Page 1

PN# 500-10420

Rev. A.3, 5/00

SECURI TRON 32, 34, 62 AND 82 SERIES MAGNALOCK

TABLE OF CONTENTS AND GUIDE TO THIS MANUAL

There are numerous Magnalock version s and n umerous different appl ications exist for them.

Accordingly, this manual provides a broad range of information- only a portion of which is

applicable to any individual use. This manual guide provides a brief summary of many of the

Sections which allows you to consult only the portions of the manual that apply to your

application.

SECTION 1. DESCRIP TION---------------------------------------------------------------------Page 1

SECTION 2. PHYSICAL INSTALLATION---------------------------------------------------Page 1

This is the largest part of the manual with sections that explain the different types of

physical installations which vary according to door or gate types as well as Magnalock

versions.

SECTION 2. 1 SURVEY---------------------------------------------------------------------------Page 1

This section concerns how to pre-plan the installation.

SECTION 2. 2 INSTALLATION TOOL KIT --------------------------------------------------Page 1

This s ec tion expl ains an avail able acc es s or y .

SECTION 2. 3 GENERAL INSTALLATION ON OUTSWINGING DOOR------------Page 1

SECTION 2. 3.1 STRIKE P LATE MOUNTING----------------------------------------------Pag e 1

SECTION 2. 3.2 MOUNTING THE MAGNET------------------------------------------------Page 3

The ab ove three sec tions exp lain t he most common Magn alock in stal lat ion on a d oor th at

swings away from the lock. They also include general mounting instructions and should

therefore b e r ead for all in s tall ations.

SECTION 2. 4 GENERAL INSTALLATION ON INSWINGING DOOR ---------------Pag e 5

This section explains inst al lation of "F" type Magnalocks on inswing in g doors.

SECTION 2. 5 MOUNTING PROCEDURES FOR SPECIFIC DOOR TYPES-------Page 6

The following six sections provide specific advice depending on door type which incl udes

recommended bracketry.

SECTION 2. 5.1 ALUM INUM FRAME GLASS DOOR MOUNTING-------------------Page 6

SECTION 2. 5.2 THE UMB BRACKET FOR ALUMINUM AND CONCRETE ------Page 7

SECTION 2. 5.3 SOLID GLASS DOOR MOUNTING--------------------------------------Page 8

SECTION 2. 5.4 DOUBLE DOOR MOUNTING ---------------------------------------------Page 9

SECTION 2. 5.5 CONCRETE HEADER OR WOOD FRAME MOUNTING ----------Page 9

SECTION 2. 6 MOUNTING THE M AGNALOCK ON EXTERIOR GATES-----------Pag e 10

This section, which includes three drawings, covers outdoor use of the Magnalock on a

variety of g ate types.

SECTION 2. 7 USE OF DRESS COVERS----------------------------------------------------Page 12

This sect ion introd uces the Dres s Cover which is used after p hys ical mou ntin g to im prove

ins tallation ap pearanc e and t am per resistance.

SECTION 2. 8 T AMPER PROOFING T HE MAGNALOCK ------------------------------Pag e 12

This s ec tion sh ould be read for an y instal lation in a high vandalism area.

Ó Copyright, 2000, all rights reserved · Securitron Magnalock Corp., 550 Vist a Blvd., Sparks NV 89434, USA

Tel: (775) 355- 5625 · ( 800) M AG LO CK · Fax: (775) 355- 5636 · Website: www.securitron.com

An ASSA ABL OY Group co m p any

Page 2

Rev. A.3, 5/00

SECTION 3. ELECTRICAL INSTALLATION-----------------------------------------------Page 13

SECTION 3. 1 GENERAL EL E CTRICAL CHARACT E RISTICS -----------------------Page 13

This s ection expl ain s t ech nic all y t h e Magn aloc k's elec tric al ch aract erist ics as a l oad an d is

for reference.

SECTION 3. 2 S TANDARD LOCK -------------------------------------------------------------Page 13

This section explains powering and switching the Magnalock.

SECTION 3. 3 AV OI DING POOR RELEASE CHARACTERIST ICS-------------------Pag e 13

This s ec tion warn s against wiring mistakes s pecific only t o the model 32 series .

SECTION 3. 4 WIRE GAUG E S IZING ---------------------------------------------------------Page 14

This reference section explains how to select wire size for app lications where the l ock is

distant from the power supply.

SECTION 3.5 SENSTAT MAGNALOCKS: “SC”------------------------------------------Page 14

Read this section if you have a Senstat Magnalock.

SECTION 3. 6 DOUBL E DOOR PROCEDURE FOR STATUS REP ORT ING-------Page 15

This section applies if you h ave Senstat locks on a dou ble door an d want them to report as

a single l ock.

SECTION 3. 7 DOUBL E DOOR CONTROL S WITCHI NG --------------------------------Page 15

This section applies whenever you have two locks controlled by a singl e switch.

SECTION 3. 8 E MERGENCY REL E AS E -----------------------------------------------------Page 16

This section should be understood by all installers.

APPENDIX A TROUBLESHOOTING----------------------------------------------------------Page i

Refer to this section before cal l ing the factory on any operating problem.

APPENDIX B CALCULATING WIRE GAUGE S IZING-----------------------------------Page ii

This detailed reference section explains how to select wire gauge in complicated multi-lock

installations.

APPENDIX C CONSIDERATI ONS FOR MAXI MUM P HYSI CAL SECURITY------Page iii

This reference section explains the technical aspects of lock holding force and resistance to

attack. It contains numerous installation techniques which act to insure high lock security. It

must be read for high security applications and also has excellent educational value.

Page 3

Rev. A.3, 5/00

Use of the Magnalock (or any lock) can lead to an unsafe

condition within the building if it is controlled in a manner that

improperly restricts passage through certain doors. The most

important area of concern is to insure that building evacuation is

not im peded in the event of a fire or other em ergency condition.

Consult with the local building or fire department to insure that

the controls installed with the Magnalock create a safe and

code legal installation.

The Magnalock has an unlimited operating life and receives a

great deal of cumulative shock over this life from the door closing

and from persons attempting to open the door when it is

secured. It is therefore vital that it be firmly m ounted to the door

header. If this is not done, a person's use of the door could

cause the m agnet body to fall and possibly cause an inj ury. The

blind nuts furnished with the Magnalock will create strong and

permanent mounting when correctly collapsed inside the

header. If they are not collapsed, an unsafe condition will re sult .

Make sure you understand section 2.3.2 in the manual on

magnet mounting and collapsing the nuts.

- SHOCK HAZARD. The Magnalock must

be operated from a DC power supply of appropriate capacity

and voltage. The DC output of the power supply must not be

connected to earth ground but must be isolated, or a shock

hazard and possible damage to the product could result. All

Securitron power supplies are delivered with isolated DC outputs

and the majority of commercial supplies are also furnished this

way. If you are not certain that the DC outputs of your power

supply are isolated, check with an Ohmmeter between earth

ground and +V, and then between earth and 0V (negative). You

should not have continuity.

Page 4

Rev. A.3, 5/00 Page- 1

SECURI TRON 32, 34, 62 AND 82 SERIES MAGNALOCK

INSTALLATION INSTRUCTIONS

1. DESCRIPTION

Secu rit ron ’s Magnal ock famil y rep resen ts the stat e of th e art in el ect ric l ock ing . Three d if feren t

size models are available: The Model 32 and M odel 34 s eries wit h a h ol d ing f orce of 600 lb s.

(275 Kg. ); Th e Model 62 series with a h old in g forc e of 1, 200 lb s. (550 Kg .) and the model 82

series wit h a h oldin g f orce of 1,800 lbs. (820 Kg.). Several mou nting and electronic options

are available whic h are des c r ibed in this manual. Note that m os t points in this manu al appl y to

the entire Magnalock series. When a point applies to a particular Magnalock version, this will

be specifically noted.

2. PHYSICAL INSTALLATION

2.1 SURV E Y

Becau se of th e wide variety of situ ations in whic h th e Magnal ock m ay b e ut ilized , f irst survey

the physical area in which it is to be installed and determine the best method of mounting it. In

this initial planning two considerations come into play: the mounting method must be strong

enough so that the full holding power of the Magnalock can be effective, and the Magnalock

and wiring must be protected to a reasonable degree from damage by intruders or vandals.

Often an accessory bracket is necessary, either furnished by Securitron or made up by the

install er. The brackets that can be used are covered later. Note that Magnal ocks are supplied

with a complete set of fasteners. When s hipped outside of North America, metric fast eners ar e

supplied and therefore the drawings in this manual show both US and metric fasteners.

2.2 INSTALLATION TOOL KIT

Secu rit ron offers an in st al lat ion tool kit (p art # IK or IKM, for m etr ic u se) wh ich in cl ud es s pec ial

drills, a drilling template, a blind nut collapsing tool and extra fasteners and hardware. If the

install ation is for a larg e n umber of locks or if the installer exp ects to p erform oth er inst al lations,

we recommend the purchase of this kit as it reduces installation labor and improves job quality.

2.3 GENERAL INSTALLATION ON OUTSWINGING DOOR

The Magnalock should be mounted under the door frame header in the corner farthest from the

hinges (see Figure 4). Most commonly, it is positioned horizontally but vertical positioning

sh oul d also be cons ider ed. In some cases f or examp le, th e h oriz ont al head er on an al um inu m

frame glass door is not as strong as the vertical extrusion, so vertical mounting would be

pr eferr ed. This ty pe of in stal l ation p l aces t he Mag nal ock su ch th at th e d oor swin g s away f rom

it. Th is configuration is necessary for all facility exit doors (otherwise, the Magnalock would be

on t he out side of the b uil din g). F or int erior d oors, the Magnal ock shou ld stil l be m ount ed in

this manner unless security planning anticipates a physical assault on the Magnalock from that

sid e of the door in which cas e s ee s ec tion 2.4 on inswingin g door instal lation .

2.3. 1 S TRIKE PLATE MOUNT ING

The strike should be mounted before the magnet on the upper corner of the door. The first

step is to locate the precise place you intend to mount the strike including deciding whether

you want to m oun t th e Magn al ock h orizon t all y or vertical l y (s ee Sect ion 2. 3.2). Th e top of th e

strike should be positioned about 1/10" (2.5mm) below the line where the door meets the

door stop, or below the header if there is no door stop to permit free closing. If the strike is

mounted vertically instead of horizontally, increase this stand-off distance to 2/10" (5mm).

