Page 1

Service manual

Washing Machine Top Loader

Page 2

Page 3

THE TOP LOADING WASHING MACHINE

Technical Training

1 - INTRODUCTION ............................................................................................................................... 5

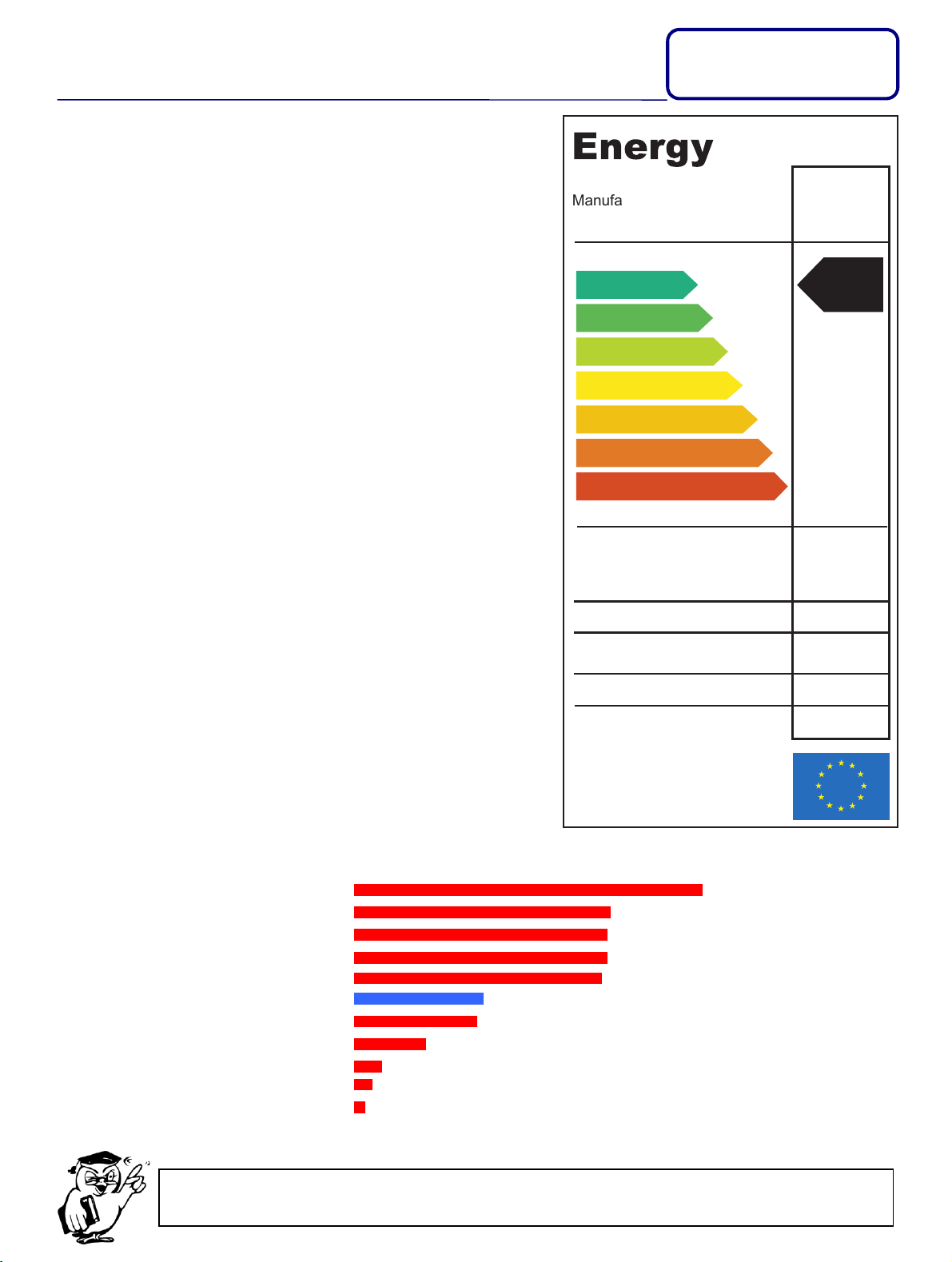

2 - THE ENERGY LABEL ....................................................................................................................... 7

2.1. - What you must know ..................................................................................................................... 7

2.2. - Consumption level of the main appliances..................................................................................... 7

3 - THE WASHING MACHINE................................................................................................................ 8

3.1. - Operating principle ........................................................................................................................ 8

4 - THE WATER ..................................................................................................................................... 9

4.1. - The noxious effects of limestone ...................................................................................................9

4.2. - The effects of too soft a water ....................................................................................................... 9

5 - THE DETERGENTS ........................................................................................................................ 10

5.1. - Washing is removing the dirt ....................................................................................................... 10

5.2. - How to choose the washing detergent ? ...................................................................................... 10

CONTENTS

6 - THE LAUNDRY ............................................................................................................................... 11

6.1. - The various fibres........................................................................................................................ 11

6.2. - The sensitivity of fibres................................................................................................................ 11

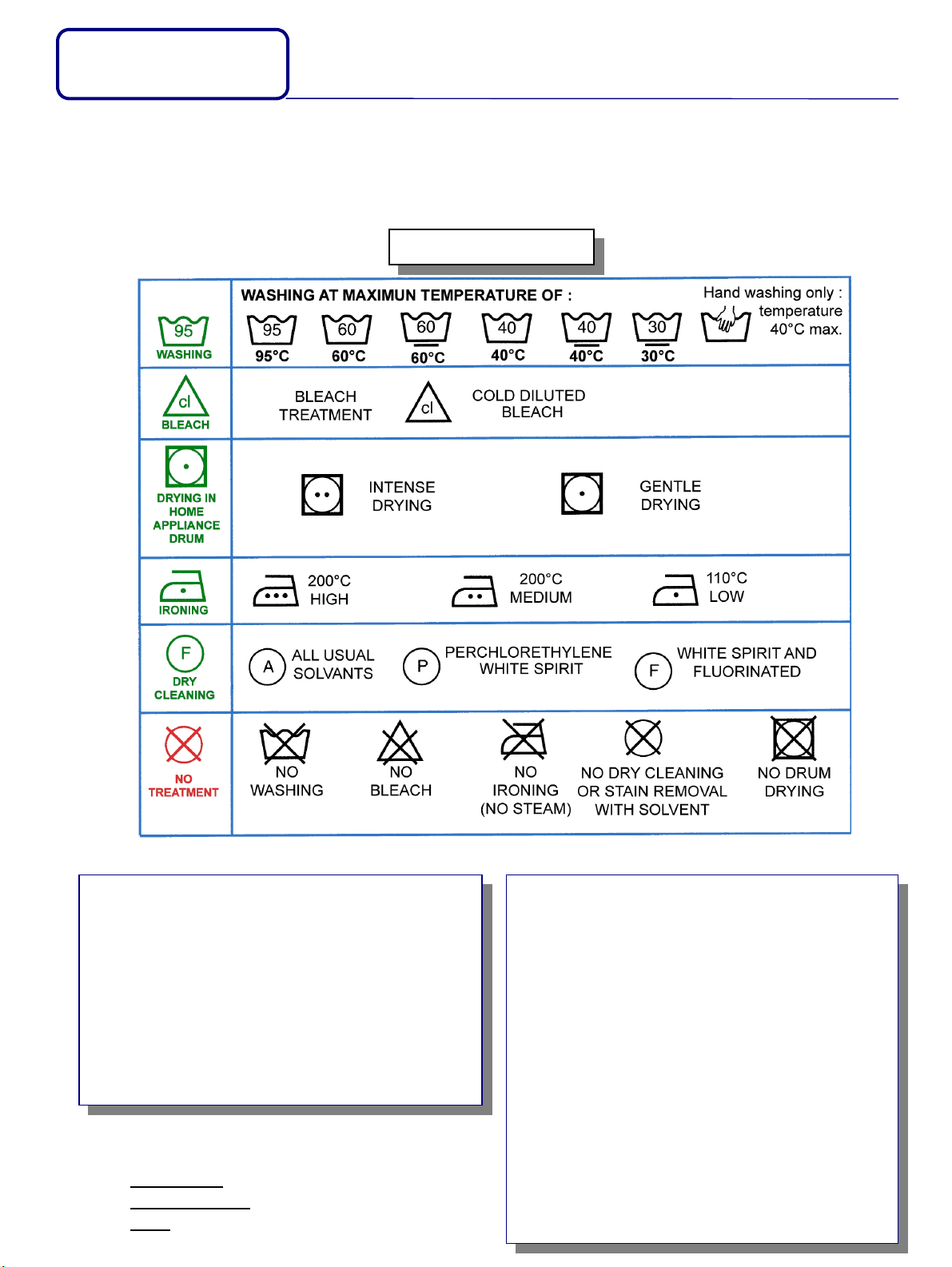

6.3. - Wash and laundry load symbols .................................................................................................. 12

7 - INSTALLATION............................................................................................................................... 13

