Page 1

PN# 500-10420

Rev. A.5, 8/03

SECURITRON 32, 34, 62 AND 82 SERIES MAGNALOCK

TABLE OF CONTENTS AND GUIDE TO THIS MANUAL

There are numerous Magnalock versions and numerous different applications exist for them.

Accordingly, this manual provides a broad range of information- only a portion of which is

applicable to any individual use. This manual guide provides a brief summary of many of the

Sections which allows you to consult only the portions of the manual that apply to your

application.

SECTION 1. DESCRIPTION --------------------------------------------------------------------Page 1

SECTION 2. PHYSICAL INSTALLATION---------------------------------------------------Page 1

This is the largest part of the manual with sections that explain the different types of physical

installations which vary according to door or gate types as well as Magnalock versions.

SECTION 2.1 SURVEY---------------------------------------------------------------------------Page 1

This section concerns how to pre-plan the installation.

SECTION 2.2 INSTALLATION TOOL KIT --------------------------------------------------Page 1

This section explains an available accessory.

SECTION 2.3 GENERAL INSTALLATION ON OUTSWINGING DOOR------------Page 1

SECTION 2.3.1 STRIKE PLATE MOUNTING----------------------------------------------Page 1

SECTION 2.3.2 MOUNTING THE MAGNET------------------------------------------------Page 3

The above three sections explain the most common Magnalock installation on a door that

swings away from the lock. They also include general mounting instructions and should

therefore be read for all installations.

SECTION 2.4 GENERAL INSTALLATION ON INSWINGING DOOR ---------------Page 5

This section explains installation of "F" type Magnalocks on inswinging doors.

SECTION 2.5 MOUNTING PROCEDURES FOR SPECIFIC DOOR TYPES-------Page 7

The following seven sections provide specific advice depending on door type which includes

recommended bracketry.

SECTION 2.5.1 ALUMINUM FRAME GLASS DOOR MOUNTING-------------------Page 7

SECTION 2.5.2 THE UMB BRACKET FOR ALUMINUM AND CONCRETE-------Page 8

SECTION 2.5.3 SOLID GLASS DOOR MOUNTING -------------------------------------Page 8

SECTION 2.5.4 DOUBLE DOOR MOUNTING---------------------------------------------Page 10

SECTION 2.5.5 DM-62 DOUBLE 62 LOCK-------------------------------------------------Page 10

SECTION 2.5.6 CONCRETE HEADER OR WOOD FRAME MOUNTING ----------Page 10

SECTION 2.6 MOUNTING THE MAGNALOCK ON EXTERIOR GATES-----------Page 11

This section, which includes three drawings, covers outdoor use of the Magnalock on a

variety of gate types.

SECTION 2.7 USE OF DRESS COVERS ---------------------------------------------------Page 13

This section introduces the Dress Cover which is used after physical mounting to improve

installation appearance and tamper resistance.

SECTION 2.8 TAMPER PROOFING THE MAGNALOCK ------------------------------Page 14

This section should be read for any installation in a high vandalism area.

© Copyright, 2003, all rights reserved • Securitron Magnalock Corp., 550 Vista Blvd., Sparks NV 89434, USA

Tel: (775) 355-5625 • (800) MAGLOCK • Fax: (775) 355-5636 • Website: www.securitron.com

An ASSA ABLOY Group company

Page 2

Rev. A.5, 8/03

SECTION 3. ELECTRICAL INSTALLATION -----------------------------------------------Page 14

SECTION 3.1 GENERAL ELECTRICAL CHARACTERISTICS -----------------------Page 14

This section explains technically the Magnalock's electrical characteristics as a load and is

for reference.

SECTION 3.2 STANDARD LOCK-------------------------------------------------------------Page 14

This section explains powering and switching the Magnalock.

SECTION 3.3 AVOIDING POOR RELEASE CHARACTERISTICS ------------------Page 15

This section warns against wiring mistakes specific only to the model 32 series.

SECTION 3.4 WIRE GAUGE SIZING---------------------------------------------------------Page 15

This reference section explains how to select wire size for applications where the lock is

distant from the power supply.

SECTION 3.5 SENSTAT MAGNALOCKS: “SC”------------------------------------------Page 16

Read this section if you have a Senstat Magnalock.

SECTION 3.6 DOUBLE DOOR PROCEDURE FOR STATUS REPORTING ------Page 16

This section applies if you have Senstat locks on a double door and want them to report as

a single lock.

SECTION 3.7 DOUBLE DOOR CONTROL SWITCHING -------------------------------Page 17

This section applies whenever you have two locks controlled by a single switch.

SECTION 3.8 EMERGENCY RELEASE-----------------------------------------------------Page 17

This section should be understood by all installers.

APPENDIX A TROUBLESHOOTING---------------------------------------------------------Page i

Refer to this section before calling the factory on any operating problem.

APPENDIX B CALCULATING WIRE GAUGE SIZING-----------------------------------Page ii

This detailed reference section explains how to select wire gauge in complicated multi-lock

installations.

APPENDIX C CONSIDERATIONS FOR MAXIMUM PHYSICAL SECURITY------Page iii

This reference section explains the technical aspects of lock holding force and resistance to

attack. It contains numerous installation techniques which act to insure high lock security. It

must be read for high security applications and also has excellent educational value.

Page 3

Rev. A.5, 8/03

Use of the Magnalock (or any lock) can lead to an unsafe

condition within the building if it is controlled in a manner that

improperly restricts passage through certain doors. The most

important area of concern is to insure that building evacuation is

not impeded in the event of a fire or other emergency condition.

Consult with the local building or fire department to insure that

the controls installed with the Magnalock create a safe and

code legal installation.

The Magnalock has an unlimited operating life and receives a

great deal of cumulative shock over this life from the door

closing and from persons attempting to open the door when it is

secured. It is therefore vital that it be firmly mounted to the door

header. If this is not done, a person's use of the door could

cause the magnet body to fall and possibly cause an injury.

The blind nuts furnished with the Magnalock will create strong

and permanent mounting when correctly collapsed inside the

header. If they are not collapsed, an unsafe condition will

result. Make sure you understand section 2.3.2 in the manual

on magnet mounting and collapsing the nuts.

- SHOCK HAZARD. The Magnalock must

be operated from a DC power supply of appropriate capacity

and voltage. The DC output of the power supply must not be

connected to earth ground but must be isolated, or a shock

hazard and possible damage to the product could result. All

Securitron power supplies are delivered with isolated DC

outputs and the majority of commercial supplies are also

furnished this way. If you are not certain that the DC outputs of

your power supply are isolated, check with an Ohmmeter

between earth ground and +V, and then between earth and 0V

(negative). You should not have continuity.

Page 4

Rev. A.5, 8/03 Page- 1

SECURITRON 32, 34, 62 AND 82 SERIES MAGNALOCK

INSTALLATION INSTRUCTIONS

1. DESCRIPTION

Securitron’s Magnalock family represents the state of the art in electric locking. Three different

size models are available: The Model 32 and Model 34 series with a holding force of 600 lbs.

(275 Kg.); The Model 62 series with a holding force of 1,200 lbs. (550 Kg.) and the model 82

series with a holding force of 1,800 lbs. (820 Kg.). Several mounting and electronic options are

available which are described in this manual. Note that most points in this manual apply to the

entire Magnalock series. When a point applies to a particular Magnalock version, this will be

specifically noted.

2. PHYSICAL INSTALLATION

2.1 SURVEY

Because of the wide variety of situations in which the Magnalock may be utilized, first survey the

physical area in which it is to be installed and determine the best method of mounting it. In this

initial planning two considerations come into play: the mounting method must be strong enough

so that the full holding power of the Magnalock can be effective, and the Magnalock and wiring

must be protected to a reasonable degree from damage by intruders or vandals. Often an

accessory bracket is necessary, either furnished by Securitron or made up by the installer. The

brackets that can be used are covered later. Note that Magnalocks are supplied with a

complete set of fasteners. When shipped outside of North America, metric fasteners are

supplied and therefore the drawings in this manual show both US and metric fasteners.

2.2 INSTALLATION TOOL KIT

Securitron offers an installation tool kit (part # IK or IKM, for metric use) which includes special

drills, a drilling template, a blind nut collapsing tool and extra fasteners and hardware. If the

installation is for a large number of locks or if the installer expects to perform other installations,

we recommend the purchase of this kit as it reduces installation labor and improves job quality.

2.3 GENERAL INSTALLATION ON OUTSWINGING DOOR

The Magnalock should be mounted under the door frame header in the corner farthest from the

hinges (see Figure 5). Most commonly, it is positioned horizontally but vertical positioning

should also be considered. In some cases for example, the horizontal header on an aluminum

frame glass door is not as strong as the vertical extrusion, so vertical mounting would be

preferred. This type of installation places the Magnalock such that the door swings away from it.

This configuration is necessary for all facility exit doors (otherwise, the Magnalock would be on

the outside of the building). For interior doors, the Magnalock should still be mounted in this

manner unless security planning anticipates a physical assault on the Magnalock from that side

of the door in which case see section 2.4 on inswinging door installation.

2.3.1 STRIKE PLATE MOUNTING

The strike should be mounted before the magnet on the upper corner of the door. The first

step is to locate the precise place you intend to mount the strike including deciding whether you

want to mount the Magnalock horizontally or vertically (see Section 2.3.2). The top of the strike

should be positioned about 1/10" (2.5mm) below the line where the door meets the door

stop, or below the header if there is no door stop to permit free closing. If the strike is

mounted vertically instead of horizontally, increase this stand-off distance to 2/10" (5mm).

More clearance is needed on a vertical mount because the strike projects out from the door and

can scrape the side frame as the door swings closed on its arc. Final positioning of the strike is

dictated by the desired position of the magnet. The strike must be centered on the magnetic

poles (3 bars) and the magnet is normally moved an inch or so in (or down) from the frame

corner so that the magnet mounting holes will not have to be drilled awkwardly in the corner.

When the strike position has been chosen, step two is to drill three holes in the door following

the template. Step three is mounting the white plastic bushings which surround and insulate

the roll pins into the 1/2" (12.7mm) holes. The bushings are employed to insulate the strike

electrically from a metal door and also help prevent the roll pins from wearing the door.

