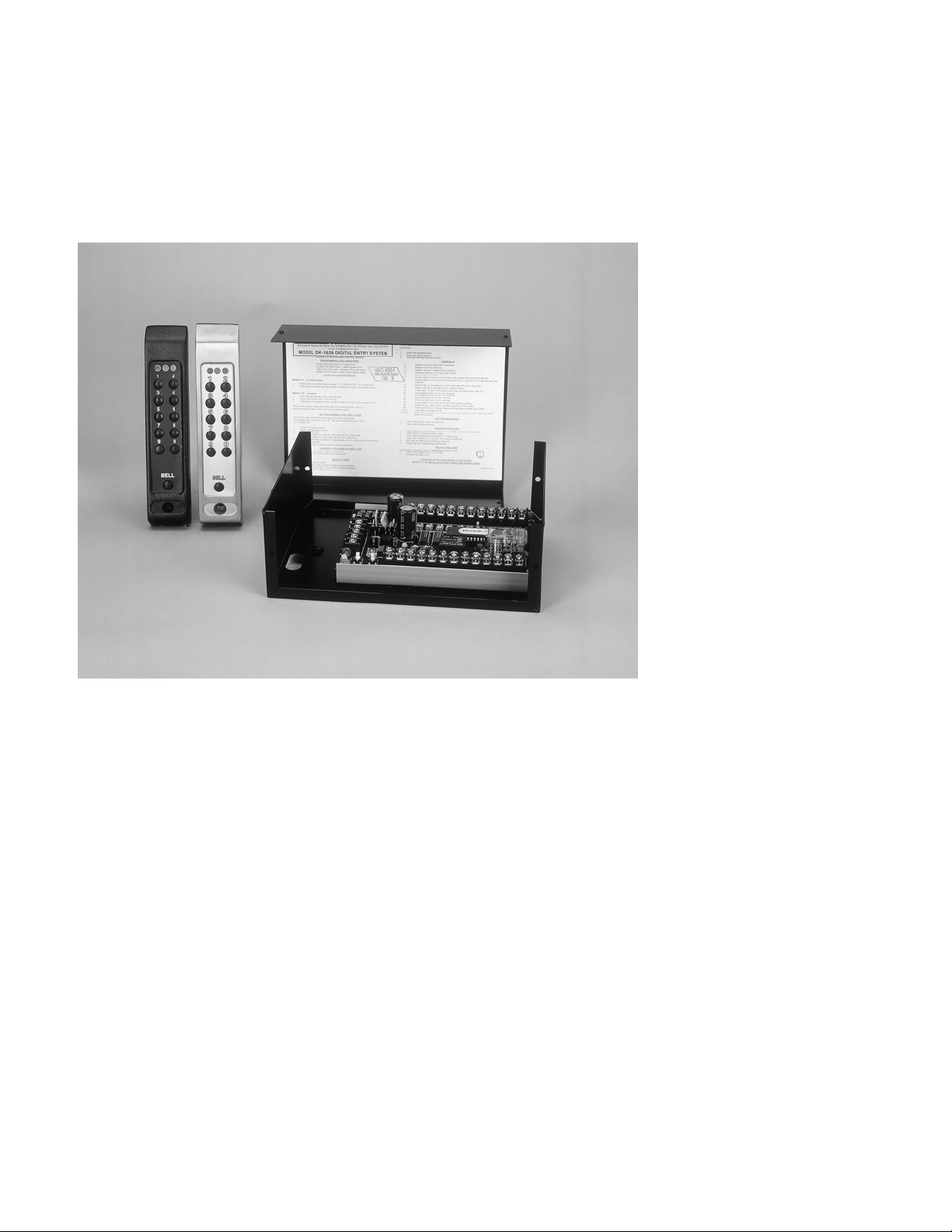

Securitron's DK-26 is a

digital keypad system

designed for medium/high

security control of electric

locks. It consists of two

components: the keypad

and the CPU board

connected by a 16 ft.

cable. This allows the

CPU board to be mounted

within the protected

area for higher security.

Tampering with or even

destroying the keypad will

not release the door. The

rugged stainless steel

keypad may be mounted

outdoors in any

environment as it is fully

weatherproof. The

keypad features true 10

digit operation (keys are

not paired), three LED’s

and a beeper.

2. PHYSICAL INSTALLATION

The first step is to plan the physical location of the two components. The keypad is normally

surface mounted on the outside of the door to be controlled, and the CPU Board is mounted

inside the protected area safe from tampering.

To install the keypad, holes must be drilled for the 2 mounting screws and the cable. A template

is not provided due to unavoidable variations on the cable exit of each keypad. Referring to

Figure 1, note that the top screw engages the slot at the top of the keypad. Once the top screw

has been installed, the location of the cable hole should be set roughly by positioning the

keypad and marking the cable hole point. Make sure the keypad is pulled down firmly on to the

screw. A 3/8" (10MM) hole is then drilled for the cable. After the cable has been pulled through,

the final screw secures the keypad to the wall. Note that 2 alternate bottom screws are supplied

with the unit. One is a #10 spanner head for improved tamper resistance. Alternately the #8

Phillips standard screw may be used. After this, peel the backing of the enclosed Securitron

DK-26 label and affix it to the bottom of the keypad covering the head of the screw. This

not only improves the appearance of the keypad but helps foil casual vandalism. Note finally

that a blank rectangular label has also been furnished. This can be used to cover up the

“BELL” legend if you don’t intend to utilize the doorbell function and are concerned that people

will press the BELL key and expect someone to come to the door.

Page 5

Rev. A.2, 10/03 Page-2

FIG. 1: PHYSICAL INSTALLATION OF KEYPAD

(1) MOUNT SCREW TO ENGAGE SLOT AT

TOP OF KEYPAD

DRILL 1/8" (3MM) HOLE

MOUNTING

SURFACE

CABLE

(2) DRILL 3/8" (10 M M ) HOLE FOR CABLE

(3) SECURE BOTTOM WI TH SECOND

SCREW. COVER SCREW HEAD WITH

"DK-26" LABEL.

DRILL 1/8" (3MM) HOLE

NOTE: CHOOSE PHILIPS OR SPANNER

(TAMPER) HEAD SCREW

The CPU Board is furnished in a snap-apart steel enclosure with the board itself mounted on

plastic snap-trak. The CPU Board must be installed in a dry location free of extremes of

temperature and humidity. If the 16 ft., twelve conductor cable that is included is not of sufficient

length, additional cabling can be spliced by the installer. However, a long cable run can give

rise to electronic noise problems in certain environments. It should therefore be avoided where

possible and in no case should cable length exceed 100 ft. (30 meters).

Cable entry to the CPU board enclosure can be handled in one of two ways. There is a hole in

the bottom of the enclosure, the use of which creates the most attractive installation as the cable

is completely hidden. Alternately, there is a side knockout in the enclosure cover which permits

surface mounting of the cable. The side knockout also permits a wiring technique which is

convenient when the CPU board enclosure is to be mounted in an awkward location such

as above a drop ceiling. You can pop the board itself out of its snap track and make all your

connections with the board in your hands. The board is then re-snapped into the plastic trak.

The enclosure cover snaps on with the wires emerging from the side knockout. If you use this

technique, avoid touching the components or rear pins on the board as much as possible.

Static electricity can destroy the processor. Also when you snap the board back in its track,

make sure it’s securely done. Sometimes you need to squeeze the outer lips of the track to

insure that the board edges are really seated in the slot.

Page 6

Rev. A.2, 10/03 Page-3

3. WIRING

3.1 POWER SELECTION

The DK-26 operates on 12 to 24 volts AC or DC. Nearly all electric locks operate on voltage

within this range, so the power supply you would normally utilize to operate the electric lock will

also operate the DK-26. Power consumption of the DK-26 depends on voltage and is shown on

the following chart:

DK-26 POWER CONSUMPTION: 12 VOLTS 24 VOLTS

REST STATE (MIN) 7 mA 20 mA

RELAYS, LED’S, + BEEPER ON (MAX) 160 mA 190 mA

Be sure that your power source is of adequate capacity to operate both the lock and DK-

26. If the installation is "under-powered", the voltage of the supply will drop rapidly when the

lock is energized and this can crash the microprocessor.