More clear ance is n eeded on a vert ic al mount b ec ause the strike projects out from the door and

can s c r ape the s ide frame as the d oor s wings c losed on its arc . Final posit ioning of the strike is

dictated by the desired position of the magnet. The strike must be centered on the magnetic

poles (3 bars) and th e magnet is n ormally moved an inch or so in (or down) from the frame

corner so that the magnet mounting holes will not have to be drilled awkwardly in the corner.

When the strike position has been chosen, step t wo is to d ril l th ree h ol es in th e d oor f oll owin g

the template. Step three is mounting the white plastic bushings which surround and insulate

the roll pins in to the 1/2" (12.7mm) holes. The bu shing s are employed to insu late th e strike

electrically from a metal door and also help preven t the r oll pins f r om wear ing t he door.

Page 5

Rev. A.3, 5/00 Page- 2

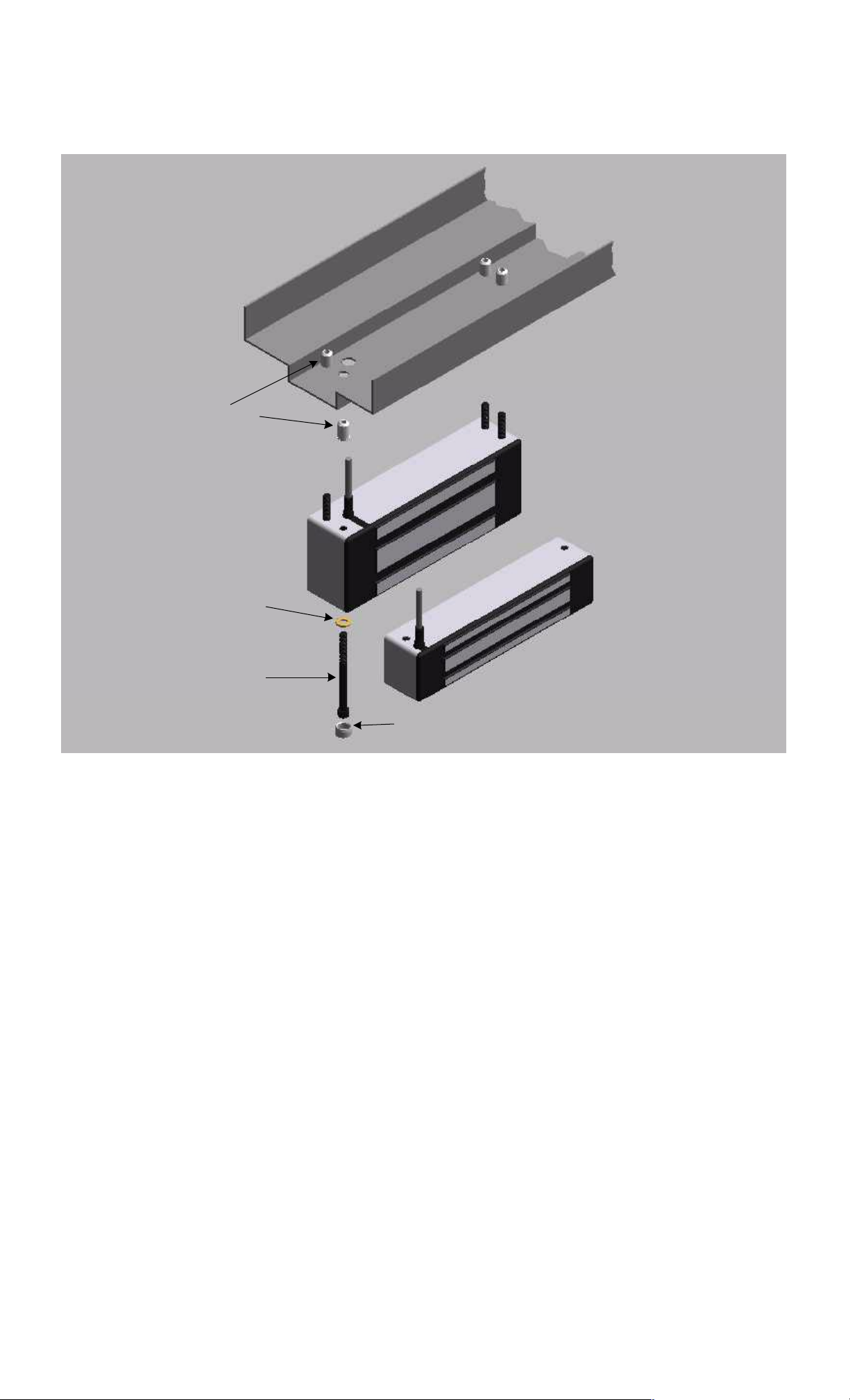

FIG. 1: STANDARD MAGNET DIMENS IONS AND ASSEMBLY

If "G" option is furnished, (62

and 82 series only), the wire

cable emerges from a 3/4"

male; 1/2" female conduit

fitting on the end of the

magnet. The mounting holes

are counterbored from both

sides to make the magnet

non-handed

Blind Nut

PN# BN-250 or

PN# BN-6MM (Metric)

(Pack of 40 with tool)

Gold Washer

PN# FW-1

(Pack of 24)

32 8" 1.88 1.5

(mm) 203 47.8 38.1

34 9.5" 1.75 1.125

(mm) 241 44.5 28.6

62 8" 2.9 1.75

(mm) 203 73.7 44.5

82 12" 2.9 1.75

(mm) 305 73.7 44.5

2

6

l

e

d

o

M

2

3

l

e

d

o

M

Length Width Depth

Recommended Tools:

1/2" or 3/8" Drill Motor

1/8", 3/8", 1/2" Drill Bits

1/2" Open or Crescent Wrench

3/16" Hex Key (Allen Wrench)

Hammer, Center Punch

Masking Tape, Fish Tape or

Leed Wire

Wire Strippers/Cutters

Crimp Wire Connectors

Multi-Meter

1/4-20 x 3" Cap Screw

PN# SCS-35 (Pack of 4)

6mm-1mm x 75mm

PN# 300-12650

Tamper Cap

PN# FC-1

(Pack of 24)

1/4-20 x 2 1/4" Cap Screw

PN# 300-12750 or

6mm-1mm x 55mm

PN# 300-12925

(For Model 32 Magnalock)

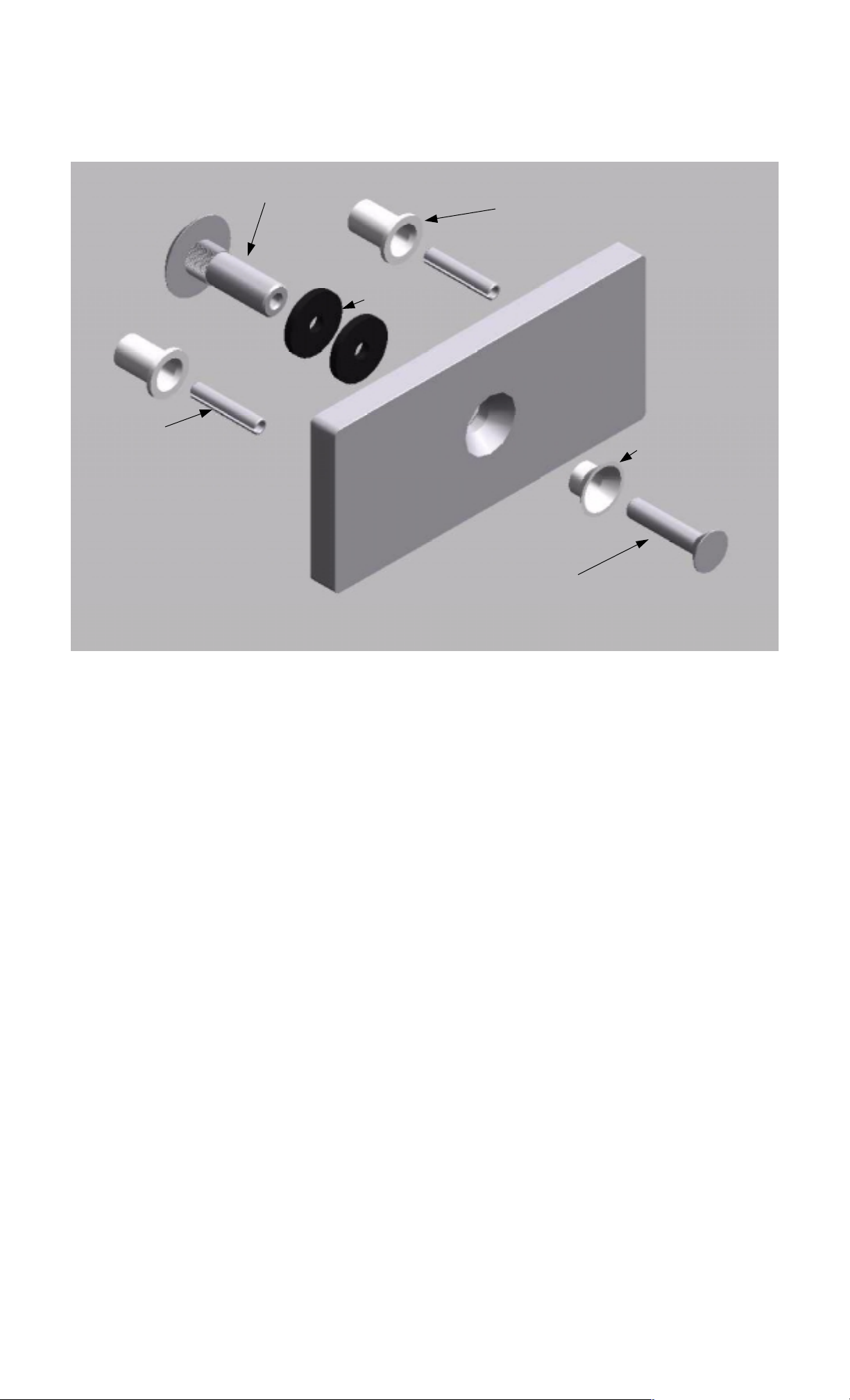

Step four is to insert the strike mounting hardware. Roll pins furnished with the strike should

be hammered into th e strike. Be careful not to hit them too hard as it is possible to raise

dents on the strike surface by over driving the pins which degrades strike flatness and

therefore holding force. The strike is secured by the central strike mounting screw. Two

flexible washers are then placed between the strike and the door with the strike mounting

screw passing through the washers to provide flexibility. A third rubber washer is furnished.