Page 5

Rev. A.5, 8/03 Page- 2

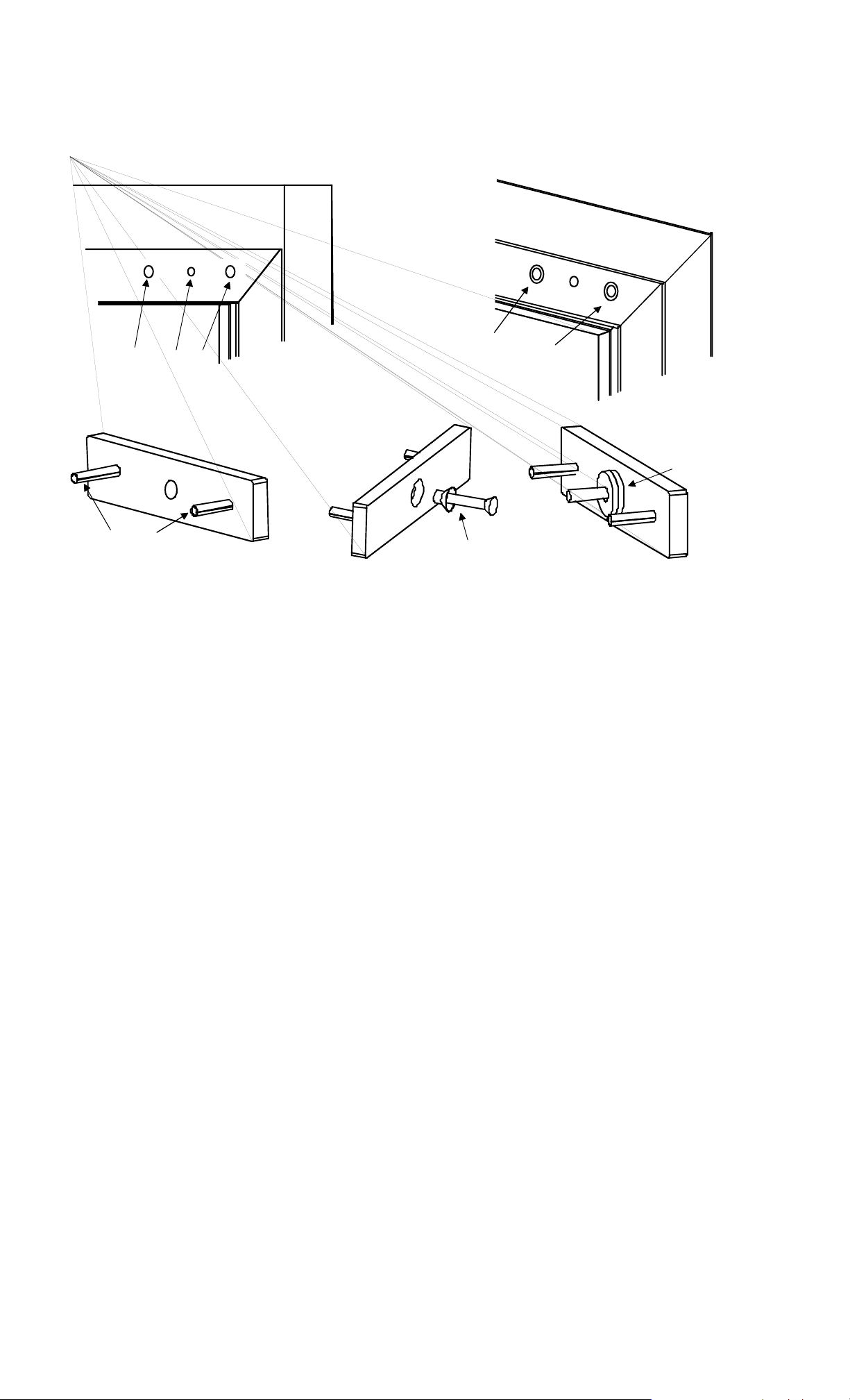

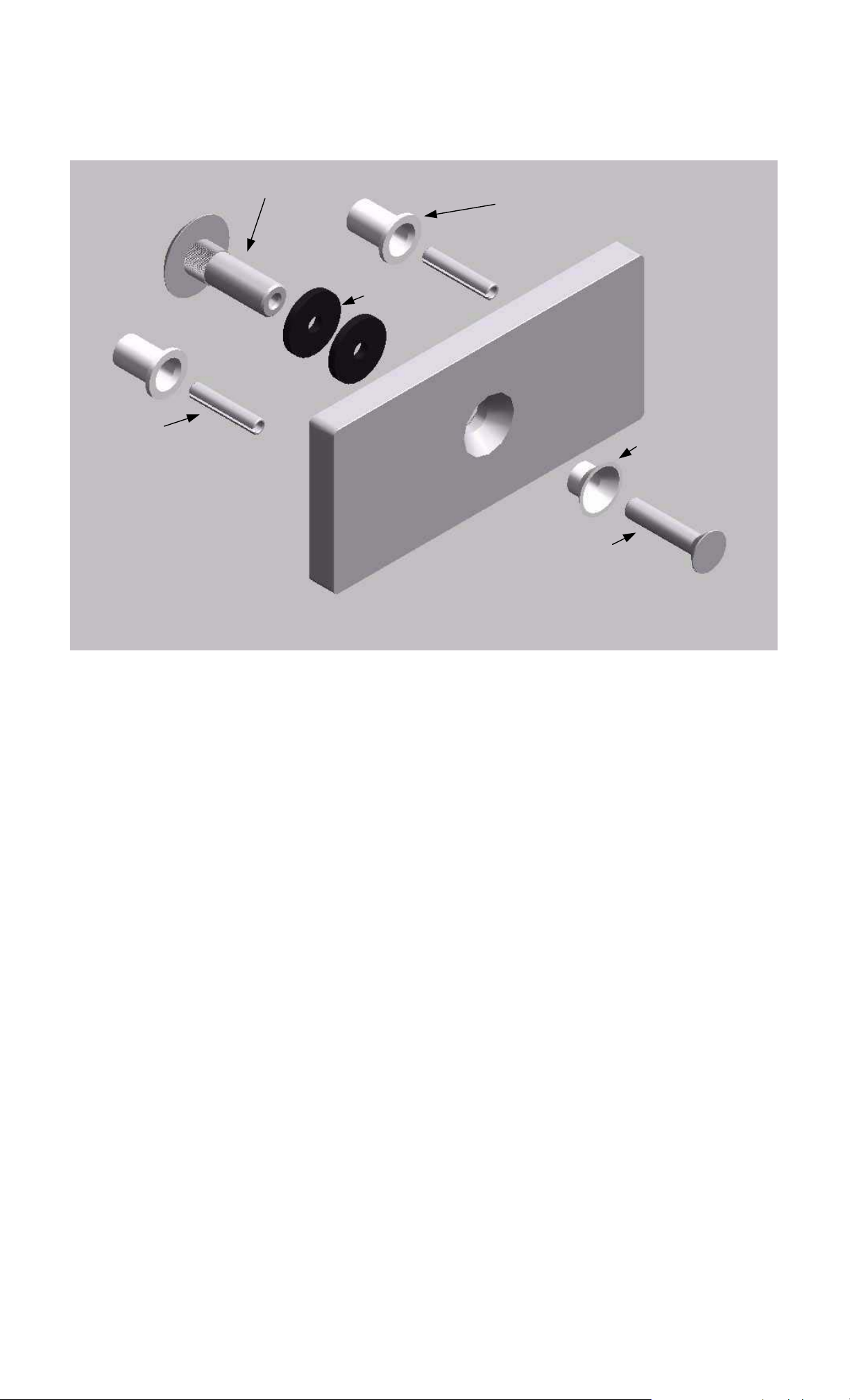

FIG. 1: STEPS IN MOUNTING THE STRIKE

STEP 1 : LOCATE STRIKE PO SITION ON DOOR

STEP 3: INSERT

STEP 2: DRILL 3 HOLES IN DOOR

FOLLOWIN G TH E TEMPLAT E

PLASTIC BUSHINGS

STEP 6: INSTALL

2 OR 3 RUB BER

WASHERS

ON STRIKE

MOUNTING

SCREW

STEP 4: LIGHTLY HAMM ER

IN ROLL PINS,

STEP 7: SECURE STRIKE TO DOOR USING SEX BOLT (SEE FIGURE 5)

STEP 8: VERIFY MOUNTI NG

STEP 5: INSERT STRIKE

MOUNTING SCREW THROUGH

WHITE PLASTIC BUSHING

Step four is to insert roll pins furnished with the strike. The pins are hammered into the strike

but be careful not to hit them too hard as it is possible to raise dents on the strike surface by

over driving the pins which degrades strike flatness and therefore holding force. In step five, the

strike is secured by the central strike mounting screw. In step six two flexible washers are then

placed between the strike and the door with the strike mounting screw passing through the

washers to provide flexibility. A third rubber washer is furnished. This is not normally used but

may be employed in case the spacing of the magnet and strike is a little off. Adding the third

washer will move the strike closer to the magnet. Do not place the washers around the roll

pins. The roll pins should "float" in their holes and not bind. Their only purpose is to prevent

the strike from rotating or spinning.

In step seven, the strike is secured to the door via the supplied sex bolt. Note that we supply a

massive 1 1/4” diameter sex bolt as it is the only point of attack from the outside of the door. It

can be difficult to align the strike mounting screw with the sex bolt, so the following technique is

recommended: Start the sex bolt in its 1/2" (12.7 mm) hole but thread the strike mounting screw

into it (with strike plate and washers) before hammering the sex bolt down. Next, hammer the

sex bolt down and then screw the strike mounting screw in the rest of the way. This makes

alignment much easier.

Step eight is to verify proper mounting. When the strike is mounted, make sure it flexes

freely around the washer stack. This flexing allows the Magnalock to pull the strike into

perfect alignment for maximum holding force. It is never possible for a door and frame to line

up well enough for the Magnalock to function unless the strike is allowed to flex.