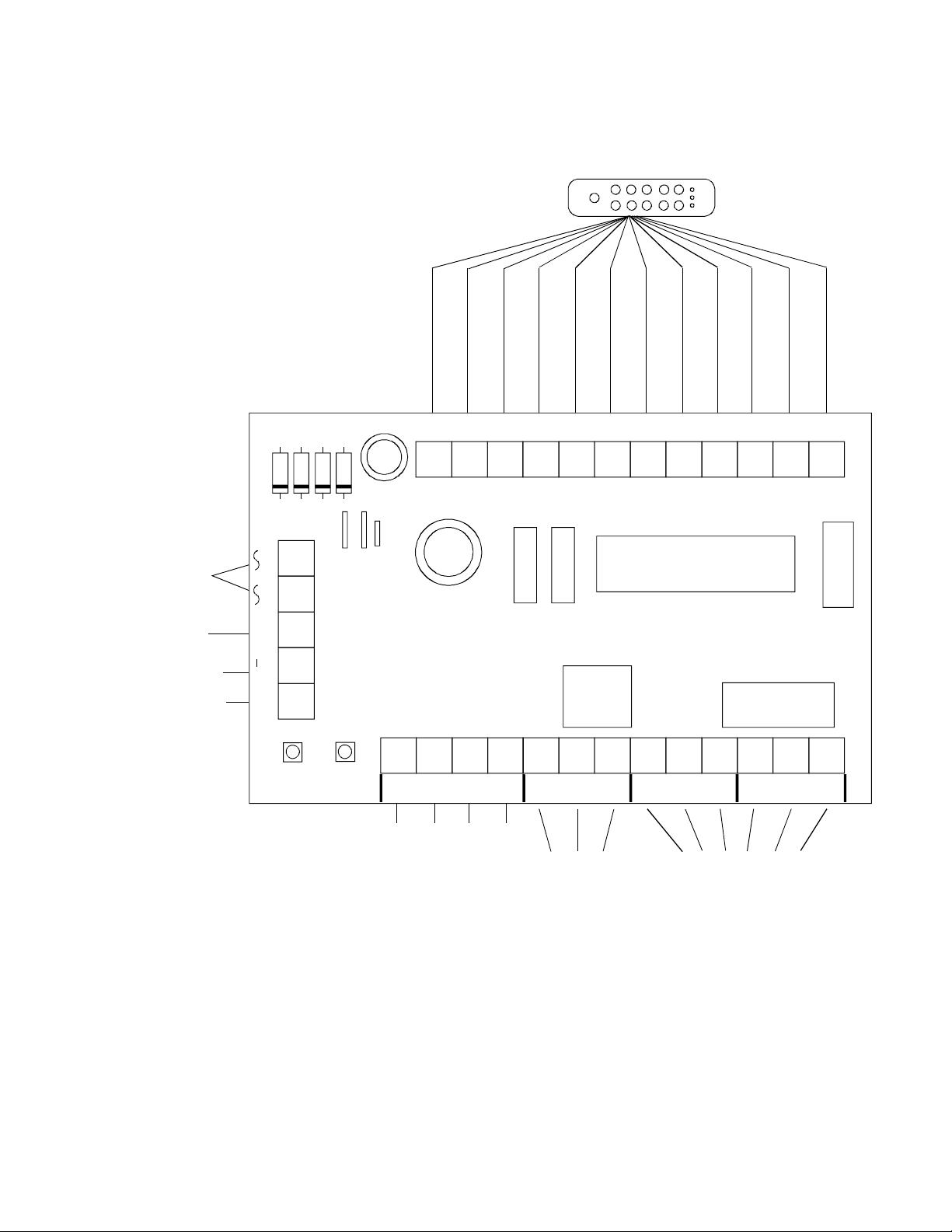

3.2 CONNECTING THE KEYPAD CABLE TO THE CPU BOARD

There are 12 color coded wires in the keypad cable. Refer to Figure 2 and connect each wire to

the indicated terminal on the CPU Board. No other connections may be made to these

terminals (except if two keypads are used with one CPU board).

3.3 POWER AND ELECTRIC LOCK WIRING

The wiring scheme for electric lock control varies depending on the type of lock and the desired

control. The following sections provide drawings and explanations for different types. One

general point is that the DK-26’s lock control relay has 5 Amp contacts. Most electric locks draw

much less. If, however, you are using a specialty lock which draws more than 5 Amps or

has a higher in-rush current, purchase a high current relay and use the DK-26’s contacts to

switch this relay while using its high capacity contacts to switch the lock. Note finally that the

DK-26 includes additional options which are covered in Sections 6 and 7. To determine the

complete wiring for your installation, begin with the drawings shown in Section 3 and then check

Sections 6 and 7 to see if you will require any of the additional features.

3.3.1 AC LOCK WITH AC POWER

This is the simplest installation possible with the DK-26. A fail secure lock operating on AC is

used. This is generally an electric strike. “Fail secure” means that the lock is secure when it is

not powered. Power is applied to release the lock. Referring to figure 3, select a transformer of

the same output voltage as the lock (12 or 24 VAC). Make sure the capacity of the transformer

is large enough to operate both the DK-26 and the lock and that the transformer is UL listed

under the UL 294 standard (to maintain the DK-26 UL listed status). The two transformer

secondary wires connect to the “AC input” terminals as shown (there is no polarity with AC).

Power from one terminal then goes to the common of relay #1. The NO contact of relay #1 will

power the lock (releasing the door) when a correct code is entered. Note that AC locks are

normally all fail secure. If you come across a fail safe AC lock (secure when powered) you

would merely make the connection to the lock from the NC1 rather than NO1 terminal.

Page 7

Rev. A.2, 10/03 Page-4

FIG. 2: OVERVIEW OF CPU BOARD

KEYPAD CABLE

12/24 AC POWER

FREE TERMINAL

12/24 DC NEGATIVE

12/24 DC POWER +

AC IN F DC IN/OUT

PS1

PS2

PS3

VIOLET

KEYS

VIO

BEIGE

ORANGE

PINK

KEYS

KEYS

KEYS

GRAY

BROWN

KEYS

KEYS

WHITE

BLACK

BLUE

RED

COMMON

RED LED

BEEPER

YELLOW

YEL LED

GREEN

GRN LED

KEYS

BLK GRY BRN BGE ORG PNK

WHT

GRN YEL RED BLU

MICROPROCESSOR

AUX.

SOCKET

SPDT

+

RELAY

DPDT RELAY

DC TERMINALS MAY

ALSO BE USED AS

OUTPUT TO POWER

DC LOCK, IF AC

POWER IS SUPPLIED

PRGM

CODE

PUSH TO SET PROGRAM MODE

HARD

CODE

PUSH TO PROGRAM HARD CODE

SRC

COM. FOR REX, UCD, HCD TERMS

UCD HCD NCX CX

REX

REX INPUT (REMOTE R EL EASE)

DISABLE HARD CODE

DISABLE ALL USER CODES

NOX

PROGRAM

RELAY

CONTACTS

NC2 C2

NO2

LOCK CONTROL

RELAY CONTACTS

NC1 C1

NO1

Page 8

Rev. A.2, 10/03 Page-5

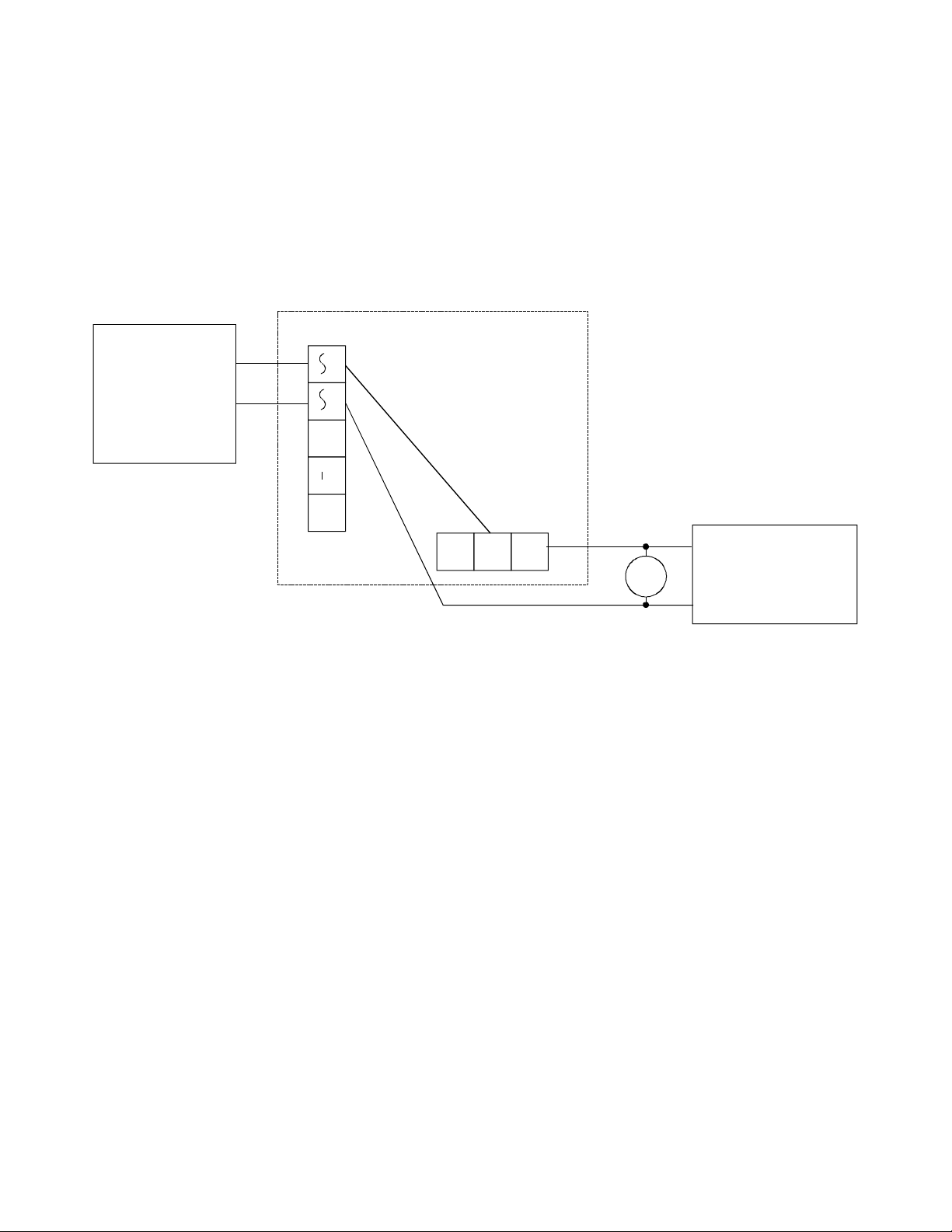

Note installation of the MOV across the power wires to the lock. The MOV is the small black

disk shaped component furnished loose with the DK-26. Its function is to absorb inductive

kickback from the lock’s coil. Without the MOV, this kickback voltage will arc over the relay

contacts and reduce the switching life of the relay. The arc also creates electronic noise which

could occasionally cause the microprocessor to malfunction. The MOV should be spliced into

the lock power wires as close to the lock as possible.

