Page 1

SBC-330

User Manual

Version 1.0

Published May 2017

Copyright©2017 ASRockInd INC. All rights reserved.

1

Page 2

Version 1.0

Published May 2017

Copyright©2017 ASRockInd INC. All rights reserved.

Copyright Notice:

No part of this documentation may be reproduced, transcribed, transmitted, or

translated in any language, in any form or by any means, except duplication of

documentation by the purchaser for backup purpose, without written consent of

ASRockInd Inc.

Products and corporate names appearing in this documentation may or may not

be registered trademarks or copyrights of their respective companies, and are used

only for identication or explanation and to the owners’ benet, without intent to

infringe.

Disclaimer:

Specications and information contained in this documentation are furnished for

informational use only and subject to change without notice, and should not be

constructed as a commitment by ASRockInd. ASRockInd assumes no responsibility

for any errors or omissions that may appear in this documentation.

With respect to the contents of this documentation, ASRockInd does not provide

warranty of any kind, either expressed or implied, including but not limited to

the implied warranties or conditions of merchantability or tness for a particular

purpose.

In no event shall ASRockInd, its directors, ocers, employees, or agents be liable

for any indirect, special, incidental, or consequential damages (including damages

for loss of prots, loss of business, loss of data, interruption of business and the

like), even if ASRockInd has been advised of the possibility of such damages arising

from any defect or error in the documentation or product.

is device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that

may cause undesired operation.

CALIFORNIA, USA ONLY

e Lithium battery adopted on this motherboard contains Perchlorate, a toxic substance

controlled in Perchlorate Best Ma nagement Practices (BMP) regulations passed by the

California Legislature. When you discard the Lithium battery in California, USA, please

follow the related regulations in advance.

“Perchlorate Material-special handling may apply, see w ww.dtsc.ca.gov/hazardouswaste/

perchlorate”

ASRockInd Website: http://www.asrockind.com

2

Page 3

Contents

1 Introduction ....................................................... 5

1.1 Package Contents ......................................................... 5

1.2 Specications ................................................................. 6

1.3 Motherboard Layout ....................................................... 8

1.4 I/O Panel ........................................................................ 10

2 Installation ......................................................... 11

2.1 Screw Holes ................................................................... 11

2.2 Pre-installation Precautions ........................................... 11

2.3 Installation of Memory Modules (SO-DIMM) .................. 12

2.4 Expansion Slots (mini-PCIe and mini-PCIe/mini-SATA

Slots) .............................................................................. 13

2.5 Jumpers Setup ............................................................... 14

2.6 Onboard Headers and Connectors ................................ 16

3 UEFI SETUP UTILITY ......................................... 21

3.1 Introduction .................................................................... 21

3.1.1 UEFI Menu Bar ............................................................ 21

3.1.2 Navigation Keys ........................................................... 22

3.2 Main Screen ................................................................... 22

3.3 Advanced Screen ........................................................... 23

3.3.1 CPU Conguration ....................................................... 24

3.3.2 Chipset Conguration .................................................. 26

3.3.3 Storage Conguration .................................................. 28

3.3.4 AMT Conguration ....................................................... 29

3.3.5 Super IO Conguration ................................................ 31

3.3.6 ACPI Conguration ...................................................... 32

3.3.7 USB Conguration ....................................................... 33

3.3.8 Trusted Computing ...................................................... 34

3.4 Hardware Health Event Monitoring Screen ................... 35

3.5 Security Screen ............................................................. 36

3.6 Boot Screen ................................................................... 37

3.7 Exit Screen .................................................................... 39

3

Page 4

4 Software Support .............................................. 40

4.1 Install Operating System ................................................ 40

4.2 Support CD Information ................................................. 40

4.2.1 Running Support CD .................................................... 40

4.2.2 Drivers Menu ............................................................... 40

4.2.3 Utilities Menu ............................................................... 40

4.2.4 Contact Information ..................................................... 40

4

Page 5

Chapter 1: Introduction

Thank you for purchasing ASRockInd SBC-330 motherboard, a reliable mother-

board produced under ASRockInd’s consistently stringent quality control. It delivers

excellent performance with robust design conforming to ASRockInd’s commitment

to quality and endurance.

In this manual, chapter 1 and 2 contain introduction of the motherboard and step-

by-step guide to the hardware installation. Chapter 3 and 4 contain the conguration

guide to BIOS setup and information of the Support CD.

Because the motherboard specications and the BIOS software might be

updated, the content of this manual will be subject to change without no-

tice. In case any modications of this manual occur, the updated version

will be available on ASRockInd website without further notice. You may

nd the latest VGA cards and CPU support lists on ASRockInd website

as well. ASRockInd website http://www.asrockind.com

If you require technical support related to this motherboard, please visit

our website for specic information about the model you are using.

www.asrockind.com/support/index.asp

1.1 Package Contents

ASRockInd SBC-330 Motherboard

(3.5” SBC (5.8-in x 4.0-in) / (146 x 102 mm))