Page 6

Rev. A.5, 8/03 Page- 3

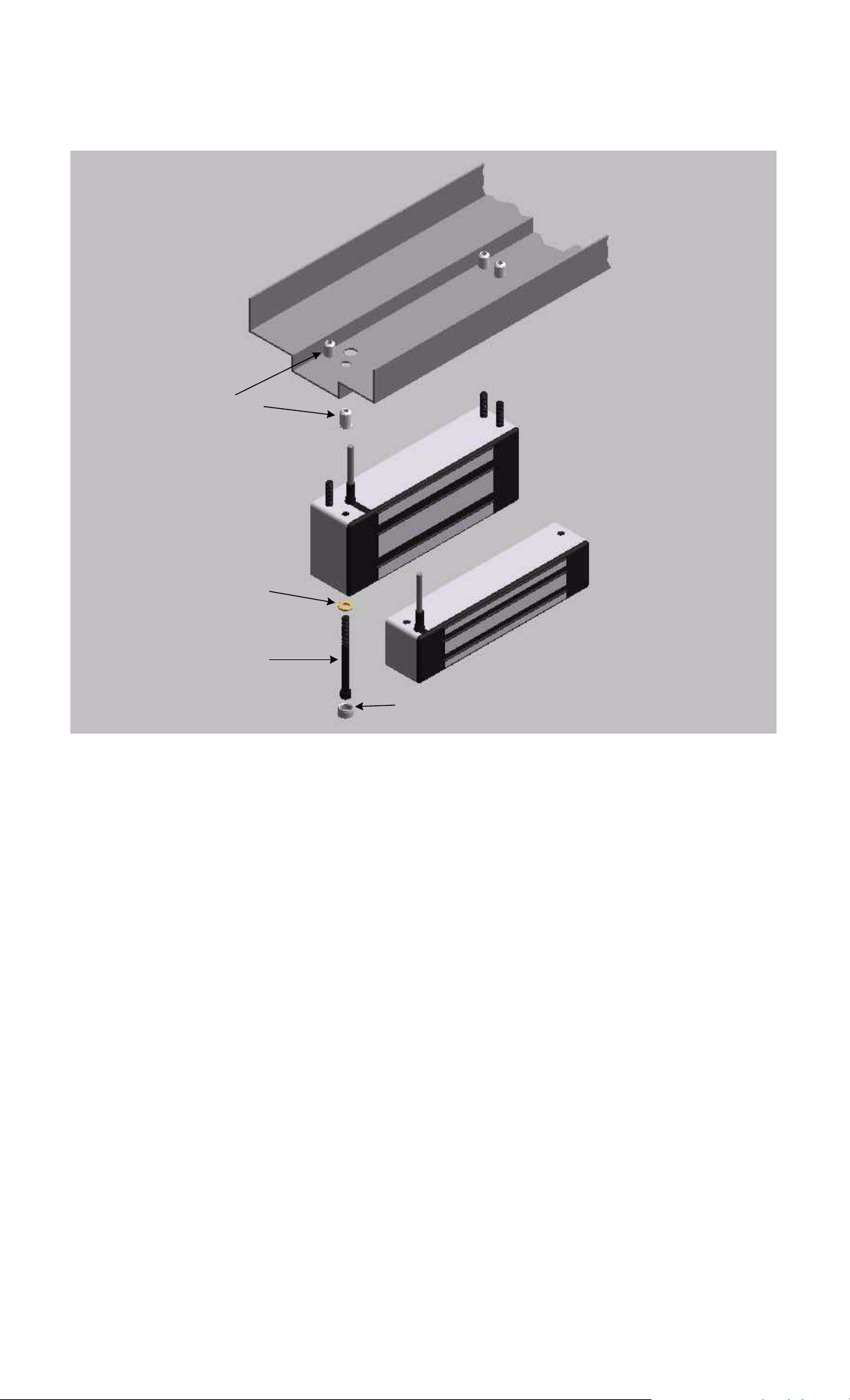

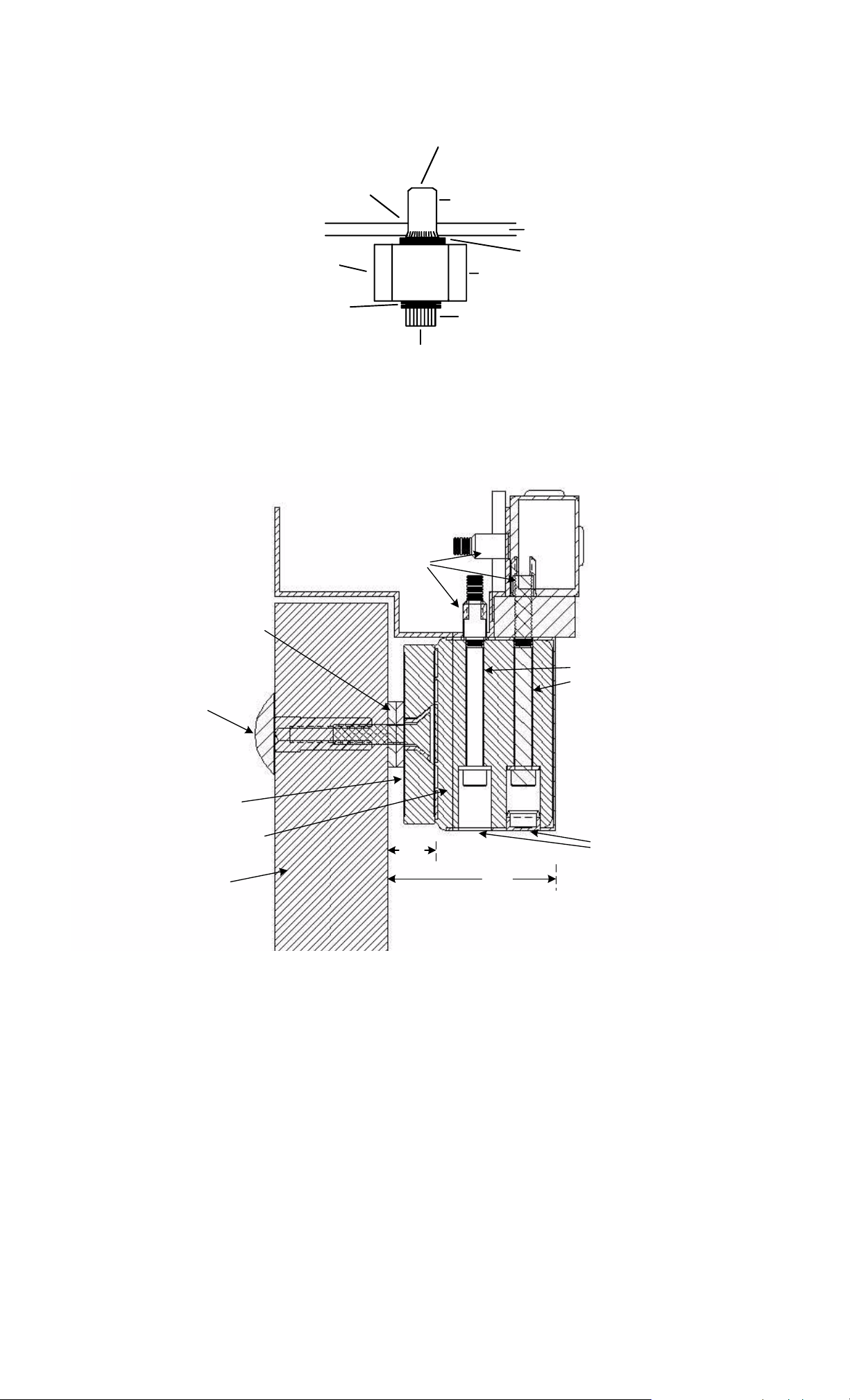

FIG. 2: STANDARD MAGNET DIMENSIONS AND ASSEMBLY

If "G" option is furnished, (62

and 82 series only), the wire

cable emerges from a 3/4"

male; 1/2" female conduit

fitting on the end of the

magnet. The mounting holes

are counterbored from both

sides to make the magnet

non-handed

Blind Nut

PN# BN-250 or

PN# BN-6MM (Metric)

(Pack of 40 with tool)

Gold Washer

PN# FW-1

(Pack of 24)

32 8" 1.88 1.5

(mm) 203 47.8 38.1

34 9.5" 1.75 1.125

(mm) 241 44.5 28.6

62 8" 2.9 1.75

(mm) 203 73.7 44.5

82 12" 2.9 1.75

(mm) 305 73.7 44.5

2

6

l

e

d

o

M

2

3

l

e

d

o

M

Length Width Depth

Recommended Tools:

1/2" or 3/8" Drill Motor

1/8", 3/8", 1/2" Drill Bits

1/2" Open or Crescent Wrench

3/16" Hex Key (Allen Wrench)

Hammer, Center Punch

Masking Tape, Fish Tape or

Leed Wire

Wire Strippers/Cutters

Crimp Wire Connectors

Multi-Meter

1/4-20 x 3" Cap Screw

PN# SCS-35 (Pack of 4)

6mm-1mm x 75mm

PN# 300-12650

Tamper Cap

PN# FC-1

(Pack of 24)

1/4-20 x 2 1/4" Cap Screw

PN# 300-12750 or

6mm-1mm x 55mm

PN# 300-12925

(For Model 32 Magnalock)

2.3.2 MOUNTING THE MAGNET

Step one is to locate the mounting position of the magnet. It will mount in the door frame

header with four socket cap machine screws for metal frames or wood screws for wood frames.

In mounting the Magnalock, six conditions must be followed:

-- The frame header must present a flat surface for the magnet to mount to. 1 7/8” (48mm) for

the model 34, 2 1/4” (57mm) for the model 32 and 2 1/2" (63.5mm) for the model 62 and 82 are

required from the door to the rear of the magnet for proper mounting (as shown in Figure 5). If

this length of flat surface is not available, the use of stop filler plates and/or header brackets

available from Securitron can usually resolve the problem. Again, refer to Figure 5.

-- The frame area selected must be structurally strong enough to yield a properly secure

installation. The issue of frame strength must be considered in selecting vertical or horizontal

mounting. One often finds on aluminum headers that the horizontal extrusion is weak and can

be snapped off, so vertical mounting would be preferred. It is also possible to reinforce the

header by adding a steel plate. The installer must avoid mounting the magnet to a wobbly or

weak support or the intrinsic security of the lock will be diminished.

-- The magnet face must be parallel to the strike plate.

-- The magnetic poles (three metal bars on the Magnalock), must be centered on the strike.

-- The magnet must make solid contact with the strike but still allow the door to close properly.

-- The direction of door opening must pull the strike directly away from the magnet rather than

sliding it away. Electromagnets hold only weakly in the shear direction of pull.

Page 7

Rev. A.5, 8/03 Page- 4

FIG. 3: STRIKE DIMENSIONS AND ASSEMBLY

Sex Bolt, Models 32, 62, 82, PN# SB-1, SB-1M (Metric)

Model 34, PN# 330-12650, 330-12750 (Metric)

R

u

P

N

#

RW

b

b

e

r

W

a

-

s

1

h

(

P

a

c

k

Bushing (2), PN# 560-12050

e

r

(

2

)

o

f

2

4

)

Roll Pin (2), PN# 330-10800

1/4" x 1 1/4"

Length Width Depth

32 6.25" 1.62 .55

(mm) 158.8 41.1 14.0

34 6.4" 1.44 .44

(mm) 162.6 36.6 11.2

62 6" 2.75 .52

(mm) 152.4 69.9 13.2

82 9.5" 2.75 .52

(mm) 241.3 69.9 13.2

Flathead Screw Models 32, 62, 82

5/16-18 x 1 3/4" P/N# 300-13600,

8mm-1.25mm x 40mm PN# 300-13750 (Metric)

Model 34: 1/4-20 x 2" PN# 300-12470,

6mm x 1.0mm x 50mm P/N# 300-12480 (Metric)

Bushing,

Model 32,62,82

PN# 330-12000

M34, PN# 330-11900

Once a solid flat surface has been prepared for the magnet, it must be positioned so that its face

is parallel and centered to the strike plate. When the magnet has been experimentally

positioned this way, it's ready for mounting.

In step two, holes must be drilled for the mounting screws, and a 1/2" (12.7mm) diameter wireway hole should be drilled. Step three is to install the blind finishing nuts. For proper strength,

the 1/4-20 (or 6mm) mounting machine screws must be secured by these nuts. They will work

on any thickness metal header and are used as follows: A 3/8" (9.5 mm) hole is drilled following

the template for each nut. The nut is then pressed up into the hole and lightly seated with a

hammer tap. The nut is then collapsed inside the header. If you have Securitron's IK

installation kit, the nuts may be collapsed by the use of the blind nut placement tool. A special

collapsing tool is also included with each Magnalock. It is somewhat slower to use than the

more elaborate tool found in the installation kit. For its use, see Figure 4.