FIG. 3: AC LOCK - AC POWER WIRING

AC IN F DC IN /OUT

TRANSFORMER

12 OR 24 VAC

+

NC1 C1 NO1

MOV

AC FAIL SECURE

LOCK

3.3.2 DC LOCK WITH AC POWER

For convenience and economy, most DC electric locks can be operated from an AC transformer

when the DK-26 is used. Select a transformer of the same voltage as the lock (12 or 24). The

CPU board converts the input AC to DC to operate the lock. Make sure the capacity of the

transformer is large enough to operate both the DK-26 and the lock and that the transformer is

UL listed under the UL 294 standard (to maintain the DK-26 UL listed status). The lock must

accept full wave rectified DC power. This is true of most DC locks (including Securitron’s

Magnalocks) but some specialty units require regulated DC power. You must operate those as

described in the next Section. Note finally that many DC lock installations call for battery

backup. To achieve this, you must employ a DC battery backup power supply and also follow

the wiring description in Section 3.3.3.

DC locks come in “fail secure” and “fail safe” versions. A fail secure lock is secure when not

powered and a fail safe lock is secure when powered. All magnetic locks are fail safe. Figure 4

shows AC power being input to the AC terminals. The DC terminals furnish output power for the

lock. DC locks operated in this way must not draw more than 2 Amps. The positive DC

terminal connects to the common of relay #1 and either the NO1 terminal (if the lock is fail

secure) or the NC1 terminal (if the lock is fail safe) connects to the lock’s positive power input.

This is shown in dotted lines. You only connect one of these terminals. Note that some DC

locks are polarized and you must connect lock power correctly to positive and negative. Others

are not polarized and can be connected either way. Consult the lock instructions.

Note installation of the MOV across the power wires to the lock. The MOV is the black disk

shaped component furnished loose with the DK-26. Its function is to absorb inductive kickback

from the lock’s coil. Without the MOV, this kickback voltage will arc over the relay contacts and

Page 9

Rev. A.2, 10/03 Page-6

reduce the switching life of the relay. The arc also creates electronic noise which could cause

the microprocessor to malfunction. The MOV should be spliced into the lock power wires as

close to the lock as possible. Some DC electric locks have internal kickback protection

including all Securitron Magnalocks. You don’t need the MOV for these locks but if you are

not sure, it does no harm to install the MOV so long as the lock power is in the 12-24 volt range.

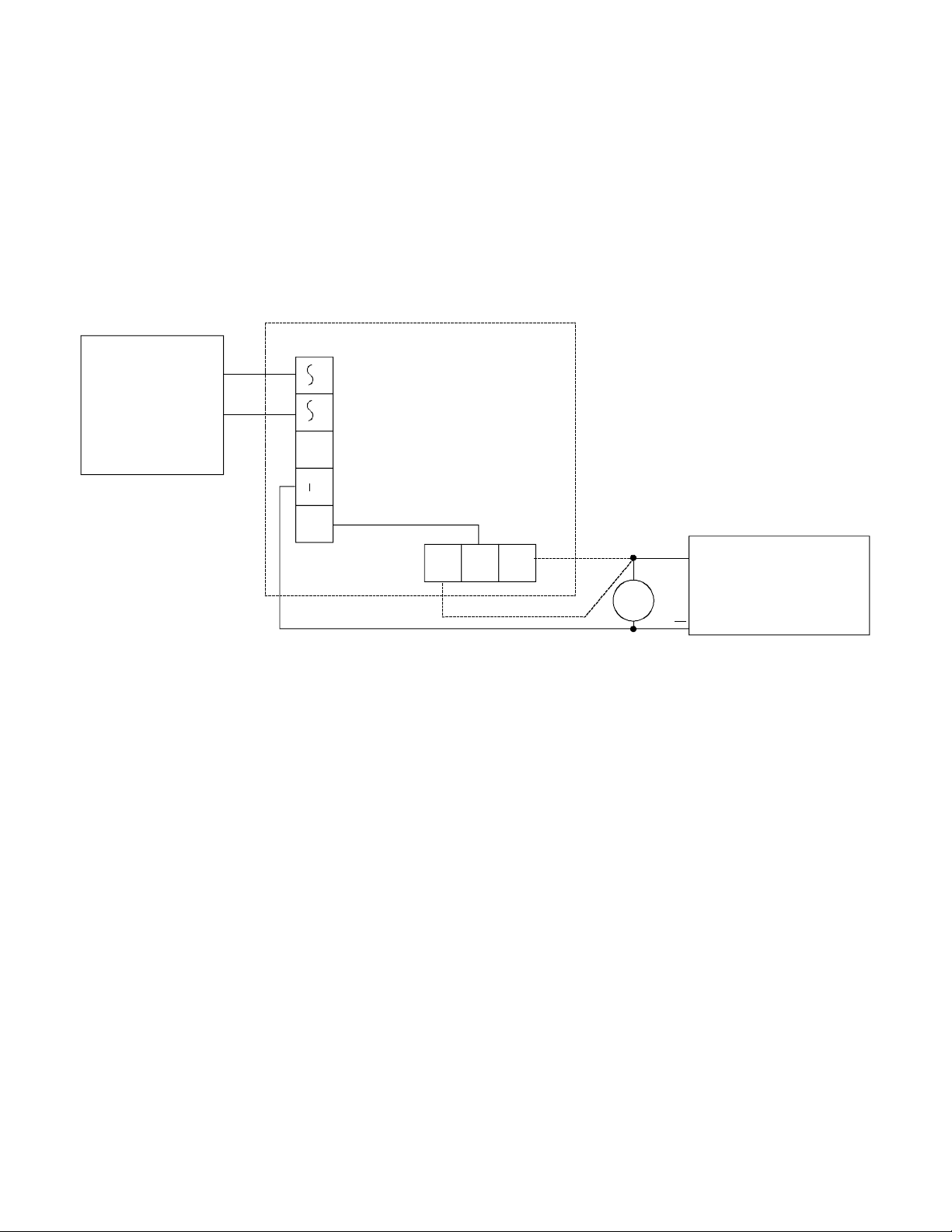

FIG. 4: DC LOCK - AC POWER WIRING

AC IN F DC IN /OUT

TRANSFORMER

12 OR 24 VAC

NOTE: MOV NOT REQUIRED IF

+

NC1 C1 NO1

IF FAIL SAFE

SECURITRON MAGNALOCK IS USED

IF FAIL SECURE

DC FAIL SECURE

+

OR FAIL SAFE LOCK

MOV

3.3.3 DC LOCK WITH DC POWER

Select a power supply of the same voltage as the lock (12 or 24). Make sure the capacity of the

supply is large enough to operate both the DK-26 and the lock. The DK-26 does not require

regulated power but certain specialized electric locks do, so follow the rule of matching the

power supply to the requirements of the lock.

DC locks come in “fail secure” and “fail safe” versions. A fail secure lock is secure when not

powered and a fail safe lock is secure when powered. All magnetic locks are fail safe. Figure 5

shows correct wiring. The positive DC terminal connects to the common of relay #1 and either

the NO1 terminal (if the lock is fail secure) or the NC1 terminal (if the lock is fail safe) connects

to the lock’s positive power input. This is shown in dotted lines. You only connect one of these

two terminals. Note that some DC locks are polarized and you must be sure to connect the lock

power wires correctly to positive and negative. Others are not polarized and it doesn’t matter

which way they are connected. Consult the lock instructions.

Note installation of the MOV across the power wires to the lock. The MOV is the small black

disk shaped component furnished loose with the DK-26. Its function is to absorb inductive

kickback from the lock’s coil. Without the MOV, this kickback voltage will arc over the relay

contacts and reduce the switching life of the relay. The arc also creates electronic noise which

could occasionally cause the microprocessor to malfunction. The MOV should be spliced into

the lock power wires as close to the lock as possible. Some DC electric locks have internal

kickback protection including all Securitron Magnalocks. You need not employ the MOV for

these locks but if you are not sure, it never does any harm to install the MOV so long as the lock

power is in the 12-24 volt range.