ASRockInd SBC-330 Driver CD

ASRockInd SBC-330 Jumper Setting Instruction

5

Page 6

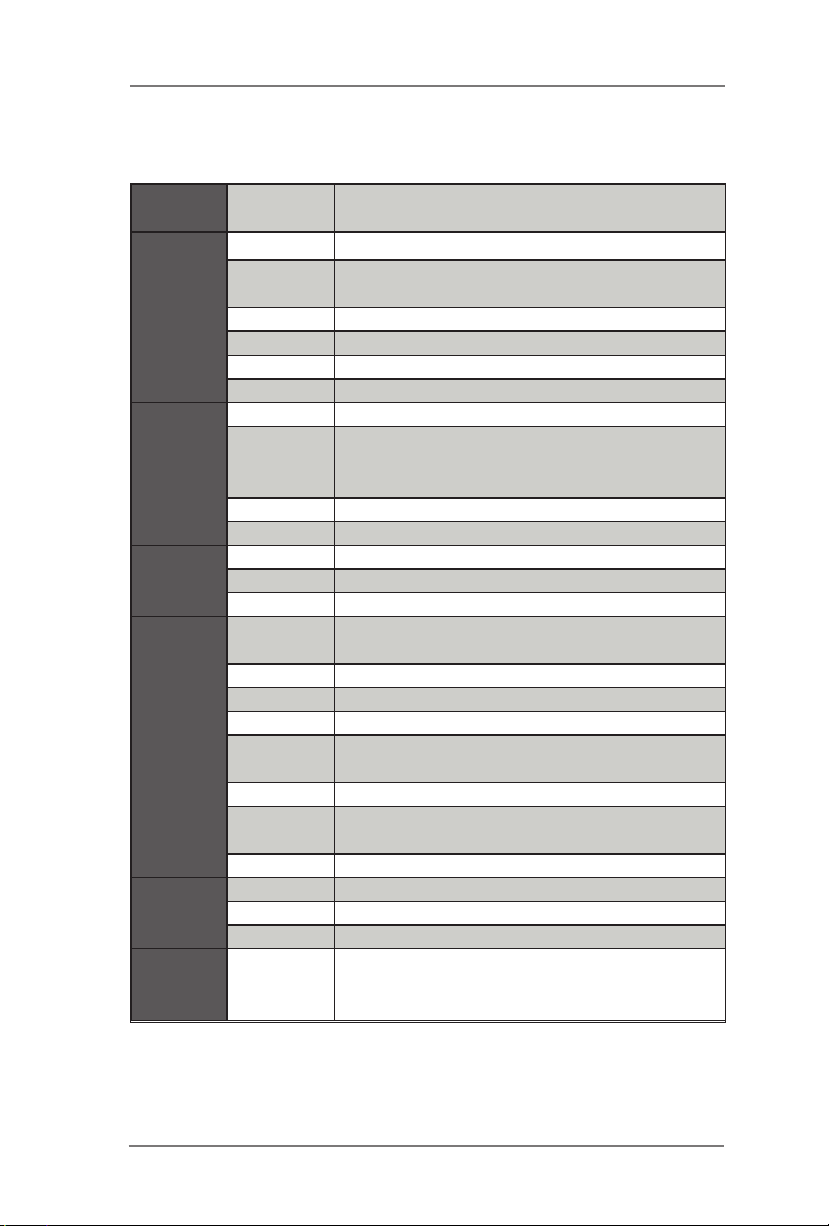

1.2 Specications

Form

Factor

Processor

System

Expansion

Slot

Memory

Graphics

Ethernet

SATA

Dimensions 3.5” SBC (5.8-in x 4.0-in) / (146 x 102 mm)

CPU BGA1356 for Intel® Skylake-U SoC

Core

Number

Max Speed (By CPU)

L3 Cache (By CPU)

Chipset (By CPU)

BIOS

PCI 0

Mini-PCIe

mSATA 1

M.2 0

Technology Dual Channel DDR4 2133 MHz

Max. 32GB

Socket 2 x SO-DIMM

Controller

VRAM Shared Memory

VGA 0

DVI 0

LVDS

HDMI 0

DisplayPort

Multi Display Yes (Triple Display)

Interface 10/100/1000 Mbps

Controller 1 x Intel® I219-LM/V, 1 x Intel® I211AT

Connector 2 x RJ-45

Max Data

Transfer

Rate

(By CPU, Max 4)

UEFI

1 x mini-PCIe (half/full/ size, PCIex1 + USB2.0),

1 x mini-PCIe (full size, shared with SATA +

USB2.0)

Intel® Gen9 Intel® Graphics DX 11/12,

OGL4.3/4.4

Supports max resolution up to 1920 x

1200@60Hz @60Hz

DP1.2 Supports max resolution up to 4096 x

2160@60Hz

SATA3 (6.0Gb/s)

6

Page 7

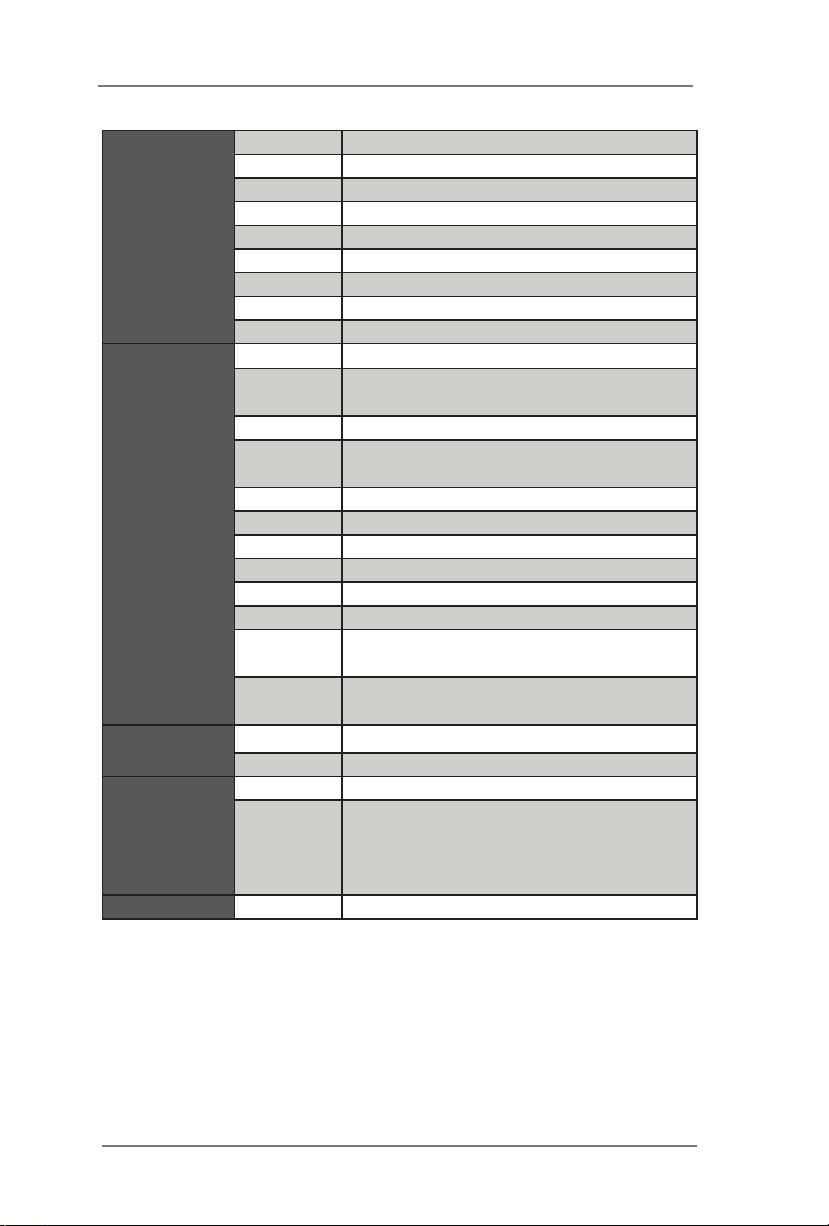

VGA 0

DVI 0

HDMI 0

DisplayPort 2 x DP1.2

Rear I/O

Internal

Connector

Watchdog

Timer

Power

Requirements

Environment Temperature 0ºC – 60ºC

Ethernet 2

USB 4 x USB3.0

Audio 0

Serial 0

PS/2 0

USB 4 x USB 2.0 (2 x 2.54 pitch header)