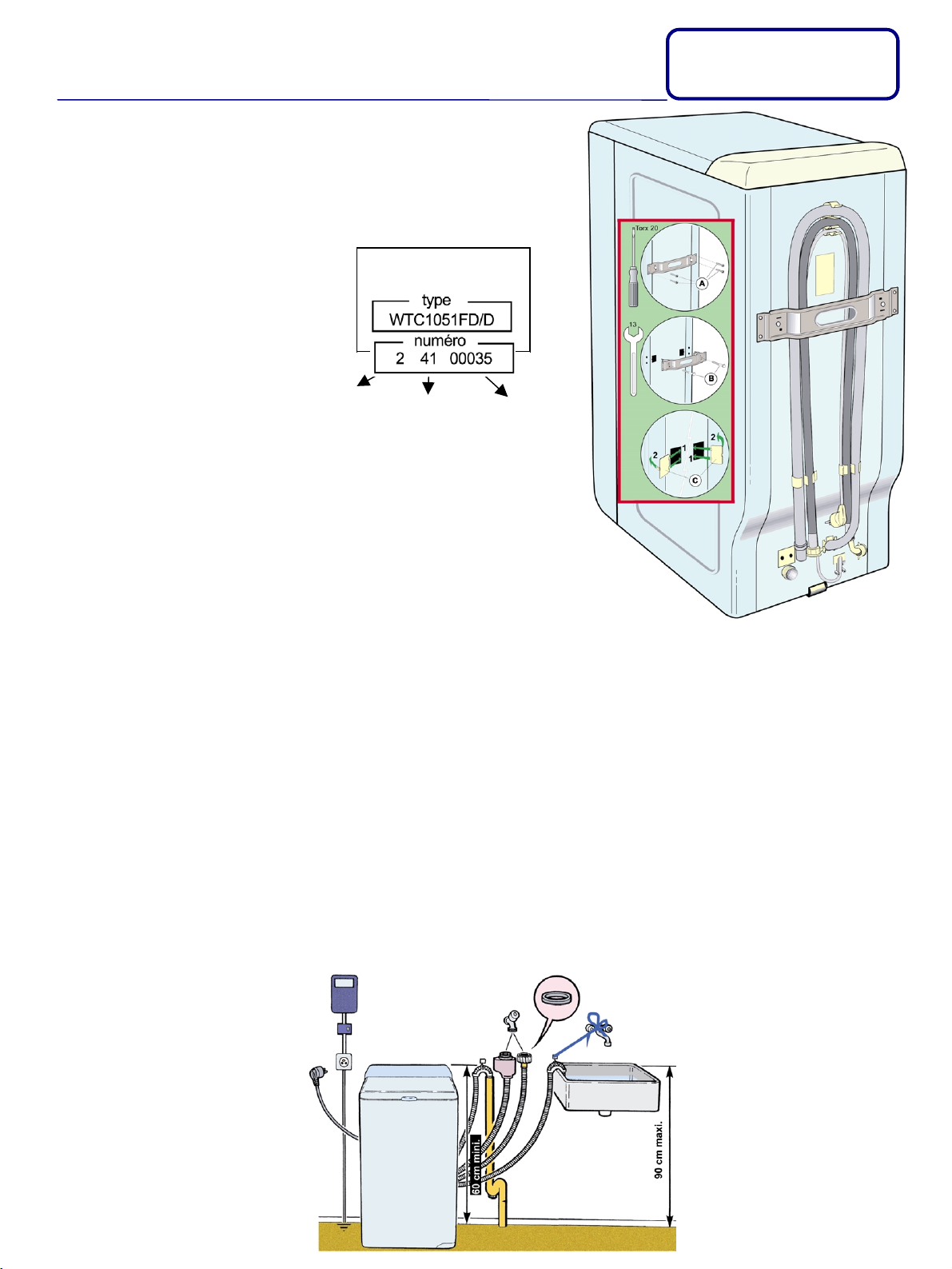

7.1. - Identification of the reference ...................................................................................................... 13

7.2. - Unclamping ................................................................................................................................. 13

7.3. - Levelling...................................................................................................................................... 13

7.4. - Electrical connection.................................................................................................................... 13

7.5. - Water supply ............................................................................................................................... 13

7.6. - Draining....................................................................................................................................... 13

8 - THE NEW TOP LOADING WASHING MACHINE ........................................................................... 14

8.1. - Presentation ................................................................................................................................ 14

8.2. - Aided drum opening .................................................................................................................... 15

8.3 - The water recirculation ................................................................................................................ 15

8.4. - Filter cleaning.............................................................................................................................. 15

8.5. - The different components............................................................................................................ 16

8.6. - P1B Programming ....................................................................................................................... 21

8.7. - P2ASIC Programming ................................................................................................................. 23

8.8. - The “Full Electronic” programming............................................................................................... 32

8.9. - The “Full electronic” electronic board........................................................................................... 42

Page 4

Page 5

THE TOP LOADING WASHING MACHINE

Technical Training

INTRODUCTION

1 - INTRODUCTION

The objective is simple : the matter is to make the dirty laundry clean. The quantity, nature, dirt level of

the laundry, the cleaning product used, or even the water hardness may act against the expected

result.

So far, all these parameters have been left to the assessment of the consumer, who alone assumed

the responsibility for poor wash. Increasingly, the new washing machines consider all these factors and

adapt :

The mixing duration in wash

•

The quantity of water and the number of rinses

•

The spin duration

•

The new top loading washing machine provides reduction in water, energy consumption, and cycle

times while assuring A level in wash.

To perform the washing machine maintenance, the technician has to identify the cause(s) at the origin

of the consumer's claim. To do so, he/she has to make a precise diagnostic in order to adopt the

appropriate for the encountered problem.

The new top loading washing machine proposes a programme of aid to diagnostic intended for the

after-sales department. Only the rigorous and systematic implementation of this programme can

definitely assure the action reliability.

A properly performed after-sales action should favour the development of customer’s loyalty to the

sales outlet, to the sign and also to the trademark concerned.

Page 6

Page 7

THE TOP LOADING WASHING MACHINE

Technical Training

2 - THE ENERGY LABEL

Energy

ENERGY

Washing

machine

2.1. - What you must know

Washing machine, dryer and dishwasher are three

appliances likely to weigh heavy on the electricity invoice if

you choose model poorly classified from the energetic

point of view. Washing machine and dishwasher each

consume about 250 kWh a year. For a few years, the

manufacturers have made efforts on the water

consumption, which has a direct effect on the power

consumption at the moment of the heating.

Initiated by the European Community, this labelling is now

compulsory in France for most household electrical

appliances. The classification from A (the most

economical) to G (the most avid on electricity), enables

the consumer to locate at a glance, the various models

proposed. For washing machines, an additional indication

concerning the wash and spin, complements the

information concerning the power consumed.

This mention must appear compulsorily on all the washing

machines marketed from the 1

st

of January 1999.

Manufacturer

Model

More efficient

A

B

C

D

Less efficient

Energy consumption

kWh/cycle

(based on standard test results

for 60 C cotton cycle)

Actual energy consumption will

depend on how the appliance is used

Washing performance

A: higher G: lower

Spin drying performance

A: higher G: lower

Spin speed (rpm)

Capacity (cotton) kg

Water consumption

Noise

(dB(A) re 1 pW)

Further information is contained

in product brochures

E

F

G

Washing

Spinning

LOGO

A B C

1 2 3

A

0.95

A

BCDEFG

ABCDEFG

1300

5.0

42

xx

xx

2.2. - Consumption level of the main appliances

Freezer

Refrigerator

Dryer

Hotplate

Dishwasher

Washing machine

Electrical oven

Television set

Microwave oven

Iron

Vacuum cleaner

A good use of the deferred start you to benefit by off-peak periods

and, therefore, to save electricity.

Norm EN 60456

Washing machine label Directive 95/12/EC

Page 8

THE WASHING

MACHINE

THE TOP LOADING WASHING MACHINE

Technical Training

3 - THE WASHING MACHINE

3.1. - Operating principle

Dirt adheres the textile fibres with some energy to be overcome in order to get rid of it. It is, therefore,

necessary to implement the following parameters :

The mechanical action

¾

The role of the mechanical action is to make the water loaded with detergent product circulate between

laundry fibres in order to enable dirt to be detached and carried away. This

action depends on the stirring duration and rotation rate and speed (from 35

to 50 rpm), and on the water level in the tank.

The thermal action

¾

Some fibres are to be washed at maximum temperatures not to be exceeded

if you want to obtain good results. Moreover, the action of the various

components of detergent products vary according to the temperature. For this

purpose, the washing bath will be heated progressively, so that each of these

components is more efficient.

The chemical action

¾

To the mechanical and thermal energy of the machine are added the

detergent physical-chemical and biological actions. The nature of dirt is most

varied. Each of the kinds of dirt is eliminated in a specific way. This is the

reason why washing products contain from 8 to 15 different components.

So, it is advisable to act on the washing conditions in order to facilitate the

quick removal of the various matters.

The duration.

¾

Everything is not so simple. If we detail the operation, then we notice that an essential element is

missing: the Water. In fact, without water, there is no wash. Water is primordial; with the support of the

active principles of the washing product, it will penetrate the depths of the laundry to destroy, extract,

dissolve and emulsify the dirt present on and within the laundry. It will do it all the best that the machine

will mix the laundry and heat the water.

The wash result depends thus on 4 factors simultaneously :

•

The washing product

•

The water

•

The temperature

•

The mechanics

These factors are interrelated. If you decrease the dose of washing product for example, then it will be

necessary to increase either the mixing (mechanical action and duration), or the temperature (thermal

action), or the volume of water. A good wash result can only be obtained if all these conditions are

respected.

The role of the drum is to make the water circulate

washing product

between the laundry fibres in order to enable dirt to be detached and carried away.

(chemical action)

and heated progressively

(mechanical action)

(thermal action)

loaded with

,

Page 9

THE TOP LOADING WASHING MACHINE

Technical Training

THE WATER

4 - THE WATER

The water covers, in the nature, a cycle due to its continuous evaporation under the action of the sun

heat; this vapour is condensed into fine droplets to produce clouds, which are transformed into rain

when they meet a cold air draft.

It is possible to assert practically that this is from the moment where the rain starts falling that it begins

to lose its purity. Actually, during its fall, the rain meets in the atmosphere a certain number of

impurities of variable nature, among which carbon gas with which it is combined to make up very

slightly acid soft water.

This water, when it arrives on earth, flows by streaming and infiltrates the cracks to reach the

groundwater tables and artesian tables that feed sources and wells. In both cases, this water dissolves

and carries with it a part of the mineral salts it meets (limestone, magnesium, etc.); this is this last

process, which causes its mineralisation. The more the water is mineralised, the

The water hardness is expressed in degrees TH.

3

1 French degree TH corresponds to 10 mg of CO

Ca per litre of water.

harder

it is !

From 0° to 5° TH very soft water

From 5° to 15° TH soft water

From 15° to 30° TH half-hard water

From 30° to 45° TH hard water

More than 45° TH very soft water

The value can be expressed in TH or DH (German) : 1° DH = 1.78° TH

4.1. - The noxious effects of limestone

Any water contains traces of minerals, mainly limestone, magnesium and iron originating from the

ground. The higher the content is, the harder the water is. These minerals reinforce the dirt catch to

fabric fibres, and the eliminated one tends to be fastened again to them. Limestone reduces the

efficiency of the washing product, makes the laundry rough, makes whites turn grey, fades colours and

accelerates the laundry wear.

4.2. - The effects of too soft a water

Too soft a water also reduces the washing efficiency (reduction in mechanical action), causes foam

overflows, leaks and accelerates the appliance ageing (the water is more aggressive).