Page 10

Rev. A.2, 10/03 Page-7

FIG 5: DC LOCK - DC POWER WIRING

AC IN F

POWER SUPPLY

+

12 OR 24 VDC

DC POWER NEED NOT

BE REGULATED

DC IN /OUT

NOTE: MOV NOT REQUIRED IF

+

NC1 C1 NO1

IF FAIL SAFE

SECURITRON MAGNALOCK IS USED

IF FAIL SECURE

DC FAIL SECURE

+

OR FAIL SAFE LOCK

MOV

3.4 USE OF THE “F” TERMINAL

The F terminal on the power strip is not connected to

anything. It is a free terminal with either of two

intended uses. First, on some complicated

installations, a large number of wires (generally DC

negative) may require termination. It can be

TRANSFORMER

FIRE ALARM

AC IN F DC IN /OUT

CONTACTS

N

C

C

convenient to run a jumper from the DC- terminal to

the F terminal so that the large number of negative

returns can be spread on to the two terminals. This

avoids putting two many wires on one terminal or

splicing into wires. Second, some magnetic lock

installations require interface with NC contacts

WHEN THE FIRE

ALARM CONTACTS

OPEN , ALL POWER

+

WILL BE REMOVED

FROM THE D OOR

controlled by the fire alarm system which will cut low

voltage power immediately releasing the magnetic lock for safety. The connection to the

fire alarm contacts is normally made in the power supply but if you are using a plug in power

supply, you’ll want to make the connection on the DK-26 CPU board where you have terminals.

The presence of the F terminal makes the connection more convenient. Using the example of a

plug in AC transformer, you would connect one leg of the transformer output to one AC IN

terminal and the other to F. You would then connect the NC contacts from the fire alarm system

to the other AC IN terminal and F. See the drawing to the right.

3.5 ADDING OTHER LOCK CONTROL SWITCHES

The drawings in Section 3.3 are valid for simple installations where the DK-26 is the only control

device that can release the electric lock. Often, however, additional control devices are called

for. The most common is some type of exit switch and this issue is covered in the next

Section. Sometimes other control switches are needed which are not appropriate for the REX

input as use of this input triggers the timed release capability of the DK-26.

A typical example would be a switch located centrally which would release the lock in response

to an intercom call for example. If the lock is fail safe, the switch will need to break power to the

Page 11

Rev. A.2, 10/03 Page-8

A

lock and if it’s fail secure, the switch will need to send power to the lock. Figure 6 shows how to

add external contacts for non timed remote release of the lock for both lock types.

FIG. 6: ADDING EXTERNAL CONTACTS FOR FAIL SAFE AND FAIL SECURE LOCKS

AC IN

AC IN F

FOR NON-TIMED REMOTE

RELEASE OF FAIL SAFE

LOCK, PLACE NC CONTACTS

F DC IN /OUT

IN CIRCUIT AS SHOWN

C

N

+

C

MOV

+

FAIL

SAFE

LOCK

NC1

C1

DC IN /OUT

+

FOR NON-TIMED REMOTE

RELEASE OF FAIL SECURE

LOCK, PLACE NO CONTACTS

IN CIRCUIT AS SHOWN

O

N

C

NO1C1

MOV

+

FAIL

SECURE

LOCK

3.6 THE REX FUNCTION

Often, when the DK-26 is used, provision must be made to allow

people to use the door freely from the inside. If an electric strike

is used, exit may be accomplished by purely mechanical means

(turning the doorknob). If, on the other hand, a solenoid

operated or electromagnetic lock is used, free exit is only

possible if a switch on the inside releases the lock.

SRC

REX

N N.O. SWITCH

CLOSING BETWEEN

"SRC" AND "REX"

CAUSES TIMED

RELEASE OF THE

DOOR.

Connection of this switch or switches is most easily

accomplished by using the DK-26's REX input terminal (see Figure 2). REX stands for

Request To Exit. When a normally open switch activates the REX terminal, the DK-26's control

relay will open the lock for the amount of time programmed into the DK-26's timer. The result is

the same as if the DK-26 was used from the outside of the door. The REX terminal is activated

by being connected to the SRC (voltage source) terminal. It will also activate if +12 or +24V

is input to the terminal from the DK-26’s external power supply. The drawing to the right

shows the simplest connection to an external normally open momentary switch. Any number of

additional switches could be connected in parallel so that pressing any of them would activate

the REX function. An example of when this multiple switch capability is used would be an

installation with an exit button at the door and a second one at a receptionist’s desk for example.

Either could open the door for the programmed time.

There are some special characteristics as to how the REX input works. First, it does not start

the timer when the input is closed but rather when it reopens. This means that you can

use the REX input to release the door for an extended period of time. As long as terminals

REX and SRC remain connected, the lock will be released. When they disconnect, the lock will

remain released for the amount of time programmed. This extended release capability is useful

in certain applications. The REX input is also retriggerable. This means that if the lock has

been released and the REX input is triggered, the release time will be extended to the full value

that has been programmed.

Page 12

Rev. A.2, 10/03 Page-9

When using exit switches, the possibility must be considered that an electronic failure may occur

to the DK-26 and a person will not be able to exit. If the DK-26 controls the only door exiting

the area, additional steps should be taken to improve the reliability of exiting so as to

avoid trapping someone. This can most easily be done by implementing a secondary means

of releasing the lock not dependent on the DK-26's REX input. Additional switch contacts

should be used which directly control the electric lock. In the case of a fail-safe lock, which

should always be employed when there is only one exit path, this can be easily accomplished

with "double break" wiring between the exit button, electric lock, and DK-26. If the exit button

has a set of normally open and normally closed contacts, it should then be wired according to

Figure 6. When the exit button is depressed, its normally closed contacts directly break power

to the lock while its normally open contacts activate the DK-26. In effect, the lock is released

twice. Note that the NC contacts are placed in the circuit before the DK-26's lock control relay.

This is to aid possible troubleshooting. It is usually easier to get to the DK-26 CPU board than

to get to the push button wiring in a service situation. With wiring as shown in Figure 6, the

push button NC contacts can be metered on the DK-26 CPU board. If for any reason a failure

occurs with the DK-26, a person can still exit by holding the exit button down while pushing the

door open. Note, you should always consult your local building or fire department when

securing doors that are part on an emergency exit path to make sure you are complying

with local codes.

FIG. 7: DOUBLE BREAK WIRING FOR FREE EGRESS (TWO POLE SWITCH)

AC IN F DC IN/OUT

NC

CPU BOARD

+

WHEN THE EXIT SWITCH IS ACTIVATED, THE NC CONTACTS OPEN WHICH RELEASES THE FAIL

SAFE LOCK. AT THE SAME TIME, THE NO CONTACTS CLOSE WHICH ACTIVATES THE REX INPUT.

THIS DEENERGIZES THE LOCK CONTROL RELAY WHICH R ELEASES THE LOCK "A SECOND TIME"

FOR THE AMOUNT OF TIME THAT HAS BEEN PROGRAMMED. IF THE DK-26 SUFFERS A FAILURE,

THE EXIT SWITCH CAN STILL RELEASE THE LOCK FOR SAFETY.

SRC REX NC1

C1

NO

2 POLE

SWITCH

NC

NO

MOV

+

FAIL SAFE

ELECTRIC

LOCK

Note that Figure 6 shows a DC fail safe lock (virtually all fail safe locks are DC). Power could

either be furnished by an AC transformer which would connect to the “AC IN” terminals or a DC

power supply which would connect to the “DC IN/OUT” terminals.

If you have an SPDT exit switch available to double break REX, the connection is shown in

Figure 7. The difference is that you don’t use the SRC terminal at all. The REX terminal is

triggered from the +DC terminal via the NO contact of the SPDT switch.

Page 13

Rev. A.2, 10/03 Page-10

FIG. 8: DOUBLE BREAK WIRING FOR FREE EGRESS (SPDT SWITCH)

AC IN F DC IN/OUT

NC

CPU BOARD

+

REX NC1

WHEN THE EXIT SWITCH IS ACTIVATED, THE NC CONTACTS OPEN WHICH RELEASES THE FAIL

SAFE LOCK. AT THE SAME TIME, THE NO CONTACT DIRECTLY ACTIVATES THE REX INPUT.

THIS DEENERGIZES THE LOCK CONTROL REL AY W HICH RELEASES THE LOCK "A SECOND TIME"

FOR THE AMOUNT OF TIME THAT H AS BE EN PROGRAMMED. IF THE DK-26 SUFFERS A FAILURE,

THE EXIT SWITCH CAN STILL RELEASE THE LOCK FOR SAFETY.

C1

NO

SPDT

SWITCH

C

+

FAIL SAFE

MOV

ELECTRIC

LOCK

4. PROGRAMMING

The DK-26 has ten numbered keys and a bell key which is used for several functions. Each of

these keys is read separately by the unit, so the DK-26 is a true 11 digit access device. This

provides excellent security against a code being guessed. Also, the DK-26 employs non-volatile

EEPROM memory so that all programming is retained in a power failure.