LVDS/

Inverter

VGA 0

Serial

SATA 2 x SATA3 (6.0Gb/s)

mPCIe 0

Parallel 0

mSATA 0

IrDA 0

GPIO 8-bit 4 x GPI + 4 x GPO

SATA PWR

Output Con

Speaker

Header

Output Output from super I/O to drag RESETCON#

Interval 256 Segments, 0,1,2…255 Sec/Min

Input PWR Input 12V-36V phone jack DC-In

Power On

1/1

4 x 2.0 pitch header RS-232 (COM1 support

RS-232/422/485)

1

0

AT/ATX Supported

AT: Directly PWR on as power input ready

ATX: Press button to PWR on after power

input ready

7

Page 8

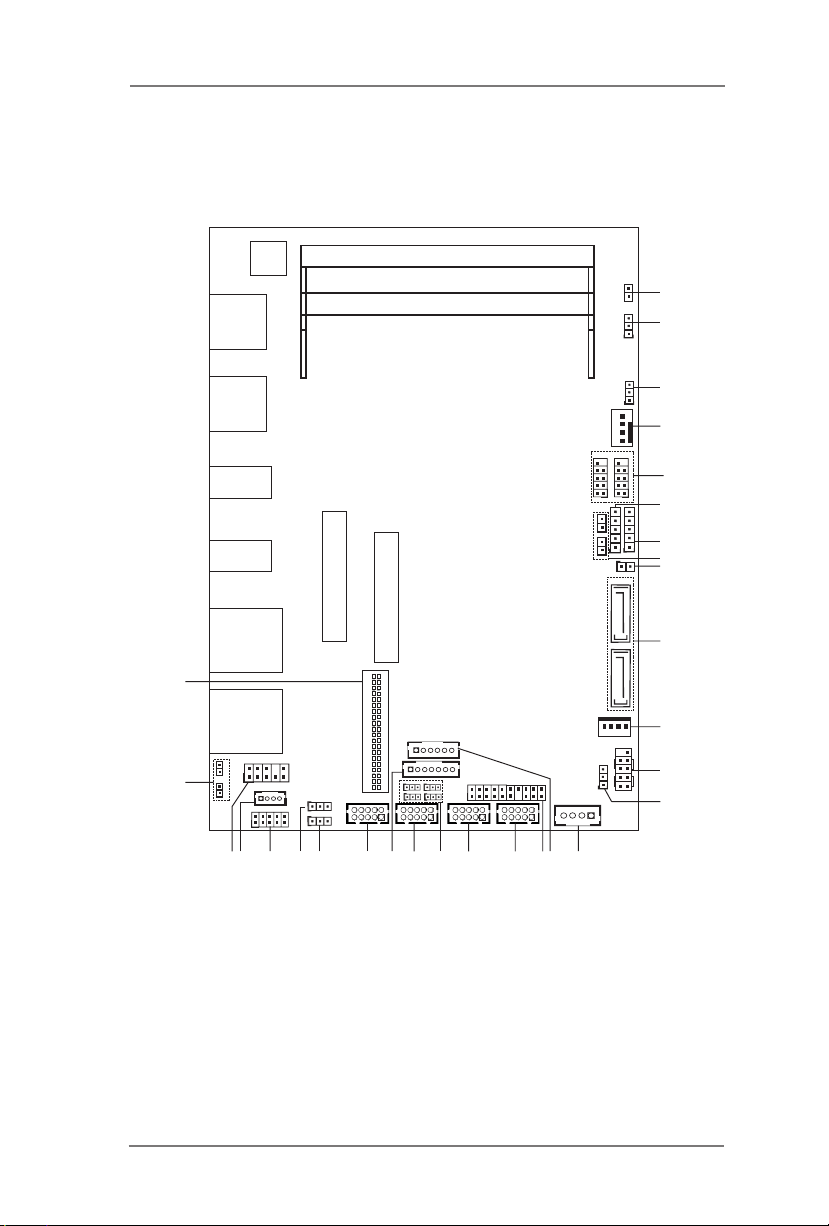

1

JGPIO1

mi ni - PC Ie

1

LPC1

SPEAKER1

1

LAN1

DP2

1

BLT_VOL1

HDLED RESE T

PLED P WRBTN

PANEL1

1

mi n i - PC I e / mi ni- SATA

SATA_PWR1

LVDS1

1

1

BLT_PWR1

USB 3.0

T: US B2

B: USB1

COM1

COM2 COM3 C OM4

JGPIO_PWR1

1

CLRMOS1

1

1

USB2_5_6

BUZZ1

1

1

BKT_PWR1

1

PNL_PWR1

1

SATA3_1

SATA3_2

USB 3.0

T: US B4

B: USB3

DP1

LAN2

CI2

1

MSATA_SEL1

1

1

USB2_7_8

DC_IN1

PWR_JP1

1

JGPIO_SET1

1

1

HD_AUD IO1

DDR4 _A 1 (Suppor t D DR4 Only)

DDR4 _B 1 (Suppor t D DR4 Only)

CI1

1

BL1

1

Bl2

1

PWR_COM1

1

PWR_COM2

1

PWR_COM4

1

PWR_COM3

1

CLRMOS1

1

1.3 Motherboard Layout

BIO S

Chi p

29

1

2

3

4

CPU_FAN 1

5

6

7

8

9

10

28

18

27

26

23

25

21

2224

19

20

8

17

16

1415

11

12

13

Page 9

1 : 2-Pin Buzzer Header

2 : Clear CMOS Header

3 :

mSATA Select

4 :

4-Pin CPU FAN Connector (+12V)

5 :

USB2.0 Headers (USB2_5_6, USB2_7_8)

6

: Backlight Power Select

7

: Panel Power Selection (LCD_VCC) (PNL_PWR1)

8 : BL1, BL2

9 : Clear CMOS Header (CLRMOS1)

10 : SATA3 Connectors (SATA3_1, SATA3_2)