Page 10

THE DETERGENTS

5 - THE DETERGENTS

5.1. - Washing is removing the dirt

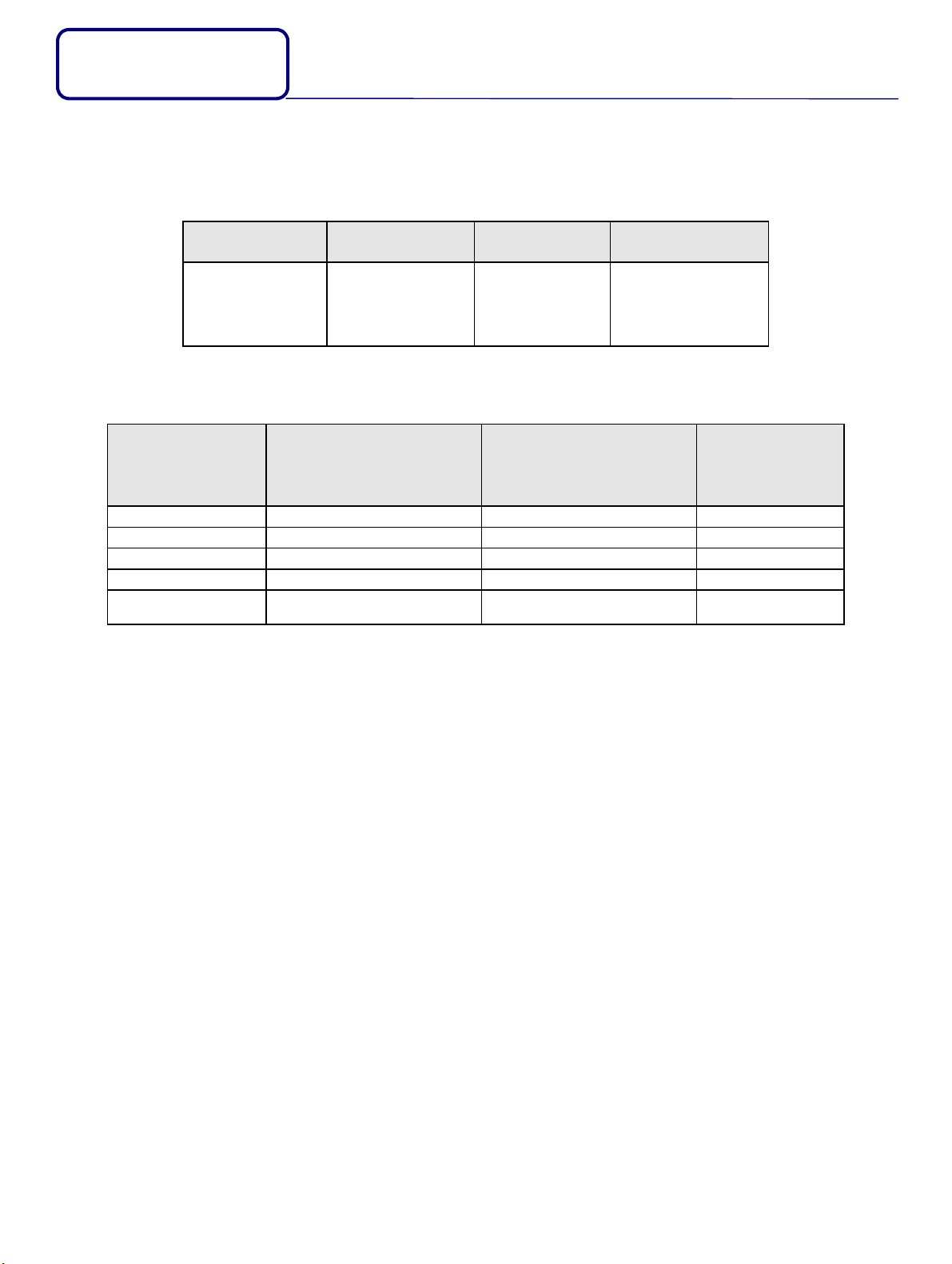

Pigmentary dirt Washable dirt Proteinic dirt Grease dirt

THE TOP LOADING WASHING MACHINE

Technical Training

Skin cells, Dust,

Soot, Earth, Sand,

Vegetal debris,

Pollen

Coffee, Tea, Wine,

Beer, Fruit,

Vegetables, Grass

Blood, Eggs, Meat,

Fish

Food or industry oils,

Butter, Margarine,

Lard, Mayonnaise,

Animal or human

greases

5.2. - How to choose the washing detergent ?

Which washing

product for

which laundry ?

Standard powder

Micro powder

Tabs

Liquid

Dedicated washing

products

Contrary to many received ideas, all the washing products are not identical. They contain specific

ingredients. Several types of product may not be used for washing :

The powders

¾

Efficient on most dirt and at any temperatures. They contain whitening agents and optical brightness.

So-called "standard" powders and concentrated powders exist.

The tabs

¾

The dosage easiness explains certainly the development of their market share (15% two years after

their launch). In fact, they are compacted powder. Manufacturers recommend from one to three tabs

according to the water hardness and the laundry dirt level. They are to be placed either directly before

placing the laundry, or in the supplied small net, in the middle of the laundry. They are not to be placed

in the product compartments. The dissolution time may vary from 10 seconds to more than 10 minutes.

The liquids

¾

They ensure perfect dissolving from the lowest temperatures. Liquid washing products make the stain

pre-treatment easier and they never contain whitening agents.

The liquid washing product in dose

¾

This is a dose of concentrated liquid washing product, which does not dissolve entirely during the

wash. It is to be placed in the bottom of the drum before the laundry. It shall not be placed in the

product compartments.

The dedicated products

¾

Specifically formulated washing products exist to take care of delicate fibres and delicate coloureds.

Free of whitening agent, these washing products contain fibre and colour protecting agents. These

products exist as "standard" or concentrated powders or liquids.

The softeners

¾

These are comfort additives. Such products have no effect on the wash performance. Using softener

on the last rinse is used to obtain soft and agreeable laundry, and prevents the generation of static

electricity.

The chlorine (bleach)

¾

Chlorinated product may not be used for white or colourfast cotton articles.

Whites, household

laundry, very resistant

cotton, very dirty

laundry

90°C - 60°C 40°C

60°C 40°C

60°C 40°C

Fast colours, blended

cotton, normally dirty

laundry

40°C 30°C

Delicate fibres

machine-

washable

30°C

Page 11

THE TOP LOADING WASHING MACHINE

Technical Training

THE LAUNDRY

6 - THE LAUNDRY

6.1. - The various fibres

The laundry is today composed of a very large variety of textile fibres, each of them requiring an

appropriate wash reacting differently to water, temperature, and also to the mechanical action.

NATURAL FIBRES ARTIFICIAL FIBRES SYNTHETIC FIBRES

Animal :

Vegetal :

Mineral :

Wool and Silk

Cotton, Linen and Jute

Asbestos

Viscose Polyamide, Nylon and Perlon

Cellulose acetate Polyester, Tergal, Dacron

Cellulose triacetate Polyacrylic, Courtelle, Dralon

6.2. - The sensitivity of fibres

Fragility is more related to the ennoblement than to the matter.

•

Dyeing

•

Printing

•

Finish

Natural absorbing fibres that may retain natural colouring

Cotton, Linen

Wool, Silk

Viscose, Rayon, Acetate

agents (coffee, wine, tea, fruit, …). Persistence of stains if

washed too cold. Creases and turns yellow by light.

Delicate natural fibres, difficult to dye, sensitive to oxidizers,

alkaline agents and friction (felting, shrinkage of wool).

Artificial cellulose fibres more delicate than cotton wool with

the same defects.

Chlorofibre, Rhovyl

Elastomer, Lycra

Polypropylene, Meraklon

Polyester, Polyamide

Acrylic, Chlorofibre

Synthetic fibres resistant but sensitive to grease stains.

Synthetic fibres very sensitive to heat. Do not exceed 40°C.

Page 12

THE LAUNDRY

Technical Training

6.3. - Wash and laundry load symbols

It is necessary to sort the laundry and respect the load to obtain the best results, and wash in complete

safety. To do so, it is needed to read the labels providing all the information necessary for looking after

textiles.

THE COFREET*

THE TOP LOADING WASHING MACHINE

*

Registered trademark

Average weight of a few pieces of dry

« thick » laundry

Adult’s jeans....................................800g / 1kg

Large terry towel ..................................... 700g

Quilt cover............................................. 1500g

Adult’s jogging trousers ........................... 350g

Bathrobe ............................................... 1200g

Small terry towel...................................... 300g

Child’s terry pyjamas............................... 100g

Sweat-shirt.............................................. 250g

The maximum loads recommended are :

¾

•

Cotton wool : 5 kg of dry laundry

•

Synthetic fabric : 2.5 kg of dry laundry

•

Wool : 1 kg of dry laundry

Average weight of a few pieces of dry

« little thick » laundry

Sock ................................................................ 20g

Light night-dress............................................ 150g

Man’s shirt ..................................................... 200g

Sheet, 1 person...................................... 400/500g

Sheet, 2 persons ........................................... 800g

Delicate underwear ......................................... 50g

Child’s synthetic knits ...................................... 50g

Tablecloth...................................................... 100g

Adult’s cloth trousers ..................................... 500g

Child’s cloth trousers ..................................... 120g

Adult’s pyjamas ............................................

150g

Pillowcase .............................................200g

Dish towel..............................................130g

Large-size cotton tee shirt .....................150g

Page 13

THE TOP LOADING WASHING MACHINE

Technical Training

7 - INSTALLATION

7.1. - Identification of the reference

The rating plate is stuck on rear panel. The serial number is

also stuck on the back of the products dispenser.

TRADEMARK

INSTALLATION

L’INSTALLATION

7.2. - Unclamping

•

Unscrew the 4 torx n°20 screw maintaining the transversal

(A)

bar

•

Unscrew the two screws n°13 blocking the tank

•

Fill in the holes the prevent noise

Year Week Number of order

(B)

(C)

7.3. - Levelling

As the machine is setting on 3 points, the ground must be

horizontal. If it is on wall to wall carpeting, the air flow must be

correct. The maximum difference between right and left mustn’t

be more than 1 cm, and mustn’t be more than 1,5 cm between

the front and the back.