This is not normally used but may be employed in case the spacing of the magnet and strike is

a little off. Add ing th e third washer will move the strike closer to the magnet. Do not place t he

washers around the roll pins. The roll pins should "float" in their holes and not bind. Their

only purpose is to p reven t th e strike from rotating or spinning.

In step fi ve, the strike is secured to the door via the supplied sex bolt. Note that we supply a

massive 1 1/4” diamet er sex bol t as it is t he on l y p oin t of att ack f rom t he ou t sid e of t he d oor. It

can be difficult to align the strike mounting screw with the sex bolt, so the following technique

is recommended : Start the sex bolt in its 1/2" (12.7 mm) hole b ut thread t he strike mountin g

screw into it (with strike plate and washers) before hammering the sex bolt down. Next,

hammer the sex bolt d own and then screw the strike mountin g screw in the rest of the way.

This m ak es align m ent much easier .

Step six is to verify proper mounting. When the strike is mounted, make sure it flexes

freely around the washer stack. This flexing allows the Magnalock to pull the strike into

perfect align ment f or maximum hold ing f orce. It is never poss ibl e f or a d oor an d f rame to l in e

up well enough for the Magnalock to function unless the strike is allowed to flex.

Page 6

Rev. A.3, 5/00 Page- 3

FIG. 2: STRIKE DIMENSIONS AND ASSEMBLY

Sex Bolt, Models 32, 62, 82, PN# SB-1, SB-1M (Metric)

Model 34, PN# 330-12100, 330-12150 (Metric)

R

u

P

N

#

R

b

W

b

e

r

W

a

-

s

1

h

(

P

a

c

k

Bushing (2), PN# 560-12050

e

r

(

2

)

o

f

2

4

)

Roll Pin (2), PN# 330-10800

1/4" x 1 1/4"

Length Width Depth

32 6.25" 1.63 .5

(mm) 158.8 41.4 12.7

34 6.4" 1.44 .44

(mm) 164.5 37 11.3

62 6" 2.75 .5

(mm) 152.4 70 12.7

82 9.5" 2.75 .5

(mm) 240 70 12.7

Flathead Screw

5/16-18 x 1 3/4"

PN# 300-13600 or

8mm-1.25mm x 40mm

PN# 300-13750 (Metric)

Bushing,

PN# 330-12000

2.3.2 MOUNTING THE MAGNET

Step one is to locate the mounting position of the magnet. It will mount in the door frame

header with four soc k et cap mac hine sc r ews for metal fram es or wood sc r ews for wood frames.

In mounting the Magnalock, six conditions must be followed:

-- The frame header mus t present a fl at surface for th e magnet to mount to. 1 7/8” (48mm) for

the model 34, 2 1/4” (57mm) for the model 32 and 2 1/2" (63.5mm) for the model 62 an d 82 are

req uired f r om the door to the rear of the magnet f or prop er mountin g (as shown in Fig ure 4) . If

th is len g th of flat surf ace is n ot avail abl e, th e u se of stop filler plates and/or head er bracket s

availab le from Securitr on can usually r es olve the probl em . Again, r efer to Figure 4.

-- The frame area selected must be structurally strong enough to yield a properly secure

ins tal l ation . Th e issu e of fram e str eng t h m us t b e c ons ider ed in sel ectin g vertical or hor izon tal

mounting. One often finds on aluminum headers that the horizontal extrusion is weak and can

be snapped off, so vertical mounting would be preferred. It is also possible to reinforce the

head er b y ad d in g a s teel p lat e. Th e in stal l er mu st avoid mou n tin g t h e m agn et t o a wob b l y or

weak support or the intrinsic security of the lock will be diminished.

-- The magnet face must be parallel to the strike plate.

-- The magnetic poles (three metal bars on the Magnalock), must be centered on t he strike.

-- The magnet must make solid contact with the strike but still allow the door to close

properly.

-- Th e direction of door opening must p ull the st r ik e d irect ly aw ay from the magnet rather than

sl iding it away. Electromagnet s hold only weak ly in the shear direc tion of pul l.

On ce a solid fl at sur face has been p repar ed for t he mag net, it mu st be posit ioned so that its

face is parallel an d centered to the strike pl ate. When th e magnet has been experimentally

positioned this way, it's ready for mounting.

Page 7

Rev. A.3, 5/00 Page- 4

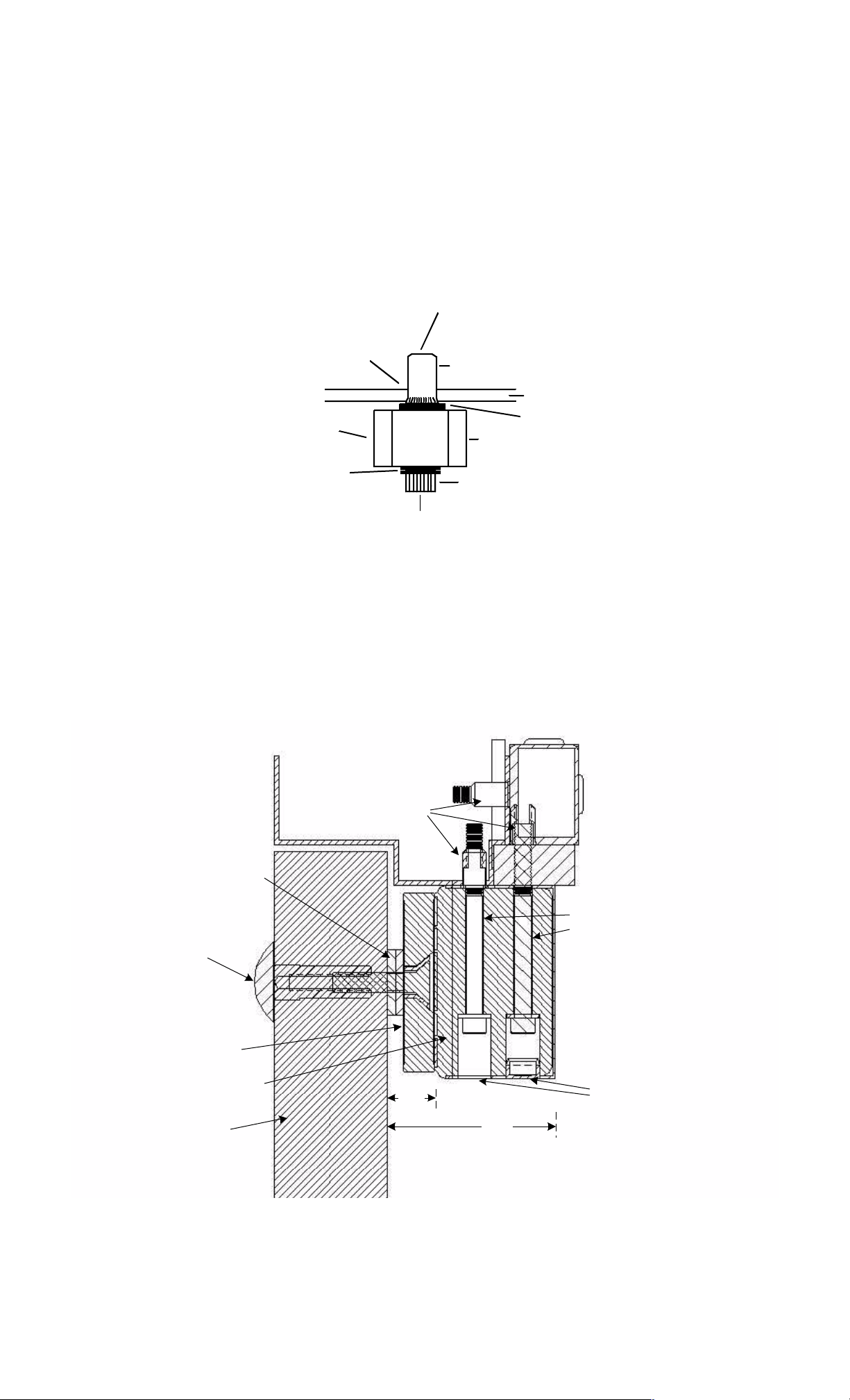

In step two, hol es mu st be drilled for the mounting screws, and a 1/2" (12.7mm) d iameter wireway hole should be drilled. Step three is to install the blind finishing nuts. For proper

strengt h, the 1/4-20 (or 6mm) mountin g machine screws must be secured by t hese nuts. They

will work on any th ickn ess metal header and are used as fol lows: A 3/8" (9.5 mm) hole is drilled

following the template for each nut. The nut is then pressed u p into the hole and lightly seated

with a hammer tap. The nut is then collapsed inside the header. If you have Securitron's IK

ins tallation kit , the nut s m ay be collapsed by t he use of the blin d nut placem ent tool. A s pecial

collapsing tool is also included with each Magnalock. It is somewhat slower to use than the

more elaborate tool found in the installation kit. For its use, see Figure 3.

FIG. 3: COLLAPSING THE BLIND NUTS

COLLAPSES WHEN CAP SCREW

DRILL 3/8" (9.5MM) HOLE

PRESS IN BLIND

NUT AS SHOWN

HOLD WITH WRENCH OR

VISE GRIP WHILE TURNING

CAP SCREW

IS TURNED WITH ALLEN WRENCH

WHILE TOOL IS HELD FAST

WITH BOX WRENCH

BLIND NUT

HEADER

KNURL

TOOL

TWO FLAT WASHERS

IF SCREW IS STIFF TO TURN,

ADD LU BRICANT TO WASHERS

WHILE TURNING WITH ALLEN

WRENCH, PRESS IN TO KEEP

NUT SEATED IN HEADER

CAP SCREW

1/4-20 X 1" (US) OR

6MM-1MM X 2 5MM (METRIC)

Step four is to make the necessary wire connections. S t ep five is to mount the magnet via the

supplied machine screws (see Figure 1). Don't forget to use the gold flat washers. They

prevent the narrow screw heads from digging into the resin which could cause damage.

Tighten the screws to a snug fit only. Use the supplied thread-lock on t he screw t hread s t o

avoid th e p ossib il ity of t he s crews l oosen in g over time. Do not drill out the mounting holes

to make f or an easier fit. You may cut an internal wire and void the warranty.