Another point to note is that all DK-26 codes will operate the unit when their sequence is

entered regardless if other incorrect digits were entered before. For instance, if the correct code

is 2-2-6-7, the unit will operate if 8-2-2-6-7 is entered. An exception to this is if a total of 16

wrong digits are entered. In that case, an alarm function comes into play. The keypad will lock

itself out for 30 seconds and the beeper will sound continuously. This feature discourages

attempts to guess the code.

Before learning all programming options for the DK-26, you should decide how you want the

unit to be used. Then learn only the appropriate programming for that use. This simplifies the

task of operating the unit and cuts down on unneeded service calls.

The programming questions to ask are: do you want a “fixed” code that will either never be

changed or changed only rarely? Or do you want regular code changes from the keypad?

This issue depends on the amount of security called for in the application. Finally, do you want

multiple codes? The DK-26 supports 59. The purpose of multiple codes is to assign different

codes to individuals or groups. Then if a code needs to be changed, the other individuals or

groups need not go to the trouble of learning a new code. This is a convenience issue.

4.1 FIXED PROGRAMMING

Employ fixed programming in a situation where the end user is not likely to ever change the

code, or at least that changes would be rare. Fixed programming can be used in lower security

Page 14

Rev. A.2, 10/03 Page-11

"traffic control" applications, as the longer the code remains unchanged, the greater the risk that

an unauthorized person will be able to learn it.

The DK-26 makes it simple for you to program the unit in this “fixed” way. You will utilize a push

button set, single code called the “Hard code”. With power applied to the unit, note that the

yellow LED is on steadily. This signals that all code memories are empty. This is important

as you don’t want any unknown codes present in the unit. If the yellow LED is not on, read the

last two paragraphs in this section now for the procedure to erase existing codes.

Once you have confirmed the steady yellow light on the keypad, go to the CPU board and press

the button marked “Hard Code” for about one second (see Figure 2). Returning to the keypad,

you will see the yellow LED flashing slowly (about once per second). This indicates “hard

programming mode”. Within 30 seconds, simply enter your code from two to seven digits (you

can’t use the bell key but repeating digits is OK). If you wait longer than 30 seconds to start

your code entry, the “programming window” will terminate and you’ll have to press the Hard

Code button again. In general, longer codes provide more security but are less convenient to

remember and enter. However, many users like seven digit codes as they can be phone

numbers, which are easy to remember. Do not pause while you’re entering the code as any

time there is more than a five second gap between keys being pressed, the unit will stop

reading the sequence. Note that a successful button press is echoed by a beep and a flash of

the green LED. When you have completed entering your code, hit the Bell key and you should

see the red LED display two pulses within a second. If you don’t hit the Bell key, your code

will be accepted anyway but it will take five seconds to see the two red flashes. If you have

selected a seven digit code, the two red flashes will occur immediately as the digit limit has been

reached. The two pulses signal that your code has been accepted. If you get a single one

second long red pulse, you’ve done something wrong. Pressing one key and waiting for over

5 seconds, for example, would be would be interpreted as a disallowed single digit code.

If you get the single red flash, press the Hard Code button again and you can attempt to re-enter

a successful code. Once you get the two red flashes, re-enter your code and the door should

open. “Fixed” programming is complete. Should you ever want to change the code, just press

the Hard Code button on the CPU board again and repeat the procedure described above.

There is a minor wiring step that increases the reliability of a “fixed” code installation. Since the

DK-26 has multiple code capability but you only require single code use, it’s important to be sure

that no other codes can operate the unit. Following the programming steps in this Section will

assure that only a single Hard code is in memory but to be extra sure, install a wire jumper

between terminal SRC and terminal UCD (see Figure 2). This will disable any of the possible

User codes so if somehow one was programmed in, it would not open the door.

Below we show a step by step summary.

Power up unit; confirm steady yellow LED

Press the “Hard Code” button on the CPU board for one second

Confirm slow flashing yellow LED

Within 30 seconds of pressing Hard Code button, enter a 2-7 digit code

End your entry with Bell key or wait 5 seconds

Note two red LED flashes for confirmation

Re-enter code (door should open)

Finally, as mentioned at the beginning of this section, here is the procedure to follow if you

don’t get a steady yellow light on power up. The absence of the yellow light means that for

any reason, the unit already has one or more codes in memory. You must erase these other

Page 15

Rev. A.2, 10/03 Page-12

codes to be certain that the unit will operate only on the single code you plan to enter. Follow

the steps shown below.

Press the “Prgm Code” button on the CPU board for one second.

Confirm fast flashing yellow LED

Enter 0-0 followed by the Bell key (or wait 5 seconds). Confirm two red flashes

Enter 8-8 followed by the Bell key (or wait 5 seconds). Confirm two red flashes

Extinguish the fast yellow flashing LED by pressing the Bell Key or waiting 30 seconds

This procedure has erased any program code that was present and all User codes. The yellow

LED will usually come on steadily. If it doesn’t, it means that the unit has a previous Hard code

in memory and this is no problem as you will be overwriting the old Hard code. Return to the

beginning of this Section for fixed code programming.

4.2 KEYPAD CHANGEABLE PROGRAMMING

In this application, two codes are programmed into the DK-26. The first, called the Program

code acts as a password which allows changing the User code. It is the User code which is

employed regularly to gain access. Knowledge of the Program code should be restricted to

security management as its only use is to change the User code. With this method of operation,

higher security is obtained because the end user can change the User code regularly or any

time he feels it has been compromised.

With power applied to the unit, note that the yellow LED is on steadily. This signals that all

code memories are empty (you don’t want any unknown codes present). If the yellow LED is

not on, read the last two paragraphs in this section for the procedure to erase existing codes.

Once you have confirmed the steady yellow light on the keypad, go to the CPU board and press

the button marked “Prgm Code” for about one second (see Figure 2). Returning to the keypad,

note the yellow LED flashing rapidly (about three times a second). This indicates “program

mode”. Within 30 seconds, enter the prefix 0-0 and then your Program code from five to

seven digits (you can’t use the bell key but repeating digits is OK). If you wait longer than 30

seconds to start your code entry, the “programming window” will automatically terminate, so

press the Prgm Code button again. Do not pause while you’re entering all these digits as any

time there is more than a five second gap between keys being pressed, the unit will stop

reading the sequence. Note that a successful button press is echoed by a beep and a flash of

the green LED. When you have completed entering your Program code, hit the Bell key and

you should see the red LED display two pulses within a second. If you don’t hit the Bell key,

your code will be accepted anyway but it will take five seconds for the two red flashes to come.

If you have selected a seven digit code, the two red flashes will occur immediately as the digit

limit has been reached. The two pulses signal that your code has been accepted. If you get a

single one second long red pulse, you’ve done something wrong. Pressing fewer than 5

keys, for example, would be would be interpreted as a disallowed Program code.

You’ll note that after the two confirming red flashes are seen, the unit automatically returns to

program mode (rapid yellow flash). You could exit program mode by either hitting the Bell key

or waiting 30 seconds, but you now want to program your User code. Immediately enter the

prefix 0-1 and then your user code from two to seven digits. When you see the two

confirming red flashes, exit program mode by hitting the Bell key or waiting 30 seconds. If you

get the single “error” pulse, note that the unit will automatically return to program mode and you

can attempt to re-enter your user code. If you continuously get the error signal, refer to the

troubleshooting section which explains all the possible reasons for a code not being accepted.

Page 16

Rev. A.2, 10/03 Page-13

After you’ve completed your entries, test your user and program codes by entering them.

The user code should open the door. The program code should cause the yellow LED to flash

rapidly (program mode). Exit the program mode by hitting the Bell key. Below we show a step

by step summary of programming the two codes.

Power up unit; confirm steady yellow LED

Press the “Prgm Code” button on the CPU board for one second

Confirm rapid flashing yellow LED

Within 30 seconds of pressing Prgm Code button, enter prefix 0-0 followed immediately

by a 5-7 digit Program code

End your entry with Bell key or wait 5 seconds

Note two red LED flashes for confirmation, note rapid yellow flashing LED returns

Enter prefix 0-1 followed immediately by a 2-7 digit User code

End your entry with Bell key or wait 5 seconds

Note two red LED flashes for confirmation, note rapid yellow flashing LED returns

Press Bell key to terminate program mode or wait 30 seconds

Re-enter User code (door should open)

Re-enter Program code followed by the Bell key (yellow LED should rapidly flash),

terminate with Bell key

Finally, as mentioned at the beginning of this section, here is the procedure to follow if you

don’t get a steady yellow light on power up. The absence of the yellow light means that for

any reason, the unit already has one or more codes in memory. You must erase these other

codes to be certain that the unit will operate only on the codes you plan to enter. Follow the

steps shown below.

Press the “Hard Code” button on the CPU board for one second.

Confirm slow flashing yellow LED

Press the Bell key (yellow flashing stops). Confirm two red flashes

Press the “Prgm Code” button on the CPU board for one second.