7.4. - Electrical connection

Use a plug with a ground, easy to reach and protected by a 16A fuse. Never use an extension cord or

an adapter. In a bathroom, the machine must be 60cm away from a water arrival. The installation must

respect the standards of the country.

7.5. - Water supply

Machines with two valves can be supplied with hot water (maximum 60°C), which reduces the heating

duration and the cycle duration ( about 15 minutes). This option is interesting if the water is cheap.

7.6. - Draining

The draining pipe must be tied so that it doesn’t move. If the installation is not equipped with ventilated

U-bend, the joining mustn’t be air-proof. Let the air flow between the pipe and the draining hose (inside

diameter : minimum 34 mm).

Page 14

THE RANGE

Technical Training

8 - THE NEW TOP LOADING WASHING MACHINE

8.1. - Presentation

The electromechanical programming P1B

¾

•

Programmes : Cotton, Colours / Synthetics and Delicate / Wool

•

Asynchronous motor and 500 rpm spin

•

Thermostat adjustable from cold to 90°C or chronometric heating

•

Options : 1/2 load, Full Tank Stop, and draining

The electromechanical programming P2 ASIC

¾

•

Programmes : Cotton, Colours / Synthetics and Delicate / Wool

•

Universal motor piloted by board P2Asic. Fixed spin, two-speed button or for speed adjustable

from 100 (Draining) to 1000 rpm

•

Thermostat adjustable from cold to 90°C or chronometric heating

•

Options : Rinse +, 1/2 load, Full Tank Stop and pendulous wool

•

C.V.A

•

THE TOP LOADING WASHING MACHINE

Positioned drum stop (

The "all electronic" programming level L0

¾

•

A switch to select laundry nature and wash temperature

•

A multi-led display and three buttons for

-

the start deferred

-

the options: freshness

-

the spin

•

3 leds for the cycle run (wash, rinse and spin)

•

A button

The "Full electronic" programming level L1

¾

•

A switch to select laundry nature and wash temperature

•

A display and 4 buttons for

-

the spin

-

the deferred start

-

the time left

-

the options prewash

-

the options: freshness

•

3 leds for the cycle run (wash, rinse and spin)

•

A button

The "Full electronic" programming level L4

¾

•

A Hi-Fi type encoder and 9 leds to select the programme

•

A display and 6 buttons for

-

the options : Intensive, Eco and Freshness

-

the options : Prewash and Rinse +

-

the temperature

-

the spin

-

display of the time left

-

the deferred start adjustable from 1 to 19 hours by pressing

•

5 leds for the cycle run (Prewash, Wash, Rinse, Spin and Stop)

•

A button

•

3 leds to warn :

-

‘cock closed'

-

‘child safety activated’

-

‘excess foam’

, draining at 100 rpm or Full Tank Stop.

to select "Start", "Pause", or cancel the cycle

. Adjust the speed or select F.T.S. and draining (100 rpm) with

to select "Start", "Pause", or cancel the cycle

from 1300 rpm to F.T.S.. via draining (100)

to select "Start", "Pause", or cancel the cycle

by 3, 6 or 9h

surfliss

adjustable from 1 to 19 hours by pressing

during cycle

and rinse +

surfliss

from cold to 90°C

(control locking / unlocking by simultaneous pressure on and )

(in this case, the spin stops, the tank is drained and then the cycle resumes,

adapting rates and spins, and adding a rinse)

•

A buzzer (signals the end of a cycle with freshness

)

, prewash and rinse +

, Eco and Intensive

surfliss

surfliss

+/-

+/-

stop

for 10 minutes)

+/-

.

Page 15

THE TOP LOADING WASHING MACHINE

Technical Training

8.2. - Aided drum opening

Brakes, assembled to ends of door pivots, are used to provide the

consumer with smooth and non-aggressive door opening that remains

rapid (< 2 seconds).

This option called is not fitted to all the models.

8.3. - The water recirculation

THE RANGE

A recirculation pump equips "all electronic" programming, which improves the laundry moistening,

decreases (or even eliminates) detergent losses and increases washing performances. The water is

pumped, filtered (only one tank filter for draining and recirculation) and sprayed onto laundry through

the tank and drum (perforated around its shaft). The recirculation is used at the beginning of cycle

(during the cold mixing) to increase the laundry impregnation by the detergent bath, and then after

heating, to improve washing performances, and lastly during rinses, to decrease the water

consumption.

8.4. - Filter cleaning

For efficient recirculation, the tank filter of "all electronic" machines shall be cleaned every 100 washes.

The electronics signals the moment where this operation shall be performed :

•

2 spin LEDs slowly flash on L0 :

•

"Filt" flashes slowly on the display for L1 and L4 :

A long pressure on "Start/Pause

display

cleaning information will be displayed at the end of each cycle until the reinitialisation.

It is also impossible to reinitialise the counter before the expiration of the 100 cycles.

. The user can restart a cycle without having reinitialised the counter; in this case, the

" reinitialises the cycle counter and restores the normal completion

Replace the

2

filter

1

3

4

Reinitialize the

cycle counter

5

Page 16

THE COMPONENTS

8.5. - The different components

Designation Function Characteristics

THE TOP LOADING WASHING MACHINE

Technical Training

Water valve

Products dispenser

Used to fill the washing machine and

acquire the products.

The products dispenser is compatible

with:

•

Standard powder

•

Standard liquid

or

(never pre-wash with liquid washing

product)

Other types of concentrated washing

product, in tabs or in doses shall not be

put in.

(concentrated softener or bleach shall be

diluted)

•

220/240 V~

•

•

•

•

Ω

3,75 K

1 way

8 l/mn

Water feed pressure : 1 to 10 bar

4 compartments :

•

Pre-wash I (powder only)

•

•

•

II

Wash

Bleach

Softener

(powder or liquid)

Compartment filling through back

distributor washing product evacuation by

front overflow.

Box removable and dismountable for

cleaning product compartments and

softener and chlorine siphons.

Water distribution

Programmer or

RS30

Water distribution by rotary nozzle

actuated by a cam and a cable.

The cam is driven by:

- the programmer for programming P1

and P2ASIC

- a micro-motor (RS30) for "all-electronic"

programming.

A cam, with a special profile

(different from the distribution one),

located in the RS30, is used to open and

close a positioning contact.

By means of opening and closing times

of this contact, the board knows the

distribution cam position.

It can thus cut the power supply to

micro-motor when the distributor is

facing the right compartment.

For programmer-driven distributors, it is

necessary to adjust the cable tension in

case of a disassembly.

This adjustment is not necessary on

distributor controls by the RS30

Driving by the RS30

•

220/240 V~

•

•

Ω

6.5 K

Positioning contact open in all filling

positions

(Pre-wash, Wash, Bleach and

softener)

•

1 revolution in 20 seconds

•

No adjustment necessary

Driving by programmer

•

Adjustment: set the programmer to

"Pre-wash" start and adjust the cable

tension for the distributor to be

directed to the left (compartment I)

and without slack.

Page 17

THE TOP LOADING WASHING MACHINE

Technical Training

Designation Function Characteristics

Compression chamber and pressure

switch

When the water rises in tank, it also rises

in compression chamber (clipped in tank

bottom) and compresses the air that acts

on the pressure switch rubber diaphragm.

Mechanical Programming P1B

The pressure switch checks the water

level in tank and cuts the electrical power

supply to electrovalve.

It prohibits the heating without water and

allows the rinse.

Hybrid programming

In addition to the above functions, the

pressure switch anti-overflow by feeding

directly the draining pump.

"All electronic" programming

The pressure switch informs the board

that it is feeding or not the electrovalve.

It allows the heating and supplies directly

the draining pump in the event of safety

level triggering.

(P2ASIC)

THE COMPONENTS

•

Low level : 11/12

•

High level : 11/14

•

Safety : 11/16

Disassembly of compression chamber:

4

2

1

•

Remove the machine right-hand panel

•

Gently pull the compression chamber

pipe rearwards (at the bottom, behind

the tank) in order not to break the

chamber tube

•

Remove the omega

•

Turn doors over to drum inside and

hold them open using wood sticks of

approximately 27cm

•

With doors down, it is possible to

disassemble the filter

•

Pick the compression chamber by

passing for example a suspension

spring through the top notch and pull

up to unclip it

•

Lift the compression chamber along

the groove

tank

CAUTION

•

Check for O-ring on the chamber

•

Assemble the compression chamber

by passing it behind the groove in

(5)

tank

•

Clip it back by pushing the striated

section up

•

Reconnect the pipe coming from the

pressure switch

3

(1)

(3)

(5)

to take it out of the

for the assembly

(2)

5

Draining pump

Evacuate wastewater.

The synchronous pump can turn

clockwise or counter-clockwise.

To reach its synchronism rate, the turbine

must have a freedom degree of

approximately 180° with respect to the

rotor.

The synchronism rate is reached very

easily when loaded (with water),

the off-load start is, as for it, very irregular

(the rotation direction may be reversed

several times).

The pump is embarked on the tank, and its

filter (also used by the recirculation pump)

is accessible in tank bottom through the

drum removable omega.

•

220/240V~

•

•

•

•

Ω

155

30W

16 l/mn

Synchronous

Page 18

THE COMPONENTS

Designation Function Characteristics

Objet trap

Regulation

Electromechanical programming

THE TOP LOADING WASHING MACHINE

Retains textile fibres and foreign matters,

in order not to lock the draining pump and

possibly the recirculation pump or its

lines.

Caution:

interchangeable.

Depending on its position, it cuts off the

power supply to immersion heater for P1

and P2ASIC with oven-controlled heating.

the various filters are not

Technical Training

•

Clipped in the lower part of the tank

•

Easy to remove after removing the

omega

On "all electronic" machines fitted with

recirculation pump, an indication on the

board warns the user that it is necessary

to clean the filter every 100 cycles and to

reset the counter to 0.

or ⇒

•

Adjustable from cold to 90°C

•

Bulb thermostat in contact with the

tank

Regulation

“All electronic” programming

NTC

Safety thermostat

Immersion heater

The NTC :

informs the microprocessor on

printed circuit board.

The ohmic value of this item decreases

as the temperature increases. Used on

washing machines with "all electronic"

programming L0, L1, L4 only.

The thermostat :

ensures safety in the

event of an abnormal overheating. It

opens before burst of the immersion

heater thermal fuse.

Performs heating of the detergent bath.