FIG. 4: TYPICAL MOUNTING ON OUTSWINGING DOOR

Header Bracket if

frame is too narrow

Blind Nuts

Stop Filler Plate if

Washer Stack

Stop

stop is too narrow

Sex Bolt

Strike

Magnet Body

Door

.75"

(19mm)

1/4-20 (6mm)

Mounting Screws

Model 62 or 82 is shown

with four magnet mounting

screws. Model 32 or 34

employs only two.

Tamper Caps

(One shown)

2.5"

(63.5mm)

Page 8

Rev. A.3, 5/00 Page- 5

2.4 G ENE RAL INSTALLATI ON ON INS WINGI NG DOOR WITH Z BRACKET

In cas es where th e Mag nalock m ust be mounted on the inswinging side of the door to protect it

from physical assault, the m agnet body is m ount ed fl ush on the wall ab ove the door frame and

a "Z" bracket is affixed to the door which positions the strike in front of the Magnet (part # Z-32,

Z-62 or Z-82 with the su ffix “M” for metric). The model 34 series is not offered in a face

mount version. Securitron's "F" series Magnalocks are used, as they have mounting holes

through the face of the magnet and wire exit to the rear. Figure 5 shows this configuration.

Note that the model 62F has five mounting holes through the face. The “extra” hole is t o

provide flexibility in mounting when the magnet bod y is positioned partly on th e top of the

door frame and partly on the wal l . In that instance, it becomes possible to secure the model 62

mag net b ody with th ree screws wh ich al l g o into t he fr ame head er (man y wal l typ es su ch as

sheet rock do not constitute a secure mounting substrate). Note that when the roll pin

bushings are used, they protrude through the Z bracket and interfere with the Z bracket cover.

If a Senstat lock is being employed, the roll pin bushings must be u sed t o provide in sul ation.

They shoul d be cu t with a hacksaw to fun ction in the bracket. If th e lock is not Senstat, omit

use of the roll pin bushings and drill 3/8" (9.5mm) diameter holes for the roll pins instead of

1/2" (12.7mm). Read sections 2.3, 2.3.1, and 2.3.2 for additional general information on

mounting.

Blind Nut

PN# BN-250 or

PN# BN-6MM (Metric)

(Pack of 24 with tool)

1/4-20 x 2 1/2" Cap Screw

PN# SCS-25 or

6mm-1mm x 60mm

PN# SCS-60mm (Metric)

Pack of four screws

FIG. 5: F M AGNET DIMENSIONS

Model 62F

)

4

2

f

o

r

e

k

h

c

s

a

a

P

(

W

1

-

d

l

o

W

F

G

#

N

P

Tamper Cap

PN# FC-1 (Pack of 24)

If "G" option is furnished, the

wire cable emerges from a 3/4"

male; 1/2" female conduit fitting

on the end of the magnet (62

and 82 models only)

Model 32F

Length Width Depth

32 8" 1.88 1.5

(mm) 203 47.8 38.1

62 8" 2.9 1.75

(mm) 203 73.7 44.5

82 12" 2.9 1.75

(mm) 305 73.7 44.5

Page 9

Rev. A.3, 5/00 Page- 6

FIG. 6: F M AGNALOCK MOUNTING

Architectural Cover slides on

last with open side up and is

attached with supplied double

Roll pin plastic bushing

require 1/2" (12.7mm)

holes and must be

shortened to work in Z

bracket. Roll pin bushings

may be omitted if lock is

not Senstat. Then drill 3/

8" (9.5mm) holes for roll

pins.

Sex Bolt

Drill 1/2" (12.7mm) hole

Strike

Magnet

Header

Z Bracket

Cap Screw:

5/16" x 18, PN# 300-13500 or

8mm-1.25mm, PN# 300-13425 (metric)

stick tape

Z Bracket

T-Nut requires 3/8" (9.5mm) Dia

hole in bracket and accepts

strike mounting screw

Use 1" mounting screw supplied

with Z bracket, PN# 300-13400

or 300-13450 (metric)

Washer Stack

#14 Hex Sheet Metal Screw (2)

PN# 300-13200

Door

2.5 MOUNTING PROCEDURES FOR SPECIFIC DOOR TYPES

2.5. 1 ALUMINUM FRAME GL AS S DOOR MOUNTING

This is a common door type that utilizes the Magnalock. Certain mounting problems can arise

depending on th e configuration of the door and frame. Often, the head er is not wid e enough

for the depth of the magnet. This can mean that none of the mounting screws can be run into

the h eader or that in the case of th e model 62 an d 82, only two of the four will fit. Another

aspect of the mounting screw problem is that the screws might line up with the end of the

head er extru sion. Al so the wir es may exit bey ond t he en d of th e h eader so t hat they will b e

exposed and vulnerable to tampering.

Most of the prob lems are sol ved by the use of Securitron's Universal Header Bracket (part #

UHB-CL or UHB-BK). This bracket will function with the model 32, model 34 or model 62

Magnalock. A separate version (UHB-82) is offered for use with the longer model 82. The UHB

extends t he depth of the header either 1" (25mm) or 1 1/2" (38mm) dependin g on which way

it's oriented. This usually allows mounting of all screws and since the bracket is itself a hollow

extrusion, the wire is run inside the bracket and therefore is hidden. Even with use of the

br acket , it is p ossib l e th at on e set of m oun t ing sc rews may l in e up with th e en d of t h e h ead er

when t he m odel 62 or 82 is us ed. To deal wit h t h is situ at ion, some ad ju st men t of t h e m agn et

mounting position is possible. Instead of the two rubber washers supplied with the strike, one

or th ree may b e used . If th e door is secured onl y by t he Magn alock (th ere is no mechan ical

swingbolt) the door closed position may be altered to allow all mounting screws to be used.

Fin al ly note t hat a mod el 62 ins tal l ation on th is t yp e of d oor is ac cep tab l e if on l y two m oun t ing

screws are used. Since the screws run into steel nuts, the fastening technique is very strong.

It is best to use all four screws, but particularly on this type of door, which is inherently not high

security (the g lass may be shattered for forced entry) firml y mou nting two screws is acceptable.

Aluminum frame headers typically employ a “blade” stop which is far too thin to provide a

mou nt in g su rfac e for t h e mag net . Not e th at Fig u re 4 sh ows t he Mag net mou n tin g on t h e door

stop. Accordingly, on aluminum frame glass doors, the magnet body mounts directly onto the

header. This c an be acc om plished by cutting away a section of the blade stop. This techniq ue

is preferred in th at the p rojection of th e magnet into the opening is minimized. An altern ate

Page 10

Rev. A.3, 5/00 Page- 7

method is to sp ace the mag n et down so as to clear the blade stop . This generally requires 1/2”

of spacing (12.7mm) and Securitron offers brackets of the appropriate width with pre-drilled

cl earan ce h oles for t h e Magn et mou n tin g scr ews. Th ese are t he ASB-32, AS B-62 or ASB-82

(with finish suffix CL or BK). Figu re 6 shows the use of the Al uminu m Shim Bracket (ASB).

Note that this bracket is not offered with the mod el 34. The UMB-34 bracket accomplishes the

same function .

FIG. 7: USE OF THE ASB BRACKET ON ALUM INUM DOOR/F RAME WI TH BLADE ST OP

BLADE

HEADER

DOOR

STOP

ASB BRACKET

MAGNE T

ALUMINUM DOOR AND FRAME

WITH BLADE STOP

O

M

R

O

F

2

3

-

B

S

A

I

W

O

H

S

S

B

S

A

.

N

K

C

O

L

A

N

G

A

M

2

3

L

E

D

6

-

A

H

2

8

/

2

E

V

I

F

S

S

E

L

O

H

STRIKE

SEX BO L T, STRI KE MOUNT IN G SCR EW AND HOLE IN DO O R CAN ALL BE RAI SE D BY

1/4" W HEN OFFSET STRIK E IS U SED WITH MODEL 62 TO SUI T NARROW RAIL

Anoth er pr oblem that can arise wit h al umin um fr ame gl ass doors is that in certain cases with

th e model 62, th e heig ht of the al umin um rail at th e top of th e door is n ot su fficien t to m ount

the strike and sex bolt. Even when the sex bolt is in stalled in the lowest area of the top rail, the

top ed ge of th e st rike wil l p rotr ud e ab ove th e rail . To sol ve th is p rob l em, S ecu ritr on of fers t h e

off set st rike. The holes in t he strike pl ate are offset 1/4" (6.4mm) from the center of the strike

and this allows successful mounting on a narrow top rail. An approximate 10% loss of holding

force results from the skewed position of the strike mounting screw b u t this is not significan t on

aluminum frame glass doors which are not high security barriers. The offset strike is supplied

at n o ad dit ion al c har ge if it' s cal l ed out with t he or der or may be s ent as a rep l acemen t for t he

standard strike. This p r oblem does not occur wit h th e m or e narrow model 32 or 34 so no offset

strike is offered with them.

2.5.2. THE UMB-BRACKET F OR AL UMINUM AND CONCRETE FILLED HE ADE RS

The UMB-34 bracket repl aces t he f u nc tion s of th e ASB b racket (s ee pr evious d rawin g ) an d t h e

CWB bracket (see Section 2.5.5) which permits mounting on wood or concrete filled steel

headers. Th e UMB has th e unique b enefit of being reversible wh ic h al ters the projec tion of the

bracket with respect to the top of the magnet body and allows coping with different stop

thicknesses. The bracket is delivered with a selection of fasteners for different applications.

Wood screws are present for mounting on wood headers; cap screws are present for

ins tall ation in to b lind nu ts an d sh eet metal screws are p resen t for op tional mou ntin g on s teel

headers.

Page 11

Rev. A.3, 5/00 Page- 8

FIG. 8: USE OF THE UMB BRACKET W ITH THE MODEL 34 MAGNALOCK

NOTE HOW BRA CKET CAN BE REVER SED TO COPE WITH DIFFEREN T STOP THICKNESSES

BLADE

HEADER

STOP

HEADER

STOP

UMB BRACKET

DOOR

MAGNET

STRIKE

ALUMINUM DOOR AND FRAME

WITH BLADE STOP

UMB BRACKET

DOOR

MAGNET

STRIKE

AL UMINUM DOOR AND FRAME

WITH BLADE STOP

THE TWO LAR GER HOLES ARE FOR THE

CABLE EXIT. THE TW O THREADED HOLES

ACCEPT THE MAGNET MOUNTING SCREWS.

THE REMAINING FIVE HOLES ACCEPT

DIFFERENT FASTENER TYPES TO MOUNT

TO DIFFERENT HEADERS.