1

1 : SATA Power Output Connector

12 :

System Panel Header

13 : ATX/AT Mode Select (PWR_JP1)

14 : ATX Power Connector (Input 12V-36V)

15 : Inverter Power Control Wafer (BLT_PWR1)

16 : LPC Header

17 : COM Port Header (COM4)

18 : COM Port Header (COM3)

19 : COM Port Pin9 PWR Setting Jumpers

PWR_COM1 (For COM Port1)

PWR_COM2 (For COM Port2)

PWR_COM3 (For COM Port3)

PWR_COM4 (For COM Port4)

20 : COM Port Header (COM2)

21 : Backlight & Amp Volume Control

22 : COM Port Header (COM1)

23

: GPIO Default Setting (JGPIO_SET1)

24 : Digital Input / Output Power Select (JGPIO_PWR1)

25 : Digital Input / Output Pin Header (JGPIO1)

26 : 3W Audio AMP Output Wafer

27 :

Front Panel Audio Header

2

8 : Chassis Intrusion Headers

29 : LVDS Panel Connector

(LCD_BLT_VCC)

(BLT_VOL1)

(CI1, CI2)

(BKT_PWR1)

9

Page 10

1.4 I/O Panel

1

1 USB 3.0 Ports (USB12)

2 USB 3.0 Ports (USB34)

3 DisplayPort 1.2 (DP2)

* There are two LED next to the LAN port. Please refer to the table below for the LAN port LED

indications.

Activity/Link LED SPEED LED

Status Description Status Description

LAN Port LED Indications

3

2 4

4 DisplayPort 1.2 (DP1)

5 LAN RJ-45 Port (LAN1)*

6 LAN RJ-45 Port (LAN2)*

5

ACT/LINK

LED

6

SPEED

LED

Off No Link Off 10Mbps connection

Blinking Data Activity Off 100Mbps connection

On Link Green 1Gbps connection

LAN Port

10

Page 11

Chapter 2: Installation

This is a 3.5” SBC (5.8-in x 4.0-in) form factor (146 x 102 mm) motherboard. Before

you install the motherboard, study the conguration of your chassis to ensure that

the motherboard ts into it.

motherboard. Failure to do so may cause physical injuries to you and

damages to motherboard components.

Make sure to unplug the power cord before installing or removing the

2.1 Screw Holes

Place screws into the holes to secure the motherboard to the chassis.

Do not over-tighten the screws! Doing so may damage the motherboard.

2.2 Pre-installation Precautions

Take note of the following precautions before you install motherboard components

or change any motherboard settings.

1. Unplug the power cord from the wall socket before touching any component.

2. To avoid damaging the motherboard components due to static electricity,

NEVER place your motherboard directly on the carpet or the like. Also

remember to use a grounded wrist strap or touch a safety grounded object

before you handle components.

3. Hold components by the edges and do not touch the ICs.

4. Whenever you uninstall any component, place it on a grounded antistatic pad or

in the bag that comes with the component.

Before you install or remove any component, ensure that the power is

switched off or the power cord is detached from the power supply.

Failure to do so may cause severe damage to the motherboard, peripherals,

and/or components.

11

Page 12

2.3 Installation of Memory Modules (SO-DIMM)

SBC-330 provides two 204-pin DDR4 (Double Data Rate 4) SO-DIMM slots.

Step 1. Align a SO-DIMM on the slot such that the notch on the SO-DIMM

matches the break on the slot.

1. The SO-DIMM only ts in one correct orientation. It will cause permanent damage

to the motherboard and the SO-DIMM if you force the SO-DIMM into the slot at

incorrect orientation.

2. Please do not intermix different voltage SO-DIMMs on this motherboard.

Step 2. Firmly insert the SO-DIMM into the slot until the retaining clips at both

ends fully snap back in place and the SO-DIMM is properly seated.

12

Page 13

2.4 Expansion Slots (mini-PCIe and mini-PCIe/mini-SATA

Slots)

There is 1 mini-PCIe slot and 1 mini-PCIe/mini-SATA slot on this motherboard.

mini-PCIe slot:

MINI_PCIE1 (mini-PCIe slot; full size) is used for PCI Express mini

cards.

mini-PCIe/mini-SATA slot:

MINI_SATA1 (mini-PCIe/mini-SATA slot; full size) is used for PCI Ex-

press mini cards or mSATA cards.

Installing an expansion card

Step 1. Before installing the expansion card, please make sure that the power

supply is switched off or the power cord is unplugged. Please read the

documentation of the expansion card and make necessary hardware

settings for the card before you start the installation.

Step 2. Remove the system unit cover (if your motherboard is already installed

in a chassis).

Step 3. Remove the bracket facing the slot that you intend to use. Keep the

screws for later use.

Step 4. Align the card connector with the slot and press rmly until the card is

completely seated on the slot.

Step 5. Fasten the card to the chassis with screws.

Step 6. Replace the system cover.

13

Page 14

2.5 Jumpers Setup

The i llust rat io n shows h ow jum pers a re

setup. When the jumper cap is placed on

pins, the jumper is “Short”. If no jumper cap

is placed on pins, the jumper is “Open”. The

illustration show s a 3-pin jum pe r w hose

pin1 and pin2 are “Short” when jumper cap

is placed on these 2 pins.

Clear CMOS Jumper

(CLRMOS1)

(see p.8, No. 2)

Note: CLRMOS1 allows you to clear the data in CMOS. To clear and reset the

system parameters to default setup, please turn off the computer and unplug

the power cord from the power supply. After waiting for 15 seconds, use a

jumper cap to short pin2 and pin3 on CLRMOS1 for 5 seconds. However,

please do not clear the CMOS right after you update the BIOS. If you need

to clear the CMOS when you just nish updating the BIOS, you must boot up

the system rst, and then shut it down before you do the clear-CMOS action.

Please be noted that the password, date, time, user default prole and MAC

address will be cleared only if the CMOS battery is removed.

Digital Input/Output Power Select 1-2: +12V

(3-pin JGPIO_PWR1)

(see p.8 No. 24)

2-3: +5V

Clear CMOSDefault

ATX/AT Mode Select

(3-pin PWR_JP1)

(see p.8 No. 13)

1-2: AT Mode

2-3: ATX Mode

Panel Power Select (LCD_VCC) Use this to set up the VDD

(5-pin PNL_PWR1)

(see p.8 No. 7)

power of the LVDS connector.