In case of replacement, it is imperative to

re-wire the immersion heater in the same

direction. The side with thermal fuse is

marked with a red pearl and this symbol :

NTC :

•

12 kΩ at 20°C

•

Delivered assembled to the

immersion heater

Safety thermostat :

•

In contact with the tank

•

Cut-off at 80°C

•

Auto-reclosing

•

220/240V~

Ω

•

25

•

2000W

•

Thermal fuse at 141°C

•

Fitted with the NTC on "all electronic"

programming

READ PE ARL

Page 19

THE TOP LOADING WASHING MACHINE

Technical Training

Designation Function Characteristics

THE COMPONENTS

Programmer

Electronic board

P2Asic

N0 - N1 - N4

Only for electromechanical programming

P1B and P2ASIC.

A micro-motor drives cams used to open

or close contacts that feed the various

items (electrovalve, heating elements,

draining pump, latch).

It feeds and controls motor reversals for

P1B programming.

It controls board P2ASIC (code A and B),

that manages the motor power supply,

reversals and safety devices.

Programming P2ASIC:

At the left bottom of the frame, it manages

the motor power supply, safety devices,

rates and reversals, with programmer

codes A and B.

"All electronic" programming

L0, L1 and L4:

Assembly (power and access boards +

buttons + support) located in the machine

headboard, and that manages:

•

The programme management

•

The motor reversal, rotation speed

and rates

•

The temperature

•

The water level

•

The supply to power items

•

The safety devices

•

The D.A.P

•

220/240V~

•

ohmic value of the micro-motor : 7K

•

220/240V~

•

60Hz

Ω

Asynchronous motor

Universal motor

S1

S2

Only on mechanical programming P1B, it

drives the drum at 50 rpm for wash and

500 rpm for spin through a pulley and a

Poly V belt.

Fitted to machines with variable spin

(programming P2ASIC and L0, L1, L4) It

drives the drum in wash and in spin

through a pulley and a Poly V belt.

Speeds:

•

35 or 50 rpm in wash

•

up to 1300 rpm in spin

The motor pulley diameter defines the

washing machine transmission ratio.

Single-phase asynchronous motor with

two speeds:

•

2/16 poles

•

220/240V~

Capacitor

•

16 µF

•

Rotor (M) : 1.7Ω to 2.3

•

Tachometer (G) : 90

Ω

Ω

1.2 V~/1000 rpm

Motor < 1000 rpm

•

Single stator : 1.7Ω to 2.8

Ω

Motor > 1000 rpm

•

Stator 1 (S1) : approximately 1

•

Stator 2 (S2) : approximately 1

Ω.

Ω

"All electronic" models :

Above 1000 rpm, the motor with 2 stators

with common point (terminal no.7).

During the cycle or at the beginning of

spin start, the two stators are in series

(5 and 6) to obtain a significant torque.

At 1020 rpm, relay KL3 cuts off the stator

between 5 and 7 to decrease the torque

and increase the speed up to 1300 rpm.

Page 20

THE COMPONENTS

Designation Function Characteristics

THE TOP LOADING WASHING MACHINE

Technical Training

Washing unit

Drum and bearing housing rail

4

2

1

Assembly suspended by 4 springs and

placed on 2 shock absorbers, consisting

of :

•

An upper half-tank integrated the

concrete ballasting

•

A lower half-tank, of basin type, to

which the compression chamber,

draining pump, filter, vent, overflow

and immersion heater are secured.

2 inlets, under the level of the drum shaft

leave the water flow from the recirculation

pump.

The sealing between the two half-tanks is

obtained by a seal in groove, 55X2935,

which is to be installed as per the

opposite drawing.

The drum receives the laundry to be

washed.

The stainless steel surface is drilled with

many small holes for the water to be able

to flow in and out freely.

Two crossbars, 55X2983, support the

bearings that hold the drum in the tank

and allow its rotation.

A ‘V-ring’ gasket installed on the drum

shaft ensures the sealing between drum

shaft and spacer ring.

•

Plastic material Polytenax

•

16 kg ballast for spin speeds smaller

than 1000 rpm.

•

20 kg ballast for spin speeds bigger

than 1000 rpm.

Position of the sealing seam in groove bottom

•

42-liters drum

•

Stainless steel

•

Ferrule thickness: 0.5 or 0.6 mm

•

Side thickness: 0.4 or 0.5 mm

•

Omega easily removable and

ballasted or not (at 400gr) depending

on models

•

Braked doors on certain models

3

ACS recirculation pump

Door safety

Cross bar assembly:

Clip spacer ring (1), with its O-ring, on

cross bar (2). Check for ‘V-ring’ gasket on

drum shaft (3). Use the crossbar to

position correctly the ring in tank (4).

Perforations around the shaft enable the

water sent by the recirculation pump to

reach the heart of the laundry.

Only on "all electronic" machines, it is

used to improve the laundry moistening,

the mechanical action, rinses, and to

decrease detergent losses while allowing

decreasing the water consumption (42

litres) and thus to save energy (notes

AA).

The water is sucked under the tank by the

filter, and then returned through the tank

and drum to the heart of the laundry.

Prevents the washing machine start-up or

the motor run with door open, and

prohibits its opening during operation.

The door is locked after 30 seconds of

latch control throughout the cycle, except

during the period of wait for deferred start

of an "all electronic" machine.

•

220/240V~

•

156

•

25 W

•

21 l/mn

•

Synchronous

•

•

Ω

220/240V~

Ω

4.4 k

Page 21

THE TOP LOADING WASHING MACHINE

Technical Training

P1B

8.6. - P1B Programming

8.6.1. - Characteristics

•

Key « On / Off »

•

3 programmer sections (Cottons / Synthetics and Delicate / Wool)

•

Fixed spin-speed 500 rpm

•

Thermostat adjustable from cold to 90°C or chronometric heating

•

Energy mark : B or C

•

Wash mark : C or D

•

Spin mark : E

•

Water consumption : 64 or 69 litters

Possible options

¾

•

Half load : The option suppresses the rinse n°3 for cotton or color and synthetic programs.

•

Full tank stop : the program stops before the drain step of the final spin cycle in order to keep

floated the linen in the drum. It avoids to crumple the linen if it is not immediately taken out of the

washing-machine.

•

Drainage : this option cancels the spin ; the cycle is finishing with a drain.

8.6.2. - P1B Block diagram

PH1

2

A

FULL TUB STOP

3

4

COLD

B

A

A

B

ADJUSTABLE

THERMOSTAT

HALF LOAD

FILTER

PTC

IMMERSION HEATER 2000W

+ THERMAL FUSE

M

TIMER

WATER VALVE

DRAINING PUMP

ON/OFF

DOOR LOCK CONTACT

B

A

7

PRESSURE

SWITCH

13

N1

11

P

12

PH2

23

WASHING MOTOR

A

6

B

22

B

A

A

16 F

B

A

1

B

1

2

5

4

SPINING MOTOR

3

6

WITHOUT SPIN

Page 22

P1B

8.6.3. - P1B Linear diagram

THE TOP LOADING WASHING MACHINE

Technical Training

Without rate

Slow rate

Normal rate

Inter spin 3"

Spinning

Heating

DISTRIBUTION

CAM

8

7

6

5

4

3

2

DOUBLE ACTION

1

PREWASH

WASH

SOFTENER

BLEACH

STARTS

PROGRAM

TIMING

A

SPIN

B

RATE + / -

A

TIMER

B

HEATING

A

COND WASHING

B

COND SPINNING

A

HALF LOAD

B

NORMAL RATE

A

DRAINING PUMP

B

WATER VALVE

A

GENERAL

B

A

COND WASHING

B

COND SPINNING

S

37,5"

7,5"

37,5"

T

O

P

Fr

40

Vid

40

12’

1,5’

1,5’

7,5"

N+3’

82,5"

N+12’

STOP

P-WASH R1 R2 R3 R4 SPIN WASH R1 R2 R3 SPIN

Niveau

Vide

THERMO

CHRONO

PL

1,5’

N+12’

7,5"

82,5"

90

N+3’

60

E60

N+12’

N+6’

N+6’

40

60

N+6’

WASH

Fr

30

40

N+3’

N+12’

N+3’

30

N+6’

Fr

N+12’

1,5’

N+12’

7,5"

cl

82,5"

1/2

CH

6’

1,5’

7,5"

37,5"

7,5"

37,5"

6’

6’

1,5’

1,5’

7,5"

82,5"

7,5"

82,5"

Rin .

6’

ACP

7,5"

ACP/7,5"

Ess

7,5"

75"/90"

51015202530354045505560

51015202530354045505560

N+3’3’N+3’

S

T

O

P

ACP

Ess

Rin .

3’

6’

7,5"

7,5"

75"/90"

ACP/7,5"

82,5"

3’

STOP

SLOW CAMS

FAST CAMS

A

FULL TUB STOP

23

B

SLOW RATE

A

WASHING -

22

B

WASHING +

1/2 load option:

Full tank stop :

3" 0,4" 14,6" 18" 3" 3" 6" 34" 2"3" 3"

3" 5" 8" 5" 6" 6" 6" 3" 6" 6" 6" 6" 6" 7" 6" 2" 3"

1T/90sec

The draining pump is fed by programmer contact 4-4A from the end

of the second rinse (step no. 26). If the "1/2 load" button is pressed, then the pump

supply circuit is cut off. Therefore, the level remained high does not allow a new filling

for rinse no. 3. This is then performed with the previous bath.

This option suppresses then a rinse (the no.3). Actually, choosing this option is

motivated by a less significant and little dirty load to be washed with an appropriate

quantity of washing product, and therefore a less significant need in water during the

rinse.

On the steps 35 and 55 of cotton/synthetic and delicate cycles, the main power contact

2-2A is open. The electric supply of the timer is still possible with the contact 23-23A

(contact of the speedy cam of the timer closed 14.6s by revolution) provided that the

option button is not pushed.

Page 23

THE TOP LOADING WASHING MACHINE

Technical Training

P2ASIC

8.7. - P2ASIC Programming

There is two programming :

P2ASIC Mécanique

•

P2ASIC Mécanique +

•

8.7.1. - Characteristics

•

Key « On / Off »

•

3 programmer sections (Cottons / Synthetics and Delicate / Wool)

•

Fixed spin-speed 700 rpm, two spin-speed (350 and 700 rpm) or adjustable spin-speed from 110

to 1000 rpm

•

Posistop system

•

Universal motor

•

Thermostat adjustable from cold to 90°C or chronometric heating

•

Automatic Variable Capacity (AVC)

•

Energy mark : B or C

•

Wash mark : A or B

•

Spin mark : D or C

•

Water consumption : 54 or 64 litters

Possible options

¾

•

Half load : The option suppresses the rinse n°3 for cotton or colour and synthetic programs.