Step four is to make the necessary wire connections. Step five is to mount the magnet via the

supplied machine screws (see Figure 2). Don't forget to use the gold flat washers. They

prevent the narrow screw heads from digging into the resin which could cause damage. Tighten

the screws to a snug fit only. Use the supplied thread-lock on the screw threads to avoid the

possibility of the screws loosening over time. Do not drill out the mounting holes to make for

an easier fit. You may cut an internal wire and void the warranty.

Page 8

Rev. A.5, 8/03 Page- 5

FIG. 4: COLLAPSING THE BLIND NUTS

COLLAPSES WHEN CAP SCREW

IS TURNED WITH ALLEN WREN CH

DRILL 3/8" (9.5MM) HOLE

PRESS IN BLIND

NUT AS SHOWN

HOLD WITH WRENCH OR

VISE GRIP WHILE TURNING

CAP SCREW

WHILE TOOL IS H ELD FAS T

WITH BOX WRENCH

BLIND NUT

HEADER

KNURL

TOOL

TWO FLAT WASHERS

IF SCREW IS STIFF TO TU RN,

ADD L UBRICANT T O WASHERS

WHILE TURNING WITH ALLEN

WRENCH, PRESS IN TO KEEP

NUT SEATED IN HEADER

CAP SCREW

1/4-20 X 1" (US) OR

6MM-1MM X 25MM (METRIC)

FIG. 5: TYPICAL MOUNTING ON OUTSWINGING DOOR

Blind Nuts

Stop

Washer Stack

Sex Bolt

Header Bracket if

frame is too narrow

Stop Filler Plate if

stop is too narrow

1/4-20 (6mm)

Mounting Screws

Model 62 or 82 is shown

with four magnet mounting

screws. Model 32 or 34

employs only two.

Strike

Magnet Body

Door

.75"

(19mm)

2.5"

(63.5mm)

Tamper Caps

(One shown)

2.4 GENERAL INSTALLATION ON INSWINGING DOOR WITH Z BRACKET

In cases where the Magnalock must be mounted on the inswinging side of the door to protect it

from physical assault, the magnet body is mounted flush on the wall above the door frame and a

"Z" bracket is affixed to the door which positions the strike in front of the Magnet (part # Z-32,

Z-62 or Z-82 with the suffix “M” for metric). The model 34 series is not offered in a face

mount version. Securitron's "F" series Magnalocks are used, as they have mounting holes

through the face of the magnet and wire exit to the rear. Figure 6 shows this configuration.

Note that the model 62F has five mounting holes through the face. The “extra” hole is to

provide flexibility in mounting when the magnet body is positioned partly on the top of the

door frame and partly on the wall. In that instance, it becomes possible to secure the model 62

magnet body with three screws which all go into the frame header (many wall types such as

Page 9

Rev. A.5, 8/03 Page- 6

sheet rock do not constitute a secure mounting substrate). Note that when the roll pin bushings

are used, they protrude through the Z bracket and interfere with the Z bracket cover. If a

Senstat lock is being employed, the roll pin bushings must be used to provide insulation. They

should be cut with a hacksaw to function in the bracket. If the lock is not Senstat, omit use of

the roll pin bushings and drill 3/8" (9.5mm) diameter holes for the roll pins instead of 1/2"

(12.7mm). Read sections 2.3, 2.3.1, and 2.3.2 for additional general information on mounting.

FIG. 6: F MAGNET DIMENSIONS

If "G" option is furnished, the

Blind Nut

PN# BN-250 or

PN# BN-6MM (Metric)

(Pack of 24 with tool)

Model 62F

wire cable emerges from a 3/4"

male; 1/2" female conduit fitting

on the end of the magnet (62

and 82 models only)

1/4-20 x 2 1/2" Cap Screw

PN# SCS-25 or

6mm-1mm x 60mm

PN# SCS-60mm (Metric)

Pack of four screws

)

4

2

f

o

r

e

k

c

h

s

a

a

P

(

W

1

-

d

l

o

W

F

G

N#

P

Tamper Cap

PN# FC-1 (Pack of 24)

Model 32F

Length Width Depth

32 8" 1.88 1.5

(mm) 203 47.8 38.1

62 8" 2.9 1.75

(mm) 203 73.7 44.5

82 12" 2.9 1.75

(mm) 305 73.7 44.5

Page 10

Rev. A.5, 8/03 Page- 7

FIG. 7: F MAGNALOCK MOUNTING

Architectural Cover slides on

last with open side up and is

attached with supplied double

Roll pin plastic bushing

require 1/2" (12.7mm)

holes and must be

shortened to work in Z

bracket. Roll pin bushings

may be omitted if lock is

not Senstat. Then drill 3/

8" (9.5mm) holes for roll

pins.

Sex Bolt

Drill 1/2" (12.7mm) hole

Strike

Magnet

Header

Z Bracket

Cap Screw:

5/16" x 18, PN# 300-13500 or

8mm-1.25mm, PN# 300-13425 (metric)

stick tape

Z Bracket

T-Nut requires 3/8" (9.5mm) Dia

hole in bracket and accepts

strike mounting screw

Use 1" mounting screw supplied

with Z bracket, PN# 300-13400

or 300-13450 (metric)

Washer Stack

#14 Hex Sheet Metal Screw (2)

PN# 300-13200

Door

2.5 MOUNTING PROCEDURES FOR SPECIFIC DOOR TYPES

2.5.1 ALUMINUM FRAME GLASS DOOR MOUNTING

This is a common door type that utilizes the Magnalock. Certain mounting problems can arise

depending on the configuration of the door and frame. Often, the header is not wide enough for

the depth of the magnet. This can mean that none of the mounting screws can be run into the

header or that in the case of the model 62 and 82, only two of the four will fit. Another aspect of

the mounting screw problem is that the screws might line up with the end of the header

extrusion. Also the wires may exit beyond the end of the header so that they will be exposed

and vulnerable to tampering.

Most of the problems are solved by the use of Securitron's Universal Header Bracket (part #

UHB-CL or UHB-BK). This bracket will function with the model 32, model 34 or model 62

Magnalock. A separate version (UHB-82) is offered for use with the longer model 82. The UHB

extends the depth of the header either 1" (25mm) or 1 1/2" (38mm) depending on which way it's

oriented. This usually allows mounting of all screws and since the bracket is itself a hollow

extrusion, the wire is run inside the bracket and therefore is hidden. Even with use of the

bracket, it is possible that one set of mounting screws may line up with the end of the header

when the model 62 or 82 is used. To deal with this situation, some adjustment of the magnet

mounting position is possible. Instead of the two rubber washers supplied with the strike, one or

three may be used. If the door is secured only by the Magnalock (there is no mechanical

swingbolt) the door closed position may be altered to allow all mounting screws to be used.

Finally note that a model 62 installation on this type of door is acceptable if only two mounting

screws are used. Since the screws run into steel nuts, the fastening technique is very strong. It

is best to use all four screws, but particularly on this type of door, which is inherently not high

security (the glass may be shattered for forced entry) firmly mounting two screws is acceptable.

Aluminum frame headers typically employ a “blade” stop which is far too thin to provide a

mounting surface for the magnet. Note that Figure 5 shows the Magnet mounting on the door

stop. Accordingly, on aluminum frame glass doors, the magnet body mounts directly onto the

header. This can be accomplished by cutting away a section of the blade stop. This technique

is preferred in that the projection of the magnet into the opening is minimized. An alternate

Page 11

Rev. A.5, 8/03 Page- 8

method is to space the magnet down so as to clear the blade stop. This generally requires 1/2”

of spacing (12.7mm) and Securitron offers brackets of the appropriate width with pre-drilled

clearance holes for the Magnet mounting screws. These are the ASB-32, ASB-62 or ASB-82

(with finish suffix CL or BK). Figure 8 shows the use of the Aluminum Shim Bracket (ASB).

Note that this bracket is not offered with the model 34. The UMB-34 bracket accomplishes the

same function.

FIG. 8: USE OF THE ASB BRACKET ON ALUMINUM DOOR/FRAME WITH BLADE STOP

BLADE

HEADER

DOOR

STOP

ASB BRACKET

MAGNET

ALUMINUM DOOR AND FRAME

WITH BL ADE STOP

D

O

M

R

O

F

2

3

-

B

S

A

I

W

O

H

S

S

B

S

A

.

N

K

C

O

L

A

N

G

A

M

2

3

L

E

6

-

A

H

2

8

/

2

E

V

I

F

S

S

E

L

O

H

STRIKE

SEX BOLT, STRIKE MOUNTING SCREW AND HOLE IN DOOR CAN ALL BE RAISED BY

1/4" WHEN OFFSET STRIKE IS USED WITH MODEL 62 TO SUIT NARROW RAIL

Another problem that can arise with aluminum frame glass doors is that in certain cases with the

model 62, the height of the aluminum rail at the top of the door is not sufficient to mount the

strike and sex bolt. Even when the sex bolt is installed in the lowest area of the top rail, the top

edge of the strike will protrude above the rail. To solve this problem, Securitron offers the offset

strike. The holes in the strike plate are offset 1/4" (6.4mm) from the center of the strike and this

allows successful mounting on a narrow top rail. An approximate 10% loss of holding force

results from the skewed position of the strike mounting screw but this is not significant on

aluminum frame glass doors which are not high security barriers. The offset strike is supplied at

no additional charge if it's called out with the order or may be sent as a replacement for the

standard strike. This problem does not occur with the more narrow model 32 or 34 so no offset

strike is offered with them.