1-2: +3V

2-3: +5V

3-4: +5V

4-5: +12V

14

Page 15

Backlight Power Select Use this to set up the backlight

(LCD_BLT_VCC) power of the LVDS connector.

(5-pin BKT_PWR1)

(see p.8 No. 6)

1-2: +5V

2-3: +12V

3-4: +12V

4-5: DC_IN Power

COM1 Pin9 PWR Setting Jumpers 1-2: +5V

(3-pin PWR_COM1)

(3-pin PWR_COM2)

(3-pin PWR_COM3)

(3-pin PWR_COM4)

(see p.8 No. 19)

2-3: +12V

mSATA Select 1-2: mini-PCIe

(3-pin MSATA_SEL1)

(see p.8 No. 3)

2-3: mSATA

GPIO Default Setting 1-2: Pull-High

(3-pin JGPIO_SET1)

(see p.8 No. 23)

2-3: Pull-Low

Clear CMOS Header Open: Normal

(2-pin CLRMOS1)

(see p.8 No. 9)

Short : Auto Clear CMOS When

AC Power On

1

15

Page 16

2.6 Onboard Headers and Connectors

Onboard headers and connectors are NOT jumpers. Do NOT place

jumper caps over these headers and connectors. Placing jumper caps

over the headers and connectors will cause permanent damage of the

motherboard!

SATA3 Connectors These two Serial ATA3

(SATA3_1, SATA3_2: see p.8, No. 10)

SATA data cables for internal

storage devices. The current

SATA3 interface allows up to

6.0 Gb/s data transfer rate.

SATA3_2

(SATA3) connectors support

SATA3_1

USB 2.0 Headers There are two USB 2.0

(9-pin USB2_5_6, USB2_7_8)

(see p.8 No. 5)

System Panel Header This header accommodates

(9-pin PANEL1)

(see p.8 No. 12)

several system front panel

functions.

DUM MY

headers on this motherboard.

GND GN D

USB _PW R

GND

PWR BTN #

PLE D-

PLE D+

+A

+B

-A

-B

USB _PW R

1

GND

RES ET#

GND

HDL ED-

HDL ED+

1

Connect the power switch, reset switch and system status indicator on the

chassis to this header according to the pin assignments below. Note the

positive and negative pins before connecting the cables.

PWRBTN (Power Switch):

Connect to the power switch on the chassis front panel. You may congure

the way to turn off your system using the power switch.

RESET (Reset Switch):

Connect to the reset switch on the chassis front panel. Press the reset

switch to restart the computer if the computer freezes and fails to perform a

normal restart.

PLED (System Power LED):

Connect to the power status indicator on the chassis front panel. The LED

is on when the system is operating. The LED keeps blinking when the sys-

tem is in S1 sleep state. The LED is off when the system is in S3/S4 sleep

state or powered off (S5).

16

Page 17

HDLED (Hard Drive Activity LED):

FAN_ S PEE D

FAN_ S PEE D_C ONT ROL

+12 V

GND

1

2

3

4

Connect to the hard drive activity LED on the chassis front panel. The LED

is on when the hard drive is reading or writing data.

The front panel design may differ by chassis. A front panel module mainly

consists of power switch, reset switch, power LED, hard drive activity LED,

speaker and etc. When connecting your chassis front panel module to this

header, make sure the wire assignments and the pin assign-ments are

matched correctly.

3W Audio AMP Output Wafer

(4-pin SPEAKER1)

(see p.8 No. 26)

1

PIN Signal Name

1 SPK L-

2 SPK L+

3 SPK R+

4 SPK R-

CPU Fan Connector Please connect the fan cable

(4-pin CPU_FAN1)

(see p.8 No. 4)

to the fan connector and

match the black wire to the

ground pin.

ATX Power Connector (Input 12V-36V) Please connect a DC power

(4-pin ATX12V1)

(see p.8 No. 14)

supply (Input 12V-36V)

to this connector.

1-4 : GND

2-3 : DC Input

SATA Power Output Connector

(4-pin SATA_PWR1)

(see p.8 No. 11)

Inverter Power Control Wafer

(6-pin BLT_PWR1)

(see p.8 No. 15)

1

+12 V

GND

1

+5V

GND

PIN Signal Name

1 GND

2 GND

3 CON_LBKLT_CTL

4 CON_LBKLT_EN

5 LCD_BLT_VCC

6 LCD_BLT_VCC

17

Page 18

COM Port Headers

(10-pin COM1)

(see p.8 No. 22)

2

(10-pin COM2)

(see p.8 No. 20)

(10-pin COM3)

(see p.8 No. 18)

(10-pin COM4)

(see p.8 No. 17)

PIN

10

9

Signal

Name

DUMMY

DUMMY

PIN

8

7

1

Signal

Name

CCTS#

RRTS#

PIN

6

5

Signal

Name

DDSR#

GND

PIN

Signal

Name

DDTR#

4

TTXD

3

PIN

2

1

Signal

Name

RRXD

DDCD#

This motherboard supports RS232/422/485 on COM1 port. Please refer to

below table for the pin denition. In addition, COM1 port (RS232/422/485) can

be adjusted in BIOS setup utility > Advanced Screen > Super IO Conguration. You

may refer to page 31 for details.

COM1 Port Pin Denition

PIN RS232 RS422 RS485

1 DCD TX- RTX-

2 RXD RX+ N/A

3 TXD TX+ RTX+

4 DTR RX- N/A

5 GND GND GND

6 DSR N/A N/A

7 RTS N/A N/A

8 CTS N/A N/A

9 NA/+5V/+12V N/A N/A

Buzzer Header

(2-pin BUZZ1)

(see p.8 No. 1)

SPK R

+5V

1

Chassis Intrusion Headers This motherboard supports

(2-pin CI1, CI2)

(see p.8 No. 28)

CASE OPEN detection feature

that detects if the chassis cover

GND

Sig nal

1

has been removed. This feature

requires a chassis with chassis

intrusion detection design.