•

Rinse plus : it allows you to add an extra rinse plus.

•

Full tank stop : the program stops before the drain step of the final spin cycle in order to keep

floated the linen in the drum. It avoids to crumple the linen if it is not immediately taken out of the

washing-machine.

•

Wool gentle rocking action : it reproduces the gentle rocking motion of hand washing to protect

delicate fabric.

Page 24

P2ASIC

THE TOP LOADING WASHING MACHINE

Technical Training

8.7.2. - P2 ASIC operating principle

The main current supplies to the board card :

•

A power supply for the motor command

•

A supply to get continuous current used by the electronic components.

•

An electric base (0V) for the command of the triac which supplies the motor and the time base.

The timer supplies to the board card

•

The code of the task to carry out (wash rates, type of spin), thanks to 2 contacts of the timer 6 and 4.

The tachometer supplies to the board card :

•

Information concerning the speed of the motor on 1.2V~/1000rpm motor form.

The « stop position » sensor indicates to the board card :

•

The position of the small doors thanks to a contact fixed on the tank and commanded by a

magnet fixed onto a disc located at the extremity of the drum axle.

The P2 ASIC board card insures the following functions :

•

Supplying current for the motor by a triac and regulation of the speed of the drum with the help of

information supplied by the tachometer.

•

Motor rotation reversed by 2 relays which reverse the way of current only in the stator. The relay

reverses only when there is no tachometer signal and when the triac is not commanded.

•

Positioning of the small door with the command of the motor and reading of the « stop position »

sensor.

•

Control of the safety « short circuit triac »

•

Reading of the A and B timer codes, transmitted by the timer (depending on the position).

This indicates the rates and type of spin to use.

Synoptic

¾

230V~

PTC

Water

valve

On / Off

or

Timer

Water valve

Pressure

switch

µM

Options

T°

Speed

Code A Code B

Immersion heater

Electronic board

P2 ASIC

µP

Drum position

M

T

Page 25

THE TOP LOADING WASHING MACHINE

Technical Training

Logic of the board card command

¾

P2ASIC

The timer transmit it code by positioning 2 contacts which supply the 2 A and B input of the board card.

These codes allow the board card to manage some rates and motor speed.

Low rate :

•

Pendular rate :

•

Normal rate :

•

No rate :

•

when contact of timer is on CL position and the « wool » option is not selected

when contact of timer is on CL position and the « wool » option is selected

when contact of timer is on CN position

when contact of timer is on middle position

Touche Laine

Code

CADENCE

Position

CL ou CP

PH1

MODULE

P2ASIC

Motor rates and speed

¾

Code A

Code B

6

Potar Vitesse

Essorage

The inversion of the way of rotation is done by the

direction of the current in the stator. This function

is realised by switching on/off both relays. During

this function the motor is not driven.

Intermediate spin model

¾

6A

6B

220K

47K

ΩΩΩΩ

Position

Position

ΩΩΩΩ

40 Volts =

OSCILLATING SPEED

Arret

CN

Contact

Programmateur

4A 4

LOW SPEED

NORMAL SPEED

POSISTOP SPEED

100K

ΩΩΩΩ

Pressostat

NIVEAU Bas

P

3'' On / 12'' Off

12'' On / 3'' Off

1'' On / 9'' Off 1/3

N'' On / 1'' Off

This model, generated with a timer code (4-4A and 6-6B closed), is used during the rinse phase.

The step of the timer defines the spinning time. However, these times can be shortening if unbalances

are detected or if there is high deceleration of the drum (in case of overloading). The speed

potentiometer has no influence on the maximum speed of this spin model.

speed

(rpm)

750

1min 30

35 rpm

50 rpm

35 rpm

50 rpm

500

450

110

80

50

0

3 minutes

6 minutes

Duration

Page 26

P2ASIC

Final spin model

¾

THE TOP LOADING WASHING MACHINE

Technical Training

This model, generated with a timer code (4-4A and 6-6A closed), is used for the final spin of every

program and for the intermediate spin of the delicate program. The step of the timer (3,6 or 12 min)

defines the time and the spinning speed. However, these times can be shortening if unbalances are

detected or if there is high deceleration of the drum (in case of overloading). The speed potentiometer

determinates the maximum speed if the spin model is reached. Any speed adjustment is immediately

taken into account.

Speed (rpm)

Inter spinning= 3 min

Delicate spinning= 6 min

Cotton spinning= 12 min

1120 rpm

1020 rpm

820 rpm

750 rpm

600 rpm

Dripping

Posistop

Duration

Maxi : 15 min

8.7.3. - The P2ASIC safety devices

Failure of the motor or connection cut off

•

speed increases is cut off after 2.4 seconds. A second testing, is carried out. If the failure is going

on, only a disconnection of the machine can initialise the memory of the failure.

Triac in short circuit :

•

as the board card detects a very high speed motor, it stops the supplying

of the motor. As soon as the speed is equal to 0, the relay is commuted again without

commanding the triac. If the tachometer signals that the motor is in rotation, the triac is therefore

considered in short circuit and the relay is cut off. An On/Off of the machine must be effected in

order to cancel the memory of the failure.

Cut of the speed potentiometer or high level during spinning :

•

and speed limited to 50rpm

Door unlocked :

•

Heat without water

•

Overflow level reached :

•

no rotation of the motor without supplying or command of the board card.

: a thermal fuse inside the heater cuts it.

contact 11-14 of the pressure switch supplies directly the drain pump

to reach the safety level.

Unbalance

•

: the board card analyses the tachometer signal when 80 and 110rpm are reached, in

order to get the smallest unbalance and insure a safety spin. The number of attempts are limited

by the spinning time and directed by the timer (15 min with cotton program).

: without any tachometer signal, the motor whose

cancelling of the spin period

Page 27

THE TOP LOADING WASHING MACHINE

p

p

g

p

p

p

Technical Training

8.7.4. - The P2ASIC electronic board

P2ASIC

Components Mark Values / Reports

Posistop

Tachometer

Rotor

Stator

Programmer

Code A

and

Wool key

Programmer

Code B

and

Speed

potentiometer

* : 6-6A closed

6-6A opened

** : 4-4A closed

Supply motor wiring diagram

¾

ARPO 1 ARPO 3

MOTEUR 1/6 MOTEUR 2/6

MOTEUR 3/6 MOTEUR 4/6

MOTEUR 5/6 MOTEUR 6/6

PROG 2/7 PROG 3/7

PROG 2/7 PROG 4/7

6-6B opened

and

6-6B closed

and

only in spin.

Ω (

0

closed)

infinity (open)

infinity A=0

Ω

0

47 k

147 k

infinity B=0

0 kΩ to

Ω

220k

in Delicate / wool for exple.

in Cotton washing for exple.

Ω

Ω

Opening at the top

Opening others positions

Ω

90

1,7 to 2,3

1,7 to 2,8

6-6A + 6-6B opened (*)

A=1

A=1

A=1

6-6B closed(*)

and 6-6A closed (*)

and 6-6A closed (*)

and / or 4-4A opened (**)

B=1

and 4-4A closed (**)

Ω

Ω

Wool key off

Wool key on

High level

Low level

eed

s

eed

eed

in.

Slow s

Motor stopNormal s

Inter s

Oscillatin

in

Final s

3/6 4/6 2/7

5/6 6/6

1/7

Ph1

KL1

STATOR

KL2

ROTOR

Ph2

Page 28

P2ASIC

8.7.5. - P2ASIC MECANIQUE Block diagram

230V

Ph1 Ph2

THE TOP LOADING WASHING MACHINE

Technical Training

2

1A

1

1B

LIGHT WOOL

2B

2A

DRAINING PUMP

WATER VALVE

FULL TUB STOP

LIGHT LOCKING

LIGHT POSISTOP

ADJUSTABLE

THERMOSTAT

FILTER

IMMERSSION HEATER

+ Thermal fuse

2000W

4B

4A

PTC

ON/OFF

TIMER

M

DOOR LOCK CONTACT

5B

5

5A

3

N1

4

6B

6

6A

P

2

PRESSURE SWITCH

47kΩ

4

1

HALF LOAD

RINSE PLUS

100 kΩ

4

1

2

WOOL

DRUM

POSITION

LIGHT ON/OFF

1/3

3/3

1/7 2/7 3/7 4/7

P2 ASIC

MECA

1/6

2/6 3/6 4/6 5/6 6/6

2

1

Tachy

R

S

Motor

SPEED POTENTIOMETER

220kΩ

Page 29

THE TOP LOADING WASHING MACHINE

Technical Training

P2ASIC

8.7.6. - P2ASIC MECANIQUE Linear diagram

CAM

1

2

4

5

6

1A

1B

2A

2B

4A

4B

5A

5B

6A

6B

LOW RATE

NORMAL RATE

51015202530354045505560

SPIN / LOW LEVEL

WATER VALVE

HALF LOAD

DRAINING PUM

LIGHT POSISTOP

PTC

FULL TUB STOP

HEATING

6’

3’

3’

6’

51015202530354045505560

6’

6’

6’

6’

3’

3’

6’

6’

6’

3’

3’

3’

3’

6’

6’

6’

6’

6’

3’

3’

3’

7,5"

2’52

3’

3’

3’

3’

3’

3’

3’

3’

ACP ou 3’

3’

6’

3’

3’

STOP

3’

3’

3’

3’

6’

3’

3’

3’

3’

3’

3’

3’

3’

ACP ou 7,5"

2’52

7,5"

2’52

3’

STOP

PROGRAM

THERMO

CHRONO

PL

90

60

E60

60

40

30

40

Fr

30

Fr

Rin .

Ess

Vid

40

40

Fr

Fr

Rin .

Ess

Vid

STARTS

SOFTENER

BLEACH

DISTRIBUTION

Inter spin 3"

Spinning

Heating

PREWASH

WASH

Empty

cl

ACP

ACP

then 14mn [9"On-6"Off (50rpm)

then [11"On-4"Off (50rpm)].