2.5. 3 S OL ID GLASS DOOR MOUNTING

The Magn alock is an excell ent choice for securing 100% gl ass doors with no aluminum rail.

The magnet is suspended in normal fashion from the header and the difficulty in the

installation is mounting the strike plate on the glass door as glass cannot be drilled. This is

accomplished by using Securitron's model GDB (or G DBM with metric fasten ers) Gl ass Door

Bracket and model AKG Adhesive Kit for Glass (see Figure 7). The GDB bracket will work with

either the model 32, model 62, or model 82 Mag nalock (but not with the model 34). The

bracket is affixed to the glass surface by a special adhesive and the strike screws into the

bracket conventionally. The adhesive provides a permanent bond stronger than the holding

forc e of the Mag nalock.

Note t hat we h ave said "100% g lass d oor". Some door s that app ear to b e g lass are ac tual ly

laminated with plastic. I f the M agnal ock wit h g lass door bracket is used on this type of

door, it is possible that failure will occur via delamination.

In som e cases th e head er of a gl ass d oor is vertical glas s. The magn et can b e mou nt ed on

su c h a head er by us ing a 3" X 3" aluminum angl e bracket ( part number HEB- 3G). The bracket

is glued to the vertical glass header with Securitron's adhesive kit for glass and the magnet is

screwed to the bracket.

Page 12

Rev. A.3, 5/00 Page- 9

FIG. 9: STRIKE INSTALLATION ON 100% GLASS DOOR

S

S

A

L

G

A

L

G

ADHESIVE

BOND

2 X RUBBER

WASHERS

R

O

O

D

B

R

O

O

D

S

S

T

E

K

C

A

R

E

K

I

R

T

S

1/4" X 3/ 4"

ROLL PINS

NOTE: OMIT ROLL PIN WHITE PLASTIC BUSHINGS

5/16-18 x 1" (US) O R

8MM - 1.25MM X 25MM

(METR IC)

FLATHEAD SCREW

WHITE PLASTIC

BUSHING

2.5. 4 DOUBL E DOOR MOUNTING

Several p oss ibil it ies exist f or th is ap p l ication . In som e cases, on e of th e door l eaves is pi nn ed

so that onl y one leaf is used and this is secu red b y a sing le Magn alock . If bot h l eaves are to

be active, two Magnalocks can be used. For the most attractive installation, they should be

butted together but if obstructions exist in th e header that interfere with mounting, the magnets

can be separated somewhat. Another possibility is to use Securitron's split strike which is

available for the model 62 and model 82 (use of a split strike with the model 32 or 34 series

would provide inadequate security) In this method, a single Magnalock is mounted in the

cen ter of th e h ead er an d a h al f s ize st rike is m oun t ed on each leaf . This r ed uc es th e hol d in g

forc e t o abou t 550 l bs. (250 KG) for each leaf with t he mod el 62 and abou t 850 lb s. ( 385 KG)

for eac h leaf with the model 82. The s plit s trike (p ar t num ber ASS-62 or ASS-82 with “M” suffix

for metric) is available either as part of a complete Magnalock or supplied separately as a

rep lacemen t for t he st andar d str ike. Read s ection 2. 7 for in formation on Dress Covers wh ich

improve the appearance of a d ouble door install ation. Certain electronic consideration s also

appl y wh en Magnal ocks are used on double doors. See section 3.5.4.

2.5. 5 STEEL HEADE R FILL E D WITH CONCRET E OR W OOD FRAME MOUNTING

Securitron offers a combined bracket in three versions to suit the three Magnalock families.

The part number of the “Concrete/Wood Bracket” is CWB-32, CWB-62 or CWB-82. Two

finishes are available (suff ix CL or BK) and for metric locks, the b rackets inclu de th e suffix “M”.

Note that the CWB bracket is not offered with the mod el 34. It’s fun ctions are accomplished by

the UMB bracket for the model 34.

In concrete filled headers, the blind nuts function normally but a problem can occur in pulling

the hook up wires as it is difficult to run a wireway in con crete. The center of th e bracket for the

model 62 and model 82 versions forms a splice chamber if it's difficult to pull the wires back

int o th e h eader . Th e mod el 32 version h as a s lot to b rin g th e wire in to t he h ead er bec aus e of

the narrowness of the lock. Alternately the wires may be pulled through the edge of the

bracket by drilling a hole if it's impractical to drill the concrete. A final technique for concrete

headers is the use of Secur itron' s "G" version Magn alock (n ot available in the 32 or 34 series)

which incorporates a 1/2" female/-3/4" male universal threaded conduit fitting. The conduit

fitting is placed on the end of the magnet body, and the problem of pulling wires into concrete

is bypassed as the wires may be run in pipe in a surface mount configuration. The mounting

holes on " G " locks are counter-bored from both sides to make the lock non-handed.

With a wooden frame, lon g wood screws are used to mou n t t h e Magn aloc k. Th e scr ews mu st

penetrate as deeply as possible through the stop and frame into the header to yield adequate

mounting strength. The Magnalock mounts to the bracket via machine screws and the bracket

per m its wood sc r ews ( furn i s hed) t o penet r ate deep ly into the header (s ee Figu r e 10)

Page 13

Rev. A.3, 5/00 Page- 10

FIG. 10: WOOD FRAME AND CONCRET E HE ADE R BRACKE T

CWB-32

R

E

B

M

A

H

C

E

C

I

L

P

S

1/2"

WO OD SCRE WS U SED

FO R WOOD FRAME

MAGNET SCREWS INTO

2 OUTSIDE TAPPED HOLES

SHEET METAL

SCREWS

FOR CONCRETE

HEADER

USED

USE ALL FURNISHED SCREWS FOR

PROPER MOUNTING SECURITY

CWB-62 AND CWB-82

R

E

B

M

A

H

C

E

C

I

L

P

S

1/2"

WOOD SCREWS USED

FOR WOOD FRAM E

SHEET METAL SCREWS

USED FOR CONCRETE

MAGNET SCREWS INTO

4 OUTSIDE TAPPED HOLES

HEADER

2.6 MOUNTING THE MAGNALOCK ON EXTERIOR GATES

A popular application for the Magnalock is to secure motorized or manual exterior gates. The

Magnalock has several benefits in this application. Gates tend not to be precisely fitted so

electric bolts suffer from alignment failures. The Magnalock is designed to be self aligning and

tolerates considerable inconsistency in the gate closed position as regards upward/downward

alignment, side alignment and twisting. The Magnalock is al s o fully seal ed and waterp r oof so it

is generally unaffected by tough environments.

The drawings and descriptions which follow, show conceptual installation concepts for different

typ es of g ate sec ur ity ap p l ication s. Note t h at t h e mod el 62 an d mod el 82 are most common l y

used in gate installations. They have conduit fittings available (“G” option) while this is not

available on the model 32 or 34 Most g ate installations also call for higher levels of holding

forc e as gat es are often lar ge and poorl y fit tin g . It ’s al so oft en th e case t h at an in tru d er is ab l e

to physically apply more force to defeat a gate lock than is the case with (especially) an

outswing ing door wherein th e intru der can only pull on it. The model 32 or 34 h owever may be

us ed on certain g ates wit h su ccess. A g ood exampl e is a slid ing gate wh ere th e Magnet can

be mortised into a post against wh ich the gate sl ides. Securitron also offers the model 34R

Magnalock which is specifically designed for mortising (see catalog).

Becau se of th e wide variety of gates in existence, each in s tall ation h as to be considered special

and normally, bracketry must be made up on site. The concept is to mount the magnet on a

fixed post and the strike plate to the swinging or sliding member of the gate. Position both

components so that the strike p late slaps against the magnet face on cl osure. Usuall y, the

"GF" version of the Magnalock is used for gates. "G" calls out a conduit fitting mounted on the

magnet end and "F" calls out mounting holes through the face (see Figure 5). The magnet

typically screws onto a b ac k plat e fashioned on s ite and the b ac k plat e is welded onto the f ixed

post.

Page 14

Rev. A.3, 5/00 Page- 11

A back p l ate or Secu rit ron 's Z b rack et mu st al so ty pic all y b e p rovid ed f or t he s trik e pl at e. The

strike plate cannot be directly welded to the gate as it will not be able to flex and self

align. It must be screwed onto a surface with the washer stack used to provide

flexibility. Note th at if Securitron 's Z bracket is used, it typically bolts to the gate rather than is

welded as it is aluminum. Read sections 2. 3, 2.3.1, and 2. 3.2 for ad dition al general inf or m ation

on mounting.

FIG. 11: MOUNTING TECHNIQUES FOR GAT E S

SINGLE SWING G ATE

CONDUI T FI TTING MAY EXIT TOP OR BOT TOM

GF MAGNET

Z BRACKET BO LT ED TO SWIN G AR M

STRIKE

INTERFERENCE PIECE MUST

BE ADDED TO Z BRACKET

CONDUIT FITTING

DOUBLE SWING GATE

Z BRACKET BOLTED TO SWING ARM

DIRECTION OF OPE NING

SLIDING GA TE

GATE

EDGES

MOT ORIZED OPENING MU ST BE

COORDINA TED

EXTENDED ROLL PIN

ANGLE BRACKET

GF MA GNET

LOCK NUTS

ANG L E BRACKE T

SPRING

EXTENDED ROLL PIN

STRIKE

Page 15

Rev. A.3, 5/00 Page- 12

In th e case of very tal l an d l arg e g ates , a l evering p rob l em can exist. By t h is we mean th at an

intruder may be able to flex the gate enough to take up the slack in the strike mounting screw

and th en lever off the st rike pl ate. If the in stal ler or u ser d etermin es that this may hap pen , a

single Magnalock will not provide adequate security and two must be used, typically at the top

and bottom of the gate.

Figure 11 (above) shows preferred special techniques for Magnalock mounting on 3 types of

gat es. The f irst d rawing shows a

single swinging gate. The general technique follows the

principles discussed above but the use of Securitron's Z bracket which creates a neat

installation is also shown. Note that in some cases, the post which mounts the magnet is

hollow. It is possible to use the "F" version (without conduit fitting) and pull the wires through

the post which m ay y ield a neater an d more secure install ation.

The second drawing shows a

double swinging gate which presents a unique problem. The

Magnalock is mounted in the same general way as on a single swinging gate but since both

arms move, an intruder pushing on the gate exerts a shearing force on the Magnalock.