18

Page 19

LVDS Connector

(40-pin LVDS1)

2

1

(see p.8 No. 29)

39

40

PIN Signal Name PIN Signal Name

2 LCD_VCC 1 LCD_VCC

4 LDDC_CLK 3 +3.3V

6 LVDS_A_DATA0# 5 LDDC_DATA

8 GND 7 LVDS_A_DATA0

10 LVDS_A_DATA1 9 LVDS_A_DATA1#

12 LVDS_A_DATA2# 11 GND

14 GND 13 LVDS_A_DATA2

16 LVDS_A_DATA3 15 LVDS_A_DATA3#

18 LVDS_A_CLK# 17 GND

20 GND 19 LVDS_A_CLK

22 LVDS_B_DATA0 21 LVDS_B_DATA0#

24 LVDS_B_DATA1# 23 GND

26 GND 25 LVDS_B_DATA1

28 LVDS_B_DATA2 27 LVDS_B_DATA2#

30 LVDS_B_DATA3# 29 DPLVDD_EN

32 GND 31 LVDS_B_DATA3

34 LVDS_B_CLK 33 LVDS_B_CLK#

36 CON_LBKLT_EN 35 GND

38 LCD_BLT_VCC 37 CON_LBKLT_CTL

40 LCD_BLT_VCC 39 LCD_BLT_VCC

Digital Input/Output Pin Header

(10-pin JGPIO1)

(see p.8 No. 25)

PIN Signal Name PIN Signal Name

1 SIO_GP34 2 SIO_GP30

3 SIO_GP35 4 SIO_GP31

5 SIO_GP36 6 SIO_GP32

7 SIO_GP37 8 SIO_GP33

9 JGPIO_PWR 10 GND

Parameter Range

GPI/O input Low Voltage Max. 0.8V

GPI/O input High Voltage Min. 2.0V

GPI/O output Low Voltage Max. 0.4V

GPI/O output High Voltage Min. 2.4V

Note:

Max. load per GPI/O pin : 12mA

Current Max. 1A per power pin.

Front Panel Audio Header

(9-pin HD_AUDIO1)

(see p.8 No. 27)

1

GND

PRE SEN CE#

MIC 2_R

MIC 2_L

MIC _RE T

J_S ENS E

OUT 2_R

OUT _RE T

OUT 2_L

19

Page 20

Backlight & Amp Volume Control

(7-pin BLT_VOL1)

(see p.8 No. 21)

PIN Signal Name

1 GPIO_VOL_UP

1

2 GPIO_VOL_DW

3 PWRDN

4 GPIO_BLT_UP

5 GPIO_BLT_DW

6 GND

7 GND

LPC Header This connector supports

(19-pin LPC1)

(see p.8 No. 16)

Trusted Platform Module (TPM)

system, which can securely

SMB_ DAT A_MA IN

SMB_ CLK _MAI N

GND

S_PW RDW N#

SERI RQ#

LAD2

LAD1

48MH z

GND

GND

store keys, digital certicates,

passwords, and data. A TPM

system also helps enhance

1

LAD3

PCIR ST#

LAD0

FRAM E

PCIC LK

+3V

+5V

GND

+3VS B

network security, protects

digital identities, and ensures

platform integrity.

BL1, BL2 Headers

(2-pin BL1, BL2)

(see p.8 No. 8)

1

20

Page 21

Chapter 3: UEFI SETUP UTILITY

3.1 Introduction

This section explains how to use the UEFI SETUP UTILITY to congure your

system. The UEFI chip on the motherboard stores the UEFI SETUP UTILITY. You

may run the UEFI SETUP UTILITY when you start up the computer. Please press

<F2> or <Del> during the Power-On-Self-Test (POST) to enter the UEFI SETUP

UTILITY, otherwise, POST will continue with its test routines.

If you wish to enter the UEFI SETUP UTILITY after POST, restart the system by

pressing <Ctl> + <Alt> + <Delete>, or by pressing the reset button on the system

chassis. You may also restart by turning the system off and then back on.

Because the UEFI software is constantly being updated, the

following UEFI setup screens and descriptions are for reference

purpose only, and they may not exactly match what you see on

your screen.

3.1.1 UEFI Menu Bar

The top of the screen has a menu bar with the following selections:

Main To set up the system time/date information

Advanced To set up the advanced UEFI features

H/W Monitor To display current hardware status

Security To set up the security features

Boot To set up the default system device to locate and load the

Operating System

Exit To exit the current screen or the UEFI SETUP UTILITY

Use < > key or < > key to choose among the selections on the menu

bar, and then press <Enter> to get into the sub screen. You can also use the

mouse to click your required item.

21

Page 22

3.1.2 Navigation Keys

Please check the following table for the function description of each navigation

key.

Navigation Key(s) Function Description

/ Moves cursor left or right to select Screens

/ Moves cursor up or down to select items

+ / - To change option for the selected items

<Enter> To bring up the selected screen

<F1> To display the General Help Screen

<F7> Discard changes

<F9> To load optimal default values for all the settings

<F10> To save changes and exit the UEFI SETUP UTILITY

<F12> Print screen

<ESC> To jump to the Exit Screen or exit the current screen

3.2 Main Screen

When you enter the UEFI SETUP UTILITY, the Main screen will appear and display

the system overview.

22

Page 23

3.3 Advanced Screen

In this section, you may set the congurations for the following items: CPU Congu-

ration, Chipset Conguration, Storage Conguration, AMT Conguration, Super IO

Conguration, ACPI Conguration, USB Conguration and Trusted Computing.

Setting wrong values in this section may cause

the system to malfunction.

Instant Flash

Instant Flash is a UEFI ash utility embedded in Flash ROM. This conve-

nient UEFI update tool allows you to update system UEFI without entering

operating systems rst like MS-DOS or Windows®. Just launch this tool

and save the new UEFI le to your USB ash drive, oppy disk or hard

drive, then you can update your UEFI only in a few clicks without prepar-

ing an additional oppy diskette or other complicated ash utility. Please

be noted that the USB ash drive or hard drive must use FAT32/16/12 le

system. If you execute Instant Flash utility, the utility will show the UEFI

les and their respective information. Select the proper UEFI le to update

your UEFI, and reboot your system after UEFI update process completes.

23

Page 24

3.3.1 CPU Conguration

Intel Hyper Threading Technology

To enable this feature, a computer system with an Intel processor that sup-

ports Hyper-Threading technology and an operating system that includes

optimization for this technology, such as Microsoft® Windows® 7 / 8 / 8.1 /

10 is required. Set to [Enabled] if using Microsoft® Windows® 7, 8, 8.1, 10

or Linux kernel version 2.4.18 or higher. This option will be hidden if the

installed CPU does not support Hyper-Threading technology.

Active Processor Cores

Select the number of cores to enable in each processor package.

CPU C States Support

Enable CPU C States Support for power saving. It is recommended to

keep C3, C6 and C7 all enabled for better power saving.

Enhanced Halt State (C1E)

Enable Enhanced Halt State (C1E) for lower power consumption.