Confirm fast flashing yellow LED

Enter 8-8 followed by the Bell key (or wait 5 seconds). Confirm two red flashes

Extinguish the fast yellow flashing LED by pressing the Bell Key or waiting 30 seconds

This procedure has erased any Hard code that was present (see Section 4.1) and all user

codes. The yellow LED will usually come on steadily. If it doesn’t, it means that the unit has a

previous Program code in memory and this is no problem as you will be overwriting the old

Program code. Return to the beginning of this section for keypad changeable programming.

4.2.1 CHANGING THE USER AND PROGRAM CODE FROM THE KEYPAD

This is the day to day procedure that should be taught to the end user. Normally the end user

will not access the CPU board. Everything should be done from the keypad. To change the

User code:

Page 17

Rev. A.2, 10/03 Page-14

Enter program code, followed by the Bell Key, note rapid yellow flashing LED (program

mode)

Enter prefix 0-1 followed immediately by a new 2-7 digit User code

End your entry with Bell key or wait 5 seconds

Note two red LED flashes for confirmation, note rapid yellow flashing LED returns

Press Bell key to terminate program mode or wait 30 seconds

Re-enter new User code (door should open)

The program code should need changing much less often. To do it:

Enter old program code followed by the Bell Key, note rapid yellow flashing LED

(program mode)

Enter prefix 0-0 followed immediately by a 5-7 digit new Program code

End your entry with Bell key or wait 5 seconds

Note two red LED flashes for confirmation, note rapid yellow flashing LED returns

Press Bell key to terminate program mode or wait 30 seconds

Re-enter new Program code followed by the Bell Key (to test it), note rapid yellow

flashing LED returns

Press Bell key to terminate program mode or wait 30 seconds

The logic behind this procedure is as follows. All programming for the DK-26 starts with putting

the unit into program mode (except entering the single Hard code). The unit is put into program

mode by either pressing the “Prgm Code” button on the CPU board or entering a valid program

code. When you enter a program code, however, you have to terminate the sequence with

the Bell Key. This is for a little extra security. An unauthorized person who came across a

copy of the Program code might not know he had to press the Bell key after entering it. The

prefix 0-0 causes the code which follows to be stored as the Program code. The prefix 0-1

causes the code to be stored as a user code.

4.2.2 ADDING MULTIPLE USER CODES

The DK-26 has memory locations for up to 59 User codes. This allows separate codes for

individuals or groups which is a benefit because when one code is changed (usually owing to a

security worry), the people who use the other codes don’t have to learn a new code. To

program additional User codes, you follow the procedures described above for setting the User

code in memory location 01 but you employ memory locations 02 through 59. For example,

once the unit is in program mode (rapid yellow flash), entering 0-2 followed by a code sequence

will enter a second User code. The same is true when you enter prefixes 0-3, 0-4 up to 5-9.

When you’re programming multiple User codes, note that you can enter them one right after

another. When a code is accepted, the unit signals by two red flashes. It then automatically

goes back into program mode and another code can be immediately entered without exiting

program mode. Be sure to test all the codes you have entered before you consider

programming complete. You can individually erase any code (including the Program code) by

entering program mode, pressing the prefix for the code (01-59) and then pressing the Bell key

or waiting 5 seconds until you get the two red flashes.

4.3 “MASTERKEY” USE OF THE HARD CODE

The primary use for the Hard code is to allow simple single code “fixed” operation as is

described in Section 4.1. The Hard code can only be set or changed from the “Hard Code”

Page 18

Rev. A.2, 10/03 Page-15

button in the CPU board. It is deliberately kept separate from all programming functions.

Another use for it, however, is as a “masterkey” code. For example, consider a facility with

multiple DK-26’s under the control of different departments. Each department might want to

employ different Program and User codes to restrict cross access but a common Hard code

could be established for all of the units so that security management personnel could enjoy

universal access. This Hard code will never be lost from keypad operations (the CPU board has

to be accessed).

4.4 SUBSET CODES

When you recognize that the DK-26 accepts multiple codes of different lengths, it is possible

that one code will be a subset of another. For example, suppose you programmed “1-3-3-5-8”

and then programmed “3-3-5” as another code. When you try to enter 1-3-3-5-8, you can’t

complete the entry because when the unit sees the sequence 3-3-5, it will operate. A real

problem could occur if a User code was a subset of the Program code. The unit could not be

put into program mode from the keypad.

The DK-26, however, avoids this problem by rejecting any code that is a subset of another

code in memory. It signals this rejection by showing the single red (error) flash instead of the

two-flash confirmation signal. You’ll get the same error if you try to enter a duplicate code. If

you are trying to enter a code and see it rejected by the error signal, carefully check your list of

other codes. You are probably attempting to enter a subset code. If the security procedures of

the installation allow individuals to choose their own codes without reference to a list, the users

need to be advised that they may have to try alternate codes if the one they prefer is rejected as

a subset. Other typical reasons for code rejection are covered in the troubleshooting section at

the end of the manual.

4.5 DELETING CODES

Any code can be deleted by “calling it up” and hitting the Bell key rather than entering a new

code (which would over-write the old one). Alternately, if you don’t hit the Bell key but don’t

enter a new code, the unit will time out and still delete the code.

To delete the Hard code, press the “Hard Code” button on the CPU board, confirm that you are

in hard program mode (slow yellow flash) and press the Bell key or wait 30 seconds.

To delete the Program code, put the unit into program mode (fast yellow flash) from the “Prgm

Code” button or from the existing Program code. Enter 0-0 and press the Bell key or wait five

seconds. You’ll see the two red confirmation flashes. You’ll need to then press the Bell key

again to exit program mode or wait 30 seconds. Note that it can be considered logical to

operate without a Program code. It is more difficult to put the unit into program mode (it can

only be done from the “Prgm Code” button in the CPU board) but User codes can still be

changed and some users may feel that this is a more secure code changing procedure.

To delete any individual User code, put the unit into program mode (fast yellow flash) from the

“Prgm Code” button or from the existing Program code. Enter the prefix for the code you wish

to delete (01 - 59) and press the Bell key or wait five seconds. You’ll see the two red flashes.

You’ll then need to press the Bell key again to exit program mode or wait 30 seconds.

An alternate method to delete any individual User code when you know the actual code but

not the two digit prefix is as follows. Put the unit into program mode (fast yellow flash) from

the “Prgm Code” button or from the existing Program code. Enter 7-9 followed immediately by

the complete code you wish to delete. If it’s a seven digit code you’ll immediately see the two

red confirmation flashes. Otherwise press the Bell key or wait five seconds. If you get the

single red error flash, it is probably because the code you thought was in memory was not.

You’ll then need to press the Bell key again to exit program mode or wait 30 seconds.

Page 19

Rev. A.2, 10/03 Page-16

To delete all User codes, there is a special prefix. Put the unit into program mode (fast yellow

flash) from the “Prgm Code” button or from the existing Program code and enter 8-8. This

special prefix will immediately delete all User codes and you’ll immediately receive the two red

flashes. There is no need to hit the Bell key as it is used for early termination of sequences that

don’t have a fixed length (typically codes). 8-8 as a prefix is a complete command. You will

then need to press the Bell key to exit program mode (or wait 30 seconds). Deletion of all codes

is typically done when you have lost accurate knowledge of what codes are in memory. It’s best

to delete them all and program a new set.

4.6 SETTING THE TIME RANGE AND TOGGLE MODE

The DK-26 will release the lock it controls for a default time of 5 seconds when a correct User

code is entered. This can be changed to any value from 1-99 seconds by entering a special

programming sequence. With the unit in program mode, enter key 9 followed by any two digit

entry from 01 to 99. You will then see the double red flash immediately. If you get the single

“error” flash, you probably entered only one digit. Then exit program by hitting the Bell key or

waiting 30 seconds. Enter a correct User code to test that the changed time is working.

The DK-26 will operate in toggle mode if key 9 followed by 00 is entered when the unit is in

program mode. In toggle mode operation, the relay will energize when a correct code is entered

and deenergize when a correct code is entered a second time. Toggle mode is generally used

for the application where the door is released all day by entering a User code and then secured

all night by entering a User code again. When you have enabled toggle mode, activation of

the REX input will successively energize and deenergize the lock control relay (just as if you

entered the User code).

5. CHANGING LED AND BEEPER OPERATION

As delivered, the DK-26 echoes key presses by a short beep and a short flash of the green

LED. The red LED comes on to show that the door has been released and also to confirm or

reject programming commands (two flashes confirm; one rejects). As an issue of individual

preference, these operating defaults can be changed.

The beeper can be assigned to sound when the door is released. If this is done, it will

continue to sound for its other functions (echoing keys and continuously sounding for 30

seconds if 16 wrong keys have been entered). Users find this function helpful if a silent type of

electric lock is being employed (such as an electromagnetic lock). When the person attempting

to enter hears the beeper, he is prompted to open the door. To set this change, put the unit

into program mode and enter 7-0. You will see the two flash confirmation. Exit program mode

by hitting the Bell key or waiting 30 seconds.

Some customers want to silence the beeper as its sound can be considered annoying in some

environments. . To set this change, put the unit into program mode and enter 7-1. You will

see the two flash confirmation. Exit program mode by hitting the Bell key or waiting 30 seconds.