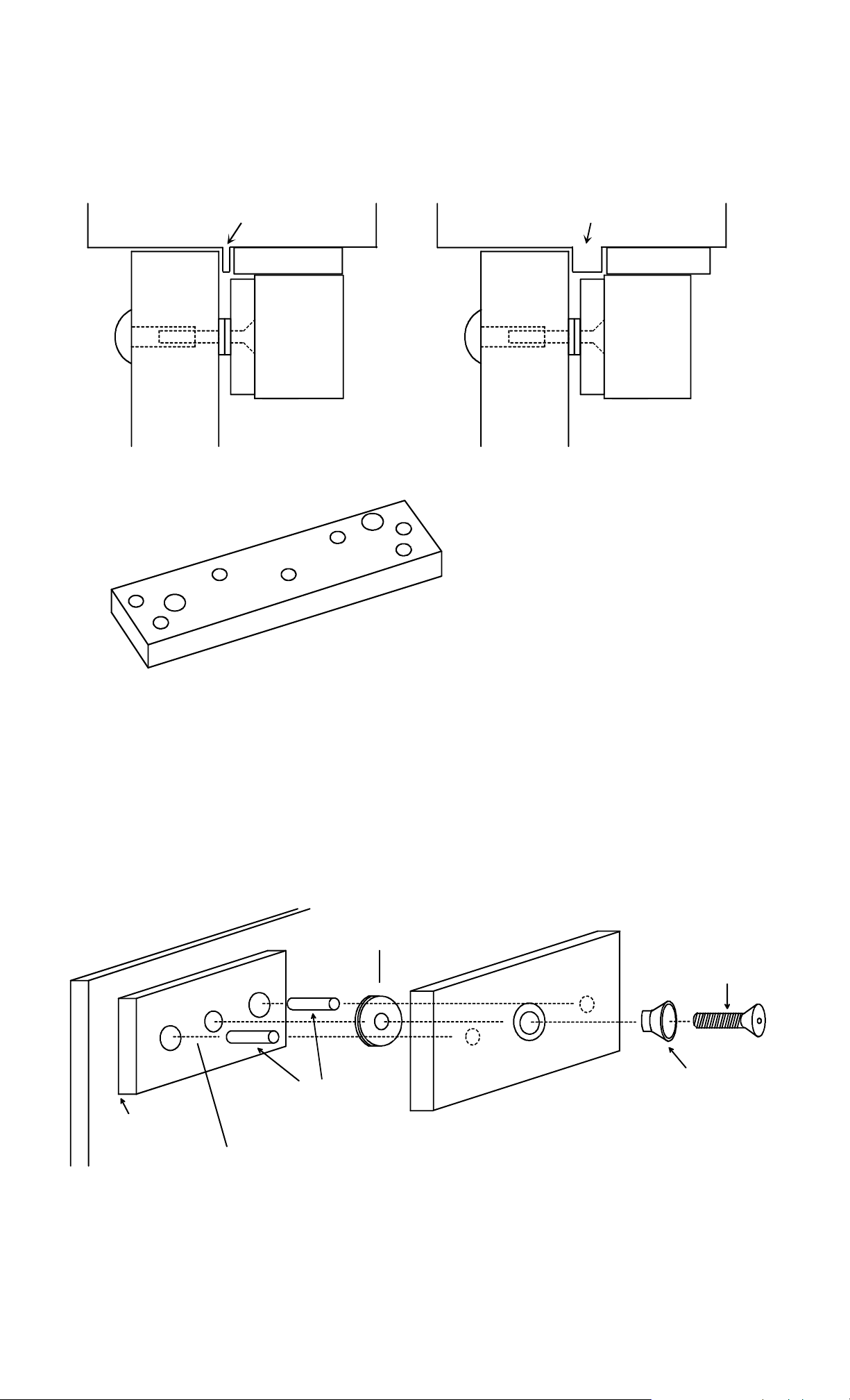

2.5.2. THE UMB-BRACKET FOR ALUMINUM AND CONCRETE FILLED HEADERS

The UMB-34 bracket replaces the functions of the ASB bracket (see previous drawing) and the

CWB bracket (see Section 2.5.5) which permits mounting on wood or concrete filled steel

headers. The UMB has the unique benefit of being reversible which alters the projection of the

bracket with respect to the top of the magnet body and allows coping with different stop

thicknesses. The bracket is delivered with a selection of fasteners for different applications.

Wood screws are present for mounting on wood headers; cap screws are present for installation

into blind nuts and sheet metal screws are present for optional mounting on steel headers.

2.5.3 SOLID GLASS DOOR MOUNTING

The Magnalock is an excellent choice for securing 100% glass doors with no aluminum rail. The

magnet is suspended in normal fashion from the header and the difficulty in the installation is

mounting the strike plate on the glass door as glass cannot be drilled. This is accomplished by

using Securitron's model GDB (or GDBM with metric fasteners) Glass Door Bracket and model

AKG Adhesive Kit for Glass (see Figure 10). The GDB bracket will work with either the model

32, model 62, or model 82 Magnalock (but not with the model 34). The bracket is affixed to

the glass surface by a special adhesive and the strike screws into the bracket conventionally.

The adhesive provides a permanent bond stronger than the holding force of the Magnalock.

Page 12

Rev. A.5, 8/03 Page- 9

FIG. 9: USE OF THE UMB BRACKET WITH THE MODEL 34 MAGNALOCK

NOTE HOW BRACKET CAN BE REVERSED TO COPE WITH DIFFERENT STOP THICKNESSES

BLADE

HEADER

STOP

HEADER

STOP

UMB BRACKET

DOOR

MAGNET

STRIKE

ALUMINUM DOOR AND FRAME

WITH BLADE STOP

UMB BRACKET

DOOR

MAGNET

STRIKE

ALUMINUM DOOR AND FRAME

WITH BLADE STOP

THE TWO LARGER HOLES ARE FOR THE

CABLE EXIT. THE TWO THREADED HOLES

ACCEPT THE MAGNET MOUNTING SCREWS.

THE REMAINING FIVE HOLES ACCEPT

DIFFEREN T FAST EN E R TYP ES TO MO UN T

TO DIFFERENT HEADERS.

Note that we have said "100% glass door". Some doors that appear to be glass are actually

laminated with plastic. If the Magnalock with glass door bracket is used on this type of

door, it is possible that failure will occur via delamination.

In some cases the header of a glass door is vertical glass. The magnet can be mounted on

such a header by using a 3" X 3" aluminum angle bracket (part number HEB-3G). The bracket

is glued to the vertical glass header with Securitron's adhesive kit for glass and the magnet is

screwed to the bracket.

FIG. 10: STRIKE INSTALLATION ON 100% GLASS DOOR

GL

2 X RUBBER

WASHERS

R

O

O

D

S

S

A

S

S

LA

G

D

B

R

O

O

T

E

K

C

A

R

5/16-18 x 1" (US) OR

8MM - 1.25MM X 25MM

(METRIC)

FLATHEAD SCREW

ADHESIVE

BOND

E

K

I

R

T

S

1/4" X 3/4"

ROLL PINS

NOTE: OMIT ROLL PIN WHITE PLASTIC BUSHINGS

WHITE PLASTIC

BUSHING

Page 13

Rev. A.5, 8/03 Page- 10

2.5.4 DOUBLE DOOR MOUNTING

Several possibilities exist for this application. In some cases, one of the door leaves is pinned

so that only one leaf is used and this is secured by a single Magnalock. If both leaves are to be

active, two Magnalocks can be used. For the most attractive installation, they should be butted

together but if obstructions exist in the header that interfere with mounting, the magnets can be

separated somewhat. Another possibility is to use Securitron's split strike which is available for

the model 62 and model 82 (use of a split strike with the model 32 or 34 series would provide

inadequate security) In this method, a single Magnalock is mounted in the center of the header

and a half size strike is mounted on each leaf. This reduces the holding force to about 550 lbs.

(250 KG) for each leaf with the model 62 and about 850 lbs. (385 KG) for each leaf with the

model 82. The split strike (part number ASS-62 or ASS-82 with “M” suffix for metric) is

available either as part of a complete Magnalock or supplied separately as a replacement for the

standard strike. Read section 2.7 for information on Dress Covers which improve the

appearance of a double door installation. Certain electronic considerations also apply when

Magnalocks are used on double doors. See section 3.5.4.

2.5.5 DM-62 DOUBLE 62 LOCK

This is a special order lock which provides two Model 62’s in a single, stainless steel housing. It

is intended for mounting on any double door with no center mullion. The advantage of this

product is solely in its esthetic appearance. Mounting procedures are somewhat different from

the standard Magnalock. As Figure 11 shows, the magnet body housing mounts first. When

this has been accomplished locate the center points for mounting the two strike plates by

measuring in 4” (102 mm) from the housing end. Then, simply use the supplied strike templates

on the doors, making sure to drop the top edge of each strike about 1/10” below the point at

which the door stop meets the door. Note that on certain door types, spacing brackets may be

employed as with single Magnalocks.

FIG. 11: MOUNTING THE DM-62 MAGNET BODY HOUSING

MOUNT DUAL MAGNET BODY HOUSING FIRST

(1) LOCATE CENTER POIN T BETWE EN DOOR S

(2) MEASURE BACK ON STOP, 7/8" (22 mm) FROM DOOR

CLOSE POINT (FRONT EDGE OF STOP)

(3) DRAW PENCIL LINE ON DOOR STOP, PARALLEL

TO STOP BUT 7/8" (22 mm) SET BACK FRO M

FRONT EDGE

(4) ONE PE R S ON SH OULD HO L D MAGNET

BODY ON STOP SO THAT FRONT

HOUSING EDGE

LINES UP WITH PENCIL LINE

HOUSING WHILE IT IS BEING HELD BY FIRST PERSON

(7) BEFORE DRILLING MAGNET MOUNTING AND WIRE WAY

HOLES,

REFERRING TO THE DIAGRAM SUPPLIED WITH THE PRODUCT

(8) MOUNT BLIND NUTS AND MAGNET BODY USING PROCEDURES

CALLED OUT IN SECTION 2.3.2

CAREFULLY

(5) INSURE MAGNE T BO DY

HOUSING IS SQUARE TO PENCIL LINE

(6) SECOND PERSON SHOULD CENTER PUNCH

EIGHT MAGNET MOUNTING HOLES THROUGH THE

, CHECK THE SPACING BETWEEN THEM BY

2.5.6 STEEL HEADER FILLED WITH CONCRETE OR WOOD FRAME MOUNTING

Securitron offers a combined bracket in three versions to suit the three Magnalock families. The

part number of the “Concrete/Wood Bracket” is CWB-32, CWB-62 or CWB-82. Two finishes

are available (suffix CL or BK) and for metric locks, the brackets include the suffix “M”. Note

that the CWB bracket is not offered with the model 34. It’s functions are accomplished by the

UMB bracket for the model 34.

Page 14

Rev. A.5, 8/03 Page- 11

FIG. 12: WOOD FRAME AND CONCRETE HEADER BRACKET

CWB-32

R

E

B

M

A

H

C

E

C

I

L

P

S

1/2"

WOOD SCREWS USED

FOR WOOD FRAME

MAGNET SCRE WS INTO

2 OUTSIDE TAPPED HOLES

SHEET METAL

SCREWS

FOR CONCRETE

HEADER

USED

USE ALL FURNISHED SCREWS FOR

PROPER MOUNTING SECURITY

CWB-62 AND CWB-82

R

E

B

M

A

H

C

E

C

I

L

P

S

1/2"

WOOD SCREWS USED

FOR WOOD FRAME

SHEET METAL SCREWS

USED FOR CONCRETE

MAGNET SCRE WS INTO

4 OUTSIDE TAPPED HOLES

HEADER

In concrete filled headers, the blind nuts function normally but a problem can occur in pulling

the hook up wires as it is difficult to run a wireway in concrete. The center of the bracket for the

model 62 and model 82 versions forms a splice chamber if it's difficult to pull the wires back into

the header. The model 32 version has a slot to bring the wire into the header because of the

narrowness of the lock. Alternately the wires may be pulled through the edge of the bracket by

drilling a hole if it's impractical to drill the concrete. A final technique for concrete headers is the

use of Securitron's

"G" version Magnalock (not available in the 32 or 34 series) which

incorporates a 1/2" female/-3/4" male universal threaded conduit fitting. The conduit fitting is

placed on the end of the magnet body, and the problem of pulling wires into concrete is

bypassed as the wires may be run in pipe in a surface mount configuration. The mounting holes

on "G" locks are

counter-bored from both sides to make the lock non-handed.