Electromagnets are not at all strong in this orientation of attack. Therefore, as the drawing

shows, Securitron's Z bracket should be used with an interference piece which blocks the

shearing effect while the strength of the magnet blocks one arm moving while the other is

stationary. For this technique to work, the motorized operator must be

coordinated which

mean s th at one ar m mu st move first to c l ear th e in ter feren ce p iece b ef ore th e oth er arm s tart s

moving. Gate operators c an norm ally ac c om plish th is .

The final drawing on Figure 11 shows a special mounting technique for

sliding gates. We

recommend the use of the "GF" type magnet and two 3" angle brackets (available from

Secu rit ron ) for a neat instal l ation . A spec ial s trik e mou nt in g t ech n iq ue is s hown in th e d rawin g

which imp roves reliability. The probl em is that if the strike is mounted normally to th e angle

bracket and the gate is a powerful one which slams shut, the magnet may be impacted to the

point where its mounting screws loosen or the bracket bends. The strike mounting technique

th at is sh own c reates a "sh oc k ab sorb er" eff ect by th e u se of l ock nu t s at t h e rear of th e st rike

and the rear of the bracket together with a spring. A through hole (rather than tapped) is

drilled in the angle bracket mounting the strike and extra long roll pins are used. When the

gate closes, the s trike moves in against the spring which is the shock absorb ing action.

2.7 USE OF DRESS COVERS

Once th e physical in stall ation is complete, you may want t o consider the use of a dress cover.

Dress covers are metal stampings which slip over the magnet body and are affixed with

permanent double stick tape (supplied). The dress cover accomplishes three functions: First,

it makes for a more attracti ve in stall ati on by concealing the strike plate and mounting holes.

All that is seen is an attractive rectangular form on the door. Second, the cover provides an

extra degree of tamper proofing and finally it allows easy alteration of the finish for

architectural com patib ility. Dr es s c overs ar e avail able in clear aluminum, s atin black aluminu m ,

polished st ainless and polish ed brass finishes.

Double d r es s c overs ar e also availab le for in s tall ations on dou ble doors. In th is case, th e cover

fits over two locks so long as they are not separated by more than 2" (50mm). Doub le dress

covers h ave all th e ad vantag es m ent ion ed ab ove and in ad dit ion pr od uc e th e app earan ce of a

single device which inside is really two. Consult the catalog for dress cover part numbers.

2.8 TAMPER PROOFING THE MAGNALOCK

In situ ation s wher e vand al ism is expect ed, th e Magn al ock sh oul d b e pr otect ed from tamp erin g .

The magnet itself is inherently tamper-proof being totally sealed. The magnet mounting screws

are vulnerable in that the magnet can be dismounted if the screws are loosened. The all en

holes on the screws can be filled with a potting compound, such as Devcon, or silicone.

Alternatel y, the entire hole in the mag net wh ere the screw heads fit could be filled. Butyrate

caps are supplied to close the mounting holes. These provide some tamper proofing as they

can't be removed by hand, but can be pried out with a tool. Regarding the strike plate

mounting screw, it is covered by the strike when the magnet is energized. If tampering is

anticipated when the door is op en, the screw socket head may be fill ed.

Another possibility is that

Securitron inventories special tamper proof screws for both

magnet and strike mounting. These screws are identical allen head types except that it

requires a special key to install and remove the screws. It is unlikely that a vandal would have

access to this type of key. Securitron optionally supplies the tamper proof screw sets with keys

both in the form of a man u al allen wrench and in a bit key usable with a drill.

Page 16

Rev. A.3, 5/00 Page- 13

3. ELECTRICAL INSTALLAT ION

3.1 GE NE RAL ELECT RICAL CHARACTERISTICS

The Magnalock constitutes a low current electric load. Owing to internal circuitry, the

Magnalock does not show the normal characteristics of an electromagnetic or other inductive

load. Inductive kickback is suppressed, so arcing across switch contacts need not be a

concern. This suppression also protects nearby access control or computer equipment from

possible interference. The circuitry performs the additional functions of canceling residual

magnetism ("stickiness" on release) and accelerating field collapse so that the Magnalock

rel eas es nearly instantly when power is removed. El ec trically s peaking, the load is nearly pu r e

resistive in nature although there is a modest capacitive component which depends on the

series. The fol l owin g c har t sh ows t h e cu rren t dr aw for eac h version an d th e d egr ee of in ter nal

capacitance.

32 @ 12V 32 @ 24V 34 @ 12V 34 @ 24V 62 @ 12V 62 @ 24V 82 @ 12V 82 @ 24V

CURRENT 300 mA 150 mA 350 mA 175 mA 250 mA 125 mA 350 mA 175 mA

CAPACITANCE 0 0 0 0 30 M fd 15 Mfd 30 Mfd 15 Mfd

Capacitance can be an issue if very sensitive switch contacts are used to control the Magnalock

(such as a low cu rrent reed switch). A capacitive load incl ud es some inrush cu rrent wh ich can

stress these contacts. Note however that the probl em is dimin ished wh en the Magnalock is

mounted some distance from the control switch as the interconnecting wiring adds a series

resistance to the circuit which sharply limits th e inrush.

3.2 STANDARD LOCK

For operation, DC voltage must be provided to the lock. The red wire receives +12VDC or

+24VDC, an d the black wir e, 0V (negative). If the l ock i s con nect ed w it h reverse p ol arity, it

will not function at all. The voltage source may be regulated, filtered or pulsating DC

(transformer + bridge rectifier). Half wave pulsating DC generated by a transformer and

single diode will not properly operate the Magnalock. An exact voltage level is not

nec essary . Less than st an dar d vol tag e wil l p rop or tion atel y r edu ce h ol d ing f orce b u t wil l cau se

no harm. O vervol tage up to 30% is acc eptab le.

The model 34, 62 and 82 series Magnal ocks are

du al vo ltag e un it s. Th is mean s t hat you can

apply either 12 or 24 volts to the same unit and it will operate equally well. Dual voltage

Magn alocks are auto-switching which means that you still apply power to the red and black

wires, while observing correct pol arity. The lock, however, aut omati call y det ects wh eth er it is

receiving 12 or 24 volts and d raws t h e correc t amou n t of cu rr ent for th at vol tag e (t he c ur ren t is

twice as hig h when th e lock is r eceiving 12 volt s th an wh en it is rec eiving 24 volts ). Th e mod el

32 series has sep ar ate models for 12 an d 24 volt operation .

It is good practice to use power supplies with 1/3 extra capacity beyond the current

requirements of the load. This greatly reduces the possibility of heat induced power supply

failure and also allows for future expansion. Power supply cost is a small fraction of the job

cost and sh ou ld not b e skimped on.

Switches may be wired as necessary between the Magnalock and power source. Internal

circuitry eliminates inductive kickback, so neither electromechanical switches nor solid state

devices will be damaged by arcing when the Magnalock is shut off.

3.3 AVOIDING POOR RELEAS E CHARACTERIST ICS

One of the exceptional features of Magnalocks is near instantaneous release. This is

par ticul arly valu abl e when t he l ock is bein g swit ched off an d th e door is being open ed at t he

same time as occurs when a switched exit device l ike Securitron ’s Touch Sen se Bar is b eing

us ed. Two separate wirin g errors can however cau se Magn alocks t o release s lowly (in on e or

two seconds) and this is annoying.

The first probl em is

con nectio n of a reverse d iode i n paral lel w ith th e lock' s power i nput.

This is often done to suppress inductive kickback from a coil such as a relay coil or solenoid.

Magnal ocks already have internal inductive kickback protection, so addition of a reverse diode

is pointless. The diode does act to "recirculate" current flow through the magnet coil and

th ereby c onsid erabl y slows r elease. A d iode sh ould never be c onnec ted as sh own in Figu re

12.

Page 17

Rev. A.3, 5/00 Page- 14

The second problem is when any load is operated in parallel with the Magnalock. A good

example would be adding an incandescent lamp in parallel with the lock so that the lamp

would be illuminated when the lock is powered. The lamp acts like a resistor and allows

current recirculation which will greatly slow lock release time. When you want to add a resistive

load in parallel with the lock, you must put a fo rward diode in series with t he resist ive load.

This wil l b lock r ecircul ation and r estore q uick rel ease. Corr ect pr actice is s hown in Fig ure 12

below.

A special case exists when you use an

LED connected in parallel with the Magnalock (to

sh ow th at t h e Magn aloc k is on for exampl e). This d oes n ot sl ow r el ease as th e LED does n ot

all ow rec ircu l ation b ut th e l imit ed r ecirc ul at ion en erg y wil l event ual l y b u rn ou t t h e LE D. LED’s

are susc eptib le to even a tiny amou nt of reverse volt age. Th erefore ad d th e forward diod e as

you would with an incandescent lamp (see Figure 12) to extend the life of the LED.

FIG. 12: WIRING CONSIDERATIONS TO AVOID SLOW RELEASE

RED

RED

MAGNALOCK

BLACK

NEVER CONNECT PARALLEL

REVERSE DIODE AS SHOWN

BLACK

USE A FORWARD DIODE WITH ANY PARALLEL

RESISTIVE LOAD SUCH AS A LAMP

MAGNALOCK

3.4 W IRE GAUGE S IZING

If the power supply is distant from the lock, voltage will be lost (dropped) in the connecting

wires so that the Magnalock will not receive full voltage. The following chart shows the

minimum wire gauge that will hold voltage drop to an acceptable 5% for different lock to

power supply distances. Proper use of the chart assumes a dedicated pair of wires to

power each Magnal ock (n o common n eg ative). Not e th at a Magn al ock op erat ing on 24 volt s is

a much bett er choic e for long wire run s as it has 4 times th e res istan ce of a 12 volt ins tal l ation .

Also not e t hat th e correct calcu lation of wire siz ing is a very imp ortan t issu e as th e instal ler is

responsible to insure that adequate voltage is supplied to any load. In multiple device

installations, the calculation can become quite complex so

refer to Appendix B for a more

comp lete discussion.

Distance Gau ge 12V Gau ge 24V Dist ance Gau ge 12V Gauge 24V

80 FT 20 GA 24 GA 800 FT 10 GA 16 GA

200 FT 17 GA 22 GA 1500 FT. 8 GA 14 GA

400 FT 14 GA 20 GA 3000 FT N/A 12 GA

3.5 SENS TAT M AGNALOCKS: “SC”

Securitron's optional patented Senstat feature provides true lock status sensing. In many

electrically controlled door security systems, status sensing is provided by a magnetic switch

on th e d oor itsel f. This ind icates t he door is closed bu t not necess arily sec ured . Secu ritron 's

Sens tat monit ors th e loc k rat her th an th e d oor an d th eref ore p rovides h ig h er secu rit y ( bu t not e

that it can’t be used as an auto-relock input to an access control system).