CPU C3 State Support

Enable C3 sleep state for lower power consumption.

CPU C6 State Support

Enable C6 deep sleep state for lower power consumption.

CPU C7 State Support

Enable C7 deep sleep state for lower power consumption.

Package C State Support

Enable CPU, PCIe, Memory, Graphics C State Support for power saving.

Intel SpeedStep Technology

Intel SpeedStep technology is Intel’s new power saving technology. Pro-

cessors can switch between multiple frequencies and voltage points to en-

able power saving. The default value is [Enabled]. Conguration options:

24

Page 25

[Enabled] and [Disabled]. If you install Windows® 7 / 8 / 8.1 / 10 and want

to enable this function, please set this item to [Enabled]. This item will be

hidden if the current CPU does not support Intel SpeedStep technology.

Please note that enabling this function may reduce CPU voltage and lead to system

stability or compatibility issues with some power supplies. Please set this item to

[Disabled] if above issues occur.

Intel Turbo Boost Technology

Use this item to enable or disable Intel Turbo Boost Mode Technology.

Turbo Boost Mode allows processor cores to run faster than marked fre-

quency in specic conditions. The default value is [Enabled].

CPU Thermal Throttling

You may select [Enabled] to enable CPU internal thermal control

mechanism to keep the CPU from overheating.

No-Execute Memory Protection

No-Execution (NX) Memory Protection Technology is an enhancement

to the IA-32 Intel Architecture. An IA-32 processor with “No Execute (NX)

Memory Protection” can prevent data pages from being used by malicious

software to execute codes. This option will be hidden if the current CPU

does not support No-Excute Memory Protection.

Intel Virtualization Technology

When this option is set to [Enabled], a VMM (Virtual Machine Architecture)

can utilize the additional hardware capabilities provided by Vanderpool

Technology. This option will be hidden if the installed CPU does not

support Intel Virtualization Technology.

Hardware Prefetcher

Use this item to turn on/off the MLC streamer prefetcher.

Adjacent Cache Line Prefetch

Use this item to turn on/off prefetching of adjacent cache lines.

SW Guard Extensions (SGX)

Intel SGX is a set of new CPU instructions that can be used by applica-

tions to set aside private regions of code and data.

25

Page 26

3.3.2 Chipset Conguration

Top of Lower usable DRAM

Set the maximum value of TOLUD. Set this item to Dynamic to allow

TOLUD to adjust automatically based on the largest MMIO length of the

installed graphic controller.

VT-d

Use this to enable or disable Intel® VT-d technology (Intel® Virtualization

Technology for Directed I/O). The default value of this feature is [Disabled].

Share Memory

Congure the size of memory that is allocated to the integrated graphics

processor when the system boots up.

Onboard LAN1

This allows you to enable or disable the Onboard LAN1 feature.

Onboard LAN2

This allows you to enable or disable the Onboard LAN2 feature.

Onboard HD Audio

Select [Auto], [Enabled] or [Disabled] for the onboard HD Audio feature. If

you select [Auto], the onboard HD Audio will be disabled when PCI Sound

Card is plugged.

Front Panel

Select [HD] or [AC 97] for the onboard HD Audio Front Panel.

Deep Sleep

Mobile platforms support Deep S4/S5 in DC only and desktop platforms

support Deep S4/S5 in AC only. The default value is [Disabled].

26

Page 27

Active LVDS

Use this to enable or disable the LVDS. The default value is [Disabled].

Set the item to [enable]. Then press <F10> to save the setting and restart

the system. Now the default value of Active LVDS is changed to ENABLE

(F9 load default is also set to ENABLE)

Change the setting from [Enable] to [Disable], and then press <F10> to

save the setting and restart the system. Likewise, the default value of Ac-

tive LVDS is changed to DISABLE (F9 load default is also set to DISABLE)

Panel Type Selection

Use this to select panel type. This item appears when you enable Active

LVDS.

The default values of Active LVDS and Panel Type Selec-

tionwill be changed only when the users manually adjust

them. They will keep at the default values no matter you clear

CMOS, use Instant Flash or press <F9>.

Primary IGFX Boot Display

Use this to select primary internal graphics boot display. The default value

is [VBIOS Default].

27

Page 28

3.3.3 Storage Conguration

SATA Controller(s)

Use this item to enable or disable the SATA Controller feature.

SATA Mode Selection

Use this to select SATA mode. The default value is [AHCI Mode].

AHCI (Advanced Host Controller Interface) supports NCQ

and other new features that will improve SATA disk perfor-

mance but IDE mode does not have these advantages.

SATA Aggressive Link Power Management

Use this item to congure SATA Aggressive Link Power Management.

Hard Disk S.M.A.R.T.

Use this item to enable or disable the S.M.A.R.T. (Self-Monitoring, Analy-

sis, and Reporting Technology) feature. Conguration options: [Disabled]

and [Enabled].

28

Page 29

3.3.4 AMT Technology

Intel AMT

Use this to enable or disable Intel(R) Active Management Technology

BIOS Extension. The default is [Enabled].

BIOS Hotkey Pressed

Use this to enable or disable BIOS hotkey press. The default is [Disabled].

MEBx Selection Screen

Use this to enable or disable MEBx Selection Screen. The default is [Dis-

abled].

Hide Un-Congure ME Conrmation

Hide Un-Congure ME without password conrmation prompt. The default

is [Disabled].

MEBx Debug Message Output

Use this to enable or disable MEBx Debug Message Output. The default is

[Disabled].

Un-Congure ME

Un-Congure ME without password. The default is [Disabled].

Amt Wait Timer

Set timer to wait before sending ASF_GET_BOOT_OPTIONS.

ASF

Use this to enable or disable Alert Specication Format. The default is [En-

abled].

Activate Remote Assistance Process

Trigger CIRA boot. The default is [Disabled].

USB Congure

Use this to enable or disable USB Congure function. The default is

[Enabled].

29

Page 30

PET Progress

User can enable or disable PET Events progress to receive PET events or

not. The default is [Enabled].

30

Page 31

3.3.5 Super IO Conguration

COM1 Conguration

Use this to set parameters of COM1. Select COM1 port type: [RS232],

[RS422] or [RS485].

COM2 Conguration

Use this to set parameters of COM2.

COM3 Conguration

Use this to set parameters of COM3.

COM4 Conguration

Use this to set parameters of COM4.

Watchdog Conguration

Use this to set the Watch Dog Timer.