With a

wooden frame, long wood screws are used to mount the Magnalock. The screws must

penetrate as deeply as possible through the stop and frame into the header to yield adequate

mounting strength. The Magnalock mounts to the bracket via machine screws and the bracket

permits wood screws (furnished) to penetrate deeply into the header (see Figure 12)

2.6 MOUNTING THE MAGNALOCK ON EXTERIOR GATES

A popular application for the Magnalock is to secure motorized or manual exterior gates. The

Magnalock has several benefits in this application. Gates tend not to be precisely fitted so

electric bolts suffer from alignment failures. The Magnalock is designed to be self aligning and

tolerates considerable inconsistency in the gate closed position as regards upward/downward

Page 15

Rev. A.5, 8/03 Page- 12

alignment, side alignment and twisting. The Magnalock is also fully sealed and waterproof so it

is generally unaffected by tough environments.

FIG. 13: MOUNTING TECHNIQUES FOR GATES

SINGLE SWING GATE

CONDUIT FITTING MAY EXIT TOP OR BOTTOM

GF MAGNET

Z BRACKET BOLTED TO SWING ARM

STRIKE

INTERFERENCE PIECE MUST

BE ADDED TO Z BRACKET

CONDUIT FITTING

DOUBLE SWING GATE

Z BRACKET BOLTED TO SWING ARM

DIRECTION OF OPE NING

SLIDING GATE

GATE

EDGES

MOTORIZED OPENING MUST BE

COORDINATED

EXTENDED ROLL PIN

ANGLE BRACKET

GF MAGNET

STRIKE

LOCK NUTS

ANGLE BRACKET

SPRING

EXTENDED ROLL PIN

Page 16

Rev. A.5, 8/03 Page- 13

The drawings and descriptions, show conceptual installation concepts for different types of gate

security applications. Note that the model 62 and model 82 are most commonly used in gate

installations. They have conduit fittings available (“G” option) while this is not available on the

model 32 or 34 Most gate installations also call for higher levels of holding force as gates are

often large and poorly fitting. It’s also often the case that an intruder is able to physically apply

more force to defeat a gate lock than is the case with (especially) an outswinging door wherein

the intruder can only pull on it. The model 32 or 34 however may be used on certain gates with

success. A good example is a sliding gate where the Magnet can be mortised into a post

against which the gate slides. Securitron also offers the model 34R Magnalock which is

specifically designed for mortising (see catalog).

Because of the wide variety of gates in existence, each installation has to be considered special

and normally, bracketry must be made up on site. The concept is to mount the magnet on a

fixed post and the strike plate to the swinging or sliding member of the gate. Position both

components so that the strike plate slaps against the magnet face on closure. Usually, the "GF"

version of the Magnalock is used for gates. "G" calls out a conduit fitting mounted on the

magnet end and "F" calls out mounting holes through the face (see Figure 6). The magnet

typically screws onto a back plate fashioned on site and the back plate is welded onto the fixed

post.

A back plate or Securitron's Z bracket must also typically be provided for the strike plate.

The

strike plate cannot be directly welded to the gate as it will not be able to flex and self

align. It must be screwed onto a surface with the washer stack used to provide flexibility.

Note that if Securitron's Z bracket is used, it typically bolts to the gate rather than is welded as it

is aluminum. Read sections 2.3, 2.3.1, and 2.3.2 for additional general information on mounting.

In the case of very tall and large gates, a levering problem can exist. By this we mean that an

intruder may be able to flex the gate enough to take up the slack in the strike mounting screw

and then lever off the strike plate. If the installer or user determines that this may happen, a

single Magnalock will not provide adequate security and two must be used, typically at the top

and bottom of the gate.

Figure 13 shows preferred special techniques for Magnalock mounting on 3 types of gates. The

first drawing shows a

single swinging gate. The general technique follows the principles

discussed above but the use of Securitron's Z bracket which creates a neat installation is also

shown. Note that in some cases, the post which mounts the magnet is hollow. It is possible to

use the "F" version (without conduit fitting) and pull the wires through the post which may yield a

neater and more secure installation.

The second drawing shows a

double swinging gate which presents a unique problem. The

Magnalock is mounted in the same general way as on a single swinging gate but since both

arms move, an intruder pushing on the gate exerts a shearing force on the Magnalock.

Electromagnets are not at all strong in this orientation of attack. Therefore, as the drawing

shows, Securitron's Z bracket should be used with an interference piece which blocks the

shearing effect while the strength of the magnet blocks one arm moving while the other is

stationary. For this technique to work, the motorized operator must be

coordinated which

means that one arm must move first to clear the interference piece before the other arm starts

moving. Gate operators can normally accomplish this.

The final drawing on Figure 13 shows a special mounting technique for

sliding gates. We

recommend the use of the "GF" type magnet and two 3" angle brackets (available from

Securitron) for a neat installation. A special strike mounting technique is shown in the drawing

which improves reliability. The problem is that if the strike is mounted normally to the angle

bracket and the gate is a powerful one which slams shut, the magnet may be impacted to the

point where its mounting screws loosen or the bracket bends. The strike mounting technique

that is shown creates a "shock absorber" effect by the use of lock nuts at the rear of the strike

and the rear of the bracket together with a spring. A through hole (rather than tapped) is drilled

in the angle bracket mounting the strike and extra long roll pins are used. When the gate

closes, the strike moves in against the spring which is the shock absorbing action.

2.7 USE OF DRESS COVERS

Once the physical installation is complete, you may want to consider the use of a dress cover.

Dress covers are metal stampings which slip over the magnet body and are affixed with

permanent double stick tape (supplied). The dress cover accomplishes three functions: First, it

makes for a

that is seen is an attractive rectangular form on the door. Second, the cover provides an

more attractive installation by concealing the strike plate and mounting holes. All

extra

degree of tamper proofing and finally it allows easy alteration of the finish for architectural

Page 17

Rev. A.5, 8/03 Page- 14

compatibility. Dress covers are available in clear aluminum, satin black aluminum, polished

stainless and polished brass finishes.

Double dress covers are also available for installations on double doors. In this case, the cover

fits over two locks so long as they are not separated by more than 2" (50mm). Double dress

covers have all the advantages mentioned above and in addition produce the appearance of a

single device which inside is really two. Consult the catalog for dress cover part numbers.

2.8 TAMPER PROOFING THE MAGNALOCK

In situations where vandalism is expected, the Magnalock should be protected from tampering.

The magnet itself is inherently tamper-proof being totally sealed. The magnet mounting screws

are vulnerable in that the magnet can be dismounted if the screws are loosened. The allen

holes on the screws can be filled with a potting compound, such as Devcon, or silicone.

Alternately, the entire hole in the magnet where the screw heads fit could be filled. Butyrate

caps are supplied to close the mounting holes. These provide some tamper proofing as they

can't be removed by hand, but can be pried out with a tool. Regarding the strike plate mounting

screw, it is covered by the strike when the magnet is energized. If tampering is anticipated

when the door is open, the screw socket head may be filled.

Another possibility is that

Securitron inventories special tamper proof screws for both

magnet and strike mounting. These screws are identical allen head types except that it requires

a special key to install and remove the screws. It is unlikely that a vandal would have access to

this type of key. Securitron optionally supplies the tamper proof screw sets with keys both in the

form of a manual allen wrench and in a bit key usable with a drill.

3. ELECTRICAL INSTALLATION

3.1 GENERAL ELECTRICAL CHARACTERISTICS

The Magnalock constitutes a low current electric load. Owing to internal circuitry, the

Magnalock does not show the normal characteristics of an electromagnetic or other inductive

load. Inductive kickback is suppressed, so arcing across switch contacts need not be a

concern. This suppression also protects nearby access control or computer equipment from

possible interference. The circuitry performs the additional functions of canceling residual

magnetism ("stickiness" on release) and accelerating field collapse so that the Magnalock

releases nearly instantly when power is removed. Electrically speaking, the load is nearly pure

resistive in nature although there is a modest capacitive component which depends on the

series. The following chart shows the current draw for each version and the degree of internal

capacitance.

32 @ 12V 32 @ 24V 34 @ 12V 34 @ 24V 62 @ 12V 62 @ 24V 82 @ 12V 82 @ 24V

CURRENT 300 mA 150 mA 350 mA 175 mA 250 mA 125 mA 350 mA 175 mA

CAPACITANCE 0 0 0 0 30 Mfd 15 Mfd 30 Mfd 15 Mfd

Capacitance can be an issue if very sensitive switch contacts are used to control the Magnalock

(such as a low current reed switch). A capacitive load includes some inrush current which can

stress these contacts. Note however that the problem is diminished when the Magnalock is

mounted some distance from the control switch as the interconnecting wiring adds a series

resistance to the circuit which sharply limits the inrush.

3.2 STANDARD LOCK

For operation, DC voltage must be provided to the lock. The red wire receives +12VDC or

+24VDC, and the black wire, 0V (negative).

If the lock is connected with reverse polarity, it

will not function at all. The voltage source may be regulated, filtered or pulsating DC

(transformer + bridge rectifier).

Half wave pulsating DC generated by a transformer and

single diode will not properly operate the Magnalock. An exact voltage level is not

necessary. Less than standard voltage will proportionately reduce holding force but will cause

no harm. Overvoltage up to 30% is acceptable.

The model 34, 62 and 82 series Magnalocks are

dual voltage units. This means that you can

apply either 12 or 24 volts to the same unit and it will operate equally well. Dual voltage

Magnalocks are

auto-switching which means that you still apply power to the red and black

Page 18

Rev. A.5, 8/03 Page- 15

wires, while observing correct polarity. The lock, however, automatically detects whether it is

receiving 12 or 24 volts and draws the correct amount of current for that voltage (the current is

twice as high when the lock is receiving 12 volts than when it is receiving 24 volts). The model

32 series has separate models for 12 and 24 volt operation.

It is good practice to use power supplies with 1/3 extra capacity beyond the current

requirements of the load. This greatly reduces the possibility of heat induced power supply

failure and also allows for future expansion. Power supply cost is a small fraction of the job cost

and should not be skimped on.

Switches may be wired as necessary between the Magnalock and power source. Internal

circuitry eliminates inductive kickback, so neither electromechanical switches nor solid state

devices will be damaged by arcing when the Magnalock is shut off.