80 rpm /110 rpm

N1

Without rate

Low rate 3"On-12"Off

Normal rate :

3mn [9"On-6"Off (35rpm)],

PL R1 R2 R3 R4 SPIN WASH R1 R2 R3 R4 SPIN

WASH

CH

1/2

O

S

P

T

O

S

P

T

programmer and the door safety device remain fed.

Full tank stop :

On steps no.36 and 55, at the end of the last rinses in programmes cotton / synthetics and delicates programmes,

contact 2-2A

is open. The power supply to programmer and door safety device is then cut off. When the latch opens, the board

power supply is cut off and the motor no longer runs. With contact 1-1A closed, if the option is not selected, then the

Page 30

P2ASIC

8.7.7. - P2ASIC MECANIQUE + Block diagram

230V

Ph1 Ph2

THE TOP LOADING WASHING MACHINE

Technical Training

2

DRAINING PUMP

1

LIGHT WOOL

2B

2A

FULL TUB STOP

1A

1B

ADJUSTABLE

THERMOSTAT

LIGHT LOCKING

LIGHT POSISTOP

IMMERSION HEATER

+ Thermal fuse

2000W

WATER VALVE

FILTER

4A

4B

PTC

5

3

N1

2

PRESSURE SWITCH

4

6B

6

6A

TIMER

M

DOOR LOCK CONTACT

5B

5A

4

1

P

Ω

47k

HALF LOAD

RINSE PLUS

4B

100k

Ω

4

1

2

WOOL

ON/OFF

3B

DRUM

POSITION

LIGHT ON/OFF

1/7 2/7 3/7 4/7

1/3

3/3

P2 ASIC

MECA

+

1/6

2/6 3/6 4/6 5/6 6/6

RS

Tachy

Motor

Ω

POTENTIOMETER

220k

S

SPEED

Page 31

THE TOP LOADING WASHING MACHINE

Technical Training

8.7.8. - P2ASIC MECANIQUE + Linear diagram

6

6A

6B

SLOW RATE

NORMAL RATE

51015202530354045505560

4

5

4A

4B

5A

5B

SPIN / LOW LEVEL

WATER VALVE

HALF LOAD

DRAINING PUMP

4B

3B

WATER VALVE CHRONO

2B

LIGHT POSISTOP

2

2A

PTC

1

1A

1B

FULL TUB STOP

HEATING

6’

3’

3’

6’

51015202530354045505560

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

6’

3’

3’

45"

2’15"

3’

3’

45"

2’15"

6’

3’

6’

3’

45"

2’15"

3’

6’

3’

3’

STOP

3’

30"

2’30"

6’

6’

3’

3’

30"

2’30"

3’

1’

30"

1’30"

3’

1’

30"

1’30"

3’

7,5"

2’52,5"

3’

STOP

STARTS

DISTRIBUTION

CAM

WASH

SOFTENER

BLEACH

PREWASH

Inter spin 3"

Spinning

Heating

Empty

cl

then 14mn [9"On-6"Off 50rpm],

then [11"On-4"Off 50rpm].

80 rpm /110 rpm

Ni1

Without rate

Slow rate 3"On-12"Off

Normal rate:

3mn [9"On-6"Off 35rpm],

N1 +45"

N1+30"

PL R1 R2 R3 R4 SPIN WASH R1 R2 R3 SPIN

WASH

1/2 CH

O

P

T

O

P

T

P2ASIC

On this type of programming, the draining pump and the electrovalve are wired in series.

Moreover, the pressure switch is calibrated to have lower water height in tank and thus provide reduced consumption (water and

energy). To obtain a mark A in wash quality, a chronometric filling complement of 30 or 45 seconds (contact 4B-3B) is performed on

rinses no.1, 2 and 4 of cotton / synthetics programmes, and also on the filling and and the 3 rinses of delicates programme.

S

S

Page 32

FULL ELECTRONIC

8.8. - The “Full Electronic” programming

8.8.1. - Characteristics

•

Three programming levels (L0, L1 and L4)

•

Spin variable up to 1300 rpm

•

Universal motor

•

Temperature adjustable from cold to 90°C

•

Automatic weighing

•

Drum positioning

•

Energy mark : A

•

Wash mark : A

•

Spin mark : C (900 to 1100 rpm) or B (1200 to1300 rpm)

•

Consumption : 42 litres

Buttons and options

¾

•

Freshness

Smoother wash rate (10/5), cooling on wash completion (+ 4 litres) and addition of 7 litres on

each rinse.

•

Eco : reduced temperature but extended mechanical action.

•

Intensive : increased mixing temperature and time.

•

Prewash

surfliss

: cold mixing and then heating at 30°C to eliminate stains of blood, mud …

or Care + : makes ironing easier.

THE TOP LOADING WASHING MACHINE

Technical Training

L0

L1

L4

•

Rinse +

This rinse can also be performed in automatic mode if there is foam detection during intermediate

rinses.

•

Deferred start

•

Time left

•

Start / Pause or Cancellation

unlocks). A long pressure cancels a programme.

CAUTION

!

90°C, depending on the chosen programme.

Pre selections

¾

The machine proposes the temperature (only on L4) and spin speed best suited to the chosen textile.

: for the persons sensible to the products or to avoid traces on dark textiles.

: 3, 6, 9 hours on L0 or 1 to 19 hours on L1 and L4.

: is used to display (on L1 and L4) the time to reach the end of cycle.

: a short pressure starts or interrupts a cycle (in pause, the door

: On cover opening, the drum and laundry temperature may attain

Temperature Spinning

Cotton

Mixte or Colour

Synthetic

Delicate

Wool

Hand wash

Flash 30'

Rinsing

Spinning

60°C Max

40°C Max

40°C 1000 rpm.

30°C 600 rpm.

30°C 600 rpm.

Cold 600 rpm.

40°C 1000 rpm.

Cold Max

Cold Max

Page 33

THE TOP LOADING WASHING MACHINE

Technical Training

FULL ELECTRONIC

8.8.2. - Specific feature of the "Full electronic" programming L4

Memorisation of the favourite cycle

¾

On start-up of all the first cycles, the machine proposes at once the colour programme at 40°C with

maximum spin speed (up to 1300 rpm) and for a duration of 1H58.

It is possible to modify this programme configuration. If the user often makes the same type of

selection, then the machine will take its preferences into account and will then propose it the most used

programme from the last 5 performed ones.

Calculation of achieved savings

¾

On completion of "Cotton" or "Resistant" and "Colour" or "Mixed"

programmes, the "Stop" indicator light comes on and the display

indicates alternately the saving (

and then in time (number of minutes) that can have been achieved

with respect to load of 5 kg.

) in water (number of litres)

On completion of all other programmes, the "Stop" indicator light

comes on and the display indicates :

Additional information to the user

¾

•

Cock closed

•

Child safety

•

Excess foam

. (access locking and unlocking from buttons + for 1’’.

:The detection occurs if the pressure switch switches again to high level (11-13)

during intermediate spins in rinses. Rinse + is then performed after the 2nd, next spin rates and

profiles are modified (less high and less long speed dwells).

•

A buzzer signals for 10 minutes the end of a cycle with ‘Freshness

leaving wet laundry become shrieked and creased.

surfliss

’ option to avoid

Page 34

FULL ELECTRONIC

THE TOP LOADING WASHING MACHINE

Technical Training

8.8.3. - Operating principle of the "Full electronic" programming

•

The 230V~ mains provides the module with a power supply to create a DC voltage used by the

electronics (components and relays)

•

The board manages the run of programmes according to the consumer's choice and to the

information read by its sensors (NTC, pressure switch, tachometer, posistop, RS30 contact, door

safety contact). It also informs the consumer on the cycle run, signals the presence of a possible

fault, and manages several safety devices.

•

The motor power supply is managed by the board that pilots a triac and regulates the drum speed

(from 35 rpm to 1300 rpm), using the information given by the tachometer (as a 1.2 V~ voltage /

1000 motor revolutions)

•

Two relays reverse the current direction in the stator reverse the motor direction.

They change when the tachometer signal is zero and the triac is not piloted.

•

A relay shuts down a stator for changeover to motor overspeed (from 1020 to 1300 rpm).

•

A contact (secured to the tank) controlled by a magnet (assembled to a disk at drum shaft end) is

used to control the up position of doors.

•

Motor, pumps, latch, electrovalve and RS30 are fed by triacs. The immersion heater is fed by a

relay.

Synoptic

¾

230V~

Pressure

On / Off

switch

Overflow

Low level

level

Draining

Pump

Recirculation

pump

EV

µP

PTC

RS30

Drum

position

NTC

Heating

relay

Electronic boards

Inversions

and

over speed

Immersion heater

M

T

Page 35

THE TOP LOADING WASHING MACHINE

Technical Training

FULL ELECTRONIC

8.8.4. - The block diagram

N

L

FilterFilter

MC1MC1

N

J7J7

11

PTCPTC

Lock doorLock door

Stop positionStop position

3 3

2 2

J3J3

3

0V= 0V=

Signal Signal

2

1

- 5V= - 5V=

MM

12 34 6

J4J4

SwitchSwitch

SwitchSwitch

MicromotorMicromotor

TC3TC3

TC2TC2

MicromotorMicromotor

RS30

Electronic boardElectronic board

NN

power side seeing

KL4KL4

TC4TC4

TC7TC7

TC6TC6

Recirculation water pumpRecirculation water pump

TC5TC5

Lower levelLower level

Overflow level Overflow level

HeatHeat

Water valve hotWater valve hot

Water valve hotWater valve hot

Microswitch Microswitch

Microswitch Microswitch

DrainingDraining

pumppump

DrainingDraining

pumppump

Water valve coldWater valve cold

Water valve coldWater valve cold

RecirculationRecirculation

water pumpwater pump

LL

MC2MC2

On / OffOn / Off

J2J2

J5J5

J6J6

Pressure switchPressure switch

P

12

33

22

11

SafetySafety

thermostatthermostat

ImmersionImmersio

heaterheater

11

22

33

44

leakage detection*leakage detection*

66

55

44

33

22

11

Water valve hot*Water valve hot*

MicroswitchMicroswitch

DrainingDraining

Water valve coldWater valve cold

RecirculationRecirculation

water pumpwater pump

11 14

13

pump pump

NTC SensorNTC Sensor

LEGEND

Connection (J)Connection (J)

on diplay cardon diplay card

Connection (J)Connection (J)

on power cardon power card

MC : Terminal spade tagMC : Terminal spade tag

TC : Triac TC : Triac

KL : RelayKL : Relay

* : Option* : Option

KL1KL1

TC1TC1

J5J5

-5V=-5V=

3

2

SensorSensor

1

SensorSensor

J1J1

Access card / power card link

KL2KL2

KL3KL3

J3J3

CommonCommon

77

stator stator

66

Stator Stator

55

Stator Stator

44

Rotor Rotor

33

Rotor Rotor

Tachy Tachy

22

Tachy Tachy

11

MotorMotor

RotorRotor

TachyTachy

Page 36

FULL ELECTRONIC

THE TOP LOADING WASHING MACHINE

Technical Training

8.8.5. - The load recognition (automatic weighing)

In cotton only : the filling time before heating as compared to factory tests is used to determine four

load levels and to launch an appropriate wash recipe.