An “SC” Mag nalock provides a dry SPDT ou tpu t which c hanges stat e when t he lock is reporting

secure

(1 Amp @ 30 V DC maximum) . This is accomplished by conducting the input power of

the lock through the strike and employing it to energize an internal SPDT relay. The white wire

is th e Sen st at r elay common . Green is c los ed t o wh ite wh en th e l ock is s ecu re an d O ran g e is

cl os ed to white when the l oc k is not secure.

Page 18

Rev. A.3, 5/00 Page- 15

FIG. 13: “SC” SENSTAT WIRING

BLK

POWER

SUPPLY

+

WHITE AND GREEN WIRES PROVIDE ISOLATED CLOSURE WHEN LOCK IS SECURE.

ORAN GE AND WHITE ARE CLOSED WHEN LOCK IS NOT SECURE (AS SHO WN ABOVE).

"SC" LOCK

RED

ORANGE

GREEN

WHITE

3.6 DOUBLE DOOR PROCEDURE FOR STATUS RE P ORT ING

Often two Magn alocks are mount ed on a doubl e door and are tu rned on and off together (no

separate control). As to status reporting, it is of course possible to receive a separate Senstat

status signal from each door or you can co mbi ne th e ou tp ut s so that if both locks are secure,

the double door is secure and if either lock is not secure, the double door is not secure.

Simply tie the two wh ite wires t ogether from th e two locks. A circuit will be cl osed between the

two green wires only when b oth locks are reporting secure. If either is not secure, t he circuit

between the two gr een wires wil l be open. The orang e wir es are not used. See Fig ure 14.

FIG. 14: DOUBLE DOOR WIRING WITH "SC" LOCKS

GREEN

GREEN

"SC" LOCKS ARE INTERWIRED AS SHOWN TO P ROVIDE STA TUS MONITORING. AN IS OLATED CLOSU RE

WILL EXIST BETWEEN THE GREEN WIRES ONLY IF BOTH LOCKS ARE SECURE.

"S C" L OCK

"S C" L OCK

WHITE

WHITE

3.7 DOUBLE DOOR CONTROL S WITCHING

It’s common t o control two locks from a sing le access and/or exit switch on doub le doors or on

an install ation where two locks are mounted on a single door. In nearly al l cases, th is works

with n o problem but occasional ly the release can appear to be “sticky” for simil ar reasons to

those discussed in Section 3.3 This h appens when one of the locks is poorly coupled to its

str ike pl ate. This cou ld occu r becaus e of an in stal lation prob lem ( the st rike pl ate is n ot bein g

allowed to swivel) or because of some obstruction between the plate and magnet surface.

When an electromagnet is n ot well coupled to its strike plate, its magnetic fiel d coll apses so

rapidly that it provides some energy to recirculate in the second magnetic lock, slowing the

rel eas e of that lock.

FIG. 14: DOUBLE POLE SWITCHING OF TWO LOCK INSTALLATION

TWO POLE

POWER

SUPPLY

+

SWITCH

RED

MAGNAL OCK #1

RED

MAGNAL OCK #2

BLK

BLK

Page 19

Rev. A.3, 5/00 Page- 16

So if you notice sl ow release on a doub le lock instal lation, this is telling you that one of the

locks is not holding properly and that the problem should be corrected. Alternately, any

ch ance of slow release c an be eliminat ed by c ontrol ling the two locks with a doub le pole s witch

or relay. This blocks th e recircul ation path and is shown in F ig ure 15.

3.8 EMERGENCY REL E AS E

Magnal ocks are often wired into a system such that they can b e released in an emergen cy -either manually from one switch or automatically, often from the fire alarm system. It is the

user's responsibility to accomplish this hookup correctly according to these instructions and

good el ect rical p ract ices. In g en eral , we rec ommen d th at a switc h or rel ay b e us ed t o p erfor m

a series break of all DC power which is the simp le and sure way to make sure the d oors do

release. Securitron power supplies have terminals for interconnection of such emergency

release switches. Finally please note that

it is the responsibility of the end user and

deal er/inst aller to insu re t hat Magn alock i nstall ation s compl y with any appl icabl e fire or

building codes.

MAGNACARE LI MITED LIFETIME WARRANTY

SECURITRON MAGNALOCK CO RPORATI ON warr ants t hat it w ill replac e at cust omer’s r equest, at any t ime for

any reason, products manufact ured and branded by SECURITRON.

SECURITRON will use its best efforts to ship a replacement product by next day air freight at no cost to the

customer within 24 hour s of SECURITRON’s receipt of the product from customer. I f t he cus tomer has an account

with SECURITRON or a valid credit card, the customer may order an advance replacement product, whereby

SECURITRON will char ge the customer’s a c c o unt fo r the pric e o f the pro duct plus next day air fre ight , and will credit

back to t he cust omer the full amount of the charge, including outbound fr eight, upon SECURI TRON’s r eceipt of the

original product from the customer.

SECURITRON’s sole and exclusive liability, and customer’s sole remedy, is limited to the replacement of the

SECURITRON product when delivered to SECURITRON’s facility (freight and insurance charges prepaid by

customer). The replacement, at SECURITRON’s sole option, may be t he identical item or a newer unit which ser ves

as a functional r eplacement. In the event that the product type has become obsolete in SECURITRO N’s product

line, this M AGNACARE warranty will not apply. This MAGNACARE warr anty also does not apply to custom, built to

order, or non-catalog items, items made by others (such as batteries), returns for payment, distributor stock

reductions, returns seeking replacement wit h anyt hing ot her than the ident ical pr oduct, or products installed outside

of the United St ates or Canada. This MAGNACARE warranty also does not apply to removal or installation c ost s .

SECURITRON will not be liable to the purchaser, the customer or anyone else for incidental or consequential

damages arising from any defect in, or malfunction of, its products. SECURITRON does not assume any

res po nsibility for damage or injury to per son or property due to improper care, st orage, handling, abuse, misuse, or

an act of God.

EXCEPT AS STATED ABOVE, SECURI TRON MAKES NO WARRANTIES, EITHER EXPRESS O R IM PLIED, AS

TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION THE CONDITION OF ITS PRODUCTS,

THEIR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

PATENTS

Securitron’s Magnalock is covered under U.S. patents #4,516,114 and 4,682,801.

Page 20

Rev. A.3, 5/00 Page- i

APPEND IX A

TROUBLESHOOTING

PROBLEM-- No magnetic attr act ion bet ween magnet and strike plate.

First be sure the lock is being correct ly powered wit h DC voltage. This includes connect ing t he pow er wires w ith

correct polarity. Positive must go to red and negative to black. If t he Magnalock is wired in reverse polarity, it w ill

not be damaged, but it w ill not oper ate. I f t he unit continues t o appear dead, it must be electrically checked with an

Ammeter. It must be powered with the correct input voltage and checked to see if it dr aw s the specified current. If

the unit meters correct ly, it is putting out the correct magnetic field and the pr oblem must lie in the mounting of t he

strike ( see next paragraph). Sect ion 3.1 includes a c hart showing current draw for all Magnalock versions.

PROBLEM-- Reduced holding force.

This problem usually expresses itself in terms of being able to kick the door open or to open it with a shoulder.

Check the st rike and magnet face t o see if some small obstruction is interfering with a flat fit . Even a small air gap

can grea tly reduce the holding force. Another p os s ib ility is if the strik e plate has a dent on it f rom being dropped for

example. Remove the strike from the door and try to rock it on the magnet f ace to insure it is flat. I f the str ike and

magnet are flat and clean, t he cause is near ly alway s impr oper mounting of the strike in that the strike is mount ed

too rigidly. The strike

mounting screw. The magnet then pulls it into flat alignment. To correct the problem, try loosening the strike

mounting sc rew to see if t he lock then holds properly. Another possibility is if you are operating the lock on AC

instead of DC or on half wave rectif ied DC (tr ansfor mer + single diode). Half wave rectified DC is unacceptable; you

must, at a minimum employ full wave rectified DC (transformer + br idge) .

must be allowed to float around the r ubber washer stack w hich must be on the strike center

PROBLEM-- The Senstat output does not r epor t secur e.

Because of the simplicity of Securitron's patented Senstat design, this is almost always a c ase of the lock st atus

sensor doing its job. It is not reporting secure because a small obstruction or too stiff ly mounted strike is causing the

Magnalock to hold at reduced f orce. The problem is correct ed by cleaning t he surfaces of the magnet and strike or

establishing pr oper play in the strike mount ing. If this doesn't work, you can verify function of the Senstat feature as

follows. Note t hat there are 2 t hin vertical lines on t he magnet face t hat can be said to s eparate t he core int o 3

sections from left t o right. The Senstat output is created by the str ike establishing electrical contact bet ween the

leftmost and rightmost core segments. With the lock powered, use a pair of scissors and press the points

respectively into the leftmost and rightmost core segments. The Senstat output should then report secure. This

shows that the problem lies in the strike not making correct flat contact with the magnet face. If the scissors

technique doesn't cause the lock to report secure, check to see if t here is a broken Senst at w ire. If t his is not the

case, t he lock must be ret urned to the fact or y for replacement.

PROBLEM-- The lock does not release.

When power is removed from it, the Magnalock must release. If internal circuitry, which eliminates residual

magnetism, wer e to fail completely, t he lock would only exhibit "s tickiness" at a rough level of 5 pounds. Therefore

the compla int of " lock w ill not r elea se" is either mechanical bonding via vandalism or a f ailure to c omplet ely re lease

power. By mechanical bonding, we simply mean that glue has been applied between the strike and magnet as a

prank. Failure to completely release power is generally a wiring integrity problem. What happens is that an

upstream switch removes power fr om the wires going to the Magnalock, but through an installation er ror, t he wires

have their insulation abraded between the switch and lock so that partial or full power can leak in from another

Magnalock or other DC device with similarly abraded wiring. This is most likely to occur at the point where the wire

cable leaves the lock case and ent ers t he door frame. Another area is via an improper splice on w iring in conduit .