3.3 AVOIDING POOR RELEASE CHARACTERISTICS

One of the exceptional features of Magnalocks is near instantaneous release. This is

particularly valuable when the lock is being switched off and the door is being opened at the

same time as occurs when a switched exit device like Securitron’s Touch Sense Bar is being

used. Two separate wiring errors can however cause Magnalocks to release slowly (in one or

two seconds) and this is annoying.

The first problem is

connection of a reverse diode in parallel with the lock's power input.

This is often done to suppress inductive kickback from a coil such as a relay coil or solenoid.

Magnalocks already have internal inductive kickback protection, so addition of a reverse diode is

pointless. The diode does act to "recirculate" current flow through the magnet coil and thereby

considerably slows release. A diode should never be connected as shown in Figure 14.

The second problem is when any load is operated in parallel with the Magnalock. A good

example would be adding an incandescent lamp in parallel with the lock so that the lamp would

be illuminated when the lock is powered. The lamp acts like a resistor and allows current

recirculation which will greatly slow lock release time. When you want to add a resistive load in

parallel with the lock, you

must put a forward diode in series with the resistive load. This

will block recirculation and restore quick release. Correct practice is shown in Figure 14 below.

A special case exists when you use an

LED connected in parallel with the Magnalock (to

show that the Magnalock is on for example). This does not slow release as the LED does not

allow recirculation but the limited recirculation energy will eventually burn out the LED. LED’s

are susceptible to even a tiny amount of reverse voltage. Therefore add the forward diode as

you would with an incandescent lamp (see Figure 14) to extend the life of the LED.

FIG. 14: WIRING CONSIDERATIONS TO AVOID SLOW RELEASE

RED

RED

MAGNALOCK

BLACK

NEVER CONNECT PARALLEL

REVERSE DIODE AS SHOWN

BLACK

USE A FORWARD DIODE WITH ANY PARALLEL

RESISTIVE LOAD SUCH AS A LAMP

MAGNALOCK

3.4 WIRE GAUGE SIZING

If the power supply is distant from the lock, voltage will be lost (dropped) in the connecting wires

so that the Magnalock will not receive full voltage. The following chart shows the

gauge that will hold voltage drop to an acceptable 5% for different

lock to power supply

minimum wire

distances. Proper use of the chart assumes a dedicated pair of wires to power each

Magnalock (no common negative). Note that a Magnalock operating on 24 volts is a much

better choice for long wire runs as it has 4 times the resistance of a 12 volt installation. Also

note that the correct calculation of wire sizing is a very important issue as the installer is

responsible to insure that adequate voltage is supplied to any load. In multiple device

Page 19

Rev. A.5, 8/03 Page- 16

installations, the calculation can become quite complex so refer to Appendix B for a more

complete discussion.

Distance Gauge 12V Gauge 24V Distance Gauge 12V Gauge 24V

80 FT 20 GA 24 GA 800 FT 10 GA 16 GA

200 FT 17 GA 22 GA 1500 FT. 8 GA 14 GA

400 FT 14 GA 20 GA 3000 FT N/A 12 GA

3.5 SENSTAT MAGNALOCKS: “SC”

Securitron's optional patented Senstat feature provides true lock status sensing. In many

electrically controlled door security systems, status sensing is provided by a magnetic switch on

the door itself. This indicates the door is closed but not necessarily secured. Securitron's

Senstat monitors the lock rather than the door and therefore provides higher security (but note

that it can’t be used as an auto-relock input to an access control system).

An “SC” Magnalock provides a dry SPDT output which changes state when the lock is reporting

secure

(1 Amp @ 30 VDC maximum). This is accomplished by conducting the input power of

the lock through the strike and employing it to energize an internal SPDT relay. The white wire

is the Senstat relay common. Green is closed to white when the lock is secure and Orange is

closed to white when the lock is not secure.

FIG. 15: “SC” SENSTAT WIRING

BLK

"SC" LOCK

POWER

SUPPLY

+

WHITE AND GREEN WIRES PROVIDE ISOLATED CLOSURE WHEN LOCK IS SECURE.

ORANGE AND WHITE ARE CLOSED WHEN LOCK IS NOT SECURE (AS SHOWN ABOVE).

RED

ORANGE

GREEN

WHITE

3.6 DOUBLE DOOR PROCEDURE FOR STATUS REPORTING

Often two Magnalocks are mounted on a double door and are turned on and off together (no

separate control). As to status reporting, it is of course possible to receive a separate Senstat

status signal from each door or you can

combine the outputs so that if both locks are secure,

the double door is secure and if either lock is not secure, the double door is not secure.

Simply tie the white and green wires together from the two locks. A circuit will be closed

between the other white and green wires only when both locks are reporting secure. If either is

not secure, the circuit between other white and green wires will be open. The orange wires are

not used. See Figure 16.

FIG. 16: DOUBLE DOOR WIRING WITH "SC" LOCKS

WHITE

GREEN

"SC" LOCKS ARE INTERWIRED AS SHOWN TO PROVIDE STATUS MONITORING. AN ISOLATED CLOSURE

WILL EXIST BETWEEN THE GREE N A ND WHI TE WIRES ONLY IF BOTH LOCKS ARE SECURE.

"SC" LOCK

"SC" LOCK

GREEN

WHITE

Page 20

Rev. A.5, 8/03 Page- 17

3.7 DOUBLE DOOR CONTROL SWITCHING

It’s common to control two locks from a single access and/or exit switch on double doors or on

an installation where two locks are mounted on a single door. In nearly all cases, this works

with no problem but occasionally the release can appear to be “sticky” for similar reasons to

those discussed in Section 3.3 This happens when one of the locks is poorly coupled to its

strike plate. This could occur because of an installation problem (the strike plate is not being

allowed to swivel) or because of some obstruction between the plate and magnet surface.

When an electromagnet is not well coupled to its strike plate, its magnetic field collapses so

rapidly that it provides some energy to recirculate in the second magnetic lock, slowing the

release of that lock.

FIG. 17: DOUBLE POLE SWITCHING OF TWO LOCK INSTALLATION

TWO POLE

POWER

SUPPLY

+

SWITCH

RED

MAGNALOCK #1

RED

MAGNALOCK #2

BLK

BLK

So if you notice slow release on a double lock installation, this is telling you that one of the locks

is not holding properly and that the problem should be corrected. Alternately, any chance of

slow release can be eliminated by controlling the two locks with a double pole switch or relay.

This blocks the recirculation path and is shown in Figure 17.

3.8 EMERGENCY RELEASE

Magnalocks are often wired into a system such that they can be released in an emergency -either manually from one switch or automatically, often from the fire alarm system. It is the

user's responsibility to accomplish this hookup correctly according to these instructions and

good electrical practices. In general, we recommend that a switch or relay be used to perform a

series break of all DC power which is the simple and sure way to make sure the doors do

release. Securitron power supplies have terminals for interconnection of such emergency

release switches. Finally please note that

it is the responsibility of the end user and

dealer/installer to insure that Magnalock installations comply with any applicable fire or

building codes.

Page 21

Rev. A.5, 8/03 Page- 18

MAGNACARE® LIMITED LIFETIME WARRANTY

SECURITRON MAGNALOCK CORPORATION warrants that it will replace at customer’s request, at any time for

any reason, products manufactured and branded by SECURITRON.

SECURITRON will use its best efforts to ship a replacement product by next day air freight at no cost to the

customer within 24 hours of SECURITRON’s receipt of the product from customer. If the customer has an account

with SECURITRON or a valid credit card, the customer may order an advance replacement product, whereby

SECURITRON will charge the customer’s account for the price of the product plus next day air freight, and will

credit back to the customer the full amount of the charge, including outbound freight, upon SECURITRON’s receipt

of the original product from the customer.

SECURITRON’s sole and exclusive liability, and customer’s sole remedy, is limited to the replacement of the

SECURITRON product when delivered to SECURITRON’s facility (freight and insurance charges prepaid by

customer). The replacement, at SECURITRON’s sole option, may be the identical item or a newer unit which

serves as a functional replacement. In the event that the product type has become obsolete in SECURITRON’s

product line, this MAGNACARE warranty will not apply. This MAGNACARE warranty also does not apply to

custom, built to order, or non-catalog items, items made by others (such as batteries), returns for payment,

distributor stock reductions, returns seeking replacement with anything other than the identical product, or products

installed outside of the United States or Canada. This MAGNACARE warranty also does not apply to removal or

installation costs.

SECURITRON will not be liable to the purchaser, the customer or anyone else for incidental or consequential

damages arising from any defect in, or malfunction of, its products. SECURITRON does not assume any

responsibility for damage or injury to person or property due to improper care, storage, handling, abuse, misuse, or

an act of God.

EXCEPT AS STATED ABOVE, SECURITRON MAKES NO WARRANTIES, EITHER EXPRESS OR IMPLIED, AS

TO ANY MATTER WHATSOEVER, INCLUDING WITHOUT LIMITATION THE CONDITION OF ITS PRODUCTS,

THEIR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

PATENTS

Securitron’s Magnalock is covered under U.S. patents #4,516,114 and 4,682,801.

Page 22

Rev. A.5, 8/03 Page- i

APPENDIX A

TROUBLESHOOTING

PROBLEM-- No magnetic attraction between magnet and strike plate.

First be sure the lock is being correctly powered with DC voltage. This includes connecting the power wires with

correct polarity. Positive must go to red and negative to black. If the Magnalock is wired in reverse polarity, it will

not be damaged, but it will not operate. If the unit continues to appear dead, it must be electrically checked with an

Ammeter. It must be powered with the correct input voltage and checked to see if it draws the specified current. If

the unit meters correctly, it is putting out the correct magnetic field and the problem must lie in the mounting of the

strike (see next paragraph). Section 3.1 includes a chart showing current draw for all Magnalock versions.

PROBLEM-- Reduced holding force.

This problem usually expresses itself in terms of being able to kick the door open or to open it with a shoulder.

Check the strike and magnet face to see if some small obstruction is interfering with a flat fit. Even a small air gap

can greatly reduce the holding force. Another possibility is if the strike plate has a dent on it from being dropped for

example. Remove the strike from the door and try to rock it on the magnet face to insure it is flat. If the strike and

magnet are flat and clean, the cause is nearly always improper mounting of the strike in that the strike is mounted

too rigidly. The strike must be allowed to float around the rubber washer stack which must be on the strike center

mounting screw. The magnet then pulls it into flat alignment. To correct the problem, try loosening the strike

mounting screw to see if the lock then holds properly. Another possibility is if you are operating the lock on AC

instead of DC or on half wave rectified DC (transformer + single diode). Half wave rectified DC is unacceptable;

you must, at a minimum employ full wave rectified DC (transformer + bridge).

PROBLEM-- The Senstat output does not report secure.