This function will override the one discussed in the previous paragraph.

To return the beeper to factory set default, put the unit into program mode and enter 7-2.

Finally, you can reverse the red/green LED logic so that the green light comes on when the

red light did, and visa versa. To set this change, put the unit into program mode and enter 7-3.

You will see the two flash confirmation. Exit program mode by hitting the Bell key or waiting 30

seconds. If you make this change, note that every time this manual discusses something that

the red or green LED does, it will be reversed.

Page 20

Rev. A.2, 10/03 Page-17

To return the red/green LED logic to factory set default, put the unit into program mode and

enter 7-4.

6. USE OF THE PROGRAMMABLE RELAY

The DK-26 CPU board includes a second relay whose 5 Amp, SPDT contacts are marked CX,

NCX and NOX (see Figure 2). This relay is employed for different functions which are selected

by commands sent to the CPU board while the unit is in program mode. In general, you need to

choose the function you want to make active for this relay (if any) and the following sections lay

out the choices.

6.1 DOORBELL FUNCTION

As delivered, the programmable relay will operate when the Bell key is pressed when the unit is

in “normal” operating mode (ready to accept a code). The Bell key is used a great deal in

programming operations but the relay will not operate during programming (including

initiating and exiting programming mode).

The purpose for this is to operate a real doorbell so that unauthorized

persons outside the controlled door can request entry. Most

commercial doorbells are furnished with their own power supply, so

typical wiring is as shown in the drawing to the right.

Note that if you don’t plan to use this function, a blank rectangular

label is supplied which can be used to cover the “BELL” legend on

the keypad face. This avoids misleading a person on the outside of

the door.

CX

NOX

DOORBELL

POWER

SUPPLY

6.2 DURESS FUNCTION

The duress function is used for high security applications. It allows a person being threatened

to release the door but simultaneously create a silent alarm which would be employed to

summon assistance. To make this work, obviously the threatened authorized person has to

enter something different than a standard User code.

The DK-26 handles this requirement by establishing the Hard code as a duress code. You need

to do several things however to implement this.

Ordinary operation must be via one or more User codes (see Section 4.2 for

programming)

Program the Hard code as your duress code (see Section 4.1).

Put the unit in program mode , and enter 7-5. You will see the two flash confirmation.

Exit program mode by pressing the Bell key or waiting 30 seconds.

Now, when you enter a user code, the door will open but when you enter the Hard code, the

door will open and the programmable relay will switch. The door will remain open for the

amount of time programmed but the programmable relay will stay switched (it latches) until

the hard code is entered a second time to reset it. Use the programmable relay contacts

(CX, NOX and NCX) to report the releasing of the door under duress. This can be done by

interfacing with an alarm panel or dialer. Note that a duress code is rarely used. To make the

code easier to remember, you can select a Hard code that is close to the User code (if only one

User code is being employed) or you can select a short hard code. Note finally that selection of

this option means you give up the opportunity to implement a doorbell or other use of the

programmable relay.

Page 21

Rev. A.2, 10/03 Page-18

6.3 ANTI-TAMPER ALARM FUNCTION

A person attempting to guess the code and pressing 16 wrong digits will put the DK-26 into

alarm. The keypad's beeper and green LED will operate for 30 seconds during which time the

keypad will accept no input. This is usually sufficient to deter anyone from trying to guess a

valid code as millions of codes are possible with the DK-26’s true 10 digit operation. However,

for high security applications, particularly when a lot of User codes are active, you can assign

the programmable relay to operate during the alarm period. Put the unit into program mode and

enter 7-6. You will see the two flash confirmation. Then, exit program mode. You have now

the means to report attempts to guess a valid code. This can be done by interfacing with an

alarm panel or dialer. Note finally that selection of this option means you give up the opportunity

to implement a doorbell or other use of the programmable relay.

6.4 DOOR PROP ALARM FUNCTION

This function provides enhanced security at the

door by creating an alarm signal any time the door

is left open too long while being used for entry or

exit. With the function enabled, select a relatively

long door open time (see Section 4.5 to set

timer). You will then need a door switch whose

contacts open when the door opens. To wire the

door switch, follow the drawing to the right. You

SRC

DOOR SWITCH

UCD HCD

CON NECT A DOOR

SWITCH WHICH

OPENS WHEN THE

DOOR OPENS TO

UCD OR HCD

DEPENDING ON WHICH

COMMAND YOU CHOOSE

will give up the function of disabling either the Hard

code or all the User codes (see Section 7.2). Put the unit into program mode and enter 8-2 to

put this feature on the HCD terminal or 8-3 to put it on the UCD terminal. You will see the

two flash confirmation. Then, exit program mode. The respective input terminal will have its

meaning redefined. You will also give up the opportunity to implement a doorbell or other use of

the programmable relay.

Now, when a code is entered (or the REX input is used), the door will release for the relatively

long period of time programmed. If the door is not opened at all, the lock will resecure when the

set time expires and nothing further will happen. If the door is opened and recloses before the

time expires, it will resecure immediately upon closure. This is called anti-tailgating and means

that although you have selected a long release time, a second person will not be able to use the

door after a first person has, because the door resecures immediately upon reclosure. If the

door remains open for a longer period of time than is set on the timer, the programmable relay

will switch and will remain energized until the door closes or the keypad is used again. Note

that if you are using the programmable relay for another function you can enable anti-tailgating

alone (no alarm signal) as is described in Section 7.4.

DC IN /OUT

Connection from the programmable relay is generally

not made to an alarm system, as if an alarm system is

active on the door, you can get the same “door open too

long” signal more simply by using the second pole of the

lock control relay to shunt the door switch (see Section

AUDIBLE DOOR PROP ALARM

SONALERT

+

CX NOX

7.3). Generally, you mount a Sonalert on the CPU

board enclosure. It will sound if the door is left open too

long and this will act as a prompt for someone near the

door to close it. Sonalerts operate on 12-24 VDC so the wiring shown on the drawing to the

right should be used.

To terminate this function and return the HCD or UCD input to its standard use (and return the

programmable relay to the doorbell function), put the unit into program mode and enter 8-4.

You will see the two flash confirmation. Then, exit program mode.

Page 22

Rev. A.2, 10/03 Page-19

6.5 NIGHTLIGHT FUNCTION

When this function is selected, the act of touching any key will operate the programmable relay

for five seconds. This may be used to turn on a lamp directed at the Keypad at night so that the

person using the Keypad can see to enter the code. Put the unit into program mode and enter

7-7. You will see the two flash confirmation. Then, exit program mode. Note that selection of

this option means you give up the opportunity to implement a doorbell or other use of the

programmable relay.

To return the programmable relay to factory set (doorbell) function, put the unit into

program mode and enter 7-8. You will see the two flash confirmation. Then, exit program

mode.

7. ADDITIONAL HARD WIRED OPTIONS

7.1 DUAL PAD OPERATION

If keypad control from both sides of the door is desired, two keypads can be connected to

one CPU Board. Simply put the colored wires from both keypads into the appropriate terminals

on the CPU Board such that 2 wires are in each terminal. Either keypad will then be able to

release the lock and both keypads will beep and illuminate their LED's when either one is used.

Two is the maximum number of keypads that can be connected to one CPU Board. Note that in

the unusual case where both keypads are being used simultaneously, the door will not release

as the sequence will certainly be disturbed. Only one keypad may be used at a time. Be sure

you don’t violate egress building codes when employing a keypad on the inside of a

door. Check with your local building or fire department.

7.2 HARDWIRED CODE DISABLING

This means making a switch connection to the CPU board which will cause valid codes to not be

accepted. The DK-26 has two terminals marked “HCD” and “UCD” which will respectively

disable the Hard code and all User codes. Simply connect the SRC terminal to either of

these terminals via an external switch and the respective codes will not function while the switch

is closed. Alternately if you supply +12V or +24V from the DC+ terminal to either of these

terminals, it will have the same effect.

The main reason for doing this is to support

day/night operations. For example, you could

SRC

REX UCD HCD

allow all User codes to be active during the day

but disable them at night by closing a switch

between SRC and UCD. The Hard code would

be the only method of entry at night. Or, you

could have no Hard code programmed so that

there would be no entry at night. This could be

done by timer controlled contacts from a timer

SPDT

SWITCH

OR RELAY

NO

C

NC

WITH THE CON TACTS

AS SHOWN, THE HARD

CODE IS DISABLED.

WHEN THEY SWITCH,

ALL USER CODES

WILL BE DISABLED.

such as Securitron’s model DT-7. It’s finally

possible to flip the codes (Hard and all User) so that, for example, User codes are active only

during the day and the Hard code is active only at night. An SPDT switch or relay is needed to

do this as the drawing to the right shows. Note that you won’t be able to use one of these

disabling features (Hard or User) if you have implemented the door prop alarm (Section 6.4) or

anti-tailgating (Section 7.4) features. These reassign one of the terminals.