Either a metal door frame or t he metal conduit is capable of leaking power bet ween multiple devices with abr aded

wires, thereby bypassing switches. A good way to check this electrically (as opposed to visually removing and

inspecting the wires) is t o use a meter and check for leakage between the power supply posit ive or negative and the

door fr ame and conduit. M agnalocks should be power ed by isolated DC voltage wit hout any eart h gr ound refer ence

to positive or negative. Not e that tw o types of wir ing errors can cause

you are making either of these error s.

slow release. Review Section 3.3 to see if

PROBLEM-- The lock rusts

Both the Magnalock core and strik e plate ar e plate d and sealed f ollowing a militar y specif icatio n. Because of this

plating and t he sealed nat ure of the magnet, t he Magnalock is weatherproof and may be used outdoors. I f rusting

appears, the mos t common cause is t hat improper cleaning (with steel wool for instance) has occurred and this has

stripped off t he relatively soft plating. Once the plating has been removed, it cannot be restored in the field, so the

lock will have to b e pe riodically c le aned and co a ted wit h oil or other r ust inhibitor . A rusty Magnalock w ill s till function

but at reduced holding force. If the product is installed in a heavily c or r os ive at mosphere, s uch as near the ocean, it

will eventually rust even with no n abras ive cleaning. The only answ er then becomes continued per iodic removal of

the rust.

Page 21

Rev. A.3, 5/00 Page- ii

PROBLEM-- Apparent electronic noise interfer ence with t he access contr ol system.

Electric locks, being induct ive devices, return voltage spikes on their power wir es and also emit microwave radiation

when switched. This can int erfere w ith access contr ol electronics causing malfunctions. Access cont rol contractors

often employ installation techniques designed to isolate the access control electronics from the electric lock. These

include separate circuits for the lock, shielded wiring and other techniques. These techniques will vary with the

sensitivity of the access control system electronics and should, of course, be followed. Note that Magnalocks

include internal elect r onics which suppres s both inductive kickback and radiation. They have been extensively tested

and accept ed by numerous acces s cont rol manufact ur ers and have been used in t housands of installations without

incident. An apparent noise problem is therefore usually not caused by the Magnalock. The access control

equipment may be itself f aulty or have been installed improperly. One problem can ar ise with the M agnalock. If the

Senstat version is being used, the strike plate (which passes cur rent) must be isolated from a metal door and frame.

Securitron supplies insulating har dwar e to accomplish this but the har dware might not have been used or the str ike

may be scraping against the header for instance. Check for full isolation between the strike and the door frame

(when the door is secure) w it h an Ohmmeter. The presence of lock voltage pot ential in the door fr ame can interf ere

with the ground ref erence of access control system data communication and therefore cause a problem.

IF YOUR PROBLE M PERS ISTS

CALL SECURIT RON T OLL FREE

1-800-MAG-LOCK

APPEND IX B

CALCULATING WI RE GAUGE SIZING

The gener al practice of wire sizing in a DC circ uit is to avoid causing voltage dr ops in connecting w ir es which reduce

the voltage available to operate the device. As Magnalocks are very low power devices, they can be oper ated long

distances from their power source.

calculate the correct gauge of wire to avoid excessive voltage drops.

This is done by adding t he r esistance of the Magnalock to the resistance in the power w ires and then dividing the

wire r esistance by the total resist ance. This yields the fraction of voltage drop in the wires. For example, a single

model 62 Magnalock has a resistance of 192 ohms when being operated on 24 volts. If t he wires completing the

circuit between the Magnalock and it s power source have a resistance of 10 ohms, the total r esistanc e is 202 O hms.

Dividing 10 Ohms (the wire resistance) by 202 (the total resistance) yields roughly 1/20 or 5% . If the input voltage is

24 volts, 5% of t his voltage will be dropped in the wires (1.2 volts) leaving 22.8 volts to oper at e the Magnalock. This

will ca use a s mall reduction in holding force but in general, will be ac c e ptable.

To calculate the wire resistance, you need to know the distance from the power supply to the Magnalock and the

gauge (thickness) of the wire. The following chart shows w ir e r esist ance per 1000 f t (305 meters):

Wire Gauge Resistance/1,000 ft Wire Gauge Resistance/1,000 ft

8 Gauge .6 Ohms 16 Gauge 4.1 Ohms

10 Gauge 1.0 Ohms 18 Gauge 6.4 Ohms

12 Gauge 1.6 Ohms 20 Gauge 10.1 Ohms

14 Gauge 2.5 Ohms 22 Gauge 16.0 Ohms

For any job that includes long wire runs, the installer must be able to

Model 32 resistances are 160 O hms for t he 24 VDC version and 40 Ohms for t he 12 VDC version.

Model 34 resistances are 136 O hms for 24 VDC operat ion and 34 Ohms for 12 VDC operat ion.

Model 62 resistances are 192 O hms for 24 VDC operat ion and 48 Ohms for 12 VDC operat ion.

Model 82 resistances are 136 O hms for 24 VDC operat ion and 34 Ohms for 12 VDC operat ion.

Let's look at some other sample calculations. Suppose a single 62 Magnalock operat ing on 24 volts is 1200 ft from

its power supply and w e're using 20 gauge w ire. Firs t, t he total length of the pow er wires is 2400 ft.

that you combine the wire lengths from the power supply to t he lock and back to the power supply to get

the total circuit wire length. The wire r esist ance than becomes 2.4 X 10.1 O hms which is 24. 2 Ohms. Adding this

to the Model 62 Magnalock resistance of 192 Ohms (at 24 volts) yields a t otal res istance of 216.2 Ohms . 24.2

divided by 216. 2 y ields the percent drop in the wires w hich is over 11% which w e would consider excessive. The

problem can be dealt with in 2 ways. You can utilize 16 gauge wire which would reduce the drop to a more

acceptable 5% range or y ou can provide extra voltage at t he pow er supply. For instance, Securitron 24 V power

supplies are adjustable from 24 to 28 volts. You can therefore easily set the power supply to output 11%

overvoltage which will then deliver 24 volt s at t he lock. The Magnaloc k will a ccep t up t o 30% overvoltage w ithout ill

effects.

Remember

Page 22

Rev. A.3, 5/00 Page- iii

Note that a Magnalock operat ing on 12 volts has 1/4th the resistance of a unit operating on 24 VDC. This means

that wire voltage drops are 4 t imes more significant in a 12 volt system t han in a 24 volt system.

has wire runs long enough to be of concern, always use 24 volts. Note also that it's common to mount 2

Magnalocks on a double door and operate them as one lock (only 2 power w ires) . In this case, the resistance of t he

pair of locks is half t he resistance of a single lock.

In mult iple lock jobs with a single pow er supply, the calculation of wiring voltage drops is more diff icult. So long as

you run a separate pair of pow er wires to each lock, t he calculation is as simple as has been described above, but if

a common power wire is used in a loop str ucture, t he locks powered by the single loop will have an increas ingly low

combined resistance so that the loop wire r es ist ance will become mor e signific ant t o the point where the locks don't

receive enough voltage. To find t he combined resistance of multiple locks powered by a common wire, divide the

resistance of one lock by t he number of locks. For example, eight 62 Magnalocks operating on 24 volts would have

a combined r esistance of 192 divided by 8 which is only 24 Ohms. Another method is to calculat e the current in

Amps in t he w ire and divide that into the circuit voltage. Since each 62- Magnalock oper ating on 24 volts draws

1/8th of an Amp, eight would draw 1 Amp. Dividing this into the same 24 volt input voltage yields a 24 Ohm

combined resistance.

In general, you have t o be c autious about using c ommon wires for loads in long distanc e sit uations unless y ou're very

confident about your ability to calculate the correct configuration. Bear in mind, however, that anytime you're

uncer tain about the voltage drop in wiring, you can met er t he volt age at the lock

be able to see if it's receiving adequate voltage. I f t he lock is not connected when you make t his measurement , the

res ult will be fa ls e a s the circuit will not s e e a ny loc k resist ance to compar e to the wire resis tance. You w ill read the

full input voltage.

while it 's con necte d and you will

In any job that

APPEND IX C

CONSIDERATI ONS FOR MAXIMUM PHYSICAL SE CURITY

Magnalocks carries rated holding forces of 600 lbs. (275 Kg.), 1200 lbs. (550 Kg.) and 1800 lbs. (815 Kg.) for

respect ively the model 32/34, 62 and 82. The figures are derived by using a calibrated hydraulic press to separat e

the magnet and strike. The installer and user, however, are logically most interested in how Magnalocks perform on

a door rat her than on a laborator y instrument and there are several installation and application variables t hat af fect

the security level attained while using the Magnalock.

First, t o ac hieve the rated holding f orce, the magnet face and strike plat e must be clean. Even a small amount of

contamination will materially reduce the holding force.

abrasive such as steel wool which can remove the plating on the magnet face and str ike. A sponge or plastic

pad such as Scot chbrite must be used.

Another requirement for maximum holding is that the strike plate must be centered on t he magnet face and must

cover the magnetic core (3 bars). As is said in ot her parts of these instructions, the str ike plate must be allowed t o

swivel around the washer stack placed on the center strike mounting screw (not on the roll pins). Assuming the

magnet and strike are clean and are mounted in good alignment, the Magnalock will deliver its rated degree of

holding force on the door and t he question becomes how much security does t hat provide on dif ferent door types ?

In furnishing the answer we have to consider both the door construction and the likely type of attack.

In the case of wooden doors (ot her than solid hardwoods), aluminum fr ame glass doors, and hollow aluminum door s,

the model 32 or 34 should be employed in a “ traffic contr ol” mode. This means t hat a determined assault on the

door can “pop” these models open. The model 62 or model 82 Magnalock is gener ally stronger than the door itself.

Users have logged periodic cases of an assault destroying the door but leaving the Magnalock intact and still holding

a piece of the door. This raises the question of whether it ever makes sense to install the model 82 Magnalock on

non- steel doors since the model 62 is str onger than t he door. Justification for using the model 82 lies in margin f or

error . The gr eater str ength of the model 82 can compensat e for a dir t build-up or improper installation and t his may

be warr ant ed for the protec tion of critical areas. St eel clad fire doors or solid steel door s uch as are sometimes

found in prisons, are generally stronger than t he model 62 Magnalock so the use of the model 82 Magnalock can

provide extra security for critical applications on steel doors.

If cleaning is necessary, avoid the use of a heavy

In looking at methods of att ack,

attacker t o pull the door open r at her t han t o allow him to push it. This is controlled by whether the door swings

away f r om or in to the protected area with the former being preferred. If the att ack er can be forc ed t o pull the door ,