Because of the simplicity of Securitron's patented Senstat design, this is almost always a case of the lock status

sensor doing its job. It is not reporting secure because a small obstruction or too stiffly mounted strike is causing

the Magnalock to hold at reduced force. The problem is corrected by cleaning the surfaces of the magnet and

strike or establishing proper play in the strike mounting. If this doesn't work, you can verify function of the Senstat

feature as follows. Note that there are 2 thin vertical lines on the magnet face that can be said to separate the core

into 3 sections from left to right. The Senstat output is created by the strike establishing electrical contact between

the leftmost and rightmost core segments. With the lock powered, use a pair of scissors and press the points

respectively into the leftmost and rightmost core segments. The Senstat output should then report secure. This

shows that the problem lies in the strike not making correct flat contact with the magnet face. If the scissors

technique doesn't cause the lock to report secure, check to see if there is a broken Senstat wire. If this is not the

case, the lock must be returned to the factory for replacement.

PROBLEM-- The lock does not release.

When power is removed from it, the Magnalock must release. If internal circuitry, which eliminates residual

magnetism, were to fail completely, the lock would only exhibit "stickiness" at a rough level of 5 pounds. Therefore

the complaint of "lock will not release" is either mechanical bonding via vandalism or a failure to completely release

power. By mechanical bonding, we simply mean that glue has been applied between the strike and magnet as a

prank. Failure to completely release power is generally a wiring integrity problem. What happens is that an

upstream switch removes power from the wires going to the Magnalock, but through an installation error, the wires

have their insulation abraded between the switch and lock so that partial or full power can leak in from another

Magnalock or other DC device with similarly abraded wiring. This is most likely to occur at the point where the wire

cable leaves the lock case and enters the door frame. Another area is via an improper splice on wiring in conduit.

Either a metal door frame or the metal conduit is capable of leaking power between multiple devices with abraded

wires, thereby bypassing switches. A good way to check this electrically (as opposed to visually removing and

inspecting the wires) is to use a meter and check for leakage between the power supply positive or negative and

the door frame and conduit. Magnalocks should be powered by isolated DC voltage without any earth ground

reference to positive or negative. Note that two types of wiring errors can cause slow release. Review Section 3.3

to see if you are making either of these errors.

PROBLEM-- The lock rusts

Both the Magnalock core and strike plate are plated and sealed following a military specification. Because of this

plating and the sealed nature of the magnet, the Magnalock is weatherproof and may be used outdoors. If rusting

appears, the most common cause is that improper cleaning (with steel wool for instance) has occurred and this has

stripped off the relatively soft plating. Once the plating has been removed, it cannot be restored in the field, so the

lock will have to be periodically cleaned and coated with oil or other rust inhibitor. A rusty Magnalock will still

function but at reduced holding force. If the product is installed in a heavily corrosive atmosphere, such as near the

ocean, it will eventually rust even with non abrasive cleaning. The only answer then becomes continued periodic

removal of the rust.

Page 23

Rev. A.5, 8/03 Page- ii

PROBLEM-- Apparent electronic noise interference with the access control system.

Electric locks, being inductive devices, return voltage spikes on their power wires and also emit microwave

radiation when switched. This can interfere with access control electronics causing malfunctions. Access control

contractors often employ installation techniques designed to isolate the access control electronics from the electric

lock. These include separate circuits for the lock, shielded wiring and other techniques. These techniques will vary

with the sensitivity of the access control system electronics and should, of course, be followed. Note that

Magnalocks include internal electronics which suppress both inductive kickback and radiation. They have been

extensively tested and accepted by numerous access control manufacturers and have been used in thousands of

installations without incident. An apparent noise problem is therefore usually not caused by the Magnalock. The

access control equipment may be itself faulty or have been installed improperly. One problem can arise with the

Magnalock. If the Senstat version is being used, the strike plate (which passes current) must be isolated from a

metal door and frame. Securitron supplies insulating hardware to accomplish this but the hardware might not have

been used or the strike may be scraping against the header for instance. Check for full isolation between the strike

and the door frame (when the door is secure) with an Ohmmeter. The presence of lock voltage potential in the

door frame can interfere with the ground reference of access control system data communication and therefore

cause a problem.

IF YOUR PROBLEM PERSISTS

CALL SECURITRON TOLL FREE

1-800-MAG-LOCK

APPENDIX B

CALCULATING WIRE GAUGE SIZING

The general practice of wire sizing in a DC circuit is to avoid causing voltage drops in connecting wires which

reduce the voltage available to operate the device. As Magnalocks are very low power devices, they can be

operated long distances from their power source. For any job that includes long wire runs, the installer must

be able to calculate the correct gauge of wire to avoid excessive voltage drops.

This is done by adding the resistance of the Magnalock to the resistance in the power wires and then dividing the

wire resistance by the total resistance. This yields the fraction of voltage drop in the wires. For example, a single

model 62 Magnalock has a resistance of 192 ohms when being operated on 24 volts. If the wires completing the

circuit between the Magnalock and its power source have a resistance of 10 ohms, the total resistance is 202

Ohms. Dividing 10 Ohms (the wire resistance) by 202 (the total resistance) yields roughly 1/20 or 5%. If the input

voltage is 24 volts, 5% of this voltage will be dropped in the wires (1.2 volts) leaving 22.8 volts to operate the

Magnalock. This will cause a small reduction in holding force but in general, will be acceptable.

To calculate the wire resistance, you need to know the distance from the power supply to the Magnalock and the

gauge (thickness) of the wire. The following chart shows wire resistance per 1000 ft (305 meters):

Wire Gauge Resistance/1,000 ft Wire Gauge Resistance/1,000 ft

8 Gauge .6 Ohms 16 Gauge 4.1 Ohms

10 Gauge 1.0 Ohms 18 Gauge 6.4 Ohms

12 Gauge 1.6 Ohms 20 Gauge 10.1 Ohms

14 Gauge 2.5 Ohms 22 Gauge 16.0 Ohms

Model 32 resistances are 160 Ohms for the 24 VDC version and 40 Ohms for the 12 VDC version.

Model 34 resistances are 136 Ohms for 24 VDC operation and 34 Ohms for 12 VDC operation.

Model 62 resistances are 192 Ohms for 24 VDC operation and 48 Ohms for 12 VDC operation.

Model 82 resistances are 136 Ohms for 24 VDC operation and 34 Ohms for 12 VDC operation.

Let's look at some other sample calculations. Suppose a single 62 Magnalock operating on 24 volts is 1200 ft from

its power supply and we're using 20 gauge wire. First, the total length of the power wires is 2400 ft. Remember

that you combine the wire lengths from the power supply to the lock and back to the pow er supply to get

the total circuit wire length. The wire resistance than becomes 2.4 X 10.1 Ohms which is 24.2 Ohms. Adding

this to the Model 62 Magnalock resistance of 192 Ohms (at 24 volts) yields a total resistance of 216.2 Ohms. 24.2

divided by 216.2 yields the percent drop in the wires which is over 11% which we would consider excessive. The

problem can be dealt with in 2 ways. You can utilize 16 gauge wire which would reduce the drop to a more

acceptable 5% range or you can provide extra voltage at the power supply. For instance, Securitron 24 V power

supplies are adjustable from 24 to 28 volts. You can therefore easily set the power supply to output 11%

overvoltage which will then deliver 24 volts at the lock. The Magnalock will accept up to 30% overvoltage without ill

effects.

Page 24

Rev. A.5, 8/03 Page- iii

Note that a Magnalock operating on 12 volts has 1/4th the resistance of a unit operating on 24 VDC. This means

that wire voltage drops are 4 times more significant in a 12 volt system than in a 24 volt system. In any job that

has wire runs long enough to be of concern, always use 24 volts. Note also that it's common to mount 2

Magnalocks on a double door and operate them as one lock (only 2 power wires). In this case, the resistance of

the pair of locks is half the resistance of a single lock.

In multiple lock jobs with a single power supply, the calculation of wiring voltage drops is more difficult. So long as

you run a separate pair of power wires to each lock, the calculation is as simple as has been described above, but

if a common power wire is used in a loop structure, the locks powered by the single loop will have an increasingly

low combined resistance so that the loop wire resistance will become more significant to the point where the locks

don't receive enough voltage. To find the combined resistance of multiple locks powered by a common wire, divide

the resistance of one lock by the number of locks. For example, eight 62 Magnalocks operating on 24 volts would

have a combined resistance of 192 divided by 8 which is only 24 Ohms. Another method is to calculate the current

in Amps in the wire and divide that into the circuit voltage. Since each 62- Magnalock operating on 24 volts draws

1/8th of an Amp, eight would draw 1 Amp. Dividing this into the same 24 volt input voltage yields a 24 Ohm

combined resistance.

In general, you have to be cautious about using common wires for loads in long distance situations unless you're

very confident about your ability to calculate the correct configuration. Bear in mind, however, that anytime you're

uncertain about the voltage drop in wiring, you can meter the voltage at the lock while it's connected and you will

be able to see if it's receiving adequate voltage. If the lock is not connected when you make this measurement, the

result will be false as the circuit will not see any lock resistance to compare to the wire resistance. You will read

the full input voltage.

APPENDIX C

CONSIDERATIONS FOR MAXIMUM PHYSICAL SECURITY

Magnalocks carries rated holding forces of 600 lbs. (275 Kg.), 1200 lbs. (550 Kg.) and 1800 lbs. (815 Kg.) for

respectively the model 32/34, 62 and 82. The figures are derived by using a calibrated hydraulic press to separate

the magnet and strike. The installer and user, however, are logically most interested in how Magnalocks perform

on a door rather than on a laboratory instrument and there are several installation and application variables that

affect the security level attained while using the Magnalock.

First, to achieve the rated holding force, the magnet face and strike plate must be clean. Even a small amount of

contamination will materially reduce the holding force. If cleaning is necessary, avoid the use of a heavy

abrasive such as steel wool which can remove the plating on the magnet face and strike. A sponge or

plastic pad such as Scotchbrite must be used.

Another requirement for maximum holding is that the strike plate must be centered on the magnet face and must

cover the magnetic core (3 bars). As is said in other parts of these instructions, the strike plate must be allowed to

swivel around the washer stack placed on the center strike mounting screw (not on the roll pins). Assuming the

magnet and strike are clean and are mounted in good alignment, the Magnalock will deliver its rated degree of

holding force on the door and the question becomes how much security does that provide on different door types?

In furnishing the answer we have to consider both the door construction and the likely type of attack.

In the case of wooden doors (other than solid hardwoods), aluminum frame glass doors, and hollow aluminum

doors, the model 32 or 34 should be employed in a “traffic control” mode. This means that a determined assault on

the door can “pop” these models open. The model 62 or model 82 Magnalock is generally stronger than the door

itself. Users have logged periodic cases of an assault destroying the door but leaving the Magnalock intact and still

holding a piece of the door. This raises the question of whether it ever makes sense to install the model 82

Magnalock on non-steel doors since the model 62 is stronger than the door. Justification for using the model 82

lies in margin for error. The greater strength of the model 82 can compensate for a dirt build-up or improper

installation and this may be warranted for the protection of critical areas. Steel clad fire doors or solid steel door