Page 23

Rev. A.2, 10/03 Page-20

7.3 ALARM SYSTEM SHUNTING

The DK-26's lock control relay is of the double pole, double throw type. Note that in all the other

drawings in this manual, we show only one of the poles being used (C1, NC1 and NO1). The

most common use for the second pole (C2, NC2 and NO2) is to shunt out an alarm system,

which would be connected to the door when the DK-26 is being utilized. The idea is that if the

door opens without the DK-26 having been activated, an alarm signal should result. When the

DK-26 is employed to open the door, the alarm signal should be shunted.

The alarm system will be connected to a door switch or other detector at the door via two wires.

You will need to determine if this “loop” is closed when the door is closed and opens when the

door opens (the most common) or is open when the door is closed and closes when the door

opens. In the former case (closed when the door is closed), splice wires respectively from C2

and NO2 into the wires from the detector or switch. When the DK-26 operates, this connection

will close preventing the alarm loop from opening (alarm condition). In the latter case (open

when the door is closed), cut one of the alarm loop wires and splice wires respectively from C2

and NC2 into the ends of this wire. When the DK-26 operates, this connection will open

preventing the alarm loop from closing (alarm condition).

FIG 8 WIRING TO SHUNT ALARM SYSTEM ON DOOR

TO ALARM PANEL TO ALARM PANEL

NC2 C2

DOOR

SWITCH

ALARM SIGNAL WHICH IS

CLOSED WHEN DOOR IS CLOSED;

OPENS TO ALARM

NO2

CUT EITHER

WIRE FROM

SWITCH

ALARM SIGNAL WHICH IS

OPEN WHEN DOOR IS CLOSED;

CLOSES TO ALARM

NC2 C2

DOOR

SWITCH

NO2

7.4 ANTI-TAILGATING

Particularly when using the longer time ranges, the end user may be concerned that after an

authorized person has used the door, a second unauthorized person can also use it before the

lock has reset. By the addition of a door switch which opens when the door opens, the DK26 can be made to re-engage the lock as soon as the door has re-closed regardless of the

status of the timer. To implement this feature, a special command has to be sent to the CPU

board which will alter the function of either the HCD or UCD input terminal. When you enable

this anti-tailgating feature, you must give up the capability of disabling either the Hard code or all

the User codes.

Page 24

Rev. A.2, 10/03 Page-21

Put the unit into program mode and enter 8-0 to

assign this function to the HCD terminal or 8-1

to assign it to the UCD terminal. You will see

the two flash confirmation. Then, exit program

mode.

Finally connect a door switch as shown in the

drawing to the right and you will see that the door

will always relock immediately when it recloses

SRC

DOOR SWITCH

UCD HCD

CON NECT A DOOR

SWITCH WHICH

OPENS WHEN THE

DOOR OPENS TO

UCD OR HCD

DEPENDING ON WHICH

COMMAND YOU CHOOSE

regardless of how much time is left on the timer.

The feature will operate when the door has been released from the keypad or from the REX

input (see Section 3.6). Note that to disable the anti-tailgating feature and return full function to

the HCD and UCD terminals, put the unit into program mode and enter 8-4. Note that the DK26 supports a more powerful anti-tailgating feature which incorporates an alarm signal through

the use of the programmable relay. Read Section 6.4 for details.

7.5 WIRING WITH SECURITRON'S TOUCH SENSE BAR AND MAGNALOCK

The DK-26 is often used with Securitron's Touch Sense Bar and magnetic lock. The following

drawing shows wiring for this particular configuration. Note that the REX input is not used.

Since touching the bar opens the door in a single motion, you do not want to activate the DK26's timer which would only serve to keep the lock released for a longer time, thereby reducing

security. Another potentially confusing element is that the Touch Sense Bar is also a powered

device which operates most reliably when it is constantly powered. The drawing shows a wiring

method that is applicable for either an AC or DC power supply (naturally, the supply voltage

must be matched to the lock voltage). Note that a variation of this wiring scheme could be

desired if you are using the second pole of the DK-26’s lock control relay to shunt an alarm

system (see Section 7.3). You would then want the Touch Bar to operate the DK-26’s lock

control relay in double break fashion so that the alarm system is shunted both for entry and exit.

Simply follow Figure 9 except also connect the blue and orange wires from the Touch Sensor to

terminals SRC and REX on the CPU board (as well as connecting the second pole of the lock

control relay to the alarm point as shown in Section 7.3).

FIG. 9: WIRING OF DK-26, TOUCH SENSE BAR AND MAGNALOCK

IF AC POWER IS

BEING USED,

CONNECT 12

OR 24 VAC TO

AC IN TERMINALS

IF DC POWER IS

BEING USED,

CONNECT 12

OR 24 VDC TO

DC IN/OUT

TERM INALS. BE

SURE TO OBSERVE

POLARITY

NOTE: SEE FIG. 2 FOR 12 WIRE

KEYPAD CABLE CONNECTIONS

AC IN

DC IN/OUT

F

+

DC IN/OUT

+

POWER SUPPLY VOLTAGE MUST MATCH VOLTAGE OF MAGNALOCK

CPU BOARD

C1

NC1

WHITE

TOUCH

SENSOR

GREEN

RED

BLACK

RED

MAGNALOCK

BLACK

Page 25

Rev. A.2, 10/03 Page-22

MAGNACARE® LIMITED LIFETIME WARRANTY

SECURITRON MAGNALOCK CORPORATION warrants that it will replace at customer’s request, at any time for

any reason, products manufactured and branded by SECURITRON.

SECURITRON will use its best efforts to ship a replacement product by next day air freight at no cost to the

customer within 24 hours of SECURITRON’s receipt of the product from customer. If the customer has an account

with SECURITRON or a valid credit card, the customer may order an advance replacement product, whereby

SECURITRON will charge the customer’s account for the price of the product plus next day air freight, and will

credit back to the customer the full amount of the charge, including outbound freight, upon SECURITRON’s receipt

of the original product from the customer.

SECURITRON’s sole and exclusive liability, and customer’s sole remedy, is limited to the replacement of the

SECURITRON product when delivered to SECURITRON’s facility (freight and insurance charges prepaid by

customer). The replacement, at SECURITRON’s sole option, may be the identical item or a newer unit which

serves as a functional replacement. In the event that the product type has become obsolete in SECURITRON’s

product line, this MAGNACARE warranty will not apply. This MAGNACARE warranty also does not apply to

custom, built to order, or non-catalog items, items made by others (such as batteries), returns for payment,

distributor stock reductions, returns seeking replacement with anything other than the identical product, or products

installed outside of the United States or Canada. This MAGNACARE warranty also does not apply to removal or

installation costs.

SECURITRON will not be liable to the purchaser, the customer or anyone else for incidental or consequential

damages arising from any defect in, or malfunction of, its products. SECURITRON does not assume any

responsibility for damage or injury to person or property due to improper care, storage, handling, abuse, misuse, or

an act of God.

EXCEPT AS STATED ABOVE, SECURITRON MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, AS

TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION THE CONDITION OF ITS PRODUCTS,

THEIR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

Page 26

Rev. A.2, 10/03 Page-i

APPENDIX A: COMMAND SUMMARY

WITH THE UNIT IN PROGRAM MODE (FAST YELLOW FLASH):

00 followed by 5-7 digits sets Program code

01 followed by 2-7 digits set first User code

02-followed by 2-7 digits sets second User code

Additional User codes can be set up to the prefix 59 (total 59 User codes)

70 will sound beeper when door is open (except toggle mode). Echo and prompt beeps are retained

71 will silence beeper at all times

72 will return beeper to factory set

73 will reverse light logic (red to echo, green to show door is open)

74 will return light logic to normal

75 will direct Hard code to programmable relay for duress (entering Hard code releases door and switches

programmable relay)

76 will transfer programmable relay to alarm function (16 wrong digits switches programmable relay as well as

locking out keypad for 30 seconds)

77 will transfer programmable relay to light function (relay operates for 5 seconds when any key is pressed.)

78 will return programmable relay to doorbell function.

79 is alternate code delete. Any valid code entered directly after the 79 command will be deleted

80 re-assigns the HCD terminal to anti-tailgating

81 re-assigns the UCD terminal to anti-tailgating

82 re-assigns the HCD terminal to door prop alarm

83 re-assigns the UCD terminal to door prop alarm

(Note the door prop alarm function automatically includes anti-tailgating)

84 returns either input to original (code disable) meaning

88 will erase all user codes (not Program or Hard code)

89 will return all functions (including timer) to factory set. Codes are unchanged.

Pressing 9 when in program mode sets the timer. Two digit codes must be entered from 01 to 99 seconds. Default

is 5 seconds. Entering 00 sets toggle mode.

Page 27

Rev. A.2, 10/03 Page-ii

APPENDIX B: TROUBLESHOOTING

Note first that the DK-26 replaces older Securitron keypads: the DK-20, DK-20+ and DK-25.

The DK-26 keypad and CPU board are not compatible with any of the older units so make sure

you have both a DK-26 keypad and DK-26 CPU board. If the keypad label is missing, you can

identify a DK-26 keypad by the fact that it has three LED’s. The DK-26 circuit board is marked

with its name. Also, as you are going through these troubleshooting points, note that the goal is

to get the unit working, but if this is not possible, to identify whether the failure is in the keypad

or in the CPU board.

PROBLEM-- Unit appears dead.