AVC1 AVC2 AVC3 AVC4

Small load Half load Usual load Full load

0kg

1.5kg

2kg

2.5kg

3kg

3.5kg

4kg

4.5kg

5kg

Depending on loads, the following phases can be modified :

•

Mixing duration after heating (differs depending on the chosen temperature : cf. table b)

•

Quantity of water taken during rinses

•

Number of rinses (if CV1, rinse no.2, from the 3 normally programmed, is deleted)

•

Duration of the speed dwell at 850 rpm of the final spin

Run of the weighing

¾

Filling

Level

4

3

2

1

Duration

1 min 11 1 min 41

Phase 1 :

Phase 2 :

Phase 3 :

Phase 4 :

Static and chronometric filling for 71 seconds (cf. cotton chart step 11)

Dynamic and chronometric moistening for 30 seconds (cf. cotton chart step 12)

Mixing + water complement up to L1 and measurement of Q2

Mixing + water complement to maintain L1 and calculation of Qt

These measurements of filling times require very precise electrovalve and pressure switch.

8.8.6. - Energy Labelling EL60° (cotton 60°C without option)

As soon as the consumer selects a cotton cycle, without option, at 60°C with maximum spin speed,

and if during the weighing the board determines that the load is 5 kg, then the electronics executes

automatically an optimised cycle corresponding to the specific features of the standard, as regards the

energy label.

8.8.7. - The unbalance

At the start of spin profiles, the board analyses the tachometer information and looks for a minimum

unbalance (speed as stable as possible) on the dwell at 80 rpm. Then, if it obtains it, a new search,

finer, is performed on the dwell at 110 rpm, before continuing the spin without any risk. The machine

has a time sufficient (variable according to the spin profile) to make several attempts before finding the

minimum unbalance allowing its speed rise. In the case where a significant unbalance could not be

eliminated, a spin with limited speed (different according to the chosen programme and the measured

unbalance) would be nevertheless performed (450 rpm in the worst case)

Page 37

THE TOP LOADING WASHING MACHINE

Technical Training

8.8.8. - The spin curves

FULL ELECTRONIC

700

600

500

400

300

200

100

0

060120180

-100

1000

800

600

400

200

0

0 40 80 120 160 200 240

-200

Profil SP1

Profil SP2

1000

800

600

400

200

0

0 60 120 180 240 300

-200

1400

1200

1000

800

600

400

200

0

0 200 400 600 800

-200

Profil SP1Bis

Profil SP 3

1200

1000

800

600

400

200

0

0 100 200 300 400

-200

900

800

700

600

500

400

300

200

100

0

0 50 100 150 200

-100

Profil SP4

Profil SP6

700

Profil SP5

600

500

400

300

200

100

0

0 20 40 60 80 100

-100

1400

1200

1000

800

600

400

200

0

0 100 200 300 400 500

-200

Profil SP7

Page 38

FULL ELECTRONIC

THE TOP LOADING WASHING MACHINE

Technical Training

8.8.9. - Foam detection

The foam detection is validated if high level of the pressure switch is read during speed rises of

intermediate spins. If there is foam detection, then the motor is no longer fed and the spin is cancelled.

The phase intended for spin ends at 5/10 rate at 50 rpm. The "Rinse +" is then performed automatically

after the second rinse, and spin profiles following the foam detection are different (shorter speed

dwells, and addition of a dynamic draining).

8.8.10. - Temperature cut for options

Table a

Temperature

30° 40° 50° 60° 90°

Without option

Anti-creased option

Intensive

ECO

30° 40° 50° 61° 80°

30° 34° 44° 54° 80°

34° 44° 54° 64° 80°

30° 30° 40° 50° 70°

8.8.11. - Wash time after heating

Table b

Charge Temperature

90° 35'-Tc 90° 59'-Tc

60° 25'-Tc 60° 43'-Tc

CV1

CV2

50° 20'-Tc 50° 40'-Tc

40° 15'-Tc 40° 37'-Tc

30° 12'-Tc

90° 47'-Tc 90° 70'-Tc

60° 34'-Tc 60° 53'-Tc

50° 30'-Tc 50° 50'-Tc

40° 26'-Tc 40° 47'-Tc

30° 20'-Tc

Tc : heating duration

8.8.12. - Filling duration in rinse

Program

without option

Charge Temperature

CV3

30° 28'-Tc

CV4

30° 35'-Tc

Program

without option

Table d

Filling (seconds)

Rinse 1

Rinse 2

Rinse 3

X = the load (kg)

EL AVC1 AVC2 AVC3 AV C4

60'' 60'' 7,5X + 34

75''

105'' 82'' 7,5X + 60

7,5X + 41

Page 39

THE TOP LOADING WASHING MACHINE

Technical Training

8.8.13. - Run of the Cotton cycle of an "Full electronic" programming

FULL ELECTRONIC

Tab a

Tab b

Tab d

Temperature cut

Wash time after heating

Filling duration in rinse

Tc

Heating duration

cancelled

↓↓↓↓

ok

√√√√

ΧΧΧΧ

→→→→

→→→→

ACS

Filling high level

N1H

Draining low level

N1B

(N1H)

High level

Page 40

FULL ELECTRONIC

8.8.14. - The programme of aid to diagnostic

THE TOP LOADING WASHING MACHINE

Technical Training

Page 41

THE TOP LOADING WASHING MACHINE

Technical Training

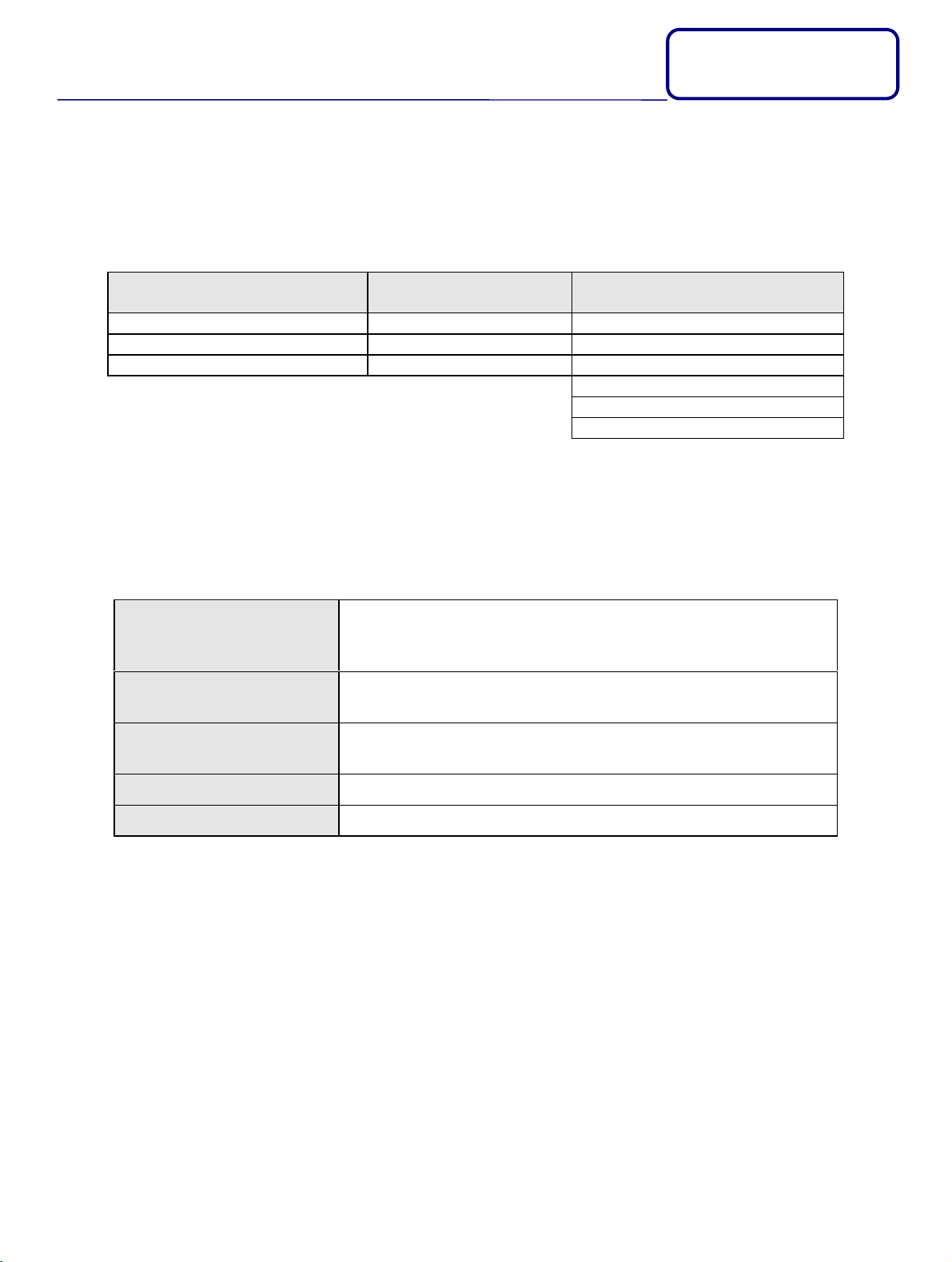

8.8.15. - Faults codes visible during the programme of aid to diagnostic

and safety devices

FULL ELECTRONIC

Failure

display

N1 - N4

or

Del

on

N4

Flickering

N0

Failure Causes Consequence

No filling

No draining

No heating

Triac motor in

short circuit

NTC sensor

No motor

work