31

Page 32

3.3.6 ACPI Conguration

Suspend to RAM

Use this item to select whether to auto-detect or disable the Suspend-to-

RAM feature. Select [Auto] will enable this feature if the OS supports it.

ACPI HPET Table

Use this item to enable or disable ACPI HPET Table. The default value is

[Enabled]. Please set this option to [Enabled] if you plan to use this

motherboard to submit Windows® certication.

PCIE Devices Power On

Use this item to enable or disable PCIE devices to turn on the system from

the power-soft-off mode.

RTC Alarm Power On

Use this item to enable or disable RTC (Real Time Clock) to power on the

system.

32

Page 33

3.3.7 USB Conguration

Legacy USB Support

Use this option to select legacy support for USB devices. There are four

conguration options: [Enabled], [Auto] and [UEFI Setup Only]. The default

value is [Enabled]. Please refer to below descriptions for the details of

these four options:

[Enabled] - Enables support for legacy USB.

[Auto] - Enables legacy support if USB devices are connected.

[UEFI Setup Only] - USB devices are allowed to use only under UEFI

setup and Windows / Linux OS.

PS/2 Simulator

Enable this item for the complete USB keyboard legacy support for

non-USB aware operating system.

33

Page 34

3.3.8 Trusted Computing

Security Device Support

Enable or disable BIOS support for security device.

34

Page 35

3.4 Hardware Health Event Monitoring Screen

In this section, it allows you to monitor the status of the hardware on your system,

including the parameters of the CPU temperature, motherboard temperature, CPU

fan speed, chassis fan speed, and the critical voltage.

CPU_FAN1 Setting

This allows you to set CPU fan 1’s speed. Conguration options: [Full On]

and [Automatic Mode]. The default value is [Full On].

Case Open Feature

This allows you to enable or disable case open detection feature. The

default is value [Disabled].

Clear Status

This option appears only when the case open has been detected. Use this

option to keep or clear the record of previous chassis intrusion status.

Over Temperature Protection

Use this to enable or disable Over Temperature Protection. The default

value is [Enabled].

35

Page 36

3.5 Security Screen

In this section, you may set, change or clear the supervisor/user password for the

system.

Supervisor Password

Set or change the password for the administrator account. Only the ad-

ministrator has authority to change the settings in the UEFI Setup Utility.

Leave it blank and press enter to remove the password.

User Password

Set or change the password for the user account. Users are unable to

change the settings in the UEFI Setup Utility. Leave it blank and press en-

ter to remove the password.

Secure Boot

Enable to support Windows 8.1 / 8 Secure Boot.

Intel(R) Platform Trust Technology

Enable/disable Intel PTT in ME. Disable this option to use discrete TPM

Module.

36

Page 37

3.6 Boot Screen

In this section, it will display the available devices on your system for you to cong-

ure the boot settings and the boot priority.

Boot From Onboard LAN

Use this item to enable or disable the Boot From Onboard LAN feature.

Setup Prompt Timeout

Thi s s hows the numb er of seconds to wait for setup a ctivation ke y.

65535(0XFFFF) means indenite waiting.

Bootup Num-Lock

If this item is set to [On], it will automatically activate the Numeric Lock

function after boot-up.

Boot Beep

Sele ct whether the B oot Beep should be tur ned on or off whe n t he

system boots up. Please note that a buzzer is needed.

Full Screen Logo

Use this item to enable or disable OEM Logo. The default value is [Enabled].

37

Page 38

CSM (Compatibility Support Module)

CSM

Enable to launch the Compatibility Support Module. Please do not disable

unless you’re running a WHCK test. If you are using Windows® 8.1 / 8 64-

bit and all of your devices support UEFI, you may also disable CSM for

faster boot speed.

Launch PXE OpROM Policy

Select UEFI only to run those that support UEFI option ROM only. Select

Legacy only to run those that support legacy option ROM only. Select Do

not launch to not execute both legacy and UEFI option ROM.

Launch Storage OpROM Policy

Select UEFI only to run those that support UEFI option ROM only. Select

Legacy only to run those that support legacy option ROM only. Select Do

not launch to not execute both legacy and UEFI option ROM.

Launch Video OpROM Policy

Select UEFI only to run those that support UEFI option ROM only. Select

Legacy only to run those that support legacy option ROM only. Select Do

not launch to not execute both legacy and UEFI option ROM.

38

Page 39

3.7 Exit Screen

Save Changes and Exit

When you select this option, it will pop-out the following message, “Save

conguration changes and exit setup?” Select [OK] to save the changes

and exit the UEFI SETUP UTILITY.

Discard Changes and Exit

When you select this option, it will pop-out the following message, “Discard

changes and exit setup?” Select [OK] to exit the UEFI SETUP UTILITY

without saving any changes.

Discard Changes

When you select this option, it will pop-out the following message, “Discard

changes?” Select [OK] to discard all changes.

Load UEFI Defaults

Load UEFI default values for all the setup questions. F9 key can be used

for this operation.

Launch EFI Shell from lesystem device

Attempts to Launch EFI Shell application (Shell64.efi) from one of the

available lesystem devices.

39

Page 40

Chapter 4: Software Support

4.1 Install Operating System

This motherboard supports various Microsoft® Windows® operating systems: 10 / 10

64-bit / 8.1 / 8.1 64-bit / 8 / 8 64-bit / 7 / 7 64-bit. Because motherboard settings and

hardware options vary, use the setup procedures in this chapter for general refer-

ence only. Refer your OS documentation for more information.

4.2 Support CD Information

The Support CD that came with the motherboard contains necessary drivers and

useful utilities that enhance the motherboard’s features.

4.2.1 Running The Support CD

To begin using the support CD, insert the CD into your CD-ROM drive. The

CD automatically displays the Main Menu if “AUTORUN” is enabled in your

computer. If the Main Menu did not appear automatically, locate and double

click on the le “ASRSETUP.EXE” from the BIN folder in the Support CD to

display the menus.

4.2.2 Drivers Menu

The Drivers Menu shows the available device’s drivers if the system detects

installed devices. Please install the necessary drivers to activate the devices.

4.2.3 Utilities Menu

The Utilities Menu shows the application software that the motherboard sup-

ports. Click on a specic item then follow the installation wizard to install it.

4.2.4 Contact Information

If you need to contact ASRockInd or want to know more about ASRockInd,

you’re welcome to visit ASRockInd’s website at http://www.asrockind.com; or

you may contact your dealer for further information.

40

Loading...

Loading...